Pine Logs Sorting as a Function of Bark Thickness

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. Results of the Log Diameter Measurements

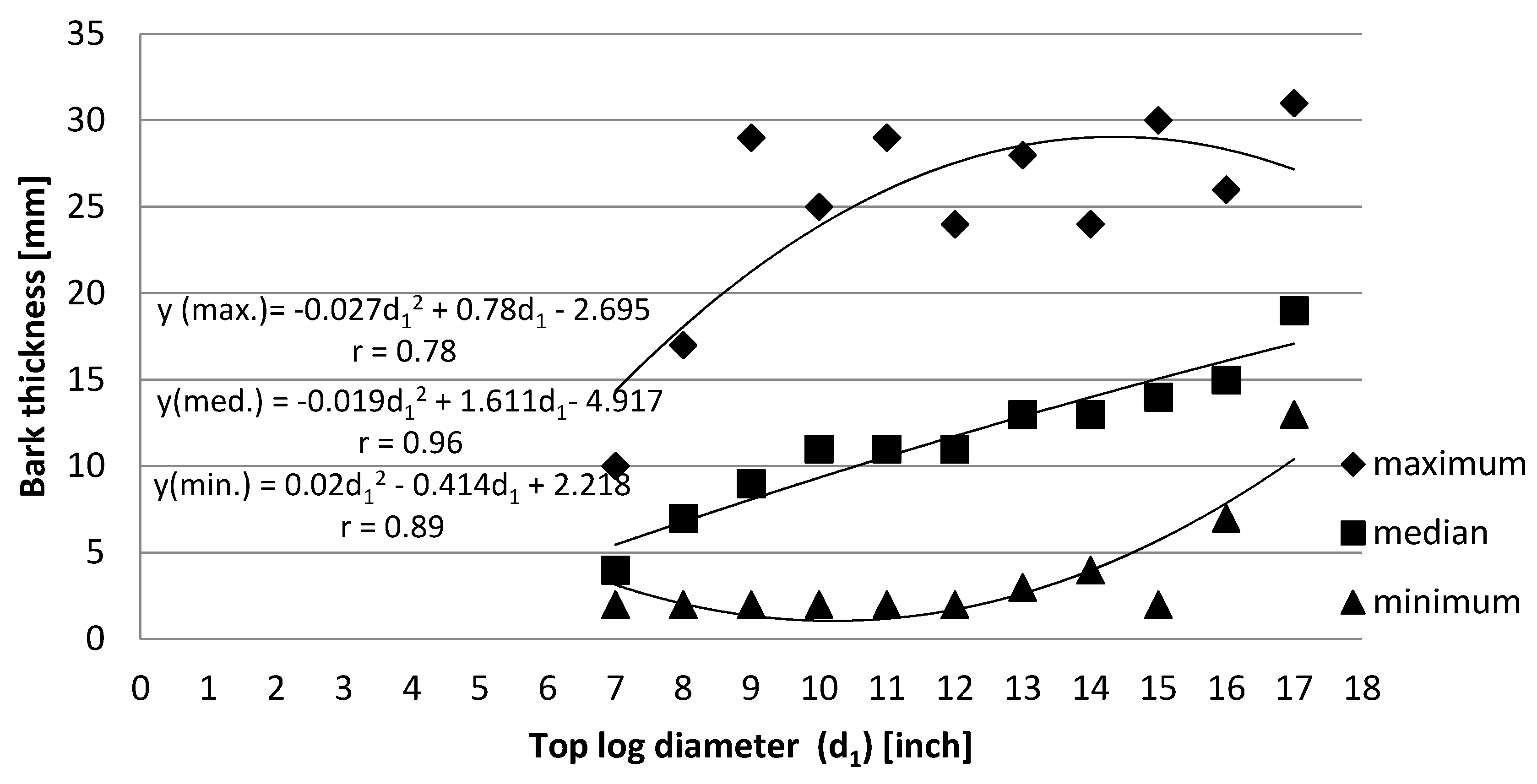

3.2. Analysis of the Bark Thickness

4. Discussion

5. Conclusions

- ▪

- The highest accuracy of automatic sorting is achieved in the boundary diametral ranges as a result of having wider ranges of diameters assigned and the lower dispersion of values in the results of the bark thickness;

- ▪

- The sorting accuracy in individual ranges is affected by significant differences between the actual thickness of the bark and the applied constant values of the deduction. The adoption of uncorrected normative values reduces the quality of sorting wood raw material by affecting the sorting accuracy;

