Microencapsulation and Nanoencapsulation Using Supercritical Fluid (SCF) Techniques

Abstract

1. Introduction

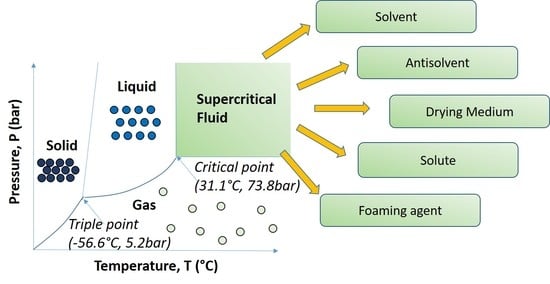

2. Supercritical Carbon Dioxide Processing Systems

3. Role of Supercritical Carbon Dioxide in Microencapsulation and Nanoencapsulation

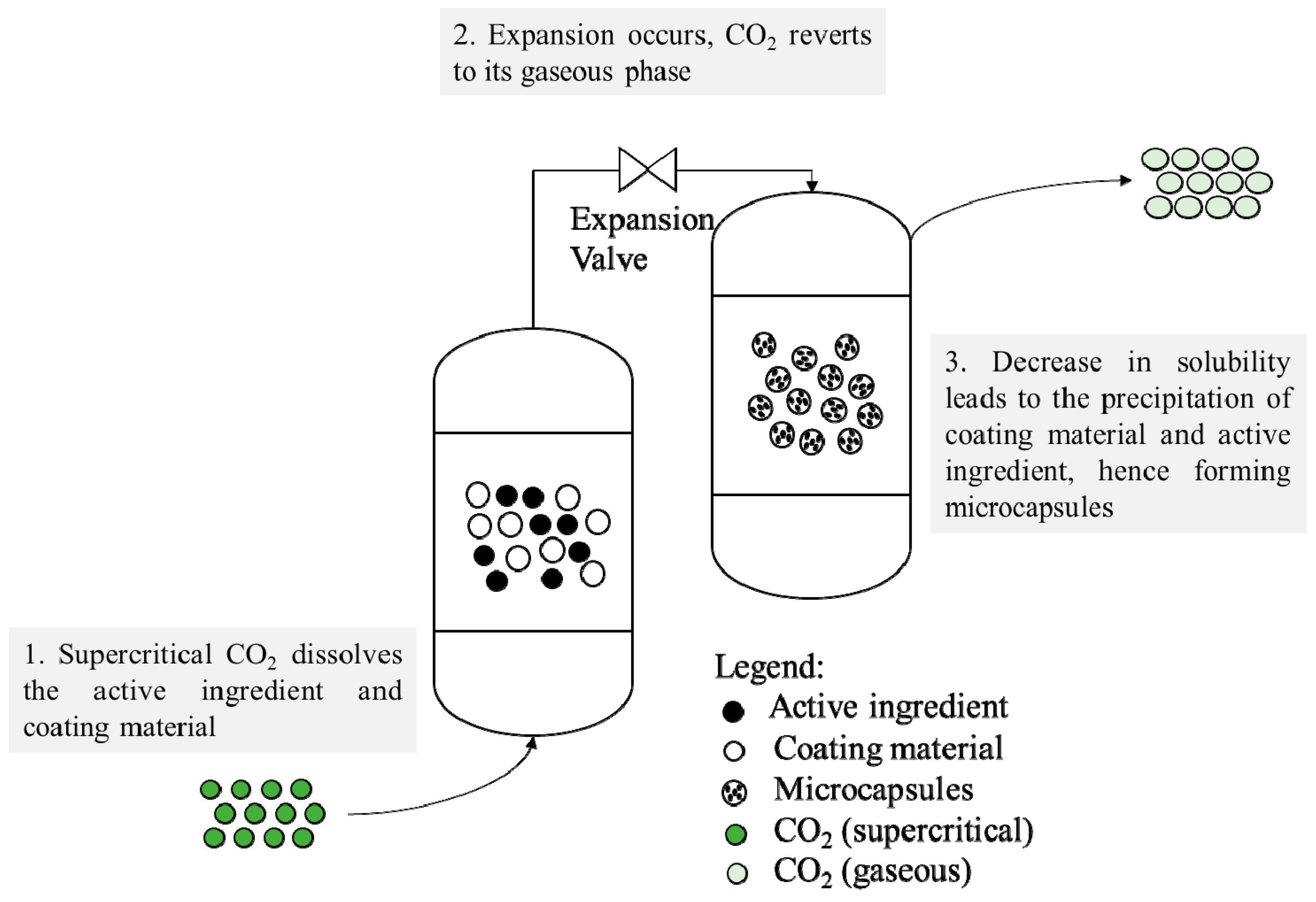

3.1. Supercritical Carbon Dioxide as a Solvent

Rapid Expansion of Supercritical Solutions (RESS)

