Transport and Dielectric Properties of Mechanosynthesized La2/3Cu3Ti4O12 Ceramics

Abstract

1. Introduction

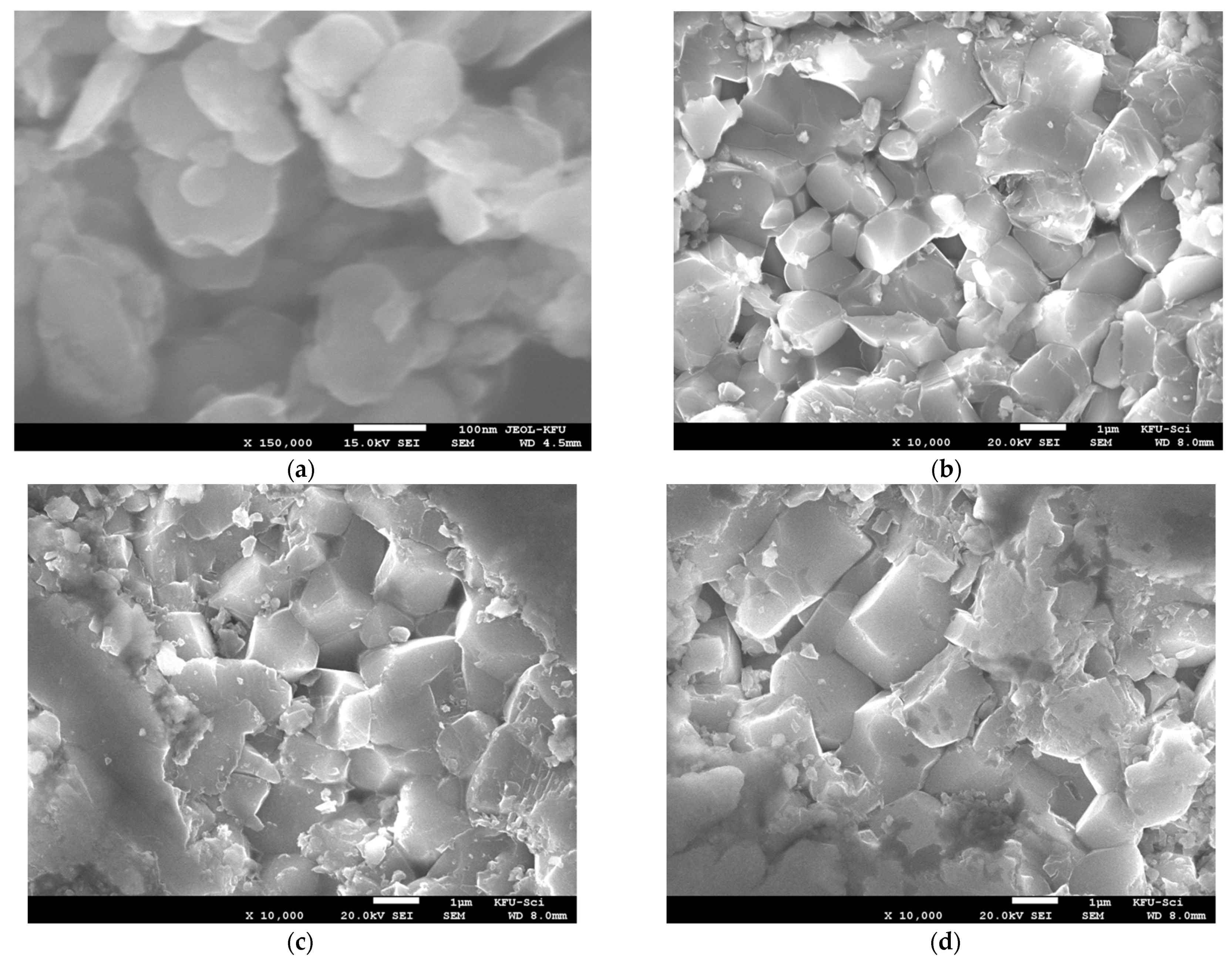

