Development of Updated Models to Characterize Skidding Performance in Romania Based on a Nation-Level Dataset

Abstract

1. Introduction

2. Materials and Methods

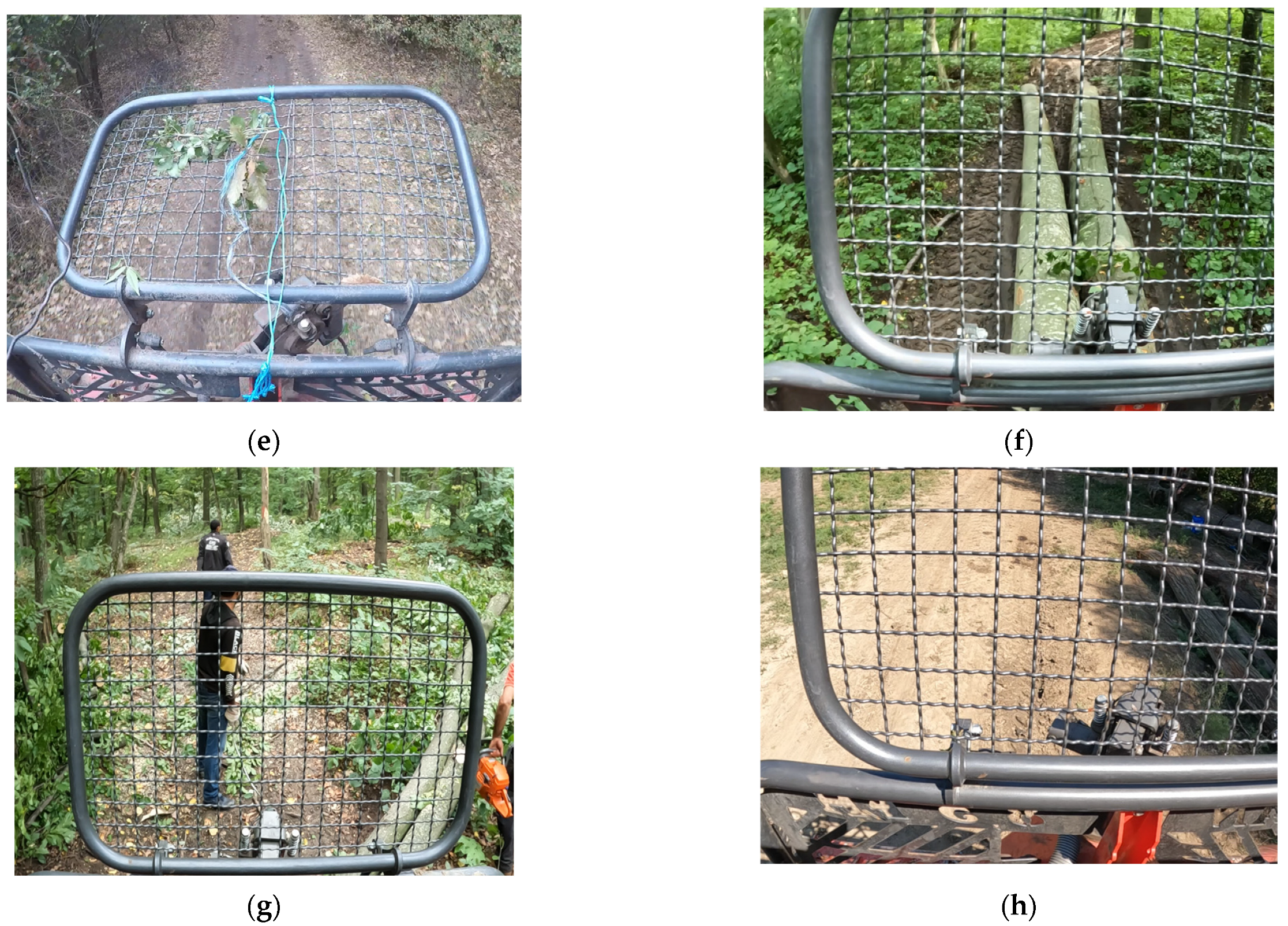

2.1. Study Locations and Machine Types

2.2. Data Collection

2.3. Data Processing

2.4. Statistical Analysis

- The variables of elemental time consumption (tDET, tMAN, tPOC, tAPL, tPIP, tDPC, tAPE, tDFR, tDPR, tMBR, tDS, tDP, tDM, tDO, converted in hours), cycle time consumption (tSWC, h), fuel consumption (FC, L), payload volume (PV, m3), number of pieces (NP), and extraction distance (ED, m) were checked for normality using the Shapiro–Wilk test;

- To characterize the data, descriptive statistics were calculated and reported for these variables, including minimum and maximum values, range, mean, and median values;

- Cycle time (CT, h) and fuel consumption (FC, L) models were developed using multiple linear regression techniques, ensuring that initial assumptions of multi-linear regression were met, as well as that the developed models were significant globally while retaining the statistically significant predictors. The initial assumptions included:

