Use of Flue Gas Desulfurization Gypsum, Construction and Demolition Waste, and Oil Palm Waste Trunks to Produce Concrete Bricks

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

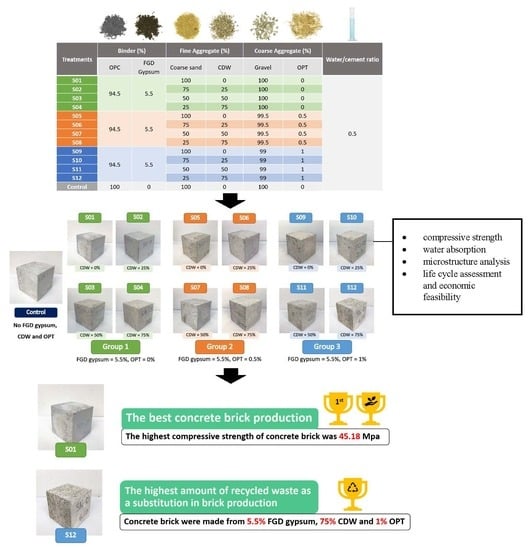

2.2. Production of Concrete Bricks

2.3. Environmental and Economic Analyses

3. Results and Discussion

3.1. Characteristics of OPC, FGD Gypsum, Coarse Sand, CDW, Gravel, and OPT

3.1.1. Chemical Composition

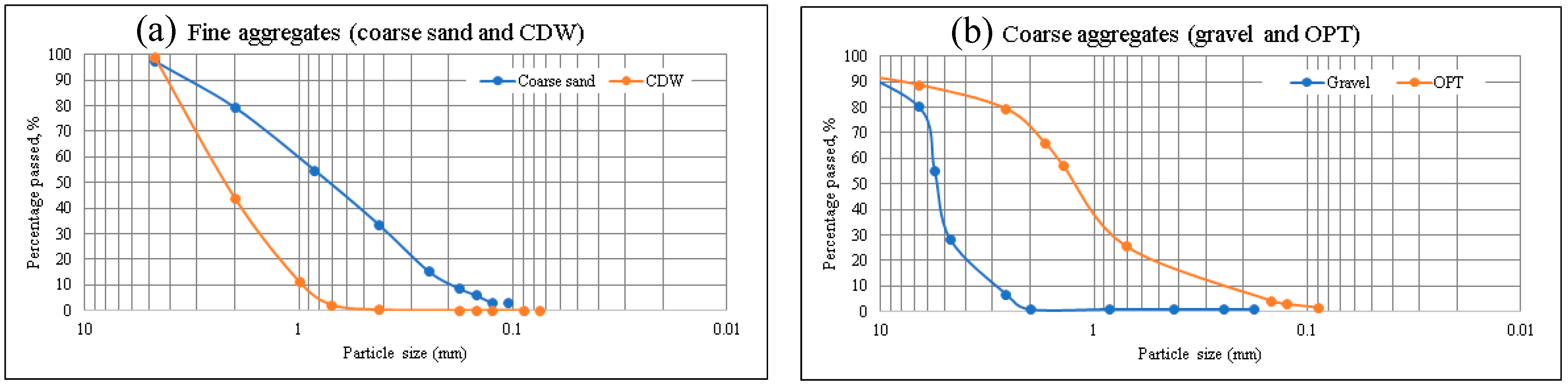

3.1.2. Particle Sizes

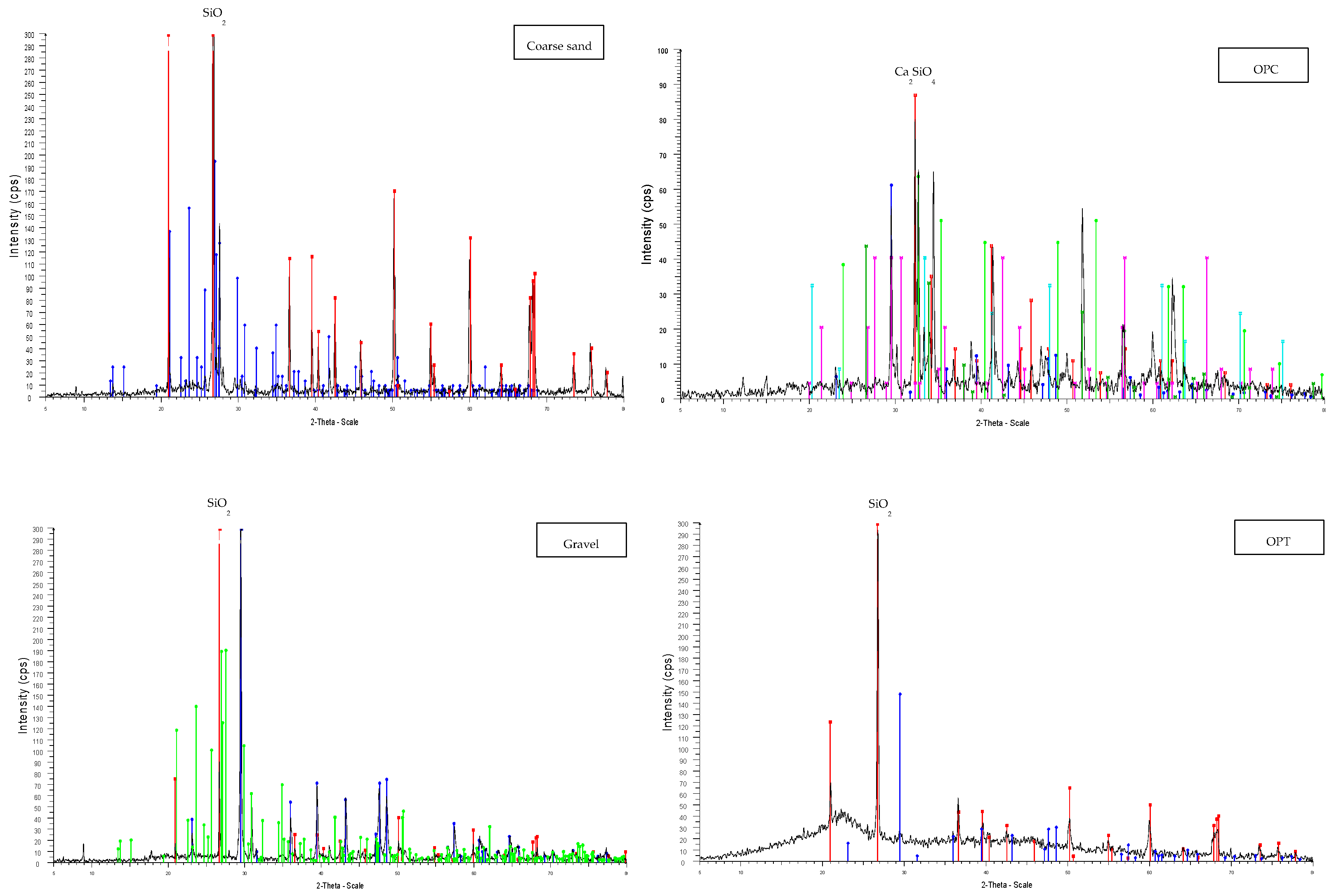

3.1.3. The Mineralogical Phase

