Influence of Timber Moisture Content on the Ultrasonic Wave Velocity Measurement of Tectona grandis L.F. and Cupressus lusitanica M. from Costa Rica

Abstract

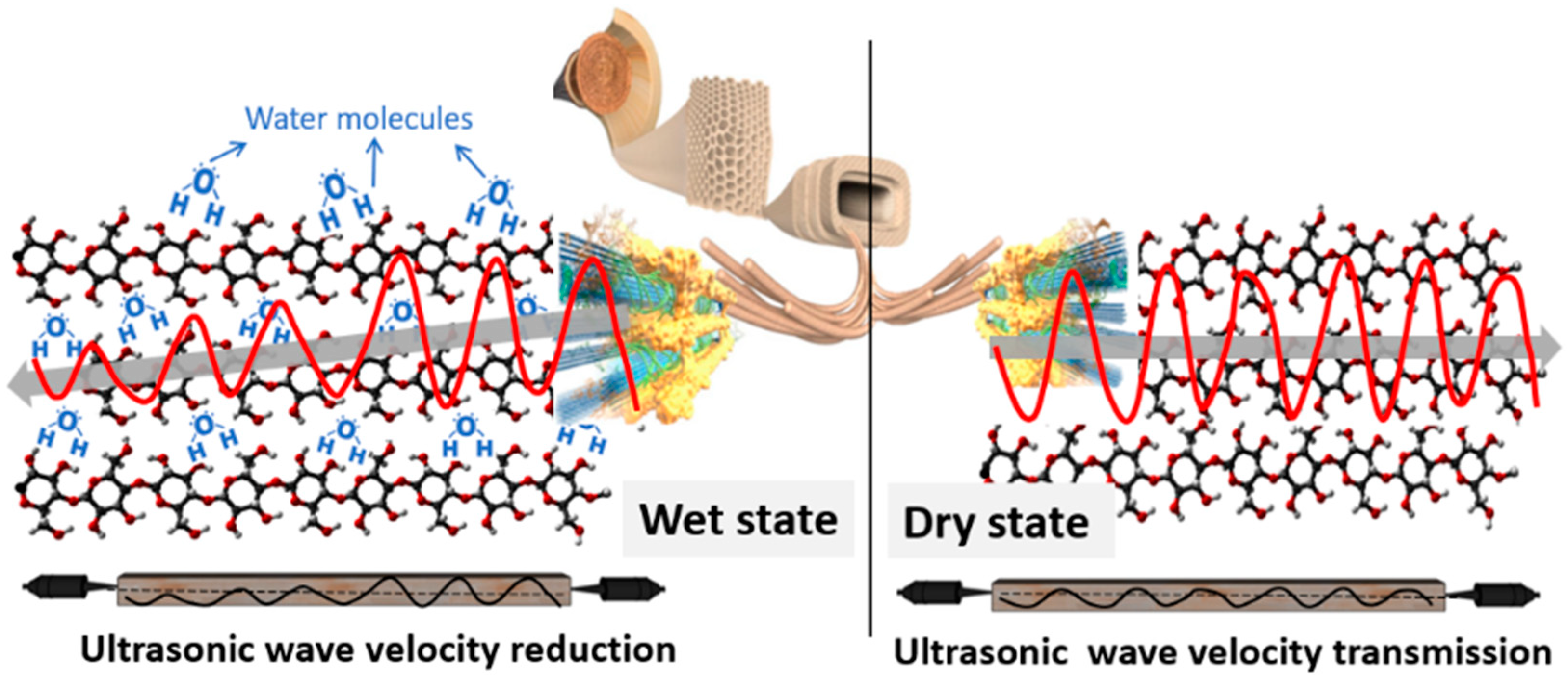

1. Introduction

2. Materials and Methods

2.1. Wood Material

2.2. General Procedure

2.3. Wave Velocity Measurement Procedure

2.4. Statistical Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mascarenhas, A.R.P.; de Melo, R.R.; Pimenta, A.S.; Stangerlin, D.M.; de Oliveira Corrêa, F.L.; Sccoti, M.S.V.; de Oliveira Paula, E.A. Ultrasound to estimate the physical-mechanical properties of tropical wood species grown in an agroforestry system. Holzforschung 2020, 75, 879–891. [Google Scholar] [CrossRef]

