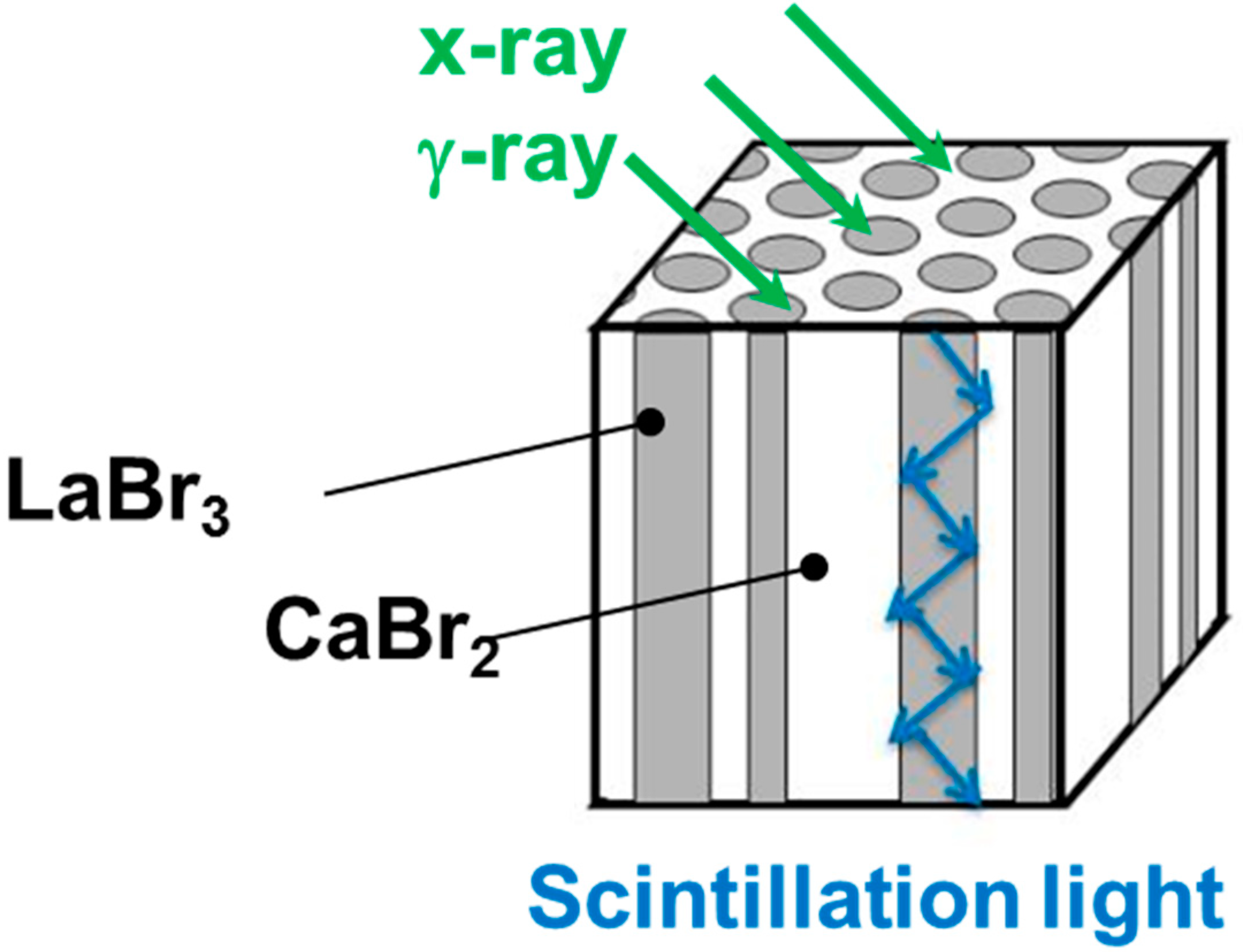

Growth and Scintillation Properties of Directionally Solidified Ce:LaBr3/AEBr2 (AE = Mg, Ca, Sr, Ba) Eutectic System

