Preparation and Characterization of Nifedipine-Loaded Dry Medium Internal-Phase Emulsions (Dry MIPEs) to Improve Cellular Permeability

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Emulsion

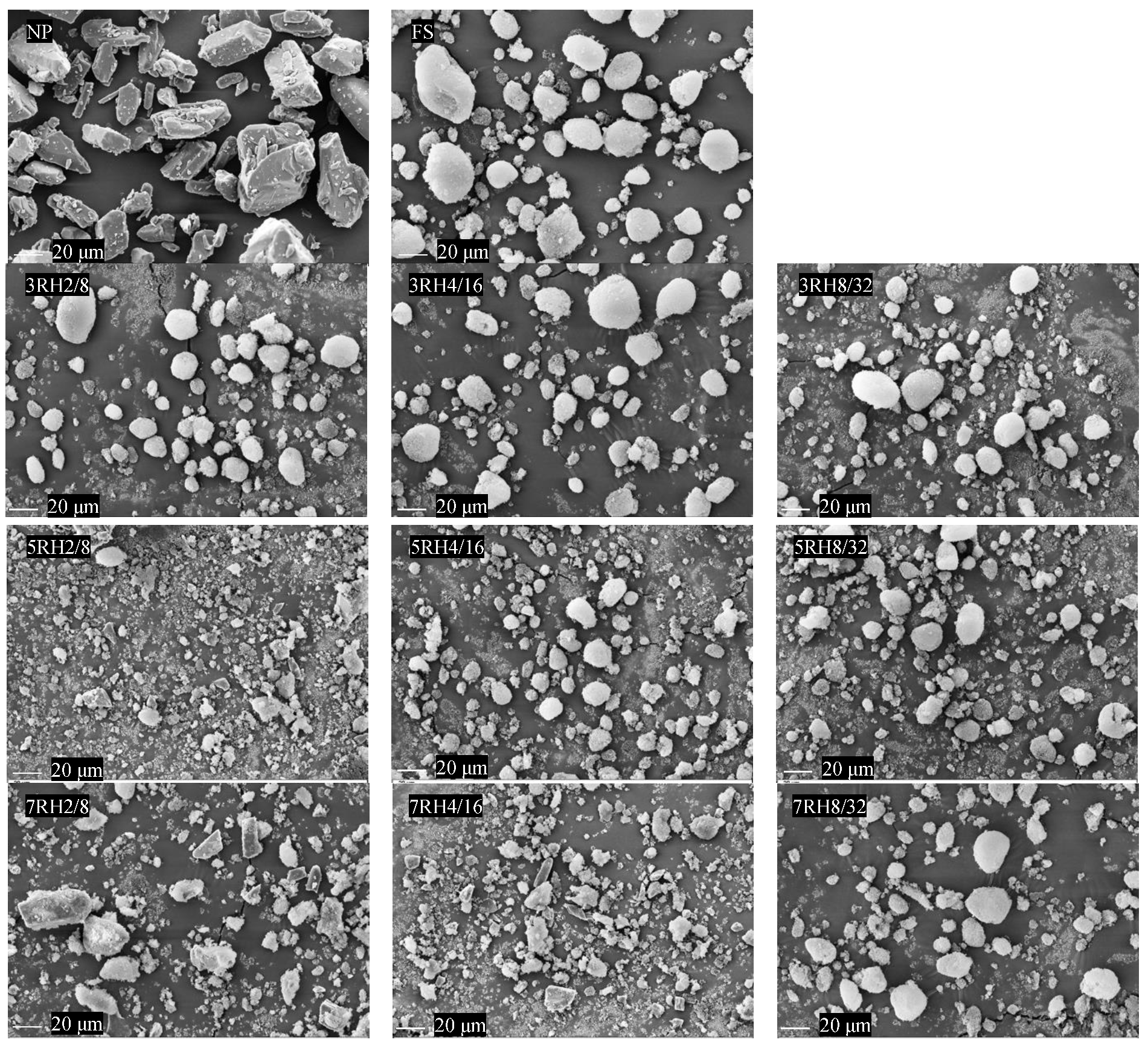

2.2. Morphological Examination

2.3. Analysis of NP

2.4. Powder X-ray Diffractometry (PXRD)

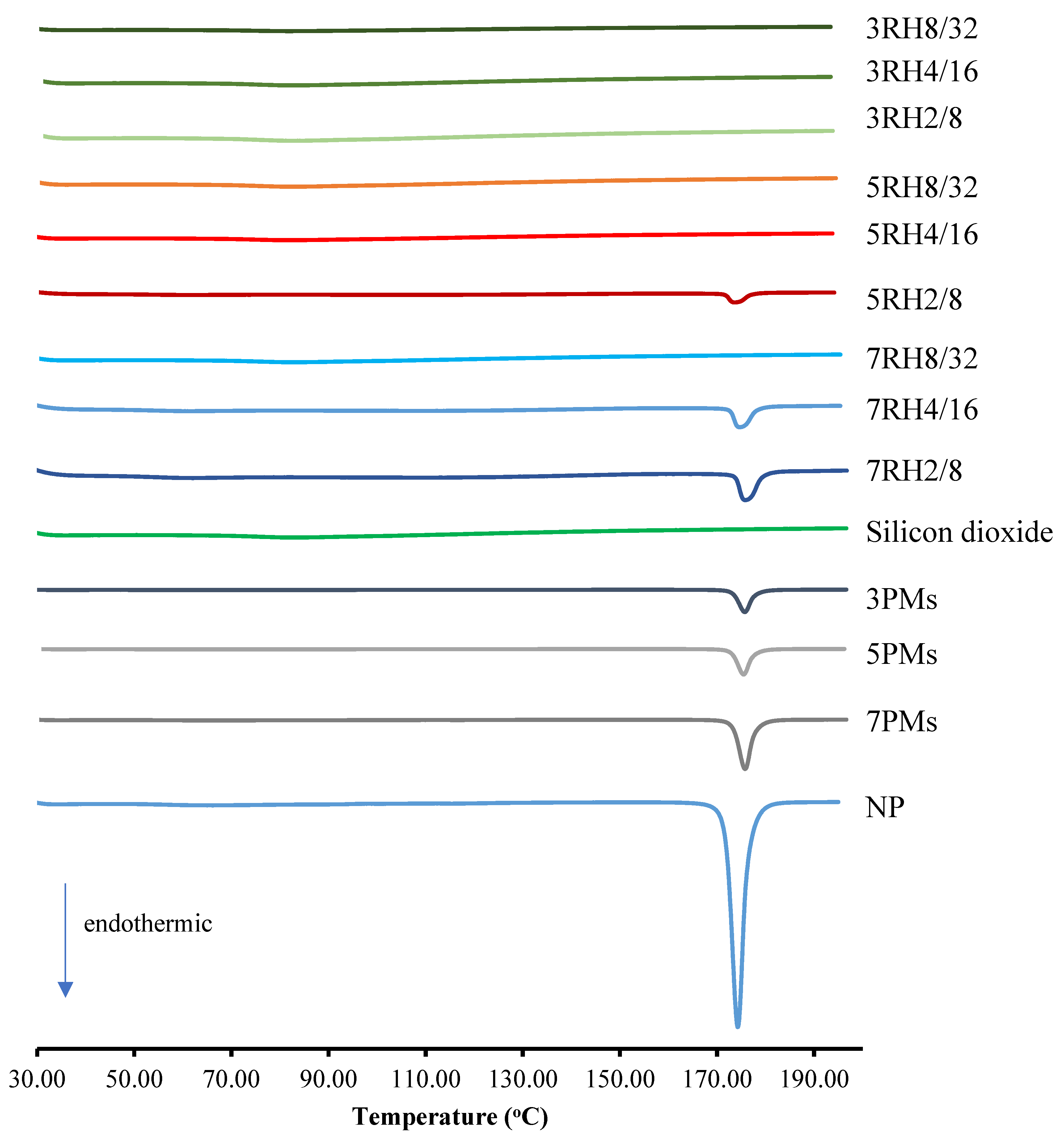

2.5. Differential Scanning Calorimetry (DSC)

2.6. Porosimetry Examination

2.7. Dissolution Study

