Advisability-Selected Parameters of Woodworking with a CNC Machine as a Tool for Adaptive Control of the Cutting Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Used Material and CNC Machine

- CNC machine specification:

- Tool Characteristics:

- Parameters of milling process:

2.2. Noise Measurement Methodology

- L is the energy mean of the equivalent sound pressure level A (dB),

- n—number of measurement repetitions (3),

- Li—sound pressure level (A) of the i measurement (dB).

2.3. Temperature Measurement Methodology

3. Results

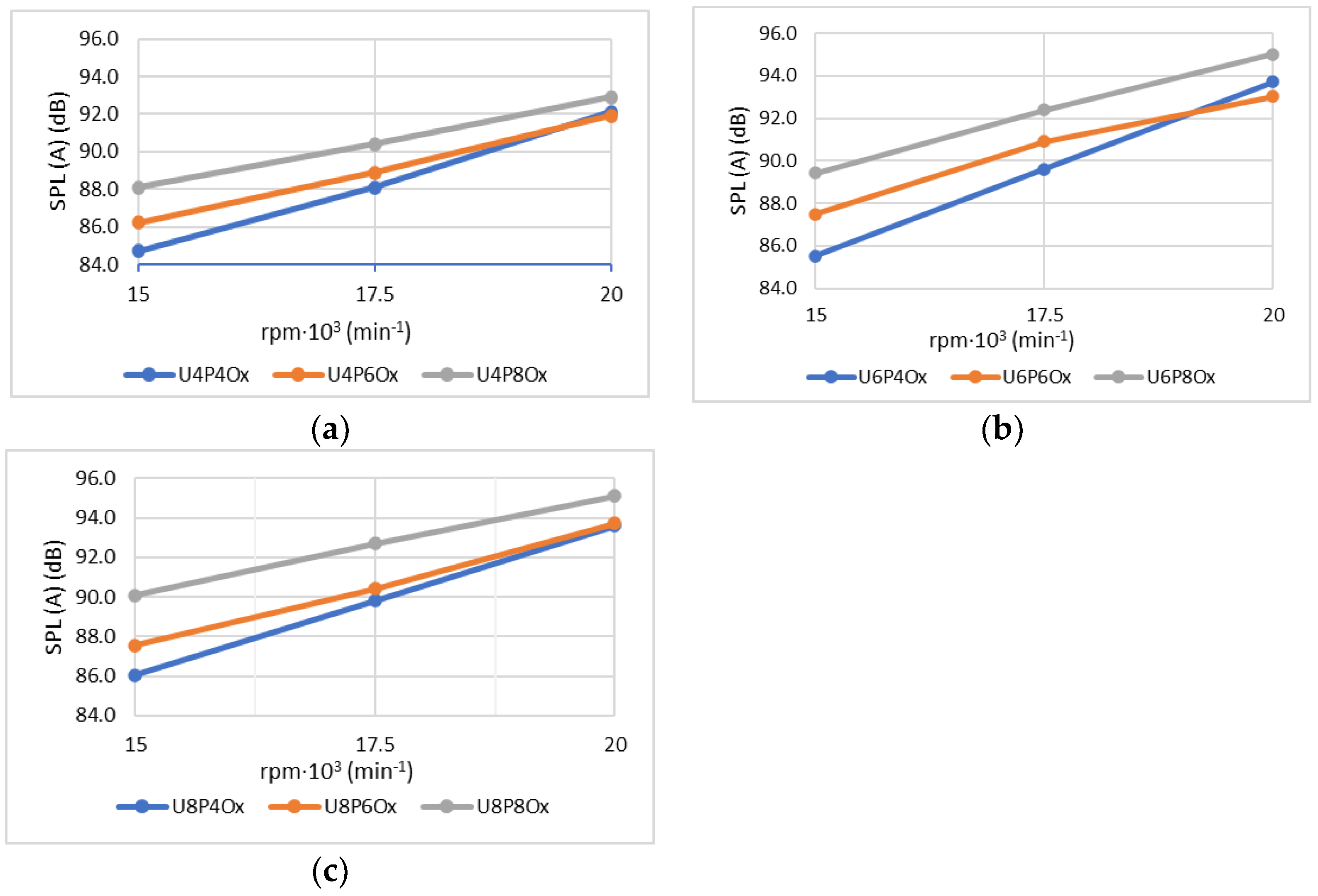

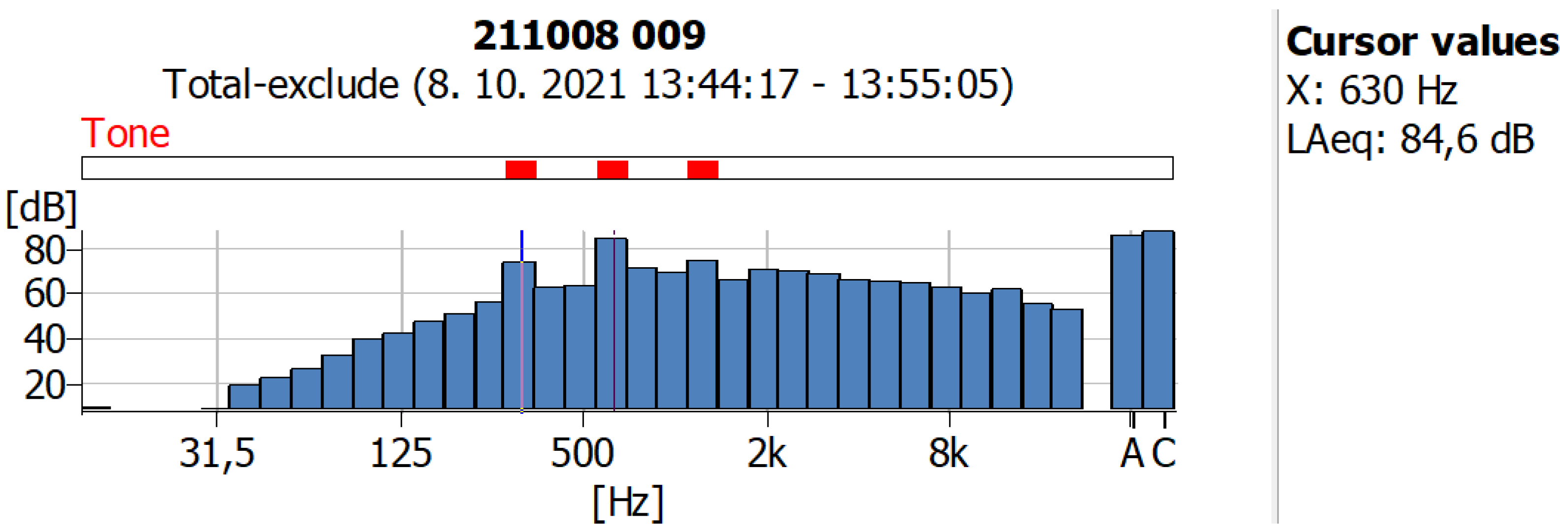

3.1. Noise

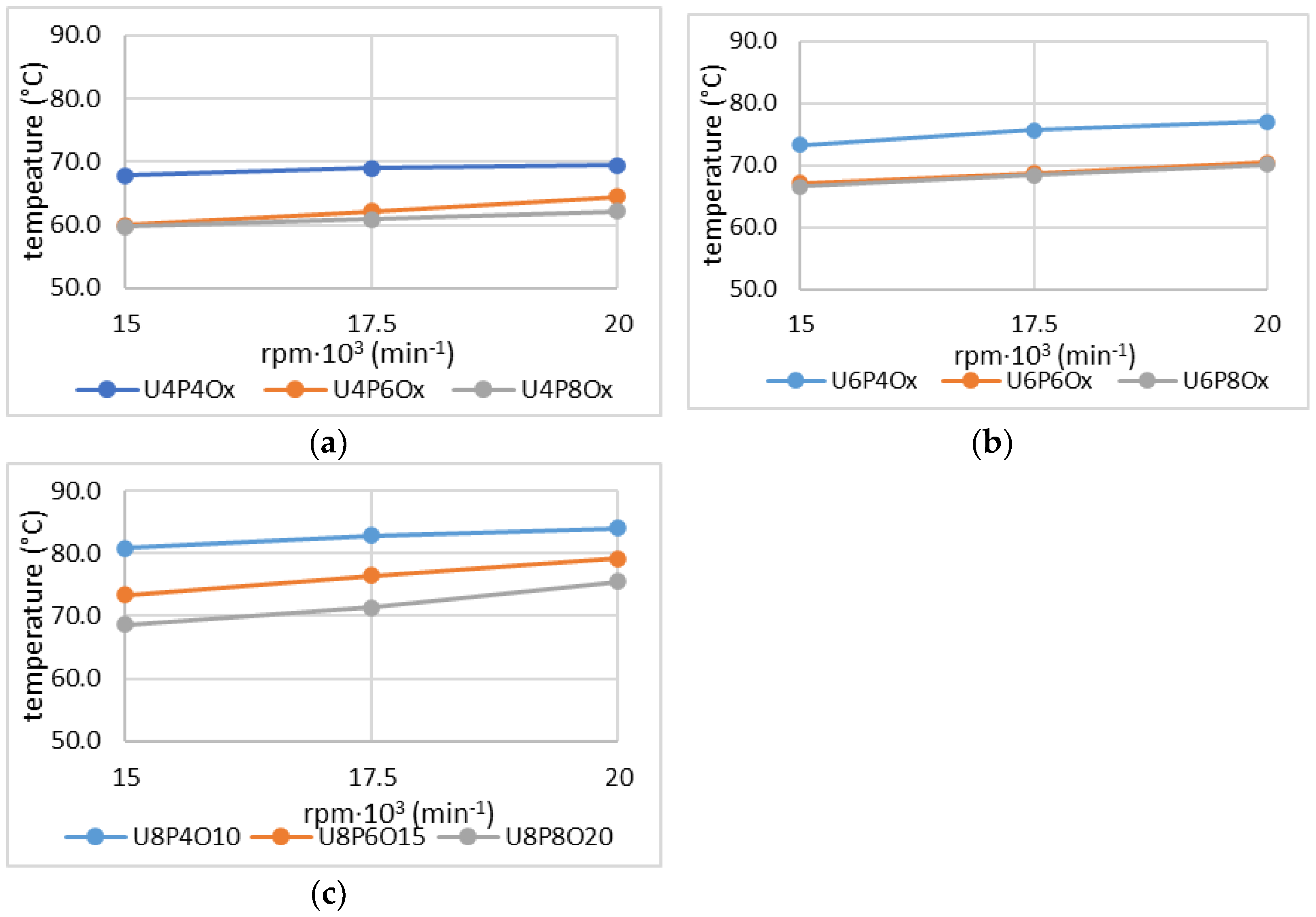

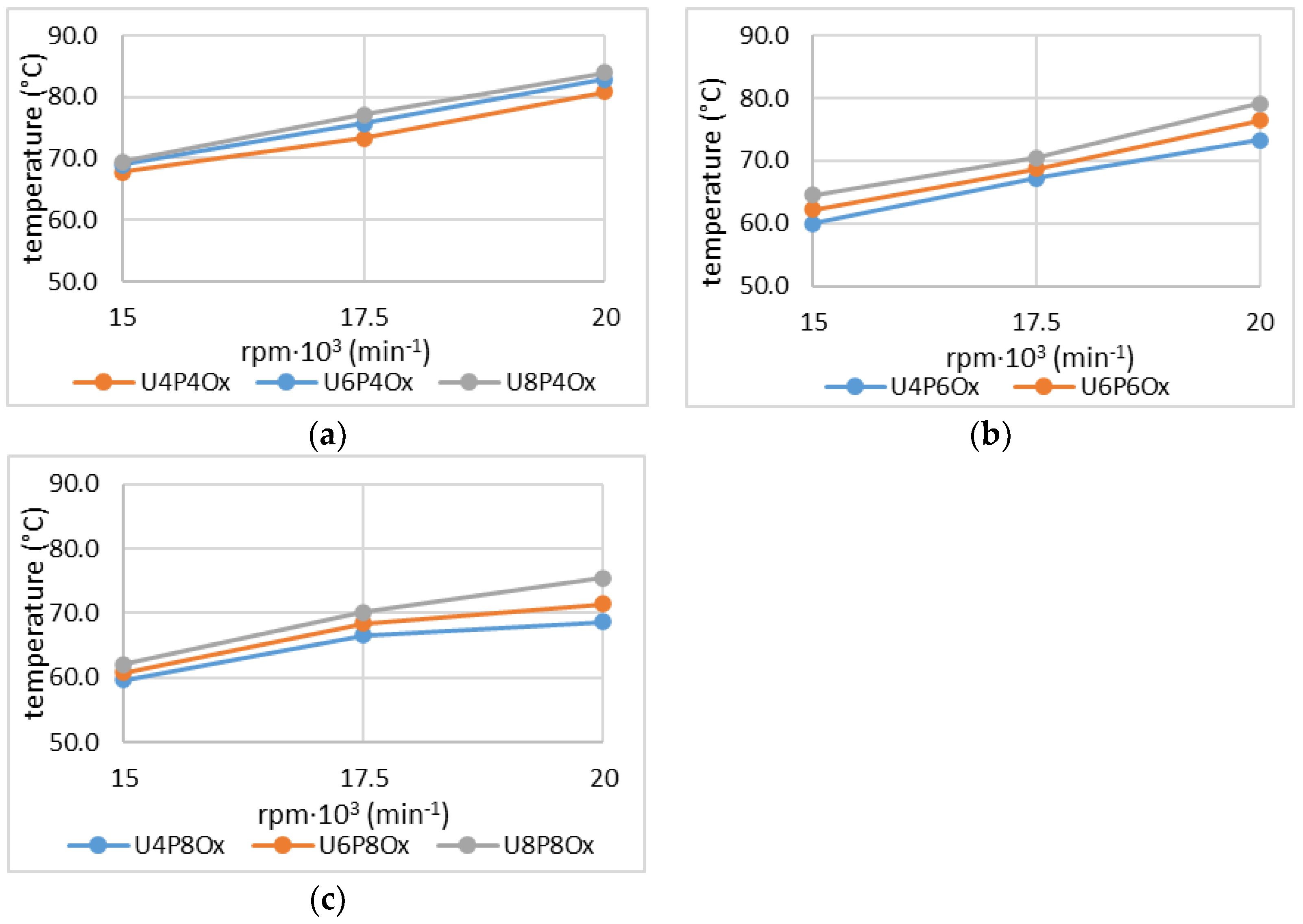

3.2. Temperature

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lin, R.S.; Chen, S.L.; Liao, J.H. A New Method for Five-Axis CNC Curve Machining. Eng. Lett. 2011, 19, 179–184. [Google Scholar]

- Xu, X.W.; Newman, S.T. Making CNC machine tools more open, interoperable and intelligent—A review of the technologies. Comput. Ind. 2006, 57, 141–152. [Google Scholar] [CrossRef]

- Shin, Y.C.; Chin, H.; Brink, M.J. Characterization of CNC Machining Centers. J. Manuf. Syst. 1991, 10, 407–421. [Google Scholar] [CrossRef]

- Petak, T.; Kurekova, E. New Methodology for Calibration of CNC Machines. Int. J. Eng. Res. Afr. 2015, 18, 144–151. [Google Scholar] [CrossRef]

- Racz, S.G.; Breaz, R.E.; Cioca, L.I. Hazards That Can Affect CNC Machine Tools during Operation-An AHP Approach. Safety 2020, 6, 10. [Google Scholar] [CrossRef]

- Gai, H.D.; Li, X.W.; Jiao, F.R.; Cheng, X.; Yang, X.H.; Zheng, G.M. Application of a New Model Reference Adaptive Control Based on PID Control in CNC Machine Tools. Machines 2021, 9, 274. [Google Scholar] [CrossRef]

