Abstract

In this study, laser rapid solidification technique was used to refine the microstructure of ternary Al–Cu–Si and binary Al–Cu eutectic alloys to nanoscales. Micropillar compression testing was performed to measure the stress–strain response of the samples with characteristic microstructure in the melt pool regions. The laser-remelted Al–Al2Cu–Si ternary alloy was observed to reach the compressive strength of 1.59 GPa before failure at a strain of 28.5%, which is significantly better than the as-cast alloy with a maximum strength of 0.48 GPa at a failure strain of 4.8%. The laser-remelted Al–Cu binary alloy was observed to reach the compressive strength of 2.07 GPa before failure at a strain of 26.5%, which is significantly better than the as-cast alloy with maximum strength of 0.74 GPa at a failure strain of 3.3%. The enhanced compressive strength and improved compressive plasticity were interpreted in terms of microstructural refinement and hierarchical eutectic morphology.

1. Introduction

Metal-based eutectic composites exhibit periodic microstructures with lamellar, fibrous, degenerate, or other morphologies and are widely studied as model systems for understanding microstructure evolution under solidification conditions [1]. These microstructures typically contain intermetallic or other hard phases, which results in high hardness, suggesting potential for technological applications at ambient and elevated temperatures [2,3]. A limitation for all the as-cast metal-intermetallic eutectic systems has been the lack of plastic deformability [2,3], often even under compression loading. Recent work on a chill cast or laser surface-remelted eutectics has shown that high strength at room temperature can be achieved without loss of plastic deformability in a wide range of refined eutectic microstructures in Al–, Ti–, Ni–, Zn–, and Fe-based alloys [4,5,6,7,8,9,10,11,12,13,14,15,16].

In our earlier work, in situ micro-pillar compression testing in a scanning electron microscope (SEM) was used to characterize the stress–strain response of laser surface remelted Al–Al2Cu eutectic alloys [15]. For micro-pillar compression from within a single eutectic colony, the plasticity mechanisms were observed to depend strongly on the orientation of the lamellae with respect to the loading direction. For compression axis 90° to the lamellae, the highest yield strength was observed with negligible global plasticity due to localized shear failure, whereas for compression axis close to 0° to the lamellae, buckling and kinking occurred. In the case of a loading axis near 45° to lamellae, sliding along Al–Al2Cu lamellar interfaces was reported with the lowest yield strength [15]. Polycrystalline eutectics with the inter-lamellar spacing of ~20 nm exhibited a maximum flow strength of approximately 1.6 GPa and plasticity of approximately 17%. Bimodal morphologies in Al–Al2Cu containing degenerate, wavy, morphology dispersed with nanoscale lamellar eutectic resulted in high plasticity that was uniformly distributed throughout the height of the compression sample at a strength level of 1.36 GPa [15]. The role of the mixed and bimodal morphology in promoting high strength and plasticity was not clearly elucidated, particularly for binary vs. ternary systems.

In this work, laser surface remelting was used to refine the eutectic morphology of Al–Al2Cu–Si eutectic and compared with binary Al–Al2Cu, processed and tested with the same approach. A focused ion beam (FIB) was employed to fabricate cylindrical micro-pillars from laser-remelted alloys. Nano-indenter was used to compress the micropillars. The compression behaviors of the micropillars were investigated systematically; the cracking and co-deformation mechanism of the binary and ternary eutectics are discussed below.

2. Experimental Procedure

The Al–Al2Cu–Si (Al81Cu13Si6, at%) and Al–Al2Cu (Al81Cu19, at%) eutectic as-cast ingots were fabricated by an arc-melter at the Materials Preparation Center, Ames Laboratory, Iowa State University, under a protective argon gas environment. Plates with dimensions of 20 × 10 × 2 mm3 were cut from the as-cast ingot. The plates were mechanically ground and polished. Laser surface processing experiments were conducted on a solid-state disk laser (TRUMPF Laser HLD 4002 (Trumpf Laser, Plymouth, MI, USA) at a wavelength of 1.03 μm. Details of synthesis and laser re-melting have also been published elsewhere [17,18]. In an earlier study [18], the effects of the processing parameters on the microstructures of Al–Cu–Si ternary eutectic were reported. The laser power was varied between 500 and 1000 W and the laser spot diameter and scan speed ranged from 0.8 to 1.2 mm and 2.54 to 101.4 mm/s, respectively. In this study, samples processed with nominal parameters of 500 W laser power, 2.54 mm/s scan speed, and 1 mm spot size were used for micropillar compression testing. Argon shielding gas (flow rate of 9.4 L/min) was used during the laser melting process to prevent oxidation. The micropillar compression tests were performed on a TI-750 TriboIndenter (Bruker, Minneapolis, MN, USA) with a conical indenter in displacement-control mode, and the experimental compressive strain rate was 2.5 × 10−2·s−1. An FEI Helios 650 NanoLab dual-beam scanning electron microscope (SEM) was used to capture the microstructures of the eutectic micropillars before and after compression tests. Thin foil samples fabricated by FIB were studied on a JEOL 3011 transmission electron microscope (TEM) with an operating voltage of 300 kV.

