Abstract

With the aim of extending the production of renewable energy from lignocellulosic materials by improving their energy characteristics, the authors have started a series of experimental activities that involve a densification process of the wood material and a subsequent quantitative and qualitative characterization of the different pellets produced. The research activity was focused on different types of pellets obtained using biomass deriving from dedicated energy crops (medium rotation forestry), pruning residues of agricultural crops, thinning interventions in planted forests, and, lastly, residues from the maintenance of urban greenery. Among the 15 parameters that were investigated, 9 (length, diameter, fusibility, As, Cr, Cu, Pb, Ni, and Zn) were within the limits set by current legislation for all the analyzed pellets. The same was not detected for the remaining 6 parameters (bulk density, heating value, ash, N, durability, and cadmium), the value of which did not reach the quality requirements established by the standards. The biomass obtained from medium rotation forestry plants (MRF) and forest residues turned out to be the best source of material to be used to produce pellets. Within these two groups, the best results were found for eucalypt, except for the heating value. Pellets from MRF also showed interesting values of durability and nitrogen content (classes A1 vs. A2).

1. Introduction

In recent years, the European Union has significantly raised its level of attention to climate change. Greater support and promotion of contrasting actions with policies to improve energy efficiency are aimed at encouraging the development of production systems that are more efficient and sustainable from an environmental, economic, and energy point of view [1,2]. With the new EU Renewable Energy Directive 2018/2001/EC [2], it has been established that 32% of the total energy consumption of the Member States must come from renewable sources by 2030, thus increasing by 12% the target previously set for 2020 with Directive 2009/28/EC [3]. The use of renewable sources has steadily increased over time, while the use of fossil fuels has decreased, as they are considered to be the main cause of the increase in greenhouse gases (GHG) released into the atmosphere [4,5].

A diversification of energy sources has therefore consolidated over time, with biomass in the foreground on the international scene [6], with reference to “carbon neutral” woody ones [7]. Several studies confirm the role and versatility played by wood-based biomass in the various mitigation scenarios of climate-altering emissions, confirming its nature as a reliable energy source, easily renewable [8,9], and able to satisfy quantitative and qualitative requirements [10,11,12]. Despite the countless advantages offered by this type of fuel, this resource is not exploited to its full potential, and the reasons are mainly to be found in the lack of organized logistics, in the difficulty of knowing the actual availability in time and space, and in the low energy density that leads to high transport costs [13,14,15].

Densification (or palletization) represents an effective strategy to optimize a series of parameters and make the use of biomass more profitable. This process, in fact, increases the energy content and combustion efficiency while reducing the moisture content and the problems related to the excessive dimensional heterogeneity of the product and its low bulk density [16,17]. In fact, with the palletization process, from a specific weight between 40–200 kg m−3 of the initial biomass, a density of approximately 600–800 kg m−3 of the final product is obtained [18,19,20]. Further benefits are highlighted considering the handling and transport phases, as well as a reduction, by 4–5 times, of the area necessary for storage [15,21,22].

The European Union is still the main consumer of pellets, with almost 80% of global consumption (over 20 million tons) [1]. Much of the consumption of pellets, about 62%, is linked to the production of heat (residential, commercial, and industrial heating), while the remaining 38% is used to produce energy [23]. In 2020, the European production of pellets grew by 5% compared to 2019, reaching almost 23 million tons [24,25]. In 2021, however, global pellet production was over 40 million tons, of which 48.3% was produced in Europe and 31.7% in North America [25].

Considering only the 27 EU countries, in 2021 production increased by almost 9%, which is equal to a total of almost 26 million tons.

Historically, the main source of biomass supply was sawdust from sawmills, but the growing demand for pellets, both at a residential and industrial level, has led to the identification of new and diversified resources [26].

The focus has therefore shifted towards the use of residual biomasses, which represent an important energy resource [27,28] and whose valorization would take place through a process of environmental and socio-economic improvement [11,29]. Pruning residues of agricultural crops, as well as those resulting from sustainable forest management and urban green maintenance, could be used for pellet production, with advantages both in environmental and economic terms linked to the disposal of the materials and the gain attributable to their valorization. The current historical moment is characterized by the increase in energy costs in general (methane and many other raw materials) caused, directly and indirectly, by the geopolitical crisis. The use of pellet production in large-scale company plants, using wood products defined as waste, could be a means to contain the increase in pellet prices.

On the other hand, pellets produced from alternative feedstock still present some drawbacks in biomass quality when compared to the traditional pellets produced from coniferous sawdust [4].

Furthermore, there is still little knowledge on the identification of suitable alternative biomass sources capable of ensuring adequate pellet quality [30]. Bearing these aspects in mind, the authors developed an experimental activity aimed at defining the quality of different types of biomasses subjected to a densification process. The activity involved the recovery, dehydration, refining, and palletization of different species present in central Italy in different contexts. The goal was to identify the types of raw materials that best correspond to the qualitative parameters required by ISO EN 17225-2 [31] and, therefore, are more suitable for their possible commercial exploitation. The possibility of improving the low commercial value of a product, such as pruning residue or shredding from dedicated energy crops, by converting it into a superior product in terms of quality, energy, and economy, represents an interesting opportunity for future challenge and development for potential small- and medium-scale agro-energy chains.

2. Materials and Methods

2.1. Investigated Pellet Typologies

The activity concerned whole plants from dedicated plantations (medium rotation forestry—MRF), pruning residues from agricultural crops, material obtained from the thinning of planned forest plants, and the maintenance of urban green areas. The various types of biomass were collected during specific harvesting and management activities in central Italy, which mainly involved the provinces of Rome for biomass plantations [32], forest residues and urban green areas [33], and Viterbo for pruning residues.