- Gutakovskis, V.; Gerins, E.; Naginevicius, V.; Gudakovskis, V.; Styps, E.; Servytis, R. Adaptive Control for the Metal Cutting Process. Int. J. Eng. Res. Afr. 2020, 51, 1–7. [Google Scholar] [CrossRef]

- Chiu, H.W.; Lee, C.H. Intelligent Machining System Based on CNC Controller Parameter Selection and Optimization. IEEE Access 2020, 8, 51062–51070. [Google Scholar] [CrossRef]

- Kasirolvalad, Z.; Motlagh, M.R.J.; Shadmani, M.A. An intelligent modeling system to improve the machining process quality in CNC machine tools using adaptive fuzzy Petri nets. Int. J. Adv. Manuf. Technol. 2006, 29, 1050–1061. [Google Scholar] [CrossRef]

- Liu, Y.M.; Wang, C.J. Neural network based adaptive control and optimisation in the milling process. Int. J. Adv. Manuf. Technol. 1999, 15, 791–795. [Google Scholar] [CrossRef]

- Yaman, K.; Basaltin, M. Investigations on the cutting parameters and the tool wear of SAE 1030 forged steel material by acoustic emission in turning operation. J. Fac. Eng. Archit. Gaz. 2017, 32, 1077–1088. [Google Scholar]

- Miao, E.M.; Liu, H.; Fan, K.C.; Lv, X.X.; Liu, Y.; Hu, Y. Analysis of CNC machining based on characteristics of thermal errors and optimal design of experimental programs during actual cutting process. Int. J. Adv. Manuf. Technol. 2017, 88, 1363–1371. [Google Scholar] [CrossRef]

- Qin, Y.M.; Park, S.S. Robust adaptive control of machining operations. In Proceedings of the IEEE International Conference on Mechatronics Automation, Vols. 1–4 Conference Proceedings, Niagara Falls, ON, Canada, 29 July–1 August 2005; pp. 975–979. [Google Scholar]

- Mika, D.; Jozwik, J. Normative measurements of noise at CNC machines work stations. Adv. Sci. Technol. 2016, 10, 138–143. [Google Scholar] [CrossRef]

- Seemuang, N.; McLeay, T.; Slatter, T. Using spindle noise to monitor tool wear in a turning process. Int. J. Adv. Manuf. Technol. 2016, 86, 2781–2790. [Google Scholar] [CrossRef]

- Igaz, R.; Kminiak, R.; Krišťák, Ľ.; Němec, M.; Gergeľ, T. Methodology of Temperature Monitoring in the Process of CNC Machining of Solid Wood. Sustainability 2019, 11, 95. [Google Scholar] [CrossRef]

- Kasim, A.; Kuntjoro, W.; Kasolang, S. Thermal Management System of CNC Machine Tool Spindle for Consistent Machining Accuracy. J. Teknol. 2015, 76, 97–101. [Google Scholar] [CrossRef]

- Smith, S.; Woody, B.; Barkman, W.; Tursky, D. Temperature control and machine dynamics in chip breaking using CNC toolpaths. CIRP Ann-Manuf. Technol. 2009, 58, 97–100. [Google Scholar] [CrossRef]

- Kowaluk, G.; Pałubicki, B.; Marchal, R.; Frąckowiak, I.; Beer, P. Friction and cutting forces when machining particleboards produced from different lignocellulose raw materials. Ann. WULS For. Wood Technol. 2007, 61, 362–365. [Google Scholar]

- Troppová, E.; Tippner, J.; Hrčka, R.; Halachan, P. Qasi-stationary measurements of lignamon thermal properties. Bioresources 2013, 8, 6288–6296. [Google Scholar] [CrossRef]

- Hrčka, R.; Babiak, M. Some non-traditional factors influencing thermal properties of wood. Wood Res.-Slovak. 2012, 57, 367–374. [Google Scholar]