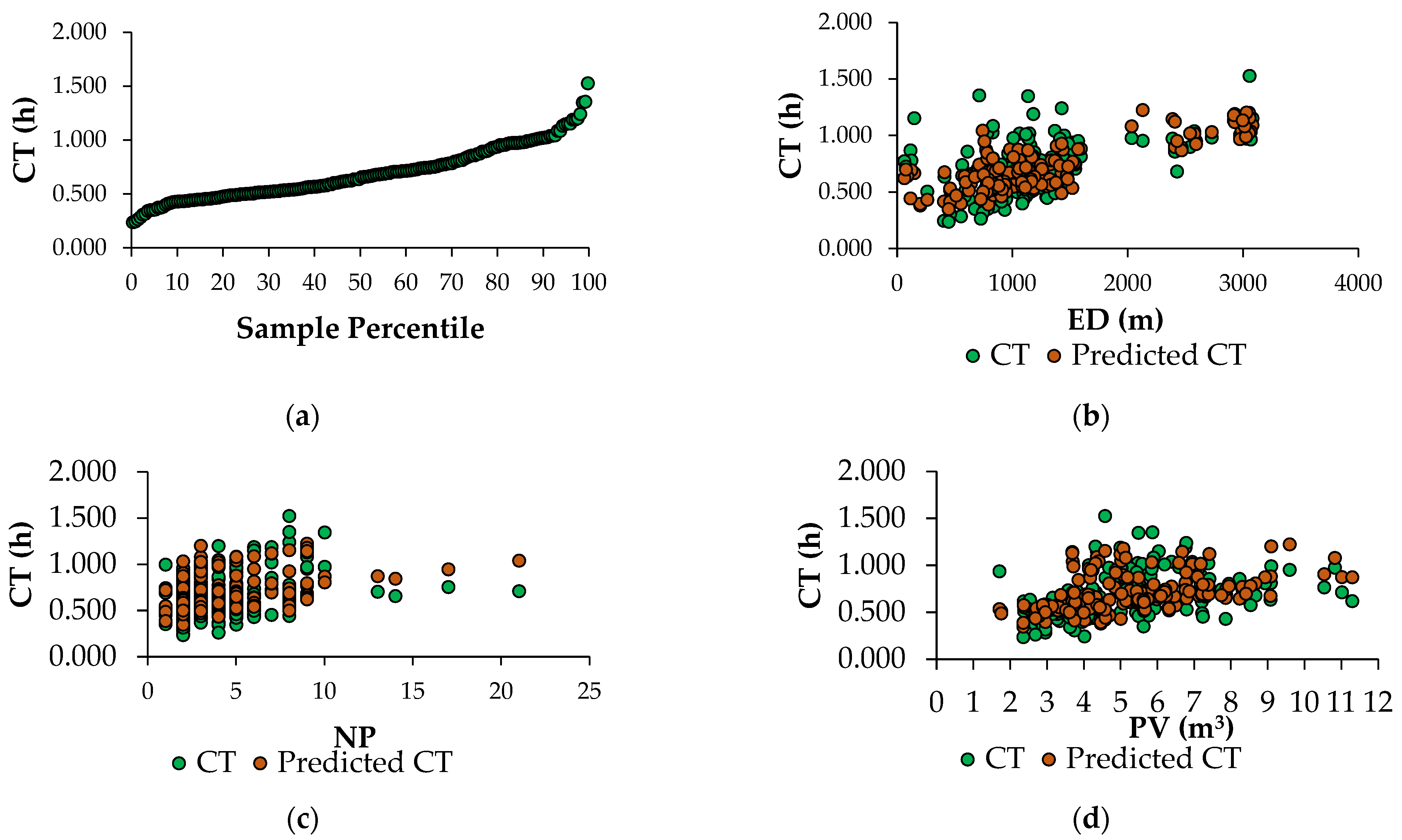

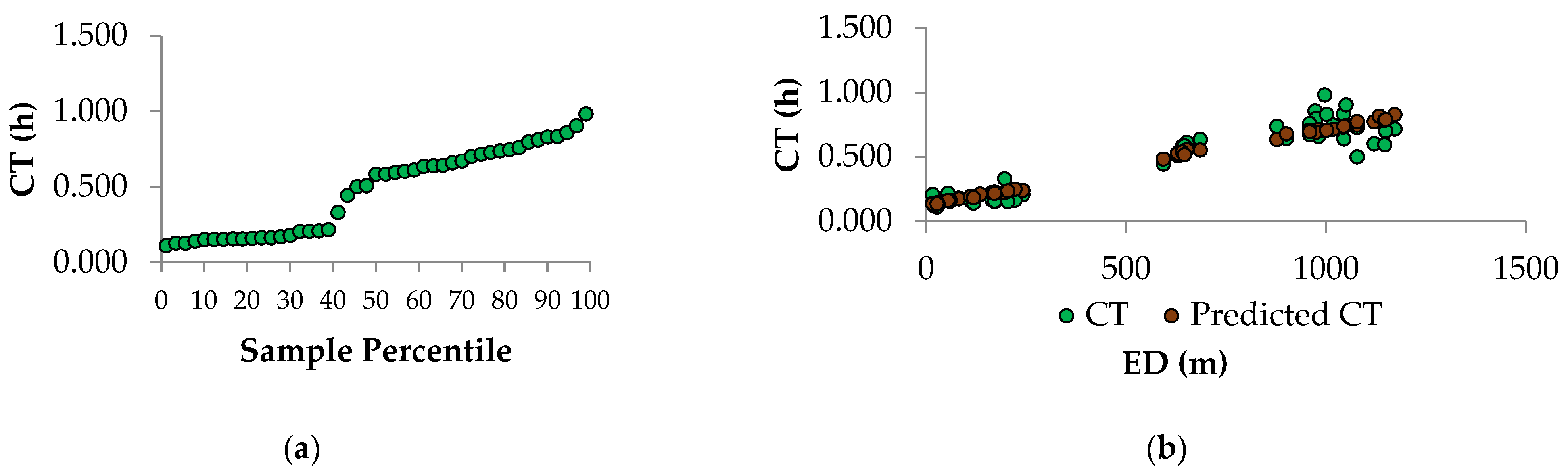

- The existence of a linear relationship between the dependent variables (time or fuel consumption) and the independent variables, which was preliminary checked by scatter plots;

