1. Introduction

Forest biomass represents one of the major renewable raw materials for bioenergy and bioproducts. Approximately 42% of currently used biomass resources in the United States are from forestlands, accounting for 154 million dry tons (short ton, US) of biomass annually. It is estimated that at a price of

$60 per dry ton an additional 103 million dry tons of forest biomass is potentially available annually [

1]. In the European Union, it is estimated the total forest biomass supply could increase to 895 million m

3 per year by 2030, which is 20% higher than its supply level in 2010 [

2]. In Brazil, Welfle [

3] evaluated the country’s potential biomass supply from forest residues and estimated the supply could increase to approximately 16 million tons in 2030, 3.6 times larger than the supply in 2015. Although there has been a growing interest in utilizing forest biomass, many factors still constrain the development of viable markets for forest biomass. One significant barrier is the high costs of feedstock logistics coupled with low marginal value.

Forest biomass feedstock logistics has been a subject of intense investigation for more than a decade in many different regions due to the interest in improving the economic viability of forest biomass utilization [

4]. Some of this research has been focused directly on the processing and transportation of biomass residues from timber harvest, fuel thinning, and forest restoration activities. For example, Harrill and Han [

5] evaluated the operational performance and costs of utilizing a hook-lift truck in centralized grinding operations in northern California. They found the hook-lift truck transportation was cost-effective in collecting previously inaccessible forest residues with the production cost at

$32.98 per bone dry ton. Zamora-Cristales et al. [

6] analyzed the economic effects of truck-grinder interference and found grinder location, available truck turnaround, turnouts and truck travel distance highly affect forest residues processing and transport economics at the operational level. Marchi et al. [

7] compared two chipping operations in Italy and found that a roadside chipping was over 4 times more productive than chipping in the forest stand.

Biomass feedstock logistics include preprocessing, storage and transportation to an end-use facility [

8,

9]. On-site preprocessing, such as grinding or chipping, is usually required to improve transportation efficiency and meet desired particle size specifications for energy and product conversion processes. In many situations, however, preprocessing is responsible for a substantial portion of feedstock costs because of high machine rates (owning and operating costs) combined with low machine utilization rates due to frequent equipment relocation between processing sites [

10]. In addition, efficiency gains in transportation from densifying materials through preprocessing can become inconsequential if poor road conditions impede large chip vans from accessing the site and dramatically increase per-unit transportation costs [

11]. Careful selection of equipment and design of efficient feedstock logistics are essential considerations for economically feasible forest biomass supply.

At their core, decisions related to grinder location are fundamentally connected to the tradeoffs between fixed and variable costs in residue processing and trucking operations. For a single pile, a simple tradeoff equation can be developed and solved for volume or distance, and many operators use conventional wisdom and simple rules of thumb to site equipment for biomass operations. However, real-world operations can be quite complex and the design of efficient biomass supply logistics involves multiple decisions that are simultaneously sensitive to numerous parameters, such as the spatial distribution and quantity of biomass sources, road infrastructure and conditions, available equipment, storage and conversion facility locations, and many other variables. Optimization techniques have been used in the past to assist forest biomass supply decisions but mostly at strategic or tactical scales [

12]. Some of the applications include selection of biomass facility location [

13], selection of conversion technology and energy products [

14], biomass procurement and supply management [

15], production planning of biomass power plants [

16], chipping facility location and transportation [

17], and truck scheduling for biomass delivery [

18].

Although these studies suggest effective solution approaches to broad forest biomass supply chain problems, many did not incorporate operational details related to feedstock logistics into their optimization frameworks. Generally, timber harvests and other silvicultural treatments that are responsible for producing residues are spatially dispersed, as they often must comply with maximum adjacency, size and green-up constraints. As a result, forest residues are geographically dispersed, which is a reality seldom considered by large-scale, strategic planning models. Furthermore, the use of certain truck configurations may be limited by changes in road conditions that occur at spatial resolutions that are finer than those used by course strategic models. Individual machines must be selected for tasks and site-specific conditions and the entire system should be carefully designed to minimize negative interactions and operational delays among machines to maximize system productivity.

Zamora-Cristales et al. [

10] is one of few studies that incorporated operational details into an optimization framework for forest biomass feedstock production. The study used simulation techniques to quantify the effects of truck-machine interactions, truck arrival rates and road conditions. The study then solved feedstock logistics problems using a mixed-integer programming approach to select the most cost-efficient biomass processing and transportation decisions at an operational level. The study took into account different transportation configurations, and comminution and densification options to provide an optimal combination of machines and operations for individual residue piles. This approach, however, assumes that multiple machines are available to the contractor at all times. Small forest contracting firms generally own a small fleet of machines, perhaps only one machine per task (e.g., one feller-buncher, one skidder, one delimber), and their short-term goal is often to make the best use of their existing and available machines through improved logistics solutions for a fixed portfolio of equipment.

Anderson et al. [

11] conducted field operations studies to explore two different logistics systems for forest biomass processing and transportation where residue sites were inaccessible to large chip vans. They compared “in-woods grinding” and “slash forwarding”, and analyzed tradeoffs in grinder and truck efficiencies between the two systems. In the conventional in-woods grinding system, the grinder moves to each of the forest residue piles and grinds them on the site. A maneuverable, small capacity dump truck is used to transport the ground material to a concentration yard (also called a “transshipment” location) where it is stored and eventually reloaded into large chip vans for long-distance highway transportation to a conversion facility. In contrast, slash forwarding uses a dump truck to forward residues to a concentration yard where the residues are ground directly into large chip vans. Anderson et al. [

11] found that processing costs were higher for in-woods grinding due to the low utilization rate of the grinder compared to slash forwarding. However, truck efficiency was higher for in-woods grinding because wood chips have a higher bulk density than unprocessed residues.