3. Experimental Results

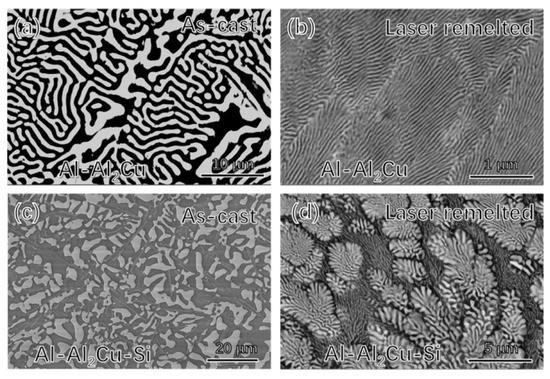

Figure 1 shows the cross-section view of the laser-remelted molten and local regions in Al–Al2Cu and Al–Al2Cu–Si eutectics. As shown in Figure 1a, the as-cast Al–Al2Cu eutectic structures can be divided into lamellae and degenerates, resulting from different heat transfer characteristics during solidification [9]. However, only lamellae Al–Al2Cu eutectics can be observed in the laser-remelted sample (Figure 1b). In the backscattered electron (BSE) images (Figure 1a,b), the phases in the bright and dark contrasts are Al2Cu and Al, respectively. The inter-lamellar spacing (λ) was statistically analyzed and was observed to decrease from 1400 ± 200 nm (as-cast) to 39 ± 4 nm (laser-treated region). The refined Al–Al2Cu eutectics should be ascribed to the high heating and cooling rate of the laser surface processing technique [7,8,13]. In the Al–Al2Cu–Si eutectics, Al (dark), Al2Cu (bright), and Si (gray) were detected in the as-cast Al–Al2Cu–Si samples (Figure 1c), while there were bimodal structures with dendrite structure of Al (dark) + Al2Cu (bright) and lamellae structure (Al–Al2Cu–Si) in the laser-remelted Al2Cu–Si eutectics (Figure 1d).

Figure 1.

Backscattered electron (BSE) images of the microstructure of as-cast Al–Al2Cu and Al–Al2Cu–Si eutectics; (a) as-cast Al–Al2Cu; (b) laser-remelted Al–Al2Cu; (c) as-cast Al–Al2Cu–Si; (d) laser-remelted Al–Al2Cu–Si.

