1. Introduction

An EPD is a type of display technology that shows the pictures in reflected mode; there are a lot of technologies that could be applied for an EPD such as Cholesterol LCD, Memory LCD, Electronic Wetting display, MEMS, and Clear ink, and an electrophoretic display is a technology that could lead to mass production. It has many advantages such as eye protection, low power consumption, and flexibility [

1,

2,

3]. This technology is widely used in e-reader products, such as Amazon’s kindle. Nevertheless, the electrophoretic display could be used in many IoT products, such as price tags in the supermarket [

4,

5,

6]. A long lifetime is necessary for these applications because it is not easy to install them, and the repair cost is high. The warranty time for the price tag is over five years, which is longer than the warranty for the reader product. The failure phenomenon after prolonged use is presented and the root cause for this failure is also discussed [

7,

8,

9,

10,

11]. The models for predicting an MED’s lifetime are studied; the purpose is to determine a fast way to verify the lifetime of the product [

12]. Additionally, the HTHH (the temperature is 60 ℃, and the relative humidity is 80%) storage test is used to evaluate the capability of the panel structure of the package. A new method for improving the lifetime of an MED is introduced, and the storage time is longer with this new method.

2. MED Panel Structure Failure Phenomenon

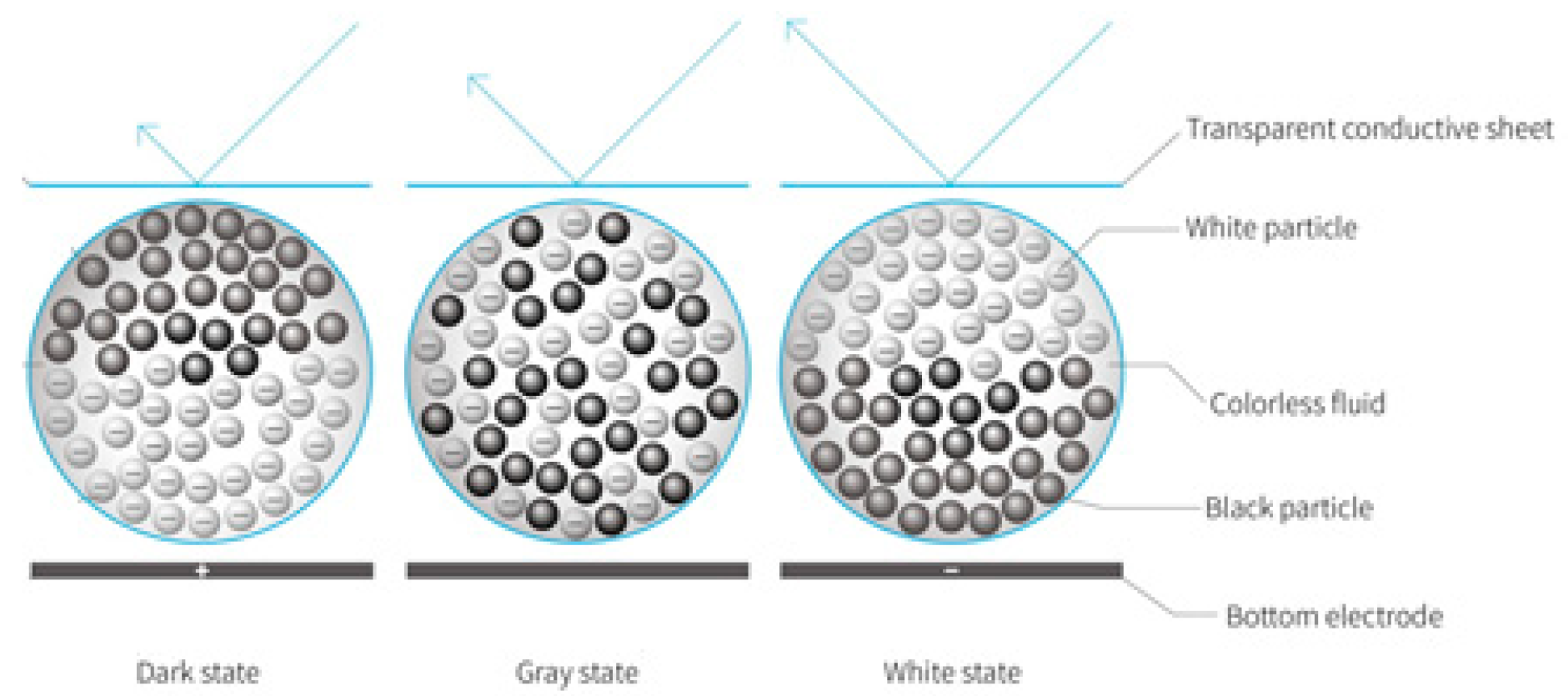

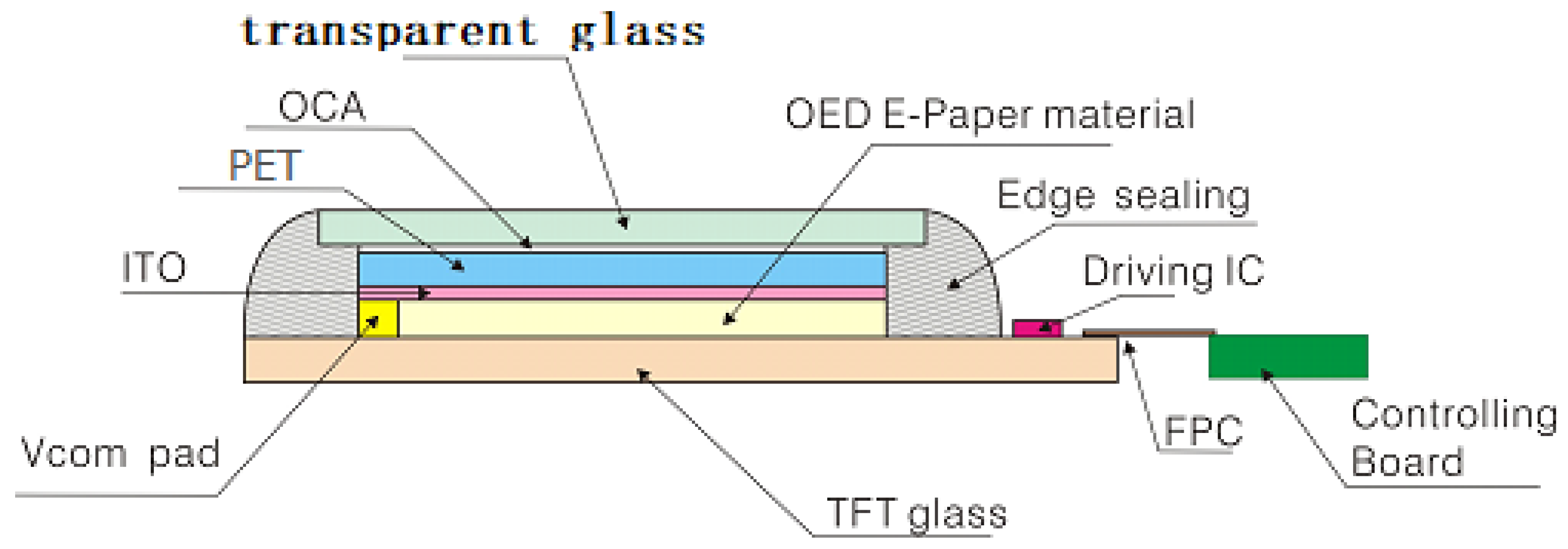

Microcapsule electrophoretic display is a technology that controls the charged nanoparticles moving up and down with an electrical field; microcapsules enwrap the particles, the cross-section of MED is showed in

Figure 1.