- ▪

- Studies have shown that as the diameter of pine logs increases, the variation in bark thickness values also increases;

- ▪

- Defects occurring in the structure of wood, such as curvature, knots, and knobs, are the factors affecting the diameter measurement’s accuracy;

- ▪

- Applying the corrected values for the bark deduction when measuring the diameter of logs has a direct impact on the quality of automatic sorting and the final design of sawmill sawing programs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Berglund, A.; Broman, O.; Grönlund, A.; Fredriksson, M. Improved Log Rotation Using Information from a Computed Tomography Scanner. Comput. Electron. Agric. 2013, 90, 152–158. [Google Scholar] [CrossRef]

- Gazo, R.; Benes, B. Computed Tomography Log Scanning: An Industrial Application. In Proceedings of the 4th International Scientific Conference on Hardwood Processing, Florence, Italy, 7–9 October 2013; pp. 140–147. [Google Scholar]

- Oja, J.; Grundberg, S.; Fredriksson, J.; Berg, P. Automatic Grading of Sawlogs: A Comparison between X-Ray Scanning, Optical Three-Dimensional Scanning and Combinations of Both Methods. Scand. J. For. Res. 2004, 19, 89–95. [Google Scholar] [CrossRef]

- Van der Jeught, S.; Dirckx, J.J. Real-Time Structured Light Profilometry: A Review. Opt. Lasers Eng. 2016, 87, 18–31. [Google Scholar] [CrossRef]

- Edlund, J.; Warensjö, M. Repeatability in Automatic Sorting of Curved Norway Spruce Saw Logs. Silva Fenn. 2005, 39, 265–275. [Google Scholar] [CrossRef][Green Version]

- Repola, J. Models for Vertical Wood Density of Scots Pine, Norway Spruce and Birch Stems, and Their Application to Determine Average Wood Density. Silva Fenn. 2006, 40, 673–685. [Google Scholar] [CrossRef]

- Zhang, S. Flexible 3D Shape Measurement Using Projector Defocusing: Extended Measurement Range. Opt. Lett. 2010, 35, 934–936. [Google Scholar] [CrossRef] [PubMed]

- Wördehoff, R.; Spellmann, H.; Evers, J.; Aydın, C.T.; Nagel, J. Kohlenstoffstudie Forst Und Holz Schleswig-Holstein; Nordwestdeutsche Forstliche Versuchsanstalt: Göttingen, Germany, 2012; pp. 5–36. [Google Scholar]

- Pająk, M.; Michalec, K.; Wąsik, R.; Kościelny, M. Quality of Scots Pine Wood on the Lands Reclaimed for Forestry-Spoil Heap after the Exploitation of Sulphur in Piaseczno Case Study. Sylwan 2016, 160, 284–291. [Google Scholar]

- Mirski, R.; Wieruszewski, M.; Malinowski, Z. Variability of the Defects Distribution Round Wood in Mature Pine Stands. Sylwan 2019, 163, 913–923. [Google Scholar]

- Thomas, L.; Mili, L.; Thomas, E.; Shaffer, C.A. Defect Detection on Hardwood Logs Using Laser Scanning. Wood Fiber Sci. 2006, 38, 682–695. [Google Scholar]

- Lin, W.; Wang, J. An Integrated 3D Log Processing Optimization System for Hardwood Sawmills in Central Appalachia, USA. Comput. Electron. Agric. 2012, 82, 61–74. [Google Scholar] [CrossRef]

- Rinnhofer, A.; Petutschnigg, A.; Andreu, J.-P. Internal Log Scanning for Optimizing Breakdown. Comput. Electron. Agric. 2003, 41, 7–21. [Google Scholar] [CrossRef]

- Sarigul, E.; Abbott, A.L.; Schmoldt, D.L. Rule-Driven Defect Detection in CT Images of Hardwood Logs. Comput. Electron. Agric. 2003, 41, 101–119. [Google Scholar] [CrossRef]

- Andrade, J.; Ares, J.; García, R.; Pazos, J.; Rodríguez, S.; Silva, A. Definition of a Problem-Sensitive Conceptual Modelling Language: Foundations and Application to Software Engineering. Inf. Softw. Technol. 2006, 48, 517–531. [Google Scholar] [CrossRef]

- Song, T.; Usenius, A.; Seminar, I. InnoSim-a Simulation Model of Wood Conversion Chain. In Proceedings of the COST Action E44 Conference on Wood Processing Strategy, Helsinki, Finland, 17–19 September 2007; pp. 95–108. [Google Scholar]