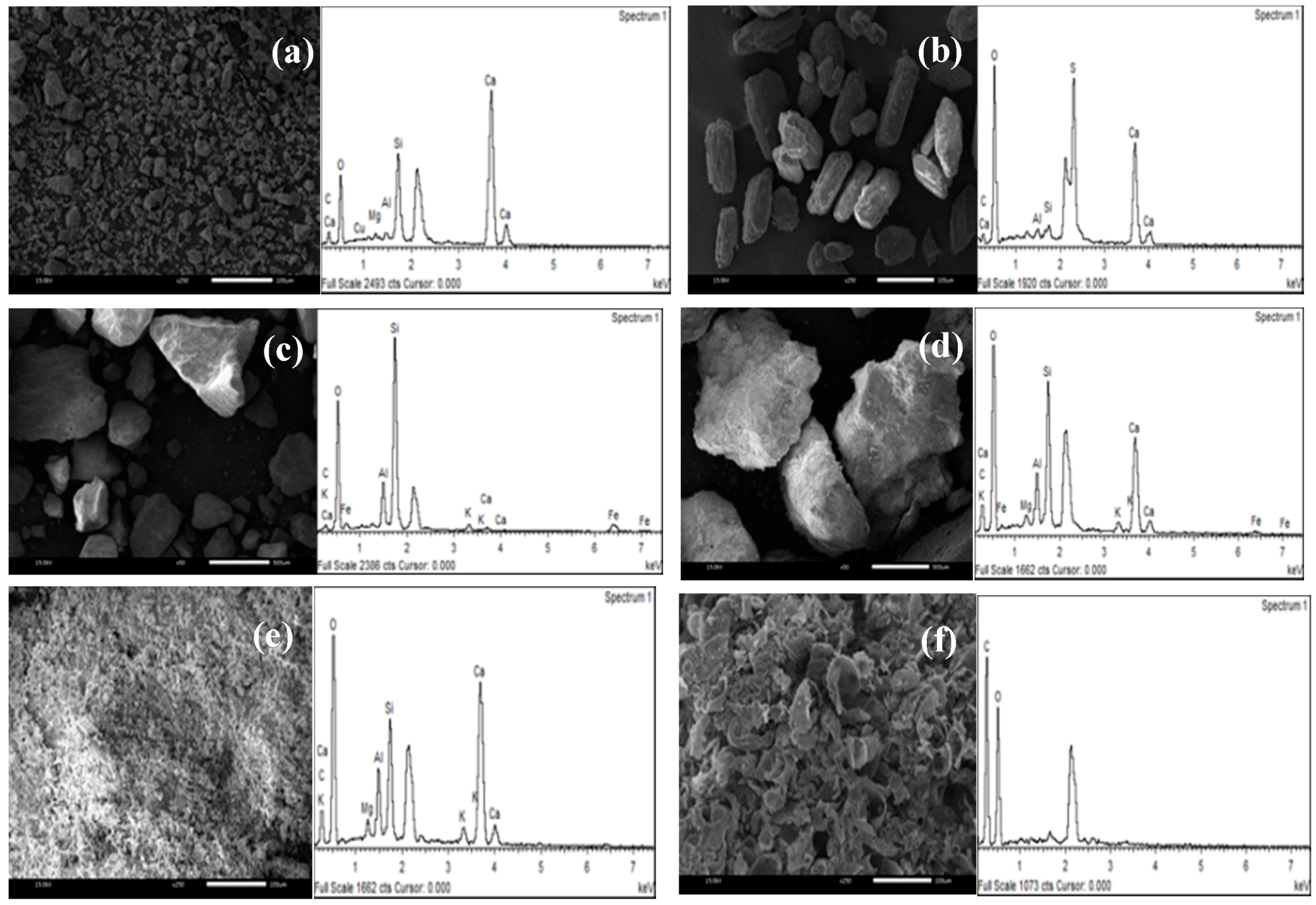

3.1.4. Microstructures of the Raw Materials

3.2. Characteristics of Concrete Bricks Made from OPC, FGD Gypsum, Coarse Sand, CDW, Gravel, and OPT

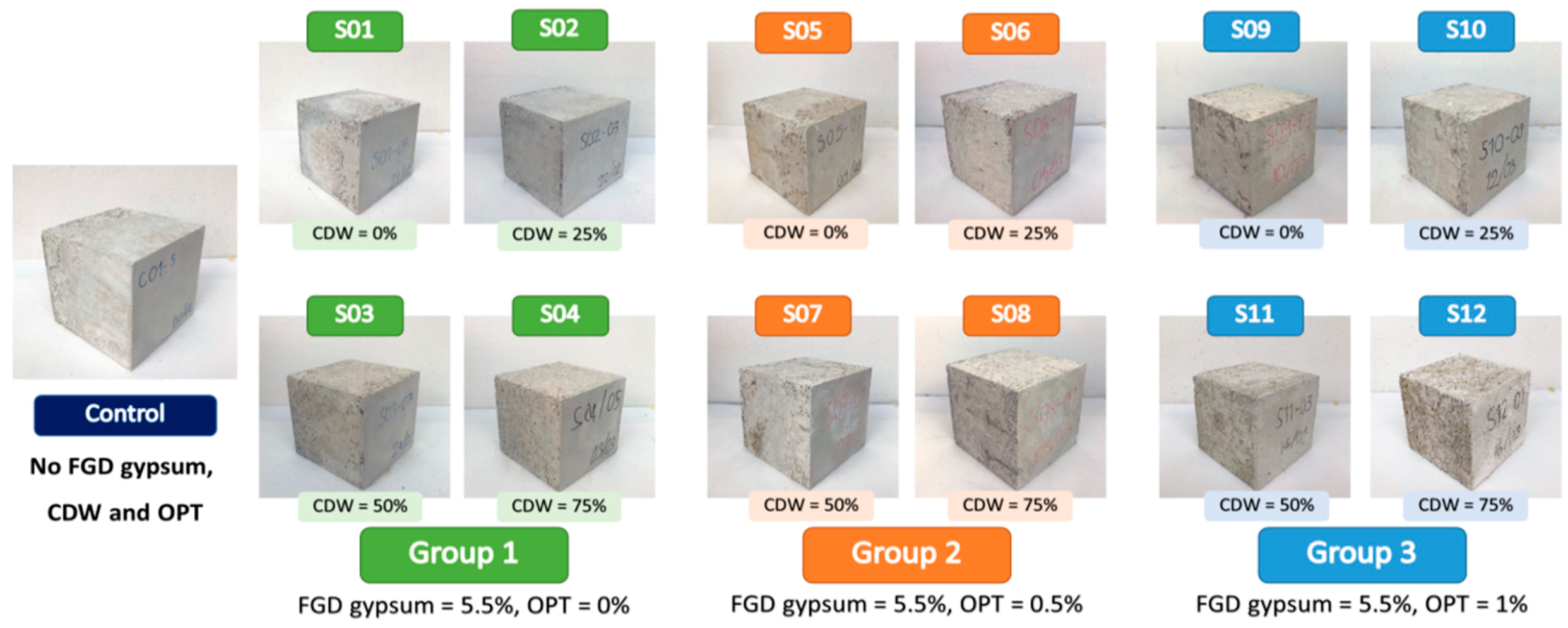

3.2.1. General Appearance of Concrete Bricks

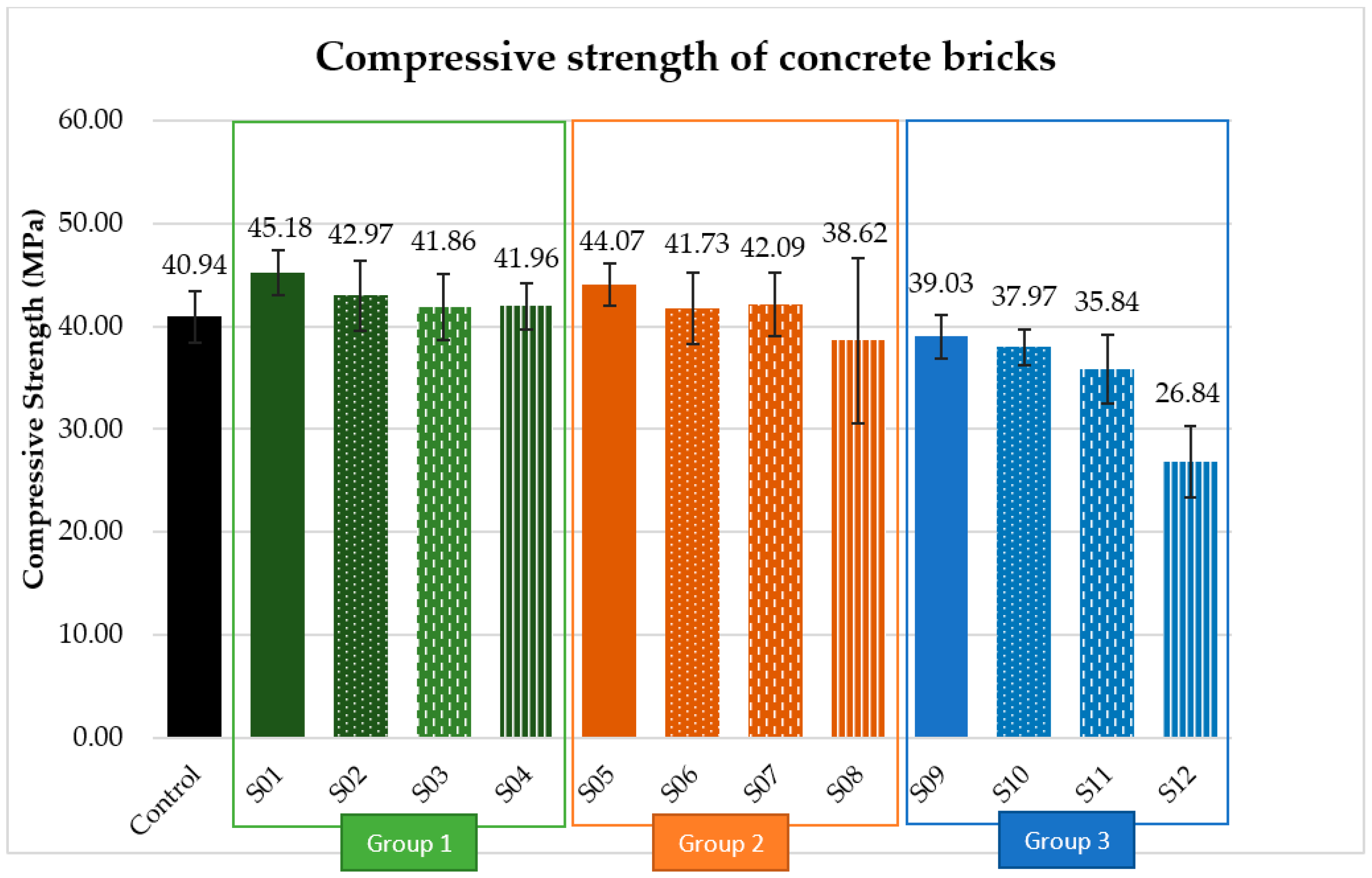