- Bachtiar, E.V.; Sanabria, S.J.; Niemz, P. Elastic Characteristics of Wood by Means of Ultrasonic Waves and Mechanical Test. Dans FPInnovations (Éd.). In Proceedings of the 5th ISCHP International Scientific Conference on Hardwood Processing, Quebec, QC, Canada, 2015; pp. 12–19. Available online: https://www.cabdirect.org/cabdirect/abstract/20183290522 (accessed on 7 July 2022).

- Chauhan, S.; Sethy, A. Differences in dynamic modulus of elasticity determined by three vibration methods and their relationship with static modulus of elasticity. Maderas. Cienc. Y Tecnol. 2016, 18, 373–382. [Google Scholar] [CrossRef]

- Casado, M.; Acuña, L.; Basterra, L.A.; Ramón-Cueto, G.; Vecilla, D. Grading of structural timber of Populus × euramericana clone I-214. Holzforschung 2012, 66, 633–638. [Google Scholar] [CrossRef]

- Marhenke, T.; Neuenschwander, J.; Furrer, R.; Twiefel, J.; Hasener, J.; Niemz, P.; Sanabria, S.J. Modeling of delamination detection utilizing air-coupled ultrasound in wood-based composites. NDT E Int. 2018, 99, 1–12. [Google Scholar] [CrossRef]

- Neuenschwander, J.; Sanabria, S.J.; Schuetz, P.; Widmann, R.; Vogel, M. Delamination detection in a 90-year-old glulam block with scanning dry point-contact ultrasound. Holzforschung 2013, 67, 949–957. [Google Scholar] [CrossRef][Green Version]

- Sobue, N. Simulation study on stress wave velocity in wood above fiber saturation point. J. Jpn. Wood Res. Soc. (Jpn.) 1993, 39, 271–276. [Google Scholar]

- Wang, S.Y.; Lin, C.J.; Chiu, C.M. The adjusted dynamic modulus of elasticity above the fiber saturation point in Taiwania plantation wood by ultrasonic-wave measurement. Holzforschung 2003, 57, 547–552. [Google Scholar] [CrossRef]

- Wang, S.Y.C. Experimental data correlation of the dynamic elastic moduli, velocity, and density of solid wood as a function of moisture content above the fiber saturation point. Holzforschung 2000, 54, 309–314. [Google Scholar] [CrossRef]

- Yamasaki, M.; Tsuzuki, C.; Sasaki, Y.; Onishi, Y. Influence of moisture content on estimating Young’s modulus of full-scale timber using stress wave velocity. J. Wood Sci. 2017, 63, 225–235. [Google Scholar] [CrossRef]

- Sanabria, S.J.; Furrer, R.; Neuenschwander, J.; Niemz, P.; Sennhauser, U. Air-coupled ultrasound inspection of glued laminated timber. Holzforschung 2011, 65, 377–387. [Google Scholar] [CrossRef]

- Sandoz, J.L. Grading of construction timber by ultrasound. Wood Sci. Technol. 1989, 23, 95–108. [Google Scholar] [CrossRef]

- Sandoz, J.L. Moisture content and temperature effect on ultrasound timber grading. Wood Sci. Technol. 1993, 27, 373–380. [Google Scholar] [CrossRef]

- Mishiro, A. Ultrasonic Velocity and Moisture Content in Wood II. Ultrasonic velocity and average moisture content in wood during desorption (1); Moisture content below the fiber saturation point. Mokuzai Gakkaishi 1996, 42, 612–617. [Google Scholar]