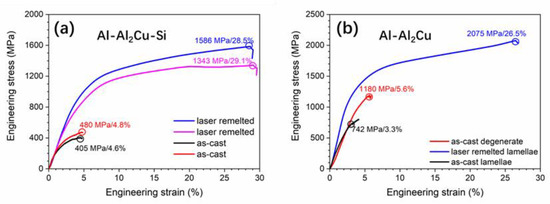

Four Al–Al2Cu–Si micropillars cut from the laser-treated (LT) region and as-cast base are named laser-remelted and as-cast lamellae, respectively. Three Al–Al2Cu micropillars cut from the laser-treated (LT) region and as-cast base are labelled as-cast lamellae, as-cast degenerate, and laser-remelted lamellae. The applied compression force (F) and the immediate height (hI) of the pillar were recorded. An average diameter (d) of the top, middle, and bottom of each pillar was employed to calculate the stress and the strain. The engineering stress (σE) was computed by dividing the applied force (F) by the average cross-section area (π × d × d/4), σE = F/(π × d × d/4). The engineering strain (εE) was obtained by dividing the height variation of the pillar by the original height of the pillar (h0), εE = (hI–h0)/h0. The engineering stress (σE) versus engineering strain (εE) curves of the Al–Al2Cu–Si and Al–Al2Cu eutectic micro-pillars are depicted in Figure 2, in which the as-cast Al–Al2Cu + Si eutectics exhibit ultimate engineering stress of 480 MPa and a total strain to fracture of 4.8%, while the laser-treated Al–Al2Cu + Si eutectics with bimodal structures exhibit both the highest ultimate engineering stress of 1586 MPa and the highest fracture strain of 28.5%. The as-cast Al–Al2Cu lamellae and degenerate eutectics exhibit ultimate engineering stress of 742 MPa and 1180 MPa and total strains to fracture of 3.3% and 5.6% respectively. The laser-treated Al–Al2Cu lamellae exhibit ultimate engineering stress of 2075 MPa and a total strain to fracture of 26.5%, as summarized in Table 1. This suggests that laser surface processing can effectively improve both the strength and plastic deformability of Al–Al2Cu–Si and Al–Al2Cu eutectics. The high strength of laser-treated Al–Al2Cu lamellae eutectics should be ascribed to the nanoscale lamellar spacing. Decreasing the inter-lamellar spacing results in more Al–Al2Cu phase boundaries (PB) being introduced, facilitates the dislocation-PB interactions, and affords more room for dislocation storage, which sustains more pronounced strain hardening in the Al–Al2Cu eutectics [16,19].

Figure 2.

Compressive engineering stress—engineering strain curves of micropillars with different microstructures: (a) Al–Al2Cu–Si eutectic; (b) Al–Al2Cu eutectic. The strain to fracture and the maximum compress flow stress before fracture are presented.

Table 1.

Microstructure and compressive properties of the studied eutectic alloys.

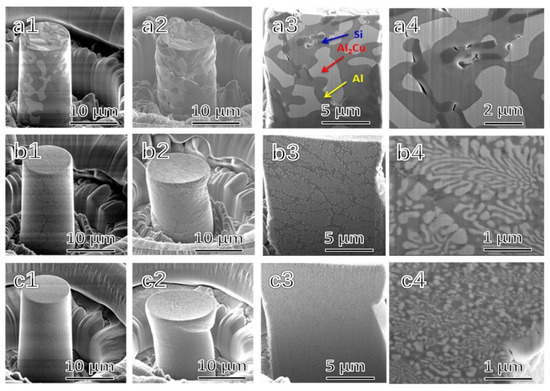

Figure 3 shows the macro- and micro-structures of the Al–Al2Cu–Si pillars before and after compression tests. Microstructures of the as-cast Al–Al2Cu–Si eutectic micropillars before and after the compression test are shown in Figure 3a1,a2. Microstructures of the laser-treated Al–Al2Cu–Si eutectic micropillars before and after the compression test are shown in Figure 3b,c. Micro-cracks were detected in the compressed as-cast Al–Al2Cu–Si eutectic micropillars (Figure 3a2–a4). The detected micro-cracks on the Si and Al2Cu phases indicated that the stress concentration occurred on the boundaries between Si and the other as-cast eutectics, while there were no micro-cracks detected in the laser-treated Al–Al2Cu+Si eutectic micropillars (Figure 3b2–c4). The laser-treated Al–Al2Cu–Si eutectics presented good deformation capability.

Figure 3.

Marco- and micro-structures of the Al–Al2Cu–Si pillars before and after compression test; (a1–c1) the as-cast, laser treated, refined laser remelted pillars before compression; (a2–c2) the pillars after compression; (a3–c3) the cross-section of the pillars after compression; (a4–c4) the high magnification images of the images from a3–c3. All the images were captured in the SEM with a tilt angle of 52°.