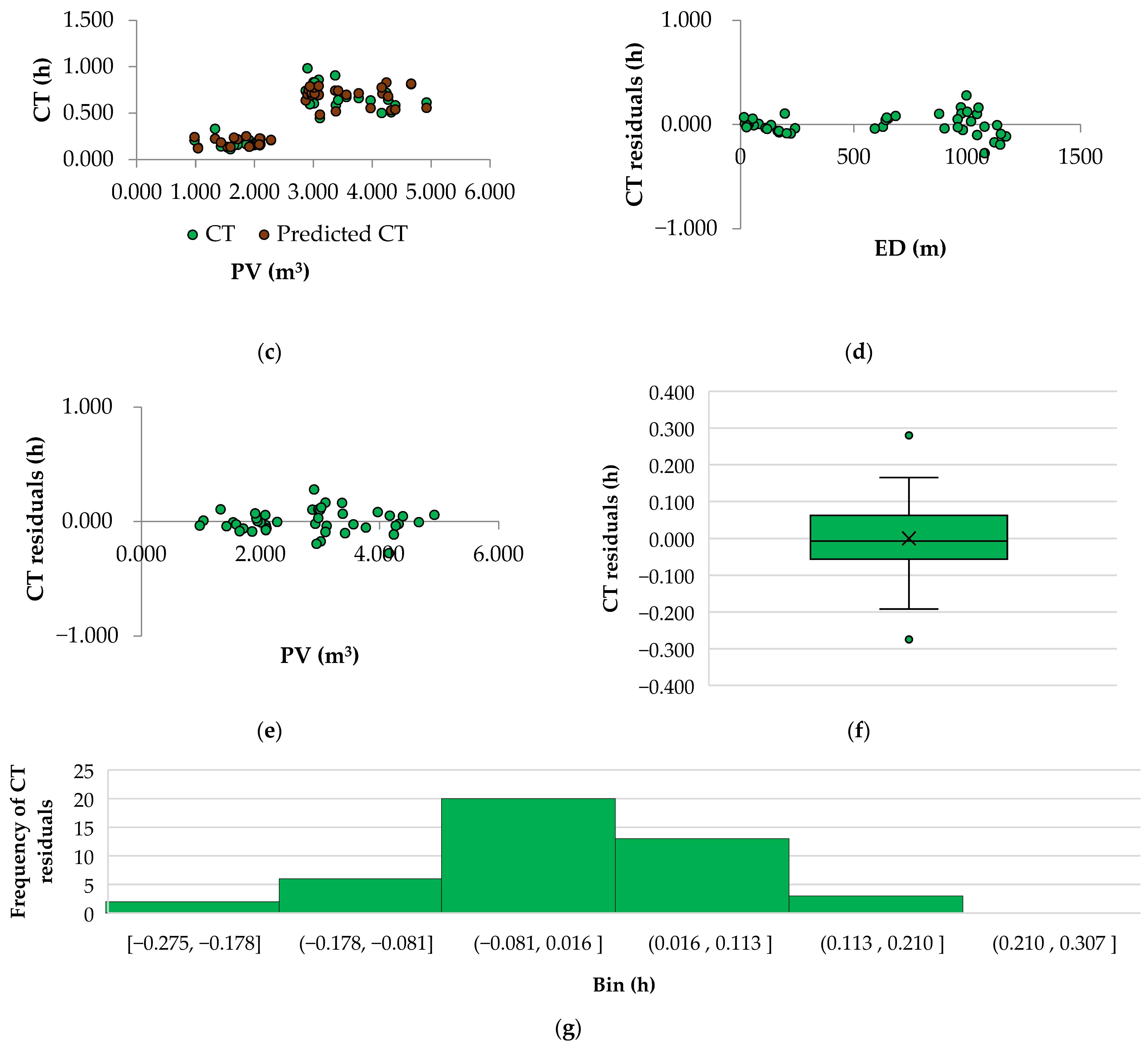

- Multivariate normality (i.e., normal distribution of residuals, which was checked by rigorous tests—Shapiro–Wilk, histograms, and boxplots);

- The absence of multicollinearity (no significant correlation between independent variables, using a correlation threshold of 0.8, which was checked by a correlation analysis based on a correlation matrix); and

- Homoskedasticity (i.e., ensuring the variance of residuals was consistent across all levels of independent variables, which was checked by rigorous techniques, i.e., Breusch–Pagan and White tests).