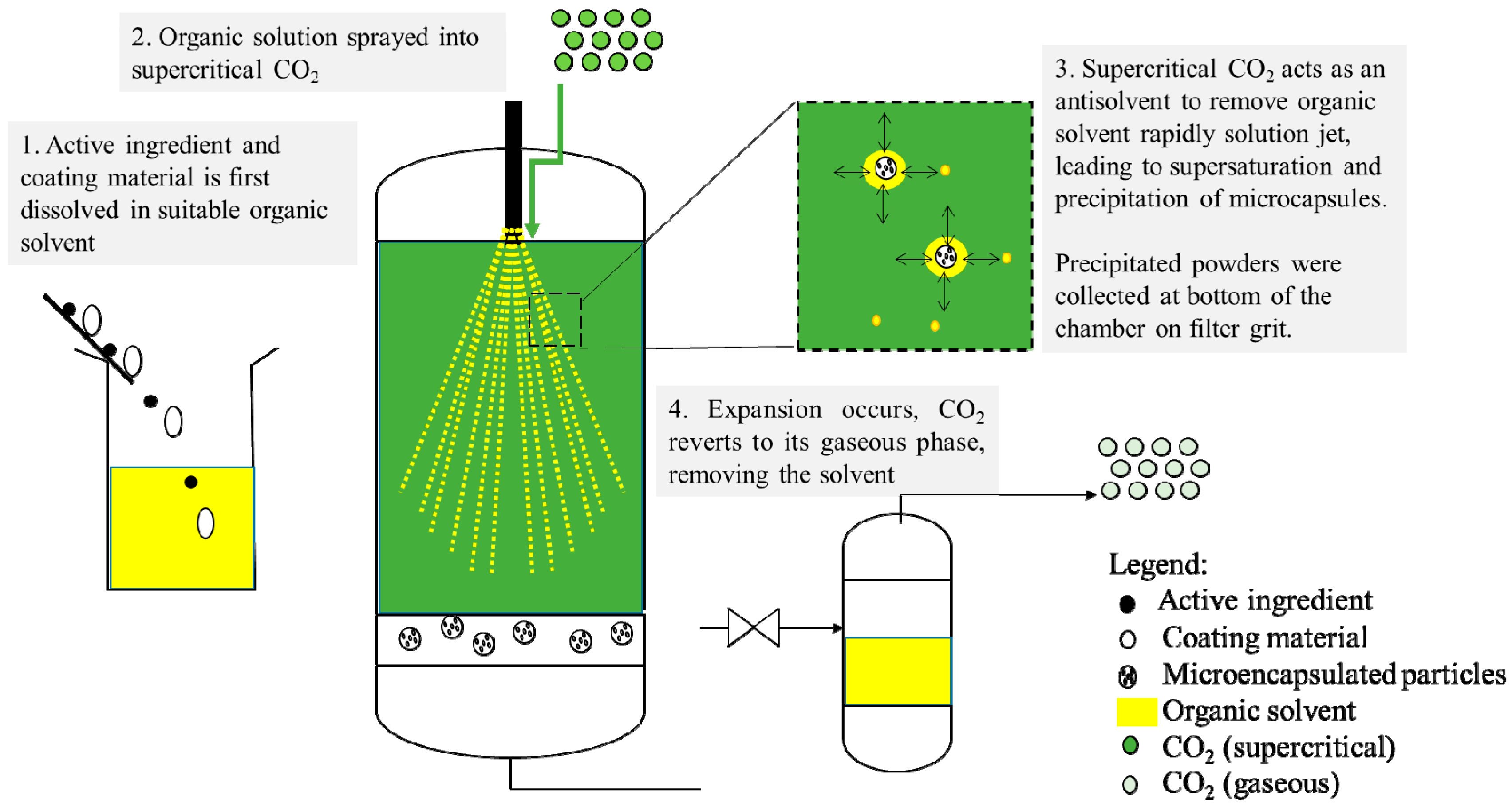

3.2. Supercritical Carbon Dioxide as an Anti-Solvent

3.2.1. Supercritical Antisolvent (SAS)

3.2.2. Supercritical Fluidized Bed Coating

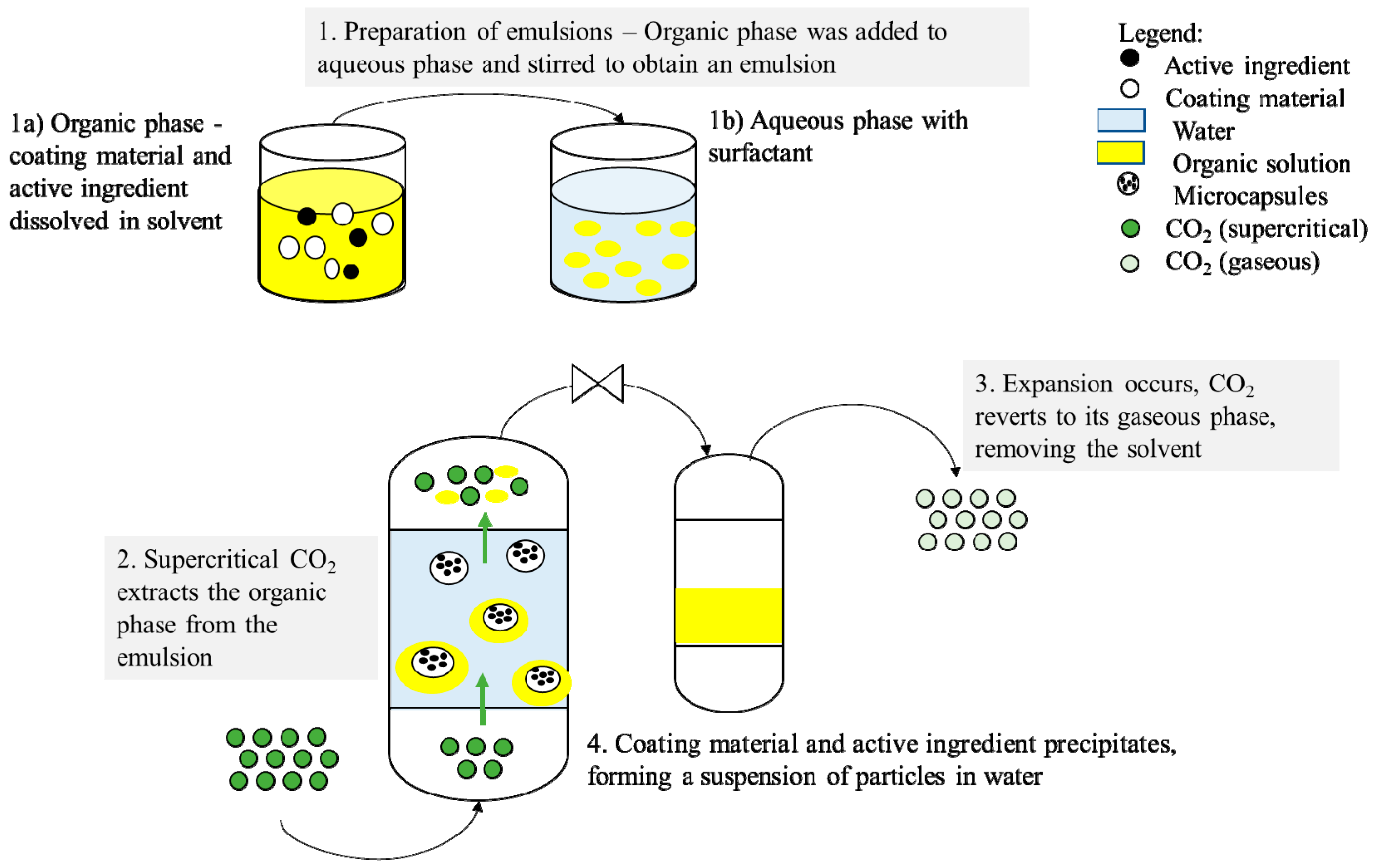

3.2.3. Supercritical Fluid Extraction of Emulsions (SFEE)

