Durability and Fire Performance of Charred Wood Siding (Shou Sugi Ban)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Durability Tests

2.3. Flammability Tests

3. Results and Discussion

3.1. Durability Tests

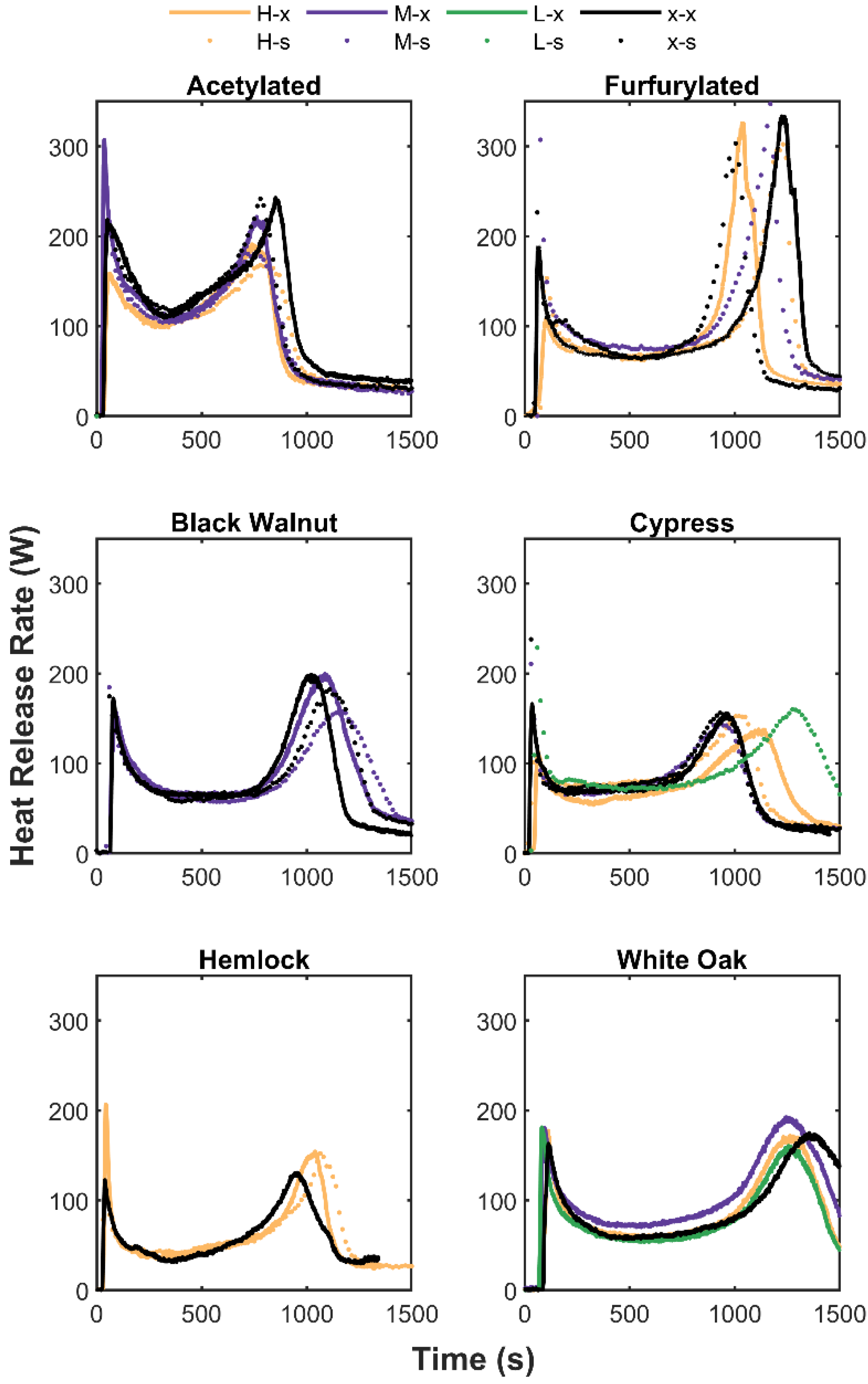

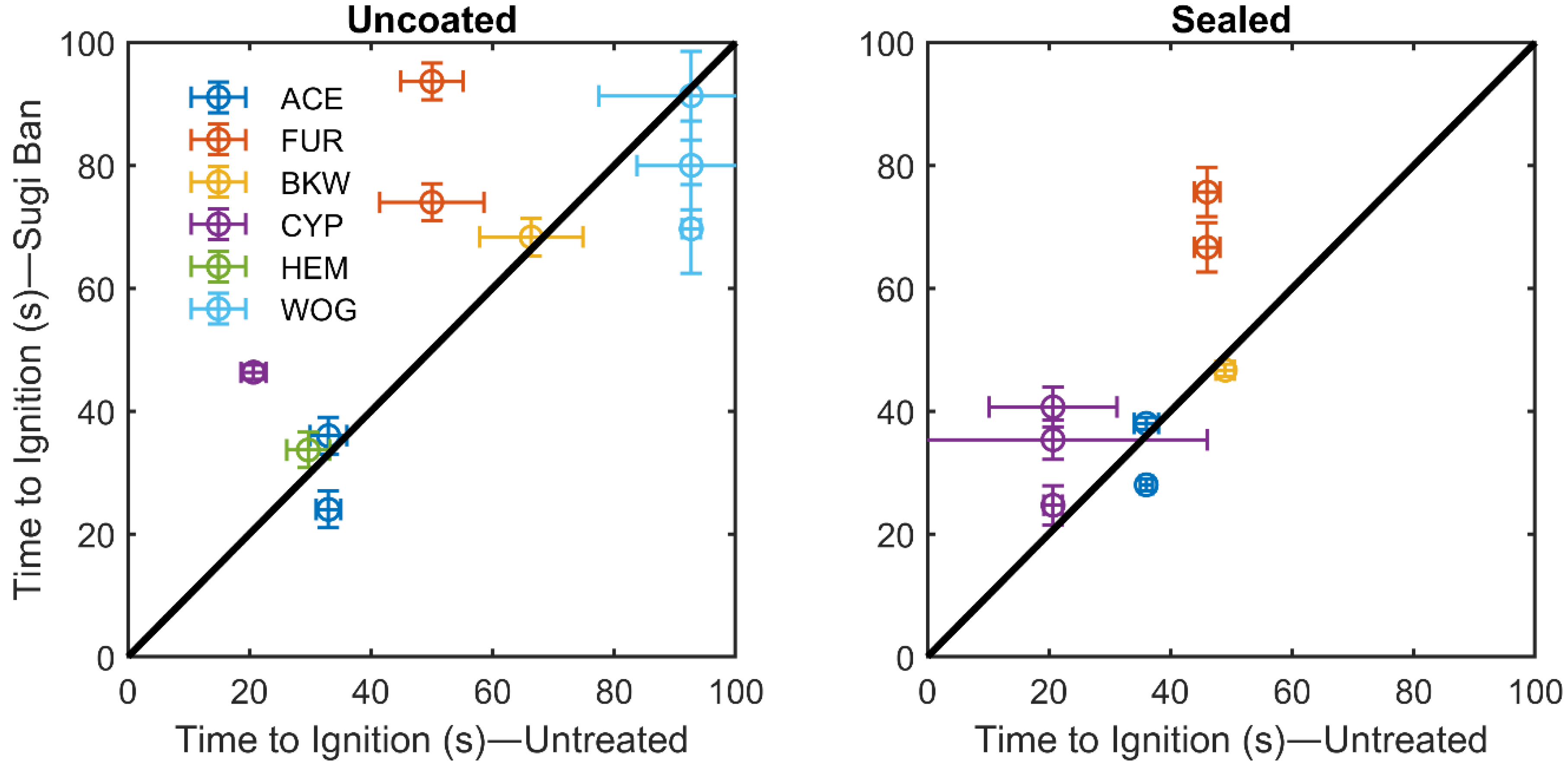

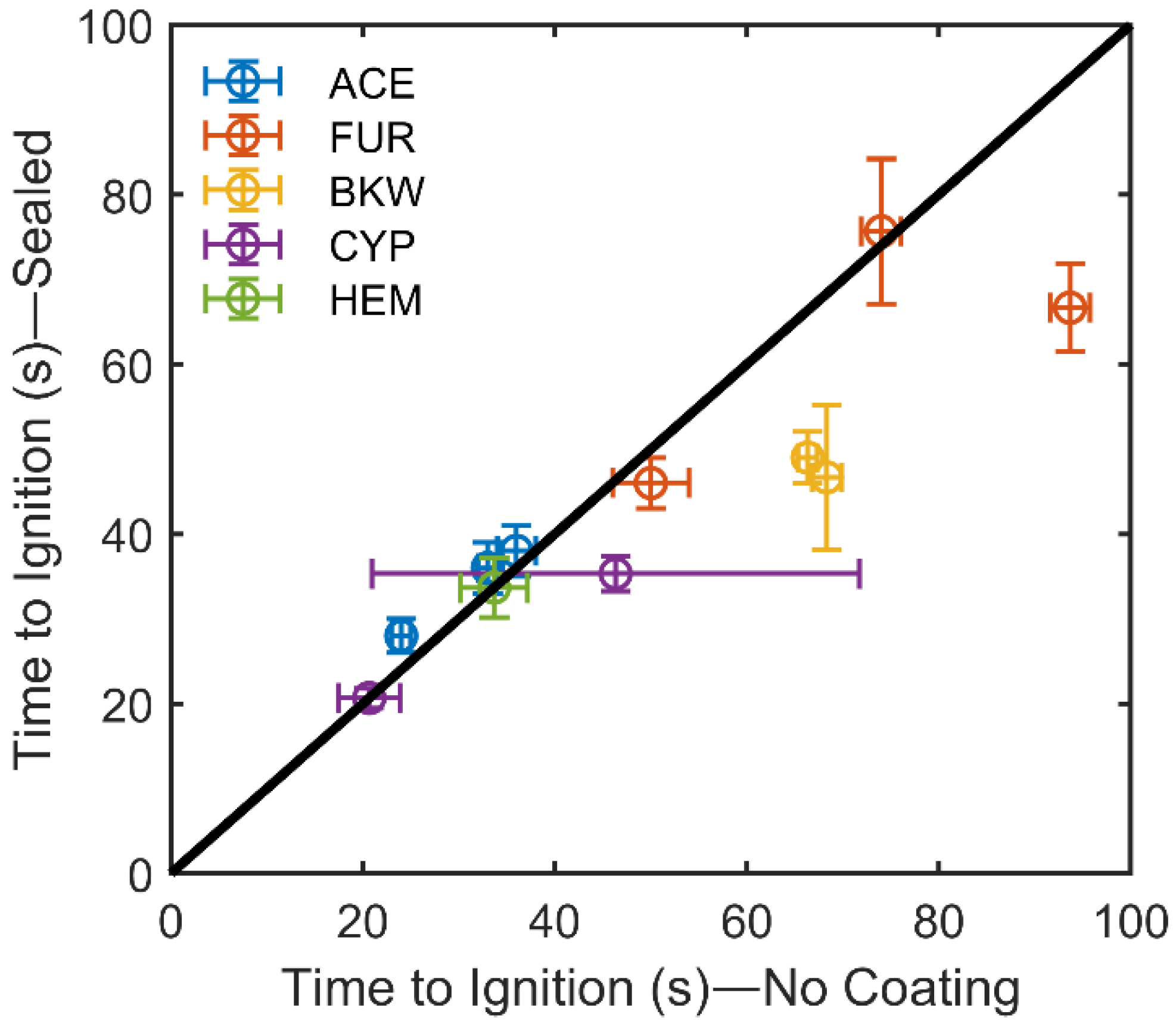

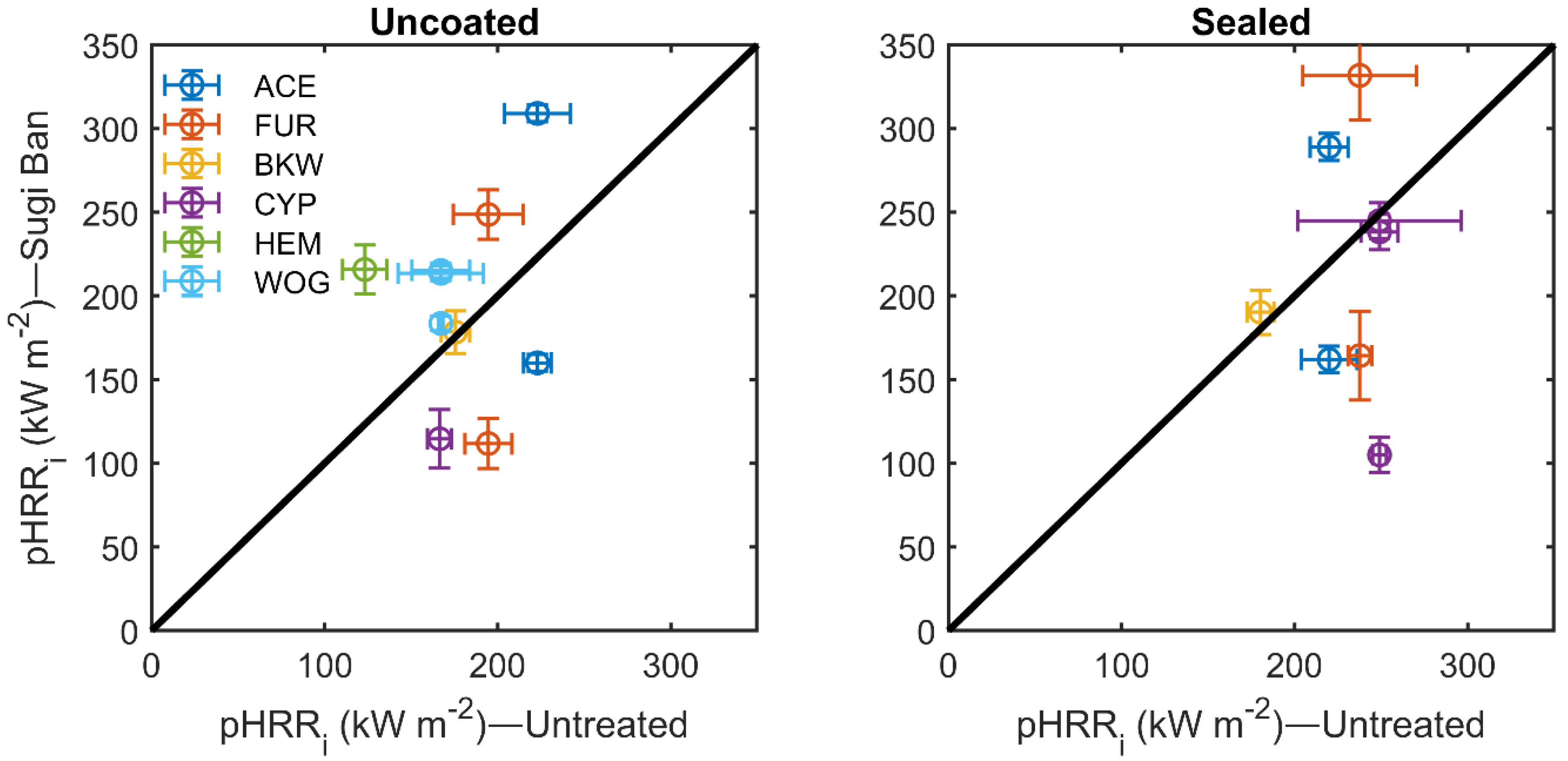

3.2. Flammability Tests

3.2.1. Time to Ignition

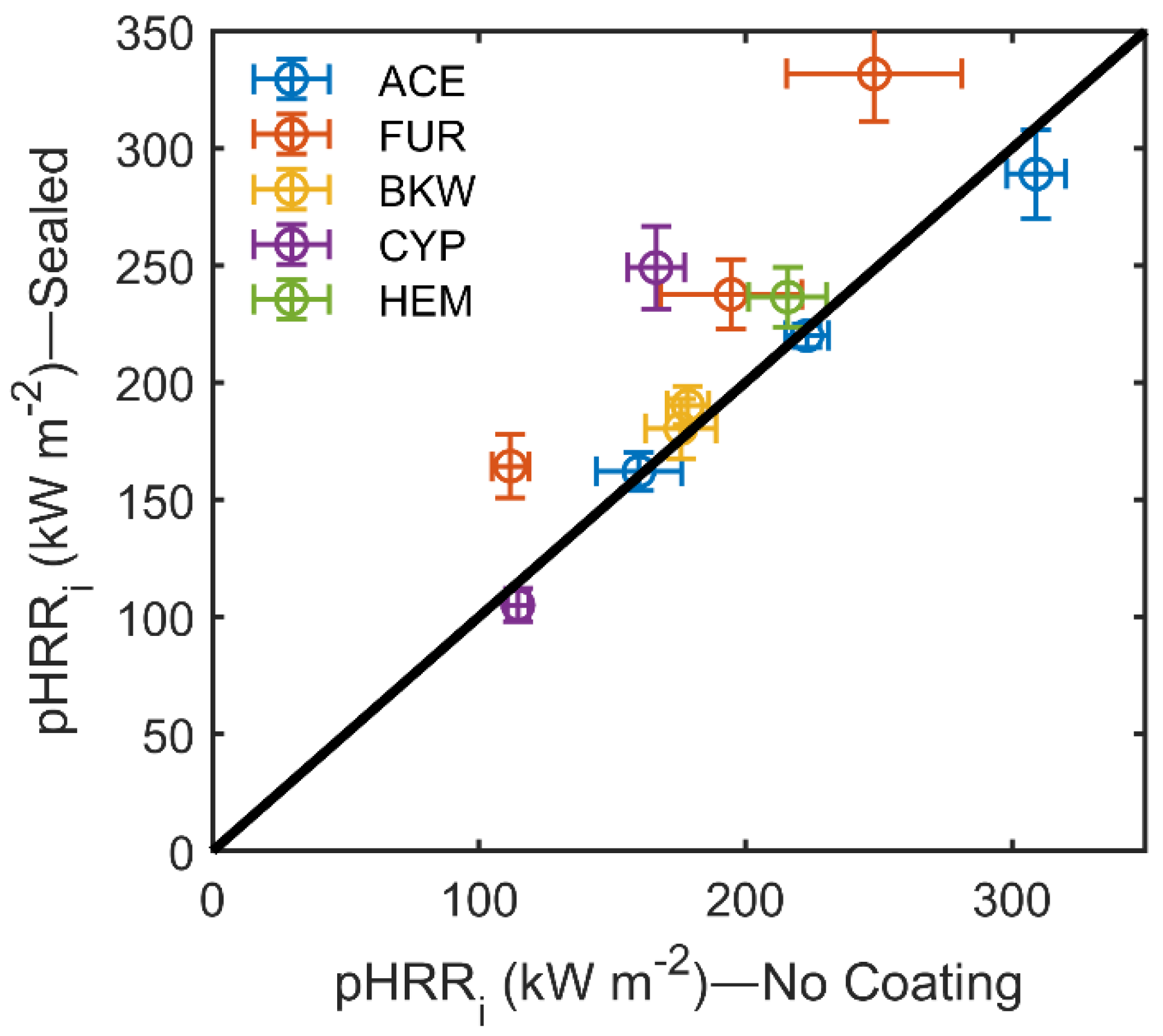