Abstract

1. Introduction

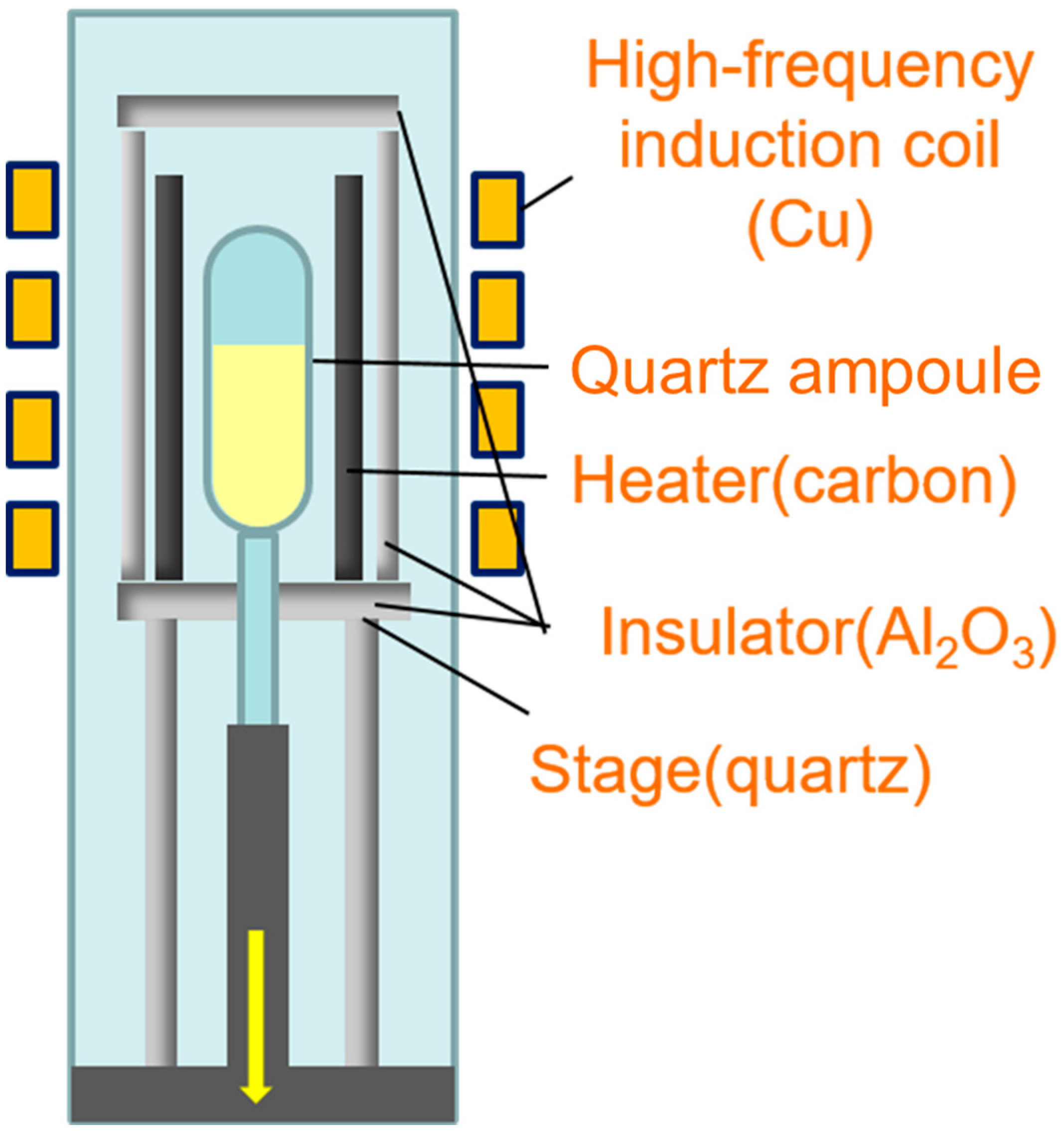

2. Experimental Procedure

2.1. Crystal Growth

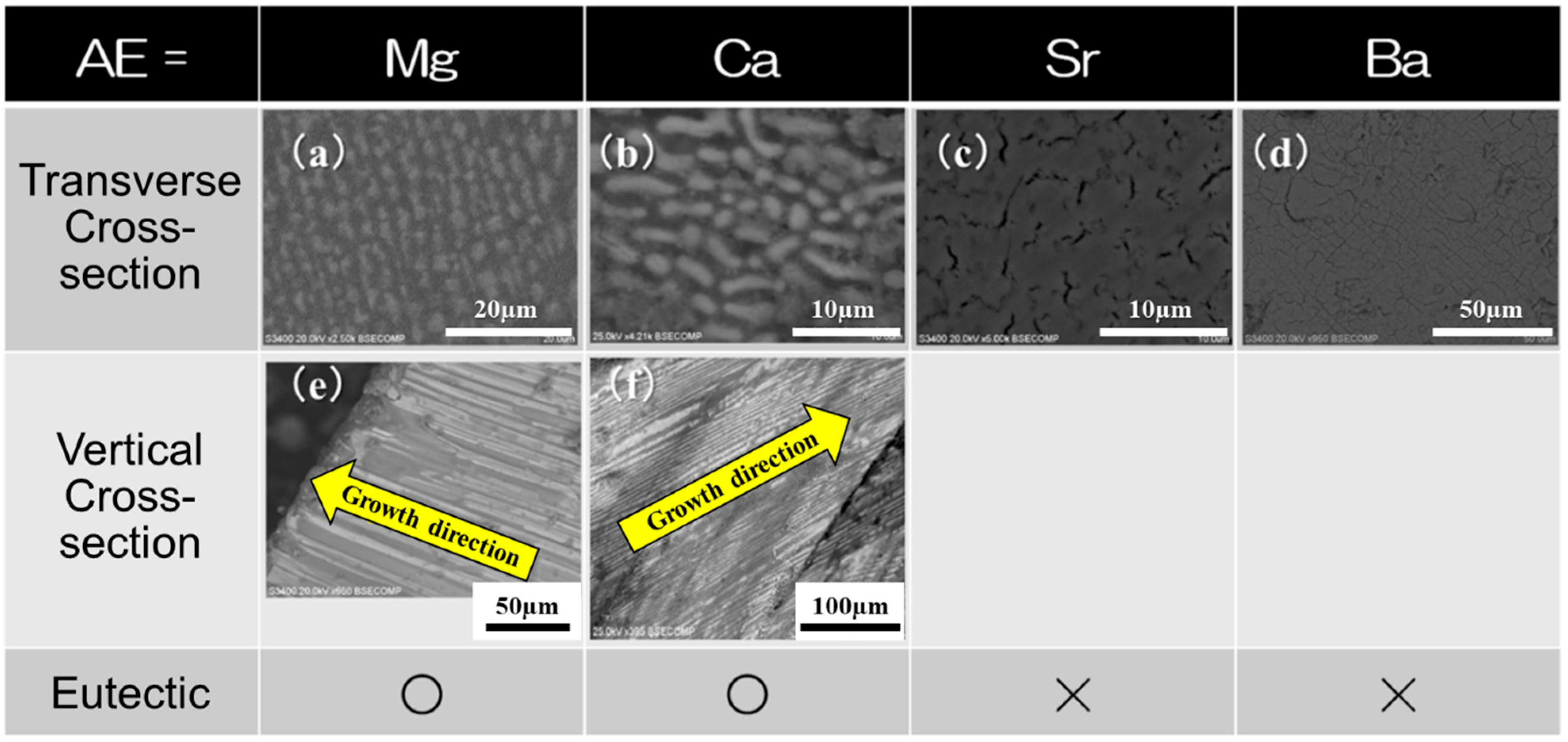

2.2. Structural Evaluation of Eutectic Composites

2.3. Measurements of Luminescence and Scintillation Properties

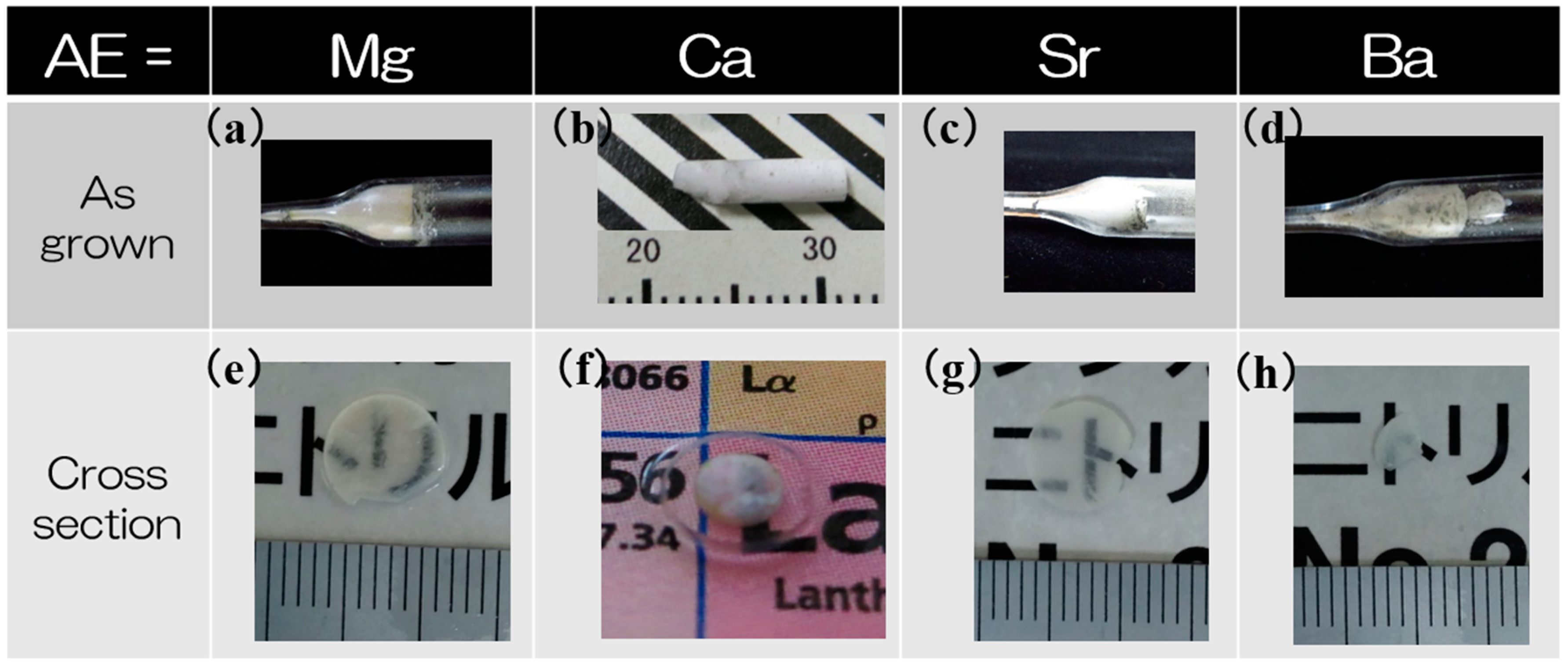

3. Results and Discussion

3.1. DSE System of LaBr3/AEBr2 Eutectic

3.2. Luminescence and Scintillation Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rinaldi, D.; Montalto, L. Scintillator crystals: Structure, characterization and models for better performances. Crystals 2020, 10, 96. [Google Scholar] [CrossRef]