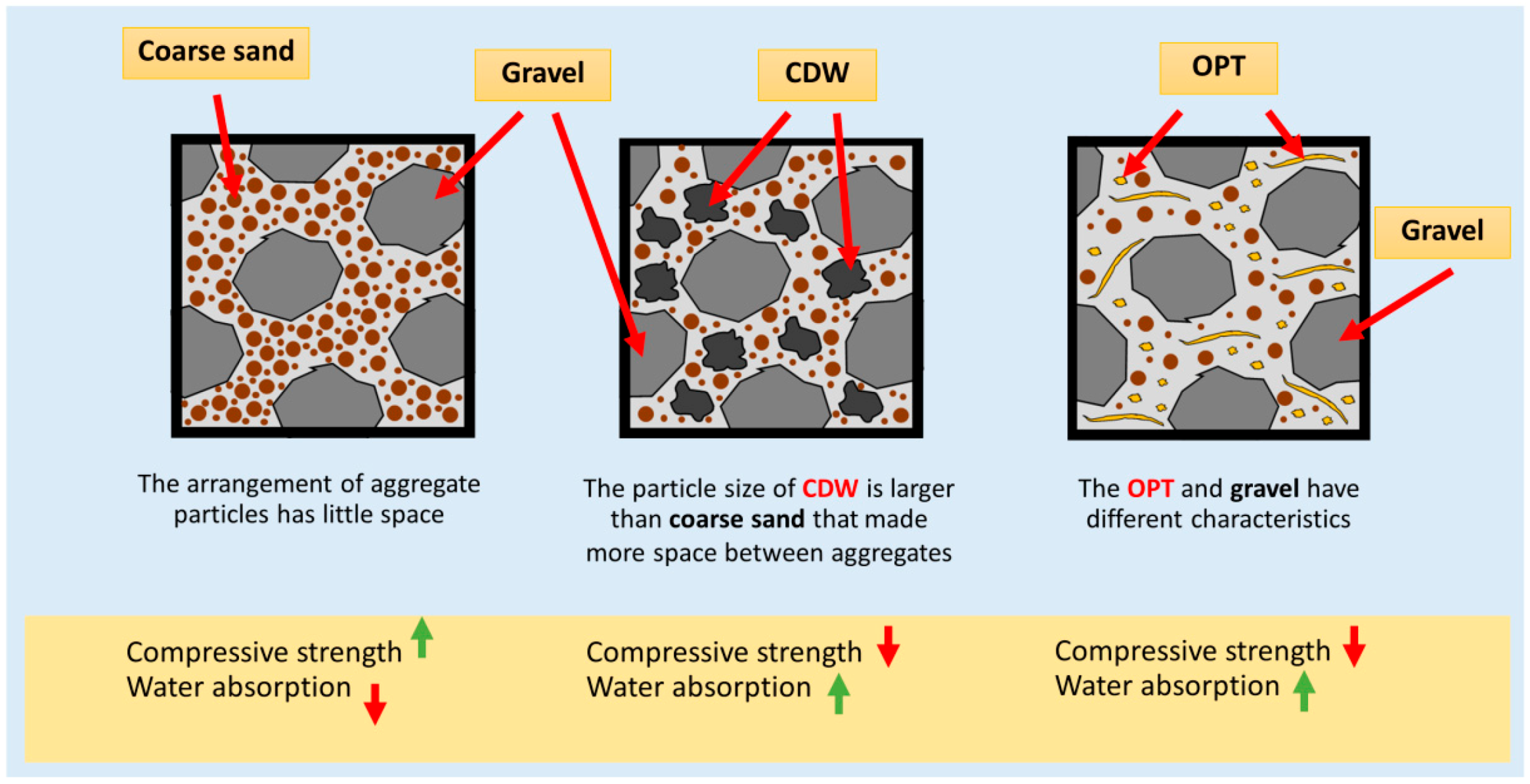

3.2.2. Compressive Strength of Concrete Bricks

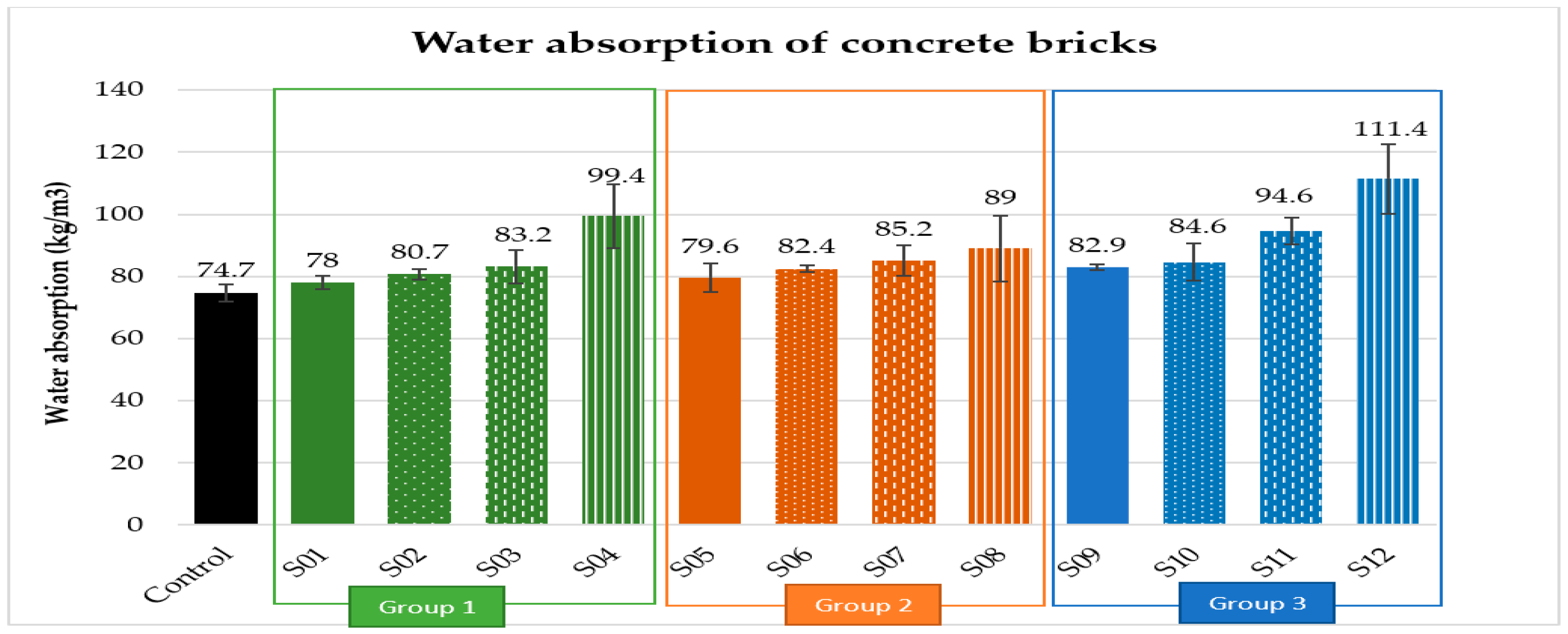

3.2.3. Water Absorption

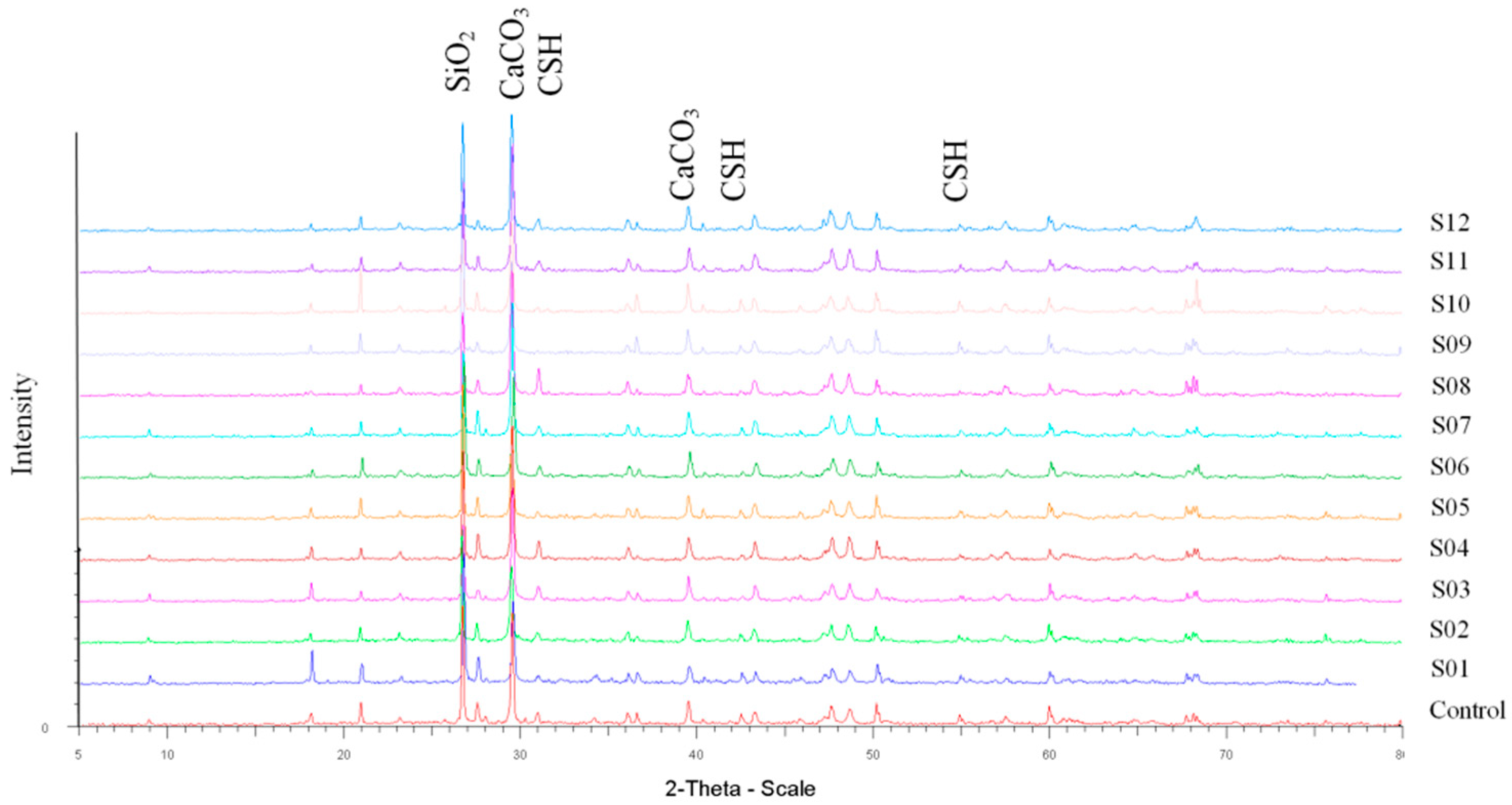

3.2.4. Mineralogical Phases of Concrete Bricks

3.2.5. Microstructure of Concrete Bricks

