Physical and Mechanical Properties Performance between Untreated and Treated with CCA Treatment at Different Age Groups of Fast-Growing Acacia Hybrid of Sarawak

Abstract

1. Introduction

2. Materials and Methods

2.1. Moisture Content Determination

2.2. Density Determination

2.3. Treatment Process

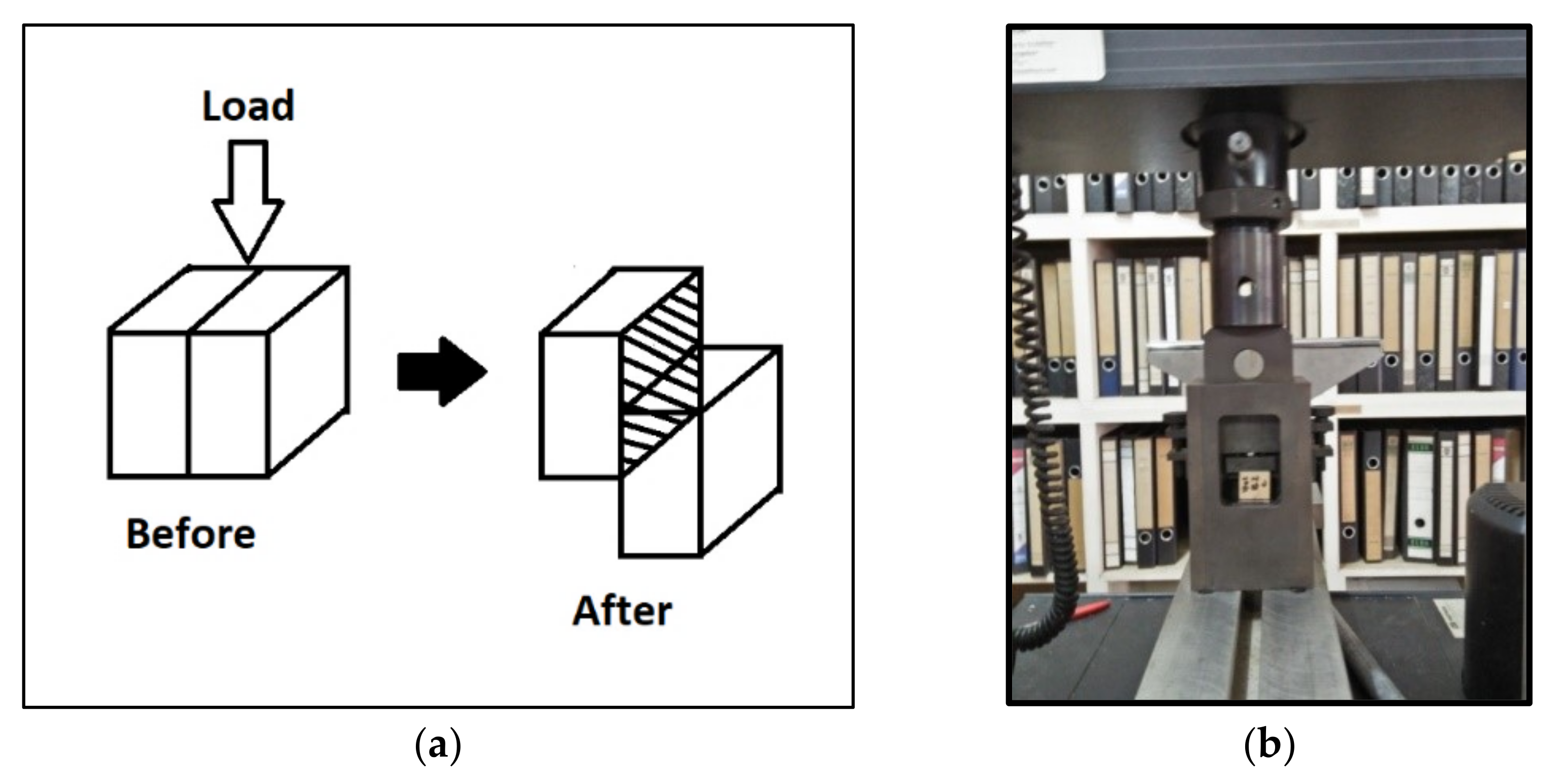