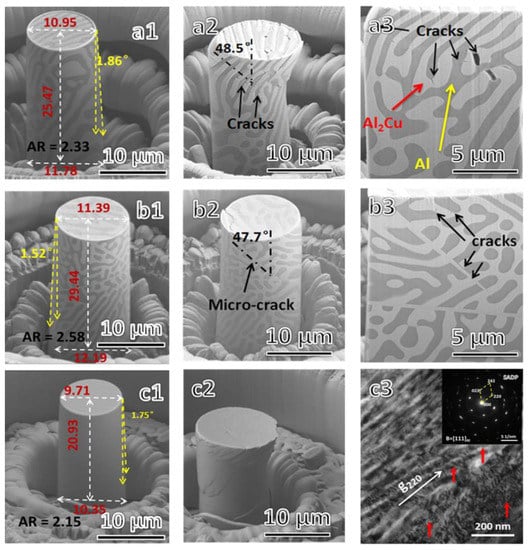

Figure 4 shows the macro- and micro-structures of the Al–Al2Cu pillars before and after compression tests. The phases in the bright and dark contrasts are Al2Cu and Al in the BSE images (Figure 4) and TEM image (Figure 4c3). Before compressive tests, the size and shape of these micro-pillars are nearly identical. Both lamellae and degenerate as-cast eutectics show the distinct interface of α–Al and θ–Al2Cu phases (Figure 4a1,b1); however, the interface cannot be distinguished clearly for the laser-treated lamellae eutectics because of their nanoscale inter-lamellar spacing (Figure 4c1). The microstructures of the as-cast Al–Al2Cu lamellar eutectics micropillars before and after the compression tests are shown in Figure 4a1,a2, and Figure 4a3 is the section view of the compressed pillar. Micro-cracks were detected on the Al2Cu lamellae inside the compressed micropillar (Figure 4a2,a3), and two voids were formed inside the Al2Cu (Figure 4a3). The microstructures of the laser-treated Al–Al2Cu+Si degenerate eutectics micropillars before and after the compression tests are shown in Figure 4b1,b2. Micro-cracks were also detected on the Al2Cu lamellae. The microstructures of the laser-treated Al–Al2Cu+Si eutectics micropillars before and after the compression test are shown in Figure 4c1,c2. There were no micro-cracks detected in the laser-treated Al–Al2Cu eutectics micropillars (Figure 4c2). Further TEM characterization in Figure 4c3 revealed that cracking in θ–Al2Cu phase was suppressed in the laser-treated nanoscale Al–Al2Cu eutectics; α–Al and θ–Al2Cu phases were observed to co-deform together with some distinct dislocation transmission across Al–Al2Cu interfaces, as pointed out by red arrows. After compressive tests, apparent cracks could be observed in θ–Al2Cu layers for as-cast lamellae eutectics with 3.22% reduction and as-cast degenerate eutectics with 4.69% reduction. A similar phenomenon was observed in our previous works, in which after indention tests, Al–Al2Cu eutectics with microscale inter-lamellar spacing exhibited cracking in the θ–Al2Cu phase, owing to their brittle nature at room temperature [2,3]. The angles of the crack propagation direction were detected to be 48.5° and 47.7° tilted along the loading direction for as-cast lamellae and as-cast degenerated, respectively (Figure 4a2,b2). However, no crack was detected in the laser-treated lamellae eutectics with a 10.36% reduction. The microstructure of the compressed micropillars indicated that the laser-treated Al–Al2Cu eutectics present much higher deformation capability than the as-cast Al–Al2Cu eutectics. The high strength of laser-treated lamellae should be ascribed to the nanoscale lamellar spacing. Decreasing the inter-lamellar spacing results in more Al–Al2Cu phase boundaries (PB) being introduced, facilitates the dislocation-PB interactions, and affords more room for dislocation storage, which sustains more pronounced strain hardening in the Al–Al2Cu eutectics [19].

Figure 4.

Macro- and micro-structures of micropillars before and after compressive tests from the Al-Al2Cu eutectics with different structures of (a) as-cast lamellae, (b) as-cast degenerate, and (c) laser-remelted lamellae; (a1–c1) the micropillars before compression; (a2–c2) the micropillars after compression; (a3,b3) the cross-section views; (c3) the TEM image of the cross-section view. All images except c3 were captured in the SEM with a tilt angle of 52°.

4. Discussion

4.1. Strengthening Mechanisms

To further understand the strengthening mechanism of the laser-treated Al–Al2Cu–Si and Al–Al2Cu eutectics, it is essential to consider the roles of interfaces (soft Al phase and hard Al2Cu or Si phase) when the interspacing is refined to nanometer size. In this case, the empirical rule of the mixture is invalid. In this work, the volume fractions of each phase in the studied eutectics are the same even though the length scale has been changed.