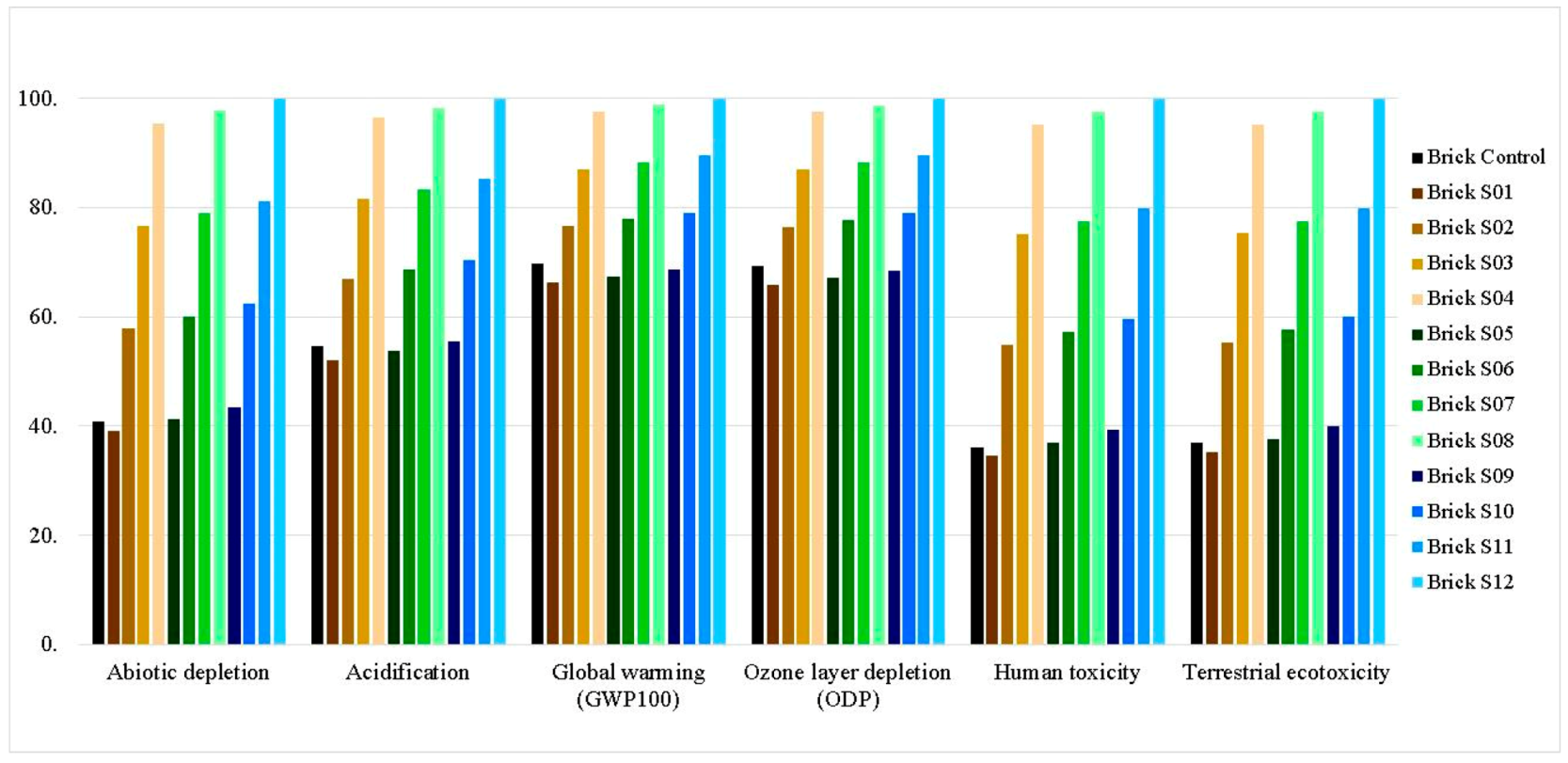

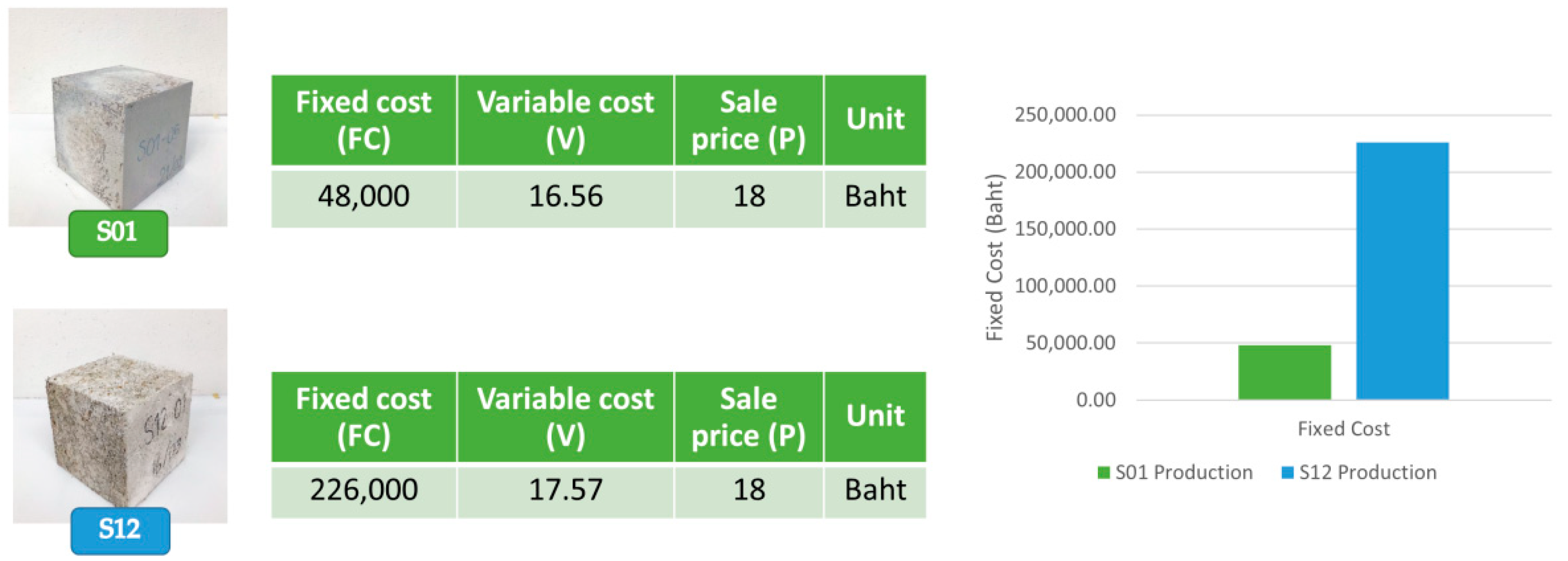

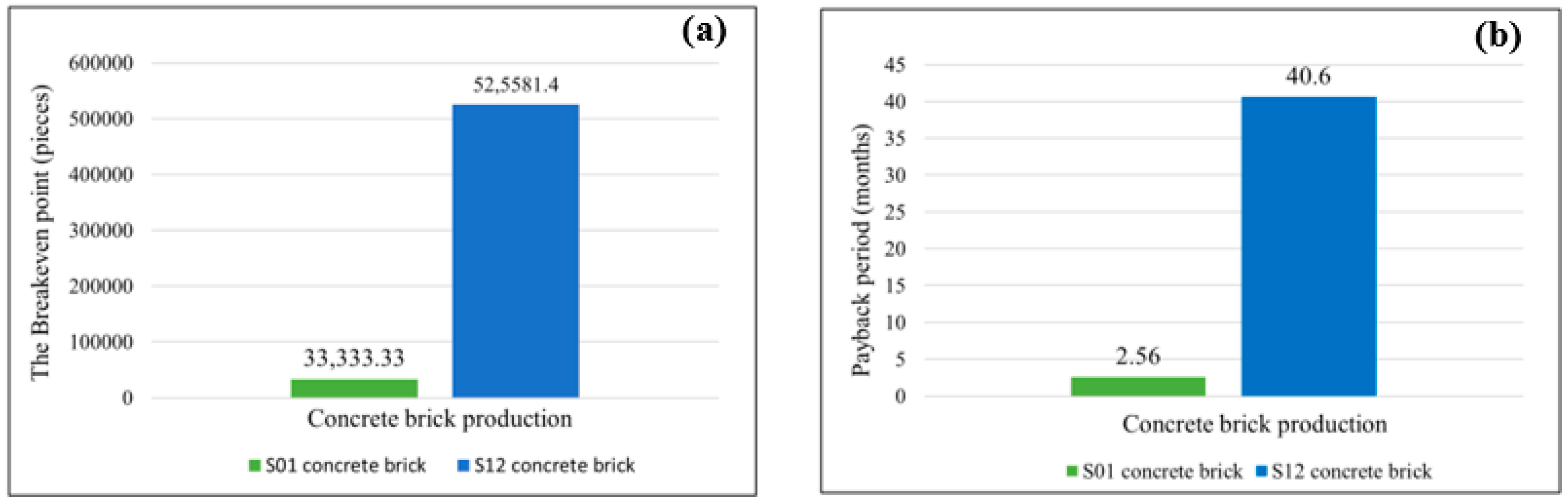

3.3. Life Cycle Assessment and Economic Feasibility of Concrete Bricks Made from OPC, FGD Gypsum, Coarse Sand, CDW, Gravel, and OPT

4. Conclusions

- Concrete brick specimen S01 produced from 5.5% FGD gypsum without CDW and OPT cured at 28 days obtained the highest compressive strength (45.18 MPa), while concrete brick specimen S12 produced from 5.5% FGD gypsum, 75% CDW, and 1% OPT obtained the lowest compressive strength (26.84 MPa).