2. Materials and Methods

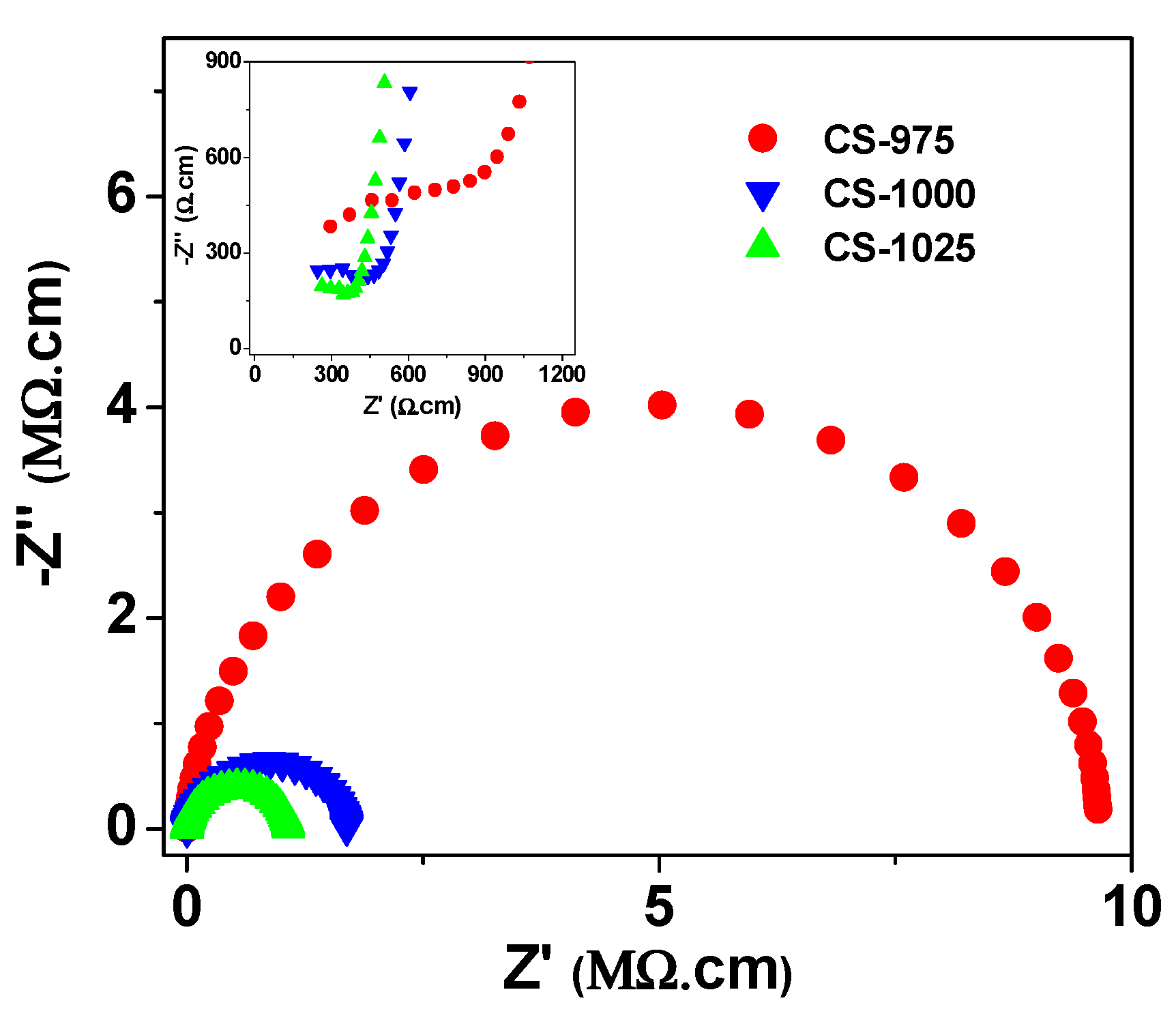

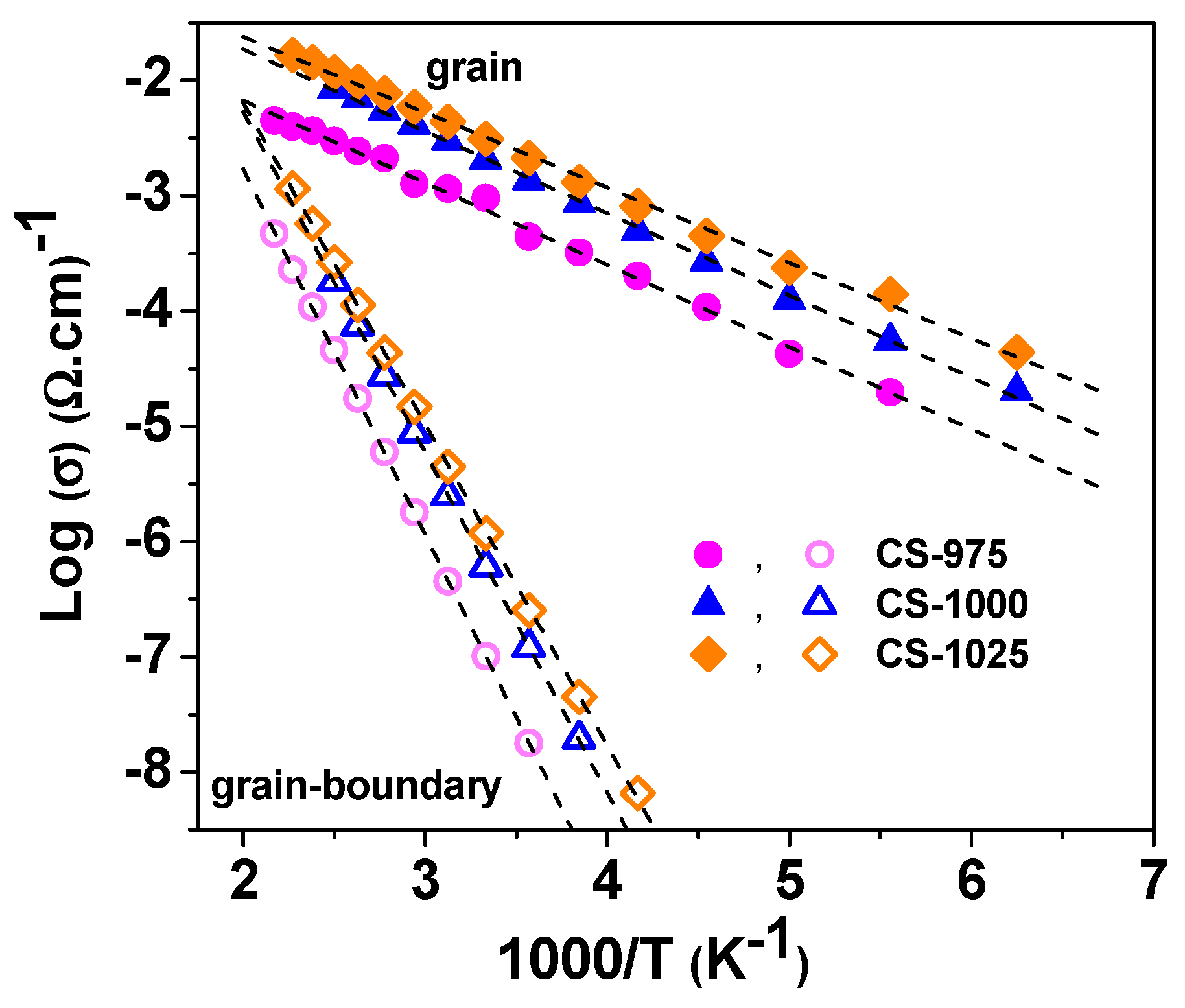

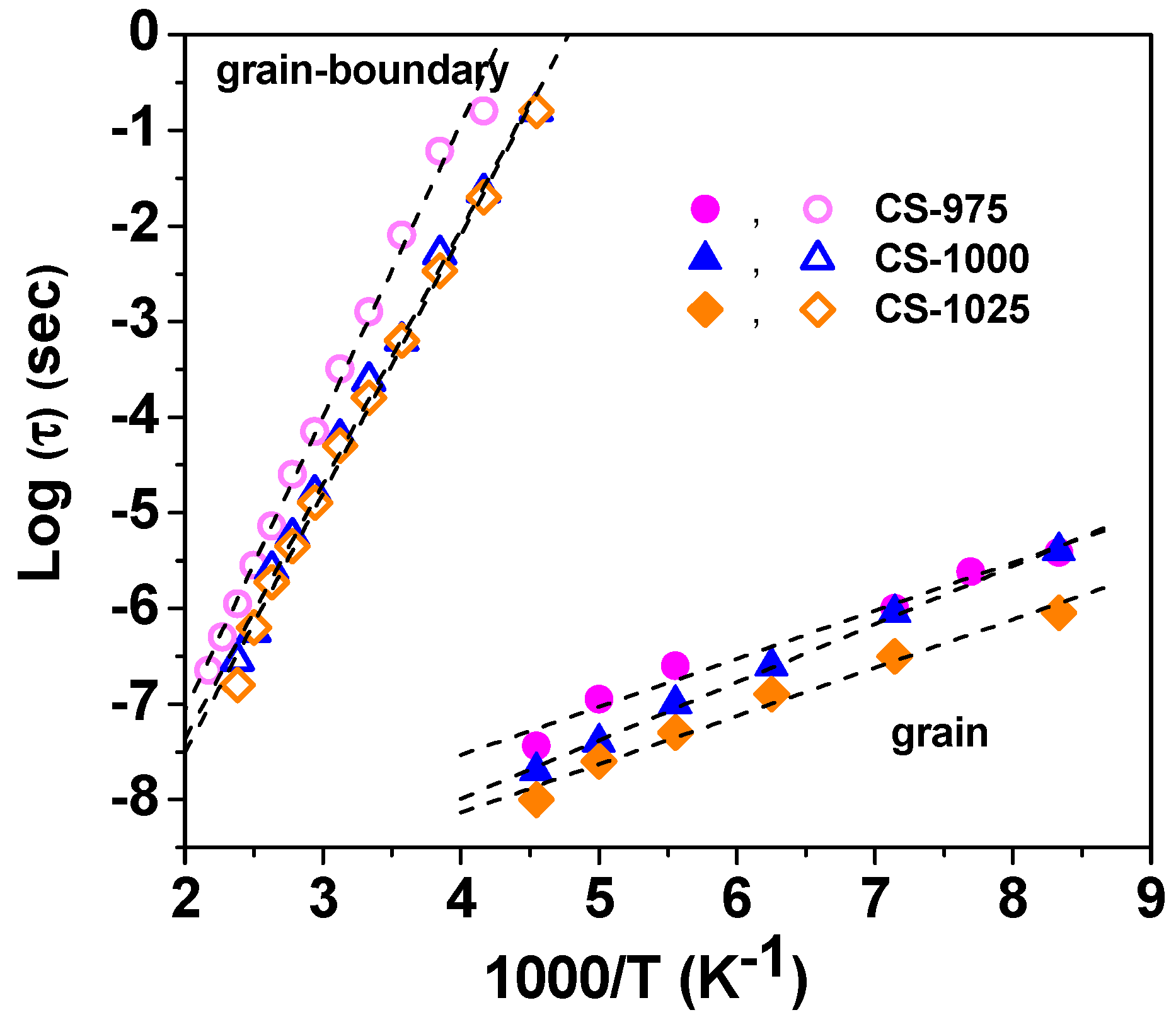

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dobal, P.S.; Dixit, A.; Katiyar, R.S.; Yu, Z.; Guo, R.; Bhalla, A.S. Micro-Raman scattering and dielectric investigations of phase transition behavior in the BaTiO3-BaZrO3 system. J. Appl. Phys. 2001, 89, 8085. [Google Scholar] [CrossRef]