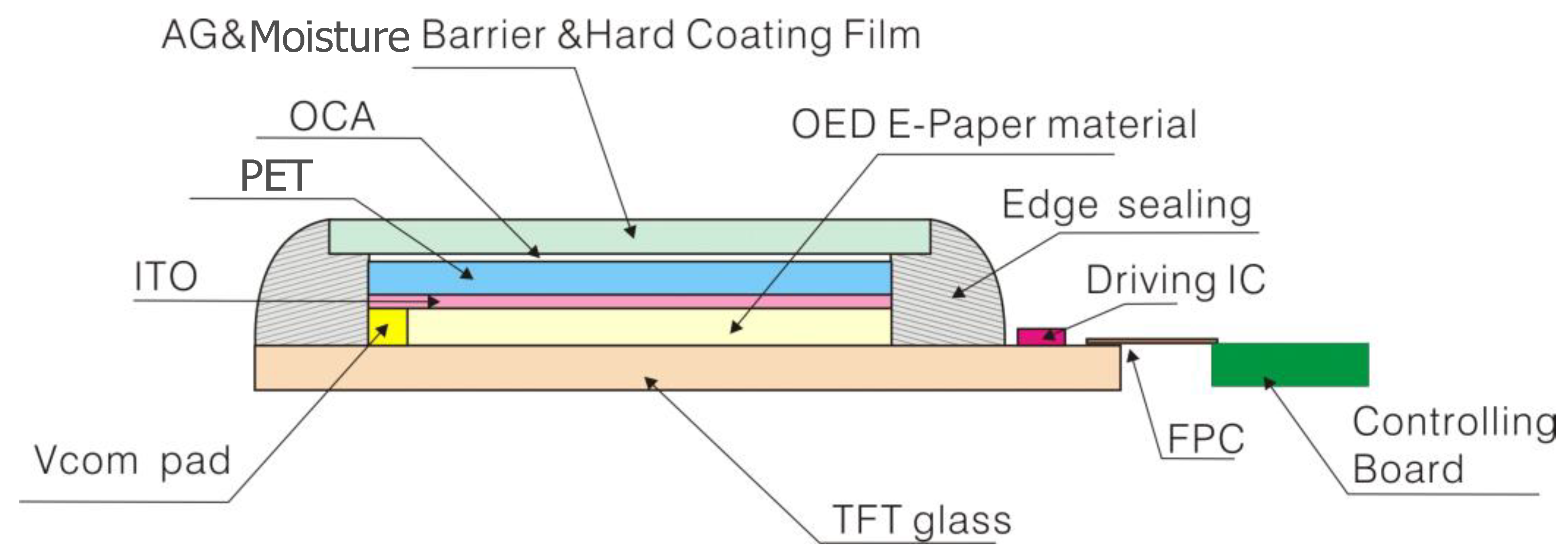

The optical performance of MED material has a direct relation to driving time and the addition of an electronic field to the material. As such, the electric resistance of microcapsule electrophoretic material between electrodes is significant. The electric resistance will change if water invades the panel. Consequently, the microcapsule electrophoretic material is packaged using TFT glass, moisture barrier film, and sealing glue, the cross-section of MED module is showed in

Figure 2.

Even with this packaging, some defects appear after a long duration of use. The main defect is mura at the edge of the panel after about 1 to 2 years of use in the customer’s application. Mura is one defect that normally comes up in displays; the picture in the mura area is different to the picture in other areas of the display. There is no mura effect when the displays have just been manufactured (

Figure 3). However, there are mura effects after 15 days of HTHH (60 °C, 80% RH) testing (

Figure 4).