A classical constitutive model of the composite structure containing the soft phase and the hard phase could be written as follows:

where the subscript (m) infers to either soft phase (s) or hard phase (h). Here, the uniform stress at the ends of the hard phase, and the soft phase is unaltered with the displacement. It is important to convert the stress and strain into a more fundamental quantity (e.g., energy density). For individual phase, the total work density can be expressed by integrating the area under the stress-strain curve as follows:

where the subscript (m) infers to either the soft phase (s) or the hard phases (h). εp, εmax, and Pmax are the plastic parts of the true-strain and maximum true-strain induced in the experiment and the corresponding maximum indentation load, respectively. We hypothesize that the energies of interaction at the lamellar interfaces (soft Al and hard Al2Cu or Si) play significant roles in the tensile test’s deformation process. The total work density of the composites () can be divided into a plastic part and an elastic part, with respective interfacial energy terms (denoted by superscript “interface”), as follows:

The elastic part of the energy of the effective composite equates to the total elastic energy, since there is no other phase combination, therefore a corresponding equation can be written as follows:

where hs is the thickness of the soft phase (Al) and hh is the thickness of the hard phase (Al2Cu or Si), and is the elastic energy contribution of the interface. The inter-lamellar spacing, λ=(h1+h2)/2, becomes the function of the lamellar geometry. The plastic part of the energy of the composite can be equated with total plastic energy due to the pure phase combination, therefore a corresponding equation can be written as follows:

Combining the above two energy equations as described in Equation (4), a total energy balance is obtained. This allows us to evaluate the effect of the length scale of microstructure as expressed through k on the mechanical properties. Therefore, with the knowledge of inter-lamellar spacing k and the properties of the composite and pure phase, one can estimate the contribution of the interface to the overall elastic energy balance.

In order to verify the above relationships, the Al–Al2Cu+Si eutectic was selected as an example. This eutectic comprises alternate plates of soft phase (Al) and hard phase (Al2Cu and Si) intermetallic phases due to the variation in the lamellar spacing with the cooling rate. The mechanical properties of localized regions were further evaluated from a load-displacement curve obtained by the use of micropillar compression technique. The measured true-stress versus true-strain curves are shown in Figure 2.

4.2. Fracture Mechanisms

Eutectic alloys often exhibit poor fracture strength, which hinders their structural applications [9]. Recent studies have revealed significant improvements in fracture strength due to refinements of the microstructure [10,11,12]. Laser surface processing is an effective way to refine the microstructure, and it leads to a reduction in interlamellar spacing; it is evidence that microstructure refinement improves the plastic or fracture strain. These findings can be explained by two kinds of theoretical methods: one is a dislocation pile-up-based approach, and the other is a fracture-based approach. According to the dislocation-based approach, the deformation of eutectics is controlled by dislocation pile-ups at the interphase boundaries [20,21,22]. The interface between the soft phase (Al) and hard phase (Al2Cu or Si) provides an obstacle for dislocation pile-ed up, which controlled the plasticity in this model. The interface hardening controls the yield strength. The stress arises irrespective of the detailed mechanism of the slip, since the plasticity is highly localized in such cases; here, the stress at the tip of the pile-up is given by [2].

where K is the constant, D is the distance between the two dislocations, b is the Burger vector (b = 0.285 nm), λ is the lamellar spacing, and is the strain. Equation (6) indicates that the shear stress increases at a given strain with the decrease of inter-lamellar spacing, resulting in improvements in the strength of the eutectic alloy. This agrees well with the experimental data in this work.

Fracture is thought to be controlled by dislocation and interface behavior [23]. Griffith relation was applied in the other model based on crack propagation [3]. The critical crack size for cleavage crack propagation can be calculated as follows:

where is the fracture stress, E is the Young’s modulus, γ is the surface energy (219.5 mJ/m2 [24], is the critical crack length, and v is the Poisson’s ratio (vAl = 0.35 and νAl2Cu = 0.34). Here, the Al–Al2Cu eutectic is taken as an example for the analysis of the fracture mechanism. The Al2Cu has a higher modulus (103 GPa ) compared to Al (69 GPa). Substituting the above value, the fracture stress could be calculated: for Al lamellar, , while for Al2Cu, . Thus, the fracture stress of Al2Cu lamellar is larger than Al lamellar. As the eutectic micropillars were compressed, both Al lamellar and Al2Cu lamellar were compressed, leading to plastic deformation. Since plastic deformation in Al lamella is easier than that in Al2Cu lamella, the load transfers to Al2Cu lamella; correspondingly, cracks were observed in Al2Cu lamella (Figure 4a2,a3). For bulk materials, the critical crack length is mostly around a few millimeters to tens of millimeters, while the eutectic microstructure had two kinds of different ductility phases, whose critical crack length was limited by the inter-lamellar spacing. Supporting that the critical crack length is equal to the inter-lamellar spacing, the fracture stress increased dramatically as the inter-lamellar spacing was reduced from microscale to nanoscale. Thus, the laser-treated Al–Al2Cu–Si and Al–Al2Cu eutectics exhibit higher fracture strength and higher total strain to failure.

