How Does Digital Capability Shape Resilient Supply Chains?—Evidence from China’s Electric Vehicle Manufacturing Industry

Abstract

1. Introduction

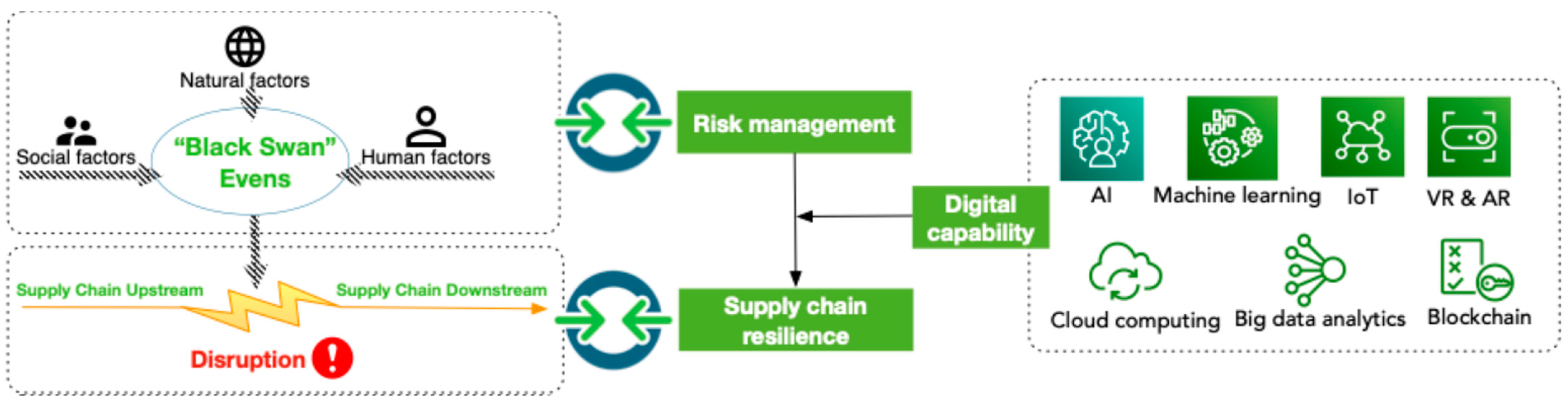

2. Theoretical Foundation

Organizational Information Processing Theory

3. Literature Review

3.1. Understanding of Supply Chain Resilience

3.2. Understanding of Supply Chain Risk Management

3.3. Understanding of Digital Capability

3.3.1. Definition of Digital Capability

3.3.2. Dimension of Digital Capability

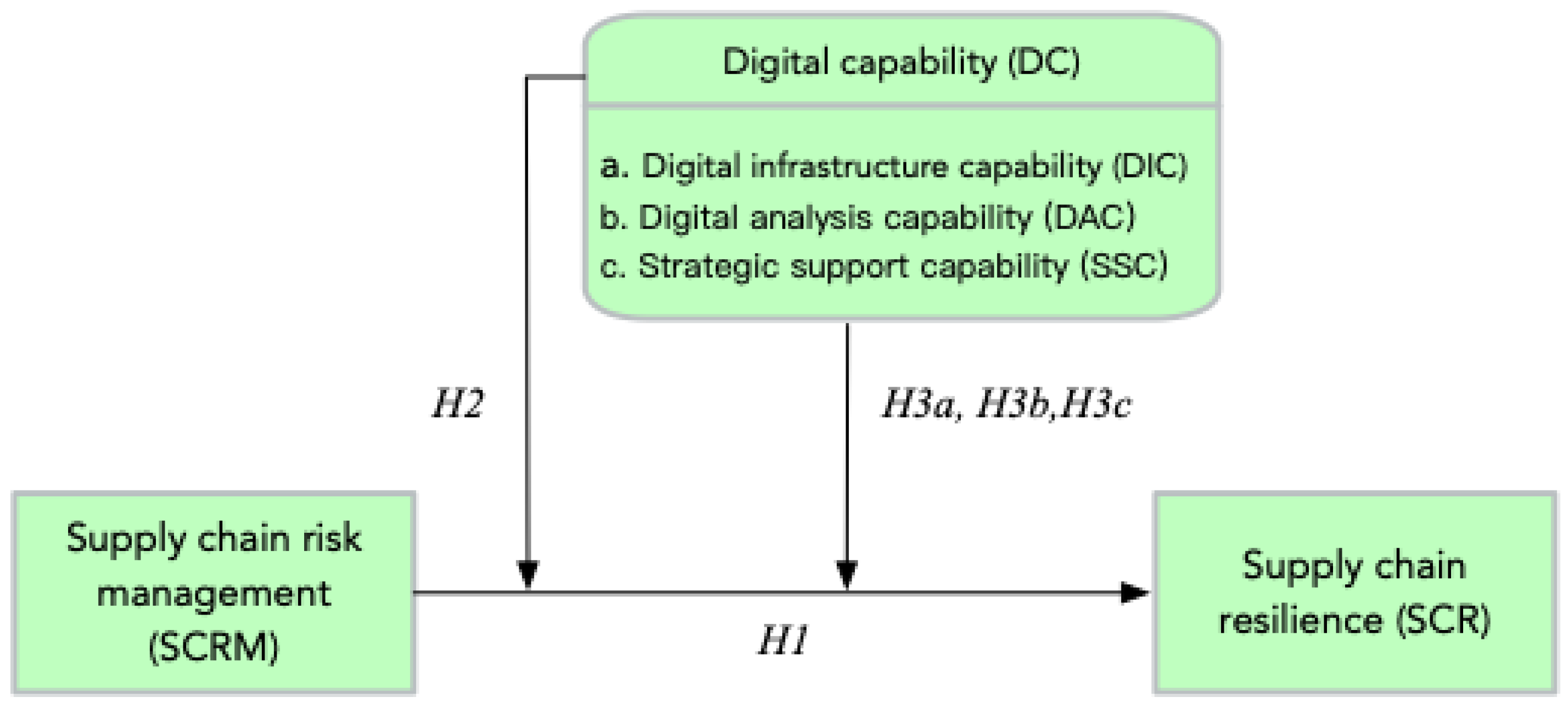

3.4. The Relationship Between Supply Chain Risk Management and Supply Chain Resilience

3.5. Moderating Effect of Digital Capability

- (1)

- Organizational Performance and Digital Transformation

- (2)

- Innovation and Institutional Environment

- (3)

- Supply Chain Management and Performance

4. Research Method

4.1. Measurement Development

4.2. Measurement Validation and Reliability

4.3. Sample and Data Collection

5. Results

5.1. Measure Validation and Reliability

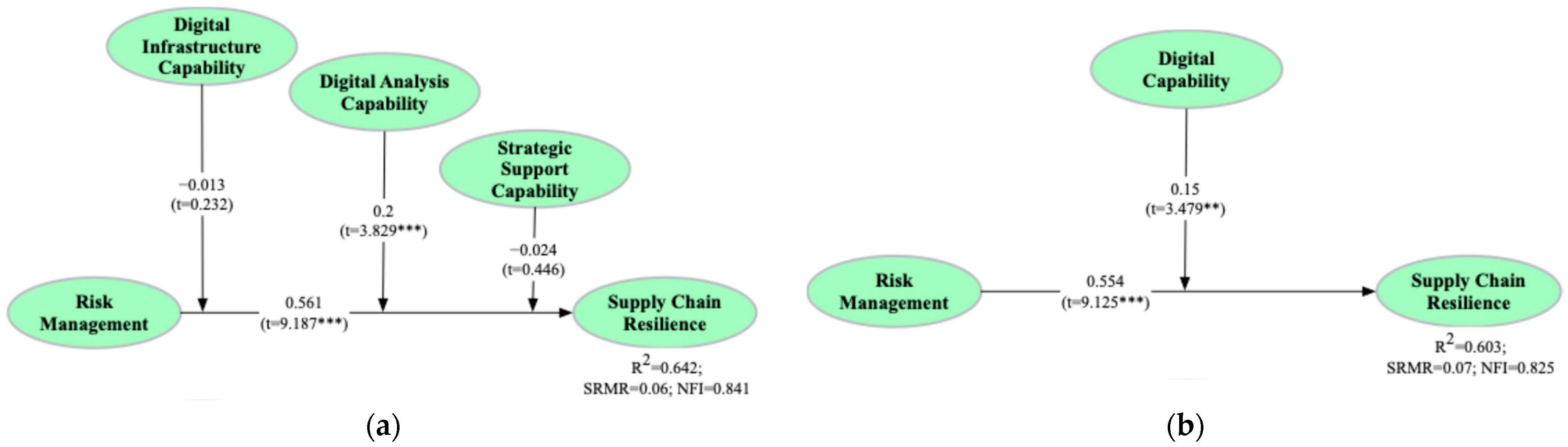

5.2. Hypothesis Testing

6. Conclusions

6.1. Discussion on Results

6.1.1. The Positive Impact of Supply Chain Risk Management on SCR Is Significant

6.1.2. The Moderating Effect of Digital Capability and Digital Analysis Capability Is Significant

6.1.3. The Moderating Effects of Digital Analysis Capability and Strategic Support Capability Are Not Significant