Two species from MRF dedicated plantations were investigated: poplar, AF6 clone (Populus nigra L. × Populus × Generosa A. Henry–Populus × Euroamericana Moench.), with 6-year stems and 11-year roots (R11S6) and eucalypt (clone Eucalyptus camaldulensis × C. bicostata), with 6-year stems and roots (R6S6). Olive tree pruning residues (Olea europaea L., 1753) and organic hazelnut residues (Corylus avellana L., 1753) were collected from two organic farms. The pruning intervention was carried out every two years in the case of the olive grove (planting year 1920) and annually for the hazel grove (planting year 1989).

For forest residues, logs from eucalypt coppices (Eucalyptus camaldulensis (Dehnh. 1832)) and Radiata pine (Pinus radiata D. Don) forests, both at the eighteenth year of age, were used.

As part of the recovery of biomass from the maintenance of urban green areas, three species were identified that are particularly present among the roads, parks, and gardens of the cities: eucalypt (Eucalyptus camaldulensis (Dehnh. 1832)), holm oak (Quercus ilex L. 1753), and Italian stone pine (Pinus pinea L. 1753). To produce the pellets, only trunks of plants approximately 40 years old, without branches, were used. Except for the material from urban green maintenance supplied from the work site in the form of wood chips, the remaining raw material used in the experimentation was dimensionally characterized before transformation. Specifically, the diameter and length of the logs taken from the forest residues, basal diameter, height, and weight of the plants grown in MRF (a sample of 30 plants), and the diameter and length of the branches of the agricultural residues (a sample of 30 plants) were measured.

2.2. Pellet Quality Assessment

The biomass, after chipping, was refined with a BL-100 shredder using a grid with 6 mm holes [34].

After reduction, we positioned the different types of biomass in bins, exposing it periodically to the sun to promote the dehydration process until reaching a proper moisture content before pelletizing (10%) [35]. Finally, pelletizing was carried out with a 4 kW Bianco Line pelletizer.

For the characterization, the following parameters were examined:

- Moisture content [36] with a Memmert UFP800 (Schwabach, Germany) drying oven at 103 ± 2 °C;

- Pellet dimensions [37], measuring length and diameter with a digital caliper;

- Bulk density [38], using a container (volume 0.005 m3), filled and weighed with a field dynamometer (d: 0.01 g);

- Mechanical durability [39] by a mechanical durability tester (Andritz Sprout rotation pellet testing apparatus, Graz, Austria);

- Heating value [40]: with the calorimeter Anton Paar 6400 (Moline, IL, USA);

- Ash content [41], using a muffle furnace at 250 °C for one hour and at 550 °C for two hours (Lenton EF11 8B, Hope Valley, UK);

- Ash melting point [42] by the analyzer Sylab SHV-IF 1500 (Metz, France);

- Heavy metals [43] with Agilent 7700 ICP MS (Santa Clara, CA, USA);

- Nitrogen [44]: the content of nitrogen (N) was measured according to EN ISO 16948 using a CHNS-O Costech ECS 4010 elemental analyzer (Cernusco sul Naviglio, Italy).

2.3. Statistical Analysis

The collected data were then statistically analyzed using PAST 2.17c and Statistica 7.0 Software (Statsoft, Tulsa, OK, USA).

Before performing the inferential statistical analysis, the data distributions were checked for normality and homoskedasticity by applying the Shapiro–Wilk test and Levene test, respectively. In the case where both assumptions of ANOVA were confirmed, a one-way ANOVA was applied to check for the presence of statistically significant differences in the values of pellet characteristics among the various investigated types, representing the experimental treatments. Tukey’s test was further applied as a post hoc. In the case where the normality assumption was not confirmed, a non-parametric Kruskal–Wallis test was applied with the Bonferroni-corrected Mann–Whitney pairwise comparison as a post hoc. In the case where the homoskedasticity assumption was not confirmed, the Welch F test was applied with the Tukey test as a post hoc. Further non-parametric investigation of the data was carried out by principal component analysis (PCA).

It is important to highlight that the grouping of the investigated types into four separate groups (MRF: agricultural residues, forest residues, and urban green residues) is merely conceptual. This subdivision does not imply any nested structure of the data, and therefore the authors did not consider any random factor and did not apply mixed-effects models, carrying out the statistical analysis in the framework of fixed-effects models.

3. Results

3.1. General Features of the Investigated Biomass Types

The average diameter, height, and weight of the 6-year-old trees were 16.09 cm, 13.07 m, and 79.63 kg for poplar and 10.7 cm, 9.8 m, and 68 kg for eucalypt, respectively. Regarding forest residues, logs derived from tree tops with a length of about 1 m and a mean diameter of 11.96 cm and 16.5 cm were used for eucalyptus and radiata pine, respectively. The diameter and average length of the branches resulting from the pruning of agricultural residues were equal to 14.06 mm and 1.27 m for the olive tree and 27.28 mm and 1.23 m for the hazelnut tree. Bulk density values reported for refined materials after chipping were less than 300 kg m−3, except for holm oak (368 kg m−3) and eucalypt from urban green areas (310 kg m−3). The moisture content, on the other hand, ranged from 10% for the poplar to 16% for the holm oak (Table 1).

Table 1.

Bulk density and moisture content of the refined biomass.

3.2. Physical, Mechanical and Energy Characteristics of the Pellets

Table 2 shows the summary of the physical and energetic parameters of the pellet (Figure 1, Figure 2, Figure 3 and Figure 4) and the related statistical analysis. The data show some variability depending on the species or group to which it belongs. The length of the cylinders ranged from 9.16 mm and 18.36 mm for 18- and 6-year-old eucalypt, respectively, while the diameter was between 6.10 mm (18-year-old eucalypt) and 6.33 mm (6-year-old poplar).