While Anderson et al. [

11] showed tradeoffs between grinder and truck efficiencies, the measured tradeoffs are only pertinent to their experiments and may not be applicable to other operational conditions. Furthermore, the research used high-resolution time study methods, but did not employ engineering approaches to optimize logistics. In this study, we developed a mixed-integer programming model that optimizes feedstock logistics on a tree-shaped road network by minimizing total feedstock processing and handling costs. Similar to Anderson et al. [

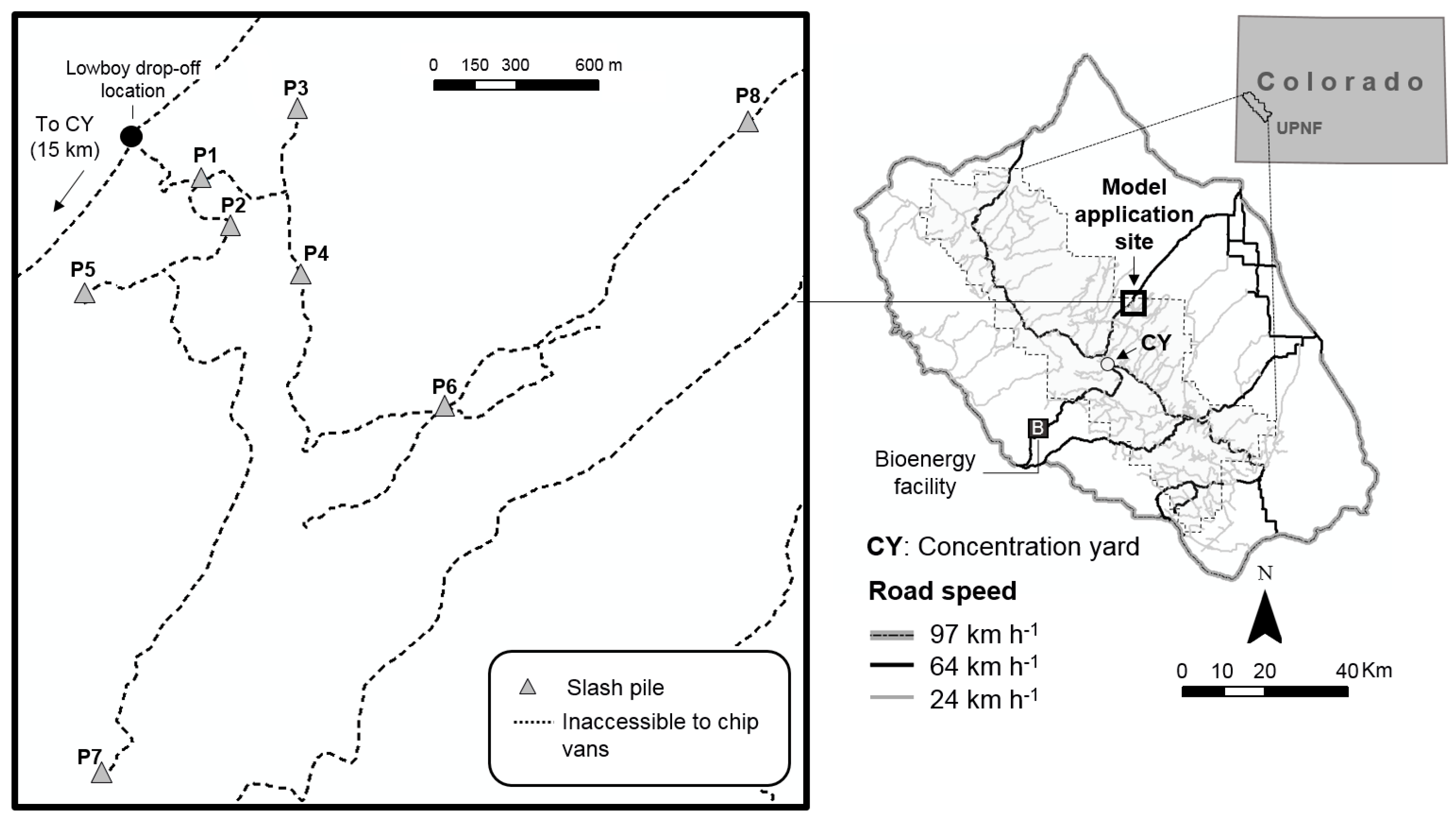

11], our model evaluates tradeoffs between slash forwarding and in-woods grinding operations, but it provides optimal configurations for equipment selection, processing and transportation for any given machine productivity and costs, potential concentration yard locations and road network. For demonstration purposes, our model was applied to different sets of residue piles dispersed across a road network in the Uncompahgre National Forest in southwestern Colorado.