2.5. Modeling of Efficiency, Productivity, and Unit Fuel Use

3. Results

3.1. Descriptive Statistics of Operational, Time and Fuel Consumption Variables

3.2. Time and Fuel Consumption Models

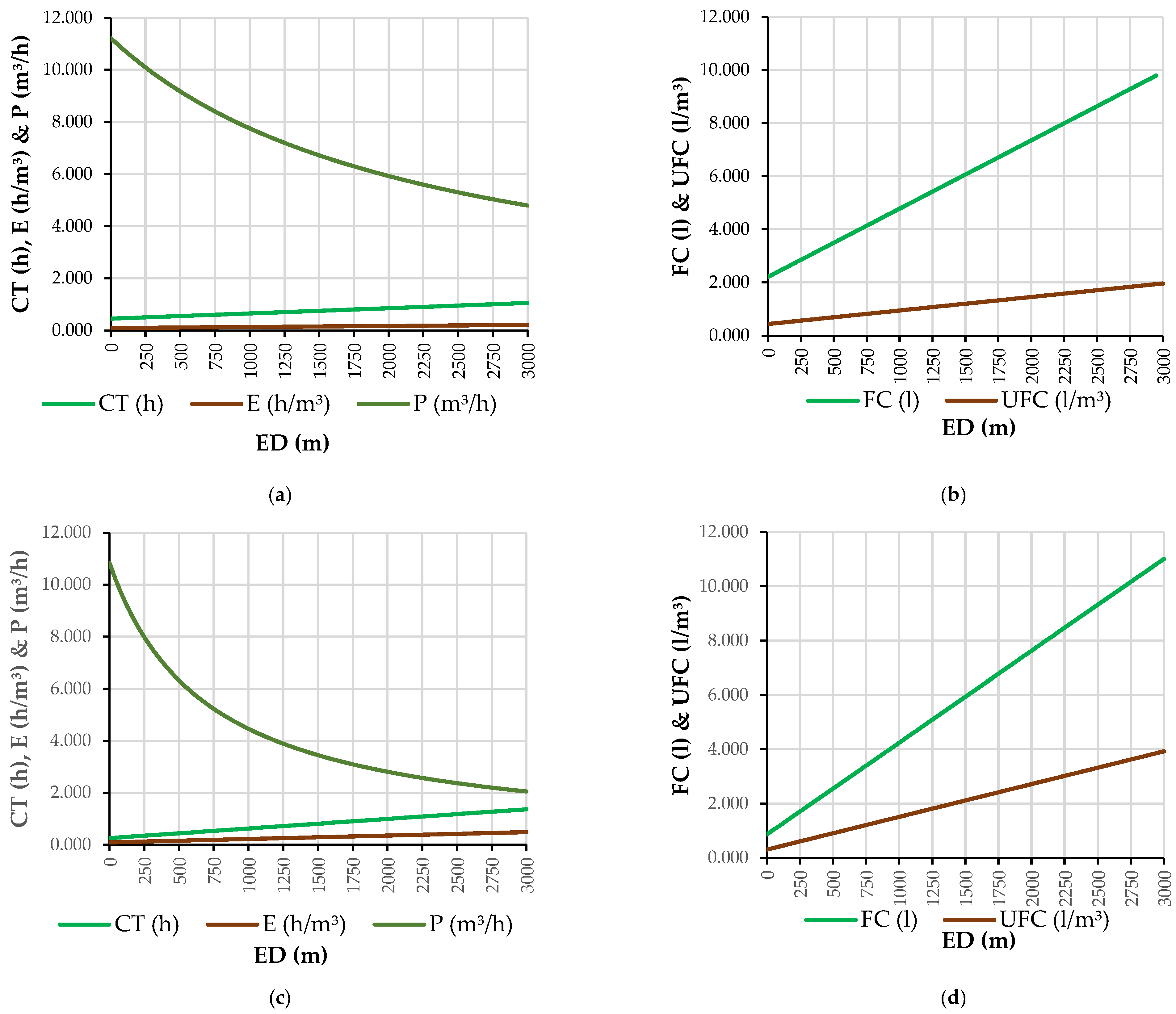

3.3. Efficiency, Productivity and Unit Fuel Consumption Models

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Lundbäck, M.; Häggström, C.; Nordfjell, T. Worldwide trends in methods for harvesting and extracting industrial roundwood. Int. J. For. Eng. 2021, 32, 202–215. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Visser, R.; O’Neal, B. A survey of skidder fleet of Central, Eastern and Southern Europe. Eur. J. For. Res. 2021, 140, 901–911. [Google Scholar] [CrossRef]

- Oprea, I. Tehnologia Exploatări Lemnului; Transilvania University Press: Brasov, Romania, 2008; pp. 11–17. [Google Scholar]

- Neruda, J.; Nevrkla, P.; Staněk, L.; Zemánek, T. Tractors and Skidders in Forestry; Mendelova University v Brně: Brno, Czech Republic, 2023. [Google Scholar]

- Nikooy, M.; Ahrari, S.; Salehi, A.; Naghdi, R. Effects of rubber-tired skidder and farm tractor on physical properties of soil in plantation areas in the north of Iran. J. For. Sci. 2015, 61, 393–398. [Google Scholar] [CrossRef]

- Erler, J.; Spinelli, R.; Borz, S.A.; Mederski, P.S. Technodiversity in Forest Operations; Transilvania University Press: Brasov, Romania, 2023; pp. 4–88. [Google Scholar]

- Marchi, E.; Chung, W.; Visser, R.; Abbas, D.; Nordfjell, T.; Mederski, P.S.; McEwan, A.; Brink, M.; Laschi, A. Sustainable Forest Operations (SFO): A new paradigm in a changing world and climate. Sci. Total Environ. 2018, 634, 1385–1397. [Google Scholar] [CrossRef] [PubMed]

- Palander, T.; Haavikko, H.; Kortelainen, E.; Kärhä, K.; Borz, S.A. Improving environmental and energy efficiency in wood transportation for a carbon-neutral forest industry. Forests 2020, 11, 1194. [Google Scholar] [CrossRef]

- Kopseak, H.; Šušnjar, M.; Bačić, M.; Šporčić, M.; Pandur, Z. Skidders fuel consumption in two different working regions and types of forest management. Forests 2021, 12, 547. [Google Scholar] [CrossRef]

- Holzleitner, F.; Stampfer, K.; Visser, R. Utilization rates and cost factors in timber harvesting based on long-term machine data. Croat. J. For. Eng. 2011, 32, 501–508. [Google Scholar]

- Borz, S.A.; Mariş, A.C.; Kaakkurivaara, N. Performance of skidding operations in low-access and low-intensity timber removals: A simulation of productivity and fuel consumption in mature forests. Forests 2023, 14, 265. [Google Scholar] [CrossRef]