- Digital Infrastructure Capability

- Strategy Support Capability

6.2. Practical Inspiration

6.2.1. Priority Investment Targets: Factors Positive Affecting SCR

- (1)

- Supply Chain Risk Management

- (2)

- Digital Capability and Digital Analysis Capability

6.2.2. Long-Term Development Strategies: Factors with Unsupported Moderating Effects

- (1)

- Digital Infrastructure Capability

- (2)

- Strategic Support Capability

6.3. Theoretical Significance

6.4. Limitations and Future Research

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Argun, I.D.; Kilic, S.A. Result of Digitalization in the Automotive Industry: Total Equipment Effectiveness and Bayesian Analysis. IEEE Trans. Eng. Manag. 2024, 71, 6205–6217. [Google Scholar] [CrossRef]

- Xing, J.; Liu, X.; Zhang, Y. Development of the electric vehicle industry in China. China Econ. J. 2023, 16, 139–184. [Google Scholar] [CrossRef]

- Bhuwalka, K.; Field, F.R., 3rd; De Kleine, R.D.; Kim, H.C.; Wallington, T.J.; Kirchain, R.E. Characterizing the Changes in Material Use due to Vehicle Electrification. Environ. Sci. Technol. 2021, 55, 10097–10107. [Google Scholar] [CrossRef]

- Seyed, R.S.N.F.; Fatemeh, G.G. The Impact of Internal and External Driving Forces and Strategic Decisions on Supply Chain Risk Management (Case Study: Automotive Industry). J. Appl. Res. Ind. Eng. 2023, 10, 472–491. [Google Scholar] [CrossRef]