Table 2.

Length, diameter, bulk density, durability, low heating value, ash, and ash fusibility revealed for the pellets analyzed. Length (Kruskal–Wallis and Mann–Whitney pairwise comparisons Bonferroni corrected): H = 102.6, Hc = 102.6, p < 0.001; diameter (Kruskal–Wallis and Mann-Whitney pairwise comparisons Bonferroni corrected): H = 44.12, Hc = 44.126, p < 0.001; bulk density (Welch F test and Tukey’s post hoc test): F = 59.18, df = 14.6, p < 0.01; durability (Kruskal–Wallis and Mann-Whitney pairwise comparisons Bonferroni corrected): H = 20.04, Hc = 20.04, p < 0.05; low heating value (Kruskal–Wallis and Mann–Whitney pairwise comparisons Bonferroni corrected): H = 37.64, Hc = 37.65, p < 0.001; ash content (Welch F test and Tuckey post hoc test): F = 67.82, df = 14.87, p < 0.001; ash melting point (Welch F test and Tuckey post hoc test): F = 28.49, df = 14.38, p < 0.001. Different letters indicate statistically significant differences between the groupings with respect to the single variable examined (p < 0.05).

Figure 1.

Pellet of eucalypt from MRF.

Figure 2.

Pellet of olive from agricultural residues.

Figure 3.

Pellet of Radiata pine from forest residues.

Figure 4.

Italian Stone pine from Urban green residues.

As regards bulk density, about 55% of the experimental treatments were characterized by values lower than 600 kg m−3 (poplar, hazelnut, olive, radiata pine, and Italian stone pine) and the remaining part by values higher than this threshold (eucalypt and holm oak). Finally, almost all the types examined had durability values above 98%, with the exception of both pine pellets and the 18-year-old eucalypt.

The heating value ranged from a minimum of 14.43 MJ kg−1, measured for 6-year-old eucalypt, to a maximum of 18.27 MJ kg−1 for Italian stone pine. As for ash content, values lower than 1% were found for radiata pine, Italian stone pine, and urban green eucalypt; values higher than 2% for agricultural residues; and values between 1% and 2% for the remaining types of products. Finally, all the pellets examined showed an ash melting point higher than 1400 °C.

Statistical analysis (Table 2) allowed for the evaluation of any significant difference not only among the various experimental treatments but also within the same group (MRF, agricultural residues, forest residues, urban green areas) or the same species (or genus) present in different groups. Starting from the single grouping, significant differences were highlighted in terms of diameter, bulk density, and LHV for MRF and in terms of length for agricultural residues. In the group of forest residues, all the parameters analyzed differed statistically except for the ash melting point, while for urban green materials, at least two of the three species considered differed statistically in length, bulk density, durability, LHV, and ash content. Comparing the single species, instead, differences were found in several parameters, with a lower incidence regarding diameter and fusibility. Eucalypt is the only species present in three different groupings: similar values were found in terms of bulk density, durability, and fusibility (p > 0.05), a higher and a lower length, respectively, in the eucalypt from MRF and forest residues, with intermediate values in the urban green group (p < 0.05). Eucalypt from MRF also differed significantly from the other two as regards the LHV, presenting the lowest values, while, for the ash content, eucalypt from urban greenery, with its lower mean values, differed statistically from the others. Finally, as regards the two pines, statistical differences were found only in terms of length, with the Italian stone pine pellet slightly longer (12.38 vs. 11.12).

3.3. Nitrogen and Heavy Metals Content

Table 3 shows the data concerning the nitrogen and heavy metal content and the corresponding statistical analysis. Similarly, to what emerged for physical and energetic parameters, there is a certain variability in the results according to the species or reference group. Poplar, olive, holm oak, and eucalypt from urban greenery were characterized by nitrogen concentrations ranging between 1.2% and 1.58%. For the other species, the values were less than 0.77%, with the absolute lowest levels for eucalypt from MRF (0.23%) and forest residues (0.40%).

Table 3.

Descriptive statistics for the nitrogen and heavy metal variables (Mean ± ST.DEV.). Welch F test and Tukey’s post hoc test: N [F = 39.75, df = 14.31, p < 0.001], Cd [F = 6502, df = 13.33, p < 0.001]; Kruskal–Wallis and Mann–Whitney pairwise comparisons Bonferroni corrected: As [H = 41.68, Hc = 41.7, p < 0.001], Cr [H = 41.91, Hc = 41.93, p < 0.001], Cu [H = 42.02, Hc = 42.04, p < 0.001], Pb [H = 41.86, Hc = 41.93, p < 0.001], Ni [H = 40.04, Hc = 40.06, p < 0.001]; one way-ANOVA and Tukey’s post hoc test: Zn [df = 8, F = 2487, p < 0.001]. Different letters indicate statistically significant differences between the groupings with respect to the single variable examined [p < 0.05].

Arsenic, cadmium, chromium, and lead were present in higher concentrations in urban green, with values not lower than 0.71, 0.66, 0.88, and 1.2 mg kg−l, respectively. In all other cases, values were lower, with zero mg kg−l for the olive tree relative to the cadmium and lead content and values close to zero for the MRF eucalypt and the radiata pine relative to arsenic content. The highest concentrations of copper have been identified in agricultural residues: 6.1 mg kg−l in the hazelnut tree and 2.9 mg kg−l in the olive tree. The values, on the other hand, were slightly lower than 1 mg kg−l for forest residues and MRF, lower than 0.5 mg kg−l for urban green residues.