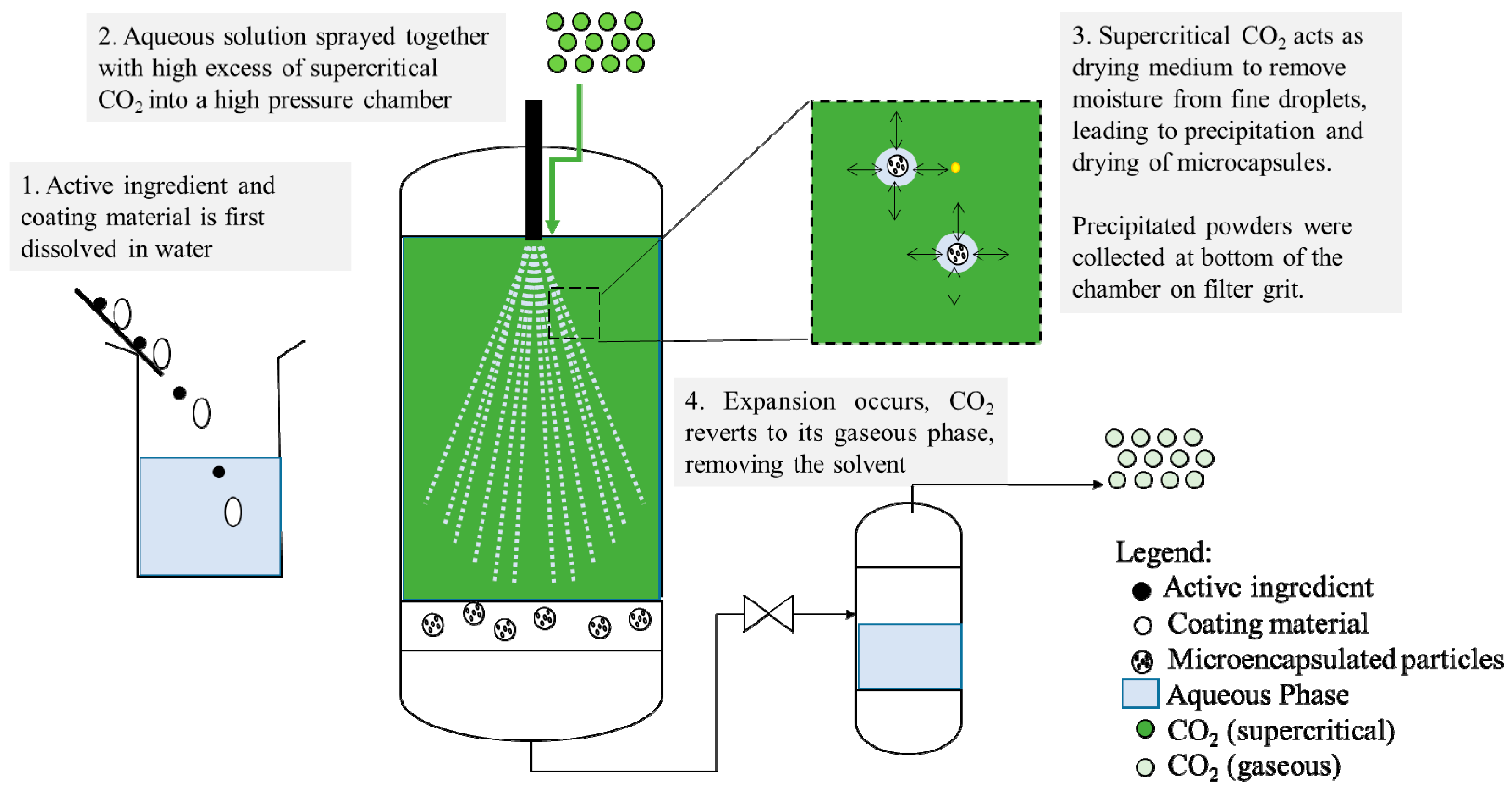

3.3. Supercritical Carbon Dioxide as a Drying Agent

Supercritical Spray Drying

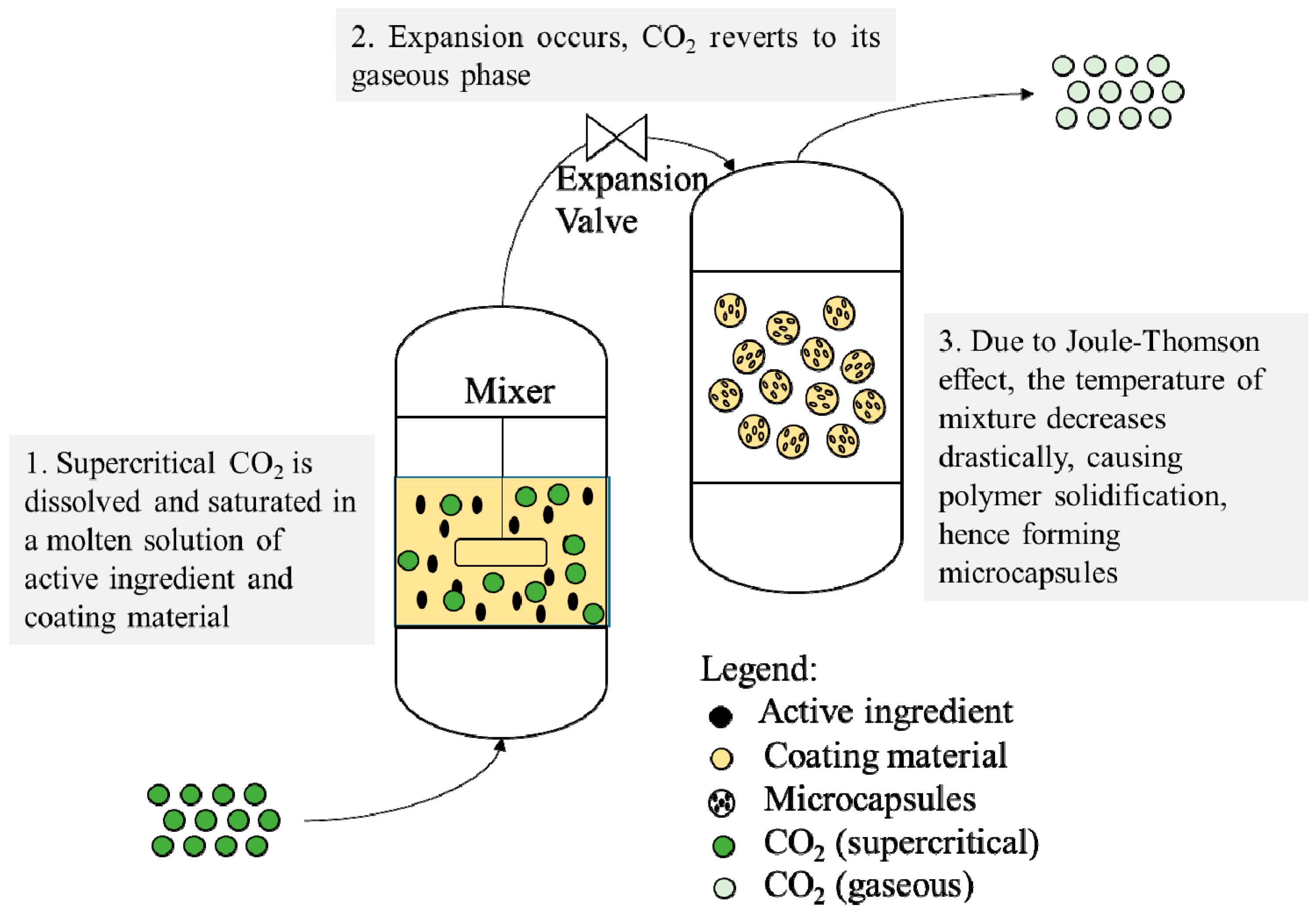

3.4. Supercritical Carbon Dioxide as a Solute

Particles from Gas-Saturated Solutions (PGSS)