- Kumar, A.; Shrivastav, S.K.; Bhattacharyya, S. Measuring strategic fit using big data analytics in the automotive supply chain: A data source triangulation-based research. Int. J. Product. Perform. Manag. 2022, 72, 2977–2999. [Google Scholar] [CrossRef]

- El Baz, J.; Ruel, S. Can supply chain risk management practices mitigate the disruption impacts on supply chains’ resilience and robustness? Evidence from an empirical survey in a COVID-19 outbreak era. Int. J. Prod. Econ. 2021, 233, 107972. [Google Scholar] [CrossRef]

- Lotfi, M.; Larmour, A. Supply chain resilience in the face of uncertainty: How horizontal and vertical collaboration can help? Contin. Resil. Rev. 2021, 4, 37–53. [Google Scholar] [CrossRef]

- Madhavika, N.; Jayasinghe, N.; Ehalapitiya, S.; Wickramage, T.; Fernando, D.; Jayasinghe, V. Operationalizing resilience through collaboration: The case of Sri Lankan tea supply chain during Covid-19. Qual. Quant. Int. J. Methodol. 2023, 57, 2981–3018. [Google Scholar] [CrossRef]

- Montanyà, O.; Amat, O. The resilience factors of the agri-food supply chain: An integrative review of the literature in the context of the COVID-19 pandemic. Intang. Cap. 2023, 19, 379–392. [Google Scholar] [CrossRef]

- Harju, A.; Hallikas, J.; Immonen, M.; Lintukangas, K. The impact of procurement digitalization on supply chain resilience: Empirical evidence from Finland. Supply Chain Manag. Int. J. 2023, 28, 62–76. [Google Scholar] [CrossRef]

- Iftikhar, A.; Purvis, L.; Giannoccaro, I.; Wang, Y. The impact of supply chain complexities on supply chain resilience: The mediating effect of big data analytics. Prod. Plan. Control 2022, 34, 1562–1582. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Fosso Wamba, S.; Roubaud, D.; Foropon, C. Empirical investigation of data analytics capability and organizational flexibility as complements to supply chain resilience. Int. J. Prod. Res. 2019, 59, 110–128. [Google Scholar] [CrossRef]

- Dubey, R.; Bryde, D.J.; Dwivedi, Y.K.; Graham, G.; Foropon, C.; Papadopoulos, T. Dynamic digital capabilities and supply chain resilience: The role of government effectiveness. Int. J. Prod. Econ. 2023, 258, 108790. [Google Scholar] [CrossRef]

- Belhadi, A.; Kamble, S.; Subramanian, N.; Singh, R.K.; Venkatesh, M. Digital capabilities to manage agri-food supply chain uncertainties and build supply chain resilience during compounding geopolitical disruptions. Int. J. Oper. Prod. Manag. 2024, 44, 1914–1950. [Google Scholar] [CrossRef]

- Zhao, N.; Hong, J.; Lau, K.H. Impact of supply chain digitalization on supply chain resilience and performance: A multi-mediation model. Int. J. Prod. Econ. 2023, 259, 108817. [Google Scholar] [CrossRef]

- Abourokbah, S.H.; Mashat, R.M.; Salam, M.A. Role of Absorptive Capacity, Digital Capability, Agility, and Resilience in Supply Chain Innovation Performance. Sustainability 2023, 15, 3636. [Google Scholar] [CrossRef]

- Liu, H.; Lu, F.; Shi, B.; Hu, Y.; Li, M. Big data and supply chain resilience: Role of decision-making technology. Manag. Decis. 2023, 61, 2792–2808. [Google Scholar] [CrossRef]

- Zamani, E.D.; Smyth, C.; Gupta, S.; Dennehy, D. Artificial intelligence and big data analytics for supply chain resilience: A systematic literature review. Ann. Oper. Res. 2023, 327, 605–632. [Google Scholar] [CrossRef] [PubMed]

- Waqas, U.; Abd Rahman, A.; Ismail, N.W.; Kamal Basha, N.; Umair, S. Influence of supply chain risk management and its mediating role on supply chain performance: Perspectives from an agri-fresh produce. Ann. Oper. Res. 2023, 324, 1399–1427. [Google Scholar] [CrossRef]

- Ivanov, D. Digital Supply Chain Management and Technology to Enhance Resilience by Building and Using End-to-End Visibility During the COVID-19 Pandemic. IEEE Trans. Eng. Manag. 2024, 71, 10485–10495. [Google Scholar] [CrossRef]

- John, K.G. Power and the Useful Economist. Am. Econ. Rev. 1973, 63, 1–11. [Google Scholar]

- Yu, W.; Chavez, R.; Jacobs, M.A.; Wong, C.Y. Openness to Technological Innovation, Supply Chain Resilience, and Operational Performance: Exploring the Role of Information Processing Capabilities. IEEE Trans. Eng. Manag. Eng. Manag. 2024, 71, 1258–1270. [Google Scholar] [CrossRef]

- Premkumar, G.; Ramamurthy, K.; Carol, S.S. Information Processing View of Organizations: An Exploratory Examination of Fit in the Context of Interorganizational Relationships. J. Manag. Inf. Syst. 2005, 22, 257–294. [Google Scholar] [CrossRef]

- Ana, S.e.; Lia, O.; José, C.R.; Orlanda, S.; Gustavo, D.; Ana, C.B. Environmental Factors Influencing the Adoption of Digitalization Technologies in Automotive Supply Chains. In Proceedings of the 2019 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Valbonne Sophia-Antipolis, France, 17–19 June 2019. [Google Scholar]