- Zhang, S.; Yau, S.-T. High-Speed Three-Dimensional Shape Measurement System Using a Modified Two-plus-One Phase-Shifting Algorithm. Opt. Eng. 2007, 46, 113603. [Google Scholar] [CrossRef]

- Wei, Q.; Chui, Y.H.; Leblon, B.; Zhang, S.Y. Identification of Selected Internal Wood Characteristics in Computed Tomography Images of Black Spruce: A Comparison Study. J. Wood Sci. 2009, 55, 175–180. [Google Scholar] [CrossRef]

- Chiorescu, S.; Grönlund, A. The Fingerprint Approach: Using Data Generated by a 3D Log Scanner on Debarked Logs to Accomplish Traceability in the Sawmill’s Log Yard. For. Prod. J. 2004, 54, 269–276. [Google Scholar]

- Westoby, M.J.; Brasington, J.; Glasser, N.F.; Hambrey, M.J.; Reynolds, J.M. ‘Structure-from-Motion’Photogrammetry: A Low-Cost, Effective Tool for Geoscience Applications. Geomorphology 2012, 179, 300–314. [Google Scholar] [CrossRef]

- Wieruszewski, M.; Mikołajczak, E. The Influence of Selected Factors on the Share of By-Products in Sawmill Processing. In Annals of Warsaw University of Life Sciences–SGGW Forestry and Wood Technology; Warsaw University of Life Sciences Press: Warsaw, Poland, 2018; Volume 104, pp. 540–548. [Google Scholar]

- Thawornwong, S.; Occena, L.G.; Schmoldt, D.L. Lumber Value Differences from Reduced CT Spatial Resolution and Simulated Log Sawing. Comput. Electron. Agric. 2003, 41, 23–43. [Google Scholar] [CrossRef]

- Wessels, C. Cant Sawing Log Positioning Optimization: A Simulation Study. For. Prod. J. 2009, 59, 17–22. [Google Scholar]

- Gotych, V.; Hruzik, G.J.; Wieruszewski, M. The Analysis of Sawmill Logs Sorting Acuteness at Automatic Sorting Lines. Intercathedra 2013, 29, 15–19. [Google Scholar]

- Kozakiewicz, P.; Krzosek, S. Resilient sorting of sawn timber. In Engineering of Wooden Materials, 1st ed.; Wydawnictwo SGGW: Warszawa, Poland, 2013; pp. 65–125. [Google Scholar]

- Marshall, H.; Murphy, G.; Lachenbruch, B. Effects of Bark Thickness Estimates on Optimal Log Merchandising. For. Prod. J. 2006, 56, 87–92. [Google Scholar]

- Johnson, T.S.; Wood, G.B. Simple Linear Model Reliably Predicts Bark Thickness of Radiata Pine in the Australian Capital Territory. For. Ecol. Manag. 1987, 22, 173–183. [Google Scholar] [CrossRef]

- Persson, B.; Downie, B. Variation in Bark Thickness of Young Pinus Contorta Var. Latifolia Engelm. in Sweden. Scand. J. For. Res. 1992, 7, 99–106. [Google Scholar] [CrossRef]

- Li, R.; Weiskittel, A. Estimating and Predicting Bark Thickness for Seven Conifer Species in the Acadian Region of North America Using a Mixed-Effects Modeling Approach: Comparison of Model Forms and Subsampling Strategies. Eur. J. For. Res. 2011, 130, 219–233. [Google Scholar] [CrossRef]

- Malone, T.; Liang, J. A Bark Thickness Model for White Spruce in Alaska Northern Forests. Int. J. For. Res. 2009, 876965. [Google Scholar] [CrossRef]

- Nilsson, D.; Edlund, U. Pine and Spruce Roundwood Species Classification Using Multivariate Image Analysis on Bark. Holzforschung 2005, 59, 689–695. [Google Scholar] [CrossRef]

- Muhairwe, C.K. Bark Thickness Equations for Five Commercial Tree Species in Regrowth Forests of Northern New South Wales. Aust. For. 2000, 63, 34–43. [Google Scholar] [CrossRef]

- Dietz, P. Dichte und Rindengehalt von Industrieholz. Holz Als Roh Und Werkst. 1975, 33, 135–141. [Google Scholar] [CrossRef]

- Stankić, I.; Kovač, S.; Poršinsky, T. Značajke kore podravske crne johe. Nova mehanizacija šumarstva: Časopis za teoriju i praksu šumarskoga inženjerstva. J. Theory Pract. For. Eng. 2010, 31, 27–36. [Google Scholar]