- Klvac, R.; Skoupy, A. Characteristic fuel consumption and exhaust emissions in fully mechanized logging operations. J. For. Res. 2009, 14, 328–334. [Google Scholar] [CrossRef]

- Heinimann, H.R. A computer model to differentiate skidder and cable-yarder based road network concepts on steep slopes. J. For. Res. 1998, 3, 1–9. [Google Scholar] [CrossRef]

- Ryan, T.; Phillips, H.; Ramsay, J.; Dempsey, J. Forest Road Manual: Guidelines for the Design, Construction and Management of Forest Roads; COFORD: Dublin, Ireland, 2004; pp. 1–155. [Google Scholar]

- Björheden, R.; Apel, K.; Shiba, M.; Thompson, M. IUFRO Forest Work Study Nomenclature; Department of Operational Efficiency, Swedish University of Agricultural Science: Grapenberg, Sweden, 1995; 16p. [Google Scholar]

- Visser, R.; Spinelli, R. Determining the shape of the productivity function for mechanized felling and felling-processing. J. For. Res. 2011, 17, 397–402. [Google Scholar] [CrossRef]

- Ackerman, P.; Belbo, H.; Eliasson, L.; De Jong, A.; Lazdins, A.; Lyons, J. The COST model for calculation of forest operation costs. Int. J. For. Eng. 2014, 25, 75–81. [Google Scholar] [CrossRef]

- Proto, A.R.; Macri, G.; Visser, R.; Russo, D.; Zimbalatti, G. Comparison of timber extraction productivity between winch and grapple skidding: A case study in Southern Italian Forests. Forests 2018, 9, 61. [Google Scholar] [CrossRef]

- Gülci, S.; Büyüksakalli, H.; Taş, I.; Akay, A.E. Productivity analysis of timber skidding operation with farm tractor. Eur. J. For. Eng. 2018, 4, 26–32. [Google Scholar] [CrossRef][Green Version]

- Özturk, T.; Varsak, M.G.; Bilici, E. Evaluating productivity and cycle time of skidding method with farm tractors in Bigadic Forest Enterprise Directorate in Turkey. Eur. J. For. Eng. 2018, 5, 77–82. [Google Scholar] [CrossRef]

- Borz, S.A.; Ignea, G.; Popa, B.; Sparchez, G.; Iordache, E. Estimating time consumption and productivity of roundwood skidding in group shelterwood system—A case study in a broadleaved mixed stand located in reduced accessibility conditions. Croat. J. For. Eng. 2015, 36, 137–146. [Google Scholar]

- Borz, S.A.; Dinulica, F.; Birda, M.; Ignea, G.; Ciobanu, V.D.; Popa, B. Time consumption and productivity of skidding Silver fir (Abies alba Mill.) round wood in reduced accessibility conditions: A case study in windthorw salvage logging from Romanian Carpathians. Ann. For. Res. 2013, 56, 363–375. [Google Scholar]

- Sowa, J.M.; Szewczyk, G. Time consumption of skidding in mature stands performed by winches powered by farm tractor. Croat. J. For. Eng. 2013, 34, 255–264. [Google Scholar]

- Gallis, C.; Spyroglou, G. Productivity linear regressions of tree-length harvesting system in natural coastal Aleppo pine (Pinus halepensis L.) forests in the Chalkidiki area of Greece. Croat. J. For. Eng. 2012, 33, 115–123. [Google Scholar]

- Gilanipoor, N.; Najafi, A.; Heshmat Alvaezin, S.M. Productivity and cost of farm tractor skidding. J. For. Sci. 2012, 58, 21–26. [Google Scholar] [CrossRef]

- Sabo, A.; Poršinsky, T. Skidding of fir roundwood by Timberjack 240C from selective forests of Groski Kotar. Croat. J. For. Eng. 2005, 26, 13–27. [Google Scholar]

- Vusić, D.; Šušnjar, M.; Marchi, E.; Spina, R.; Zečić, Ž.; Picchio, R. Skidding operations in thinning and shelterwood cut of mixed stands—Work productivity, energy inputs and emissions. Ecol. Eng. 2013, 61, 216–223. [Google Scholar] [CrossRef]

- Borz, S.A.; Mititelu, V.-B. Productivity and Fuel Consumption in Skidding Roundwood on Flat Terrains by a Zetor Farm Tractor in Group Shelterwood Cutting of Mixed Oak Forests. Forests 2022, 13, 1294. [Google Scholar] [CrossRef]

- Hiesl, P.; Benjamin, J.G. Applicability of international harvesting equipment productivity studies in Maine, U.S.A.: A literature review. Forests 2013, 4, 898–921. [Google Scholar] [CrossRef]

- Moskalik, T.; Borz, S.A.; Dvorák, J.; Ferencik, M.; Glushkov, S.; Muiste, P.; Lazdinš, A.; Styranivsky, O. Timber harvesting methods in Eastern European countries: A review. Croat. J. For. Eng. 2017, 38, 231–241. [Google Scholar]

- Ministry of Timber Industrialization and Construction Materials. Norme şi Normative de Muncă Unificate în Exploatări Forestiere; 1989; p. 493. [Google Scholar]

- Athanassiadis, D.; Lideslav, G.; Wasterlund, I. Fuel, hydraulic oil and lubricant consumption in Swedish mechanized harvesting operation. Int. J. For. Eng. 1999, 10, 59–66. [Google Scholar]

- Acuna, M.; Bigot, M.; Guerra, S.; Hartsough, B.; Kanzian, C.; Kärhä, K.; Lindroos, O.; Magagnotti, N.; Roux, S.; Spinelli, R.; et al. Good Practice Guidelines for Biomass Production Studies; CNR IVALSA Sesto Fiorentino (National Research Council of Italy—Trees and Timber Institute): Sesto Fiorentino, Firenze, Italy, 2012; 52p. [Google Scholar]

- Heinimann, H.R. Operational Productivity Studies in Forestry Based on Statistical Models. ETH Forest Engineering Research Paper. 2021. Available online: https://www.researchgate.net/publication/349636743_Operational_Productivity_Studies_in_Forestry_Based_on_Statistical_Models_-_A_Tutorial (accessed on 1 July 2025).