2. Problem Description

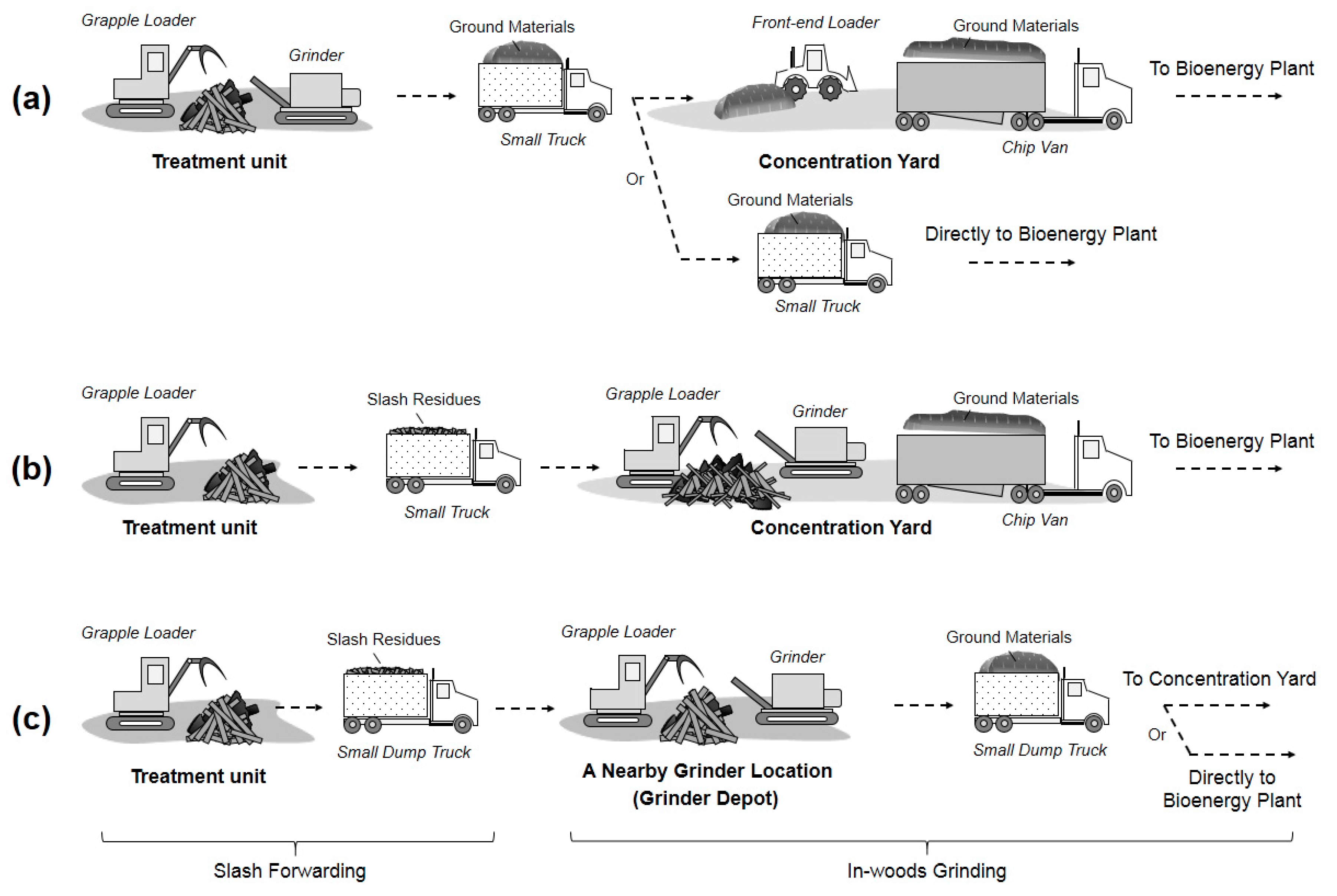

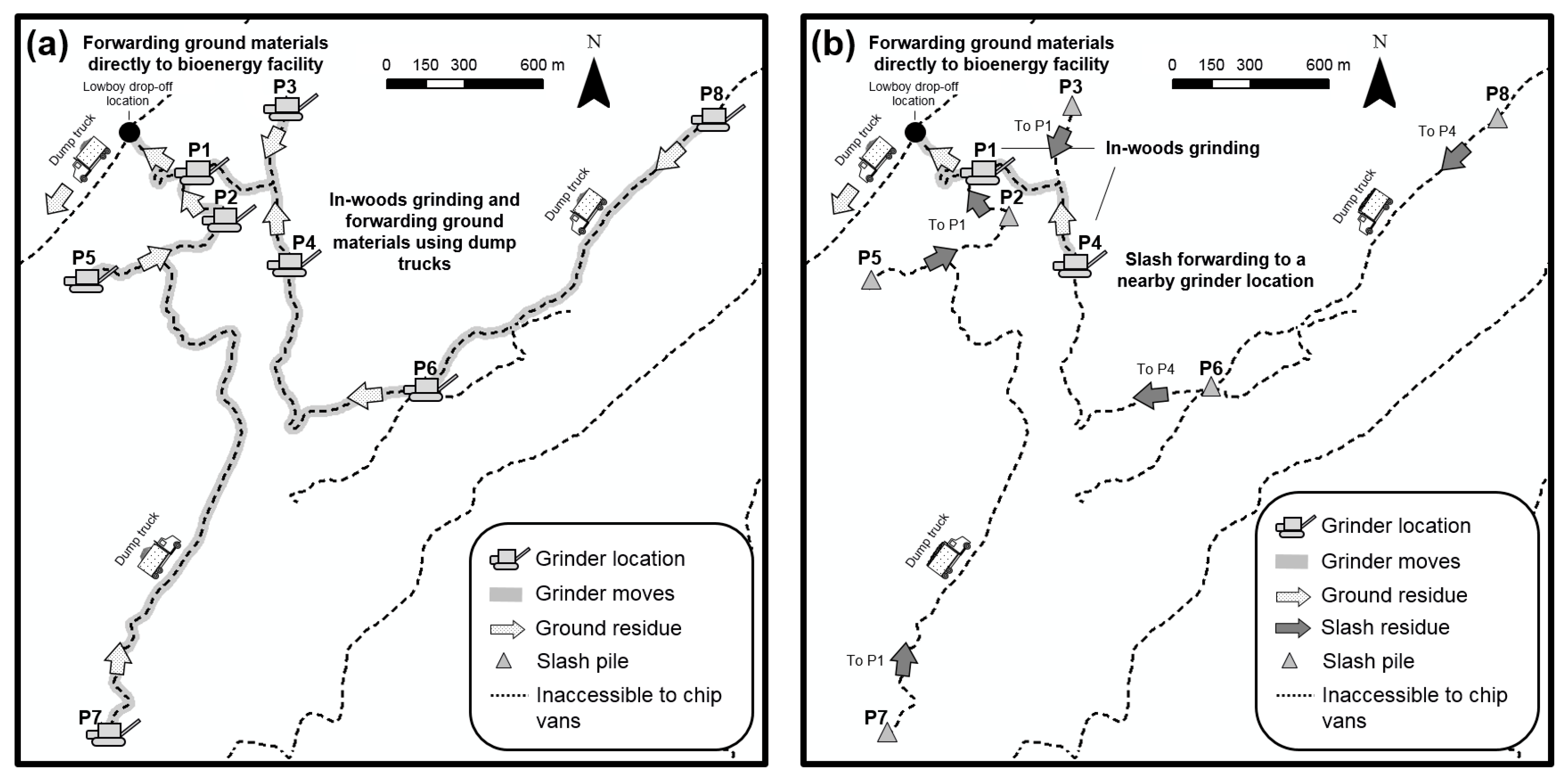

An obvious advantage of the in-woods grinding system (

Figure 1a) is increased transportation efficiency compared to slash forwarding, in which gains in transportation efficiency attributable to biomass densification are only realized after sufficiently dry residues have been ground at the concentration yard. It is clear that this system is increasingly more attractive than slash forwarding, in terms of transport efficiency, as the distance between the grinding site and the conversion facility increases. However, even though slash is much less dense than chipped or ground residues, move-in and move-out costs of walking or trucking the grinder to the residue pile location and its low utilization rate due to frequent relocation and unproductive wait time for trucks can make in-woods grinding economically inefficient compared to slash forwarding. Moreover, reloading the ground materials into large chip vans at the concentration yard involves additional handling costs.

In situations where in-woods grinding becomes inefficient, slash forwarding to the concentration yard using small dump trucks presents a potentially more efficient alternative recovery operation (

Figure 1b). In this configuration, the grinder is not operationally constrained by the productivity of small trucks delivering slash because a sufficient volume of residues can be stored at the concentration yard, thus maximizing grinder efficiency. However, the high cost of transporting slash residues by small dump trucks may offset reduced grinding costs if forwarding of the raw material is carried out over long distances [

11].

Another system combines these two options, including both slash forwarding and in-woods grinding components. Instead of forwarding slash directly to the concentration yard, slash from a given site can be advanced to a nearby site where it is processed and transported to the concentration yard (

Figure 1c). Rather than moving the grinder between piles, the grinder stays at one pile site, or a location on the road network central to a set of surrounding piles (hereafter called a “grinder depot”), and processes residues as they are forwarded from nearby sites. In certain situations, this option would minimize grinder mobilization and increase transportation efficiency simultaneously. However, it clearly adds an additional handling step and potentially a second loader, depending on how the logistics are timed.

Forest contractors involved in forest residue processing and handling operations need to select the most cost-efficient feedstock logistics system for a given distribution of residue pile sites, road access, and available machinery. We developed a mathematical model that can be used to: (1) inform the contractor of the best allocation of in-woods grinding and slash forwarding operations, (2) facilitate the decision to construct (or not to construct) a concentration yard, and (3) guide the minimal relocation of equipment to minimize overall costs.