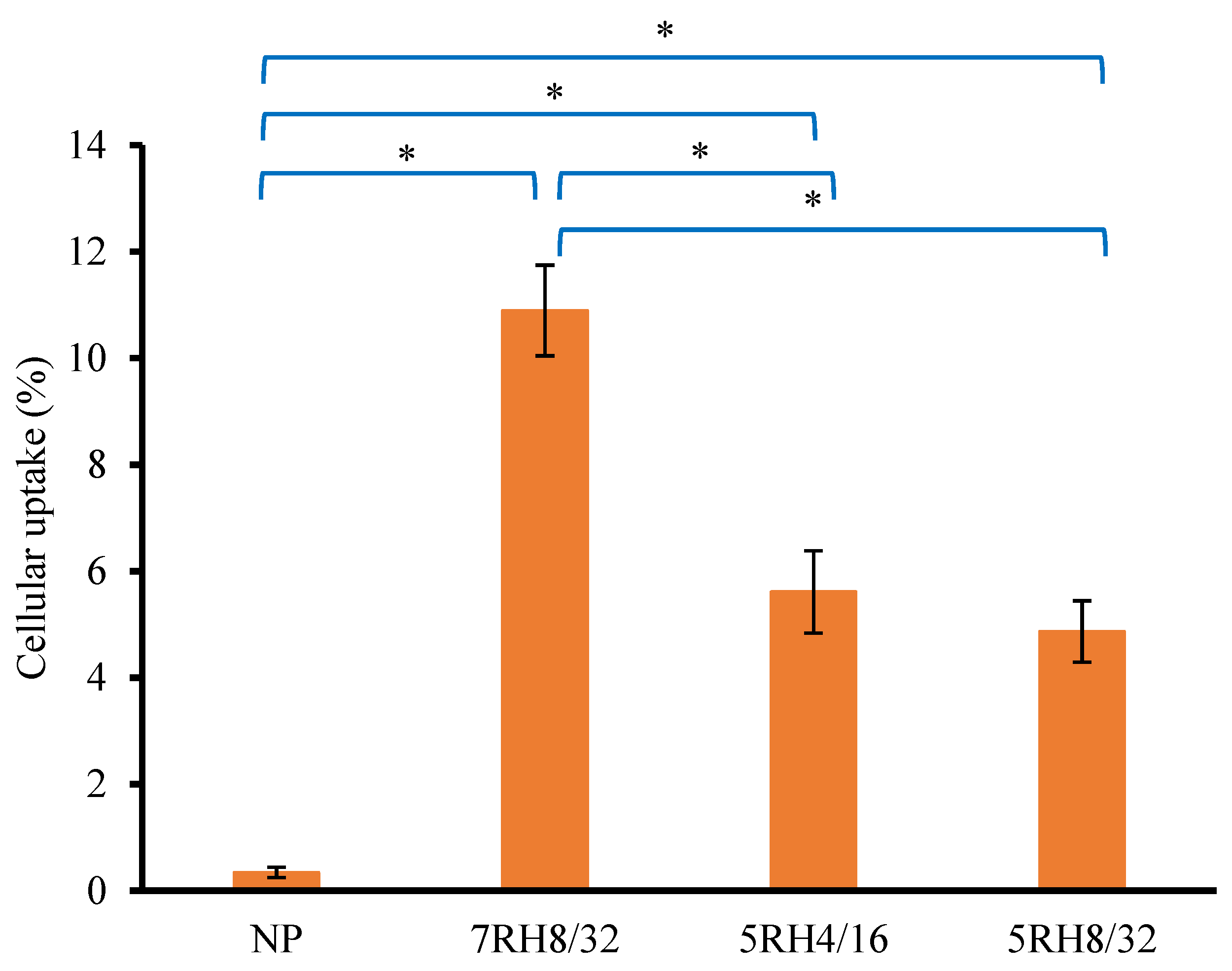

2.8. Evaluating Cellular Uptake of NP

2.9. Stability of NP

2.10. Statistical Analysis

3. Results and Discussion

3.1. Thermal Analysis

3.2. PXRD Analysis

3.3. Droplet-Size Analysis after Dilution

3.4. In Vitro Dissolution of NP

3.5. Evaluating Cellular Uptake of NP

3.6. Stability of Dry MIPEs

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Joyce, P.; Dening, T.J.; Meola, T.R.; Schultz, H.B.; Holm, R.; Thomas, N.; Prestidge, C.A. Solidification to improve the biopharmaceutical performance of SEDDS: Opportunities and challenges. Adv. Drug Deliv. Rev. 2019, 142, 102–117. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.Z.; Seow, E.K.; Lim, S.C.; Yuen, K.H.; Abdul Karim Khan, N. Formulation and in vivo evaluation of a solid self-emulsifying drug delivery system using oily liquid tocotrienols as model active substance. Pharmaceutics 2021, 13, 1777. [Google Scholar] [CrossRef] [PubMed]

