Methodology for Assessing and Managing the Environmental Performance of Skidding and Feller Buncher Tractors

Abstract

:1. Introduction

2. Materials and Methods

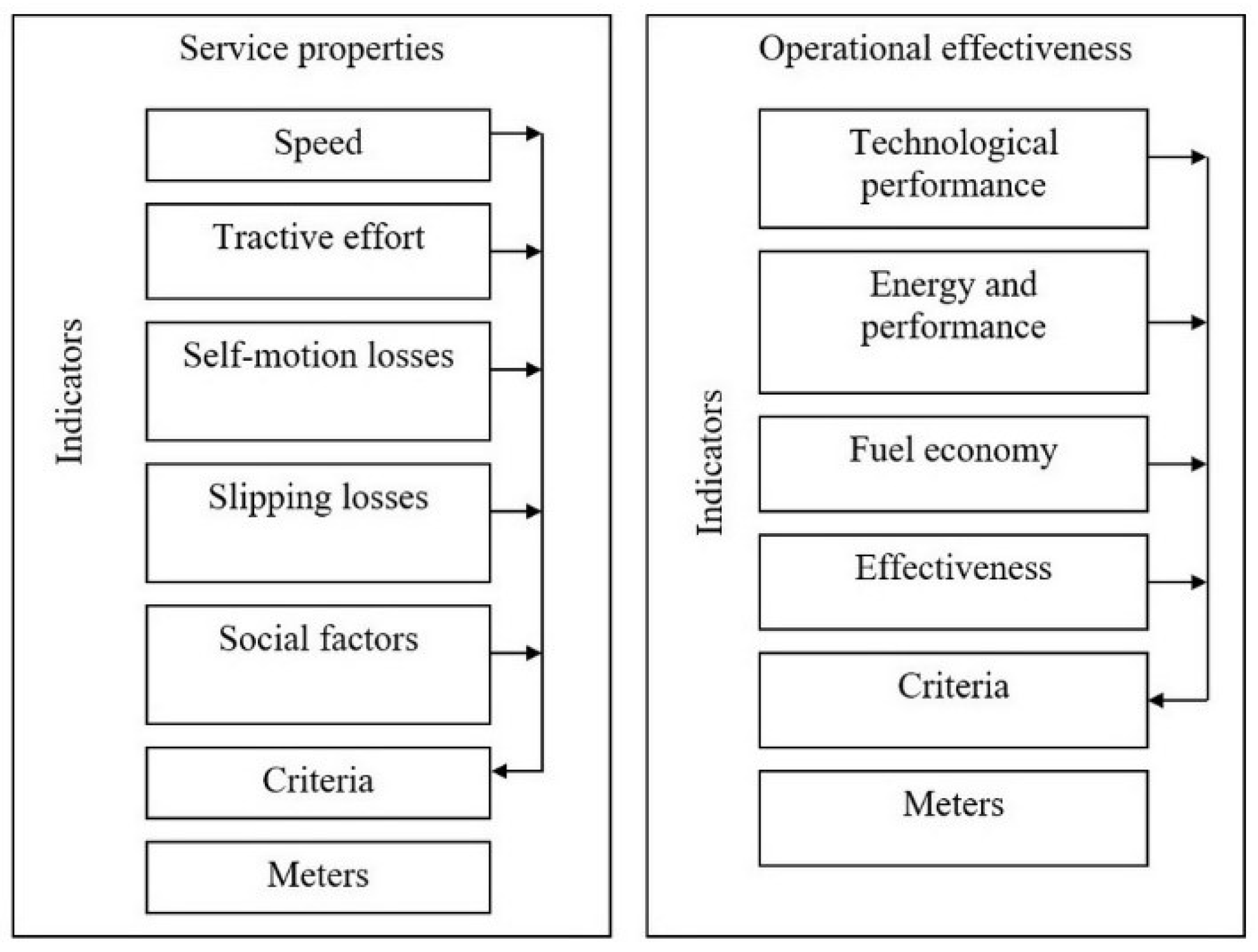

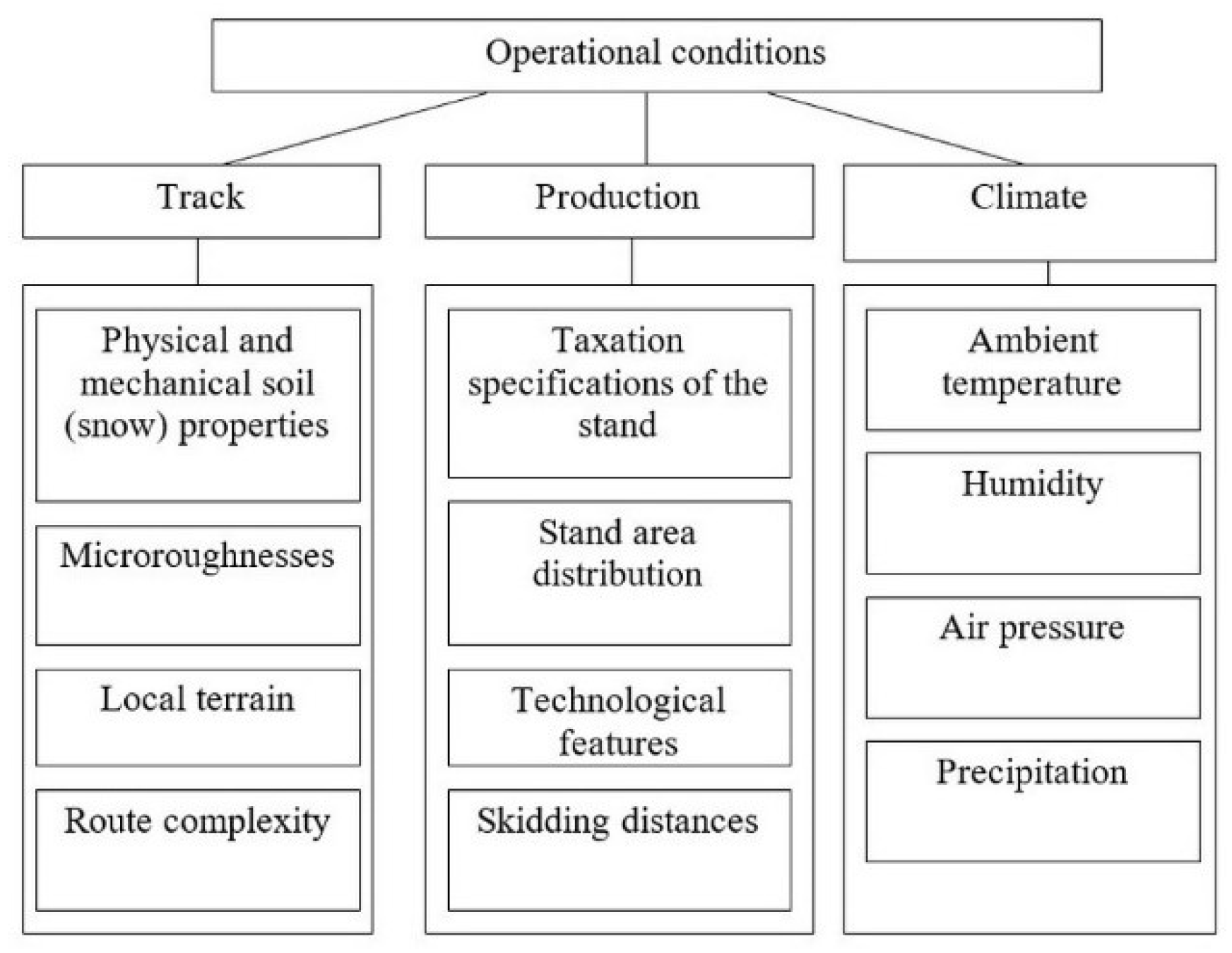

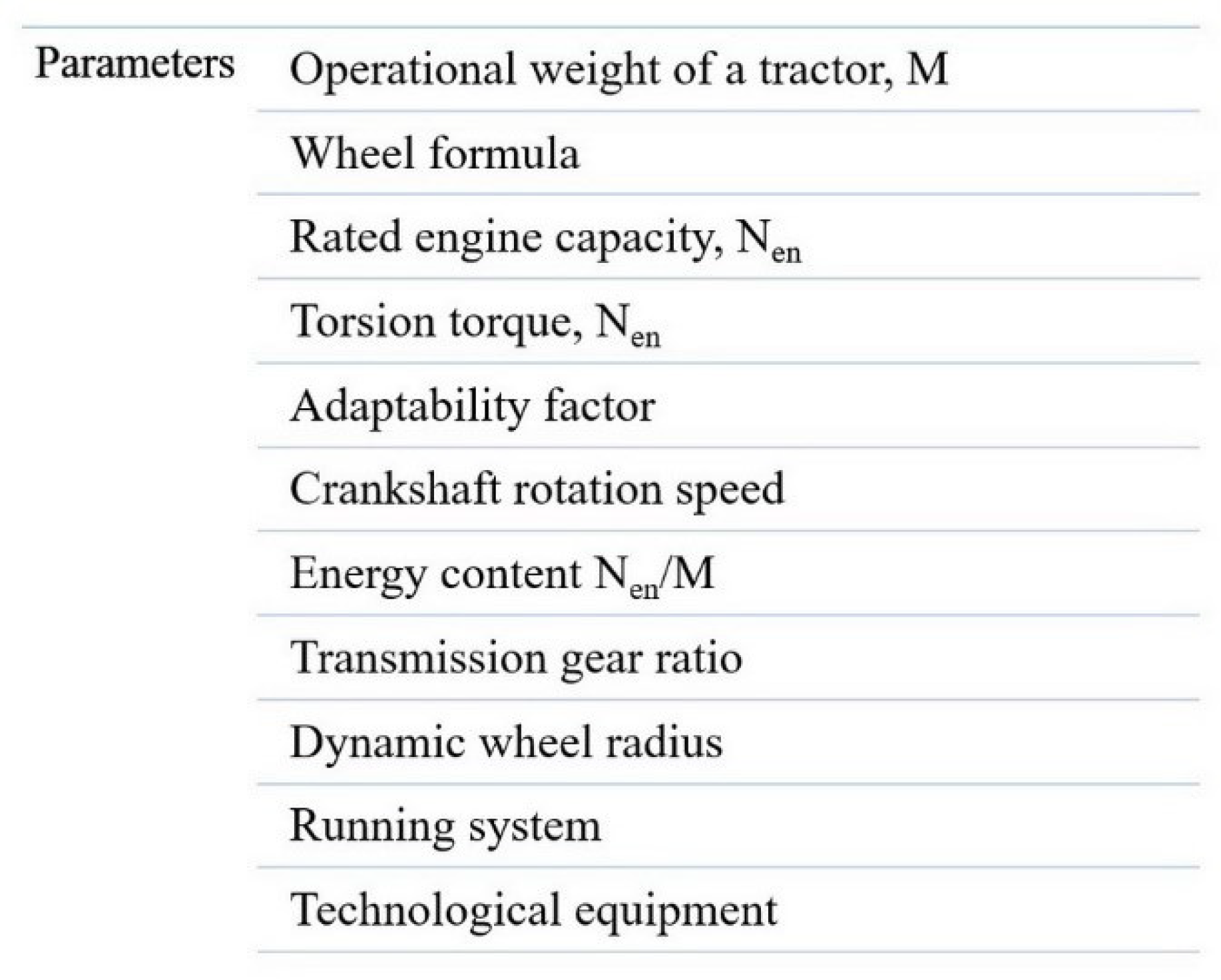

2.1. System Method of Studying the Operation of Forest Machines

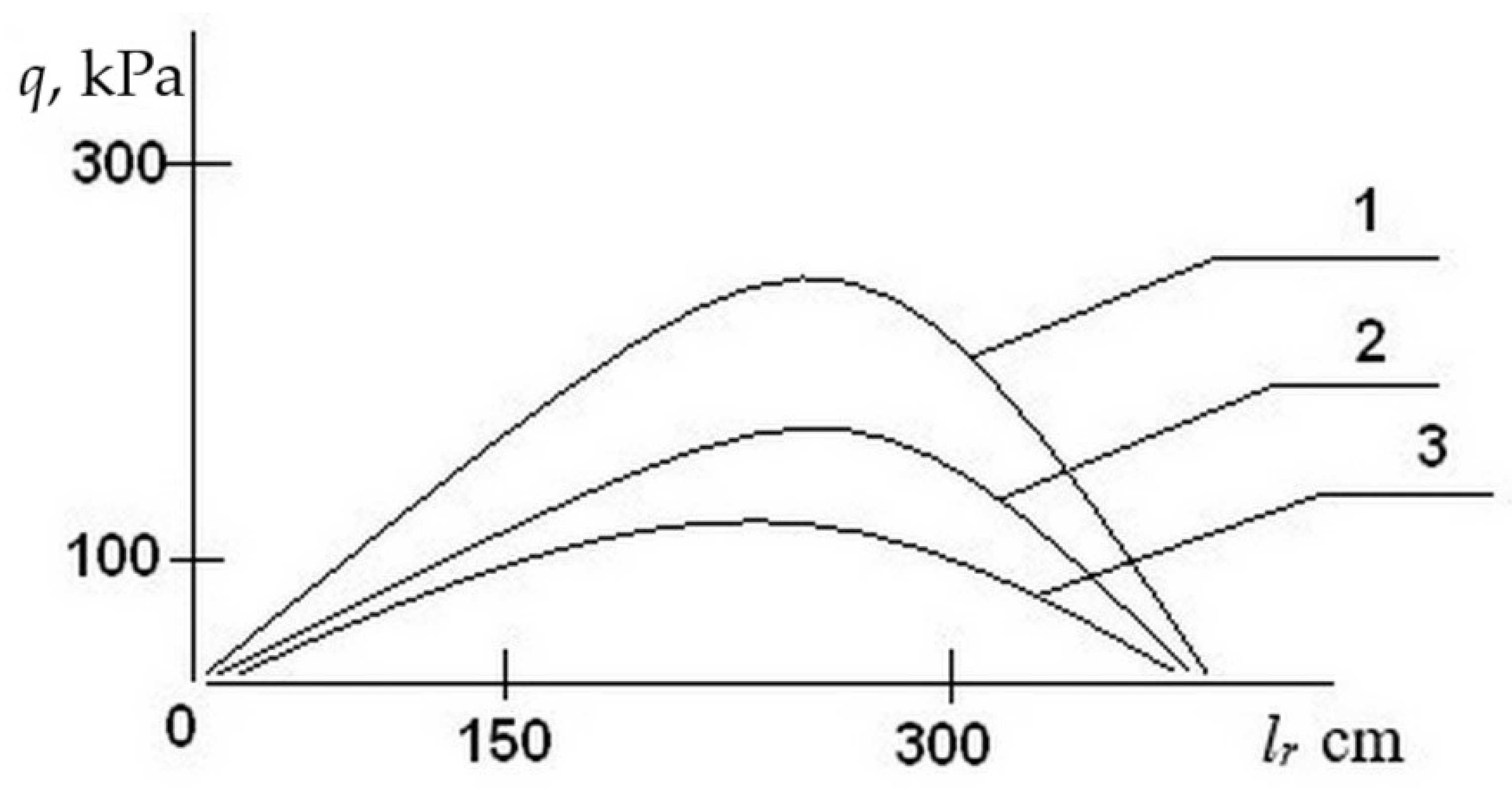