- Real Statistics Using Excel. Available online: https://real-statistics.com/ (accessed on 18 July 2025).

- Spinelli, R.; Laina-Relano, R.; Magagnotti, N.; Tolosana, E. Determining observer and method effects on the accuracy of elemental time studies in forest operations. Balt. For. 2013, 19, 301–306. [Google Scholar]

- Grzywiński, W.; Turowski, R.; Naskrent, B.; Jelonek, T.; Tomczak, A. The Impact of Season on Productivity and Time Consumption in Timber Harvesting from Young Alder Stands in Lowland Poland. Forests 2020, 11, 1081. [Google Scholar] [CrossRef]

- Melander, L.; Ritala, R. Separating the impact of work environment and machine operation on harvester performance. Eur. J. For. Res. 2020, 139, 1029–1043. [Google Scholar] [CrossRef]

- Kluender, R.; Lortz, D.; McCoy, W.; Stokes, B.; Klepac, J. Removal intensity and tree size effects on harvesting cost and profitability. For. Prod. J. 1998, 48, 54–59. [Google Scholar]

- Behjou, F.K.; Majnounian, B.; Namiranian, M.; Dvořák, J. Time study and skidding capacity of the wheeled skidder Timberjack 450C in Caspian forests. J. For. Sci. 2008, 54, 183–188. [Google Scholar] [CrossRef]

- Horvat, D.; Zečić, Ž.; Šušnjar, M. Morphological characteristics and productivity of skidder ECOTRAC 120V. Croat. J. For. Eng. 2007, 28, 11–25. [Google Scholar]

- Lopes, E.D.S.; Oliveira, D.D.; Sampietro, J.A. Influence of wheeled types of a skidder on productivity and cost of the forest harvesting. Floresta 2014, 44, 53–62. [Google Scholar] [CrossRef]

- Acar, H.H.; Kaya, A.; Ünver-Okan, S.; Üçüncü, K. Evaluation of Skidding System by MB Trac 900 Forest Tractors on Steep Slopes in Thinning Operations; University of Natural Resources and Life Sciences: Vienna, Austria, 2015; pp. 381–383. [Google Scholar]

- Spinelli, R.; Magagnotti, N. Wood extraction with farm tractor and sulky: Estimating productivity, cost and energy consumption. Small-Scale For. 2012, 11, 73–85. [Google Scholar] [CrossRef]

- Borz, S.A.; Proto, A.R. Predicting Operational Events in Mechanized Weed Control Operations by Offline Multi-Modal Data and Machine Learning Provides Highly Accurate Classification in Time Domain. Forests 2024, 15, 2019. [Google Scholar] [CrossRef]

- Keefe, R.F.; Zimbelman, E.G.; Wempe, A.M. Use of smartphone sensors to quantify the productive cycle elements of hand fallers on industrial cable logging operations. Int. J. For. Eng. 2019, 30, 132–143. [Google Scholar] [CrossRef]

- Zimbelman, E.G.; Keefe, R.F. Development and validation of smartwatch-based activity recognition models for rigging crew workers on cable logging operations. PLoS ONE 2021, 16, e0250624. [Google Scholar] [CrossRef]

- Keefe, R.F.; Wempe, A.M.; Becker, R.M.; Zimbelman, E.G.; Nagler, E.S.; Gilbert, S.L.; Caudill, C.C. Positioning Methods and the Use of Location and Activity Data in Forests. Forests 2019, 10, 458. [Google Scholar] [CrossRef]

- Keskin, M.; Say, S.M. Feasibility of low-cost GPS receivers for ground speed measurement. Comp. Elect. Agric. 2006, 54, 36–43. [Google Scholar] [CrossRef]

- Contreras, M.; Freitas, R.; Ribeiro, L.; Stringer, J.; Clark, C. Multi-camera surveillance systems for time and motion studies of timber harvesting equipment. Comp. Elect. Agric. 2017, 135, 208–215. [Google Scholar] [CrossRef]

- McDonald, T.P.; Fulton, J.P. Automated time study of skidders using global positioning system data. Comp. Elect. Agric. 2005, 48, 19–37. [Google Scholar] [CrossRef]

- Bacescu, N.M.; Piol, O.; Talbot, B.; Marchi, L.; Grigolato, S. Modelling full stems skidding in northeast Italian Alps through engine data acquisition and analysis. Eur. J. For. Res. 2025, 1–12. [Google Scholar] [CrossRef]