3.2.2. Initial Peak Heat Release Rate

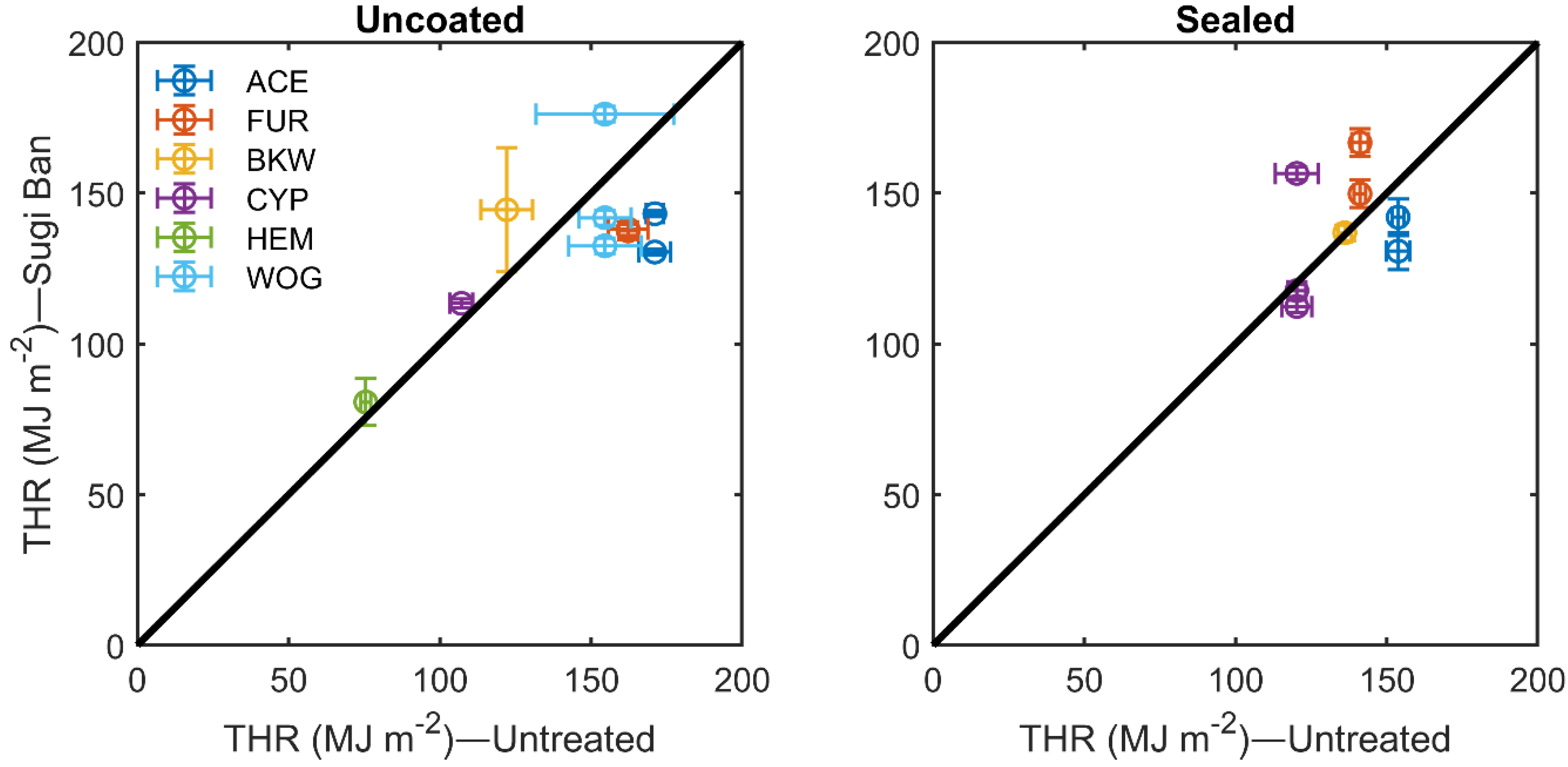

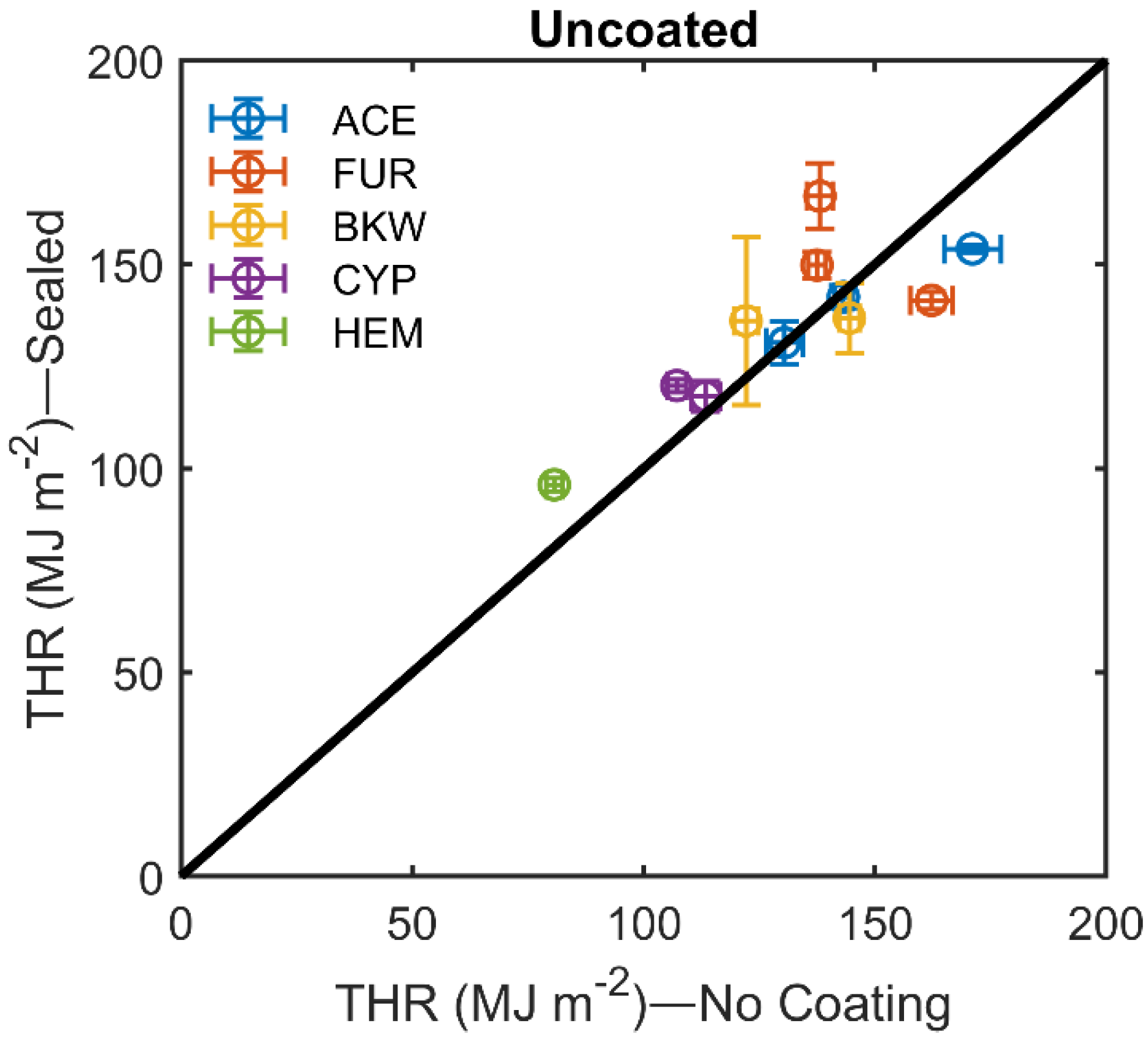

3.2.3. Total Heat Release

3.2.4. Summary of Flammability Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kilian, T. Shou-Sugi-Ban. Wood Des. Build. 2014, 66, 42–44. [Google Scholar]

- Miller, H. Japanese Wood Craftsmanship. Winston Churchill Memorial Fellowship Final Report; Hugh Miller Furniture Company: Liverpool, UK, 2016; Available online: