Initial Insights into Spruce Wood Fatigue Behaviour Using Dynamic Mechanical Properties in Low-Cycle Fatigue

Abstract

1. Introduction

2. Theory of Calculations

2.1. Dynamic Material Properties

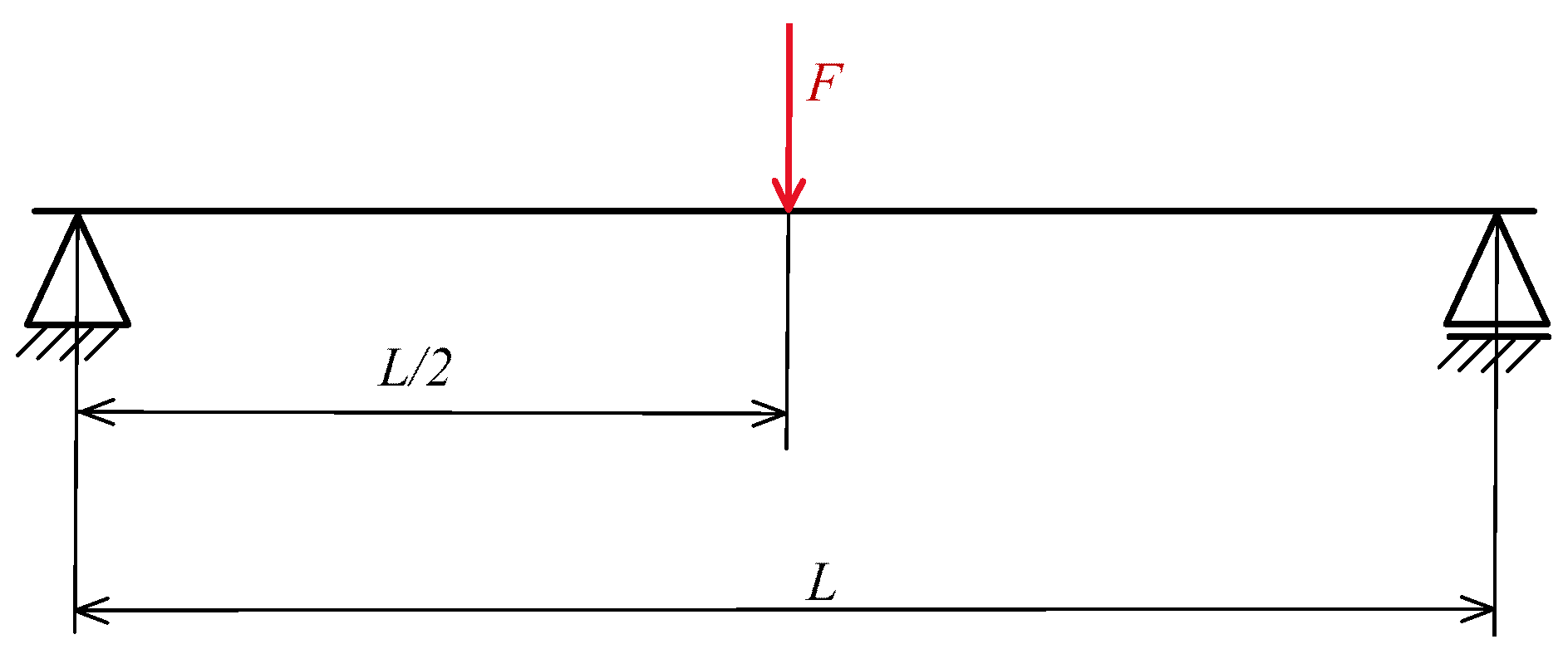

2.2. Static Material Properties

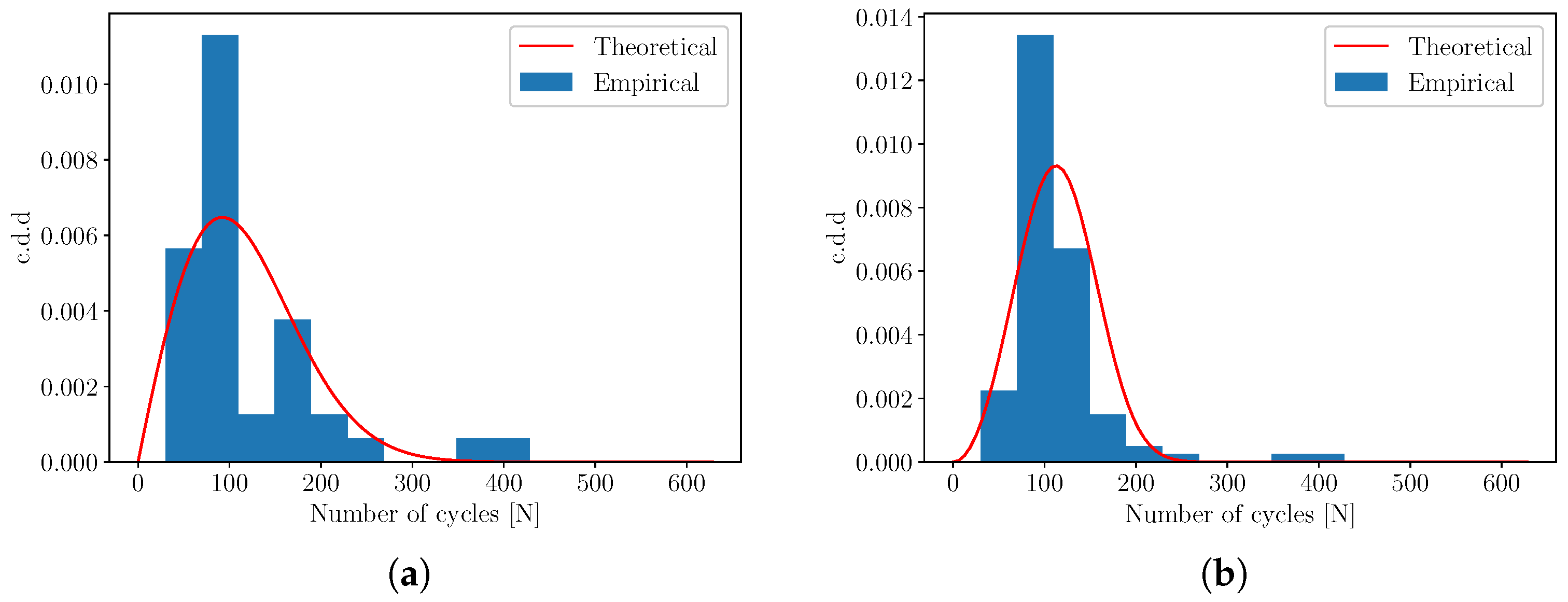

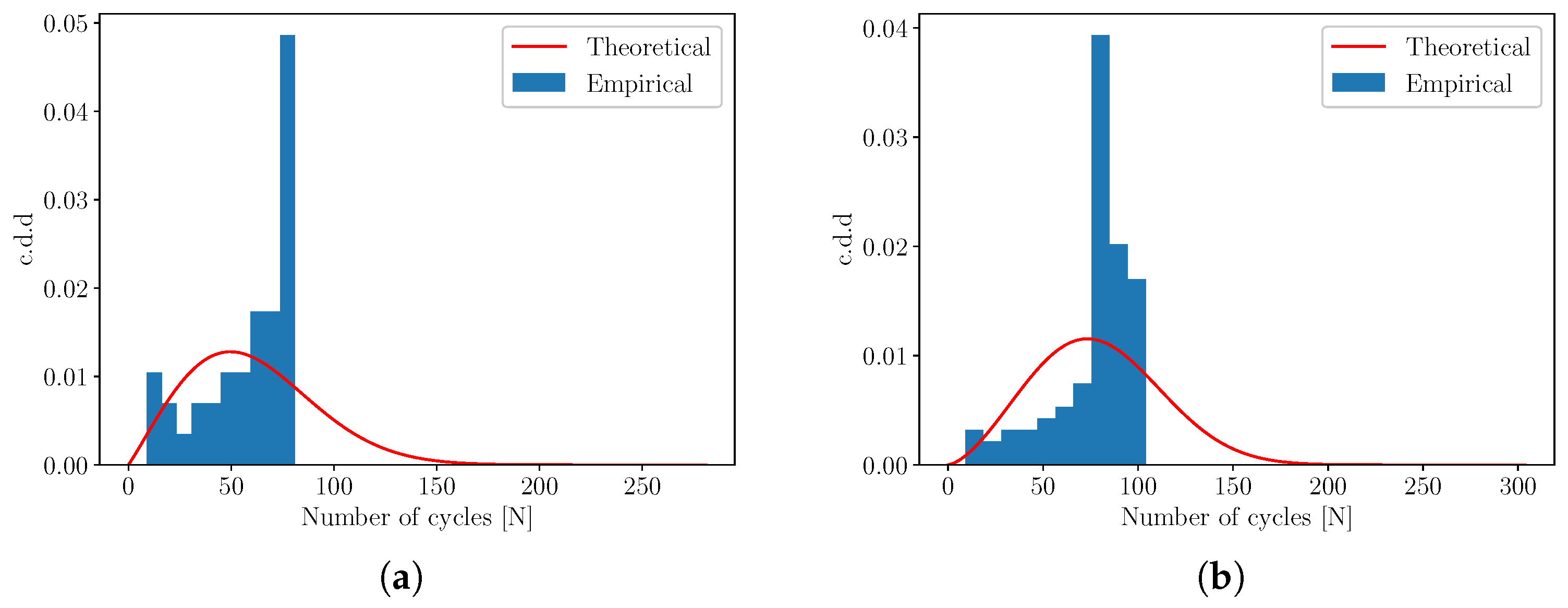

2.3. Weibull Cycle Density Distribution

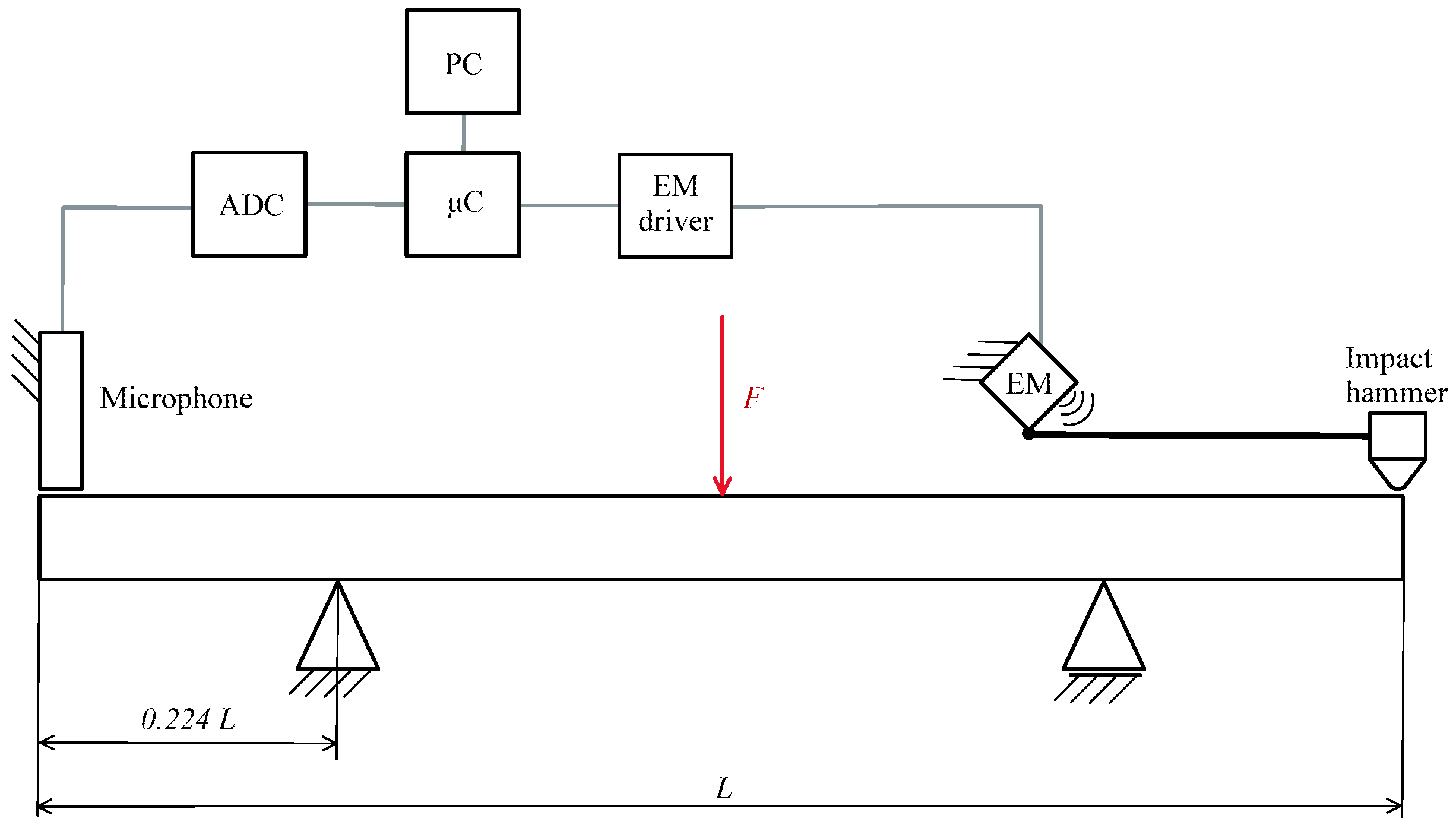

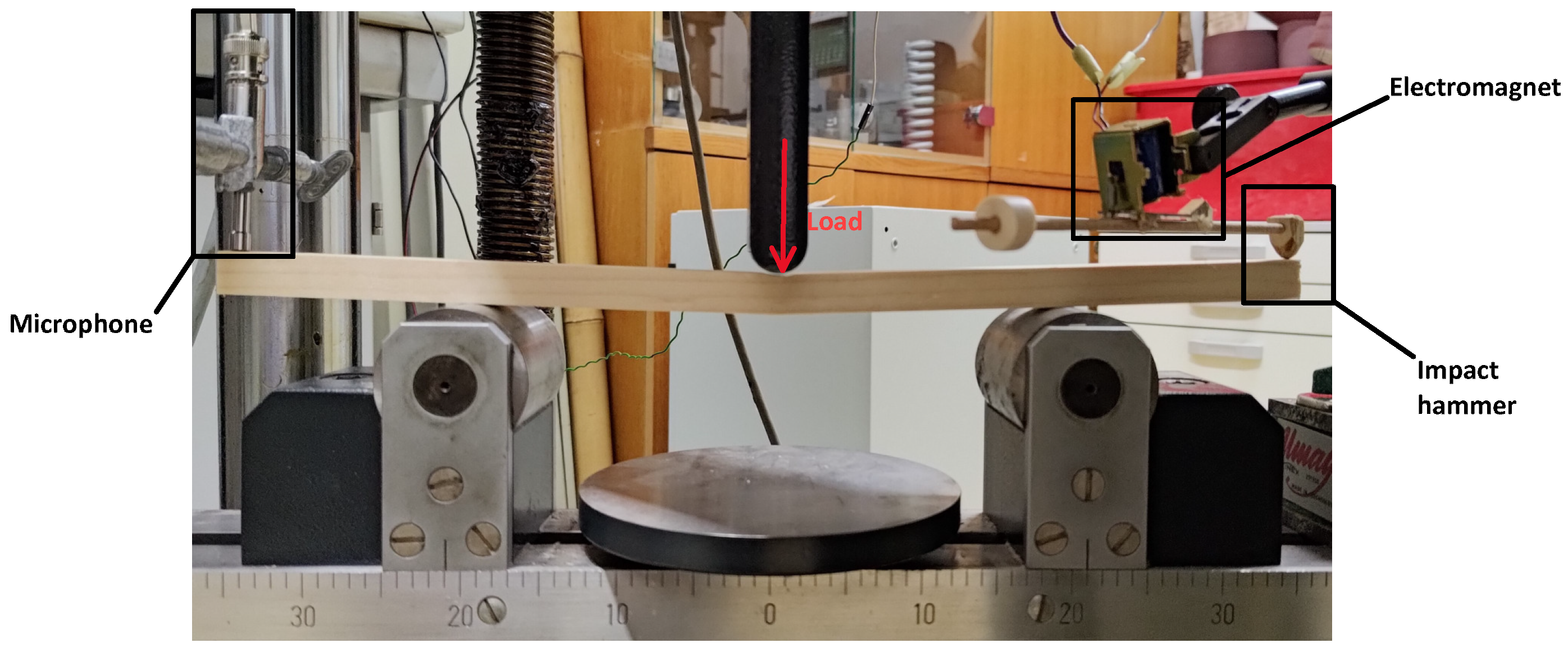

3. Research Methodology

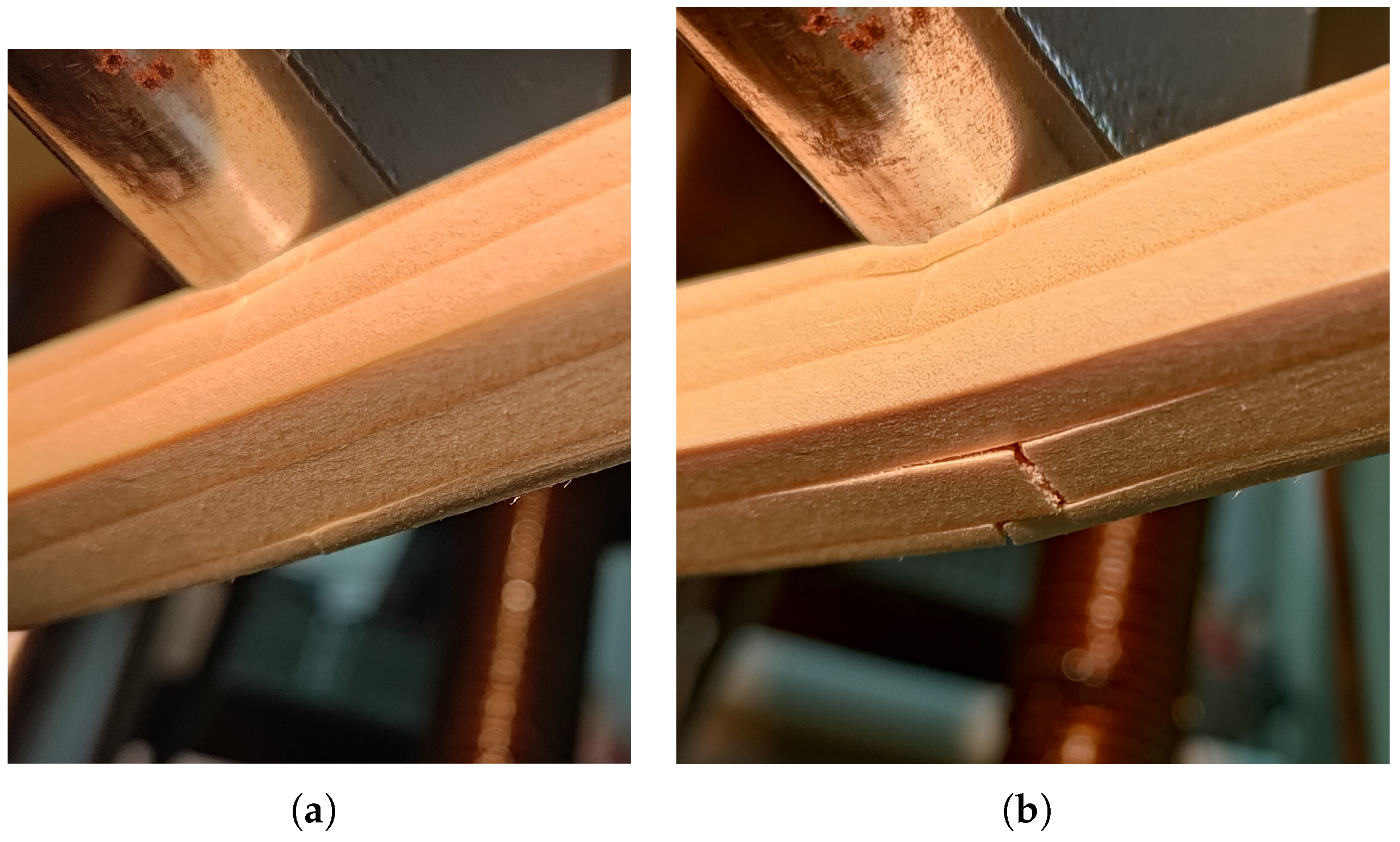

3.1. Experiment Preparation

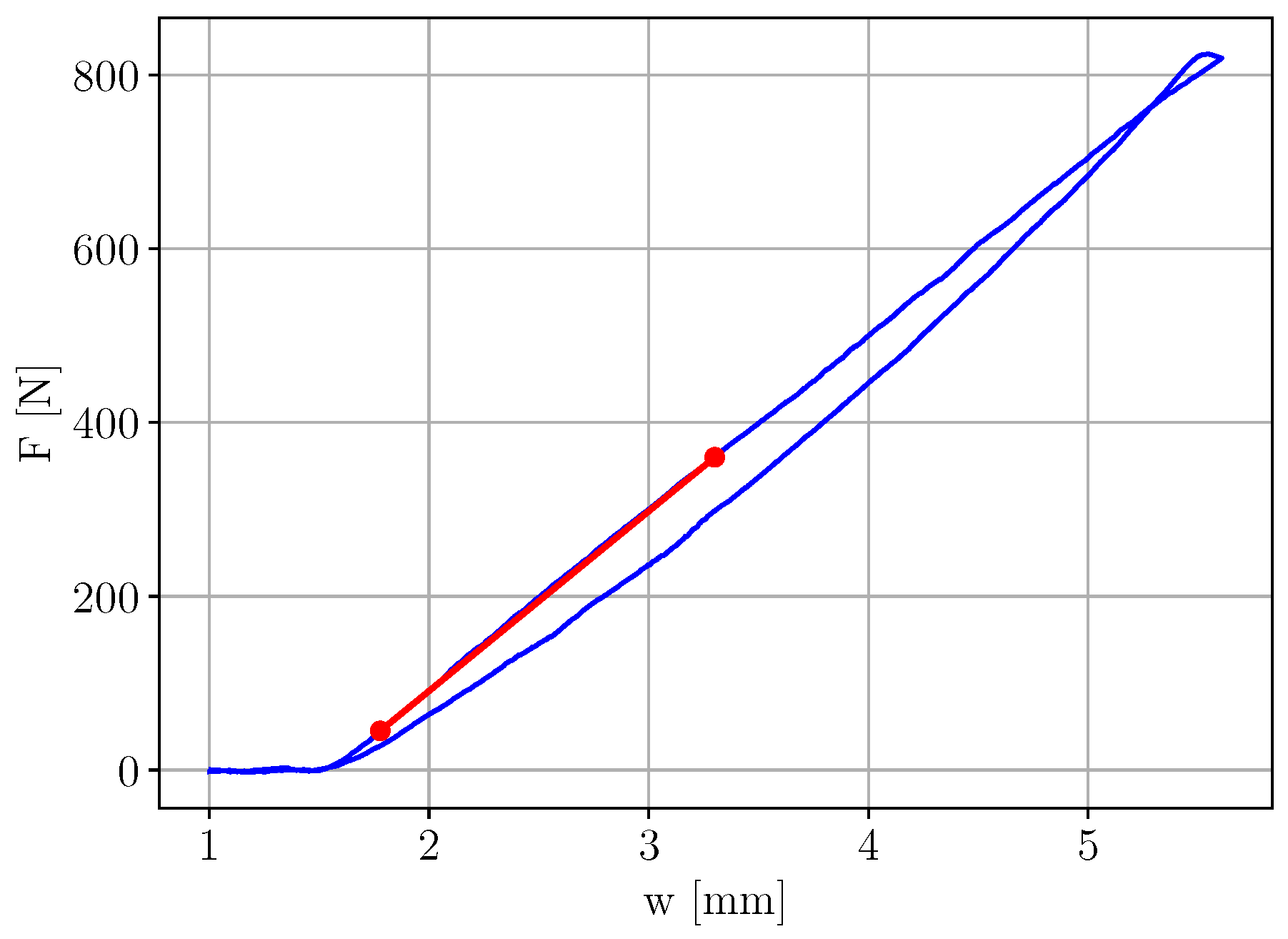

3.2. Experiment Procedure

3.3. Data Analysis

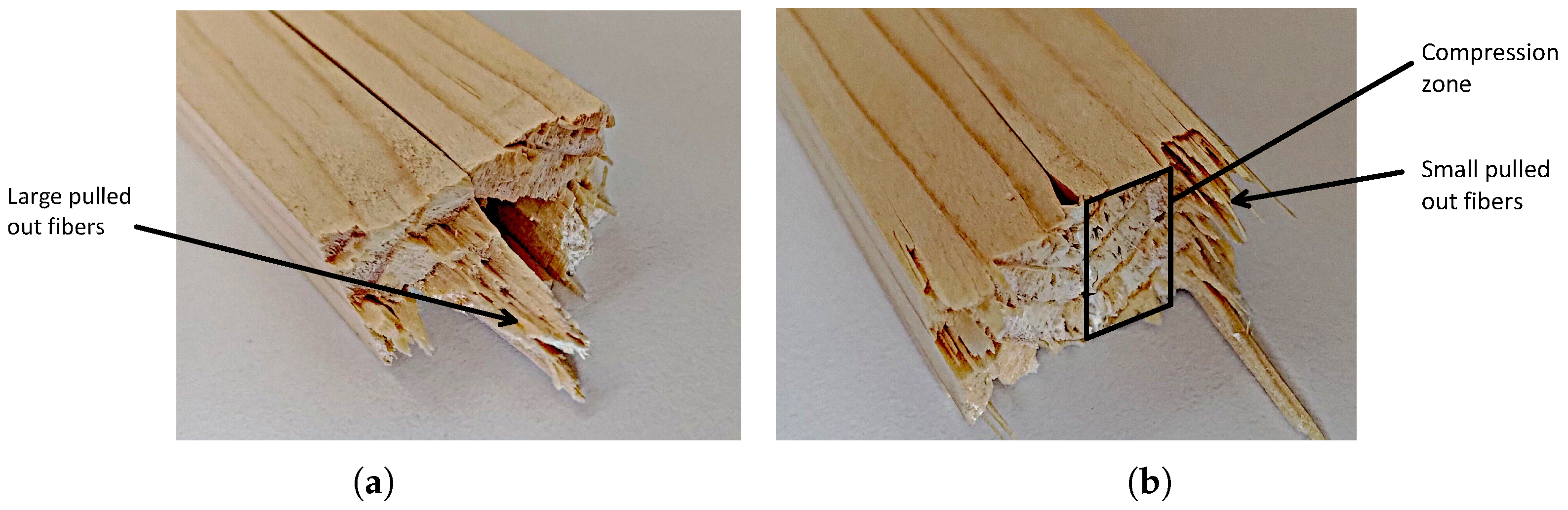