- Czajkowska-Kośnik, A.; Szekalska, M.; Amelian, A.; Szymańska, E.; Winnicka, K. Development and evaluation of liquid and solid self-emulsifying drug delivery systems for atorvastatin. Molecules 2015, 20, 21010–21022. [Google Scholar] [CrossRef] [PubMed]

- Han, J.-R.; Gu, L.-P.; Zhang, R.-J.; Shang, W.-H.; Yan, J.-N.; McClements, D.J.; Wu, H.-T.; Zhu, B.-W.; Xiao, H. Bioaccessibility and cellular uptake of β-carotene in emulsion-based delivery systems using scallop (Patinopecten yessoensis) gonad protein isolates: Effects of carrier oil. Food Funct 2019, 10, 49–60. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Xiao, H.; McClements, D.J. Impact of lipid phase on the bioavailability of vitamin e in emulsion-based delivery systems: Relative importance of bioaccessibility, absorption, and transformation. J. Agric. Food Chem. 2017, 65, 3946–3955. [Google Scholar] [CrossRef]

- Hu, Y.-T.; Ting, Y.; Hu, J.-Y.; Hsieh, S.-C. Techniques and methods to study functional characteristics of emulsion systems. J. Food. Drug. Anal. 2017, 25, 16–26. [Google Scholar] [CrossRef]

- Goodarzi, F.; Zendehboudi, S. A Comprehensive review on emulsions and emulsion stability in chemical and energy industries. Can. J. Chem. Eng. 2019, 97, 281–309. [Google Scholar] [CrossRef]

- Abou Assi, R.; M. Abdulbaqi, I.; Seok Ming, T.; Siok Yee, C.; A. Wahab, H.; Asif, S.M.; Darwis, Y. Liquid and solid self-emulsifying drug delivery systems (sedds) as carriers for the oral delivery of azithromycin: Optimization, in vitro characterization and stability assessment. Pharmaceutics 2020, 12, 1052. [Google Scholar] [CrossRef]

- Dening, T.J.; Rao, S.; Thomas, N.; Prestidge, C.A. Novel nanostructured solid materials for modulating oral drug delivery from solid-state lipid-based drug delivery systems. AAPS J. 2016, 18, 23–40. [Google Scholar] [CrossRef]

- Alvebratt, C.; Dening, T.J.; Åhlén, M.; Cheung, O.; Strømme, M.; Gogoll, A.; Prestidge, C.A.; Bergström, C.A.S. In vitro performance and chemical stability of lipid-based formulations encapsulated in a mesoporous magnesium carbonate carrier. Pharmaceutics 2020, 12, 426. [Google Scholar] [CrossRef]

- Gajendran, J.; Krämer, J.; Shah, V.P.; Langguth, P.; Polli, J.; Mehta, M.; Groot, D.W.; Cristofoletti, R.; Abrahamsson, B.; Dressman, J.B. Biowaiver monographs for immediate-release solid oral dosage forms: Nifedipine. J. Pharm. Sci. 2015, 104, 3289–3298. [Google Scholar] [CrossRef] [PubMed]

- Sardari, F.; Jouyban, A. Solubility of nifedipine in ethanol + water and propylene glycol + water mixtures at 293.2 to 313.2 K. Ind. Eng. Chem. Res. 2013, 52, 14353–14358. [Google Scholar] [CrossRef]

- Mert, H.H.; Mert, E.H. Emulsion templated hierarchical macroporous polymers. In Advanced Functional Porous Materials, 1st ed.; Thomas, S., Li, T., Maria, H., Eds.; Springer: Cham, Switzerland, 2022; pp. 43–86. [Google Scholar] [CrossRef]

- Juttulapa, M.; Piriyaprasarth, S.; Takeuchi, H.; Sriamornsak, P. Effect of high-pressure homogenization on stability of emulsions containing zein and pectin. Asian J. Pharm. Sci. 2017, 12, 21–27. [Google Scholar] [CrossRef] [PubMed]