- Tyrrell, G.C. Phosphors and scintillators in radiation imaging detectors. Nucl. Instrum. Methods Phys. Res. Sect. A 2005, 546, 180–187. [Google Scholar] [CrossRef]

- Nagarkar, V.V.; Gaysinskiy, V.; Shestakova, I.; Singh, B.; Teo, K.; Sun, M.; Barber, W.C.; Hasegawa, B. Near simultaneous combined SPECT/CT imaging using an EMCCD. IEEE Nucl. Sci. Symp. Conf. Rec. 2005, 4, 2607–2610. [Google Scholar]

- Michail, C.; Valais, I.; Seferis, I.; Kalyvas, N.; Fountos, G.; Kandarakis, I. Experimental measurement of a high resolution CMOS detector coupled to CsI scintillators under X-ray radiation. Radiat. Meas. 2015, 74, 39–46. [Google Scholar] [CrossRef]

- Blasse, G.; Grabmaier, B.C. Luminescent Materials; Springer: Berlin/Heidelberg, Germany, 1994. [Google Scholar]

- Howansky, A.; Lubinsky, A.R.; Suzuki, K.; Ghose, S.; Zhao, W. An apparatus and method for directly measuring the depth-dependent gain and spatial resolution of turbid scintillators. Med. Phys. 2018, 45, 4927–4941. [Google Scholar] [CrossRef]

- Philippov, D.; Popova, E.; Vinogradov, S.; Stifutkin, A.; Pleshko, A.; Klemin, S.; Ilyin, A.; Belyaev, V.; Besson, D.; Vandychev, M. Development of SiPM-based X-ray counting scanner for human inspection. IEEE Trans. Nucl. Sci. 2018, 65, 2013–2020. [Google Scholar] [CrossRef]

- Llorca, J.; Orera, V.M. Directionally solidified eutectic ceramic oxides. Prog. Mater. Sci. 2006, 51, 711–809. [Google Scholar] [CrossRef]