4. Results

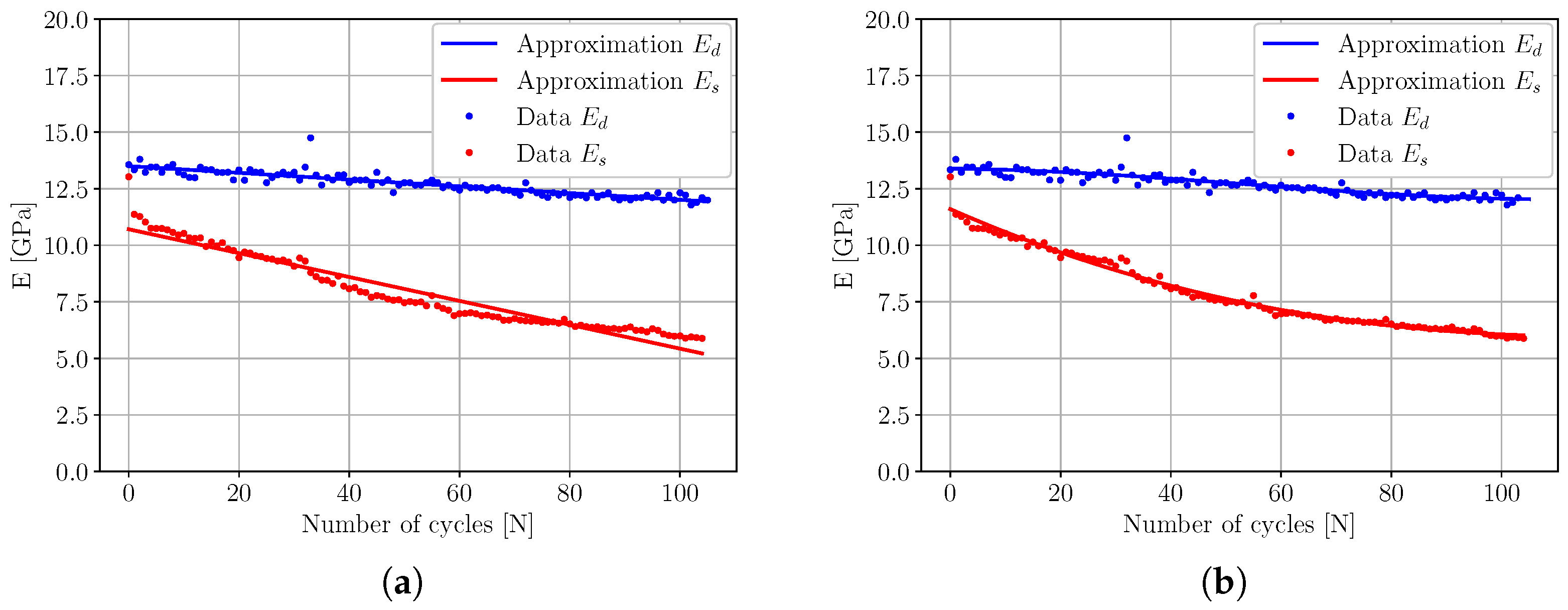

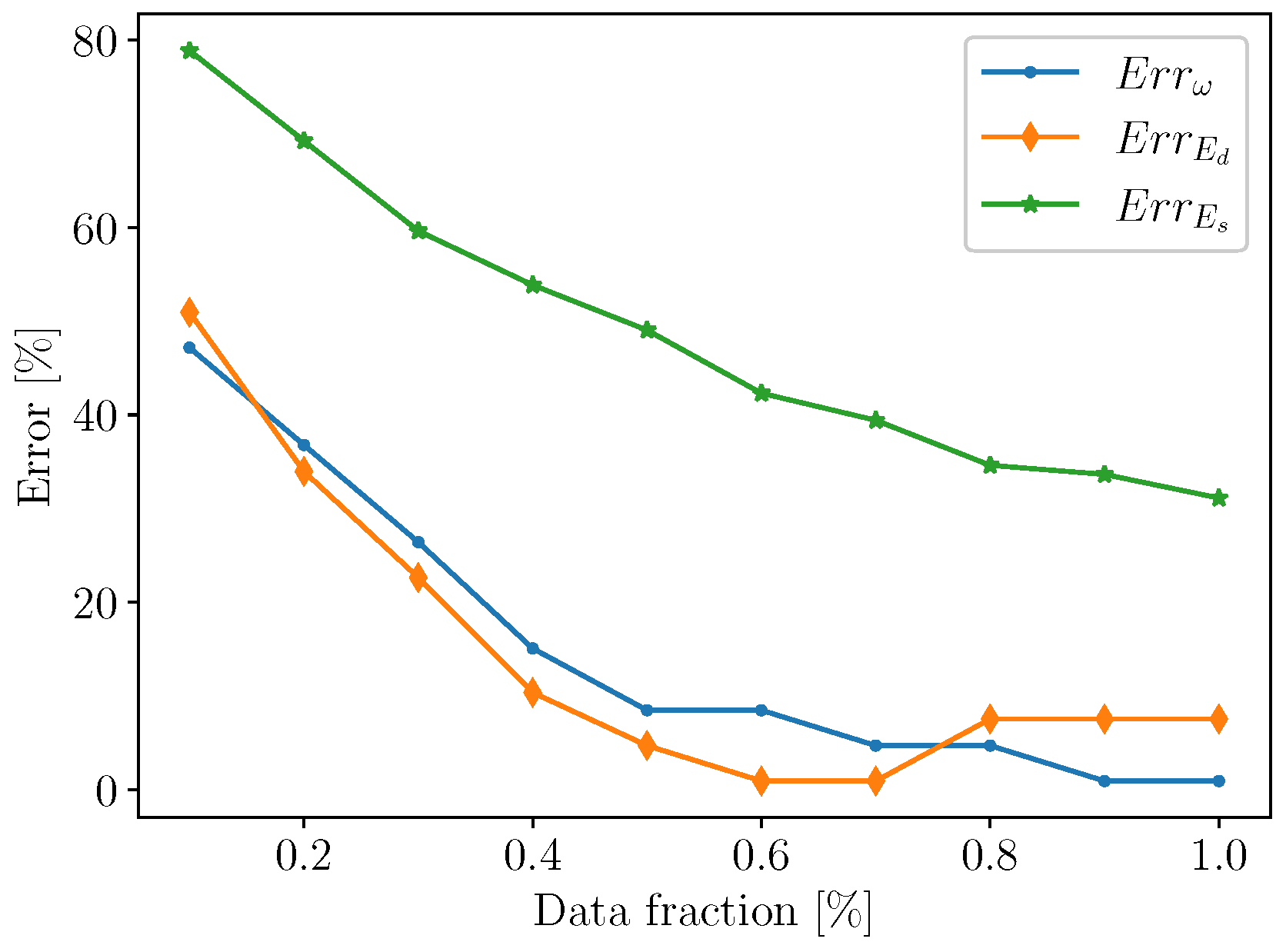

4.1. Elastic Modulus

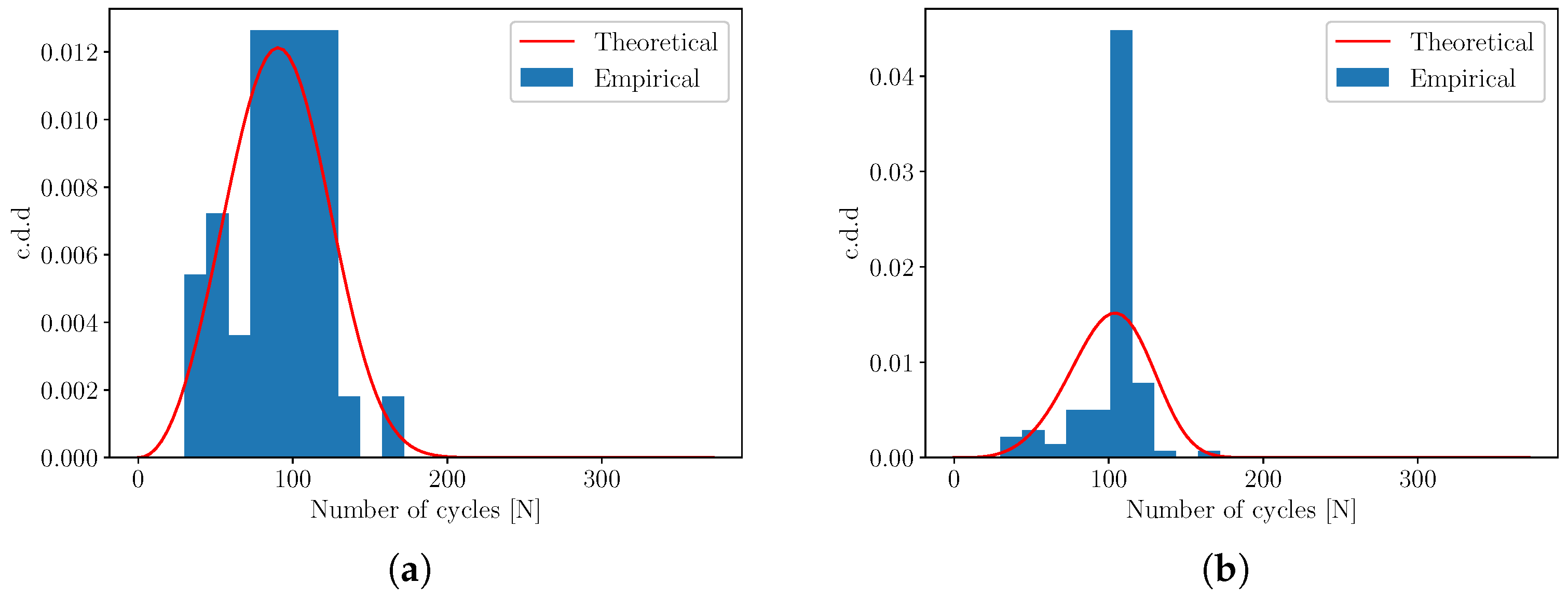

4.2. Fatigue Life Prediction

4.3. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Caicedo, D.; Lara-Valencia, L.A.; Brito, J. Frequency-Based Methods for the Detection of Damage in Structures: A Chronological Review. DYNA 2021, 88, 203–211. [Google Scholar] [CrossRef]

- Gillich, N.; Tufisi, C.; Sacarea, C.; Rusu, C.V.; Gillich, G.R.; Praisach, Z.I.; Ardeljan, M. Beam Damage Assessment Using Natural Frequency Shift and Machine Learning. Sensors 2022, 22, 1118. [Google Scholar] [CrossRef] [PubMed]