- Kim, B.G.; Cho, S.M.; Kim, T.Y.; Jang, H.M. Giant dielectric permittivity observed in Pb-based perovskite ferroelectrics. Phys. Rev. Lett. 2001, 86, 3404. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Ang, C.; Guo, R.; Bhalla, A.S. Ferroelectric-relaxor behavior of Ba(Ti0.7Zr0.3)O3 ceramics. J. Appl. Phys. 2002, 92, 2655. [Google Scholar] [CrossRef]

- Tang, X.G.; Chew, K.H.; Chan, H.L.W. Diffuse phase transition and dielectric tenability of Ba(ZryTi1-y)O3 relaxor ferroelectric ceramics. Acta Mater. 2004, 52, 5177. [Google Scholar] [CrossRef]

- Guillemet-Fritsch, S.; Valdez-Nava, Z.; Tenailleau, C.; Lebey, L.; Durand, B.; Chane-Ching, J.Y. Colossal permittivity in ultrafine grain size BaTiO3-x and Ba0.95La0.05TiO3-x materials. Adv. Mater. 2008, 20, 551. [Google Scholar] [CrossRef]

- Ahmad, M.M.; Alismail, L.; Alshoaibi, A.; Aljaafari, A.; Kotb, H.M.; Hassanien, R. Dielectric behavior of spark plasma sintered BaTi0.7Zr0.3O3 relaxor ferroelectrics. Results Phys. 2019, 15, 102799. [Google Scholar] [CrossRef]

- Cheng, Z.Y.; Katiyar, R.S.; Yao, X.; Bhalla, A.S. Temperature dependence of the dielectric constant of relaxor ferroelectrics. Phys. Rev. B 1998, 57, 8166. [Google Scholar] [CrossRef]

- Subramanian, M.A.; Li, D.; Duan, N.; Reisner, B.A.; Sleight, A.W. High Dielectric Constant in ACu3Ti4O12 and ACu3Ti3FeO12 Phases. J. Solid State Chem. 2000, 151, 323–325. [Google Scholar] [CrossRef]

- Ahmad, M.M.; Kotb, H.M. Giant dielectric properties of fine-grained Na1/2Y1/2Cu3Ti4O12 ceramics prepared by mechanosynthesis and spark plasma sintering. J. Mater. Sci. Mater. Electron. 2015, 26, 8939–8948. [Google Scholar] [CrossRef]

- Adams, T.B.; Sinclair, D.C.; West, A.R. Giant barrier layer capacitance effects in CaCu3Ti4O12 ceramics. Adv. Mater. 2002, 14, 1321. [Google Scholar] [CrossRef]

- Sinclair, D.C.; Adams, T.B.; Morrison, F.D.; West, A.R. CaCu3Ti4O12: One-step internal barrier layer capacitor. Appl. Phys. Lett. 2002, 80, 2153–2155. [Google Scholar] [CrossRef]

- Zhao, N.; Liang, P.; Wei, L.; Yang, L.; Yang, Z. Synthesis and dielectric anomalies of CdCu3Ti4O12 ceramics. Ceram. Int. 2015, 41, 8501–8510. [Google Scholar] [CrossRef]

- Sebald, J.; Krohns, S.; Lunkenheimer, P.; Ebbinghaus, S.G.; Riegg, S.; Reller, A.; Loidl, A. Colossal dielectric constants: A common phenomenon in CaCu3Ti4O12 related materials. Solid State Commun. 2010, 150, 857–860. [Google Scholar] [CrossRef]