- Gumaste, S.G.; Serajuddin, A.T.M. Development of solid sedds, vii: Effect of pore size of silica on drug release from adsorbed self-emulsifying lipid-based formulations. Eur. J. Pharm. Sci. 2017, 110, 134–147. [Google Scholar] [CrossRef]

- Weerapol, Y.; Limmatvapirat, S.; Nunthanid, J.; Konthong, S.; Suttiruengwong, S.; Sriamornsak, P. Development and characterization of nifedipine-amino methacrylate copolymer solid dispersion powders with various adsorbents. Asian J. Pharm. Sci. 2017, 12, 335–343. [Google Scholar] [CrossRef]

- Umeta, B.; Bekele, A.; Mohammed, T.; Duguma, M.; Teshome, H.; Mekonnen, Y. Dissolution profile evaluation of eight brands of metformin hydrochloride tablets available in Jimma, southwest Ethiopia. diabetes Metab. Syndr. Obes. 2021, 14, 3499–3506. [Google Scholar] [CrossRef]

- Zaichik, S.; Steinbring, C.; Friedl, J.D.; Bernkop-Schnürch, A. Development and in vitro characterization of transferrin-decorated nanoemulsion utilizing hydrophobic ion pairing for targeted cellular uptake. J. Pharm. Innov. 2021. [Google Scholar] [CrossRef]

- Diaz, D.A.; Colgan, S.T.; Langer, C.S.; Bandi, N.T.; Likar, M.D.; van Alstine, L. Dissolution similarity requirements: How similar or dissimilar are the global regulatory expectations? AAPS J. 2016, 18, 15–22. [Google Scholar] [CrossRef]

- Hebishy, E.; Zamora, A.; Buffa, M.; Blasco-Moreno, A.; Trujillo, A.-J. Characterization of whey protein oil-in-water emulsions with different oil concentrations stabilized by ultra-high pressure homogenization. Processes 2017, 5, 6. [Google Scholar] [CrossRef] [Green Version]

- Gupta, A.; Eral, H.B.; Hatton, T.A.; Doyle, P.S. Nanoemulsions: Formation, properties and applications. Soft Matter 2016, 12, 2826–2841. [Google Scholar] [CrossRef]

- Sadurní, N.; Solans, C.; Azemar, N.; García-Celma, M.J. Studies on the formation of o/w nano-emulsions, by low-energy emulsification methods, suitable for pharmaceutical applications. Eur. J. Pharm. Sci. 2005, 26, 438–445. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, V.; Siddiqui, A.; Ali, H.; Nazzal, S. dissolution and powder flow characterization of solid self-emulsified drug delivery system (SEDDS). Int. J. Pharm. 2009, 366, 44–52. [Google Scholar] [CrossRef] [PubMed]

- Ito, Y.; Kusawake, T.; Ishida, M.; Tawa, R.; Shibata, N.; Takada, K. Oral solid gentamicin preparation using emulsifier and adsorbent. J. Control. Release. 2005, 105, 23–31. [Google Scholar] [CrossRef] [PubMed]

- Weerapol, Y.; Limmatvapirat, S.; Nunthanid, J.; Sriamornsak, P. Self-nanoemulsifying drug delivery system of nifedipine: Impact of hydrophilic-lipophilic balance and molecular structure of mixed surfactants. AAPS PharmSciTech 2014, 15, 456–464. [Google Scholar] [CrossRef] [PubMed]

- Mantas, A.; Mihranyan, A. Immediate-release nifedipine binary dry powder mixtures with nanocellulose featuring enhanced solubility and dissolution rate. Pharmaceutics 2019, 11, 37. [Google Scholar] [CrossRef] [PubMed]

- Tubtimsri, S.; Weerapol, Y. Improvement in solubility and absorption of nifedipine using solid solution: Correlations between surface free energy and drug dissolution. Polymers 2021, 13, 2963. [Google Scholar] [CrossRef]

- Bodor, N. Techniques of solubilization of drugs (drugs and the pharmaceutical sciences series). J. Pharm. Sci. 1984, 73, 288. [Google Scholar] [CrossRef]

- Katev, V.; Tsibranska-Gyoreva, S.; Vinarov, Z.; Tcholakova, S. Supersaturation and solubilization upon in vitro digestion of fenofibrate type i lipid formulations: Effect of droplet size, surfactant concentration and lipid type. Pharmaceutics 2021, 13, 1287. [Google Scholar] [CrossRef]