- Dubey, A.; Denis, V.; Serra, R. A damage identification strategy in beams based on natural frequencies shift. In Proceedings of the International Conference on Noise and Vibration Engineering (ISMA 2020), Leuven, Belgium, 7–9 September 2020. [Google Scholar]

- Kouroussis, G.; Ben Fekih, L.; Descamps, T. Assessment of timber element mechanical properties using experimental modal analysis. Constr. Build. Mater. 2017, 134, 254–261. [Google Scholar] [CrossRef]

- Negru, I.; Gillich, G.R.; Praisach, Z.I.; Tufoi, M.; Gillich, N. Natural frequency changes due to damage in composite beams. J. Phys. Conf. Ser. 2015, 628, 012091. [Google Scholar] [CrossRef]

- Horta-Rangel, J.; Carmona, S.; Casta no, V.M. Shift of natural frequencies in earthquake-damaged structures: An optimization approach. Struct. Surv. 2008, 26, 400–410. [Google Scholar] [CrossRef]

- González de Paz, L.V.G.; Ortega, N.F.; Rosales, M.B. Assessment of wood utility poles’ deterioration through natural frequency measurements. J. Civ. Struct. Health Monit. 2019, 9, 53–61. [Google Scholar] [CrossRef]

- Shang, D. Effect of fatigue damage on the dynamic response frequency of spot-welded joints. Int. J. Fatigue 2003, 25, 311–316. [Google Scholar] [CrossRef]

- Shang, D. Measurement of fatigue damage based on the natural frequency for spot-welded joints. Mater. Des. 2009, 30, 1008–1013. [Google Scholar] [CrossRef]