2.4. Mechanical Testing

3. Results

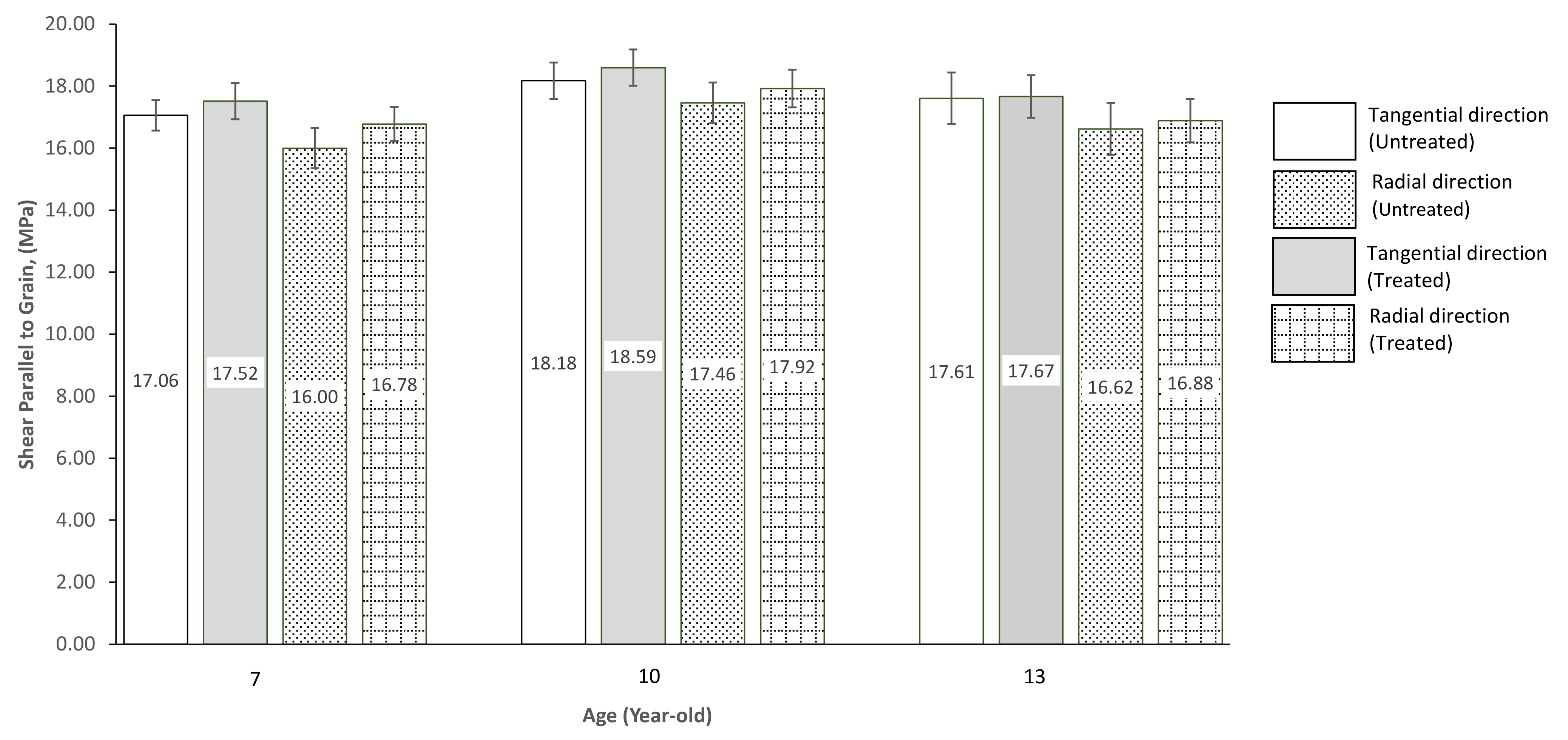

3.1. Shear Parallel to Grain

3.2. Cleavage

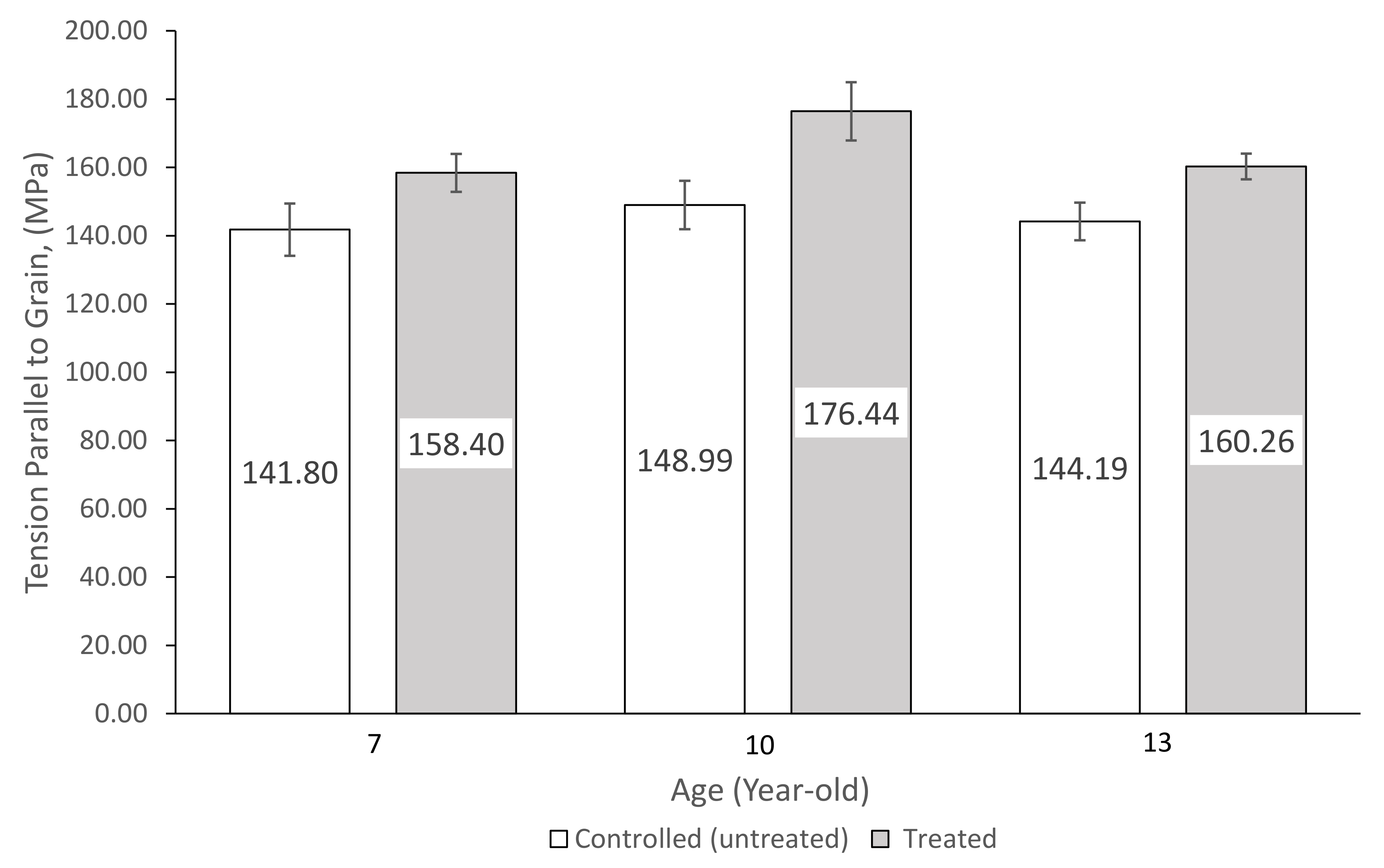

3.3. Tension Parallel to Grain

4. Conclusions

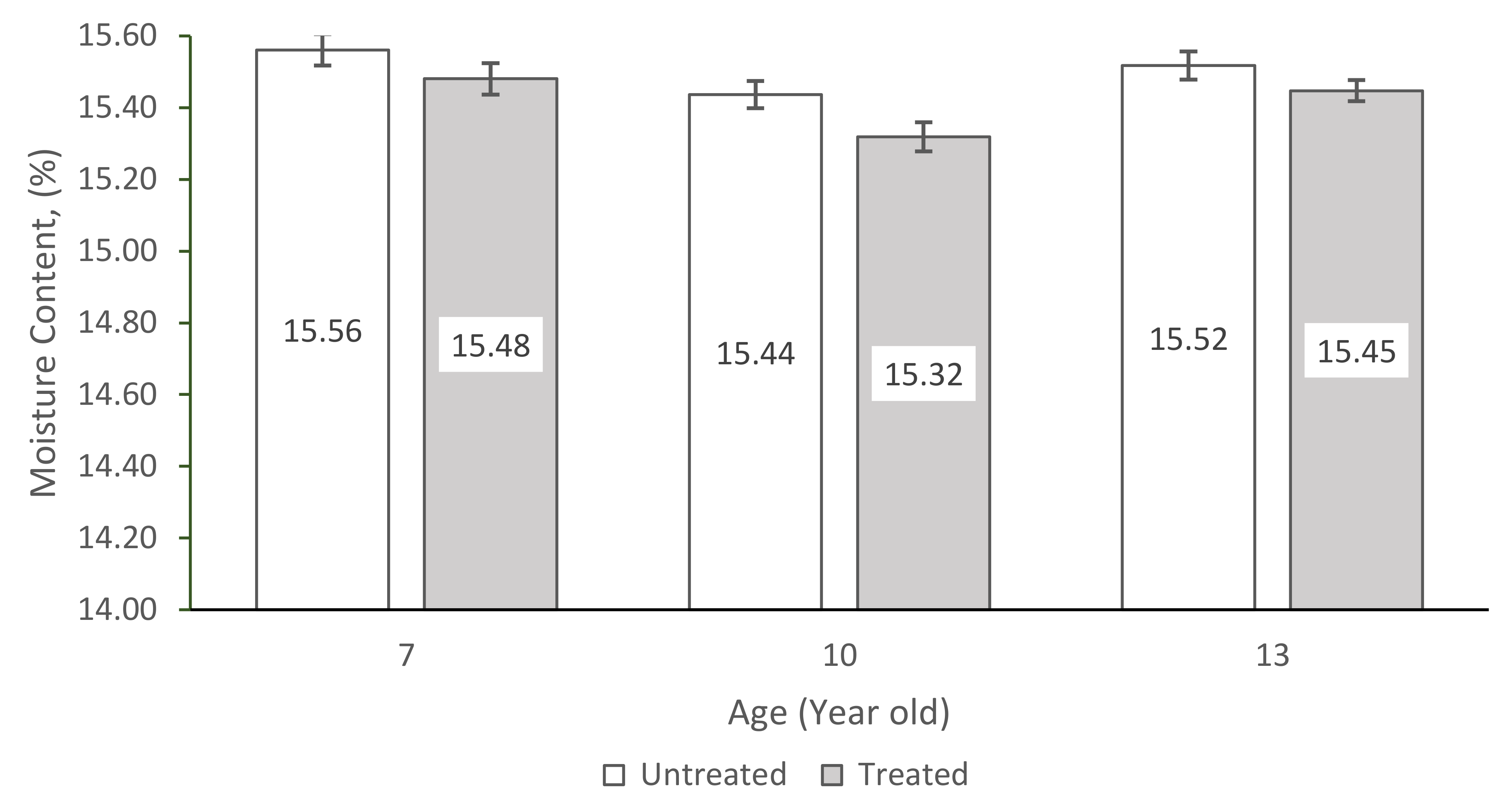

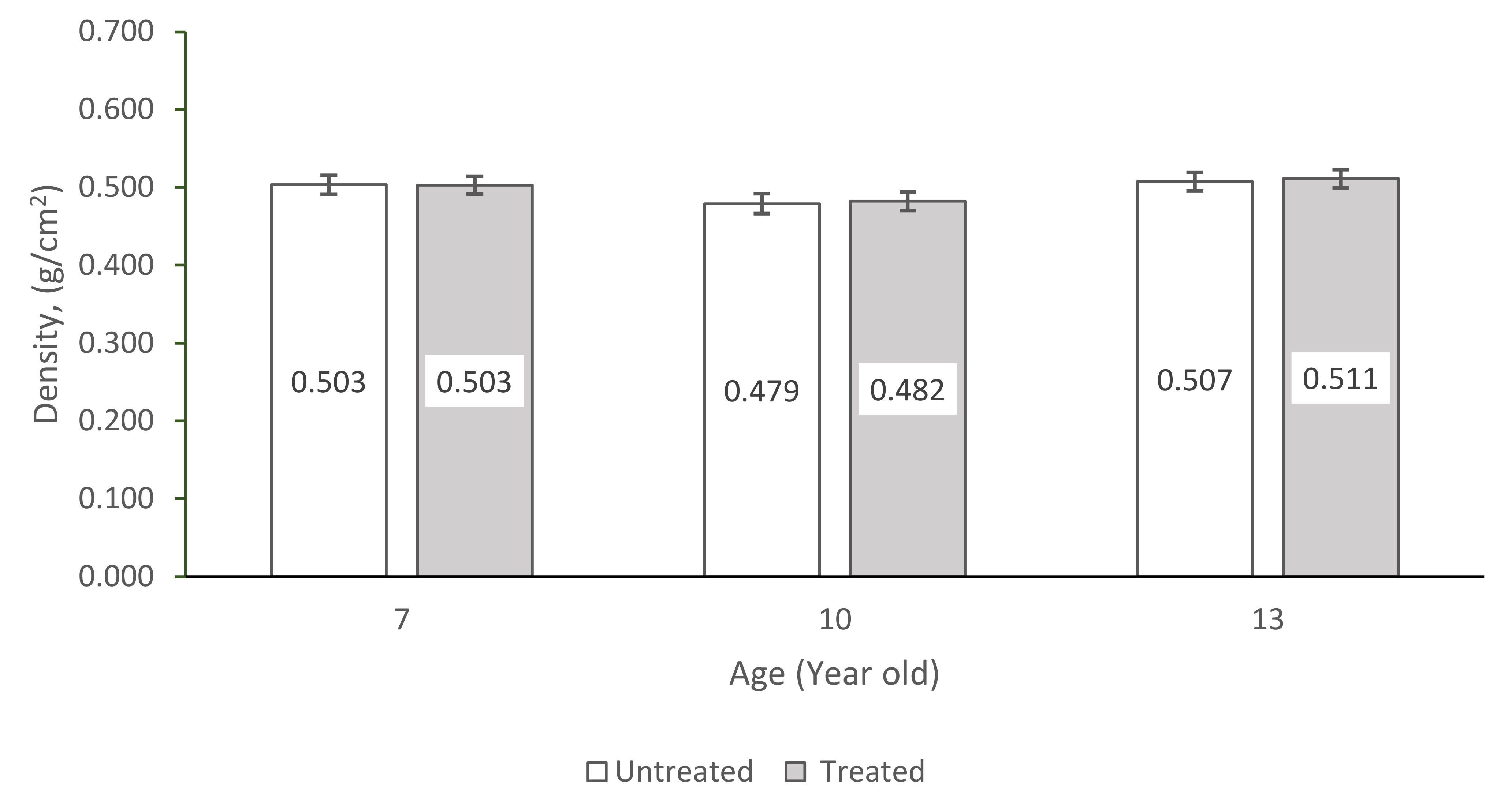

- The moisture content for the Acacia hybrid decreases when the sample is treated with an average 0.58% or 0.09% MC, whereas the treated 10-year-old sample recorded a higher mean value due to a decrement of 0.76% or 0.118% MC. The density of Acacia hybrid shows that, as a result of the sample being treated, the mean density increased with an average of 0.44% or 0.002 g/cm3, whereas the treated 13-year-old sample recorded a higher increment value of 0.74% or 0.004 g/cm3. Similarly, mechanical properties also increased with an average 6.18% increment of strength value when treated. Tension value recorded a huge average increment of 13.67% when treated.