- Mishiro, A. Ultrasonic Velocity and Moisture Content in Wood III. Ultrasonic velocity and average moisture content in wood during desorption (2): During desorption from a water-saturated condition. Mokuzai Gakkaishi 1996, 42, 930–936. [Google Scholar]

- Gerhards, C.C. Effect of moisture content and temperature on the mechanical properties of wood: An analysis of immediate effects. Wood Fiber Sci. 1982, 14, 4–36. [Google Scholar]

- Wang, X. Effects of Size and Moisture on Stress Wave E-rating of Structural Lumber. In Proceedings of the Dans 10th World Conference on Timber Engineering, Miyazaki, Japan, 2008; pp. 1–8. Available online: https://www.fs.usda.gov/treesearch/pubs/34322 (accessed on 7 July 2022).

- Unterwieser, H.; Schickhofer, G. Influence of moisture content of wood on sound velocity and dynamic MOE of natural frequency- and ultrasonic runtime measurement. Eur. J. Wood Wood Prod. 2011, 69, 171–181. [Google Scholar] [CrossRef]

- Nocetti, M.; Brunetti, M.; Bacher, M. Effect of moisture content on the flexural properties and dynamic modulus of elasticity of dimension chestnut timber. Eur. J. Wood Wood Prod. 2015, 73, 51–60. [Google Scholar] [CrossRef]

- Gonçalves, R.; Lorensani, R.; Pedroso, C.B. Moisture-related adjustment factor to obtain a reference ultrasonic velocity in structural lumber of plantation hardwood. Wood Mater. Sci. Eng. 2017, 13, 254–261. [Google Scholar] [CrossRef]

- NBR 15521; Non-Destructive Testing-Ultrasonic Testing—Mechanical Classification of Dicotyledonous Sawn Wood. ABNT—Brazilian Association of Technical Standards: Sao Pablo, Brazil, 2007.

- Llana, D.F.; Íñiguez-González, G.; Esteban, M.; Hermoso, E.; Arriaga, F. Timber moisture content adjustment factors for nondestructive testing (NDT): Acoustic, vibration and probing techniques. Holzforschung 2020, 74, 817–827. [Google Scholar] [CrossRef]

- Goncalves, R.; da Costa, O.A.L. Influence of moisture content on longitudinal, radial, and tangential ultrasonic velocity for two Brazilian wood species. Wood Fiber Sci. 2008, 40, 580–586. [Google Scholar]

- Saadat-Nia, M.A.; Brancheriau, L.; Gallet, P.; Enayati, A.A.; Pourtahmasi, K.; Honarvar, F. Ultrasonic wave parameter changes during propagation through poplar and spruce reaction wood. BioResources 2011, 6, 1172–1185. [Google Scholar]

- Peng, H.; Jiang, J.; Zhan, T.; Lü, J. Influence of density and moisture content on ultrasound velocities along the longitudinal direction in wood. Sci. Silvae Sin. 2016, 52, 117–124. [Google Scholar]

- Moya-Roque, R.; Muñoz-Acosta, F.; Salas-Garita, C.; Berrocal-Jiménez, A.; Leandro-Zúñiga, L.; Esquivel-Segura, E. Tecnología de madera de plantaciones forestales: Fichas técnicas. Rev. For. Mesoam. Kurù 2010, 7, 18–19. [Google Scholar]

- Paniagua-Hernández, V.; Torres, C.; González-Rodrigo, B.; Sasa, Z. Methodology to Analyze the Degradation of Structural Timber in Acidic Atmospheres. In Proceedings of the Dans World Conference of Timber Engineeringerence on Timber Engineering, Santiago de Chile, Chile, 2021; Available online: https://www.kerwa.ucr.ac.cr/handle/10669/85497 (accessed on 7 July 2022).