- Wang, R.; Shang, D. Fatigue life prediction based on natural frequency changes for spot welds under random loading. Int. J. Fatigue 2009, 31, 361–366. [Google Scholar] [CrossRef]

- Banks, H.T.; Emeric, P.R. Detection of Non-Symmetrical Damage in Smart Plate-Like Structures. J. Intell. Mater. Syst. Struct. 1998, 9, 818–828. [Google Scholar] [CrossRef]

- Kessler, S.S.; Spearing, S.M.; Atalla, M.J.; Cesnik, C.E.S.; Soutis, C. Damage detection in composite materials using frequency response methods. Compos. Part B 2002, 33, 87–95. [Google Scholar] [CrossRef]

- Wu, T.; Xu, C.; Li, P. A natural frequency degradation model for very high cycle fatigue of woven fiber reinforced composite. Int. J. Fatigue 2020, 134, 105398. [Google Scholar] [CrossRef]

- Liang, Z.; Ramakrishnan, K.R.; Ng, C.T.; Zhang, Z.; Fu, J. Vibration-based prediction of residual fatigue life for composite laminates through frequency measurements. Compos. Struct. 2024, 329, 117771. [Google Scholar] [CrossRef]

- Šraml, M.; Glodež, S.; Fajdiga, G. Fatigue Life Models of Wood: A Review. In Proceedings of the International Conference MATRIB, Vela Luka Island of Korčula, Croatia, 27–29 June 2019. [Google Scholar]

- Klemenc, J.; Fajdiga, G. Statistical Modelling of the Fatigue Bending Strength of Norway Spruce Wood. Materials 2022, 15, 536. [Google Scholar] [CrossRef]

- Klemenc, J.; Humar, M.; Fajdiga, G. Influence of insect damage to the fatigue life of an old larch wood. Constr. Build. Mater. 2023, 375, 130967. [Google Scholar] [CrossRef]

- Kolesnikov, N.G.; Nazarev, D.P. Monotonic and cyclic load of pine wood under uniaxial compression: Experiments and modeling. E3S Web Conf. 2023, 458, 07021. [Google Scholar] [CrossRef]

- Clorius, C.O.; Pedersen, M.U.; Hoffmeyer, P.; Damkilde, L. An experimentally validated fatigue model for wood subjected to tension perpendicular to the grain. Wood Sci. Technol. 2009, 43, 334–357. [Google Scholar] [CrossRef]

- Arriaga, F.; Wang, X.; Íniguez-González, G.; Llana, D.F.; Esteban, M.; Niemz, P. Mechanical Properties of Wood: A Review. Forests 2023, 14, 1202. [Google Scholar] [CrossRef]