In summary, laser surface processing was conducted on Al–Al2Cu–Si and Al–Al2Cu eutectics to refine and manipulate the microstructures. Both laser-remelted ternary Al–Al2Cu–Si and binary Al–Al2Cu eutectics showed high strengths with maximum compressive strength of 1586 MPa and 2075 MPa and improved compressive plasticity with a failure strain of around 26%. By comparison, the as-cast ternary and binary eutectics with coarse microstructures exhibited low strength (lower than 740 MPa) and poor compressive plasticity (failure strain less than 5%). The enhanced compressive strength and improved compressive plasticity were interpreted in terms of microstructural refinement and hierarchical eutectic morphology. Laser-processed nanoscale eutectics show a bright promise of achieving ultra-high strength without loss of plastic deformability.

Author Contributions

Writing—original draft, Q.L.; Writing—review & editing, J.W. and A.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by U.S. Department of Energy: DE-SC0016808.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

This research was sponsored by DOE, Office of Science, Office of Basic Energy Sciences, grant DE-SC0016808. The authors acknowledge the assistance of J. Mazumder, B.P. Prashanth, and Y.C. Wang at the University of Michigan in material synthesis and laser surface treatment. Nanomechanical testing and electron microscopy were performed at the Michigan Center for Materials Characterization at the University of Michigan.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chanda, B.; Potnis, G.; Jana, P.P.; Das, J. A review on nano-/ultrafine advanced eutectic alloys. J. Alloy. Compd. 2020, 827, 154226. [Google Scholar] [CrossRef]

- Cantor, B.; Chadwick, G.A. The tensile deformation of unidirectionally solidified Al–Al3Ni and Al–Al2Cu eutectics. J. Mater. Sci. 1975, 10, 578–588. [Google Scholar] [CrossRef]

- Cantor, B.; May, G.J.; Chadwick, G.A. The tensile fracture behavior of the aligned Al–Al3Ni and Al–CuAl2 eutectics at various temperatures. J. Mater. Sci. 1973, 8, 830–838. [Google Scholar] [CrossRef]

- Park, J.M.; Mattern, N.; Kühn, U.; Eckert, J.; Kim, K.B.; Kim, W.T.; Chattopadhyay, K.; Kim, D.H. High-strength bulk Al-based bimodal ultrafine eutectic composite with enhanced plasticity. J. Mater. Res. 2009, 24, 2605–2609. [Google Scholar] [CrossRef]

- Han, J.H.; Kim, K.B.; Yi, S.; Park, J.M.; Sohn, S.W.; Kim, T.E.; Kim, D.H.; Das, J.; Eckert, J. Formation of a bimodal eutectic structure in Ti–Fe–Sn alloys with enhanced plasticity. Appl. Phys. Lett. 2008, 93, 141901. [Google Scholar] [CrossRef]

- Park, J.M.; Kim, T.E.; Sohn, S.W.; Kim, D.H.; Kim, K.B.; Kim, W.T.; Eckert, J. High strength Ni–Zr binary ultrafine eutectic-dendrite composite with large plastic deformability. Appl. Phys. Lett. 2008, 93, 031913. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, X.; Cao, Y.; Huang, W. Microstructure evolution in laser surface remelting of Ni–33 wt.%Sn alloy. J. Alloy. Compd. 2013, 577, 309–314. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Q.; Guo, P.; Gao, X.; Yang, L.; Song, Z. Effects of laser surface remelting on microstructure and properties of biodegradable Zn-Zr alloy. Mater. Lett. 2018, 226, 52–54. [Google Scholar] [CrossRef]