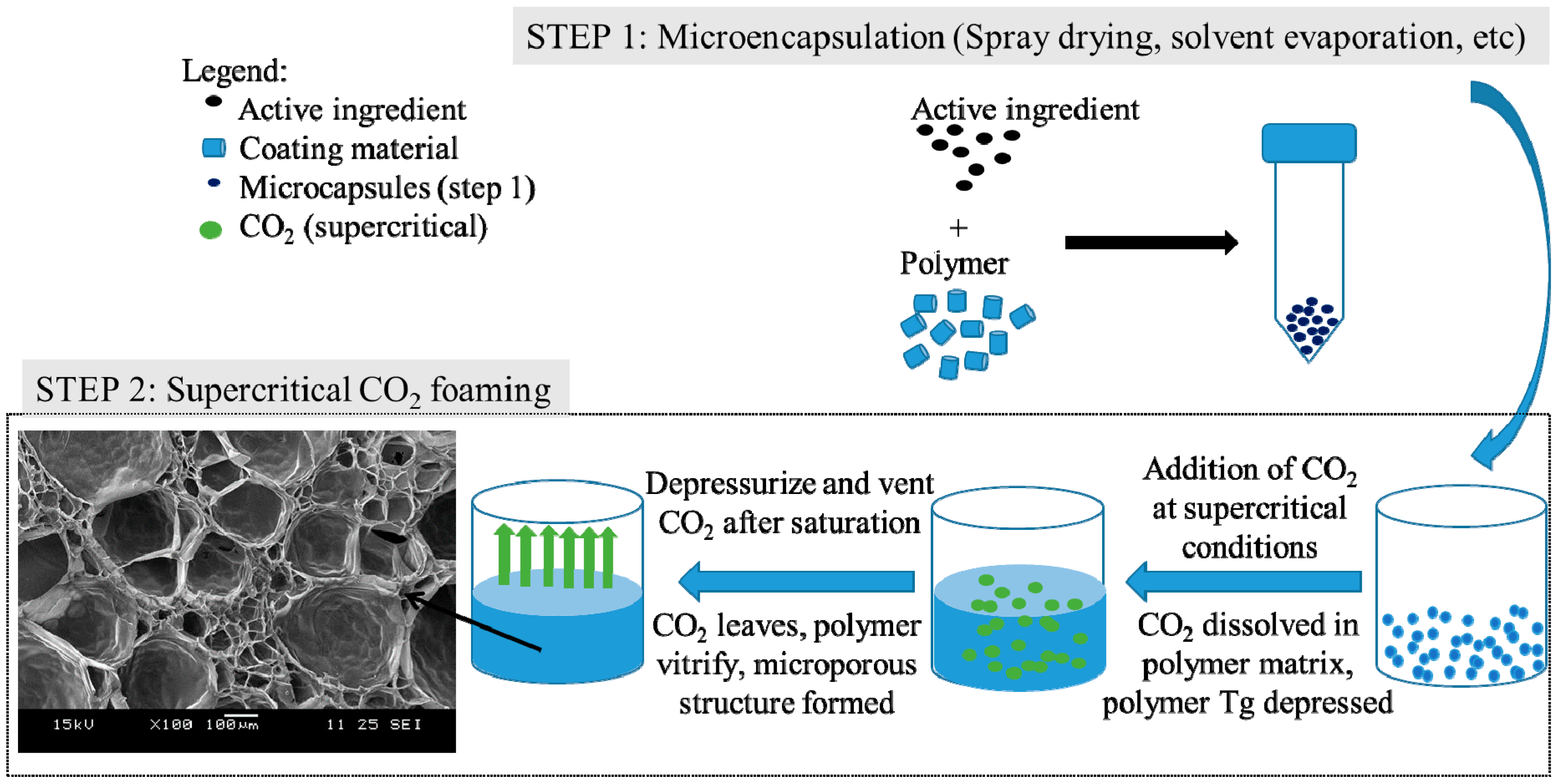

3.5. Supercritical CO2 as a Foaming Agent

3.5.1. Single-Step Impregnation and Foaming

3.5.2. Two-Step Drug Encapsulation and Foaming

4. Conclusions and Future Perspectives

Funding

Acknowledgments

Conflicts of Interest

References

- Ginty, P.J.; Whitaker, M.J.; Shakesheff, K.M.; Howdle, S.M. Drug delivery goes supercritical. Mater. Today 2005, 8, 42–48. [Google Scholar] [CrossRef]

- Nuchuchua, O.; Nejadnik, M.R.; Goulooze, S.C.; Lješković, N.J.; Every, H.A.; Jiskoot, W. Characterization of drug delivery particles produced by supercritical carbon dioxide technologies. J. Supercrit. Fluids 2017, 128, 244–262. [Google Scholar] [CrossRef]

- Davies, O.R.; Lewis, A.L.; Whitaker, M.J.; Tai, H.; Shakesheff, K.M.; Howdle, S.M. Applications of supercritical CO2 in the fabrication of polymer systems for drug delivery and tissue engineering. Adv. Drug Deliv. Rev. 2008, 60, 373–387. [Google Scholar] [CrossRef] [PubMed]

- Fahim, T.K.; Zaidul, I.S.M.; Abu Bakar, M.R.; Salim, U.M.; Awang, M.B.; Sahena, F.; Jalal, K.C.A.; Sharif, K.M.; Sohrab, M.H. Particle formation and micronization using non-conventional techniques—Review. Chem. Eng. Process. Process Intensif. 2014, 86, 47–52. [Google Scholar] [CrossRef]

- Pasquali, I.; Bettini, R. Are pharmaceutics really going supercritical? Int. J. Pharm. 2008, 364, 176–187. [Google Scholar] [CrossRef] [PubMed]

- Esfandiari, N. Production of micro and nano particles of pharmaceutical by supercritical carbon dioxide. J. Supercrit. Fluids 2015, 100, 129–141. [Google Scholar] [CrossRef]

- Cocero, M.J.; Martín, Á.; Mattea, F.; Varona, S. Encapsulation and co-precipitation processes with supercritical fluids: Fundamentals and applications. J. Supercrit. Fluids 2009, 47, 546–555. [Google Scholar] [CrossRef]

- Kankala, R.K.; Zhang, Y.S.; Wang, S.B.; Lee, C.H.; Chen, A.Z. Supercritical fluid technology: An emphasis on drug delivery and related biomedical applications. Adv. Healthc. Mater. 2017, 6. [Google Scholar] [CrossRef]

- Tabernero, A.; Martín del Valle, E.M.; Galán, M.A. Supercritical fluids for pharmaceutical particle engineering: Methods, basic fundamentals and modelling. Chem. Eng. Process. Process Intensif. 2012, 60, 9–25. [Google Scholar] [CrossRef]

- Lee, L.Y.; Wang, C.H.; Smith, K.A. Supercritical antisolvent production of biodegradable micro- and nanoparticles for controlled delivery of paclitaxel. J. Control. Release 2008, 125, 96–106. [Google Scholar] [CrossRef]

- Lee, L.Y.; Smith, K.A.; Wang, C.-H. Fabrication of controlled release devices for anticancer agents using supercritical antisolvent method. In Proceedings of the AIChE Annual Meeting, Cincinnati, OH, USA, 30 October–4 November 2005. [Google Scholar]

- Lee, L.Y.; Ranganath, S.H.; Fu, Y.; Zheng, J.L.; Lee, H.S.; Wang, C.-H.; Smith, K.A. Paclitaxel release from micro-porous PLGA disks. Chem. Eng. Sci. 2009, 64, 4341–4349. [Google Scholar] [CrossRef]

- Nie, H.; Lee, L.Y.; Tong, H.; Wang, C.-H. PLGA/chitosan composites from a combination of spray drying and supercritical fluid foaming techniques: New carriers for DNA delivery. J. Control. Release 2008, 129, 207–214. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.H.; Lee, L.Y.; Jackson, J.S.H.; Tong, Y.W.; Wang, C.-H. Characterization of porous poly(d,l-lactic-co-glycolic acid) sponges fabricated by supercritical CO2 gas-foaming method as a scaffold for three-dimensional growth of Hep3B cells. Biotechnol. Bioeng. 2008, 100, 998–1009. [Google Scholar] [CrossRef] [PubMed]

- Davoodi, P.; Lee, L.Y.; Xu, Q.; Sunil, V.; Sun, Y.; Soh, S.; Wang, C.-H. Drug delivery systems for programmed and on-demand release. Adv. Drug Deliv. Rev. 2018, 132, 104–138. [Google Scholar] [CrossRef] [PubMed]

- Badens, E.; Masmoudi, Y.; Mouahid, A.; Crampon, C. Current situation and perspectives in drug formulation by using supercritical fluid technology. J. Supercrit. Fluids 2018, 134, 274–283. [Google Scholar] [CrossRef]

- Jung, J.; Perrut, M. Particle design using supercritical fluids: Literature and patent survey. J. Supercrit. Fluids 2001, 20, 179–219. [Google Scholar] [CrossRef]

- Bahrami, M.; Ranjbarian, S. Production of micro- and nano-composite particles by supercritical carbon dioxide. J. Supercrit. Fluids 2007, 40, 263–283. [Google Scholar] [CrossRef]

- Padrela, L.; Rodrigues, M.A.; Duarte, A.; Dias, A.M.A.; Braga, M.E.M.; de Sousa, H.C. Supercritical carbon dioxide-based technologies for the production of drug nanoparticles/nanocrystals—A comprehensive review. Adv. Drug Deliv. Rev. 2018, 131, 22–78. [Google Scholar] [CrossRef]

- Lee, L.Y.; Lim, L.K.; Hua, J.; Wang, C.-H. Jet breakup and droplet formation in near-critical regime of carbon dioxide-dichloromethane system. Chem. Eng. Sci. 2008, 63, 3366–3378. [Google Scholar] [CrossRef]

- Ong, Y.X.J.; Lee, L.Y.; Davoodi, P.; Wang, C.H. Production of drug-releasing biodegradable microporous scaffold using a two-step micro-encapsulation/supercritical foaming process. J. Supercrit. Fluids 2018, 133, 263–269. [Google Scholar] [CrossRef]

- Lee, L.Y.; Lin, Y.; Wang, C.-H. Study of the supercritical drying of wet Okara. In Proceedings of the 15th International Conference on Sustainable Energy Technologies (SET2016), Singapore, 19–22 July 2016; pp. 1–7. [Google Scholar]

- Vemavarapu, C.; Mollan, M.J.; Lodaya, M.; Needham, T.E. Design and process aspects of laboratory scale SCF particle formation systems. Int. J. Pharm. 2005, 292, 1–16. [Google Scholar] [CrossRef] [PubMed]