- Shah, A.J.; Pandya, T.S.; Street, J. Study of variation in natural frequencies of bio-composites due to structural damage. Int. Wood Prod. J. 2020, 11, 166–172. [Google Scholar] [CrossRef]

- Khoshmanesh, S.; Watson, S.J.; Zarouchas, D. Characterisation of fatigue damage in a thick adhesive joint based on changes in material damping. J. Phys. Conf. Ser. 2020, 1618, 022058. [Google Scholar] [CrossRef]

- Bedewi, N.E.; Kung, D.N. Effect of fatigue loading on the modal properties of composite structures and its utilization for prediction of residual life. Compos. Struct. 1997, 37, 357–371. [Google Scholar] [CrossRef]

- Barraza-Contreras, J.M.; Pi na-Monarrez, M.R.; Molina, A. Fatigue-Life Prediction of Mechanical Element by Using the Weibull Distribution. Appl. Sci. 2020, 10, 6384. [Google Scholar] [CrossRef]

- Ibrahim, S.R. Random Decrement Technique for Modal Identification of Structures. J. Spacecr. Rockets 1977, 14, 696–700. [Google Scholar] [CrossRef]

- Wang, Z.; Li, L.; Gong, M. Measurement of dynamic modulus of elasticity and damping ratio of wood-based composites using the cantilever beam vibration technique. Constr. Build. Mater. 2012, 28, 831–834. [Google Scholar] [CrossRef]

- Divós, F.; Tanaka, T. Relation Between Static and Dynamic Modulus of Elasticity of Wood. Acta Silv. Lignaria Hung. 2005, 1, 105–110. [Google Scholar] [CrossRef]

- ASTM E606/E606M-12; Standard Test Method for Strain-Controlled Fatigue Testing. ASTM Standards: West Conshohocken, PA, USA, 2012.

- Thomson, W.T. Theory of Vibration with Application, 4th ed.; Taylor and Francis: New York, NY, USA, 2003; pp. 268–289. [Google Scholar]

- Tongue, B.H. Principles of Vibration, 2nd ed.; Oxford University Press: New York, NY, USA, 2001. [Google Scholar]

- Merhar, M. Determination of Dynamic and Static Modulus of Elasticity of Beech Plywood. Les/Wood 2020, 69, 59–69. [Google Scholar] [CrossRef]

- Straže, A.; Fajdiga, G.; Gospodarič, B. Nondestructive characterization of dry heat-treated fir (Abies alba Mill.) timber in view of possible structural use. Forests 2018, 9, 776. [Google Scholar] [CrossRef]

- Weibull, W. A Statistical Theory of The Strength of Materials; Generalstabens Litografiska Anstalts Förlag: Stockholm, Sweden, 1939; Volume 151, pp. 1–45. [Google Scholar]

- Benard, A.; Bos-Levenbach, E.C. The Plotting of Observations on Probability; van Dantzig, D., Hemelrijk, J., Eds.; Mathematisch Centrum: Amsterdam, The Netherlands, 1955. [Google Scholar]

- ISO 3129:2019(en); Wood—Sampling Methods and General Requirements for Physical and Mechanical Testing of Small Clear Wood Specimens. ISO Standards: Geneva, Switzerland, 2019.

- Ogawa, K.; Shimizu, K.; Yamasaki, M.; Sasaki, Y. Fatigue behavior of Japanese cypress (Chamaecyparis obtusa) under repeated compression loading tests perpendicular to the grain. Holzforschung 2017, 71, 499–504. [Google Scholar] [CrossRef]

- Kliger, R.; Olsson, A.; Perstorper, M. Measurement of dynamic modulus of elasticity in timber structures using frequency analysis of flexural vibrations. Wood Sci. Technol. 1997, 31, 431–441. [Google Scholar]

- Abo-Elkhier, M.; Hamada, A.A.; Bahei El-Deen, A. Prediction of Fatigue Life of Glass Fiber Reinforced Polyester Composites Using Modal Testing. Int. J. Fatigue 2014, 69, 28–35. [Google Scholar] [CrossRef]

- Omar, I.; Khan, M.; Starr, A. Suitability Analysis of Machine Learning Algorithms for Crack Growth Prediction Based on Dynamic Response Data. Sensors 2023, 23, 1074. [Google Scholar] [CrossRef] [PubMed]

| Approximation Type | |||

|---|---|---|---|

| Linear | 0.928 | 0.790 | 0.881 |

| Cubic | 0.983 | 0.797 | 0.884 |

| Relative difference | 5.61 | 0.89 | 0.35 |

| 101.9 | 3.18 | 90 | 15.1 | 118 | 11.3 | 110.3 | 4.4 | 105 | 0.94 | 99 | 6.6 | |

| 131.5 | 1.98 | 95 | 10.4 | 147 | 38.7 | 128.3 | 3.03 | 114 | 7.6 | 115 | 8.5 | |

| 68.4 | 2.06 | 48 | 53.9 | 78 | 26.4 | 89.0 | 2.56 | 73 | 31.1 | 77 | 27.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gaberšček Tuta, G.; Fajdiga, G.; Straže, A. Initial Insights into Spruce Wood Fatigue Behaviour Using Dynamic Mechanical Properties in Low-Cycle Fatigue. Forests 2025, 16, 1324. https://doi.org/10.3390/f16081324

Gaberšček Tuta G, Fajdiga G, Straže A. Initial Insights into Spruce Wood Fatigue Behaviour Using Dynamic Mechanical Properties in Low-Cycle Fatigue. Forests. 2025; 16(8):1324. https://doi.org/10.3390/f16081324

Chicago/Turabian StyleGaberšček Tuta, Gregor, Gorazd Fajdiga, and Aleš Straže. 2025. "Initial Insights into Spruce Wood Fatigue Behaviour Using Dynamic Mechanical Properties in Low-Cycle Fatigue" Forests 16, no. 8: 1324. https://doi.org/10.3390/f16081324

APA StyleGaberšček Tuta, G., Fajdiga, G., & Straže, A. (2025). Initial Insights into Spruce Wood Fatigue Behaviour Using Dynamic Mechanical Properties in Low-Cycle Fatigue. Forests, 16(8), 1324. https://doi.org/10.3390/f16081324