- Barrantes, A.; Ugalde, S. Usos y aportes de la madera en Costa Rica estadísticas 2019 precios 2020. Oficina Nacional Forestal ONF. 2019. Available online: https://catalogosiidca.csuca.org/Record/CR.UNA01000318705/Description (accessed on 7 July 2022).

- Ilic, J. Dynamic MOE of 55 species using small wood beams. Holz Als Roh-Und Werkst. 2003, 61, 167–172. [Google Scholar] [CrossRef]

- Karlinasari, L.; Azmi, M.I.; Priadi, T. The changes in color and dynamic modulus of elasticity of five important Indonesian tropical wood species after 10 months of outdoor exposure. J. Indian Acad. Wood Sci. 2018, 15, 149–157. [Google Scholar] [CrossRef]

- Solorzano, S.; Moya, R.; Murillo, O. Early prediction of basic density, shrinking, presence of growth stress, and dynamic elastic modulus based on the morphological tree parameters of Tectona grandis. J. Wood Sci. 2012, 58, 290–299. [Google Scholar] [CrossRef]

- ASTM-D143; Standard Test Methods for Small Clear Specimens of Timber. ASTM International: West Conshohocken, PA, USA, 2014.

- Steiger, R. Versuche an Fichten-Kanthölzern: Biegemoment-Normalkraft-Interaktion. Institut Für Baustatik und Konstruktion (IBK), Eidgenössische Technische Hochschule Zürich (ETH); ETH Zurich: Zïrich, Swiss, 1995. [Google Scholar] [CrossRef]

- Carrasco, E.V.M.; Alves, R.C.; Smits, M.A.; Pizzol, V.D.; Oliveira, A.L.C.; Mantilla, J.N.R. Influence of the applied pressure of the transducer on the propagation speed of the ultrasonic wave in wood. Holzforschung 2021, 75, 1097–1103. [Google Scholar] [CrossRef]

- ASTM-D4442-16; Standard Test Methods For Direct Moisture Content Measurement of Wood And Wood-Based Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- Kang, H.; Booker, R.E. Variation of stress wave velocity with MC and temperature. Wood Sci. Technol. 2002, 36, 41–54. [Google Scholar] [CrossRef]

- Bucur, V.; Eberhardsteiner, J.; Mang, H.; Waubke, H. Acoustics of Wood, 2nd ed.; Springer Series in Wood Science: New York, NY, USA, 2006. [Google Scholar]

- Nishimura, H.; Kamiya, A.; Nagata, T.; Katahira, M.; Watanabe, T. Direct evidence for α ether linkage between lignin and carbohydrates in wood cell walls. Sci. Rep. 2018, 8, 1–11. [Google Scholar] [CrossRef]

- Arriaga, F.; Llana, D.F.; Esteban, M.; Íñiguez-González, G. Influence of length and sensor positioning on acoustic time-of-flight (ToF) measurement in structural timber. Holzforschung 2017, 71, 713–723. [Google Scholar] [CrossRef]

- Castro, F.; Raigosa, J. Crecimiento y propiedades físico-mecánicas de la madea de teca (Tectona grandis) de 17 años de edad en San Joaquín, de Abangares, Costa Rica. Agron. Costarric. 2000, 24, 7–23. [Google Scholar]

- Sandoz, J.L. Triage et Fiabilité de bois de Construction (Sorting and Timber Reliability); Ecole Polytechnique Federale dee Lausanne: Lausanne, Switzerland, 1990. [Google Scholar]

- Íñiguez-González, G.; Arriaga, F.; Esteban, M.; Llana, D.F. Reference conditions and modification factors for the standardization of nondestructive variables used in the evaluation of existing timber structures. Constr. Build. Mater. 2015, 101, 1166–1171. [Google Scholar] [CrossRef]