- The tangential direction gives a high mean value in both untreated and treated samples for shear parallel to grain and cleavage. However, in terms of the percentage difference of strength increment from untreated to treated samples, radial direction samples show significant improvement where it recorded a higher percentage increment with an average of 3.02% or 0.5 MPa and 8.29% or 1.19 MPa for shear parallel to grain and cleavage, respectively. The 10-year-old age group sample showed a significant increment of strength in both the radial and tangential direction when treated, followed by 13-year-old and 7-year-old age group.

- Findings revealed that the mechanical and physical properties of Acacia hybrid obviously perform better in the 10-year-old age group, followed by the 13-year-old and 7-year-old age groups. It is demonstrated that the mechanical properties of Acacia hybrid serve better after being treated using CCA treatment.

- It is recommended that the air-dried 10-year-old Acacia hybrid is the most suitable with consistent physical property values and mechanical strength values in the shear parallel to grain at the tangential direction, cleavage in the tangential direction, and tension when treated with copper chrome arsenic (CCA) treatment. However, the radial direction selection can also be considered due to its greater percentage difference in strength increment when being treated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Davies, H.E. Timber: Structure, Properties. Conversion and Use, 7th ed.; Food Product Press: New York, NY, USA, 1996. [Google Scholar]

- Jumaat, M.Z.; Abdul Rahim, A.H.; Othman, J.; Razali, F.M. Timber engineering research and education in Malaysia. In Proceedings of the 9th World Conference on Timber Engineering 2006, WCTE, Portland, ON, USA, 6–10 August 2006. [Google Scholar]

- Ismaili, G.; Abu Bakar, B.H.; Duju, A.; Abdul Rahim, K.K.; Openg, I. Domination of Grain Bearing on The Strength Properties of Engkabang Jantong as Fast Growing Timber in Sarawak. Iran. J. Energy Environ. 2013, 4, 311–315. [Google Scholar] [CrossRef]

- Jusoh, I.; Zaharin, F.A.; Adam, N.S. Wood quality of Acacia hybrid and second-generation Acacia Mangium. BioResources 2014, 9, 150–160. [Google Scholar] [CrossRef]

- Kijkar, S.; Somyos, K. Part II, Species Description; Association of South-East Asian Nations (ASEAN) Forest Tree Seed Centre: Chiang Mai, Thailand, 2003. [Google Scholar]

- Sein, C.C.; Mitlöhner, R. Acacia Mangium Wild: Ecology and Silviculture in Vietnam; Center for International Forestry Research: Bogor Barat, Indonesia, 2011. [Google Scholar]

- Pinso, C.; Nasi, R. The Potential Use of Acacia Mangium x Acacia Auriculiformis Hybrid in Sabah. In Breeding Technologies for Tropical Acacias; Carron, L.T., Aken, K.M., Eds.; No. 37; Australian Centre for International Agricultural Research; Goanna Print Pty Ltd.: Canberra, Australia, 1992; pp. 17–21. [Google Scholar]

- Barry, K. Heartrots in Plantation Hardwoods in Indonesia and Australia; ACIAR Technical Reports No. 51e; Sun Photoset Pty Ltd.: Brisbane, Australia, 2002. [Google Scholar]

- Ng, C.H.; Lee, S.L.; Ng, K.K.S.; Muhammad, N.; Ratnam, W. Mating system and seed variation of Acacia hybrid (A. mangium x A. auriculiformis). J. Genet. 2009, 88, 25–31. [Google Scholar] [CrossRef] [PubMed]

- Choong, C.Y.; Yong, S.Y.C.; Cheong, P.L.; Pang, S.L.; Harikrishna, J.A.; Mat Isa, M.N.; Wickneswari, R. Analyses of ESTs Generated from Inner Bark Tissue of Acacia Hybrid. In Proceedings of the Acacia Research in Malaysia, Seminar on Current Updates on Acacia Genomics and Breeding 2005, Putrajaya, MA, USA, 12 July 2005. [Google Scholar]

- Sukganah, A.; Wickneswari, R.; Choong, C.Y. Full length cDNA for Cinnamoyl-CoA Reductase (CCR) and Caffeic Acid O-Methyltransferase (COMT) in Acacia mangium Willd. X Acacia auriculiformis Cunn. Ex Benth. Hybrid. In Proceedings of the Acacia Research in Malaysia, Seminar on Current Updates on Acacia Genomics and Breeding 2005, Putrajaya, MA, USA, 12 July 2005. [Google Scholar]

- Treza, C.J.; Hiroatsu, F.; Didit, N. The influence of High-Temperature and -Pressure Treatment on Physical Properties of Albizia falcataria Board. Forest 2022, 13, 239. [Google Scholar]

- Ismaili, G.; Roslani, R.; Abdul Rahim, K.K.; Duju, A.; Ismaili, Z.; Openg, I.; Ilias, M.N. Behaviour of Strength Properties of Fast-Growing Endospermum diadenum Species at Different Distance from the Vortex. Mater. Sci. 2017, 23, 254–259. [Google Scholar] [CrossRef][Green Version]