- José, M. Extraction of natural compounds using supercritical CO2: Going from the laboratory to the industrial application. J. Supercrit. Fluids 2015, 96, 180–199. [Google Scholar] [CrossRef]

- Sharif, K.M.; Rahman, M.M.; Azmir, J.; Mohamed, A.; Jahurul, M.H.A.; Sahena, F.; Zaidul, I.S.M. Experimental design of supercritical fluid extraction—A review. J. Food Eng. 2014, 124, 105–116. [Google Scholar] [CrossRef]

- De Melo, M.M.R.; Silvestre, A.J.D.; Silva, C.M. Supercritical fluid extraction of vegetable matrices: Applications, trends and future perspectives of a convincing green technology. J. Supercrit. Fluids 2014, 92, 115–176. [Google Scholar] [CrossRef]

- Vergara-Mendoza, M.D.S.; Ortiz-Estrada, C.H.; González-Martínez, J.; Quezada-Gallo, J.A. Microencapsulation of coenzyme Q10 in poly(ethylene glycol) and poly(lactic acid) with supercritical carbon dioxide. Ind. Eng. Chem. Res. 2012, 51, 5840–5846. [Google Scholar] [CrossRef]

- Chiou, A.H.J.; Cheng, H.C.; Wang, D.P. Micronization and microencapsulation of felodipine by supercritical carbon dioxide. J. Microencapsul. 2006, 23, 265–276. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Ou, C.; Ye, S.; Song, X.; Luo, S. Construction of nanoscale liposomes loaded with melatonin via supercritical fluid technology. J. Microencapsul. 2017, 34, 687–698. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.H.; Paxton, T.E.; Tomasko, D.L. Microencapsulation of naproxen using rapid expansion of supercritical solutions. Biotechnol. Prog. 1996, 12, 650–661. [Google Scholar] [CrossRef]

- O’Neill, M.L.; Cao, Q.; Fang, M.; Johnston, K.P.; Wilkinson, S.P.; Smith, C.D.; Kerschner, J.L.; Jureller, S.H. Solubility of homopolymers and copolymers in carbon dioxide. Ind. Eng. Chem. Res. 1998, 37, 3067–3079. [Google Scholar] [CrossRef]

- Mishima, K.; Matsuyama, K.; Tanabe, D.; Yamauchi, S.; Young, T.J.; Johnston, K.P. Microencapsulation of proteins by rapid expansion of supercritical solution with a nonsolvent. AIChE J. 2000, 46, 857–865. [Google Scholar] [CrossRef]

- Dixon, D.J.; Johnston, K.P.; Bodmeier, R.A. Polymeric materials formed by precipitation with a compressed fluid antisolvent. AIChE J. 1993, 39, 127–139. [Google Scholar] [CrossRef]

- Matsuyama, K.; Mishima, K.; Hayashi, K.I.; Ishikawa, H.; Matsuyama, H.; Harada, T. Formation of microcapsules of medicines by the rapid expansion of a supercritical solution with a nonsolvent. J. Appl. Polym. Sci. 2003, 89, 742–752. [Google Scholar] [CrossRef]

- Visentin, A.; Rodríguez-Rojo, S.; Navarrete, A.; Maestri, D.; Cocero, M.J. Precipitation and encapsulation of rosemary antioxidants by supercritical antisolvent process. J. Food Eng. 2012, 109, 9–15. [Google Scholar] [CrossRef]

- Mezzomo, N.; De Paz, E.; Maraschin, M.; Martín, Á.; Cocero, M.J.; Ferreira, S.R.S. Supercritical anti-solvent precipitation of carotenoid fraction from pink shrimp residue: Effect of operational conditions on encapsulation efficiency. J. Supercrit. Fluids 2012, 66, 342–349. [Google Scholar] [CrossRef]

- Martín, V.; Romero-Díez, R.; Rodríguez-Rojo, S.; Cocero, M.J. Titnium dioxide nanoparticle coating in fluidized bed via supercritical anti-solvent process (SAS). Chem. Eng. J. 2015, 279, 425–432. [Google Scholar] [CrossRef]

- Montes, A.; Kin, N.; Gordillo, M.D.; Pereyra, C.; De La Ossa, E.J.M. Polymer-naproxen precipitation by supercritical antisolvent (SAS) process. J. Supercrit. Fluids 2014, 89, 58–67. [Google Scholar] [CrossRef]

- Prosapio, V.; De Marco, I.; Reverchon, E. Supercritical antisolvent coprecipitation mechanisms. J. Supercrit. Fluids 2018, 138, 247–258. [Google Scholar] [CrossRef]

- Prosapio, V.; De Marco, I.; Scognamiglio, M.; Reverchon, E. Folic acid-PVP nanostructured composite microparticles by supercritical antisolvent precipitation. Chem. Eng. J. 2015, 277, 286–294. [Google Scholar] [CrossRef]

- Abuzar, S.M.; Hyun, S.M.; Kim, J.H.; Park, H.J.; Kim, M.S.; Park, J.S.; Hwang, S.J. Enhancing the solubility and bioavailability of poorly water-soluble drugs using supercritical antisolvent (SAS) process. Int. J. Pharm. 2018, 538, 1–13. [Google Scholar] [CrossRef]

- Machado, F.R.S.; Reis, D.F.; Boschetto, D.L.; Burkert, J.F.M.; Ferreira, S.R.S.; Oliveira, J.V.; Burkert, C.A.V. Encapsulation of astaxanthin from Haematococcus pluvialis in PHBV by means of SEDS technique using supercritical CO2. Ind. Crops Prod. 2014, 54, 17–21. [Google Scholar] [CrossRef]

- Perrut, M. Supercritical fluid applications: Industrial developments and economic issues. Ind. Eng. Chem. Res. 2000, 39, 4531–4535. [Google Scholar] [CrossRef]

- Li, Y.; Yu, Y.; Wang, H.; Zhao, F. Effect of process parameters on the recrystallization and size control of puerarin using the supercritical fluid antisolvent process. Asian J. Pharm. Sci. 2016, 11, 281–291. [Google Scholar] [CrossRef]

- Jin, H.; Li, S.; Hu, D.; Zhao, Y. Preparation of PLA-PEG nanoparticles by the solution enhanced dispersion with enhanced mass transfer using ultrasound in supercritical CO2. Powder Technol. 2012, 227, 17–23. [Google Scholar] [CrossRef]

- Kalani, M.; Yunus, R. Application of supercritical antisolvent method in drug encapsulation: A review. Int. J. Nanomed. 2011, 6, 1429–1442. [Google Scholar] [CrossRef] [PubMed]

- Zabihi, F.; Xin, N.; Jia, J.; Chen, T.; Zhao, Y. High yield and high loading preparation of curcumin–PLGA nanoparticles using a modified supercritical antisolvent technique. Ind. Eng. Chem. Res. 2014, 53, 6569–6574. [Google Scholar] [CrossRef]

- Tu, L.S.; Dehghani, F.; Foster, N.R. Micronisation and microencapsulation of pharmaceuticals using a carbon dioxide antisolvent. Powder Technol. 2002, 126, 134–149. [Google Scholar] [CrossRef]

- Elvassore, N.; Baggio, M.; Pallado, P.; Bertucco, A. Production of different morphologies of biocompatible polymeric materials by supercritical CO2 antisolvent techniques. Biotechnol. Bioeng. 2001, 73, 449–457. [Google Scholar] [CrossRef]

- Engwicht, A.; Girreser, U.; Müller, B.W. Critical properties of lactide-co-glycolide polymers for the use in microparticle preparation by the Aerosol Solvent Extraction System. Int. J. Pharm. 1999, 185, 61–72. [Google Scholar] [CrossRef]

- Karim, F.T.; Ghafoor, K.; Ferdosh, S.; Al-Juhaimi, F.; Ali, E.; Yunus, K.B.; Hamed, M.H.; Islam, A.; Asif, M.; Zaidul, I.S.M. Microencapsulation of fish oil using supercritical antisolvent process. J. Food Drug Anal. 2017, 25, 654–666. [Google Scholar] [CrossRef]