- Ferreira, A.T.B. Avaliação da Estrutura Anatômica e da Densidade Aparente do Lenho e do Carvão de Árvores de Eucalyptus sp. e de Corymbia sp. Ph.D. Thesis, Universidade de São Paulo, São Paulo, Brazil, 2013. [Google Scholar]

| MC | Moisture content (%) |

| FSP | Fiber saturation point (at 28% MC) |

| VH | Ultrasound velocity at certain moisture conditions (ms−1) |

| VH/V12 | The ratio of ultrasound velocity at certain MC (VH) to ultrasound velocity at 12% MC (V12) change rate |

| V12 | Ultrasound velocity at 12% MC (ms−1) |

| Vfsp | Ultrasound velocity at FSP 28% MC (ms−1) |

| ΔU | Moisture content variation |

| ρ | Density (kgm−3) |

| ku | Adjustment factors for each timber specie |

| ToF | Time of flight |

| MOEdyn | Dynamic modulus of elasticity (GPa) |

| ρV2 | MOEdyn by calculation of VH and density (GPa) |

| NDT | Non-destructive testing |

| Species/Age | Density ρ (kgm−3) | Vfsp (ms−1) | V12 (ms−1) |

|---|---|---|---|

| Cypress/40 years | 533.37 ± 52.73 | 3860.76 ± 397.38 | 4655.16 ± 400.27 |

| Teak/14 years | 531.30 ± 49.22 | 4463.80 ± 360.69 | 5152.39 ± 371.37 |

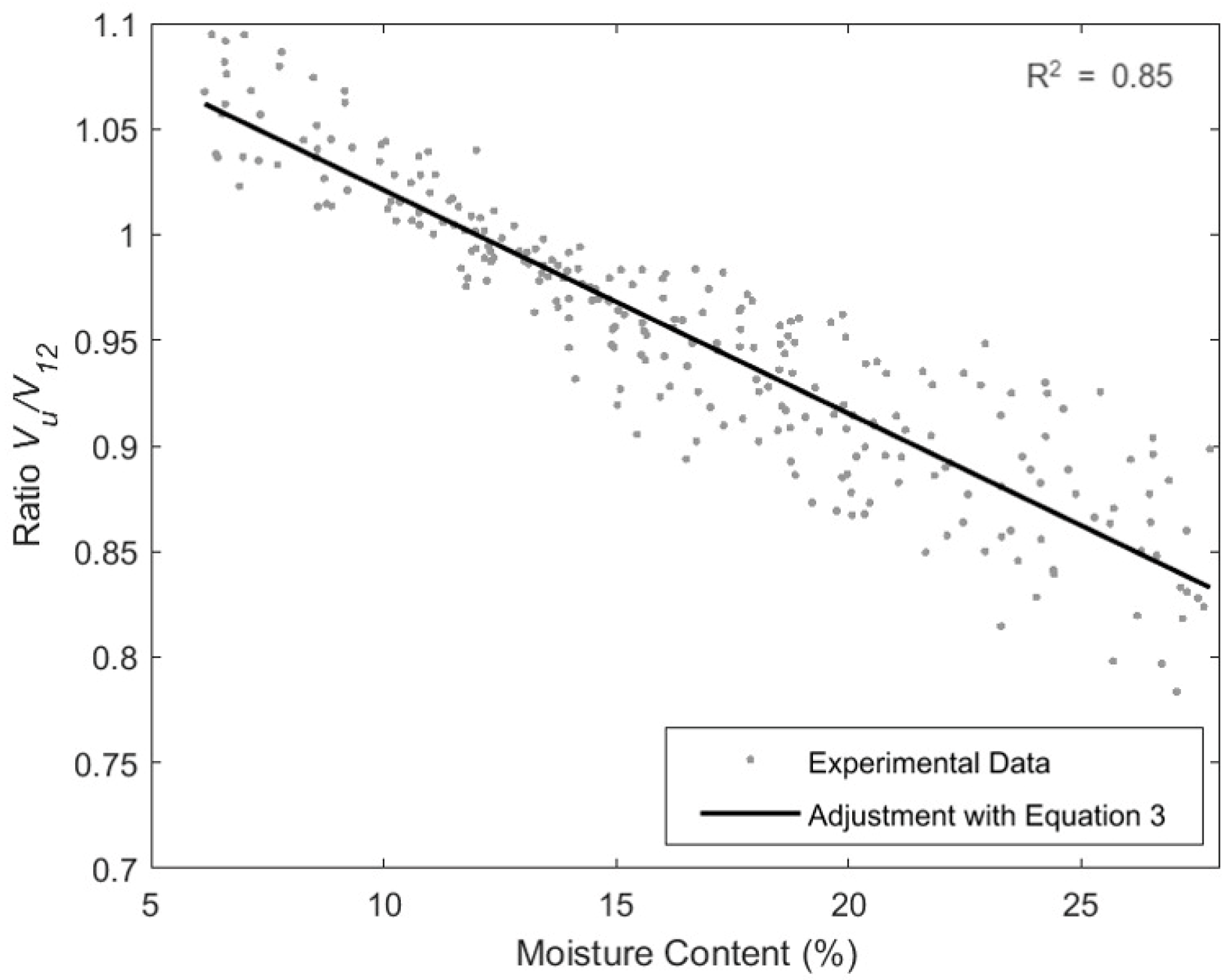

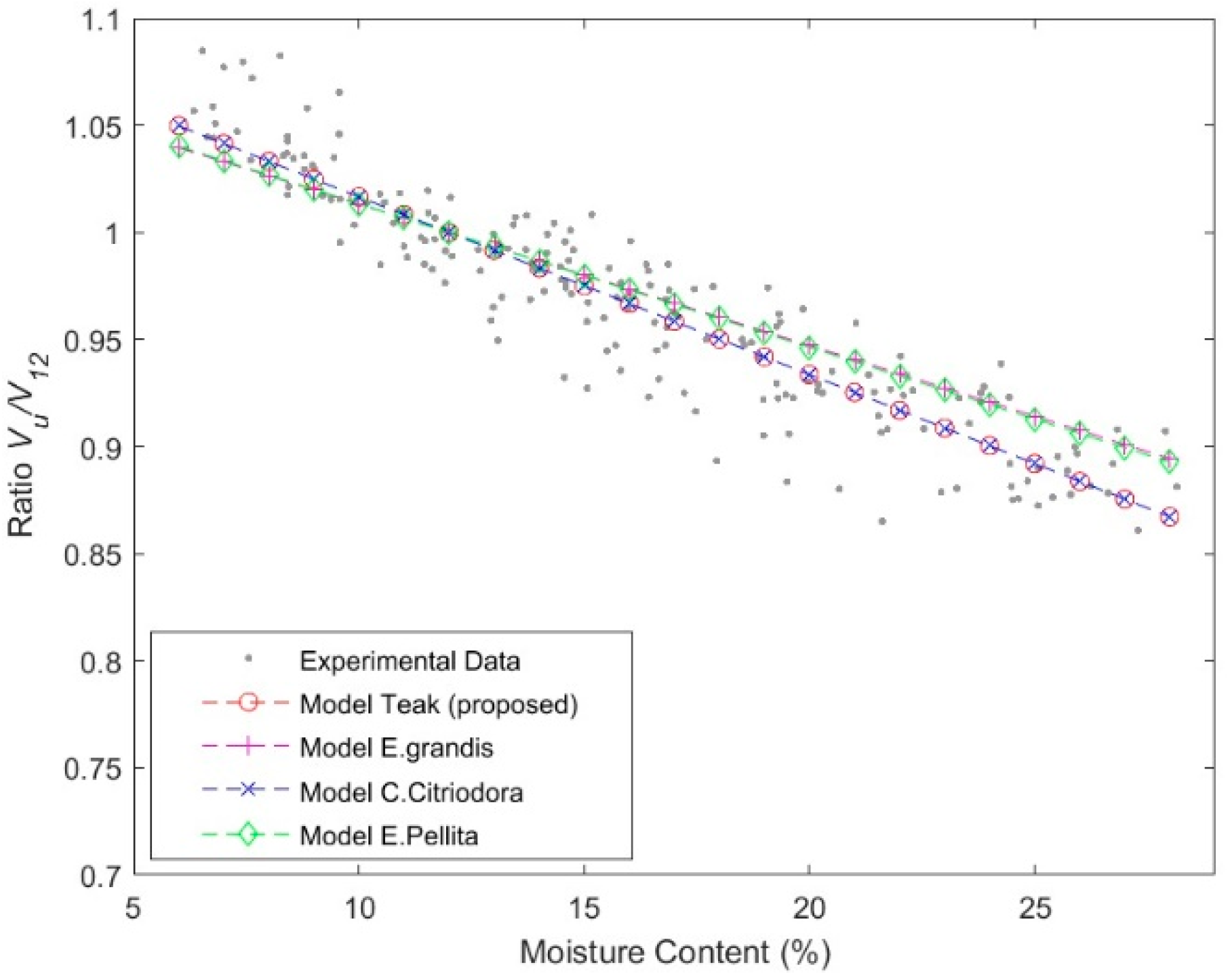

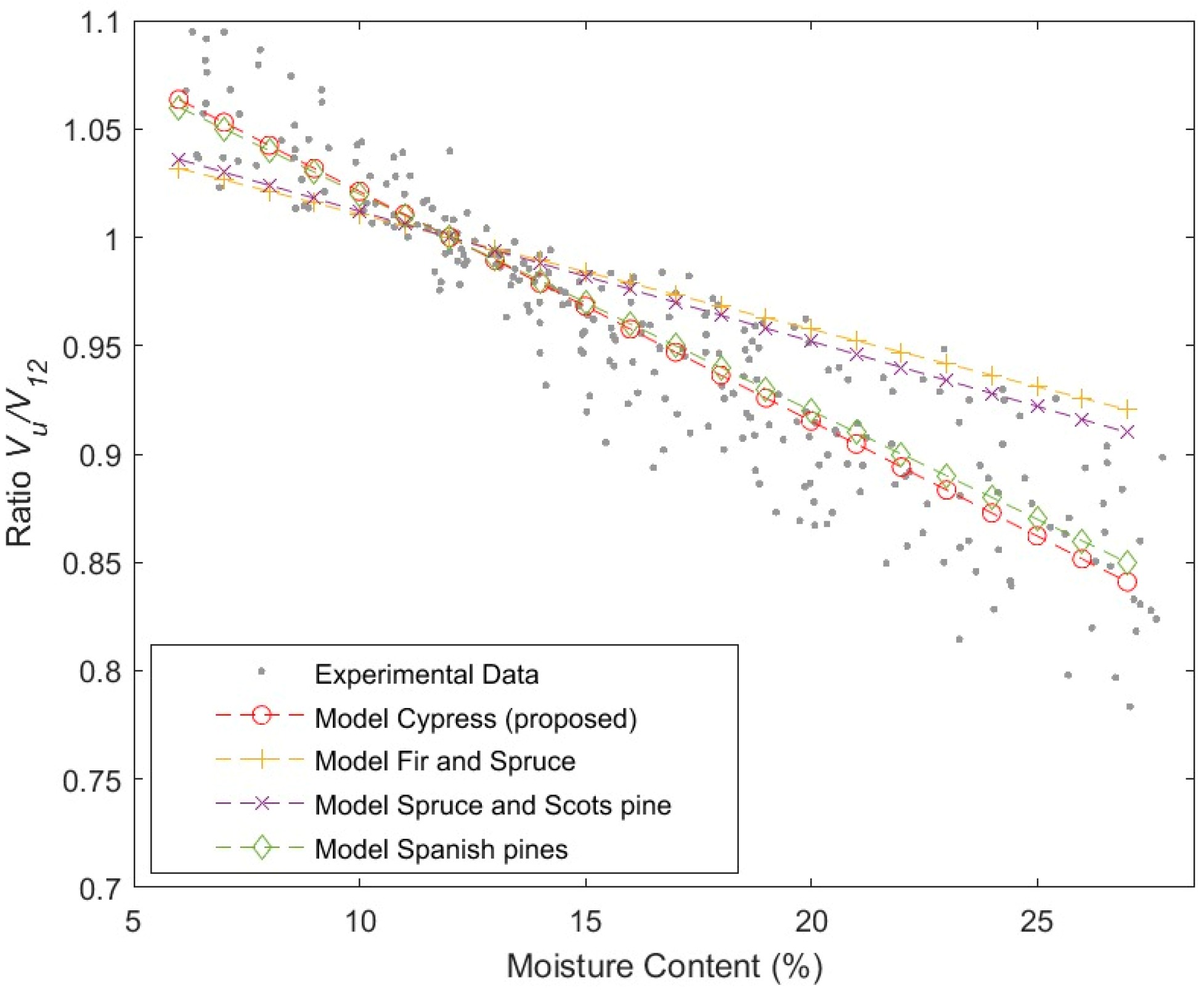

| Equation | Specie | Author | ku | R2 | MSE |

|---|---|---|---|---|---|

| Hardwood models/Dataset teak (14 years) | |||||

| T | Teak | (Proposed model) | 0.0083 | 0.8486 | 4.14 × 10−4 |

| H1 | Eucalyptus grandis | [20] | 0.0066 | 0.7893 | 5.78 × 10−4 |

| H2 | Corymbia citridora | [20] | 0.0083 | 0.8485 | 4.16 × 10−4 |