- Ling, W.C.; Wong, A.H.H. Tropical In-Ground Durability of Structural Sarawak Hardwoods Impregnated to High Retention with CCA-salts, CCA-oxide and FCAP after 20 Years Exposure; The International Research Group On Wood Protection, Wood Protecting Chemicals: Bangalore, India, 2005. [Google Scholar]

- Forest Products Laboratory. Air Drying of Lumber; General Technical Report—117; USDA Forest Service: Madison, WI, USA, 1999. [Google Scholar]

- Ismaili, G. Engineering Properties of Fast-Growing Indigenous Timber in Sarawak Compare to Acacia mangium: Aras. Int. J. Sci. Mod. Eng. 2015, 3, 8–12. [Google Scholar]

- Ismaili, G.; Abu Bakar, B.H.; Abdul Rahim, K.K. Basic and grade stress for some timber in Sarawak. J. Civ. Eng. Sci. Technol. 2011, 2, 35–38. [Google Scholar] [CrossRef]

- Gaddafi, I. Engineering Properties of Selected Sarawak Fast-Growing Indigenous Timber Species. Ph.D. Thesis, Universiti Sains Malaysia, Pulau Pinang, Malaysia, 2012. [Google Scholar]

- Ismaili, G.; Abdul Rahim, K.K.; Duju, A.; Openg, I.; Ismaili, Z. Strength Classification of Aras as Fast-Growing Indigenous Species Timber in Sarawak. Appl. Mech. Mater. 2014, 695, 617–621. [Google Scholar] [CrossRef]

- Pearson, R.G.; Kloot, N.H.; Boyd, J.D. Timber Engineering Design Handbook; Jacaranda Press Pty Ltd.: Melbourne, Australia, 1962. [Google Scholar]

- Tan, Y.E.; Lim, N.P.T.; Gan, K.S.; Wong, T.C.; Lim, S.C.; Thilagawathy, M. Testing Methods for Plantation Grown Tropical Timbers. ITTO Project on Improving Utilisation and Value Adding of Plantation Timbers from Sustainable Sources in Malaysia; FRIM: Selangor Malaysia, 2010. [Google Scholar]

- BS 373:1957; Methods of Testing Small Clear Specimens of Timber. British Standard Institution: London, UK, 1957.

- Winandy, J.E. Wood Properties; Arntzen, C.J., Ed.; Encyclopaedia of Agricultural Science; Academic Press: Orlando, FL, USA, 1994. [Google Scholar]

- Nur Emilia Azira, K.; Gaddafi, I. Strength Performance of Hevea Brasiliensis at Structural Size. Int. Adv. Res. J. Sci. Eng. Technol. 2015, 2, 144–147. [Google Scholar]

- Ferreira, B.S.; Silva, J.V.F.; Campos, C.I. Static bending strength of heat treated and chromated copper arsenate-treated plywood. BioResources 2017, 12, 6276–6282. [Google Scholar] [CrossRef]

- Epmeier, H.; Johansson, M.; Kliger, R.; Westin, M. Bending creep performance of modified timber. Holz Roh-Werkst 2007, 65, 343–351. [Google Scholar] [CrossRef]

- Bruno, E.; Lina, N.; Helena, P. Properties of furfurylated wood (Pinus pinaster). Eur. J. Wood Prod. 2011, 69, 521–525. [Google Scholar]

- Alik, D.; Naohiro, K. The relationship between basic density and mechanical strength properties of some Sarawak timber. In Proceedings of the TRTTC/STA Forest Product Seminar ‘96, TRTTC/STA, Kuching, Sarawak, 12–13 March 1996; pp. 117–126. [Google Scholar]

- Desch, H.E. Timber Its Structure Properties and Utilisation, 6th ed.; Timber Press: Forest Glove, ON, USA, 1981. [Google Scholar]

- Andy, W.C.L. Effect of CCA-Treating and Air-drying on the Properties of Southern Pine Lumber and Plywood. Wood Fiber Sci. 1985, 17, 209–213. [Google Scholar]

- Alik, D.; Lai, J.K.; Yang, M.C.; John, S. Properties and utilisation of three age groups of Acacia mangium planted in Sarawak 2015. In Proceedings of the International Science and Nature Congress 2015 (ISNaC), Kuala Lumpur, Malaysia, 21–23 September 2015. [Google Scholar]

- Riyanto, D.S.; Gupta, R. Effect of Ring Angle on Shear Strength Parallel to Grain of Wood. J. Forest Product 1995, 46, 87–92. [Google Scholar]

- McKenzie, W.M.C. Design of Structural Timber; McGraw-Hill: London, UK, 2000; pp. 2–3. [Google Scholar]

- Wallis, N.K. Australian Timber Handbook; Halstead Press: Sydney, Australia, 1970. [Google Scholar]

- Madsen, B.; Janzen, W.; Zwaagstra, T. Moisture Effects in Lumber; Structural Research Series Report No. 27; Department of Structural Engineering, U.B.C: Vancouver, BC, Canada, 1980. [Google Scholar]

- Mohd Jamil, A.W. Strength Assessment of Structural Size Malaysia Timbers. MSc, University of Malaya, Kuala Lumpur, Malaysia. 2013. Available online: http://studentsrepo.um.edu.my/8642/7/jamil.pdf (accessed on 7 October 2022).