3. Model Development

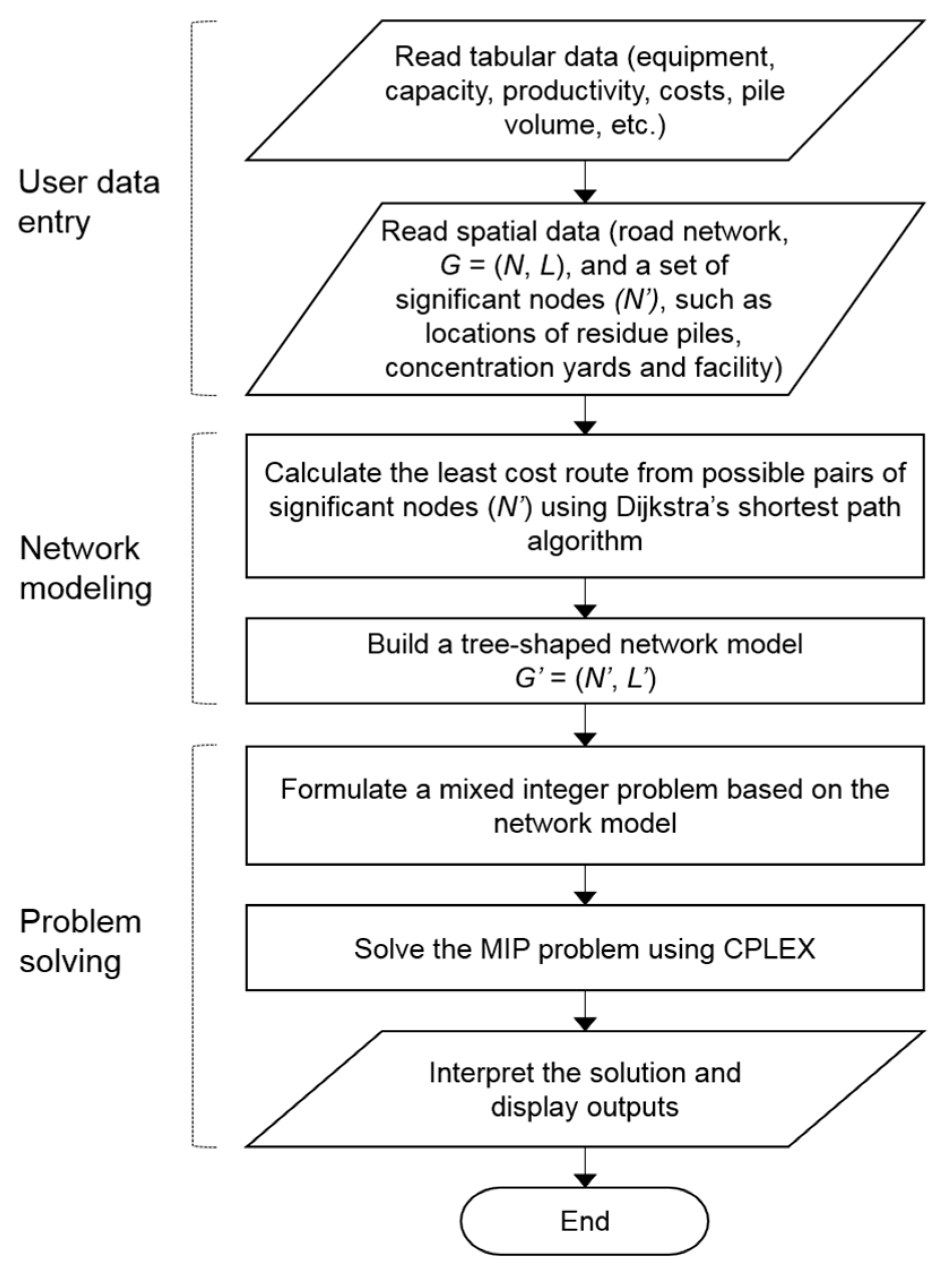

Our model consists of three components: user data entry, network modeling and problem solving (

Figure 2). The model was designed to work with any user-specific data on machine costs and productivity because individual logging contractors may have different fleets of machines with different capacities and costs. Non-spatial, user-specific data include the capacity, hourly costs and productivity of individual machines, fixed and variable costs of equipment mobilization when a lowboy is used and driving speed when the equipment is self-propelled without using a lowboy, and feedstock processing site construction costs. Another required user-specific dataset is spatial road network data in vector format consisting of nodes and links including road segment attributes, logging residue pile locations, potential concentration yard locations, road junctions, and a conversion facility location.

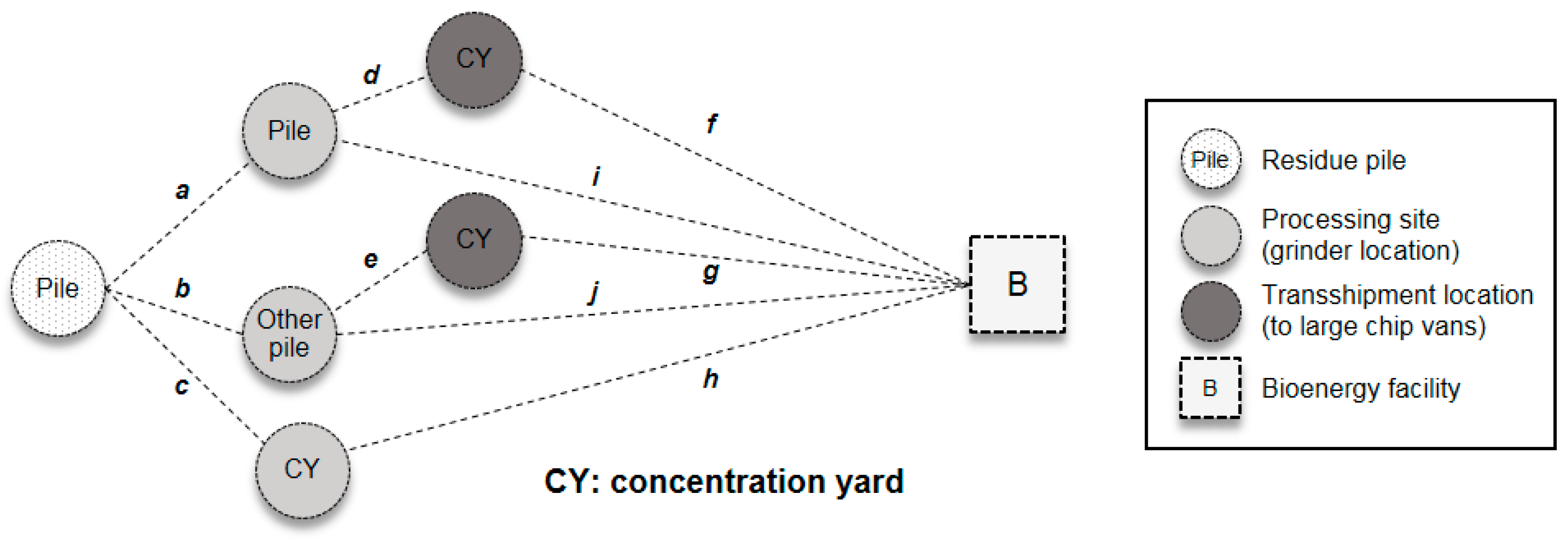

After the user-specific tabular and spatial data are entered, the model builds a network representation of the problem to accommodate the different operational configurations (

Figure 3). For the in-woods grinding option, the residues could be either processed at their current location, link

a in

Figure 3, if the landing serves as a processing site, or processed at another landing location, link

b, after forwarding the slash. The ground materials are then transported to a nearby concentration yard using dump trucks, links

d and

e, or directly to the bioenergy facility through links

i and

j, whichever is the lowest cost option. The ground materials delivered and stored at a concentration yard are reloaded into large chip vans and transported to the final destination via links

f and

g. For the slash forwarding system, the residue is forwarded to the concentration yard, link

c, and then processed and transported to the bioenergy facility through link

h. Different truck configurations and variable haul costs are used to represent truck transportation options, and the construction of processing sites is considered a fixed cost.