3. Failure Analysis and Working Time Prediction Models

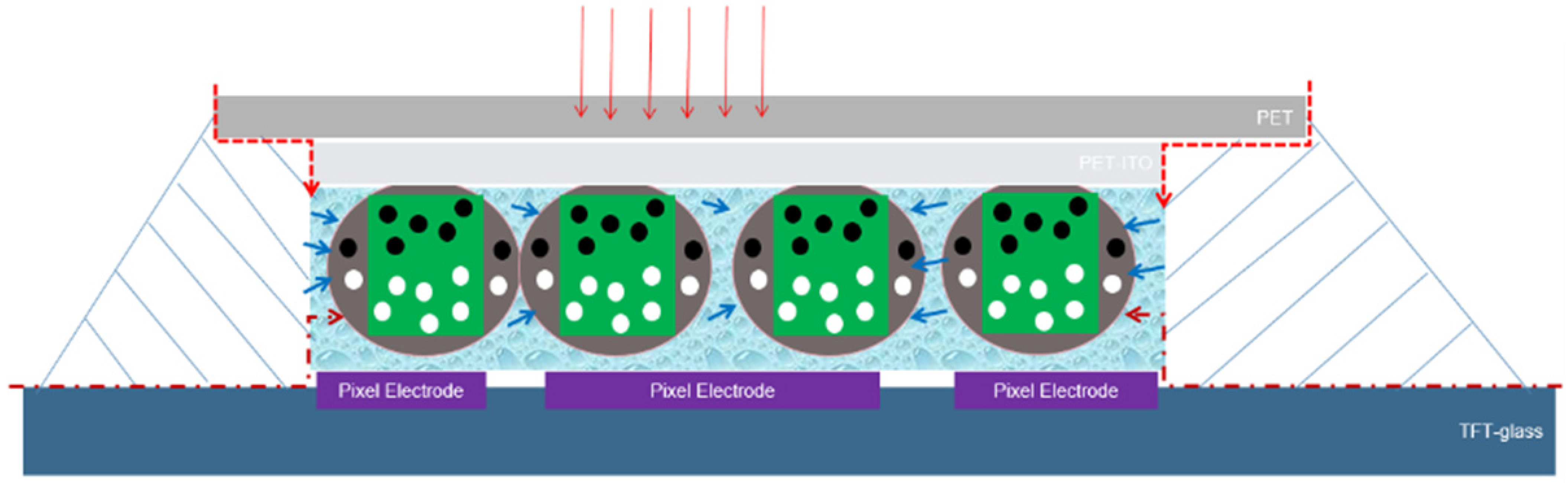

The main reason for this mura is water invading the microcapsule electrophoretic display material at the edge of the display. The pathway for water invading the display is shown in

Figure 5. The main pathway is on the top of the panel. A barrier file is necessary to protect the microcapsule electrophoretic display material. Another pathway is at the contact area between the protective film and the glue. The contact area will exhibit peeling when the long-time temperature fluctuates because the thermal contraction coefficients are different.

The package structure is the primary factor influencing the lifetime of an MED.

There are three lifetime prediction models for this kind of failure mode: the Peck model, the Eyring model, and the LWW model [

10]. The LWW model is a newly developed model and is more suitable for predicting the lifetime of a microcapsule electrophoretic display.

The lifetime can be calculated by the LWW model, and the HTHH (60 °C, 80% RH) is used for evaluating the capability of the panel structure of the package.

4. New Package Method and Test Results

The main reason for the MED failure is water invading the top barrier film and the sealing glue contact area during conditions of thermal shock. The substrate used for the barrier films is polyethylene terephthalate (PET). The water vapor transmittance rate of this material is about 10−2~10−3 g/day/m2 (60 °C, 80% RH); as such, water could invade into the panel. Furthermore, the thermal contraction coefficient of PET is 1.2–2.0%; it is more sensitive than glass. Consequently, when the temperature changes, the sealing glue between the PET and the glass will peel. Water will invade if this peeling happens.

As PET is not a good substance for protecting MED material, we changed this protective film to transparent glass. The new package method is showed in

Figure 6. The water transmission rate and the thermal contraction coefficient are very low for glass, so it is very suitable for MED protection.