- Grida, M.; Mohamed, R.; Zaied, A.N.H. Evaluate the impact of COVID-19 prevention policies on supply chain aspects under uncertainty. Transp. Res. Interdiscip. Perspect. 2020, 8, 100240. [Google Scholar] [CrossRef]

- Wong, C.W.Y.; Lirn, T.-C.; Yang, C.-C.; Shang, K.-C. Supply chain and external conditions under which supply chain resilience pays: An organizational information processing theorization. Int. J. Prod. Econ. 2020, 226, 107610. [Google Scholar] [CrossRef]

- Tiwari, M.; Bryde, D.J.; Stavropoulou, F.; Dubey, R.; Kumari, S.; Foropon, C. Modelling supply chain Visibility, digital Technologies, environmental dynamism and healthcare supply chain Resilience: An organisation information processing theory perspective. Transp. Res. Part E Logist. Transp. Rev. 2024, 188, 103613. [Google Scholar] [CrossRef]

- Fan, H.; Li, G.; Sun, H.; Cheng, T.C.E. An information processing perspective on supply chain risk management: Antecedents, mechanism, and consequences. Int. J. Prod. Econ. 2017, 185, 63–75. [Google Scholar] [CrossRef]

- Rashid, A.; Rasheed, R.; Ngah, A.H.; Pradeepa Jayaratne, M.D.R.; Rahi, S.; Tunio, M.N. Role of information processing and digital supply chain in supply chain resilience through supply chain risk management. J. Glob. Oper. Strateg. Sourc. 2024, 17, 429–447. [Google Scholar] [CrossRef]

- Jain, N.K.; Chakraborty, K.; Choudhary, P. Building supply chain resilience through industry 4.0 base technologies: Role of supply chain visibility and environmental dynamism. J. Bus. Ind. Mark. 2024, 39, 1750–1763. [Google Scholar] [CrossRef]

- Li, Y.; Li, D.; Liu, Y.; Shou, Y. Digitalization for supply chain resilience and robustness: The roles of collaboration and formal contracts. Front. Eng. Manag. 2023, 10, 5–19. [Google Scholar] [CrossRef]

- Xu, L.; Wang, Y.; He, W. Enhancing supply chain resilience through digital transformation: The role of blockchain and IoT technologies. J. Bus. Res. 2021, 132, 464–475. [Google Scholar]

- Holling, C.S. Resilience and stability of ecological systems. Annu. Rev. Ecol. Syst. 1973, 4, 1–23. [Google Scholar] [CrossRef]

- Godschalk, D.R. Urban Hazard Mitigation: Creating Resilient Cities. Nat. Hazards Rev. 2003, 4, 136–143. [Google Scholar] [CrossRef]

- Ponomarov, S.Y.; Holcomb, M.C. Understanding the concept of supply chain resilience. Int. J. Logist. Manag. 2009, 20, 124–143. [Google Scholar] [CrossRef]

- Ali, A.; Mahfouz, A.; Arisha, A. Analysing supply chain resilience: Integrating the constructs in a concept mapping framework via a systematic literature review. Supply Chain Manag. Int. J. 2017, 22, 16–39. [Google Scholar] [CrossRef]

- Stephanie, B.; Daniel, G.-S. Supply chain resilience in a pandemic: The need for revised contingency planning. Manag. Dyn. Knowl. Econ. 2020, 8, 325–343. [Google Scholar]

- Jessica, O.A.; Alejandro, V.S. Supply Chain Resilience Roadmaps for Major Disruptions. Logistics 2021, 5, 78. [Google Scholar] [CrossRef]

- Stephens, A.R.; Kang, M.; Robb, C.A. Linking Supply Chain Disruption Orientation to Supply Chain Resilience and Market Performance with the Stimulus–Organism–Response Model. J. Risk Financ. Manag. 2022, 15, 227. [Google Scholar] [CrossRef]

- Jafarnejad, A.; Momeni, M.; Razavi Hajiagha, S.H.; Faridi Khorshidi, M. A dynamic supply chain resilience model for medical equipment’s industry. J. Model. Manag. 2019, 14, 816–840. [Google Scholar] [CrossRef]

- Adnan, Z.H.; Chakraborty, K.; Bag, S.; Wu, J.S. Pricing and green investment strategies for electric vehicle supply chain in a competitive market under different channel leadership. Ann. Oper. Res. 2023. [Google Scholar] [CrossRef]

- Fan, Y.; Stevenson, M. A review of supply chain risk management: Definition, theory, and research agenda. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 205–230. [Google Scholar] [CrossRef]

- Manuj, I.; Mentzer, J.T. Global supply chain risk management strategies. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 192–223. [Google Scholar] [CrossRef]

- Badhotiya, G.K.; Soni, G.; Jain, V.; Joshi, R.; Mittal, S. Assessing supply chain resilience to the outbreak of COVID-19 in Indian manufacturing firms. Oper. Manag. Res. Adv. Pract. Through Theory 2022, 15, 1161–1180. [Google Scholar] [CrossRef]

- Parast, M.M.; Subramanian, N. An examination of the effect of supply chain disruption risk drivers on organizational performance: Evidence from Chinese supply chains. Supply Chain Manag. Int. J. 2021, 26, 548–562. [Google Scholar] [CrossRef]

- Rauniyar, K.; Wu, X.; Gupta, S.; Modgil, S.; Lopes de Sousa Jabbour, A.B. Risk management of supply chains in the digital transformation era: Contribution and challenges of blockchain technology. Ind. Manag. Data Syst. 2023, 123, 253–277. [Google Scholar] [CrossRef]