- Katamreddy, J.D.; Yalavarthi, P.R.; D, S.R.; Battu, S.; Peesa, J.P. Biopharmaceutical insights of particulate emulsified systems—A prospective overview. Lipids Health Dis. 2018, 17, 112. [Google Scholar] [CrossRef] [Green Version]

- Sarheed, O.; Dibi, M.; Ramesh, K.V.R.N.S. Studies on the effect of oil and surfactant on the formation of alginate-based o/w lidocaine nanocarriers using nanoemulsion template. Pharmaceutics 2020, 12, 1223. [Google Scholar] [CrossRef]

- Francke, N.M.; Bunjes, H. Influence of drug loading on the physical stability of phospholipid-stabilised colloidal lipid emulsions. Int. J. Pharm. X 2020, 2, 100060. [Google Scholar] [CrossRef] [PubMed]

- Sila-on, W.; Vardhanabhuti, N.; Ongpipattanakul, B.; Kulvanich, P. Influence of incorporation methods on partitioning behavior of lipophilic drugs into various phases of a parenteral lipid emulsion. AAPS PharmSciTech 2008, 9, 684–692. [Google Scholar] [CrossRef] [PubMed]

- Weerapol, Y.; Limmatvapirat, S.; Takeuchi, H.; Sriamornsak, P. Fabrication of spontaneous emulsifying powders for improved dissolution of poorly water-soluble drugs. Powder Tech. 2015, 271, 100–108. [Google Scholar] [CrossRef]

- Benjasirimongkol, P.; Piriyaprasarth, S.; Sriamornsak, P. Design and optimization of resveratrol-loaded porous calcium silicate powders for dissolution and photostability enhancement. Heliyon 2019, 5, e01399. [Google Scholar] [CrossRef]

- Pohlen, M.; Pirker, L.; Dreu, R. The Potential of macroporous silica—Nanocrystalline cellulose combination for formulating dry emulsion systems with improved flow properties: A DoE study. Pharmaceutics 2021, 13, 1177. [Google Scholar] [CrossRef]

- Pade, V.; Stavchansky, S. Link between drug absorption solubility and permeability measurements in caco-2 cells. J. Pharm. Sci. 1998, 87, 1604–1607. [Google Scholar] [CrossRef]

- Zheng, Y.; Xu, G.; Ni, Q.; Wang, Y.; Gao, Q.; Zhang, Y. Microemulsion delivery system improves cellular uptake of genipin and its protective effect against Aβ1-42-induced PC12 cell cytotoxicity. Pharmaceutics 2022, 14, 617. [Google Scholar] [CrossRef]

| Formulations | NP (%) | Surfactant (%) | Oil (%) |

|---|---|---|---|

| 3RH2/8 | 0.3 | 2 | 8 |

| 3RH4/16 | 0.3 | 4 | 16 |

| 3RH8/32 | 0.3 | 8 | 32 |

| 5RH2/8 | 0.5 | 2 | 8 |

| 5RH4/16 | 0.5 | 4 | 16 |

| 5RH8/32 | 0.5 | 8 | 32 |

| 7RH2/8 | 0.7 | 2 | 8 |

| 7RH4/16 | 0.7 | 4 | 16 |

| 7RH8/32 | 0.7 | 8 | 32 |

| Formulations | Simple Homogenizer (nm [PI]) | Microfluidizer (nm [PI]) |

|---|---|---|

| 3RH2/8 | 6721.0 ± 345.1 [0.680] | 182.3 ± 42.1 [0.342] |

| 3RH4/16 | 6319.9 ± 210.2 [0.531] | 164.3 ± 32.2 [0.323] |

| 3RH8/32 | 6313.2 ± 207.5 [0.525] | 157.7 ± 30.3 [0.310] |

| 5RH2/8 | 6540.7 ± 120.1 [0.504] | 150.2 ± 47.1 [0.401] |

| 5RH4/16 | 4427.0 ± 352.3 [0.549] | 121.2 ± 13.1 [0.463] |

| 5RH8/32 | 3080.1 ± 542.1 [0.483] | 118.7 ± 10.2 [0.405] |

| 7RH2/8 | 6403.3 ± 242.8 [0.490] | 255.7 ± 39.8 [0.311] |

| 7RH4/16 | 3652.2 ± 254.2 [0.455] | 204.7 ± 29.0 [0.357] |

| 7RH8/32 | 3221.7 ± 542.9 [0.557] | 122.7 ± 25.2 [0.352] |

| Formulations | BJH Surface Area (m2/g) | Size of Emulsion after Dilution (nm [PI]) |