- Pawlak, D.A.; Kolodziejak, K.; Turczynski, S.; Kisielewski, J.; Rozniatowski, K.; Diduszko, R.; Kaczkan, M.; Malinowski, M. Self-organized, rodlike, micrometer-scale microstructure of Tb3Sc2Al3O12-TbScO3:Pr eutectic. Chem. Mater. 2006, 18, 2450–2457. [Google Scholar] [CrossRef]

- Bei, H.; George, E.P. Microstructures and mechanical properties of a directionally solidified NiAl-Mo eutectic alloy. Acta Mater. 2005, 53, 69–77. [Google Scholar] [CrossRef]

- Yanagida, T.; Fukuda, K.; Fujimoto, Y.; Kawaguchi, N.; Kurosawa, S.; Yamazaki, A.; Watanabe, K.; Futami, Y.; Yokota, Y.; Pejchal, J.; et al. Eu-doped 6LiF-SrF2 eutectic scintillators for neutron detection. Opt. Mater. 2012, 34, 868–871. [Google Scholar] [CrossRef]

- Ohashi, Y.; Yasui, N.; Yokota, Y.; Yoshikawa, A.; Den, T. Submicron-diameter phase-separated scintillator fibers for high-resolution X-ray imaging. App. Phy. Lett. 2013, 102, 05197. [Google Scholar] [CrossRef]

- Ohashi, Y.; Yasui, N.; Suzuki, T.; Watanabe, M.; Den, T.; Kamada, K.; Yokota, Y.; Yoshikawa, A. Orientation relationships of unidirectionally aligned GdAlO3/Al2O3 eutectic fibers. J. Eur. Ceram. Soc. 2014, 34, 3849–3857. [Google Scholar] [CrossRef]

- Kamada, K.; Yasui, N.; Ohashi, Y.; Den, T.; Yamaguchi, H.; Yamaji, A.; Shoji, Y.; Yoshisno, M.; Kim, K.J.; Kurosawa, S.; et al. Optimization of dopants and scintillation fibers’ diameter of GdAlO3/α-Al2O3 eutectic for high-resolution X-ray imaging. IEEE Trans. Nucl. Sci. 2018, 65, 2036–2040. [Google Scholar] [CrossRef]

- Kamada, K.; Kurosawa, S.; Shoji, Y.; Pejchal, J.; Ohashi, Y.; Yokota, Y.; Yoshikawa, A. Luminescence and scintillation properties of Ce dope SrHfO3 based eutectics. Opt. Mater. 2015, 41, 41–44. [Google Scholar] [CrossRef]

- Kamada, K.; Kurosawa, S.; Murakami, R.; Yokota, Y.; Pejchal, J.; Ohashi, Y.; Yoshikawa, A. Growth and scintillation properties of Ce doped Gd2Si2O7/SiO2 eutectics. J. Phys. Conf. Ser. 2015, 619, 012036. [Google Scholar] [CrossRef]

- Hishinuma, K.; Kamada, K.; Kurosawa, S.; Yamaji, A.; Pejchal, J.; Yokota, Y.; Ohashi, Y.; Yoshikawa, A. LiF/CaF2/LiBaF3 ternary fluoride eutectic scintillator. Jpn. J. Appl. Phys. 2015, 54, 04DH04. [Google Scholar] [CrossRef]

- Alekhin, M.S.; de Haas, J.T.M.; Khodyuk, I.V.; Krämer, K.W.; Menge, P.R.; Ouspenski, V.; Dorenbos, P. Improvement of γ-ray energy resolution of LaBr3:Ce3+ scintillation detectors by Sr2+ and Ca2+ co-doping. App. Phy. Lett. 2013, 102, 161915. [Google Scholar] [CrossRef]

- Van Loef, E.V.D.; Dorenbos, P.; van Eijk, C.W.E.; Krämer, K.W.; Gudel, H.U. Scintillation properties of LaBr3:Ce3+ crystals: Fast, efficient and high-energy-resolution scintillators. Nucl. Instrum. Methods Phys. Res. A 2002, 486, 254–258. [Google Scholar] [CrossRef]

- Yoshikawa, A.; Epelbaum, B.M.; Hasegawa, K.; Durbin, S.D.; Fukuda, T. Microstructures in oxide eutectic fibers grown by a modified micro-pulling-down method. J. Cryst. Growth 1999, 205, 305–316. [Google Scholar] [CrossRef]