- Khan, K.; Keramati, A. A Framework for Smart Supply Chain Risk Assessment. Int. J. Inf. Syst. Supply Chain Manag. 2023, 16, 1–17. [Google Scholar] [CrossRef]

- Yang, M.; Lim, M.K.; Qu, Y.; Ni, D.; Xiao, Z. Supply chain risk management with machine learning technology: A literature review and future research directions. Comput. Ind. Eng. 2023, 175, 108859. [Google Scholar] [CrossRef]

- Annarelli, A.; Battistella, C.; Nonino, F.; Parida, V.; Pessot, E. Literature review on digitalization capabilities: Co-citation analysis of antecedents, conceptualization and consequences. Technol. Forecast. Soc. Change 2021, 166, 120635. [Google Scholar] [CrossRef]

- Gupta, S.; Bag, S.; Modgil, S.; Beatriz Lopes de Sousa Jabbour, A.; Kumar, A. Examining the influence of big data analytics and additive manufacturing on supply chain risk control and resilience: An empirical study. Comput. Ind. Eng. 2022, 172, 108629. [Google Scholar] [CrossRef]

- Khin, S.; Ho, T.C.F. Digital technology, digital capability and organizational performance. Int. J. Innov. Sci. 2019, 11, 177–195. [Google Scholar] [CrossRef]

- Proksch, D.; Rosin, A.F.; Stubner, S.; Pinkwart, A. The influence of a digital strategy on the digitalization of new ventures: The mediating effect of digital capabilities and a digital culture. J. Small Bus. Manag. 2021, 62, 1–29. [Google Scholar] [CrossRef]

- Lenka, S.; Parida, V.; Wincent, J. Digitalization Capabilities as Enablers of Value Co-Creation in Servitizing Firms. Psychol. Mark. 2017, 34, 92–100. [Google Scholar] [CrossRef]

- Sanja, T.; Nicholas, B.; Jan, v.B. Three types of chief digital officers and the reasons organizations adopt the role. In Strategic Information Managemen; Routledge Taylor & Francis Group: London, UK, 2020; pp. 292–308. [Google Scholar]

- Levallet, N.; Chan, Y.E. Role of Digital Capabilities in Unleashing the Power of Managerial Improvisation. MIS Q. Exec. 2018, 17, 3. [Google Scholar]

- Warner, K.S.R.; Wäger, M. Building dynamic capabilities for digital transformation: An ongoing process of strategic renewal. Long Range Plan. 2019, 52, 326–349. [Google Scholar] [CrossRef]

- Gong, Y.; Yao, Y.; Zan, A. The too-much-of-a-good-thing effect of digitalization capability on radical innovation: The role of knowledge accumulation and knowledge integration capability. J. Knowl. Manag. 2022, 27, 1680–1701. [Google Scholar] [CrossRef]

- Scholten, K.; Stevenson, M.; van Donk, D.P. Dealing with the unpredictable: Supply chain resilience. Int. J. Oper. Prod. Manag. 2019, 40, 1–10. [Google Scholar] [CrossRef]

- Al-Ayed, S.I.; Al-Tit, A.A. The effect of supply chain risk management on supply chain resilience: The intervening part of Internet-of-Things. Uncertain Supply Chain Manag. 2023, 11, 179–186. [Google Scholar] [CrossRef]

- Um, J.; Han, N. Understanding the relationships between global supply chain risk and supply chain resilience: The role of mitigating strategies. Supply Chain Manag. Int. J. 2020, 26, 240–255. [Google Scholar] [CrossRef]

- Chatterjee, S.; Chaudhuri, R.; Vrontis, D.; Giovando, G. Digital workplace and organization performance: Moderating role of digital leadership capability. J. Innov. Knowl. 2023, 8, 100334. [Google Scholar] [CrossRef]

- Martins, A. Dynamic capabilities and SME performance in the COVID-19 era: The moderating effect of digitalization. Asia-Pac. J. Bus. Adm. 2022, 15, 188–202. [Google Scholar] [CrossRef]

- Saleem, I.; Qureshi, T.M.; Verma, A. Task Challenge and Employee Performance: A Moderated Mediation Model of Resilience and Digitalization. Behav. Sci. 2023, 13, 119. [Google Scholar] [CrossRef]

- Aghazadeh, H.; Zandi, F.; Amoozad Mahdiraji, H.; Sadraei, R. Digital transformation and SME internationalisation: Unravelling the moderated-mediation role of digital capabilities, digital resilience and digital maturity. J. Enterp. Inf. Manag. 2023, 37, 1499–1526. [Google Scholar] [CrossRef]

- Lin, B.; Huang, C. Promoting variable renewable energy integration: The moderating effect of digitalization. Appl. Energy 2023, 337, 120891. [Google Scholar] [CrossRef]

- Zhou, L.; Li, W.; Teo, B.S.-X.; Yusoff, S.K.M. The Impact of Green M&A Listed Companies’ Size on the Rural Ecological Environment—Digitalization as Moderating Effect. Sustainability 2023, 15, 6068. [Google Scholar] [CrossRef]

- Jiao, H.; Wang, L.; Shi, Y. How does institutional environment in the digital context affect technology entrepreneurship? The moderating roles of government digitalization and gender. J. Organ. Change Manag. 2022, 35, 1089–1112. [Google Scholar] [CrossRef]