Our model takes user-provided spatial road network data, and uses Dijkstra’s shortest path algorithm [

19] to build a network representation of the problem. Any given road network (G) may include a large number of nodes (N) and links (L). In our model, a subset network, G’= (N’, L’), is developed consisting of a set of nodes, N’, and a set of directed links L’. N’ represents “significant” nodes for biomass feedstock logistics including residue piles, concentration yards, bioenergy facilities, or any major intermediate nodes (i.e., road junctions), while L’ represents transportation options between a pair of any significant nodes with different truck options. The model runs the shortest path algorithm on the entire road network (G) to calculate the least-cost routes for the possible pairs of the preselected significant nodes (N’). These least-cost routes are then converted to a set of links (L’) directly linking the preselected significant nodes via different truck options. Costs for each transportation option are also calculated by the shortest path algorithm on a dry weight basis with units of bone dry tons (bdt, 907.185 kilograms at 0% water content). Running the shortest path algorithm prior to the mixed-integer formulation significantly reduces problem size because it predetermines the least-cost routes between significant nodes, and thus removes unnecessary intermediate nodes for a simpler network representation of the problem.

The model then builds a mixed-integer programming (MIP) formulation for the cost minimization network flow problem. The sets, decision variables, and parameters used in the MIP formulation are given in

Table 1.

The mathematical formulation of the problem is as follows:

Subject to:

for

for

for

for

for

,

for

,

for

for

for

for

for

for

Equation (1) specifies the objective function of the problem: to minimize the total cost of the operation including grinding, transportation, residue loading, machine mobilization, and processing site construction. The first and second terms represent the costs of slash forwarding to processing sites (i.e., grinder depots and concentration yards shown as links

a, b and

c in

Figure 3). The third term represents the costs of in-woods grinding along with the transportation costs of ground residues from processing sites to either a concentration yard (links

d and

e) or a bioenergy facility (links

i and

j). The fourth term estimates both grinding costs at a concentration yard and transportation costs of the ground materials to the bioenergy facility (link

h). The fifth term estimates the transshipment and transportation costs of ground materials (links

f and

g). The sixth and seventh terms of the objective function represent the fixed costs of machine mobilization and processing site construction costs, respectively.

Equations (2)–(13) represent the constraints of the cost minimization problem. Equation (2) ensures the maximum available slash residues from each source node. Equation (3) provides the option of slash forwarding to a grinder depot, and ensures that ground materials can be only transported to a concentration yard for transshipment or directly to the bioenergy facility. When a residue plie location serves as a grinder depot, the slash flow variable from the location to itself has a positive value (i.e., Sii > 0). Equation (4) ensures all the slash materials arriving at the concentration yard are ground at the yard and transported to the bioenergy facility as ground residues. Equation (5) ensures all the ground materials forwarded to the concentration yard are transshipped to large chip vans for transportation to the bioenergy facility. Equations (6)–(9) trigger the use of machine m at node u required for slash forwarding (Equation (6)), residue grinding at the grinder depot (Equation (7)), residue grinding at the concentration yard (Equation (8)), or transshipment of ground materials at the concentration yard (Equation (9)). M is a large number greater than the minimum required delivered volume.

While Equations (1)–(9) are the typical MIP formulation for a network problem, Equation (10) shows the unique formulation approach developed in this study in order to model equipment mobilization between nodes in a hierarchical, tree-shaped network where equipment has to move out to the junction of the main road that connects to the final destination before it can move to another location. Consider the grinder mobilization tour illustrated in

Figure 4. Under any circumstance, this tour would be accomplished by the round-trip travel of a machine over each road segment to move from the initial location to each pile (i.e., S-P1, P1-P2, and P2-P3). Thus, the machine mobilization cost can be calculated by multiplying the move-in costs of the machine by the road segments used for relocation (Equation (1)). Assuming the machine starts at the facility location (

v), Equation (10) ensures that all of the links included in the shortest path (

Ruv) between nodes

u and

v must be used if a machine

m is located at the node

u. This equation also ensures the model does not count the previously incurred mobilization expenses multiple times when the machine makes several stops along the route. For example, processing at P1 in

Figure 4 requires that the grinder passes through road segments S-J1 and J1-P1. When the grinder visits P2 following processing at P1, the model adds the travel costs from J1 to P2 to the incurred expenses, but ignores the costs previously incurred between S and J1. This prevents the model from double counting mobilization costs.

Equation (11) represents the required minimum volume constraint for the demand of ground residues set by the bioenergy facility. The volume requirement at each biomass facility has to be fulfilled by the total amount of ground residues transported to the facility with all possible transportation options. It is not necessary to specify truck options in the formulation because material types (i.e., slash vs. ground residues) and truck options (i.e., dump truck vs. chip van) are specified by decision variables. For example,

Sij represents slash forwarding by dump truck, which is the only option of transportation for slash residue.

Gij represents ground residue transportation by dump truck, except when

i is one of the concentration yards and

j is the bioenergy facility, in which case it represents chip van transportation. Equation (12) shows the binary variables associated with machine mobilization and site construction. Equation (13) is a non-negativity constraint for continuous decision variables to guarantee that all the flows must be equal or greater than zero. All solutions presented hereafter were provided by CPLEX

® Version 12.6 (IBM ILOG, Armonk, NY, USA) [

20].