- Ping, X. The Mechanical Properties and Stability of Radiata Pine Structural Timber. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 2000. [Google Scholar]

- Moya, R.; Muñoz, F. Physical and Mechanical Properties of Eight Fast-Growing Plantation Species in Costa Rica. Trop. Forest Sci. 2010, 22, 317–318. [Google Scholar]

| Condition | Unit | Controlled | Treated | |||||

|---|---|---|---|---|---|---|---|---|

| Age Groups | 7 | 10 | 13 | 7 | 10 | 13 | ||

| Mechanical properties | Shear parallel to grain (tangential) | Nos | 40 | 40 | 40 | 40 | 40 | 40 |

| MPa | 17.06 | 18.18 | 17.61 | 17.52 | 18.59 | 17.67 | ||

| SD | 1.55 | 1.85 | 2.62 | 1.85 | 1.86 | 2.17 | ||

| CV % | 9.1 | 10.18 | 14.91 | 10.55 | 10 | 12.3 | ||

| SE | 0.25 | 0.29 | 0.42 | 0.29 | 0.29 | 0.34 | ||

| 95% CI | 0.50 | 0.59 | 0.84 | 0.59 | 0.59 | 0.70 | ||

| Shear parallel to grain (radial) | Nos | 40 | 40 | 40 | 40 | 40 | 40 | |

| MPa | 16 | 17.46 | 16.62 | 16.78 | 17.92 | 16.88 | ||

| SD | 2.06 | 2.09 | 2.64 | 1.74 | 1.92 | 2.2 | ||

| CV % | 12.86 | 11.95 | 15.88 | 10.38 | 10.71 | 13.06 | ||

| SE | 0.33 | 0.33 | 0.42 | 0.28 | 0.30 | 0.35 | ||

| 95% CI | 0.66 | 0.67 | 0.84 | 0.56 | 0.61 | 0.71 | ||

| Cleavage (tangential) | Nos | 40 | 40 | 40 | 40 | 40 | 40 | |

| N/mm | 15.82 | 17.66 | 16.19 | 16.69 | 18.12 | 16.86 | ||

| SD | 2.68 | 2.52 | 1.98 | 2.27 | 3.16 | 2.1 | ||

| CV % | 16.94 | 14.29 | 12.21 | 13.62 | 17.43 | 12.43 | ||

| SE | 0.42 | 0.40 | 0.31 | 0.36 | 0.50 | 0.33 | ||

| 95% CI | 0.85 | 0.80 | 0.63 | 0.72 | 1.00 | 0.66 | ||

| Cleavage (Radial) | Nos | 40 | 40 | 40 | 40 | 40 | 40 | |

| N/mm | 13.67 | 15 | 14.19 | 14.61 | 16.41 | 15.41 | ||

| SD | 2.57 | 2.09 | 2.16 | 2.75 | 2.75 | 1.68 | ||

| CV % | 18.78 | 13.9 | 15.18 | 18.79 | 16.77 | 10.91 | ||

| SE | 0.41 | 0.33 | 0.34 | 0.43 | 0.44 | 0.27 | ||

| 95% CI | 0.81 | 0.66 | 0.68 | 0.87 | 0.87 | 0.53 | ||

| Tension parallel to grain | Nos | 40 | 40 | 40 | 40 | 40 | 40 | |

| MPa | 141.8 | 148.99 | 144.19 | 158.4 | 176.44 | 160.26 | ||

| SD | 24.26 | 22.33 | 17.49 | 17.56 | 27.08 | 11.94 | ||

| CV % | 17.11 | 14.99 | 12.13 | 11.08 | 15.35 | 7.45 | ||

| SE | 3.84 | 3.53 | 2.77 | 2.78 | 4.28 | 1.89 | ||

| 95% CI | 7.67 | 7.06 | 5.53 | 5.55 | 8.56 | 3.78 | ||

| Condition | Unit | Controlled | Treated | |||||

|---|---|---|---|---|---|---|---|---|

| Age Groups | 7 | 10 | 13 | 7 | 10 | 13 | ||

| Physical properties | Moisture content | Nos | 200 | 200 | 200 | 200 | 200 | 200 |

| % | 15.56 | 15.44 | 15.52 | 15.48 | 15.32 | 15.45 | ||

| SD | 0.31 | 0.27 | 0.28 | 0.31 | 0.29 | 0.20 | ||

| CV % | 2.01 | 1.74 | 1.80 | 1.99 | 1.87 | 1.32 | ||

| SE | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.01 | ||

| 95% CI | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.03 | ||

| Density | Nos | 200 | 200 | 200 | 200 | 200 | 200 | |

| g/cm3 | 0.503 | 0.479 | 0.507 | 0.503 | 0.482 | 0.511 | ||

| SD | 0.09 | 0.09 | 0.08 | 0.08 | 0.08 | 0.08 | ||

| CV % | 17.03 | 18.83 | 16.67 | 15.91 | 17.37 | 16.42 | ||

| SE | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | ||

| 95% CI | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | ||

| Age Group | Treatment Condition | Shear Parallel to Grain Direction | Age Groups | Treatment Condition (UT, TD) | Significant Difference p-Values |