The highest nickel contents were found in forest residues (about 1.7 mg kg−1), in eucalypt MRF (1.65 mg kg−1), in urban green residues (between 1.31 and 1.54 mg kg−1), in hazelnut (1.21 mg kg−1), and the lowest ones in olive (0.06 to mg kg−1) and poplar (0.2 mg kg−1). Zinc was found in higher concentrations in MRF (between 12.59 and 14.16 mg kg−1) and in forest residues (about 14.5 mg kg−1), and in lower concentrations in urban green residues (between 1.3 and 1.5 mg kg−1) and agricultural residues (between 4.5 and 4.9 mg kg−1).

The two MRF species differed statistically for all parameters analyzed, except for Cd. Agricultural residues did not differ in the content of N, Cd, and Zn, while forest residues differed only in As and Ni. Considering urban green residues, significant differences emerged among all species only in the case of copper, between at least two of the three species for N, Cd, and Pb, and no statistical difference for As, Cr, Ni, and Zn.

Considering all the experimental treatments, significant differences emerged between different species, with variable results depending on the chemical parameter considered. Specifically, for the eucalypt trees, no significant differences were detected between MRF and forest residues for 8 of the 9 parameters, but both always differed from urban green eucalypt. The only parameter that differed significantly for the three eucalypt was arsenic, with the lowest and highest values for the MRF and urban green residues, respectively. Finally, the two different pines differ in all parameters except for arsenic.

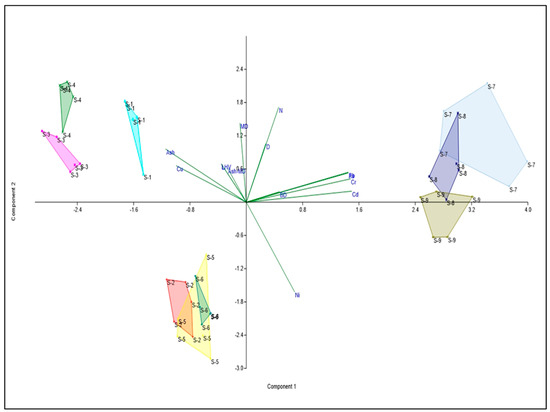

3.4. Principal Component Analysis

All 15 parameters evaluated were included in the principal component analysis (PCA). The two principal components explained 72% of the total variability. As shown in Figure 5, the principal component analysis shows that axis 1 is mainly related to mechanical durability (MD), ash melting point (Ash-MP), lower heating value (LHV), diameter (D), N content (N), and, slightly, Ni content (Ni). Axis 2 is instead related to the other variables. From the image, it is possible to identify three groups of pellet typologies that show similar features. The first group is in the upper left (S1, S3, S4), the second in the upper right (S7, S8, S9), and the last in the lower left (S2, S5, S6). The first group is characterized by high ash content, high copper content but low content of other heavy metals, high LHV, and low bulk density. The second group showed high bulk density, high LHV, low ash and copper content, but also high content of other heavy metals. Finally, the third group showed low bulk density and LHV, but also low ash and heavy metal content, apart from nichel. From the PCA, it was therefore not possible to identify a group with better overall properties than the others; indeed all groups showed some advantages or drawbacks.

Figure 5.

Principal component analysis (PCA) of the pellets produced: medium rotation forestry of poplar (S1); medium rotation forestry of eucalypt (S2); organic hazelnut residues (S3); olive tree pruning residues (S4); forest residues of radiata pine (S5); forest residues of eucalypt (S6); holm oak from urban green areas (S7); eucalypt from urban green areas (S8); Italian stone pine from urban green areas (S9).

4. Discussion

To summarize the overall results, the authors developed Table 4, which provides a summary of all the parameters analyzed for the different reference species and shows the quality class achieved or the exceeding of the limits indicated by the standard.

Table 4.

Compliance of the quality parameters of the pellets produced according to the EN ISO 17225-2 [36] classification: ✓ (complies with the standard), X (does not comply with the standard) A1–A2–B (value classes to which the reference parameter belongs).

The analysis of the data according to each parameter allows for the identification of the critical ones in general terms. Bulk density represented a criticality for five species out of nine, affecting at least one species for each group and even both agricultural species. The heating value and nitrogen were critical for four out of nine species, affecting the different groups except for agricultural residues for the heating value and nitrogen for forest residues. Cadmium exceeded the threshold values for three of the nine species, affecting only the urban green group; both the ash content and the durability represent a problem for two of the nine species examined, affecting, in the first case, only the group of agricultural residues and, in the second case, the two species of pines present in forest residues (radiata pine) and urban greenery (Italian stone pine). Of the 15 parameters examined, therefore, only 9 comply with the reference legislation in all the experimental treatments (length, diameter, fusibility, As, Cr, Cu, Pb, Ni, and Zn).

The qualitative potential of the product according to the origin of the biomass used can be evaluated by individual groups. The data were standardized by proportioning the total number of parameters in each group to the number of species present in the same group. The critical parameters found were therefore equal to 10% for MRF (3/30) and forest residues (3/30), 16.6% for agricultural residues (5/30), and 20% for urban green (9/45).

Considering the data at the level of a single species, however, it is observed that eucalypt from MRF and forest residues were not within the standard for only one parameter (heating value in both cases). Poplar, hazel tree, and radiata pine did not comply with the current standard for two parameters: precisely bulk density and nitrogen for poplar, bulk density and ash content for hazel tree, and bulk density and durability for radiata pine. Finally, for the olive tree and the urban green species, there were three parameters that did not comply with the standard: bulk density, ash content, and N for the first one; LHV, N, and Cd for holm oak and eucalypt; bulk density, durability, and Cd for Italian stone pine.