|---|---|---|

| 3RH2/8 | 169.2 ± 8.1 * | 5404.4 ± 244.3 [0.524] |

| 3RH4/16 | 145.4 ± 5.5 * | 5297.7 ± 214.4 [0.622] |

| 3RH8/32 | 108.2 ± 7.9 * | 5026.4 ± 213.3 [0.545] |

| 5RH2/8 | 163.1 ± 5.8 * | 3233.2 ± 338.3 [0.521] |

| 5RH4/16 | 143.3 ± 6.4 * | 2804.4 ± 313.3 [0.512] |

| 5RH8/32 | 100.5 ± 8.1 * | 2583.0 ± 323.2 [0.524] |

| 7RH2/8 | 160.1 ± 6.2 * | 1618.6 ± 424.1 [0.514] |

| 7RH4/16 | 140.7 ± 5.9 * | 1562.8 ± 452.1 [0.554] |

| 7RH8/32 | 99.7 ± 8.5 * | 1318.4 ± 424.0 [0.511] |

| Formulations | Day 0 (%) | 3 Months (%) | 6 Months (%) | ||

|---|---|---|---|---|---|

| Accelerated Condition | Ambient Condition | Accelerated Condition | Ambient Condition | ||

| NP powder | 100.05 ± 0.15 | 100.03 ± 0.13 | 100.02 ± 0.11 | 100.02 ± 0.09 | 100.03 ± 0.10 |

| 3RH2/8 | 100.12 ± 0.25 | 100.01 ± 3.27 | 100.02 ± 2.37 | 100.22 ± 0.17 | 100.40 ± 3.11 |

| 3RH4/16 | 100.21 ± 0.13 | 100.03 ± 2.12 | 100.01 ± 1.43 | 100.01 ± 1.17 | 100.12 ± 0.69 |

| 3RH8/32 | 100.31 ± 0.23 | 100.01 ± 2.26 | 100.01 ± 1.37 | 100.03 ± 1.53 | 100.03 ± 0.88 |

| 5RH4/16 | 100.11 ± 0.33 | 100.12 ± 2.22 | 100.08 ± 1.02 | 100.00 ± 2.01 | 100.12 ± 0.79 |

| 5RH8/32 | 100.07 ± 1.20 | 100.20 ± 1.72 | 100.02 ± 1.05 | 100.01 ± 1.03 | 100.13 ± 0.78 |

| 7RH8/32 | 100.13 ± 2.26 | 100.11 ± 1.53 | 100.02 ± 1.93 | 101.03 ± 1.31 | 100.10 ± 0.71 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tubtimsri, S.; Weerapol, Y. Preparation and Characterization of Nifedipine-Loaded Dry Medium Internal-Phase Emulsions (Dry MIPEs) to Improve Cellular Permeability. Pharmaceutics 2022, 14, 1849. https://doi.org/10.3390/pharmaceutics14091849

Tubtimsri S, Weerapol Y. Preparation and Characterization of Nifedipine-Loaded Dry Medium Internal-Phase Emulsions (Dry MIPEs) to Improve Cellular Permeability. Pharmaceutics. 2022; 14(9):1849. https://doi.org/10.3390/pharmaceutics14091849

Chicago/Turabian StyleTubtimsri, Sukannika, and Yotsanan Weerapol. 2022. "Preparation and Characterization of Nifedipine-Loaded Dry Medium Internal-Phase Emulsions (Dry MIPEs) to Improve Cellular Permeability" Pharmaceutics 14, no. 9: 1849. https://doi.org/10.3390/pharmaceutics14091849

APA StyleTubtimsri, S., & Weerapol, Y. (2022). Preparation and Characterization of Nifedipine-Loaded Dry Medium Internal-Phase Emulsions (Dry MIPEs) to Improve Cellular Permeability. Pharmaceutics, 14(9), 1849. https://doi.org/10.3390/pharmaceutics14091849