6. Conclusions

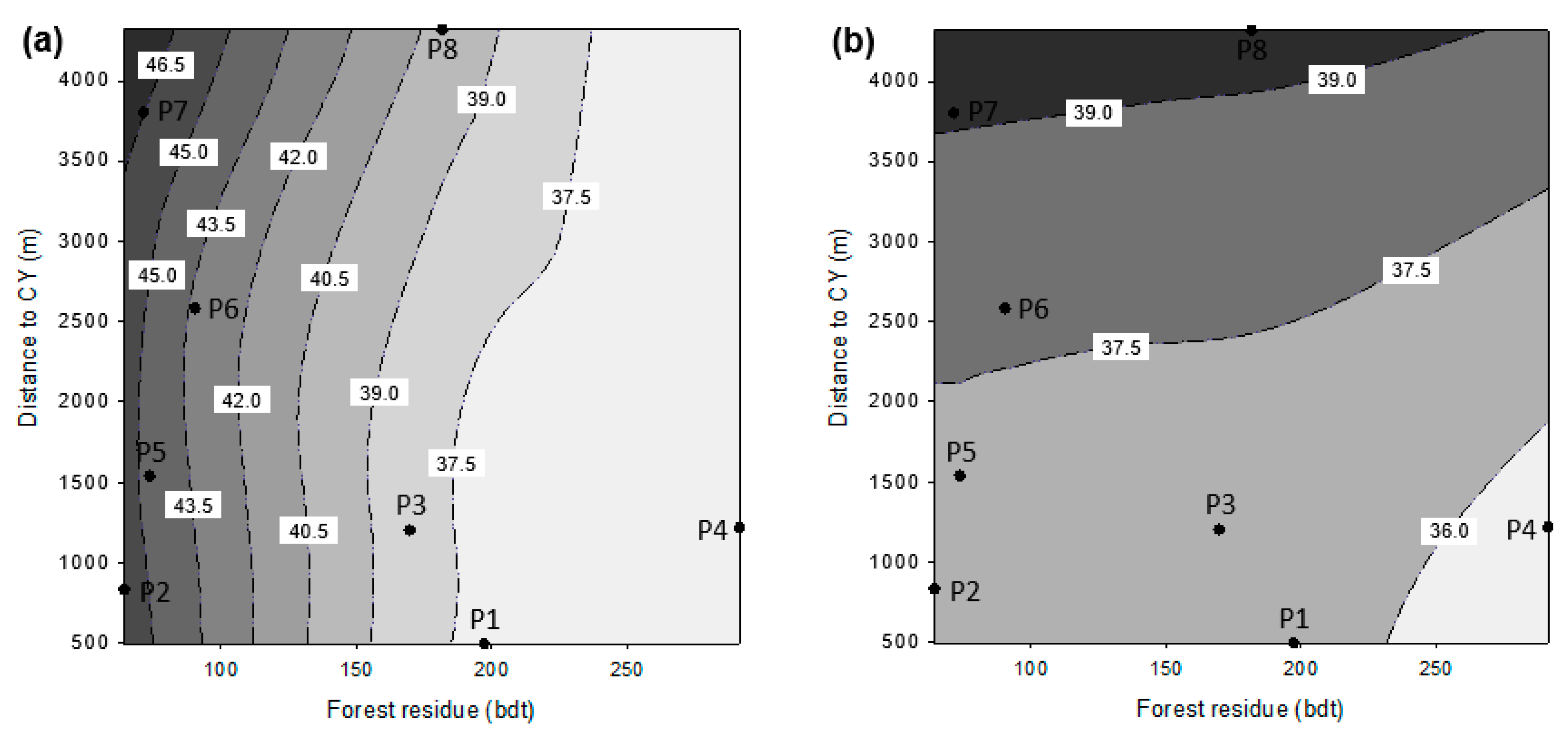

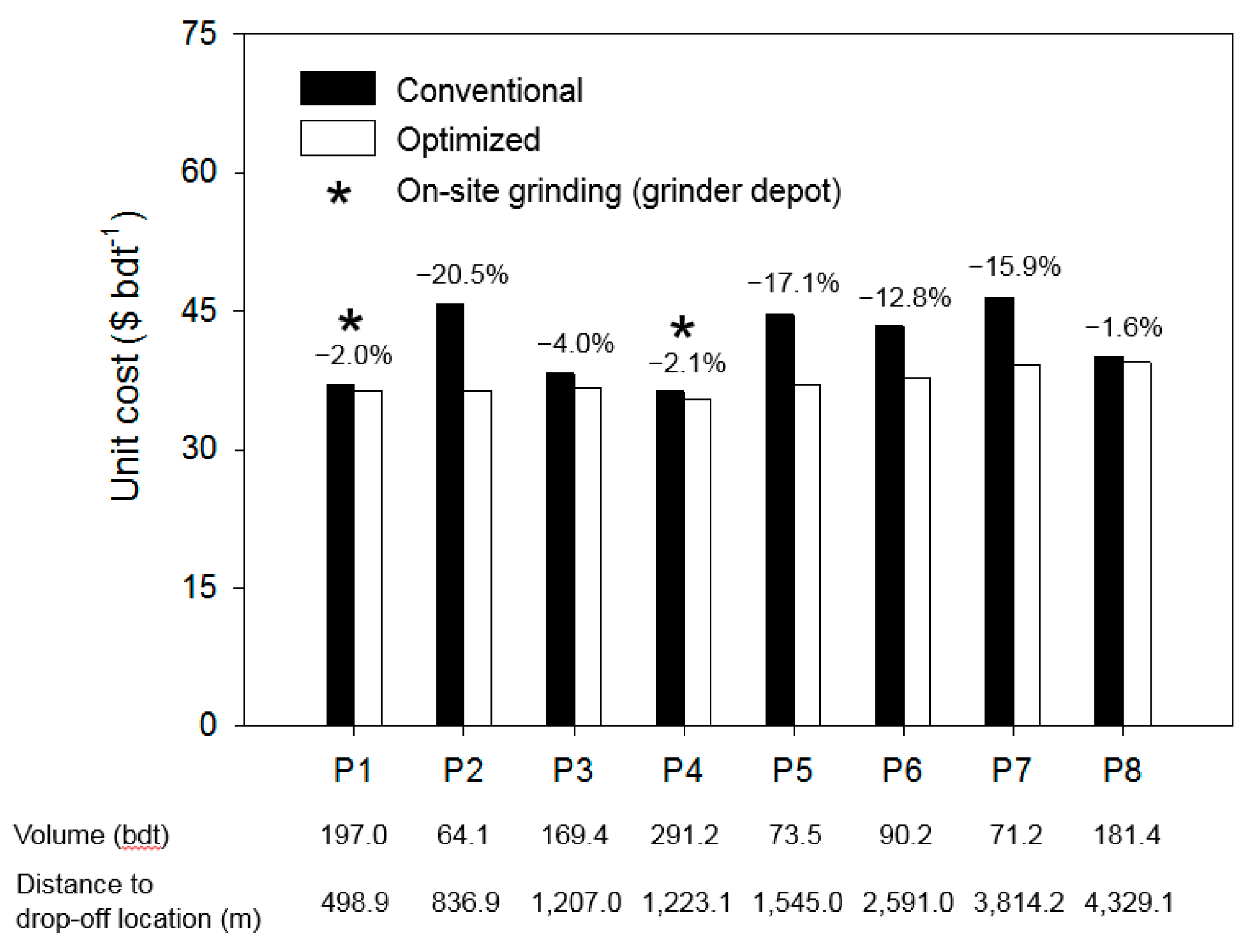

We applied a mixed-integer programming approach coupled with a network algorithm to a biomass feedstock logistics problem where the most cost-efficient grinder locations and processing and transportation operations were unknown. According to the results of our model applications, the slash forwarding option is generally beneficial if a residue pile is relatively small (e.g., residue piles P2, P5, P6 and P7 in

Table 2) or located close to a processing site (e.g., P2, P3, P5, and P6 in

Figure 6b), while in-woods grinding is more cost-efficient in situations where residue volume is relatively large and where forwarding residues from nearby sites can guarantee the economic benefits of grinding at the grinder depot (e.g., P1 and P4). The transshipment option is appropriate if the increase in transportation efficiency compensates the additional handling costs caused by reloading ground material and by front-end loader mobilization, as well as yard construction if the yard is used only for the transshipment.

Conventionally, forest contractors have used in-woods grinding in residue recovery operations, but our results showed that using this mixed-integer approach in decision making can reduce the cost of the operation with some unconventional modifications. In the first model application with a small project area, the optimized logistics forwards residues to the selected grinder depots instead of moving the grinder to each pile location, and this change results in a 7% unit cost reduction compared to the conventional logistics. For the larger project area covered in the second model application, optimized logistics reduces the unit cost by 11% compared to the conventional system. These reductions are important to forest contractors because forest residues are underutilized due to high processing, handling and transportation costs relative to their value. A decision that optimizes logistics to improve the efficiency of operations can make forest biomass utilization more economically viable, meaning more biomass can be sold profitably and less burned for disposal.