|---|---|---|---|---|---|

| 10 | UT | T | 7 | UT | 0.0044 * |

| 10 | TD | 0.3157 ns | |||

| 13 | UT | 0.2687 ns | |||

| R | 7 | UT | 0.0023 * | ||

| 10 | TD | 0.3040 ns | |||

| 13 | UT | 0.1191 ns | |||

| TD | T | 7 | TD | 0.0112 * | |

| 13 | TD | 0.0432 * | |||

| R | 7 | TD | 0.0067 * | ||

| 13 | TD | 0.0275 * | |||

| Number of frequencies having condition statistically significant difference (p < 0.05), % | 60.0 | ||||

| Age Group | Treatment Condition | Cleavage to Grain Direction | Age Groups | Treatment Condition (UT, TD) | Significant Difference p-Values |

|---|---|---|---|---|---|

| 10 | UT | T | 7 | UT | 0.0023 * |

| 10 | TD | 0.4788 ns | |||

| 13 | UT | 0.0046 * | |||

| R | 7 | UT | 0.0128 * | ||

| 10 | TD | 0.0117 * | |||

| 13 | UT | 0.0921 ns | |||

| TD | T | 7 | TD | 0.0227 * | |

| 13 | TD | 0.0383 * | |||

| R | 7 | TD | 0.0045 * | ||

| 13 | TD | 0.0527 ns | |||

| Number of frequencies having condition statistically significant difference (p < 0.05), % | 70.0 | ||||

| Age Group | Treatment Condition | Age Groups | Treatment Condition (UT, TD) | Significant Difference p-Values |

|---|---|---|---|---|

| 10 | UT | 7 | UT | 0.1719 ns |

| 10 | TD | 0.0000 * | ||

| 13 | UT | 0.2879 ns | ||

| TD | 7 | TD | 0.0007 * | |

| 13 | TD | 0.0009 * | ||

| Number of frequencies having condition statistically significant difference (p < 0.05), % | 60.0 | |||

| Engineering Properties | Mean Value for Untreated Sample | Unit | Age of Sample Factor, Yi | Mean Value for Treated Sample with 10% CCA | |||

|---|---|---|---|---|---|---|---|

| Y7 | Y10 | Y13 | |||||

| Physical properties (Air-dry) | MCC | Moisture content | % | 0.995 | 0.992 | 0.996 | MCC × Yi |

| DC | Density | g/cm3 | 0.999 | 1.006 | 1.007 | DC × Yi | |

| Strength Properties (Air-dry) | S//TC | Shear Parallel to Grain (Tangential) | MPa | 1.027 | 1.023 | 1.003 | S//TC × Yi |

| S//RC | Shear Parallel to Grain (Radial) | MPa | 1.049 | 1.026 | 1.016 | S//RC × Yi | |

| TC | Tension | MPa | 1.117 | 1.184 | 1.111 | TC × Yi | |

| CLTC | Cleavage (Tangential) | N/mm | 1.055 | 1.026 | 1.041 | CLTC × Yi | |

| CLRC | Cleavage (Radial) | N/mm | 1.069 | 1.094 | 1.086 | CLRC × Yi | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ismaili, G.; Enduat, E.; Yahya, N.S.; Malek, F.M.; Jaimudin, N.A.; Abdul Rahim, K.K.; Wasli, M.E.; Kalu, M.; Openg, I.; Rizalman, A.N.; et al. Physical and Mechanical Properties Performance between Untreated and Treated with CCA Treatment at Different Age Groups of Fast-Growing Acacia Hybrid of Sarawak. Forests 2022, 13, 1969. https://doi.org/10.3390/f13121969

Ismaili G, Enduat E, Yahya NS, Malek FM, Jaimudin NA, Abdul Rahim KK, Wasli ME, Kalu M, Openg I, Rizalman AN, et al. Physical and Mechanical Properties Performance between Untreated and Treated with CCA Treatment at Different Age Groups of Fast-Growing Acacia Hybrid of Sarawak. Forests. 2022; 13(12):1969. https://doi.org/10.3390/f13121969

Chicago/Turabian StyleIsmaili, Gaddafi, Ellyne Enduat, Nur Syahina Yahya, Fanthy Moola Malek, Noor Azland Jaimudin, Khairul Khuzaimah Abdul Rahim, Mohd Effendi Wasli, Meekiong Kalu, Iskanda Openg, Ahmad Nurfaidhi Rizalman, and et al. 2022. "Physical and Mechanical Properties Performance between Untreated and Treated with CCA Treatment at Different Age Groups of Fast-Growing Acacia Hybrid of Sarawak" Forests 13, no. 12: 1969. https://doi.org/10.3390/f13121969

APA StyleIsmaili, G., Enduat, E., Yahya, N. S., Malek, F. M., Jaimudin, N. A., Abdul Rahim, K. K., Wasli, M. E., Kalu, M., Openg, I., Rizalman, A. N., Liam, J., & Razali, B. (2022). Physical and Mechanical Properties Performance between Untreated and Treated with CCA Treatment at Different Age Groups of Fast-Growing Acacia Hybrid of Sarawak. Forests, 13(12), 1969. https://doi.org/10.3390/f13121969