2.2. Experimental Procedure

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lazdinis, M.; Angelstam, P.; Pülzl, H. Towards sustainable forest management in the European Union through polycentric forest governance and an integrated landscape approach. Landsc. Ecol. 2019, 34, 1737–1749. [Google Scholar] [CrossRef] [Green Version]

- da Silva, E.F.; da Silva, G.F.; Figueiredo, E.O.; de Mendonça, A.R.; de Oliveira Santana, C.J.; Fiedler, N.C.; Silva, J.P.M.; Aguiar, M.O.; Santos, J.S. Optimized forest planning: Allocation of log storage yards in the Amazonian sustainable forest management area. For. Ecol. Manag. 2020, 472, 118231. [Google Scholar] [CrossRef]

- Affek, A.N.; Zachwatowicz, M.; Sosnowska, A.; Gerlée, A.; Kiszka, K. Impacts of modern mechanised skidding on the natural and cultural heritage of the Polish Carpathian Mountains. For. Ecol. Manag. 2017, 405, 391–403. [Google Scholar] [CrossRef]

- Ellis, E.A.; Montero, S.A.; Gómez, I.U.H.; Montero, J.A.R.; Ellis, P.W.; Rodríguez-Ward, D.; Reyes, P.B.; Putz, F.E. Reduced-impact logging practices reduce forest disturbance and carbon emissions in community managed forests on the Yucatán Peninsula, Mexico. For. Ecol. Manag. 2019, 437, 396–410. [Google Scholar] [CrossRef]