- Sangwong, N.; Somphan, W.; Thongbai, P.; Yamwong, T.; Meansiri, S. Electrical responses and dielectric relaxations in giant permittivity NaCu3Ti3TaO12 ceramics. Appl. Phys. A 2012, 108, 385–392. [Google Scholar] [CrossRef]

- Hao, W.; Zhang, J.; Tan, Y.; Su, W. Giant Dielectric-Permittivity Phenomena of Compositionally and Structurally CaCu3Ti4O12-like oxide ceramics. J. Am. Ceram. Soc. 2009, 92, 2937–2943. [Google Scholar] [CrossRef]

- Schmidt, R.; Stennett, M.C.; Hyatt, N.C.; Pokorny, J.; Prado-Gonjal, J.; Li, M.; Sinclair, D.C. Effects of sintering temperature on the internal barrier layer capacitor (IBLC) structure in CaCu3Ti4O12 (CCTO) ceramics. J. Eur. Ceram. Soc. 2012, 32, 3313–3323. [Google Scholar] [CrossRef]

- Leret, P.; de la Rubia, M.A.; Rubio-Marcos, F.; Romero, J.J.; Fernández, J.F. Effect of Processing on the Sintering of High Dielectric constant CaCu3Ti4O12 ceramics. Int. J. Appl. Ceram. Technol. 2011, 8, 1201–1207. [Google Scholar] [CrossRef]

- Yu, H.; Liu, H.; Luo, D.; Cao, M. Microwave synthesis of high dielectric constant CaCu3Ti4O12. J. Mater. Process. Techol. 2008, 208, 145–148. [Google Scholar] [CrossRef]

- Samanta, B.; Nanda, D.; Kumar, P.; Sahu, R.; Swain, S.; Mahapatra, A. Giant dielectric response in microwave processed CaCu3Ti4O12 ceramics: A correlation among microstructure, dielectric and impedance properties. Process. Appl. Ceram. 2019, 13, 387–400. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, H.; Zhu, Z. Influence of sintering conditions and CuO loss on dielectric properties of CaCu3Ti4O12 ceramics. Mater. Res. Bull. 2019, 113, 97–101. [Google Scholar] [CrossRef]

- Boonlakhorn, J.; Kidkhunthod, P.; Thongbai, P. Investigation of the dielectric properties and nonlinear electrical response of CaCu3Ti4O12 ceramics prepared by a chemical combustion method. J. Mater. Sci. Mater. Electron. 2020, 31, 4511–4519. [Google Scholar] [CrossRef]

- Boonlakhorn, J.; Srepusharawoot, P.; Thongbai, P. Distinct roles between complex defect clusters and insulating grain boundary on dielectric loss behaviors of (In3+/Ta5+) co-doped CaCu3Ti4O12 ceramics. Results Phys. 2020, 16, 102886. [Google Scholar] [CrossRef]

- Prakash, B.S.; Varma, K.B.R. Effect of sintering conditions on the dielectric properties of CaCu3Ti4O12 and La2/3Cu3Ti4O12 ceramics: A comparative study. Phys. B Conden. Matter 2006, 382, 312–319. [Google Scholar] [CrossRef]

- Liu, Z.; Chao, X.; Liang, P.; Yang, Z.; Zhi, L.; Ihlefeld, J. Differentiated electric behaviors of La2/3Cu3Ti4O12 ceramics prepared by different methods. J. Am. Ceram. Soc. 2014, 97, 2154–2163. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, Z.; Chao, X. Structure, dielectric property and impedance spectroscopy of La2/3Cu3Ti4O12 ceramics by sol–gel method. J. Mater. Sci. Mater. Electron. 2016, 27, 8980–8990. [Google Scholar] [CrossRef]

- Fu, Z.; Nie, H.; Wei, Y.; Zhang, B.; Chang, A. Effect of Mn-doping on microstructure and electrical properties of La2/3Cu3Ti4O12 ceramics. J. Alloys Compd. 2020, 847, 156525. [Google Scholar] [CrossRef]