- Lee, M.J.; Pak, A.; Roh, T. The interplay of institutional pressures, digitalization capability, environmental, social, and governance strategy, and triple bottom line performance: A moderated mediation model. Bus. Strategy Environ. 2024, 33, 5247–5268. [Google Scholar] [CrossRef]

- Liu, K.P.; Chiu, W. Supply Chain 4.0: The impact of supply chain digitalization and integration on firm performance. Asian J. Bus. Ethics 2021, 10, 371–389. [Google Scholar] [CrossRef]

- Ali, Z.; Gongbing, B.; Mehreen, A. Does supply chain finance improve SMEs performance? The moderating role of trade digitization. Bus. Process Manag. J. 2018, 26, 150–167. [Google Scholar] [CrossRef]

- Chatterjee, S.; Chaudhuri, R.; Vrontis, D.; Maalaoui, A. Internationalization of family business and its performance: Examining the moderating role of digitalization and international networking capability. Rev. Manag. Sci. 2022, 17, 2443–2470. [Google Scholar] [CrossRef]

- Rodríguez, J.U.K.; Barbier, P.J.A. Impact of human factor management on company productivity: The moderating effect of digitalization. Cogent Bus. Manag. 2024, 11, 2371064. [Google Scholar] [CrossRef]

- Feng, B.; Zheng, M.; Shen, Y. The effect of relational embeddedness on transparency in supply chain networks: The moderating role of digitalization. Int. J. Oper. Prod. Manag. 2024, 44, 1621–1648. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, S.; Hu, Y. Internationalization and Organizational Resilience to COVID-19 Crisis: The Moderating Effect of Digitalization. Sage Open 2024, 14, 1–19. [Google Scholar] [CrossRef]

- Munir, M.; Jajja, M.S.S.; Chatha, K.A.; Farooq, S. Supply chain risk management and operational performance: The enabling role of supply chain integration. Int. J. Prod. Econ. 2020, 227, 107667. [Google Scholar] [CrossRef]

- Dawes, J. Do data characteristics change according to the number of scale points used? An experiment using 5-point, 7-point, and 10-point scales. Int. J. Mark. Res. 2008, 50, 61–104. [Google Scholar] [CrossRef]

- Likert, R. A technique for the measurement of attitudes. Arch. Psychol. 1932, 22, 1–55. [Google Scholar]

- Lynn, M.R. Determination and quantification of content validity. Nurs. Res. 1986, 35, 382–386. [Google Scholar] [CrossRef]

- Polit, D.F.; Beck, C.T. The content validity index: Are you sure you know what’s being reported? Critique and recommendations. Res. Nurs. Health 2006, 29, 489–497. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis, 7th ed.; Pearson: London, UK, 2014. [Google Scholar]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences, 2nd ed.; Lawrence Erlbaum Associates: Mahwah, NJ, USA, 1988. [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Sarstedt, M.; Ringle, C.M.; Hair, J.F. Partial Least Squares Structural Equation Modeling (PLS-SEM): A Useful Tool for Family Business Researchers. J. Fam. Bus. Strategy 2017, 8, 134–151. [Google Scholar] [CrossRef]

- Henseler, J.; Hubona, G.; Ray, P.A. Using PLS path modeling in new technology research: Updated guidelines. Ind. Manag. Data Syst. 2016, 116, 2–20. [Google Scholar] [CrossRef]

- Hair, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM), 2nd ed.; Sage Publications: Thousand Oaks, CA, USA, 2017. [Google Scholar]

- Yin, W. Identifying the pathways through digital transformation to achieve supply chain resilience: An fsQCA approach. Environ. Sci. Pollut. Res. 2023, 30, 10867–10879. [Google Scholar] [CrossRef] [PubMed]

- Sumanasena, V.; Gunasekara, L.; Kahawala, S.; Mills, N.; De Silva, D.; Jalili, M.; Sierla, S.; Jennings, A. Artificial Intelligence for Electric Vehicle Infrastructure: Demand Profiling, Data Augmentation, Demand Forecasting, Demand Explainability and Charge Optimisation. Energies 2023, 16, 2245. [Google Scholar] [CrossRef]

- Gaspar, P.G.P.; Ceryno, P.S.; Ferrer, A.L.; Thomé, A.M.T. Phases and tools for supply chain risk management: A systematic literature review. Gestão Produção 2020, 27, e4227. [Google Scholar] [CrossRef]

- Oluwafunmi Adijat, E.; Chinedu Ugochukwu, I.; Olubusola, O.; Favour Oluwadamilare, U.; Noluthando Zamanjomane, M. Ai-Driven Predictive Analytics in Agricultural Supply Chains: A Review: Assessing the Benefits and Challenges of Ai in Forecasting Demand and Optimizing Supply in Agriculture. Comput. Sci. IT Res. J. 2024, 5, 473–497. [Google Scholar] [CrossRef]

- Fauzan, H.B.; Satoto, B.; Rachman, F.H.; Husni, H.; Rochman, E.M.S.; Rachmad, A. Conformity assessment of software as a service (SaaS) for developing supply chain management applications in small and medium enterprises (SMEs) using Google Apps. AIP Conf. Proc. 2025, 3250, 050008. [Google Scholar]

- Kapsalis, P.; Rimassa, G.; Zeydan, E.; Via, S.; Risso, F.G. A Next Generation Architecture for Internet of Things in the Automotive Supply Chain for Electric Vehicles. In Proceedings of the Twenty-Fifth International Symposium on Theory, Algorithmic Foundations, and Protocol Design for Mobile Networks and Mobile Computing, Athens, Greece, 14–17 October 2024. [Google Scholar]