- De Marco, I.; Rossmann, M.; Prosapio, V.; Reverchon, E.; Braeuer, A. Control of particle size, at micrometric and nanometric range, using supercritical antisolvent precipitation from solvent mixtures: Application to PVP. Chem. Eng. J. 2015, 273, 344–352. [Google Scholar] [CrossRef]

- Liparoti, S.; Adami, R.; Caputo, G.; Reverchon, E. Supercritical assisted atomization: Polyvinylpyrrolidone as carrier for drugs with poor solubility in water. J. Chem. 2013, 2013, 801069. [Google Scholar] [CrossRef]

- Thote, A.J.; Gupta, R.B. Formation of nanoparticles of a hydrophilic drug using supercritical carbon dioxide and microencapsulation for sustained release. Nanomedicine 2005, 1, 85–90. [Google Scholar] [CrossRef]

- Lin, C.; Ng, K.M.; Wibowo, C. Producing nanoparticles using precipitation with compressed antisolvent. Ind. Eng. Chem. Res. 2007, 46, 3580–3589. [Google Scholar] [CrossRef]

- Chattopadhyay, P.; Gupta, R.B. Production of griseofulvin nanoparticles using supercritical CO2 antisolvent with enhanced mass transfer. Int. J. Pharm. 2001, 228, 19–31. [Google Scholar] [CrossRef]

- Debenedetti, P.G.; Tom, J.W.; Sang-Do, Y.; Gio-Bin, L. Application of supercritical fluids for the production of sustained delivery devices. J. Control. Release 1993, 24, 27–44. [Google Scholar] [CrossRef]

- Martín, A.; Cocero, M.J. Numerical modeling of jet hydrodynamics, mass transfer, and crystallization kinetics in the supercritical antisolvent (SAS) process. J. Supercrit. Fluids 2004, 32, 203–219. [Google Scholar] [CrossRef]

- Petit-Gas, T.; Boutin, O.; Raspo, I.; Badens, E. Role of hydrodynamics in supercritical antisolvent processes. J. Supercrit. Fluids 2009, 51, 248–255. [Google Scholar] [CrossRef]

- Sauer, D.; Cerea, M.; Dinunzio, J.; McGinity, J. Dry powder coating of pharmaceuticals: A review. Int. J. Pharm. 2013, 457, 488–502. [Google Scholar] [CrossRef]

- Niu, F.; Haslam, J.; Rajewski, R.; Subramaniam, B. A fluidized-bed coating technology using near-critical carbon dioxide as fluidizing and drying medium. J. Supercrit. Fluids 2012, 66, 315–320. [Google Scholar] [CrossRef]

- Niu, F.; Subramaniam, B. Particle fluidization with supercritical carbon dioxide: Experiments and theory. Ind. Eng. Chem. Res. 2007, 46, 3153–3156. [Google Scholar] [CrossRef]

- Matos, R.L.; Lu, T.; McConville, C.; Leeke, G.; Ingram, A. Analysis of curcumin precipitation and coating on lactose by the integrated supercritical antisolvent-fluidized bed process. J. Supercrit. Fluids 2018, 141, 143–156. [Google Scholar] [CrossRef]

- Li, Q.; Huang, D.; Lu, T.; Seville, J.P.K.; Xing, L.; Leeke, G.A. Supercritical fluid coating of API on excipient enhances drug release. Chem. Eng. J. 2017, 313, 317–327. [Google Scholar] [CrossRef]

- Leeke, G.A.; Lu, T.; Bridson, R.H.; Seville, J.P.K. Application of nano-particle coatings to carrier particles using an integrated fluidized bed supercritical fluid precipitation process. J. Supercrit. Fluids 2014, 91, 7–14. [Google Scholar] [CrossRef]

- Chattopadhyay, P.; Huff, R.; Shekunov, B.Y. Drug encapsulation using supercritical fluid extraction of emulsions. J. Pharm. Sci. 2006, 95, 667–679. [Google Scholar] [CrossRef] [PubMed]

- Giufrida, W.M.; Cabral, V.F.; Cardoso-Filho, L.; dos Santos Conti, D.; de Campos, V.E.B.; da Rocha, S.R.P. Medroxyprogesterone-encapsulated poly(3-hydroxybutirate-co-3-hydroxyvalerate) nanoparticles using supercritical fluid extraction of emulsions. J. Supercrit. Fluids 2016, 118, 79–88. [Google Scholar] [CrossRef]

- Kluge, J.; Fusaro, F.; Mazzotti, M.; Muhrer, G. Production of PLGA micro- and nanocomposites by supercritical fluid extraction of emulsions: II. Encapsulation of Ketoprofen. J. Supercrit. Fluids 2009, 50, 336–343. [Google Scholar] [CrossRef]

- Kluge, J.; Fusaro, F.; Casas, N.; Mazzotti, M.; Muhrer, G. Production of PLGA micro- and nanocomposites by supercritical fluid extraction of emulsions: I. Encapsulation of lysozyme. J. Supercrit. Fluids 2009, 50, 327–335. [Google Scholar] [CrossRef]

- Prieto, C.; Calvo, L. The encapsulation of low viscosity omega-3 rich fish oil in polycaprolactone by supercritical fluid extraction of emulsions. J. Supercrit. Fluids 2017, 128, 227–234. [Google Scholar] [CrossRef]

- Prieto, C.; Calvo, L. Supercritical fluid extraction of emulsions to nanoencapsulate vitamin E in polycaprolactone. J. Supercrit. Fluids 2017, 119, 274–282. [Google Scholar] [CrossRef]

- Prieto, C.; Calvo, L.; Duarte, C.M.M. Continuous supercritical fluid extraction of emulsions to produce nanocapsules of vitamin E in polycaprolactone. J. Supercrit. Fluids 2017, 124, 72–79. [Google Scholar] [CrossRef]

- Sabirzyanov, A.N.; Il’in, A.P.; Akhunov, A.R.; Gumerov, F.M. Solubility of water in supercritical carbon dioxide. High Temp. 2002, 40, 203–206. [Google Scholar] [CrossRef]

- Lee, B.; Choi, Y.; Lee, W. Drying characteristics of apple slabs after pretreatment with supercritical CO2. Prev. Nutr. Food Sci. 2011, 16, 261–266. [Google Scholar] [CrossRef]

- Brown, Z.K.; Fryer, P.J.; Norton, I.T.; Bakalis, S.; Bridson, R.H. Drying of foods using supercritical carbon dioxide—Investigations with carrot. Innov. Food Sci. Emerg. Technol. 2008, 9, 280–289. [Google Scholar] [CrossRef]

- Almeida-rivera, C.; Khalloufi, S.; Jansen, J.; Bongers, P. Mathematical description of mass transfer in supercritical-carbon-dioxide-drying processes. Comput. Aided Chem. Eng. 2011, 29, 36–40. [Google Scholar]

- Khalloufi, S.; Almeida-rivera, C.; Bongers, P. Supercritical-CO2 drying of foodstuffs in packed beds: Experimental validation of a mathematical model and sensitive analysis. J. Food Eng. 2010, 96, 141–150. [Google Scholar] [CrossRef]

- Şahin, İ.; Özbakır, Y.; İnönü, Z.; Ulker, Z.; Erkey, C. Kinetics of Supercritical Drying of Gels. Gels 2018, 4, 3. [Google Scholar] [CrossRef]

- Tang, Q.; Wang, T. Preparation of silica aerogel from rice hull ash by supercritical carbon dioxide drying. J. Supercrit. Fluids 2005, 35, 91–94. [Google Scholar] [CrossRef]

- Özbakır, Y.; Erkey, C. Experimental and theoretical investigation of supercritical drying of silica alcogels. J. Supercrit. Fluids 2015, 98, 153–166. [Google Scholar] [CrossRef]