- Prka, M. Debljina kore obične bukve (Fagus sylvatica L.) u sječinama bjelovarske bilogore. Šumarski List 2004, 128, 391–403. [Google Scholar]

- Liepins, J.; Liepins, K. Evaluation of Bark Volume of Four Tree Species in Latvia. In Proceedings of the Research for Rural Development Annual 21th International Scientific Conference, Jelgava, Latvia, 13–15 May 2015; pp. 22–28. [Google Scholar]

- Jansone, Z.; Muizniece, I.; Blumberga, D. Analysis of Wood Bark Use Opportunities. Energy Procedia 2017, 128, 268–274. [Google Scholar] [CrossRef]

- Kokociński, W. Anatomia Drewna; Prodruk: Poznań, Poland, 2005. [Google Scholar]

- Mirski, R.; Kawalerczyk, J.; Dziurka, D.; Wieruszewski, M.; Trociński, A. Effects of Using Bark Particles with Various Dimensions as a Filler for Urea-Formaldehyde Resin in Plywood. BioResources 2020, 15, 1692–1701. [Google Scholar]

- Božić, M.; Čavlović, J.; Vedriš, M.; Jazbec, M. Modeling Bark Thickness of Silver Fir Trees (Abies alba Mill.). Šumarski List 2007, 131, 3–12. [Google Scholar]

- Smith, J.H.G.; Kozak, A. Thickness and Percentage of Bark of the Commercial Trees of British Columbia. Univ. Br. Columbia Fac. For. 1967, 30–33. [Google Scholar]

- Doruska, P.F.; Patterson, D.; Hartley, J.; Hurd, M.; Hart, T. Newer Technologies and Bioenergy Bring Focus Back to Bark Factor Equations. J. For. 2009, 107, 38–43. [Google Scholar]

- PN-D-95000. Surowiec Drzewny-Pomiar, Obliczanie Miąższości i Cechowanie; Polish Comitte for Standardization: Warsaw, Poland, 2002. [Google Scholar]

- Krzosek, S.; Bacher, M. Aktueller Stand der maschinellen Festigkeitssortierung von Schnittholz in Polen und in Europa. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2011, 74, 254–259. [Google Scholar]

- Dassot, M.; Constant, T.; Fournier, M. The Use of Terrestrial LiDAR Technology in Forest Science: Application Fields, Benefits and Challenges. Ann. For. Sci. 2011, 68, 959–974. [Google Scholar] [CrossRef]

- Chiorescu, S.; Berg, P.; Grönlund, A. The Fingerprint Approach: Using data generated by a 2-Axis log Scanner to accomplish traceability in the sawmill’s Log Yard. For. Prod. J. 2003, 53, 78–86. [Google Scholar]

- Lindström, A.; Rune, G. Root Deformation in Plantations of Container-Grown Scots Pine Trees: Effects on Root Growth, Tree Stability and Stem Straightness. Plant Soil 1999, 217, 29–37. [Google Scholar] [CrossRef]

- Sonmez, T.; Keles, S.; Tilki, F. Effect of Aspect, Tree Age and Tree Diameter on Bark Thickness of Picea Orientalis. Scand. J. For. Res. 2007, 22, 193–197. [Google Scholar] [CrossRef]

- Wilhelmsson, L.; Arlinger, J.; Spångberg, K.; Lundqvist, S.-O.; Grahn, T.; Hedenberg, Ö.; Olsson, L. Models for Predicting Wood Properties in Stems of Picea Abies and Pinus Sylvestris in Sweden. Scand. J. For. Res. 2002, 17, 330–350. [Google Scholar] [CrossRef]

- Dashner, B. 3D Log Scanning—The next Generation. In Proceedings of the Fifth International Conference on Scanning Technology and Process Optimization for the Wood Industry (Scan Pro), Atlanta, GA, USA, 25–27 October 1993. [Google Scholar]

- Cellini, J.; Galarza, M.; Burns, S.; Lencinas, M. Equations of Bark Thickness and Volume Profiles at Different Heights with Easy-Measurement Variables. For. Syst. 2012, 21, 23–30. [Google Scholar] [CrossRef]

- Oja, J.; Källsner, B.; Grundberg, S. Predicting the Strength of Sawn Wood Products: A Comparison between x-Ray Scanning of Logs and Machine Strength Grading of Lumber. For. Prod. J. 2005, 55, 55–60. [Google Scholar]