The lifetime of the MED panel with this new method is evaluated with HTHH (60 °C, 80% RH) tests (

Table 1). The MED panels are assembled with the same set of MED materials with two different methods. The samples are tested in high-temperature and high-humidity incubators under the same conditions.

5. Discussion

The new structure of the MED panel has a longer lifetime, but the assembly process is a little different. It has been proved that the cost of panels with the new packaging method is lower because the glass is cheaper than the barrier film. If the new method is used, the main passageway for water invasion is the sealing glue area. The moisture permeability is about 4~6 g/m2/day (the thickness of the sample is 1 mm), and the coefficient of thermal expansion is about 60~70 ppm/dC. If the characteristics of this sealing glue can be improved, it will be possible to extend the lifetime of the MED panel.

6. Conclusions

Long working time is required in IoT products for MED, and the current structure of MEDs cannot meet this requirement. As a result, a new method has been developed, and the HTHH testing demonstrates that this method helps to improve the MED’s lifetime.

Author Contributions

Conceptualization, Y.C.; data curation, D.H.; writing—original draft preparation, X.W.; writing—review and editing, X.Z.; visualization, G.L.; supervision, Y.C.; project administration, X.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Innovation and Development of Advanced Manufacturing Industry in Guangzhou (C X L J TD-201605), Foshan City Science and Technology Innovation Project (FS0AA-KJ919-4402-0141).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Peng, F.B.; Robert, A.H. Review of Paper-like Display Technologies. Prog. Electromagn. Res. 2014, 147, 95–116. [Google Scholar]

- Wang, X.D.; Chen, Y.; Deng, S.Z.; Xu, N.S. An application of electrophoretic display in large area screen. In Proceedings of the 2007 Asia Display; East China Normal University Press: Shanghai, China, 2007; Volume 2, pp. 1862–1863. [Google Scholar]

- Karlheinz, B.; Peter, D. Smart Pharmaceutical Packaging with E-Paper Display for improved Patient Compliance. SID Symp. Dig. Tech. Pap. 2018, 49, 271–274. [Google Scholar]

- Henzen, A.; Kamer, J. The present and future of electronic paper. J. Soc. Inf. Disp. 2006, 14, 437–442. [Google Scholar] [CrossRef]

- Zehner, R.; Week, D. Review: Reflective displays and E-paper. SID Symp. Dig. Tech. Pap. 2008, 24, 12–16. [Google Scholar]

- French, I. Invited paper: Flexible E-books. SID Symp. Dig. Tech. Pap. 2009, 40, 100–103. [Google Scholar] [CrossRef]

- Hank, C.; Abhijit, D. A Fundamental Overview of Accelerated Testing Analytical Models. In Proceedings of the Annual Reliability and Maintainability Symposium, Anaheim, CA, USA, 19–22 January 1998; pp. 389–393. [Google Scholar]

- Guerin, F.; Dumon, B. Accelerated life testing on repairable systems. In Proceedings of the Annual Reliability and Maintainability Symposium, Los Angeles, CA, USA, 26–29 January 2004; pp. 340–345. [Google Scholar]

- Chen, B.; Li, X. Research of accelerated life testing technology application at home and abroad. Struct. Environ. Eng. 2010, 6, 31–38. [Google Scholar]

- Wu, M.; Luo, Y.; Wu, F.; Chen, Y.; Wang, X.; Zeng, X. Lifetime prediction model of electrophoretic display based on high temperature and high humidity test. J. Soc. Inf. Disp. 2020, 28, 1–13. [Google Scholar] [CrossRef]

- Wang, B. Research to the hygrothermal ageing characteristic of solid rocket motor (SRM) adhint. China Adhes. 2006, 15, 5. [Google Scholar]

- IEC 62679-4-2. Electronic Paper Displays-Part 4-2: Environmental Test Method, 1st ed.; IEC Technical Committee: Geneva, Switzerland, 2015. [Google Scholar]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).