- Hrčka, R.; Babiak, M.; Németh, R. High temperature effect on diffusion coefficient. Wood Res.-Slovak. 2008, 53, 37–46. [Google Scholar]

- Ishihara, M.; Noda, N.; Ootao, Y. Analysis of dynamic characteristics of rotating circular saw subjected to thermal loading and tensioning. J. Therm. Stress. 2010, 33, 501–517. [Google Scholar] [CrossRef]

- Ratnasingam, J.; Pew, M.; Ramasamy, G. Tool temperature and cutting forces during the machining of particleboard and solid wood. J. Appl. Sci. 2010, 10, 2881–2886. [Google Scholar] [CrossRef]

- Nasir, V.; Kooshkbaghi, M.; Cool, J.; Sassani, F. Cutting tool temperature monitoring in circular sawing: Measurement and multi-sensor feature fusion-based prediction. Int. J. Adv. Manuf. Technol. 2021, 112, 2413–2424. [Google Scholar] [CrossRef]

- Prasad, B.S.; Prasad, D.S.; Sandeep, A.; Veeraiah, G. Condition Monitoring of CNC Machining Using Adaptive Control. Int. J. Automat. Comput. 2013, 10, 202–209. [Google Scholar] [CrossRef]

- Kavaratzis, Y.; Maiden, J.D. Real-Time process monitoring and adaptive-control during CNC Deep hole drilling. Int. J. Prod. Res. 1990, 28, 2201–2218. [Google Scholar] [CrossRef]

- Ford, D.G.; Myers, A.; Haase, F.; Lockwood, S.; Longstaff, A. Active vibration control for a CNC milling machine. P. I. Mech. Eng. C-J. Mech. 2013, 228, 230–245. [Google Scholar] [CrossRef]

- Iskra, P.; Hernández, R.E. Toward a Process Monitoring and control of a CNC Wood Router: Development of an Adaptive Control System For routing White Birch. Wood Fiber Sci. 2010, 42, 523–535. [Google Scholar]

- Laszewicz, K.; Górski, J.; Wilkowski, J. Long-term accuracy of MDF milling process—Development of adaptive control system corresponding to progression of tool wear. Eur. J. Wood Wood Prod. 2013, 71, 383–385. [Google Scholar] [CrossRef]

- EN 14322; Wood-Based Panels-Melamine Faced Board for Interior Uses—Definition, Requirements and Classification. European Committee for Standardization: Brussels, Belgium, 2017.

- EN 312-2; Particleboards-Specifications-Part 2: Requirements for General Purpose Boards for Use in Dry Conditions. European Committee for Standardization: Brussels, Belgium, 1996.

- EN ISO 12460-5; Determination of Formaldehyde Release-Part 5: Extraction Method (Called the Perforator Method). European Committee for Standardization: Brussels, Belgium, 2016.

- STN EN ISO 9612; Acoustics—Determination of Occupational Noise Exposure—Engineering Method. European Committee for Standardization: Brussels, Belgium, 2009.

- Suleiman, B.M.; Larfeldt, J.; Leckner, B.; Gustavsson, M. Thermal Conductivity and Diffusivity of Wood. Wood Sci. Technol. 1999, 33, 465–473. [Google Scholar] [CrossRef]

- Hrčka, R.; Babiak, M. Wood thermal properties. In Wood in Civil Engineering, 1st ed.; Concu, G., Ed.; Intech Open: Rijeka, Croatia, 2017; pp. 25–43. [Google Scholar] [CrossRef]

- Krišťák, Ľ.; Igaz, R.; Ružiak, I. Applying the EDPS Method to the Research into Thermophysical Properties of Solid Wood of Coniferous Trees. Adv. Mater. Sci. Eng. 2019, 2019, 2303720. [Google Scholar] [CrossRef]

- Xie, C.; Roddeck, W.; Liu, C.S.; Zhang, W.M. The Analysis and Research about Temperature and Thermal Error Measurement Technology of CNC Machine Tool. Key Eng. Mater. 2009, 392–394, 40–44. [Google Scholar] [CrossRef]