- Lycken, A.; Oja, J. A Multivariate Approach to Automatic Grading of Pinus Sylvestris Sawn Timber. Scand. J. For. Res. 2006, 21, 167–174. [Google Scholar] [CrossRef]

- Olofsson, L.; Broman, O.; Fredriksson, M.; Skog, J.; Sandberg, D. Customer Adapted Grading of Scots Pine Sawn Timber: A Multivariate Method Approach. In Proceedings of the 23rd International Wood Machining Seminar, Warsaw, Poland, 28–31 May 2017; Warsaw University of Life Sciences: Warsaw, Poland, 2017; pp. 360–361. [Google Scholar]

- Berglund, A.; Broman, O.; Oja, J.; Grönlund, A. Customer Adapted Grading of Scots Pine Sawn Timber Using a Multivariate Method. Scand. J. For. Res. 2014, 30, 87–97. [Google Scholar] [CrossRef]

- Kline, D.E.; Surak, C.; Araman, P. Automated Hardwood Lumber Grading Utilizing a Multiple Sensor Machine Vision Technology. Comput. Electron. Agric. 2003, 41, 139–155. [Google Scholar] [CrossRef]

- Chiorescu, S.; Grundberg, S. The Influence of Missing Bark on Measurements Performed with a 3D Log Scanner. For. Prod. J. 2001, 51, 78–86. [Google Scholar]

| Diametral Group (inch) | Number of Pieces | Diameter Range (cm) | Applied Deduction (cm) | Deduction Acc. to PN-D-95000 [43] |

|---|---|---|---|---|

| 7 | 220 | 17.0–20.2 | 1 | 2 |

| 8 | 810 | 20.3–22.8 | 2 | 2 |

| 9 | 2220 | 22.9–25.3 | 2 | 2 |

| 10 | 1490 | 25.4–27.8 | 2 | 2 |

| 11 | 2150 | 27.9–30.4 | 2 | 2 |

| 12 | 1660 | 30.5–32.9 | 2 | 2 |

| 13 | 1150 | 33.0–35.5 | 2 | 3 |

| 14 | 880 | 35.6–38.0 | 2 | 3 |

| 15 | 650 | 38.1–40.5 | 3 | 3 |

| 16 | 380 | 40.6–43.1 | 3 | 3 |

| 17 | 70 | >43.2 | 3 | 3 |

| Diametral Group | Compliance of the Measurements | ||

|---|---|---|---|

| Above | Match with Group | Below | |

| (inch) | (%) | ||

| 7 | 0.0 | 100.0 | 0.0 |

| 8 | 0.0 | 70.0 | 30.0 |

| 9 | 13.8 | 64.8 | 21.4 |

| 10 | 13.4 | 62.4 | 24.2 |

| 11 | 4.5 | 48.2 | 47.3 |

| 12 | 10.2 | 54.9 | 34.9 |

| 13 | 5.1 | 32.8 | 62.1 |

| 14 | 9.1 | 39.8 | 51.1 |

| 15 | 9.2 | 50.8 | 40.0 |

| 16 | 39.0 | 41.5 | 19.5 |

| 17 | 0.0 | 100.0 | 0.0 |

| Diametral Group | Applied Deduction | Measurement | Results of Measurements | ||||