| H3 | Eucalyptus pellita | [20] | 0.0067 | 0.7893 | 5.78 × 10−4 |

| Softwood models/Dataset cypress (40 years) | |||||

| C | Cypress | (Proposed model) | 0.0106 | 0.8479 | 6.34 × 10−4 |

| C1 | - | [42] | 0.0100 | 0.8449 | 6.47 × 10−4 |

| C2 | Fir and Spruce | [13,41] | 0.0053 | 0.5052 | 0.0021 |

| C3 | Spruce and Scots pine | [18] | 0.0060 | 0.5914 | 0.0017 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paniagua, V.; Corrales, J.; Torres, C.; González-Rodrigo, B. Influence of Timber Moisture Content on the Ultrasonic Wave Velocity Measurement of Tectona grandis L.F. and Cupressus lusitanica M. from Costa Rica. Forests 2022, 13, 1296. https://doi.org/10.3390/f13081296

Paniagua V, Corrales J, Torres C, González-Rodrigo B. Influence of Timber Moisture Content on the Ultrasonic Wave Velocity Measurement of Tectona grandis L.F. and Cupressus lusitanica M. from Costa Rica. Forests. 2022; 13(8):1296. https://doi.org/10.3390/f13081296

Chicago/Turabian StylePaniagua, Viviana, Javier Corrales, Cindy Torres, and Beatriz González-Rodrigo. 2022. "Influence of Timber Moisture Content on the Ultrasonic Wave Velocity Measurement of Tectona grandis L.F. and Cupressus lusitanica M. from Costa Rica" Forests 13, no. 8: 1296. https://doi.org/10.3390/f13081296

APA StylePaniagua, V., Corrales, J., Torres, C., & González-Rodrigo, B. (2022). Influence of Timber Moisture Content on the Ultrasonic Wave Velocity Measurement of Tectona grandis L.F. and Cupressus lusitanica M. from Costa Rica. Forests, 13(8), 1296. https://doi.org/10.3390/f13081296