- Mologni, O.; Lahrsen, S.; Roeser, D. Automated production time analysis using FPDat II onboard computers: A validation study based on whole-tree ground-based harvesting operations. Comput. Electron. Agric. 2024, 222, 109047. [Google Scholar] [CrossRef]

| Study Site | Machine Type | Season | Trail Condition | Type of Forest | Number of Observed Work Cycles |

|---|---|---|---|---|---|

| SK1 | Skidder | Winter (November) | Moist | Mixed | 16 |

| SK2 | Skidder | Autumn (September) | Moist | Mixed | 10 |

| SK3 | Skidder | Winter (November) | Moist | Coniferous | 20 |

| SK4 | Skidder | Winter (November) | Moist | Mixed | 14 |

| SK5 | Skidder | Winter (November) | Moist | Mixed | 2 |

| SK6 | Skidder | Winter (November) | Moist | Mixed | 19 |

| SK7 | Skidder | Spring (March/May) | Moist | Mixed | 29 |

| SK8 | Skidder | Spring (March/May) | Moist | Mixed | 59 |

| SK9 | Skidder | Summer (August) | Dry | Broadleaved | 32 |

| SK10 | Skidder | Summer (July) | Dry | Broadleaved | 23 |

| SK11 | Skidder | Summer (July) | Dry | Broadleaved | 30 |

| SK12 | Skidder | Summer (August) | Dry | Broadleaved | 53 |

| FT1 | Farm tractor | Autumn (September/October) | Moist | Broadleaved | 85 |

| FT2 | Farm tractor | Summer (August) | Dry | Broadleaved | 32 |

| Task Name | Task Code | Time Consumption Code | Description |

|---|---|---|---|

| Driving to the pre-skidding site | DET | tDET | Started when the machine leaves the landing area and ended when it arrives at the pre-skidding site. It occurred in all skidding work cycles and excluded any interruptions. |

| Maneuvering at the pre-skidding site | MAN | tMAN | Started when the machine arrived at the pre-skidding site and ended when it was positioned for pre-skidding. It occurred in most of the skidding work cycles, excluded any interruptions, and included maneuvers performed outside the skid trails. |

| Pulling out the cable | POC | tPOC | Started when the driver released the cables and one or more workers started moving with the cables to the wood pieces to be attached and ended when the worker(s) arrived at the pieces of wood. It occurred one to several times in all skidding work cycles and excluded any interruptions. |

| Attachment of the payload | APL | tAPL | Started when the worker(s) arrived at the wood pieces to be attached and ended when the wood pieces were attached to the cable(s). It occurred one to several times in all skidding work cycles and excluded any interruptions. |

| Pulling in the payload | PIP | tPIP | Started when the driver operated the winch to pull in the payload and ended when the payload reached the rear of the machine. It occurred one to several times in most of the skidding work cycles and excluded any interruptions. |

| Detaching the payload from the cable | DPC | tDPC | Started when the worker(s) started to move towards the payload and ended when the payload was detached from the cable(s). It occurred one to several times in most of the skidding work cycles and excluded any interruptions. |

| Attaching the payload for extraction | APE | tAPE | Started when the cable(s) is released and ended when the payload was secured for extraction. It occurred in most of the skidding work cycles and excluded any interruptions. |

| Driving with the payload to the forest road | DFR | tDFR | Started when the machine engaged in driving loaded to the forest road and ended when it reached the place for payload detaching at the forest road (landing). It occurred in all the skidding work cycles and excluded any interruptions. |

| Detaching the payload at the forest road | DPR | tDPR | Started when the driver started to lower the payload and ended when the worker detached the cables. It occurred in all the skidding work cycles and excluded any interruptions; sometimes the payload was released without the assistance of manual worker. |

| Maneuvering and bunching at the forest road | MBR | tMBR | Started with the first maneuver to group wood and ended once the wood pieces were bunched at the required place at the landing. It occurred in most of the skidding work cycles and excluded any interruptions. |

| Skidding work cycle | SWC | CT | Groups all of the above work elements as they occurred and/or repeated between starting to move from the landing and completing the maneuvering and bunching at the forest road. It excluded any interruptions. |

| Delays caused by the study | DS | tDS | Delays attributable to the tasks of the researchers carrying out the study, such as placing and taking down the dataloggers, measuring the fuel consumption and/or the biometrics of the wood. Most of them occurred at the landing. |

| Delays caused by personal reasons | DP | tDP | Delays caused by personal activity of workers. |

| Delays caused by mechanical reasons | DM | tDM | Delays due to mechanical problems of the machine. |

| Delays caused by operational reasons | DO | tDO | Delays due to operational organization problems, including waiting and performing other tasks not related to pre-skidding and skidding operations. |

| Variable | Code and Measurement Unit | Descriptive Statistics | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Number of Observations | Minimum Value | Maximum Value | Range | Mean Value | Median Value | Sum | Share | ||

| Operational variables | |||||||||

| Number of pieces | NP | 182 | 1 | 21 | 20 | 4.27 | 3.00 | 777 | 100.00 |

| Payload volume | PV (m3) | 182 | 1.70 | 11.29 | 9.59 | 5.05 | 4.69 | 919.16 | 100.00 |

| Extraction distance | ED (m) | 182 | 63 | 3081 | 3018 | 1186 | 1037 | 215,917.00 | 100.00 |

| Time and fuel consumption variables | |||||||||

| Driving to the pre-skidding site | tDET (h) | 182 | 0.077 | 0.432 | 0.385 | 0.201 | 0.186 | 36.640 | 29.23 |

| Maneuvering at the pre-skidding site | tMAN (h) | 141 | 0.001 | 0.190 | 0.189 | 0.018 | 0.010 | 2.542 | 2.03 |

| Pulling out the cable | tPOC (h) | 182 | 0.002 | 0.110 | 0.108 | 0.030 | 0.026 | 5.508 | 4.39 |

| Attachment of the payload | tAPL (h) | 182 | 0.003 | 0.095 | 0.092 | 0.024 | 0.020 | 4.437 | 3.54 |

| Pulling in the payload | tPIP (h) | 173 | 0.003 | 0.229 | 0.226 | 0.057 | 0.043 | 9.831 | 7.84 |

| Detaching the payload from the cable | tDPC (h) | 141 | 0.002 | 0.080 | 0.078 | 0.023 | 0.018 | 3.182 | 2.54 |

| Attaching the payload for extraction | tAPE (h) | 139 | 0.002 | 0.169 | 0.167 | 0.035 | 0.025 | 4.872 | 3.89 |