Another important consideration when contractors are faced with these options is the situation where multiple businesses are involved in the recovery operation. It is possible that a contractor who owns and operates a grinder subcontracts transportation duties to an independent trucking company. This may introduce conflicts regarding the unit of payment provided to the trucking company. Depending on the contract provisions, the conventional system can be advantageous for the trucking company because transportation efficiency will be higher than forwarding slash. Conversely, grinding at a few of candidate sites is advantageous for the owner of the grinder because grinder mobilization costs can be avoided. Our model can resolve this conflict by providing a solution to the problem that represents the least expensive alternative on a common unit of cost for the entire system.

The MIP approach introduced in this study is unique in three ways. It formulates the pile-to-pile grinder movement using binary variables to account for equipment mobilization costs. To reduce the problem size, our model combines the shortest path algorithm with MIP, and formulates the problem based on the least-cost routes predetermined between possible pairs of nodes. Lastly, our model is one of few efforts to expand the application boundary of optimization to assist in forest operational decisions where high precision data and models are usually required to represent problem details. With advanced sensors and information technology used in forest operations, the data are growing both in quantity and quality, and the development of optimization applications for forest operations is expected to grow. This study provides an example of integrating detailed field data with mathematical optimization for specific operational decisions.

The application of our problem formulation for equipment mobilization is limited to hierarchical, tree-shaped road networks. Although this is common in many real-world forestry settings where most adjacent log landings share main haul direction or are accessed through a spur road, such as in hilly and mountainous terrain, our formulation would not be suitable for road systems that do not conform to this general layout, such as a grid network.

Our future research efforts include incorporating this optimization model into a practical decision support system that can be used easily and broadly by land managers and the industry. Combined with geographic information systems and a data entry user-interface, this optimization model will provide a complete tool that can help land managers and forest contractors analyze different feedstock logistics options and identify the most cost-efficient practices given conditions and objectives. Such improvements would contribute significantly to efficient expansion of the bioeconomy using forest biomass feedstocks.