- Jackson, K.A.; Hunt, J.D. Lamellar and rod eutectic growth. Trans. Metall. Soc. AIME 1966, 236, 1129. [Google Scholar]

- Hunt, J.D.; Chilton, J.P. An investigation of the lamellar and rod transition in binary eutectics. J. Inst. Met. 1962, 11, 338. [Google Scholar]

- Orera, V.M.; Pena, J.I.; Oliete, P.B.; Merino, R.I.; Larrea, A. Growth of eutectic ceramic structures by directional solidification methods. J. Cryst. Growth 2012, 360, 99–104. [Google Scholar] [CrossRef][Green Version]

- Oliete, P.B.; Mesa, M.C.; Merino, R.I.; Orera, V.M. Processing, microstructure and optical properties of the directionally solidified Al2O3–EuAlO3 eutectic rods. J. Cryst. Growth 2012, 360, 123–126. [Google Scholar] [CrossRef][Green Version]

- Liu, S.; Lee, J.H.; Trivedi, R. Dynamic effects in the lamellar–rod eutectic transition. Acta Mater. 2011, 59, 3102–3115. [Google Scholar] [CrossRef]

- Melcher, C.L.; Schweitzer, J.S. Cerium-doped lutetium oxyorthosilicate: A fast, efficient new scintillator. IEEE Trans. Nucl. Sci. 1992, 39, 502–505. [Google Scholar] [CrossRef]

- Pidol, L.; Kahn-Harari, A.; Viana, B.; Virey, E.; Ferrand, B.; Dorenbos, P.; de Haas, J.T.M.; van Eijk, C.W.E. High efficiency of lutetium silicate scintillators, Ce-doped LPS, and LYSO crystals. IEEE Trans. Nucl. Sci. 2004, 51, 1084–1087. [Google Scholar] [CrossRef]

| Peak Channel | Light Yield (Photon/MeV) | Scintillation Decay Time | ||

|---|---|---|---|---|

| 1st Component (ns) | 2nd Component (ns) | |||

| LaBr3/MgBr2 | 1512 | 34,300 | 18.8 (100%) | - |

| LaBr3/CaBr2 | 750 | ~17,000 | 22.4 (60%) | 185 (40%) |

| LaBr3/SrBr2 | 620 | ~14,000 | 38.6 (44%) | 299.8 (56%) |

| LaBr3/BaBr2 | 250 | ~6000 | N.D. | N.D. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.J.; Furuya, Y.; Kamada, K.; Murakami, R.; Kochurikhin, V.V.; Yoshino, M.; Chiba, H.; Kurosawa, S.; Yamaji, A.; Shoji, Y.; et al. Growth and Scintillation Properties of Directionally Solidified Ce:LaBr3/AEBr2 (AE = Mg, Ca, Sr, Ba) Eutectic System. Crystals 2020, 10, 584. https://doi.org/10.3390/cryst10070584

Kim KJ, Furuya Y, Kamada K, Murakami R, Kochurikhin VV, Yoshino M, Chiba H, Kurosawa S, Yamaji A, Shoji Y, et al. Growth and Scintillation Properties of Directionally Solidified Ce:LaBr3/AEBr2 (AE = Mg, Ca, Sr, Ba) Eutectic System. Crystals. 2020; 10(7):584. https://doi.org/10.3390/cryst10070584

Chicago/Turabian StyleKim, Kyoung Jin, Yuki Furuya, Kei Kamada, Rikito Murakami, Vladimir V. Kochurikhin, Masao Yoshino, Hiroyuki Chiba, Shunsuke Kurosawa, Akihiro Yamaji, Yasuhiro Shoji, and et al. 2020. "Growth and Scintillation Properties of Directionally Solidified Ce:LaBr3/AEBr2 (AE = Mg, Ca, Sr, Ba) Eutectic System" Crystals 10, no. 7: 584. https://doi.org/10.3390/cryst10070584

APA StyleKim, K. J., Furuya, Y., Kamada, K., Murakami, R., Kochurikhin, V. V., Yoshino, M., Chiba, H., Kurosawa, S., Yamaji, A., Shoji, Y., Toyoda, S., Sato, H., Yokota, Y., Ohashi, Y., & Yoshikawa, A. (2020). Growth and Scintillation Properties of Directionally Solidified Ce:LaBr3/AEBr2 (AE = Mg, Ca, Sr, Ba) Eutectic System. Crystals, 10(7), 584. https://doi.org/10.3390/cryst10070584