- Gisip, J.; Gazo, R.; Stewart, H.A. Effects of cryogenic treatment and refrigerated air on tool wear when machining medium density fiberboard. J. Mater. Process. Technol. 2009, 209, 5117–5122. [Google Scholar] [CrossRef]

- Gisip, J.; Gazor, R.; Stewart, H.A. Effects of refrigerated air on tool wear. Wood Fiber Sci. 2007, 39, 443–449. [Google Scholar]

- Gorski, J.; Szymanovwski, K.; Podziewski, P.; Smietanska, K.; Czarniak, P.; Cyrankowski, M. Use of Cutting Force and Vibro-acoustic Signals in Tool Wear Monitoring Based on Multiple Regression Technique for Compreg Milling. Bioresources 2019, 14, 3379–3388. [Google Scholar] [CrossRef]

- Osmolovsky, D.; Asminin, V.; Druzhinina, E. Reducing Noise from round woodworking machines by applying vibration damping friction pads between the saw blade and the clapmping flange. Akustika 2019, 32, 138–140. [Google Scholar] [CrossRef]

- Jungai, P.; Travnicek, P.; Ruzbarsky, J.; Kopecky, Z.; Solar, A. Noise emissions of older woodworking machines at parallel operation process. MM Sci. J. 2019, 2019, 2832–2838. [Google Scholar] [CrossRef]

| Technical Parameters of CNC Machining Center SCM Tech Z5 | |

|---|---|

| Useful desktop (mm) | X = 3050, y = 1300, z = 3000 |

| Speed X axis (m·min−1) | 0 ÷ 70 |

| Speed Y axis (m·min−1) | 0 ÷ 40 |

| Speed Z axis (m·min−1) | 0 ÷ 15 |

| Vector rate (m·min−1) | 0 ÷ 83 |

| Technical Parameters of the Main Spindle–Electric Spindle with HSK F63 Connection | |

| Rotation axis C | 640° |

| Rotation axis B | 320° |

| Revolutions (rpm) | 600 ÷ 24,000 |

| Power (kW) | 11 |

| Maximum tool dimensions (mm) | D = 160 |

| L = 180 | |

| Parameter | Value |

|---|---|

| Feed speed (vf) (m·min−1) | 4 |

| 6 | |

| 8 | |

| Radial depth of cut (ae) (mm) | 4 |

| 6 | |

| 8 | |

| Axial depth of cut (ap) (mm) | 18 |

| Tool revolutions (n) (rpm·min−1) | 15,000 |

| 17,500 | |

| 20,000 | |

| Milling direction | Conventional milling |

| Machining strategy | Finishing |

| Material orientation | Technological direction of production PB in X-axis |

| Parameter | Noise | Temperature |

|---|---|---|

| Revolutions | 0.8739 | 0.2378 |

| Feed Speed | 0.3585 | −0.5201 |

| Radial depth of cut | 0.2457 | 0.7908 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kminiak, R.; Němec, M.; Igaz, R.; Gejdoš, M. Advisability-Selected Parameters of Woodworking with a CNC Machine as a Tool for Adaptive Control of the Cutting Process. Forests 2023, 14, 173. https://doi.org/10.3390/f14020173

Kminiak R, Němec M, Igaz R, Gejdoš M. Advisability-Selected Parameters of Woodworking with a CNC Machine as a Tool for Adaptive Control of the Cutting Process. Forests. 2023; 14(2):173. https://doi.org/10.3390/f14020173

Chicago/Turabian StyleKminiak, Richard, Miroslav Němec, Rastislav Igaz, and Miloš Gejdoš. 2023. "Advisability-Selected Parameters of Woodworking with a CNC Machine as a Tool for Adaptive Control of the Cutting Process" Forests 14, no. 2: 173. https://doi.org/10.3390/f14020173

APA StyleKminiak, R., Němec, M., Igaz, R., & Gejdoš, M. (2023). Advisability-Selected Parameters of Woodworking with a CNC Machine as a Tool for Adaptive Control of the Cutting Process. Forests, 14(2), 173. https://doi.org/10.3390/f14020173