The bulk density mainly affects logistics related to the organization and management of transport and storage. It is a parameter conditioned by several factors, including the diameter and length of the material, its humidity, and the degree of compression applied during processing. Monedero et al. [45] indicate a certain difficulty in complying with the threshold of 600 kg m3 for species like poplar and pine, confirming what emerged in this study. A possible explanation of the general low bulk density level achieved can be found in the fact that in this study, the raw material applied was characterized by the presence of branches and, in some cases, leaves, thus material that is less prone to palletization in comparison to the pure sawdust that is applied at the commercial level [46].

The different length detected for the different types of pellets could also be due to the greater or lesser presence of the branch fraction in the starting biomass. This aspect could influence the densification phase, with levels of discontinuity in the product and consequent fragmentation [4]. As regards the diameter of the pellets, however, this is slightly larger than that of the hole in the die (6.00 mm), showing a natural tendency to expand immediately after the densifying step.

As previously mentioned, the pellet can undergo fragmentation processes, and this affects not only the bulk density values but also the formation of fine particles that can create problems during storage and combustion [47,48]. Mechanical durability measures the maintenance of the physical integrity of the pellets from the production plant to the combustion chamber, and this parameter, in this case, is a limitation exclusively for the two different species of pine.

As regards the heating value, the data obtained confirm what emerged in other studies [49].

As regards the ash, the pellets produced by the pruning of hazel and olive trees were characterized by the highest values, and this was probably due to the greater presence of bark in the wood material than pelletized [50]. A high presence of ashes lowers the heating value and can cause incorrect combustion, resulting in a reduction in the efficiency of the system and an increase in disposal costs [51]. The high fusibility values found (> 1400 °C), however, reduce the possibility of the formation of agglomerates that can clog the mechanical parts with potential blockages of the devices used for ash evacuation.

The ash content is related to the presence of heavy metals. The content of the latter in biofuels should be minimal in order to limit post-combustion toxicological effects [52,53], with particular attention given to small-scale systems without dust suppression accessories [54]. All the products analyzed were characterized by concentrations lower than the expected limits, with the exception of cadmium for the species belonging to the urban green group.

Finally, the high nitrogen values found for poplar, olive, and two species of urban greenery may be due to higher quantities of bark or to treatments linked to certain agronomic practices.

The pellets produced have interesting qualitative characteristics, despite some parameters not respecting the values defined by the standard. In this regard, however, it must be kept in mind that several pellets available on the market, labeled as class A1, have lower quality characteristics than those indicated in the packaging, with reference to parameters such as bulk density, ash content, and durability [55]. To correctly place a given product in each quality class, therefore, it would be desirable to exercise greater control along the entire supply chain.

Quality improvements can be achieved by pelletizing mixtures of different materials to better meet the required parameters and fall within the expected quality classes. In this regard, numerous studies have evaluated the use of mixtures of different materials in order to improve the final product from a qualitative point of view [53,54,56,57,58,59,60]. Much depends, however, on the number and type of parameters to be improved, on how much the values measured differ from the threshold, and on the effects produced by such blends on the parameters that, otherwise, do not require improvements.

For example, eucalypt from MRF and forest, both characterized by a low heating value as the only critical parameter, could be useful by mixing with species characterized by a higher heating value, as in the case of poplar, hazelnut, or stone pine. To allow the MRF eucalypt to increase the heating value from 14.43 MJ kg−1 to 16.5 MJ kg−1, it would be necessary to proceed to a mix with 61% poplar (39% eucalypt), 75% hazelnut tree (25% eucalypt), or 54% of Italian stone pine (46% eucalypt). For eucalypt from forest residues, where the starting value is slightly higher, the percentages would drop to 42% with poplar (58% eucalypt), 58% with hazelnut tree (42% eucalypt), and 37% with Italian stone pine (63% eucalypt).

These mixes, obviously, also lead to the modification of other parameters with variable and not always optimal results. With reference to ash content, for example, the mixes previously proposed would produce different effects depending on the species used in the mix. With the poplar, there would be a slight increase in the values of content in ashes while maintaining the same initial class; with hazelnut, this increase would be excessive, with values above the 2% required by the legislation (between 2.42% and 2.69%). With the pine, the ash content would be reduced from 1.52% to 0.90%, leading to an improvement in class from B to A2. The same pine would also benefit from the same percentages of mixing with eucalypt, lowering the cadmium content to values allowed by law.

Again, considering the eucalypt trees, these mixes could create problems for durability and bulk density. In the first case, the use of additives such as corn starch could favor the cohesion of particles, thus guaranteeing compliance with the reference values but, in the second case, this would not be possible due to the low basal density of the other materials used in mixing. In this specific case other parameters would be penalized, although it could be preferable to slightly reduce the bulk density in favor of a higher average heating value.

Regarding the residues from urban green, a potential 50% mixing with Italian stone pine would ensure the threshold of 16.5 MJ kg−1 for the other two species (holm oak and eucalypt), also improving the class of final products in terms of ash content, which would pass from A2 to A1 for eucalypt and from B to A2 for holm oak. In this case, however, the same problems related to bulk density would be encountered.

Lajili et al. [54], aiming to improve the quality of solid waste from olive mills, prepared mixtures of pellets with different percentages of pine sawdust (75%, 50%), obtaining a reduction in ash fractions and an increase in bulk density.

Harun and Afzal in 2016 [57] and 2018 [59] tested different mixes of agricultural residues as timothy hay and switchgrass with pine and spruce at 50%. The results showed a reduction in N, S, and ash content and an increase in heating value.