| Driving with the payload to the forest road | tDFR (h) | 182 | 0.093 | 0.565 | 0.472 | 0.269 | 0.251 | 48.928 | 39.03 |

| Detaching the payload at the forest road | tDPR (h) | 178 | 0.001 | 0.039 | 0.038 | 0.011 | 0.011 | 1.999 | 1.59 |

| Maneuvering and bunching at the forest road | tMBR (h) | 177 | 0.001 | 0.281 | 0.280 | 0.042 | 0.031 | 7.416 | 5.92 |

| Skidding work cycle | CT (h) | 182 | 0.237 | 1.527 | 1.290 | 0.689 | 0.648 | 125.354 | 100.00 |

| Fuel consumption | FC (L) | 182 | 0.900 | 12.300 | 11.400 | 5.259 | 4.450 | 957.200 | 100.00 |

| Variable | Code and Measurement Unit | Descriptive Statistics | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Number of Observations | Minimum Value | Maximum Value | Range | Mean Value | Median Value | Sum | Share | ||

| Operational variables | |||||||||

| Number of pieces | NP | 45 | 1 | 12 | 11 | 4.91 | 4 | 221 | 100.00 |

| Payload volume | PV (m3) | 45 | 0.98 | 4.92 | 3.94 | 2.80 | 2.94 | 126.05 | 100.00 |

| Extraction distance | ED (m) | 45 | 15.5 | 1171.5 | 1156.0 | 590.13 | 645 | 26,556.00 | 100.00 |

| Time and fuel consumption variables | |||||||||

| Driving to the pre-skidding site | tDET (h) | 45 | 0.019 | 0.199 | 0.180 | 0.108 | 0.130 | 4.83 | 22.57 |

| Maneuvering at the pre-skidding site | tMAN (h) | 28 | 0.001 | 0.022 | 0.021 | 0.007 | 0.005 | 0.18 | 0.87 |

| Pulling out the cable | tPOC (h) | 45 | 0.003 | 0.127 | 0.124 | 0.037 | 0.034 | 1.65 | 7.71 |

| Attachment of the payload | tAPL (h) | 44 | 0.003 | 0.079 | 0.076 | 0.025 | 0.023 | 1.10 | 5.16 |

| Pulling in the payload | tPIP (h) | 45 | 0.003 | 0.199 | 0.196 | 0.060 | 0.048 | 2.69 | 12.58 |

| Detaching the payload from the cable | tDPC (h) | 45 | 0.000 | 0.051 | 0.051 | 0.017 | 0.014 | 0.76 | 3.55 |

| Attaching the payload for extraction | tAPE (h) | 45 | 0.000 | 0.098 | 0.098 | 0.026 | 0.019 | 1.14 | 5.35 |

| Driving with the payload to the forest road | tDFR (h) | 45 | 0.035 | 0.362 | 0.327 | 0.170 | 0.198 | 7.66 | 35.77 |

| Detaching the payload at the forest road | tDPR (h) | 42 | 0.003 | 0.026 | 0.023 | 0.009 | 0.009 | 0.37 | 1.73 |

| Maneuvering and bunching at the forest road | tMBR (h) | 42 | 0.000 | 0.079 | 0.079 | 0.024 | 0.021 | 0.99 | 4.65 |

| Skidding work cycle | CT (h) | 45 | 0.112 | 0984 | 0.872 | 0.476 | 0.584 | 21.43 | 100 |

| Fuel consumption | FC (L) | 45 | 0.200 | 7.200 | 7.000 | 2.864 | 3.200 | 128.90 | 100 |

| Variable | Model | Model Statistics | ||||

|---|---|---|---|---|---|---|

| Number of Observations | R2 | Model Significance | Independent Variable | Significance of Independent Variable | ||

| Skidding work cycle time | ||||||

| Skidder | CT (h) = 0.09364 + 0.04509 × PV (m3) + 0.03014 × NP + 0.00020 × ED (m) | 182 | 0.58 | <0.001 | PV | <0.001 |

| NP | <0.001 | |||||

| ED | <0.001 | |||||

| Farm tractor | CT (h) = 0.125355 + 0.00060 × ED (m) | 45 | 0.87 | <0.001 | ED | <0.001 |

| Fuel consumption | ||||||

| Skidder | FC (L) = 0.80921 + 0.27753 × PV (m3) + 0.00257 × ED (m) | 182 | 0.54 | <0.001 | PV | <0.001 |

| ED | <0.001 | |||||

| Farm tractor | FC (L) = 0.86869 + 0.00338 × ED (m) | 45 | 0.75 | <0.001 | ED | <0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zurita Vintimilla, M.C.; Borz, S.A. Development of Updated Models to Characterize Skidding Performance in Romania Based on a Nation-Level Dataset. Forests 2025, 16, 1352. https://doi.org/10.3390/f16081352

Zurita Vintimilla MC, Borz SA. Development of Updated Models to Characterize Skidding Performance in Romania Based on a Nation-Level Dataset. Forests. 2025; 16(8):1352. https://doi.org/10.3390/f16081352

Chicago/Turabian StyleZurita Vintimilla, Monica Cecilia, and Stelian Alexandru Borz. 2025. "Development of Updated Models to Characterize Skidding Performance in Romania Based on a Nation-Level Dataset" Forests 16, no. 8: 1352. https://doi.org/10.3390/f16081352

APA StyleZurita Vintimilla, M. C., & Borz, S. A. (2025). Development of Updated Models to Characterize Skidding Performance in Romania Based on a Nation-Level Dataset. Forests, 16(8), 1352. https://doi.org/10.3390/f16081352