- Sanz-moral, L.M.; Rueda, M.; Mato, R.; Martín, Á. View cell investigation of silica aerogels during supercritical drying: Analysis of size variation and mass transfer mechanisms. J. Supercrit. Fluids 2014, 92, 24–30. [Google Scholar] [CrossRef]

- Griffin, J.S.; Mills, D.H.; Cleary, M.; Nelson, R.; Manno, V.P.; Hodes, M. Fluids continuous extraction rate measurements during supercritical CO2 drying of silica alcogel. J. Supercrit. Fluids 2014, 94, 38–47. [Google Scholar] [CrossRef]

- De Paz, E.; Martín, Á.; Every, H.; Cocero, M.J. Production of water-soluble quercetin formulations by antisolvent precipitation and supercritical drying. J. Supercrit. Fluids 2015, 104, 281–290. [Google Scholar] [CrossRef]

- Hee, Y.Y.; Tan, C.P.; Rahman, R.A.; Noranizan, M.; Smith, R.L.; Chong, G.H. Production of virgin coconut oil microcapsules from oil-in-water emulsion with supercritical carbon dioxide spray drying. J. Supercrit. Fluids 2017, 130, 118–124. [Google Scholar] [CrossRef]

- Lee, W.J.; Tan, C.P.; Sulaiman, R.; Smith, R.L.; Chong, G.H. Microencapsulation of red palm oil as an oil-in-water emulsion with supercritical carbon dioxide solution-enhanced dispersion. J. Food Eng. 2018, 222, 100–109. [Google Scholar] [CrossRef]

- Poortinga, A.T.; Trambitas, D.O.; Hofland, G.W. The Microencapsulate and Process for the Manufacture Thereof 2010. European Patent No. EP 2 315 584 B1; WO Patent Application 2010/014011 A1, 4 February 2010. [Google Scholar]

- Nuchuchua, O.; Every, H.A.; Hofland, G.W.; Jiskoot, W. Scalable organic solvent free supercritical fluid spray drying process for producing dry protein formulations. Eur. J. Pharm. Biopharm. 2014, 88, 919–930. [Google Scholar] [CrossRef] [PubMed]

- Varona, S.; Martín, Á.; Cocero, M.J.; Duarte, C.M.M. Encapsulation of lavandin essential oil in poly-(ε-caprolactones) by PGSS process. Chem. Eng. Technol. 2013, 36, 1187–1192. [Google Scholar] [CrossRef]

- Lubary, M.; De Loos, T.W.; Ter Horst, J.H.; Hofland, G.W. Production of microparticles from milk fat products using the Supercritical Melt Micronization (ScMM) process. J. Supercrit. Fluids 2011, 55, 1079–1088. [Google Scholar] [CrossRef]

- Münüklü, P.; Jansens, P.J. Particle formation of an edible fat (rapeseed 70) using the supercritical melt micronization (ScMM) process. J. Supercrit. Fluids 2007, 40, 433–442. [Google Scholar] [CrossRef]

- Letourneau, J.J.; Vigneau, S.; Gonus, P.; Fages, J. Micronized cocoa butter particles produced by a supercritical process. Chem. Eng. Process. Process Intensif. 2005, 44, 201–207. [Google Scholar] [CrossRef]

- Ciftci, O.N.; Temelli, F. Formation of solid lipid microparticles from fully hydrogenated canola oil using supercritical carbon dioxide. J. Food Eng. 2016, 178, 137–144. [Google Scholar] [CrossRef]

- Varona, S.; Kareth, S.; Martín, Á.; Cocero, M.J. Formulation of lavandin essential oil with biopolymers by PGSS for application as biocide in ecological agriculture. J. Supercrit. Fluids 2010, 54, 369–377. [Google Scholar] [CrossRef]

- Varona, S.; Martín, Á.; Cocero, M.J. Liposomal incorporation of lavandin essential oil by a thin-film hydration method and by particles from gas-saturated solutions. Ind. Eng. Chem. Res. 2011, 50, 2088–2097. [Google Scholar] [CrossRef]

- Pemsel, M.; Schwab, S.; Scheurer, A.; Freitag, D.; Schatz, R.; Schlücker, E. Advanced PGSS process for the encapsulation of the biopesticide Cydia pomonella granulovirus. J. Supercrit. Fluids 2010, 53, 174–178. [Google Scholar] [CrossRef]

- De Paz, E.; Martín, Á.; Cocero, M.J. Formulation of β-carotene with soybean lecithin by PGSS (Particles from Gas Saturated Solutions)-drying. J. Supercrit. Fluids 2012, 72, 125–133. [Google Scholar] [CrossRef]

- de Paz, E.; Martín, Á.; Duarte, C.M.M.; Cocero, M.J. Formulation of β-carotene with poly-(ε-caprolactones) by PGSS process. Powder Technol. 2012, 217, 77–83. [Google Scholar] [CrossRef]

- Getachew, A.T.; Chun, B.S. Optimization of coffee oil flavor encapsulation using response surface methodology. LWT Food Sci. Technol. 2016, 70, 126–134. [Google Scholar] [CrossRef]

- Machado, L.C.; Pelegati, V.B.; Oliveira, A.L. Study of simple microparticles formation of limonene in modified starch using PGSS—Particles from gas-saturated suspensions. J. Supercrit. Fluids 2016, 107, 260–269. [Google Scholar] [CrossRef]

- Haq, M.; Chun, B.S. Microencapsulation of omega-3 polyunsaturated fatty acids and astaxanthin-rich salmon oil using particles from gas saturated solutions (PGSS) process. LWT 2018, 92, 523–530. [Google Scholar] [CrossRef]

- Lévai, G.; Martín, Á.; Moro, A.; Matias, A.A.; Gonçalves, V.S.S.; Bronze, M.R.; Duarte, C.M.M.; Rodríguez-Rojo, S.; Cocero, M.J. Production of encapsulated quercetin particles using supercritical fluid technologies. Powder Technol. 2017, 317, 142–153. [Google Scholar] [CrossRef]

- Cabezas, L.I.; Gracia, I.; García, M.T.; De Lucas, A.; Rodríguez, J.F. Production of biodegradable porous scaffolds impregnated with 5-fluorouracil in supercritical CO2. J. Supercrit. Fluids 2013, 80, 1–8. [Google Scholar] [CrossRef]

- Cabezas, L.I.; Fernández, V.; Mazarro, R.; Gracia, I.; De Lucas, A.; Rodríguez, J.F. Production of biodegradable porous scaffolds impregnated with indomethacin in supercritical CO2. J. Supercrit. Fluids 2012, 63, 155–160. [Google Scholar] [CrossRef]

- Champeau, M.; Thomassin, J.M.; Tassaing, T.; Jérôme, C. Drug loading of polymer implants by supercritical CO2 assisted impregnation: A review. J. Control. Release 2015, 209, 248–259. [Google Scholar] [CrossRef] [PubMed]

- Velasco, D.; Benito, L.; Fernández-Gutiérrez, M.; San Román, J.; Elvira, C. Preparation in supercritical CO2 of porous poly(methyl methacrylate)-poly(l-lactic acid) (PMMA-PLA) scaffolds incorporating ibuprofen. J. Supercrit. Fluids 2010, 54, 335–341. [Google Scholar] [CrossRef]

- Lee, L.Y.; Ong, B.; Xie, J.; Smith, K.A.; Wang, C.-H. Controlled delivery of paclitaxel from micro-porous foams for the postsurgical treatment of glioma blastoma multiforme. In Proceedings of the AIChE Annual Meeting, San Francisco, CA, USA, 12–17 November 2006. [Google Scholar]

- Kfoury, M.; Hădărugă, N.G.; Hădărugă, D.I.; Fourmentin, S. 4—Cyclodextrins as encapsulation material for flavors and aroma. In Encapsulations; Grumezescu, A.M., Ed.; Nanotechnology in the Agri-Food Industry; Academic Press: Cambridge, MA, USA, 2016; pp. 127–192. ISBN 978-0-12-804307-3. [Google Scholar]