https://www.hughmillerfurniture.co.uk/blog/japanese-wood-craftsmanship/ (accessed on 10 September 2021).

- Hein, C. Shaping Tokyo: Land development and planning practice in the early modern Japanese metropolis. J. Urban. Hist. 2010, 36, 447–484. [Google Scholar] [CrossRef] [Green Version]

- Graham, R.D. Service Life of Treated and Untreated Fence Posts: 1952 Progress Report on the TJ Starker Post Farm; Progress Report 6. Project 29; Oregon Forest Products Laboratory: Corvallis, OR, USA, 1952. [Google Scholar]

- White, R.H.; Dietenberger, M.A. Wood Handbook, Chapter 18: Fire Safety of Wood Construction; Department of Agriculture: Madison, WI, USA, 2010.

- Friquin, K.L. Charring rates of heavy timber structures for Fire Safety Design: A study of the charring rates under various fire exposures and the influencing factors. Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2010. Available online: https://ntnuopen.ntnu.no/ntnu-xmlui/bitstream/handle/11250/231578/357755_FULLTEXT02.pdf?sequence=1 (accessed on 10 September 2021).

- Schaffer, E.L. Charring Rate of Selected Woods—Transverse to Grain; DTIC Document: Madison, WI, USA, 1967; Available online: https://www.fpl.fs.fed.us/documnts/fplrp/fplrp69.pdf (accessed on 10 September 2021).

- White, R.H. Charring Rates of Different Wood Species. Ph.D. Thesis, University of Wisconsin—Madison, Madison, WI, USA, 1988. [Google Scholar]

- White, R.H.; Nordheim, E.V. Charring rate of wood for ASTM E 119 exposure. Fire Technol. 1992, 28, 5–30. [Google Scholar] [CrossRef]

- White, R.H.; Tran, H.C. Charring rate of wood exposed to a constant heat flux. In Wood and Fire Safety: 3rd International Scientific Conference: Proceedings, Zvolen, Slovak Republic, 6–9 May 1996; Technical University of Zvolen, Faculty of Wood Technology: Zvolen, Slovak Republic, 1996; pp. 175–183. Available online: https://www.fs.usda.gov/treesearch/pubs/5978 (accessed on 10 September 2021).