- Manel, A.-I.; Petra, A.N.; Alexander, B. The Risk of Dissolution of Sustainable Innovation Ecosystems in Times of Crisis: The Electric Vehicle during the COVID-19 Pandemic. Sustainability 2021, 13, 1319. [Google Scholar] [CrossRef]

| Construct | Dimension | Item | Source | Critical Ratio | CITC | CIID | α | Result |

|---|---|---|---|---|---|---|---|---|

| Digital capability (DC) | Digital infrastructure capability (DIC) | DIC1 We can access large amounts of unstructured (e.g., text, images, audio) and real-time data. | Gong et al. (2022) [57] | 3.264 ** | 0.577 | 0.607 | 0.728 | Keep |

| DIC2 We can integrate data from multiple sources into databases. | 3.845 *** | 0.507 | 0.69 | Keep | ||||

| DIC3 We use digital technologies (e.g., big data, cloud computing, mobile) to process and analyze data. | 3.839 *** | 0.565 | 0.621 | Keep | ||||

| Digital analysis capability (DAC) | DAC1 We collect customer feedback through digital channels (e.g., official website, e-commerce platforms, customer management systems). | 3.399 *** | 0.237 | 0.817 | 0.741 | Delete | ||

| DAC2 We use digital technologies (e.g., OA systems) for internal connectivity. | 8.053 *** | 0.594 | 0.647 | Keep | ||||

| DAC3 We effectively predict customer demand through data analysis. | 7.151 *** | 0.578 | 0.658 | Keep | ||||

| DAC4 We support decision making through data visualization (e.g., product analysis charts, profit growth graphs). | 12.583 *** | 0.77 | 0.539 | Keep | ||||

| Strategic support capability (SSC) | SSC1 Our executives clearly understand where to use digital analytics results. | 7.458 *** | 0.667 | 0.702 | 0.789 | Keep | ||

| SSC2 Our executives are aware of the digital transformation goals and needs of each department. | 6.314 *** | 0.593 | 0.741 | Keep | ||||

| SSC3 Our executives can use digital analytics to support management decisions. | 6.717 *** | 0.533 | 0.777 | Keep | ||||

| SSC4 Our executives can use digital analytics to support management decisions. | 6.571 *** | 0.614 | 0.729 | Keep | ||||

| Supply Chain Resilience (SCR) | SCR1 The supply chain can quickly respond to disruptions during interruptions. | Madhavika et al. (2023) [8] | 5.706 *** | 0.669 | 0.847 | 0.869 | Keep | |

| SCR2 The supply chain can provide appropriate responses to crisis scenarios during interruptions. | 8.175 *** | 0.633 | 0.853 | Keep | ||||

| SCR3 The supply chain can promptly address critical situations during interruptions. | 6.658 *** | 0.683 | 0.847 | Keep | ||||

| SCR4 The supply chain can prevent disruptions before they occur. | 7.405 *** | 0.704 | 0.842 | Keep | ||||

| SCR5 The supply chain has the potential to recover from disruptions in a short time. | 7.183 *** | 0.676 | 0.845 | Keep | ||||

| SCR6 The supply chain can recover from disruptions with minimal investment. | 7.939 *** | 0.667 | 0.847 | Keep | ||||

| Supply chain risk management (SCRM) | RM1 Our company can identify potential risks and disruptions in the supply chain. | Manal Munir et al. (2020) [75] | 7.14 *** | 0.749 | 0.807 | 0.862 | Keep | |

| RM2 Our company can accurately assess the severity of risks. | 8.727 *** | 0.684 | 0.836 | Keep | ||||

| RM3 Our company has comprehensive strategies for supply chain risk prevention and response. | 6.686 *** | 0.683 | 0.834 | Keep | ||||

| RM4 Our company can flexibly implement risk response strategies to effectively mitigate supply chain risks. | 7.332 *** | 0.725 | 0.818 | Keep | ||||

| Demographic Characteristics | Frequency | Percentage | |

|---|---|---|---|

| Enterprise Type | State-Owned | 100 | 40.2 |

| Privately Owned | 149 | 59.8 | |

| Employees | <100 | 6 | 2.4 |

| 100–299 | 81 | 32.5 | |

| 300–999 | 129 | 51.8 | |

| 1000–1999 | 23 | 9.2 | |

| ≥2000 | 10 | 4 | |

| History | 1–5 years | 13 | 5.2 |

| 6–10 years | 168 | 67.5 | |

| 11–25 years | 59 | 23.7 | |

| 26–50years | 8 | 3.2 | |

| >50 years | 1 | 0.4 | |

| Role in EV supply chain | Raw Material Supplier | 33 | 13.3 |

| Component Manufacturer | 97 | 39 | |

| Vehicle Manufacturer | 19 | 7.6 | |

| Logistics Provider | 22 | 8.8 | |

| Distributor | 34 | 13.7% | |

| Technical Service Provider | 44 | 17.7% | |

| Construct | Item Numbers | Cronbach’s α | rho_A | CR | AVE |

|---|---|---|---|---|---|

| Digital infrastructure (DIC) | 3 | 0.78 | 0.78 | 0.87 | 0.7 |

| Digital analysis capability (DAC) | 3 | 0.79 | 0.82 | 0.88 | 0.7 |

| Strategic support capability (SSC) | 4 | 0.83 | 0.84 | 0.89 | 0.67 |

| Digital capability (DC) | 10 (contains items of DIC, DAC, and SSC) | 0.89 | 0.9 | 0.91 | 0.5 |