- Fenyvesi, E.; Szente, L. 18—Nanoencapsulation of flavors and aromas by cyclodextrins. In Encapsulations; Grumezescu, A.M., Ed.; Nanotechnology in the Agri-Food Industry; Academic Press: Cambridge, MA, USA, 2016; pp. 769–792. ISBN 978-0-12-804307-3. [Google Scholar]

- Osorio-Tobón, J.F.; Silva, E.K.; Meireles, M.A.A. 3—Nanoencapsulation of flavors and aromas by emerging technologies. In Encapsulations; Grumezescu, A.M., Ed.; Nanotechnology in the Agri-Food Industry; Academic Press: Cambridge, MA, USA, 2016; pp. 89–126. ISBN 978-0-12-804307-3. [Google Scholar]

- Trifković, K.; Đorđević, V.; Balanč, B.; Kalušević, A.; Lević, S.; Bugarski, B.; Nedović, V. 9—Novel approaches in nanoencapsulation of aromas and flavors. In Encapsulations; Grumezescu, A.M., Ed.; Nanotechnology in the Agri-Food Industry; Academic Press: Cambridge, MA, USA, 2016; pp. 363–419. ISBN 978-0-12-804307-3. [Google Scholar]

- Zarzycki, P.K.; ena Fenert, B.; Głód, B.K. 17—Cyclodextrins-based nanocomplexes for encapsulation of bioactive compounds in food, cosmetics, and pharmaceutical products: Principles of supramolecular complexes formation, their influence on the antioxidative properties of target chemicals, and rec. In Encapsulations; Grumezescu, A.M., Ed.; Nanotechnology in the Agri-Food Industry; Academic Press: Cambridge, MA, USA, 2016; pp. 717–767. ISBN 978-0-12-804307-3. [Google Scholar]

- Adeoye, O.; Costa, C.; Casimiro, T.; Aguiar-Ricardo, A.; Cabral-Marques, H. Preparation of ibuprofen/hydroxypropyl-γ-cyclodextrin inclusion complexes using supercritical CO2-assisted spray drying. J. Supercrit. Fluids 2018, 133, 479–485. [Google Scholar] [CrossRef]

- Münüklü, P.; Wubbolts, F.; De Loos, T.W.; Jansens, P.J. The phase behavior of systems of supercritical CO2 or propane with edible fats and a wax. J. Supercrit. Fluids 2006, 39, 1–5. [Google Scholar] [CrossRef]

- Antonie, P.; Pereira, C.G. Solubility of functional compounds in supercritical CO2: Data evaluation and modelling. J. Food Eng. 2019, 245, 131–138. [Google Scholar] [CrossRef]

- Aminian, A. Estimating the solubility of different solutes in supercritical CO2 covering a wide range of operating conditions by using neural network models. J. Supercrit. Fluids 2017, 125, 79–87. [Google Scholar] [CrossRef]

- Gupta, R.S.J. Solubility in Supercritical Carbon Dioxide, 1st ed.; CRC Press: Boca Raton, FL, USA, 2007; ISBN 9781420005998. [Google Scholar]

| Active Ingredient | Coating Material | Particle Size and Morphology | Reference |

|---|---|---|---|

| Coenzyme Q10 | Poly(ethylene glycol) (PEG) Polylactic acid (PLA) | 2–10 µm PEG: Uniform and small spheres PLA: Spherical agglomerated microparticles | [27] |

| Felodipine | PEG4000 | 2–6 µm Gel-like irregular mass | [28] |

| Melatonin | Liposomes | 66 nm Round or oval microspheres with uniform distribution | [29] |

| Naproxen | PLA | 10–90 µm Microspheres with agglomerates | [30] |

| Active Ingredient | Coating Material | Co-Solvent | Reference |

|---|---|---|---|

| Proteins (lysozyme and lipase) | PEG4000, PEG6000, PEG20000, poly(methyl methacrylate) (PMMA), PLA, polyglycolide-co-lactide (PGLA), and PEG- poly(propylene glycol) (PPG)-PEG triblock copolymer | Ethanol/methanol/propanol/acetone/toluene | [32] |

| P-acetamidophenol, acetylsalicylic acid, 1,3-dimethylxanthine, flavone, and 3-hydroxyflavone | PEG4000, PEG6000, PEG20000, PLA, PMMA, ethyl cellulose, and PEG-PPG-PEG triblock copolymer | Ethanol/methanol/propanol/acetone/toluene | [34] |

| Active Ingredient | Coating Material | Particle Size and Morphology | Reference |

|---|---|---|---|

| Indomethacin | Polylactide-co-glycolide (PLGA)/Eudragit RS | <1 µm Spherical | [66] |

| Lysozyme | PLGA | ~0.1–1 µm Spherical | [69] |

| Ketoprofen | PLGA | ~0.1–1 µm Spherical | [66,68] |

| Vitamin E | Polycaprolactone (PCL) | ~10–300 nm Spherical nanoparticles | [71,72] |

| Medroxyprogesterone | Poly(3-hydroxybutirate-co-3-hydroxyvalerate) (PHBV) | ~0.1–1 µm Spherical | [67] |

| Omega-3-rich fish oil | PCL | ~10–10 nm Spherical nanoparticles | [70] |

| Active Ingredient | Coating Material | Particle Size and Morphology | Reference |

|---|---|---|---|

| β-carotene | Soy lecithin | 10–500 μm Agglomerates of partially fused spheres | [96] |

| Polycaprolactone (PCL) (CAPA 2403D and CAPA 6100) | CAPA 2403D: 110–130 μm CAPA 6100: 270–650 μm Flat or sphere-like particles attached and agglomerated by long filaments of polymer | [97] | |

| Coffee oil | Polyethylene Glycol (PEG) | 78 μm Spherical shapes of various sizes to amorphous shapes | [98] |

| Cydia pomonella granulovirus | Palm oil-based fat: 77% Lecithin-based surfactant: 9% Modified titanium oxide and benzophenone derivative UV protectants: 2% | <85 μm Almost spherical particles were obtained | [95] |

| Lavandin essential oil | PEG 9000 | 30–100 μm Spheres and needles | [93] |

| Soy lecithin | 1.4–24.8 μm Dry and fine but aggregated particles | [94] | |

| Limonene | Modified starch | 60–90 μm Spherical shapes with few broken shapes smaller than the others | [99] |

| Omega-3 polyunsaturated fatty acids and astaxanthin-rich salmon oil | PEG 6000 | 67.26–165.81 μm Irregular spherical shapes to amorphous shapes of various sizes | [100] |

| Quercetin | Soy lecithin and Pluronic L64® | 0.138–0.158 μm Complete encapsulation of amorphous quercetin | [101] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soh, S.H.; Lee, L.Y. Microencapsulation and Nanoencapsulation Using Supercritical Fluid (SCF) Techniques. Pharmaceutics 2019, 11, 21. https://doi.org/10.3390/pharmaceutics11010021

Soh SH, Lee LY. Microencapsulation and Nanoencapsulation Using Supercritical Fluid (SCF) Techniques. Pharmaceutics. 2019; 11(1):21. https://doi.org/10.3390/pharmaceutics11010021

Chicago/Turabian StyleSoh, Soon Hong, and Lai Yeng Lee. 2019. "Microencapsulation and Nanoencapsulation Using Supercritical Fluid (SCF) Techniques" Pharmaceutics 11, no. 1: 21. https://doi.org/10.3390/pharmaceutics11010021

APA StyleSoh, S. H., & Lee, L. Y. (2019). Microencapsulation and Nanoencapsulation Using Supercritical Fluid (SCF) Techniques. Pharmaceutics, 11(1), 21. https://doi.org/10.3390/pharmaceutics11010021