5. Conclusions

The use of different types of woody material determines the production of pellets characterized by different physical and chemical properties, and this also affects the amount of final energy produced in the combustion process. With our study, we verified that by using starting biomass with a higher bark content, a pellet is obtained that has high durability but also a higher ash content. In contrast, with biomass characterized by a lower presence of bark, a final product is obtained whose combustion releases few ashes but is characterized by lower durability.

Based on the data analyzed, biomass obtained from medium rotation forestry (MRF) and forest residues were the best sources of material to be used for pellet production. Within these two groups, the eucalypt highlighted the best results, being critical only for the heating value, with a certain advantage for MRFs in terms of durability and nitrogen content (classes A1 vs. A2). It should be noted, however, that the ash content of eucalypt placed the material only in class B.

A qualitative increase following mixing can be produced by using variable percentages of other types of woody materials, thus improving the limit value of one or more critical parameters. In this case, however, the results obtained should be examined specifically in detail, taking into account possible variations that may affect and penalize other parameters that, otherwise, would not need to be improved.

Finally, if producers and users of pellets want to respect the quality standards established by the ISO, further research will be necessary to quantify the effects of the characteristics of the starting woody material on various parameters. These parameters include considering seasonal variations, the type of harvest, storage, and production process used for the refined product.

Author Contributions

Conceptualization, V.C., A.A. and G.S.; methodology, V.C., A.A. and G.S.; formal analysis, F.L., V.C., A.A. and G.S.; investigation, V.C., A.A. and B.B.; data curation, V.C., A.A. and G.S.; writing—original draft preparation, V.C. and A.A.; writing—review and editing, V.C., A.A., G.S. and B.B.; supervision, R.P. and V.C.; funding acquisition, V.C. All authors have read and agreed to the published version of the manuscript.

Funding

This study was developed within the AGROENER “Energia dall’Agricoltura: Innovazioni Sostenibili per la Bioeconomia” National Project, funded by the Italian Ministry of Agriculture, Food, and Forestry Policies (MiPAAF, D.D. n. 26329, 1 April 2016).

Data Availability Statement

Data presented within the article.

Acknowledgments

“Progetto ECS 0000024 Rome Technopole—CUP B83C22002820006, PNRR Missione 4 Componente 2 Investimento 1.5, Finanziato dall’Unione Europea—NextGener-ationEU”. The research was also carried out within the framework of the Ministry for Education, University, and Research (MIUR) initiative “Department of Excellence” (Law 232/2016) DAFNE Project 2023-27 “Digital, Intelligent, Green and Sustainable (acronym: D.I.Ver.So)”.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Padilla-Rivera, A.; Barrette, J.; Blanchet, P.; Thiffault, E. Environmental Performance of Eastern Canadian Wood Pellets as Measured Through Life Cycle Assessment. Forests 2017, 8, 352. [Google Scholar] [CrossRef]

- European Union. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the promotion of the use of energy from renewable sources. 2030 Climate and Energy Frameworks. Off. J. Eur. Union 2018, 5, 82–209. [Google Scholar]

- European Union. Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the Promotion of the use of Energy from Renewable Sources and Amending and Subsequently Repealing Directives 2001/77/EC and 2003/30/EC. Off. J. Eur. Union 2009, 5, 16–62. [Google Scholar]

- Civitarese, V.; Acampora, A.; Sperandio, G.; Assirelli, A.; Picchio, R. Production of Wood Pellets from Poplar Trees Managed as Coppices with Different Harvesting Cycles. Energies 2019, 12, 2973. [Google Scholar] [CrossRef]

- IPCC Climate Change. Synthesis Report Contribution of Working Groups I, II and III to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK. Available online: https://www.researchgate.net/publication/262260453_IPCC_2007_Climate_Change_2007_Synthesis_Report_Contribution_of_Working_Groups_I_II_III_to_the_Fourth_Assessment_Report_of_the_Intergovernmental_Panel_on_Climate_Change_Geneva (accessed on 6 February 2019).

- Panwar, N.L.; Kaushik, S.C.; Kothari, S. Role of renewable energy sources in environmental protection: A review. Renew. Sustain. Energy Rev. 2011, 15, 1513–1524. [Google Scholar] [CrossRef]

- Lauri, P.; Kallio, A.M.I.; Schneider, U.A. Price of CO2 emissions and use of wood in Europe. For. Policy Econ. 2012, 15, 123–131. [Google Scholar] [CrossRef]

- Owusu, P.A.; Asumadu-Sarkodie, S. A review of renewable energy sources, sustainability issues and climate change mitigation. Cogent Eng. 2016, 3, 1167990. [Google Scholar] [CrossRef]

- Faaij, A.P. Securing Sustainable Resource Availability of Biomass for Energy Applications in Europe; Review of Recent Literature; University of Groningen: Groningen, The Netherlands, 2018. [Google Scholar]

- Velazquez-Marti, B.; Fernandez-Gonzales, E.; Lopez-Cortez, I.; Salazar-Hernandez, D.M. Quantification of the residual biomass obtained from pruning of trees in Mediterranean olive groves. Biomass Bioenergy 2011, 35, 3208–3217. [Google Scholar] [CrossRef]

- Scarlat, N.; Blukdea, V.; Dallemand, J.F. Assessment of the availability of agricultural and forest residues for bioenergy production in Romania. Biomass Bioenergy 2011, 35, 1995–2005. [Google Scholar] [CrossRef]

- García, R.; Gil, M.V.; Rubiera, F.; Pevida, C. Pelletization of wood and alternative residual biomass blends for producing industrial quality pellets. Fuel 2019, 251, 739–753. [Google Scholar] [CrossRef]