- Adding only FGD gypsum in the production of concrete brick specimens showed that the compressive strength of these specimens increased with significant differences when compared to the compressive strength of the control.

- Using CDW and OPT led to similar effects: increasing CDW and OPT reduced the compressive strength and increased the water absorption of concrete bricks.

- All of the concrete brick proportions had compressive strength and water absorption that were compliant with the requirements of TIS 57-2530 and TIS 60-2516; thus, CDW, OPT, and FGD gypsum can be used as raw materials for bearing concrete masonry units.

- A comparison of the environmental impacts of concrete brick production showed that the production of S01 concrete bricks made with 5.5% FGD gypsum without CDW and OPT involved the lowest emissions. On the other hand, S12 concrete brick production led to the highest emissions due to the concrete bricks being made with 5.5% FGD gypsum, 75% CDW, and 1% OPT.

- The S01 concrete brick production had the shortest payback period due to the lower cost of the raw material preparation process, which does not require machinery for grinding and sieving.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Verian, K.P.; Ashraf, W.; Cao, Y. Properties of recycled concrete aggregate and their influence in new concrete production. Resour. Conserv. Recycl. 2018, 133, 30–49. [Google Scholar] [CrossRef]

- Medina, C.; Zhu, W.; Howind, T.; Frías, M.; De Sánchez Rojas, M.I. Effect of the constituents (asphalt, clay materials, floating particles and fines) of construction and demolition waste on the properties of recycled concretes. Constr. Build. Mater. 2015, 79, 22–33. [Google Scholar] [CrossRef]

- Ahmari, S.; Ren, X.; Toufigh, V.; Zhang, L. Production of geopolymeric binder from blended waste concrete powder and fly ash. Constr. Build. Mater. 2012, 35, 718–729. [Google Scholar] [CrossRef]

- Mo, K.H.; Johnson, A.U.; Jumaat, M.Z.; Yap, S.P. Feasibility study of high volume slag as cement replacement for sustainable structural lightweight oil palm shell concrete. J. Clean. Prod. 2015, 91, 297–304. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Van Den Heede, P.; De Belie, N. Environmental impact and life cycle assessment (LCA) of traditional and “green” concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Igliński, B.; Buczkowski, R. Development of cement industry in Poland—History, current state, ecological aspects. A review. J. Clean. Prod. 2017, 141, 702–720. [Google Scholar] [CrossRef]

- Jiang, L.; Li, C.; Wang, C.; Xu, N.; Chu, H. Utilization of flue gas desulfurization gypsum as an activation agent for high-volume slag concrete. J. Clean. Prod. 2018, 205, 589–598. [Google Scholar] [CrossRef]

- Nikhom, S. Characterization of Gypsum Paste Using Flue Gas Desulfurization Sludge, Rubber Wood Fly Ash and Kaolin. Master’s Thesis, Department of Civil Engineering (Structural Enginner), Prince of Songkla University, Songkhla, Thailand, 2010. [Google Scholar]

- Lei, D.Y.; Guo, L.P.; Sun, W.; Liu, J.P.; Miao, C.W. Study on properties of untreated FGD gypsum-based high-strength building materials. Constr. Build. Mater. 2017, 153, 765–773. [Google Scholar] [CrossRef]

- Caillahua, M.C.; Moura, F.J. Technical feasibility for use of FGD gypsum as an additive setting time retarder for Portland cement. J. Mater. Res. Technol. 2018, 7, 190–197. [Google Scholar] [CrossRef]

- Poon, C.S.; Qiao, X.C.; Lin, Z.S. Effects of flue gas desulphurization sludge on the pozzolanic reaction of reject-fly-ash-blended cement pastes. Cem. Concr. Res. 2004, 34, 1907–1918. [Google Scholar] [CrossRef]

- Fatemi, S.; Imaninasab, R. Performance evaluation of recycled asphalt mixtures by construction and demolition waste materials. Constr. Build. Mater. 2016, 120, 450–456. [Google Scholar] [CrossRef]

- Kongchuenak, S. Legal Measures for Recycling of Construction and Demolition Waste: A Comparative Study between Thailand and Japan. Master’s Thesis, Department of Natural Resources and Environmental Law, Faculty of Law, Thammasat University, Pathumthani, Thailand, 2016. [Google Scholar]

- Hu, K.; Chen, Y.; Naz, F.; Zeng, C.; Cao, S. Separation studies of concrete and brick from construction and demolition waste. Waste Manag. 2019, 85, 396–404. [Google Scholar] [CrossRef] [PubMed]

- Office of Agricultural Economics. Summary of Oil Palm Production in 2017. Available online: http://www.oae.go.th/assets/portals/1/fileups/prcaidata/files/oilpalm60_dis.pdf (accessed on 10 June 2019).

- Agricultural Research Development Agency. Oil Palm Production in Southern Thailand. Available online: http://www.arda.or.th/kasetinfo/south/palm/controller/01-12.php (accessed on 9 June 2019).

- Abnisa, F.; Arami-Niya, A.; Wan Daud, W.M.A.; Sahu, J.N.; Noor, I.M. Utilization of oil palm tree residues to produce bio-oil and bio-char via pyrolysis. Energy Convers. Manag. 2013, 76, 1073–1082. [Google Scholar] [CrossRef]

- Oil Palm Agronomical Research Center. Oil Palm Tree: The Propagation, Plantation Management; Knowledge book Series; Prince of Songkla University: Songkhla, Thailand, 2010; pp. 71–73. [Google Scholar]

- Traore, Y.B.; Messan, A.; Hannawi, K.; Gerard, J.; Prince, W.; Tsobnang, F. Effect of oil palm shell treatment on the physical and mechanical properties of lightweight concrete. Constr. Build. Mater. 2018, 161, 452–460. [Google Scholar] [CrossRef]

- Srisang, N.; Srisang, S.; Wongpitithawat, P.; The-Eye, K.; Wongkeaw, K.; Sinthoo, C. Production of Biomass Briquette from Residual Bleaching Earth and Empty Palm Bunch. Energy Procedia 2017, 138, 1079–1084. [Google Scholar] [CrossRef]

- Widyasti, E.; Shikata, A.; Hashim, R.; Sulaiman, O.; Sudesh, K.; Wahjono, E.; Kosugi, A. Biodegradation of fibrillated oil palm trunk fiber by a novel thermophilic, anaerobic, xylanolytic bacterium Caldicoprobacter sp. CL-2 isolated from compost. Enzym. Microb. Technol. 2018, 111, 21–28. [Google Scholar] [CrossRef]