- Bartlett, A.I.; Hadden, R.M.; Bisby, L.A. A Review of Factors Affecting the Burning Behaviour of Wood for Application to Tall Timber Construction. Fire Technol. 2019, 55, 1–49. [Google Scholar] [CrossRef] [Green Version]

- Schaffer, E.L. Review of Information Related to the Charring Rate of Wood; Forest Products Laboratory: Madison, WI, USA, 1966; Volume 145. [Google Scholar]

- Janssens, M.L.; White, R.H. Short communication: Temperature profiles in wood members exposed to fire. Fire Mater. 1994, 18, 263–265. [Google Scholar] [CrossRef]

- Bartlett, A.; Hadden, R.; Bisby, L.; Law, A. Analysis of cross-laminated timber charring rates upon exposure to non-standard heating conditions. Fire Mater. 2015, 661–687. Available online: http://www.intersciencecomms.co.uk/html/conferences/fm/fm15/fm15.htm (accessed on 10 September 2021).

- Fortini, A.P. Shou Sugi Ban: Black and Burned Wood. The New York Times Style Magazine, 19 September 2017. Available online: https://digitalscholarship.unlv.edu/english_fac_articles/149/ (accessed on 10 September 2021).

- Hill, C.A. Wood Modification: Chemical, Thermal and Other Processes; John Wiley & Sons: Chichester, UK, 2007; Volume 5. [Google Scholar]

- Tjeerdsma, B.; Boonstra, M.; Pizzi, A.; Tekely, P.; Militz, H. Characterisation of thermally modified wood: Molecular reasons for wood performance improvement. Holz Als Roh-Und Werkst. 1998, 56, 149. [Google Scholar] [CrossRef]

- Militz, H.; Altgen, M. Processes and properties of thermally modified wood manufactured in Europe. In Deterioration and Protection of Sustainable Biomaterials; ACS Publications: Washington, DC, USA, 2014; pp. 269–285. [Google Scholar]

- Candelier, K.; Thevenon, M.-F.; Petrissans, A.; Dumarcay, S.; Gerardin, P.; Petrissans, M. Control of wood thermal treatment and its effects on decay resistance: A review. Ann. For. Sci. 2016, 73, 571–583. [Google Scholar] [CrossRef] [Green Version]

- Čermák, P.; Dejmal, A.; Paschová, Z.; Kymäläinen, M.; Dömény, J.; Brabec, M.; Hess, D.; Rautkari, L. One-sided surface charring of beech wood. J. Mater. Sci. 2019, 54, 9497–9506. [Google Scholar] [CrossRef]

- Kymäläinen, M.; Turunen, H.; Čermák, P.; Hautamäki, S.; Rautkari, L. Sorption-related characteristics of surface charred spruce wood. Materials 2018, 11, 2083. [Google Scholar] [CrossRef] [Green Version]

- Kymäläinen, M.; Hautamäki, S.; Lillqvist, K.; Segerholm, K.; Rautkari, L. Surface modification of solid wood by charring. J. Mater. Sci. 2017, 52, 6111–6119. [Google Scholar] [CrossRef]

- Kymäläinen, M.; Turunen, H.; Rautkari, L. Effect of Weathering on Surface Functional Groups of Charred Norway Spruce Cladding Panels. Forests 2020, 11, 1373. [Google Scholar] [CrossRef]

- Machová, D.; Oberle, A.; Zárybnická, L.; Dohnal, J.; Šeda, V.; Dömény, J.; Vacenovská, V.; Kloiber, M.; Pěnčík, J.; Tippner, J. Surface Characteristics of One-Sided Charred Beech Wood. Polymers 2021, 13, 1551. [Google Scholar] [CrossRef] [PubMed]

- Akizuki, M.; Hasemi, Y.; Yasui, N.; Kinoshita, K.; Yammamoto, K.; Yoshida, M.; Tamura, Y.; Takeda, M. Fire Safety Studies In The Restoration Of A Historic Wooden Townhouse In Kyoto-Fire Safety Experiments On Japanese Traditional Wood-Based Constructions. Fire Saf. Sci. 2001, 5, 329–340. [Google Scholar]

- Kirker, G.T.; Lebow, S. Chapter 15. Wood Preservation. In Wood Handbook—Wood as an Engineering Material; Ross, R.J., Ed.; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2021; 508p. [Google Scholar]

- Lowden, L.A.; Hull, T.R. Flammability behaviour of wood and a review of the methods for its reduction. Fire Sci. Rev. 2013, 2, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Anonymous. AWPA E-10: Standard Method for Testing of Wood Preservatives by Laboratory Soil-block Cultures; American Wood Protection Association: Selma, AL, USA, 2012. [Google Scholar]

- Kerem, Z.; Jensen, K.A.; Hammel, K.E. Biodegradative mechanism of the brown rot basidiomycete Gloeophyllum trabeum: Evidence for an extracellular hydroquinone-driven fenton reaction. Febs Lett. 1999, 446, 49–54. [Google Scholar] [CrossRef] [Green Version]