|---|---|---|---|---|---|---|---|

| Min. | Avg. | Max. | SD | CV | |||

| (inch) | (cm) | (cm) | (%) | ||||

| 7 | 1 | w/bark | 17.3 | 18.8 | 20.5 | 0.9 | 5 |

| w/out bark | 17.0 | 18.4 | 20.1 | 0.9 | 5 | ||

| bark | 0.2 | 0.4 | 1.0 | 0.2 | 51 | ||

| 8 | 2 | w/bark | 19.6 | 21.4 | 23.3 | 0.9 | 4 |

| w/out bark | 18.7 | 20.8 | 22.8 | 0.9 | 4 | ||

| bark | 0.2 | 0.7 | 1.7 | 0.3 | 50 | ||

| 9 | 2 | w/bark | 22.1 | 24.9 | 29.0 | 1.5 | 6 |

| w/out bark | 21.0 | 24.0 | 28.4 | 1.3 | 6 | ||

| bark | 0.2 | 0.9 | 2.9 | 0.5 | 49 | ||

| 10 | 2 | w/bark | 25.1 | 27.4 | 30.6 | 1.2 | 8 |

| w/out bark | 24.2 | 26.3 | 30.1 | 1.2 | 8 | ||

| bark | 0.2 | 1.1 | 2.5 | 0.5 | 24 | ||

| 11 | 2 | w/bark | 25.9 | 29.1 | 32.5 | 1.4 | 5 |

| w/out bark | 24.5 | 27.9 | 31.4 | 1.4 | 6 | ||

| bark | 0.2 | 1.1 | 2.9 | 0.5 | 47 | ||

| 12 | 2 | w/bark | 29.2 | 32.2 | 35.8 | 1.4 | 5 |

| w/out bark | 28.4 | 31.2 | 35.1 | 1.4 | 5 | ||

| bark | 0.2 | 1.1 | 2.4 | 0.5 | 42 | ||

| 13 | 3 | w/bark | 31.3 | 34.2 | 38.7 | 1.7 | 5 |

| w/out bark | 30.4 | 32.9 | 37.5 | 1.6 | 5 | ||

| bark | 0.3 | 1.3 | 2.8 | 0.5 | 41 | ||

| 14 | 3 | w/bark | 33.5 | 36.9 | 40.0 | 1.5 | 5 |

| w/out bark | 32.4 | 35.6 | 39.0 | 1.5 | 5 | ||

| bark | 0.4 | 1.3 | 2.4 | 0.5 | 38 | ||

| 15 | 3 | w/bark | 37.4 | 39.5 | 41.8 | 1.2 | 7 |

| w/out bark | 35.0 | 38.1 | 40.5 | 1.2 | 7 | ||

| bark | 0.2 | 1.4 | 3.0 | 0.6 | 43 | ||

| 16 | 3 | w/bark | 39.8 | 43.6 | 46.6 | 1.8 | 5 |

| w/out bark | 38.1 | 42.1 | 45.2 | 1.9 | 5 | ||

| bark | 0.7 | 1.5 | 2.6 | 0.5 | 37 | ||

| 17 | 3 | w/bark | 47.5 | 53.1 | 62.8 | 5.9 | 10 |

| w/out bark | 45.8 | 51.2 | 61.5 | 5.8 | 10 | ||

| bark | 1.3 | 1.9 | 3.1 | 0.6 | 29 | ||

| Deduction for Bark | |||||||

|---|---|---|---|---|---|---|---|

| Manual Measurements | Automatic Sorting | ||||||

| Diametral Group | Med. | Max. | Applied Deduction | x | y | A | B |

| (inch) | (cm) | (cm) | (%) | (cm) | |||

| 7 | 0.4 | 1.0 | 1 | 60.0 | 0.0 | 1 | 1.0 |

| 8 | 0.7 | 1.7 | 2 | 65.0 | 15.0 | 2 | 1.7 |

| 9 | 0.9 | 2.9 | 2 | 55.0 | −45.0 | 3 | 2.9 |

| 10 | 1.1 | 2.5 | 2 | 45.0 | −25.0 | 3 | 2.5 |

| 11 | 1.1 | 2.9 | 2 | 45.0 | −45.0 | 3 | 2.9 |

| 12 | 1.1 | 2.4 | 2 | 45.0 | −20.0 | 3 | 2.4 |

| 13 | 1.3 | 2.8 | 3 | 35.0 | −40.0 | 3 | 2.8 |

| 14 | 1.3 | 2.4 | 3 | 35.0 | −20.0 | 3 | 2.4 |

| 15 | 1.4 | 3.0 | 3 | 53.3 | 0.0 | 3 | 3.0 |

| 16 | 1.5 | 2.6 | 3 | 50.0 | 13.3 | 3 | 2.6 |

| 17 | 1.9 | 3.1 | 3 | 36.7 | −3.3 | 3 | 3.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mirski, R.; Trociński, A.; Kawalerczyk, J.; Wieruszewski, M. Pine Logs Sorting as a Function of Bark Thickness. Forests 2021, 12, 893. https://doi.org/10.3390/f12070893

Mirski R, Trociński A, Kawalerczyk J, Wieruszewski M. Pine Logs Sorting as a Function of Bark Thickness. Forests. 2021; 12(7):893. https://doi.org/10.3390/f12070893

Chicago/Turabian StyleMirski, Radosław, Adrian Trociński, Jakub Kawalerczyk, and Marek Wieruszewski. 2021. "Pine Logs Sorting as a Function of Bark Thickness" Forests 12, no. 7: 893. https://doi.org/10.3390/f12070893

APA StyleMirski, R., Trociński, A., Kawalerczyk, J., & Wieruszewski, M. (2021). Pine Logs Sorting as a Function of Bark Thickness. Forests, 12(7), 893. https://doi.org/10.3390/f12070893