- Park, J.; Kim, K.; Kim, D.; Mattern, N.; Li, R.; Liu, G.; Eckert, J. Multi-phase Al-based ultrafine composite with multi-scale microstructure. Intermetallics 2010, 18, 1829–1833. [Google Scholar] [CrossRef]

- Park, J.M.; Kim, D.H.; Kim, K.B.; Eckert, J.M. Improving the plasticity of a high strength Fe–Si–Ti ultrafine composite by introduction of an immiscible element. Appl. Phys. Lett. 2010, 97, 251915. [Google Scholar] [CrossRef]

- Tiwari, C.S.; Roy Mahapatra, D.; Chattopadhyay, K. Appl. Phys. Lett. 2012, 101, 171901. [CrossRef]

- Zhang, L.; Lu, H.-B.; Mickel, C.; Eckert, J. Ductile ultrafine-grained Ti-based alloys with high yield strength. Appl. Phys. Lett. 2007, 91, 51906. [Google Scholar] [CrossRef]

- Gouveia, G.L.; Kakitani, R.; Gomes, L.F.; Afonso, C.R.M.; Cheung, N.; Spinelli, J.E. Slow and rapid cooling of Al–Cu–Si ultrafine eutectic composites: Interplay of cooling rate and microstructure in mechanical properties. J. Mater. Res. 2019, 34, 1381–1384. [Google Scholar] [CrossRef]

- Kim, J.T.; Lee, S.W.; Hong, S.H.; Park, H.J.; Park, J.Y.; Lee, N.; Seo, Y.; Wang, W.M.; Park, J.M.; Kim, K.B. Understanding the relationship between microstructure and mechanical properties of Al–Cu–Si ultrafine eutectic composites. Mater. Des. 2016, 92, 1038–1045. [Google Scholar] [CrossRef]

- Wang, S.; Xie, D.; Wang, J.; Misra, A. Deformation behavior of nanoscale Al–Al2Cu eutectics studied by in situ micropillar compression. Mater. Sci. Eng. A 2021, 800, 140311. [Google Scholar] [CrossRef]

- Lien, H.-H.; Mazumder, J.; Wang, J.; Misra, A. Ultrahigh strength and plasticity in laser rapid solidified Al–Si nanoscale eutectics. Mater. Res. Lett. 2020, 8, 291–298. [Google Scholar] [CrossRef]

- Lei, Q.; Ramakrishnan, B.P.; Wang, S.; Wang, Y.; Mazumder, J.; Misra, A. Structural refinement and nanomechanical response of laser remelted Al-Al2Cu lamellar eutectic. Mater. Sci. Eng. A 2017, 706, 115–125. [Google Scholar] [CrossRef]

- Ramakrishnan, B.P.; Lei, Q.; Misra, A.; Mazumder, J. Effect of laser surface remelting on the microstructure and properties of Al-Al2Cu-Si ternary eutectic alloy. Sci. Rep. 2017, 7, 13468. [Google Scholar] [CrossRef]

- Wang, S.; Liu, G.; Xie, D.; Lei, Q.; Ramakrishnan, B.; Mazumder, J.; Wang, J.; Misra, A. Plasticity of laser-processed nanoscale Al Al2Cu eutectic alloy. Acta Mater. 2018, 156, 52–63. [Google Scholar] [CrossRef]

- Liu, G.; Xie, D.; Wang, S.; Misra, A.; Wang, J. Mesoscale crystal plasticity modeling of nanoscale Al–Al2Cu eutectic alloy. Int. J. Plast. 2019, 121, 134–152. [Google Scholar] [CrossRef]

- Wang, J.; Misra, A. Strain hardening in nanolayered thin films. Curr. Opin. Solid State Mater. Sci. 2014, 18, 19–28. [Google Scholar] [CrossRef]

- Armstrong, R.W. Size effects on material yield strength/deformation/fracturing properties. J. Mater. Res. 2019, 34, 2161–2176. [Google Scholar] [CrossRef]

- Porter, D.; Easterling, K.; Smith, G. Dynamic studies of the tensile deformation and fracture of pearlite. Acta Met. 1978, 26, 1405–1422. [Google Scholar] [CrossRef]

- Lewandowski, J.; Thompson, A. Micromechanisms of cleavage fracture in fully pearlitic microstructures. Acta Metall. 1987, 35, 1453–1462. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).