- Kobayashi, H.; Ikei, H.; Song, C.; Kagawa, T.; Miyazaki, Y. Comparing the impact of forest walking and forest viewing on psychological states. Urban For. Urban Green. 2021, 57, 126920. [Google Scholar] [CrossRef]

- Guo, J.; Ding, L.; Gao, H.; Guo, T.; Deng, Z.; Liu, Z. Longitudinal skid model for wheels of planetary rovers based on improved wheel sinkage considering soil bulldozing effect. J. Terramechan. 2017, 74, 45–56. [Google Scholar] [CrossRef]

- Orlovský, L.; Messingerová, V.; Danihelová, Z. Analysis of the time efficiency of skidding technology based on the skidders. Lesn. Cas. 2020, 66, 177–187. [Google Scholar] [CrossRef]

- Parkhurst, B.M.; Aust, W.M.; Bolding, M.C.; Barrett, S.M.; Carter, E.A. Soil response to skidder trafficking and slash application. Int. J. For. Eng. 2018, 29, 31–40. [Google Scholar] [CrossRef]

- Picchio, R.; Venanzi, R.; Tavankar, F.; Luchenti, I.; Bodaghi, A.I.; Latterini, F.; Nikooy, M.; Di Marzio, N.; Naghdi, R. Changes in soil parameters of forests after windstorms and timber extraction. Eur. J. For. Res. 2019, 138, 875–888. [Google Scholar] [CrossRef]

- Solgi, A.; Naghdi, R.; Tsioras, P.A.; Ilstedt, U.; Salehi, A.; Nikooy, M. Combined effects of skidding direction, skid trail slope and traffic frequency on soil disturbance in north mountainous forest of Iran. Croat. J. For. Eng. 2017, 38, 97–106. [Google Scholar]

- Labelle, E.R.; Kammermeier, M. Above-and belowground growth response of Picea abies seedlings exposed to varying levels of soil relative bulk density. Eur. J. For. Res. 2019, 138, 705–722. [Google Scholar] [CrossRef] [Green Version]

- Tavankar, F.; Picchio, R.; Nikooy, M.; Jourgholami, M.; Latterini, F.; Venanzi, R. Effect of soil moisture on soil compaction during skidding operations in poplar plantation. Int. J. For. Eng. 2021, 32, 128–139. [Google Scholar] [CrossRef]

- Allman, M.; Merganič, J.; Merganičová, K. Machinery-induced damage to soil and remaining forest stands—Case study from Slovakia. Forests 2020, 11, 1289. [Google Scholar] [CrossRef]

- Nikooy, M.; Tavankar, F.; Naghdi, R.; Ghorbani, A.; Jourgholami, M.; Picchio, R. Soil impacts and residual stand damage from thinning operations. Int. J. For. Eng. 2020, 31, 126–137. [Google Scholar] [CrossRef]

- Proto, A.R.; Bacenetti, J.; Macri, G.; Zimbalatti, G. Roundwood and bioenergy production from forestry: Environmental impact assessment considering different logging systems. J. Clean. Prod. 2017, 165, 1485–1498. [Google Scholar] [CrossRef]

- Tavankar, F.; Picchio, R.; Nikooy, M.; Jourgholami, M.; Naghdi, R.; Latterini, F.; Venanzi, R. Soil natural recovery process and Fagus orientalis lipsky seedling growth after timber extraction by wheeled skidder. Land 2021, 10, 113. [Google Scholar] [CrossRef]

- Diniz, C.C.C.; Lopes, E.S.; Koehler, H.S.; Miranda, G.M.; Paccola, J. Comparative analysis of maintenance models in forest machines. Floresta Ambiente 2020, 27, e20170994. [Google Scholar] [CrossRef]

- Kormanek, M.; Głąb, T.; Banach, J.; Szewczyk, G. Effects of soil bulk density on sessile oak Quercus petraea Liebl. seedlings. Eur. J. For. Res. 2015, 134, 969–979. [Google Scholar] [CrossRef] [Green Version]

- Zhang, F.; Johnson, D.M.; Wang, J.; Yu, C. Cost, energy use and GHG emissions for forest biomass harvesting operations. Energy 2016, 114, 1053–1062. [Google Scholar] [CrossRef]

- Okey, O.B.İ.; Visser, R. Estimating the Influence of extraction method and processing location on forest harvesting efficiency—A categorical DEA approach. Eur. J. For. Res. 2020, 6, 60–67. [Google Scholar] [CrossRef]