- Velazquez-Marti, B.; Fernandez-Gonzales, E. Analysis of the process of biomass harvesting with collecting-chippers fed by pick up headers in plantations of olive trees. Biosyst. Eng. 2009, 104, 184–190. [Google Scholar] [CrossRef]

- Tumuluru, J.S. Effect of process variables on the density and durability of the pellets made from high moisture corn stover. Biosyst. Eng. 2014, 119, 44–57. [Google Scholar] [CrossRef]

- Tumuluru, J.S. Effect of pellet die diameter on density and durability of pellets made from high moisture woody and herbaceous biomass. Carbon Resour. Convers. 2018, 1, 44–54. [Google Scholar] [CrossRef]

- Audigane, N.; Bentele, M.; Ferreira, J.M.; Gyurik, A.; Jossart, J.M.; Mangel, A.C.; Masdemont, P.R.; Mörner, H.; Paniz, A. European Pellet Report—PellCert Project; Intelligent Energy Europe: Brussels, Belgium, 2012. [Google Scholar]

- Purohit, P.; Chaturvedi, V. Biomass pellets for power generation in India: A techno-economic evaluation. Environ. Sci. Pollut. Res. 2018, 25, 29614–29632. [Google Scholar] [CrossRef]

- Liu, Z.; Mi, B.; Jiang, Z.; Fei, B.; Cai, Z.; Liu, X. Improved bulk density of bamboo pellets as biomass for energy production. Renew. Energy 2016, 86, 1–7. [Google Scholar] [CrossRef]

- Karkania, V.; Fanara, E.; Zabaniotou, A. Review of sustainable biomass pellets production—A study for agricultural residues pellets’ market in Greece. Renew. Sustain. Energy Rev. 2012, 16, 1426–1436. [Google Scholar] [CrossRef]

- Monteiro, E.; Mantha, V.; Rouboa, A. Portuguese pellets market: Analysis of the production and utilization constrains. Energy Policy 2012, 42, 129–135. [Google Scholar] [CrossRef]

- Holm, J.K.; Henriksen, U.B.; Hustad, J.E.; Sørensen, L.K. Toward an Understanding of controlling parameters in Softwood and Hardwood pellets production. Energy Fuels 2006, 20, 2686–2694. [Google Scholar] [CrossRef]

- Cao, L.; Yuan, X.; Li, H.; Li, C.; Xiao, Z.; Jiang, L.; Huang, B.; Xiao, Z.; Chen, X.; Wang, H.; et al. Complementary effects of torrefaction and co-pelletization: Energy consumption and characteristics of pellets. Biores. Technol. 2015, 185, 254–262. [Google Scholar] [CrossRef]

- EPC. European Pellet Council, Pellet Statistics. Available online: https://epc.bioenergyeurope.org/about-pellets/pellets-statistics/2018 (accessed on 12 November 2018).

- AIEL. Agriforenergy. 2021. Available online: https://www.aielenergia.it/public/pubblicazioni/A4E_4-2021.pdf (accessed on 10 April 2023).

- Bioenergy Europe—Pellets Report. 2022. Available online: https://bioenergyeurope.org/article/406-annual-report-2022.html (accessed on 10 April 2023).

- Sikkema, R.; Steiner, M.; Junginger, M.; Hiegl, W.; Hansen, M.T.; Faaij, A. The European wood pellet markets: Current status and prospects for 2020. Biofules Bioprod. Biorefining 2011, 5, 250–278. [Google Scholar] [CrossRef]

- GSE (Energy Services Manager). Energia da Fonti Rinnovabili. Rapporto Statitistico; Gestore dei Servizi Energetici: Rome, Italy, 2015. [Google Scholar]

- Carone, M.T.; Pantaleo, A.; Pellerano, A. Influence of process parameters and biomass characteristics on the durability of pellets from the pruning residues of Olea europaea L. Biomass Bioenergy 2011, 35, 402–410. [Google Scholar] [CrossRef]

- Di Blasi, C.; Tanzi, V.; Lanzetta, M. A study on the production of agricultural residues in Italy. Biomass Bioenergy 1997, 12, 321–331. [Google Scholar] [CrossRef]

- Picchio, R.; Latterini, F.; Venanzi, R.; Stefanoni, W.; Suardi, A.; Tocci, D.; Pari, L. Pellet production from woody and non-woody feedstocks: A review on biomass quality evaluation. Energies 2020, 13, 2937. [Google Scholar] [CrossRef]

- EN ISO 17225-2; Solid Biofuels—Fuel Specifications and Classes—Part 2: Graded wood pellets. The British Standards Institution: London, UK, 2014.

- Sperandio, G.; Acampora, A.; Del Giudice, A.; Civitarese, V. Models for the Evaluation of Productivity and Costs of Mechanized Felling on Poplar Short Rotation Coppice in Italy. Forests 2021, 12, 954. [Google Scholar] [CrossRef]

- Biocca, M.; Gallo, P.; Sperandio, G. Potential Availability of Wood Biomass from Urban Trees: Implications for the Sustainable Management of Maintenance Yards. Sustainability 2022, 14, 11226. [Google Scholar] [CrossRef]

- Bergström, D.; Israelsson, S.; Öhman, M.; Dahlqvist, S.A.; Gref, R.; Boman, C.; Wästerlund, I. Effects of raw material particle size distribution on the characteristics of Scots pine sawdust fuel pellets. Fuel Process. Technol. 2008, 89, 1324–1329. [Google Scholar] [CrossRef]

- Ungureanu, N.; Vladut, V.; Voicu, G.; Dinca, M.-N.; Zabava, B.-S. Influence of biomass moisture content on pellet properties—Review. In Proceedings of the 17th International Scientific Conference—Engineering for Rural Development, Jelgava, Latvia, 23–25 May 2018. [Google Scholar] [CrossRef]

- EN ISO 18134-1; Solid Biofuels—Determination of Moisture Content—Oven Dry Method. ISO: Geneva, Switzerland, 2015.