| Supply chain resilience (SCR) | 6 | 0.87 | 0.88 | 0.9 | 0.61 |

| Supply chain risk management (SCRM) | 4 | 0.84 | 0.84 | 0.89 | 0.67 |

| Constructs | Items | Model 1 | Model 2 | ||

|---|---|---|---|---|---|

| Loading (>0.6) | VIF (<3) | Loading (>0.6) | VIF (<3) | ||

| Digital infrastructure capability (DIC) | DIC1 | 0.902 | 2.514 | 0.75 | 2.856 |

| DIC2 | 0.761 | 1.337 | 0.641 | 1.554 | |

| DIC3 | 0.832 | 2.192 | 0.634 | 2.26 | |

| Digital analysis capability (DAC) | DAC1 | 0.821 | 1.755 | 0.646 | 1.824 |

| DAC2 | 0.821 | 1.632 | 0.672 | 1.848 | |

| DAC3 | 0.867 | 1.615 | 0.684 | 1.791 | |

| Strategic support capability (SSC) | SSC1 | 0.786 | 1.661 | 0.726 | 1.758 |

| SSC2 | 0.799 | 1.846 | 0.752 | 2.044 | |

| SSC3 | 0.85 | 2.08 | 0.79 | 2.207 | |

| SSC4 | 0.825 | 1.741 | 0.764 | 1.908 | |

| Supply chain resilience (SCR) | SCR1 | 0.723 | 1.616 | 0.72 | 1.616 |

| SCR2 | 0.863 | 2.774 | 0.862 | 2.774 | |

| SCR 3 | 0.74 | 1.718 | 0.739 | 1.718 | |

| SCR 4 | 0.746 | 1.749 | 0.748 | 1.749 | |

| SCR5 | 0.816 | 2.003 | 0.818 | 2.003 | |

| SCR 6 | 0.795 | 2.127 | 0.795 | 2.127 | |

| Supply chain risk management (SCRM) | SCRM1 | 0.827 | 1.941 | 0.827 | 1.941 |

| SCRM2 | 0.823 | 1.897 | 0.823 | 1.897 | |

| SCRM3 | 0.805 | 1.664 | 0.805 | 1.664 | |

| SCRm4 | 0.829 | 1.86 | 0.829 | 1.86 | |

| Model 1 | Model 2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Construct | DAC | DIC | SCR | SCRM | SSC | Construct | DC | SCR | SCRM |

| DAC | 0.837 | DC | 0.708 | ||||||

| DIC | 0.545 | 0.834 | SCR | 0.66 | 0.782 | ||||

| SCR | 0.468 | 0.453 | 0.782 | SCRM | 0.652 | 0.718 | 0.821 | ||

| SCRM | 0.551 | 0.453 | 0.718 | 0.821 | |||||

| SSC | 0.602 | 0.639 | 0.688 | 0.63 | 0.815 | ||||

| Hypothesis | Path | ß | M | STDEV | t-Value | p-Value | CI | f2 | Decision |

|---|---|---|---|---|---|---|---|---|---|

| Model 1: R2 = 0.642 (strong explanatory power); SRMR = 0.06 (good fit); NFI = 0.841(acceptable fit) | |||||||||

| H1 | SCRM->SCR | 0.561 | 0.563 | 0.061 | 9.187 | 0.000 | [0.442, 0.684] | 0.436 | accepted |

| H3a | Moderating of DIC | −0.013 | −0.009 | 0.057 | 0.232 | 0.817 | [−0.115, 0.109] | 0.000 | rejected |

| H3b | Moderating of DAC | 0.200 | 0.196 | 0.052 | 3.829 | 0.000 | [0.091, 0.299] | 0.061 | accepted |

| H3c | Moderating of SSC | −0.024 | −0.027 | 0.054 | 0.446 | 0.655 | [−0.131, 0.081] | 0.001 | rejected |

| Model 2: R2 = 0.603(strong explanatory power); SRMR = 0.07(good fit), NFI = 0.825 (acceptable fit) | |||||||||

| H1 | SCRM->SCR | 0.554 | 0.556 | 0.061 | 9.125 | 0.000 | [0.437, 0.676] | 0.415 | accepted |

| H2 | Moderating of DC | 0.150 | 0.147 | 0.043 | 3.479 | 0.001 | [0.061, 0.228] | 0.058 | accepted |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Sukhotu, V. How Does Digital Capability Shape Resilient Supply Chains?—Evidence from China’s Electric Vehicle Manufacturing Industry. Future Internet 2025, 17, 123. https://doi.org/10.3390/fi17030123

Li Y, Sukhotu V. How Does Digital Capability Shape Resilient Supply Chains?—Evidence from China’s Electric Vehicle Manufacturing Industry. Future Internet. 2025; 17(3):123. https://doi.org/10.3390/fi17030123

Chicago/Turabian StyleLi, Yanxuan, and Vatcharapol Sukhotu. 2025. "How Does Digital Capability Shape Resilient Supply Chains?—Evidence from China’s Electric Vehicle Manufacturing Industry" Future Internet 17, no. 3: 123. https://doi.org/10.3390/fi17030123

APA StyleLi, Y., & Sukhotu, V. (2025). How Does Digital Capability Shape Resilient Supply Chains?—Evidence from China’s Electric Vehicle Manufacturing Industry. Future Internet, 17(3), 123. https://doi.org/10.3390/fi17030123