- Liu, J.; Duan, C.G.; Mei, W.N.; Smith, R.W.; Hardy, J.R. Dielectric properties and Maxwell-Wagner relaxation of compounds ACu3Ti4O12 (A = Ca, Bi2/3, Y2/3, La2/3). J. Appl. Phys. 2005, 98, 093703. [Google Scholar] [CrossRef]

- Pelster, R.; Simon, U. Nanodispersions of conducting particles: Preparation, microstructure and dielectric properties. Colloid Polym. Sci. 1999, 277, 2–14. [Google Scholar] [CrossRef]

- Cabanas, M.C.; Reynaud, M.; Rikarte, J.; Horbach, P.; Carvajal, J.R. FAULTS: A program for refinement of structures with extended defects. J. Appl. Crystallogr. 2016, 49, 2259. [Google Scholar] [CrossRef]

- Koops, C.G. On the dispersion of resistivity and dielectric constant of some semiconductors at audiofrequencies. Phys. Rev. 1951, 83, 121–124. [Google Scholar] [CrossRef]

- Sinclair, D.C.; West, A.R. Impedance and modulus spectroscopy of semiconducting BaTiO3 showing positive temperature coefficient of resistance. J. Appl. Phys. 1989, 66, 3850–3856. [Google Scholar] [CrossRef]

- Costa, S.I.R.; Li, M.; Frade, J.R.; Sinclair, D.C. Modulus spectroscopy of CaCu3Ti4O12 ceramics: Clues to the internal barrier layer capacitance mechanism. RSC Adv. 2013, 3, 7030–7036. [Google Scholar] [CrossRef]

| Sample | CS-975 | CS-1000 | CS-1025 |

|---|---|---|---|

| Space group | Im3 | Im3 | Im3 |

| a = b = c (Å) | 7.416(3) | 7.417(1) | 7.422(1) |

| V (Å3) | 407.858(2) | 408.023(1) | 408.848(9) |

| χ2 | 1.17 | 1.19 | 1.22 |

| Sample | Rg (Ω·cm) | Rgb (Ω·cm) | ε′ (at 10 kHz) | tanδ (at 10 kHz) | Eg (eV) | Egb (eV) | ER(g) (eV) | ER(g.b) (eV) |

|---|---|---|---|---|---|---|---|---|

| CS-975 | 945 | 9.6 × 106 | 1.7 × 103 | 0.09 | 0.141 | 0.628 | 0.099 | 0.608 |

| CS-1000 | 452 | 1.7 × 106 | 3 × 103 | 0.16 | 0.141 | 0.585 | 0.121 | 0.535 |

| CS-1025 | 400 | 1.1 × 106 | 3.4 × 103 | 0.17 | 0.129 | 0.552 | 0.099 | 0.528 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, M.M.; Kotb, H.M.; Joseph, C.; Kumar, S.; Alshoaibi, A. Transport and Dielectric Properties of Mechanosynthesized La2/3Cu3Ti4O12 Ceramics. Crystals 2021, 11, 313. https://doi.org/10.3390/cryst11030313

Ahmad MM, Kotb HM, Joseph C, Kumar S, Alshoaibi A. Transport and Dielectric Properties of Mechanosynthesized La2/3Cu3Ti4O12 Ceramics. Crystals. 2021; 11(3):313. https://doi.org/10.3390/cryst11030313

Chicago/Turabian StyleAhmad, Mohamad M., Hicham Mahfoz Kotb, Celin Joseph, Shalendra Kumar, and Adil Alshoaibi. 2021. "Transport and Dielectric Properties of Mechanosynthesized La2/3Cu3Ti4O12 Ceramics" Crystals 11, no. 3: 313. https://doi.org/10.3390/cryst11030313

APA StyleAhmad, M. M., Kotb, H. M., Joseph, C., Kumar, S., & Alshoaibi, A. (2021). Transport and Dielectric Properties of Mechanosynthesized La2/3Cu3Ti4O12 Ceramics. Crystals, 11(3), 313. https://doi.org/10.3390/cryst11030313