- Behjou, F.K. Shape of skidder productivity function for ground based skidding system in Caspian forests. For. Res. Eng. Int. J. 2018, 2, 00020. [Google Scholar] [CrossRef] [Green Version]

- Moskalik, T.; Borz, S.A.; Dvořák, J.; Ferencik, M.; Glushkov, S.; Muiste, P.; Lazdiņš, A.; Styranivsky, O. Timber harvesting methods in Eastern European countries: A review. Croat. J. For. Eng. 2017, 38, 231–241. [Google Scholar]

- Kormanek, M.; Banach, J.; Sowa, P. Effect of soil bulk density on forest tree seedlings. Int. Agrophys. 2015, 29, 67–74. [Google Scholar] [CrossRef]

- Kulak, D.; Stańczykiewicz, A.; Szewczyk, G. Disturbance to outer soil layers depending on the season of timber harvesting. Balt. For. 2019, 25, 289–295. [Google Scholar]

- Kulak, D.; Sowa, J.M.; Szewczyk, G.; Stańczykiewicz, A. The accessibility of post-fire areas for mechanized thinning operations. Forests 2020, 11, 471. [Google Scholar] [CrossRef]

- Kormanek, M.; Dvořák, J. Ground pressure changes caused by MHT 8002HV crawler harvester chassis. Croat. J. For. Eng. 2021, 42, 201–211. [Google Scholar] [CrossRef]

- GOST. GOST 23734-79. Industrial Tractors. Test Methods. 1979. Available online: https://files.stroyinf.ru/Index2/1/4294830/4294830411.htm (accessed on 17 August 2021).

- GOST. GOST 7057-81 Industrial Tractors. Test Methods. 1981. Available online: https://files.stroyinf.ru/Index2/1/4294822/4294822677.htm (accessed on 17 August 2021).

- ISO. ISO 5353:1995 Earth-Moving Machinery, and Tractors and Machinery for Agriculture and Forestry—Seat Index Point. 1995. Available online: https://www.iso.org/standard/11375.html (accessed on 17 August 2021).

- GOST. GOST 26953-86 Mobile Agricultural Machinery. Methods of Determining the Impact of Forwarders on the Soil. 1986. Available online: https://docs.cntd.ru/document/1200023337 (accessed on 17 August 2021).

- Grigoriev, I.V.; Grigorieva, O.I. Logging machines on excavator base. In Improving the Efficiency of the Forest Sector: Proceedings of the IV All-Russian Scientific and Practical Conference with International Engagement; Petrozavodsk State University: Petrozavodsk, Russia, 2018; pp. 45–46. [Google Scholar]

- Shegelman, I.R.; Budnik, P.V. Typification of forest areas by natural-production conditions based on cluster analysis. Lesn. Zhurnal 2021, 1, 120–137. [Google Scholar] [CrossRef]

- Seryi, V.S.; Zasukhin, D.P.; Vyalykh, N.U. The impact of soil disturbance during thinning on the subsequent regeneration and growth of young trees. Forestry 1991, 3, 27–28. [Google Scholar]

- Najafi, A.; Solgi, A.; Sadeghi, S.H. Soil disturbance following four wheel rubber skidder logging on the steep trail in the north mountainous forest of Iran. Soil Tillage Res. 2009, 103, 165–169. [Google Scholar] [CrossRef]

- Solgi, A.; Naghdi, R.; Nikooy, M. Effects of skidder on soil compaction, forest floor removal, and rutting. Madera Y Bosques 2015, 21, 147–155. [Google Scholar]

- Solgi, A.; Naghdi, R.; Tsioras, P.A.; Nikooy, M. Soil compaction and porosity changes caused during the operation of Timberjack 450C skidder in northern Iran. Croat. J. For. Eng. 2015, 36, 217–225. [Google Scholar]

- Grigoryev, I.V.; Kunitskaya, O.A. Optimal choice of timber road train. In Transportation and Transport-Technological Systems: Materials of International Scientific-Technical Conference; Tyumen Industrial University: Tyumen, Russia, 2019; pp. 74–78. [Google Scholar]