- Anonymous. ASTM E1354-17: “Standard Test Method for Heat and Visible Smoke Release Rates for Materials and Products Using an Oxygen Consumption Calorimeter”; American Society for Testing and Materials: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Parker, W.J. Calculations of the Heat Release Rate by Oxygen Consumption for Various Applications. J. Fire Sci. 1984, 2, 380–395. [Google Scholar] [CrossRef]

- Kirker, G.; Blodgett, A.; Arango, R.; Lebow, P.; Clausen, C. The role of extractives in naturally durable wood species. Int. Biodeterior. Biodegrad. 2013, 82, 53–58. [Google Scholar] [CrossRef]

- Freeman, M.A.; McIntyre, C.R. A comprehensive review of copper-based wood preservatives with a focus on new micronized or dispersed copper systems. For. Prod. J. 2008, 58, 6–27. [Google Scholar]

- Lebow, S.; Lebow, P.; Woodward, B.; Kirker, G.; Arango, R. Fifty-year durability evaluation of posts treated with industrial wood preservatives. For. Prod. J. 2015, 65, 307–313. [Google Scholar] [CrossRef]

- Lebow, S.; Woodward, B.; Kirker, G.; Lebow, P. Long-term durability of pressure-treated wood in a severe test site. Adv. Civ. Eng. Mater. 2013, 2, 178–188. [Google Scholar] [CrossRef]

- Alfredsen, G.; Pilgård, A.; Fossdal, C.G. Characterisation of Postia placenta colonisation during 36 weeks in acetylated southern yellow pine sapwood at three acetylation levels including genomic DNA and gene expression quantification of the fungus. Holzforschung 2016, 70, 1055–1065. [Google Scholar] [CrossRef] [Green Version]

- Peterson, M.; Thomas, R. Protection of wood from decay fungi by acetylation—An ultrastructural and chemical study. Wood Fiber Sci. 1978, 10, 149–163. [Google Scholar]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies—A review. Iforest-Biogeosci. For. 2017, 10, 895–908. [Google Scholar] [CrossRef] [Green Version]

- Esteves, B.; Nunes, L.; Pereira, H. Properties of furfurylated wood (Pinus pinaster). Eur. J. Wood Wood Prod. 2011, 69, 521–525. [Google Scholar] [CrossRef]

- Venås, T.M. A Study of Mechanisms Related to the Fungal Decay Protection Rendered by Wood Furfurylation. Ph.D. Thesis, University of Copenhagen, Copenhagen, Denmark, 2008. [Google Scholar]

- Rapp, A.O.; Brischke, C.; Welzbacher, C.R.; Jazayeri, L. Increased resistance of thermally modified Norway spruce timber (TMT) against brown rot decay by Oligoporus placenta—A study on the mode of protective action. Wood Res. 2008, 53, 13–25. [Google Scholar]

- White, R.H.; Dietenberger, M.A. Cone calorimeter evaluation of wood products. In Proceedings of the Conference on Recent Advances in Flame Retardancy of Polymeric Materials, Stamford, CT, USA, 6–9 June 2004; Applications, research and industrial development, markets; Business Communications Company, Inc.: Norwalk, CT, USA, 2004; Volume XV, pp. 331–342. [Google Scholar]

- Grexa, O.; Lübke, H. Flammability parameters of wood tested on a cone calorimeter. Polym. Degrad. Stab. 2001, 74, 427–432. [Google Scholar] [CrossRef]

- LeVan, S.L.; Tran, H.C. The role of boron in flame-retardant treatments. In Proceedings of the First International Conference on Wood Protection with Diffusible Preservatives, Nashville, TN, USA, 28–30 November 1990; Forest Products Research Society: Madison, WI, USA, 1990; pp. 39–41. [Google Scholar]

| Title 1 | Char Levels (1) | Coatings (2) |

|---|---|---|

| Acetylated (ACE) | x, M, H | x, S |

| Black Walnut (BKW) | x, M | x, S |

| Cypress (CYP) | x, L, M, H | x, S |

| Hemlock (HEM) | x, H | x, S |

| Furfurylated (FUR) | x, M, H | x, S |

| White Oak (WOG) | x, M | x, S |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasburgh, L.E.; Zelinka, S.L.; Bishell, A.B.; Kirker, G.T. Durability and Fire Performance of Charred Wood Siding (Shou Sugi Ban). Forests 2021, 12, 1262. https://doi.org/10.3390/f12091262

Hasburgh LE, Zelinka SL, Bishell AB, Kirker GT. Durability and Fire Performance of Charred Wood Siding (Shou Sugi Ban). Forests. 2021; 12(9):1262. https://doi.org/10.3390/f12091262

Chicago/Turabian StyleHasburgh, Laura E., Samuel L. Zelinka, Amy B. Bishell, and Grant T. Kirker. 2021. "Durability and Fire Performance of Charred Wood Siding (Shou Sugi Ban)" Forests 12, no. 9: 1262. https://doi.org/10.3390/f12091262

APA StyleHasburgh, L. E., Zelinka, S. L., Bishell, A. B., & Kirker, G. T. (2021). Durability and Fire Performance of Charred Wood Siding (Shou Sugi Ban). Forests, 12(9), 1262. https://doi.org/10.3390/f12091262