- Selamat, M.E.; Hashim, R.; Sulaiman, O.; Kassim, M.H.M.; Saharudin, N.I.; Taiwo, O.F.A. Comparative study of oil palm trunk and rice husk as fillers in gypsum composite for building material. Constr. Build. Mater. 2019, 197, 526–532. [Google Scholar] [CrossRef]

- Gambhir, M.L. Grades of Concrete. In Concrete Technology, 3rd ed.; McGraw-Hill Publishing Co. Ltd.: New York, NY, USA, 2004; pp. 5–6. [Google Scholar]

- ASTM C39/39M-18. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM C642-13. Standard Test Method for Density, Absorption, and Voids in Hardened Concrete; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- TIS 57-2530. Standard for hollow load-bearing concrete masonry units. In Thailand Industrial Standard; Ministry of Industry: Bangkok, Thailand, 1990. [Google Scholar]

- TIS 60-2516. Standard for solid load-bearing concrete masonry units. In Thailand Industrial Standard; Ministry of Industry: Bangkok, Thailand, 1973. [Google Scholar]

- Li, D.; Zhuge, Y.; Gravina, R.; Mills, J.E. Compressive stress strain behavior of crumb rubber concrete (CRC) and application in reinforced CRC slab. Constr. Build. Mater. 2018, 166, 745–759. [Google Scholar] [CrossRef]

- Zahra, T.; Dhanasekar, M. Prediction of masonry compressive behaviour using a damage mechanics inspired modelling method. Constr. Build. Mater. 2016, 109, 128–138. [Google Scholar] [CrossRef]

- Mohamad, G.; Lourenço, P.B.; Roman, H.R. Mechanics of hollow concrete block masonry prisms under compression: Review and prospects. Cem. Concr. Compos. 2007, 29, 181–192. [Google Scholar] [CrossRef]

- Ahmad, M.R.; Chen, B. Influence of type of binder and size of plant aggregate on the hygrothermal properties of bio-concrete. Constr. Build. Mater. 2020, 251, 1–14. [Google Scholar] [CrossRef]

- Diquélou, Y.; Gourlay, E.; Arnaud, L.; Kurek, B. Impact of hemp shiv on cement setting and hardening: Influence of the extracted components from the aggregates and study of the interfaces with the inorganic matrix. Cem. Concr. Compos. 2015, 55, 112–121. [Google Scholar] [CrossRef]

- Dinh, T.M. Contribution to the Development of Precast Hempcrete Using Innovative Pozzolanic Binder; University of Toulouse: Toulouse, France, 2014. [Google Scholar]

- Hunnicutt, W. Characterization of Calcium-Silicate-Hydrate and Calcium-Alumino-Silicate-Hydrate. Master’s Thesis, Department of Civil Engineering. Graduate College, University of Illinois at Urbana-Champaign, Urbana, IL, USA, 2013. [Google Scholar]

- Afkhami, B.; Akbarian, B.; Beheshti, A.N.; Kakaee, A.H.; Shabani, B. Energy consumption assessment in a cement production plant. Sustain. Energy Technol. Assess. 2015, 10, 84–89. [Google Scholar] [CrossRef]

| Treatments | Binder (%) | Fine Aggregate (%) | Coarse Aggregate (%) | Water/Cement Ratio | |||

|---|---|---|---|---|---|---|---|

| OPC | FGD Gypsum | Coarse Sand | CDW | Gravel | OPT | ||

| S01 | 94.5 | 5.5 | 100 | 0 | 100 | 0 | 0.5 |

| S02 | 75 | 25 | 100 | 0 | |||

| S03 | 50 | 50 | 100 | 0 | |||

| S04 | 25 | 75 | 100 | 0 | |||

| S05 | 94.5 | 5.5 | 100 | 0 | 99.5 | 0.5 | |

| S06 | 75 | 25 | 99.5 | 0.5 | |||

| S07 | 50 | 50 | 99.5 | 0.5 | |||

| S08 | 25 | 75 | 99.5 | 0.5 | |||

| S09 | 94.5 | 5.5 | 100 | 0 | 99 | 1 | |

| S10 | 75 | 25 | 99 | 1 | |||

| S11 | 50 | 50 | 99 | 1 | |||

| S12 | 25 | 75 | 99 | 1 | |||

| Control | 100 | 0 | 100 | 0 | 100 | 0 | |

| Oxides | Content (wt%) | |||||

|---|---|---|---|---|---|---|

| OPC | FGD Gypsum | Coarse Sand | CDW | Gravel | OPT | |

| CaO | 68.78 | 43.84 | 1.34 | 27.90 | 68.98 | 20.32 |

| SiO2 | 16.85 | 2.36 | 85.82 | 55.12 | 17.32 | 26.90 |

| Al2O3 | 4.10 | 0.88 | 7.25 | 7.74 | 5.47 | 2.22 |

| SO3 | 3.94 | 49.45 | 0.03 | 0.67 | 0.11 | 4.05 |

| Fe2O3 | 3.60 | 0.82 | - | 3.34 | 3.36 | 8.75 |

| MgO | 1.30 | 1.79 | 0.21 | 1.56 | 2.20 | 3.09 |

| K2O | 0.54 | 0.14 | 4.47 | 2.67 | 1.88 | 22.75 |

| TiO2 | 0.28 | 0.03 | 0.16 | 0.36 | 0.30 | 0.47 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Phutthimethakul, L.; Kumpueng, P.; Supakata, N. Use of Flue Gas Desulfurization Gypsum, Construction and Demolition Waste, and Oil Palm Waste Trunks to Produce Concrete Bricks. Crystals 2020, 10, 709. https://doi.org/10.3390/cryst10080709

Phutthimethakul L, Kumpueng P, Supakata N. Use of Flue Gas Desulfurization Gypsum, Construction and Demolition Waste, and Oil Palm Waste Trunks to Produce Concrete Bricks. Crystals. 2020; 10(8):709. https://doi.org/10.3390/cryst10080709

Chicago/Turabian StylePhutthimethakul, Lalitsuda, Park Kumpueng, and Nuta Supakata. 2020. "Use of Flue Gas Desulfurization Gypsum, Construction and Demolition Waste, and Oil Palm Waste Trunks to Produce Concrete Bricks" Crystals 10, no. 8: 709. https://doi.org/10.3390/cryst10080709

APA StylePhutthimethakul, L., Kumpueng, P., & Supakata, N. (2020). Use of Flue Gas Desulfurization Gypsum, Construction and Demolition Waste, and Oil Palm Waste Trunks to Produce Concrete Bricks. Crystals, 10(8), 709. https://doi.org/10.3390/cryst10080709