- Grigoryev, I.V.; Kunitskaya, O.A. Durability management of automobile tires. In Problems of Transport System Functioning. Materials of the International Scientific-Practical Conference of Students, Graduate Students, and Young Scientists; Yakutsk State Agricultural Academy: Yakutsk, Russia, 2020; pp. 68–71. [Google Scholar]

| Tractor Model | Specifications | |||||

|---|---|---|---|---|---|---|

| Engine Power, kW | Maximum Speed, km/h | Width, m | Length, m | Height, m | Mass, kg | |

| TLC 4-01 | 147 | 32.2 | 3.04 | 8 | 3.505 | 14,500 |

| LP-19 | 126 | 15 | 3.15 | 8 | 3.19 | 26,000 |

| LP-49 | 84.6 | 30 | 2.8 | 7.9 | 3.6 | 17,300 |

| No | Tractor’s Operation Mode | Air Pressure, MPa | |

|---|---|---|---|

| Front Wheels | Rear Wheels | ||

| 1 | No load when passing with the rear-wheel drive off | 0.18 | 0.15 |

| 2 | On a skidding track with dense soil | 0.18 | 0.18 |

| 3 | On a skidding track with soft soil and virgin snow | 0.15 | 0.15 |

| Type of Forest after Logging | Length of Transport Routes, km/ha | |||

|---|---|---|---|---|

| Total | Roads | Skidding Tracks | Places of Skidder Pass | |

| Logging with feller bunchers and tractors with pincer grab | ||||

| Freshly cut | 0.89 | 0.08 | 0.47 | 0.34 |

| Wet | 1.26 | 0.14 | 0.44 | 0.68 |

| Felling with gasoline-powered saws, skidding with choker-skidding tractors | ||||

| Freshly cut | 0.9 | 0.08 | 0.82 | |

| Type of Forest after Logging | Density, g/cm3 | Track Parameters | |||

|---|---|---|---|---|---|

| Loading Platform | Control | Area, m2/100 m2 | Depth, cm | Volume, m3/100 m2 | |

| Freshly cut | 5.8 ± 0.04 | 2.8 ± 0.14 | 40.0 | 14 | 56.0 |

| Wet | 8.2 ± 0.02 | 3.7 ± 0.04 | 47.5 | 10 | 47.5 |

| Number of Passes | Sand | Sandy Clay | Light Loam | ||||||

|---|---|---|---|---|---|---|---|---|---|

| TLC 4-01 | LP-19 | LP-49 | TLC 4-01 | LP-19 | LP-49 | TLC 4-01 | LP-19 | LP-49 | |

| 0 | 1.31 | 1.33 | 1.31 | 1.02 | 1.03 | 1.27 | 1 | 1.15 | 1.09 |

| 1–2 | 1.33 | 1.37 | 1.41 | 1.1 | 1.17 | 1.4 | 1.25 | 1.33 | 1.37 |

| % to control | 2 | 3 | 8 | 8 | 15 | 10 | 25 | 16 | 26 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grigorev, I.; Kunickaya, O.; Tikhonov, E.; Hertz, E.; Khakhina, A.; Burmistrova, O.; Sukhomlinova, N.; Zhuk, A. Methodology for Assessing and Managing the Environmental Performance of Skidding and Feller Buncher Tractors. Forests 2021, 12, 1723. https://doi.org/10.3390/f12121723

Grigorev I, Kunickaya O, Tikhonov E, Hertz E, Khakhina A, Burmistrova O, Sukhomlinova N, Zhuk A. Methodology for Assessing and Managing the Environmental Performance of Skidding and Feller Buncher Tractors. Forests. 2021; 12(12):1723. https://doi.org/10.3390/f12121723

Chicago/Turabian StyleGrigorev, Igor, Ol’ga Kunickaya, Evgeniy Tikhonov, Edward Hertz, Anna Khakhina, Olga Burmistrova, Natalia Sukhomlinova, and Artem Zhuk. 2021. "Methodology for Assessing and Managing the Environmental Performance of Skidding and Feller Buncher Tractors" Forests 12, no. 12: 1723. https://doi.org/10.3390/f12121723

APA StyleGrigorev, I., Kunickaya, O., Tikhonov, E., Hertz, E., Khakhina, A., Burmistrova, O., Sukhomlinova, N., & Zhuk, A. (2021). Methodology for Assessing and Managing the Environmental Performance of Skidding and Feller Buncher Tractors. Forests, 12(12), 1723. https://doi.org/10.3390/f12121723