- EN ISO 17829; Solid Biofuels—Determination of Length and Diameter of Pellets. ISO: Geneva, Switzerland, 2016.

- EN ISO 17828; Solid Biofuels—Determination of Bulk Density. ISO: Geneva, Switzerland, 2016.

- EN ISO 17831–1; Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes. Part 1: Pellets. ISO: Geneva, Switzerland, 2016.

- EN ISO 18125; Solid Biofuels—Determination of Heating Value. ISO: Geneva, Switzerland, 2018.

- EN ISO 18122; Solid Biofuels—Determination of Ash Content. ISO: Geneva, Switzerland, 2016.

- CEN/TS 15370-1; Solid Biofuels—Method for the Determination of Ash Melting Behaviour. Part 1: Characteristic Temperatures Method. SIST: Ljubljana, Slovenia, 2006.

- EN ISO 16968; Solid Biofuels—Determination of Minor Elements. ISO: Geneva, Switzerland, 2015.

- EN ISO 16948; Solid Biofuels—Determination of Total Content of Carbon. Hydrogen and Nitrogen. ISO: Geneva, Switzerland, 2015.

- Monedero, E.; Portero, H.; Lapuerta, M. Pellet blends of poplar and pine sawdust: Effects of material composition. additive. moisture content and compression die on pellet quality. Fuel Process. Technol. 2015, 132, 15–23. [Google Scholar] [CrossRef]

- Latterini, F.; Civitarese, V.; Walkowiak, M.; Bembenek, M.; Mederski, P.S. Quality of Pellets Obtained from Whole Trees Harvested from Plantations, Coppice Forests and Regular Thinnings. Forests 2022, 13, 502. [Google Scholar] [CrossRef]

- Vinterback, J. Pellets 2002: The first world conference on pellets. Biomass Bioenergy 2004, 27, 513–520. [Google Scholar] [CrossRef]

- Filbakk, T.; Skjevrak, G.; Høibø, O.; Dibdiakova, J.; Jirjis, R. The influence of storage and drying methods for Scots pine raw material on mechanical pellet properties and production parameters. Fuel Process. Technol. 2011, 92, 871–878. [Google Scholar] [CrossRef]

- Telmo, C.; Lousada, J. Heating values of wood pellets from different species. Biomass Bioenergy 2011, 35, 2634–2639. [Google Scholar] [CrossRef]

- Toscano, G.; Riva, G.; Pedretti, E.F.; Corinaldesi, F.; Mengarelli, C.; Duca, D. Investigation on wood pellet quality and relationship between ash content and the most important chemical elements. Biomass Bioenergy 2013, 56, 317–322. [Google Scholar] [CrossRef]

- Ružinská, E.; Štollmann, V.; Hagara, V.; Jabło’nski, M. Analysis of selected heavy metals in biomass for preparation of biofuels—Part, I. Toxicological effects of heavy metals. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2015, 92, 383–389. [Google Scholar]

- Obernbergera, I.; Theka, G. Physical characterisation and chemical composition of densified biomass fuels with regard to their Combustion behavior. Biomass Bioenergy 2004, 27, 653–669. [Google Scholar] [CrossRef]

- Barbanera, M.; Lascaro, E.; Stanzione, V.; Esposito, A.; Altieri, R.; Bufacchi, M. Characterization of pellets from mixing olive pomace and olive tree pruning. Renew. Energy 2016, 88, 185–191. [Google Scholar] [CrossRef]

- Lajili, M.; Jeguirim, M.; Kraiem, N.; Limousy, L. Performance of a household boiler fed with agropellets blended from olive mill solid waste and pine sawdust. Fuel 2015, 153, 431–436. [Google Scholar] [CrossRef]

- Kamperidou, V. Quality Analysis of Commercially AvailableWood Pellets and Correlations between Pellets Characteristics. Energies 2022, 15, 2865. [Google Scholar] [CrossRef]

- Stasiak, M.; Molenda, M.; Bańda, M.; Wiącek, J.; Parafiniuk, P.; Gondek, E. Mechanical and combustion properties of sawdust—Straw pellets blended in different proportions. Fuel Process. Technol. 2017, 156, 366–375. [Google Scholar] [CrossRef]

- Harun, N.Y.; Afzal, M.T. Effect of Particle Size on Mechanical Properties of Pellets Made from Biomass Blends. Procedia Eng. 2016, 148, 93–99. [Google Scholar] [CrossRef]

- Fernández-Puratich, H.; Hernández, D.; Lerma Arce, V. Characterization and cost savings of pellets fabricated from Zea mays waste from corn mills combined with Pinus radiata. Renew. Energy 2017, 114 Pt B, 448–454. [Google Scholar] [CrossRef]

- Yub Harun, N.; Parvez, A.M.; Afzal, M.T. Process and Energy Analysis of Pelleting Agricultural and Woody Biomass Blends. Sustainability 2018, 10, 1770. [Google Scholar] [CrossRef]

- Bezerra da Silva, S.; Chaves Arantes, M.D.; Batista de Andrade, J.K.; Andrade, C.R.; de Cássia Oliveira Carneiro, A.; de Paula Protásio, T. Influence of physical and chemical compositions on the properties and energy use of lignocellulosic biomass pellets in Brazil. Renew. Energy 2020, 147 Pt 1, 1870–1879. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).