Abstract

In the context of global climate change, energy conservation and greenhouse effect gases (GHG) reduction are major challenges to mankind. The forestry-pulp and paper industry is a typical high energy consumption and high emission industry. We conducted in-depth research on the energy flows and carbon footprint of the forestry-pulp paper industry. The results show that: (1) The main sources of energy supply include external fossil fuel coal and internal biomass fuel black liquor, which supply 30,057,300 GJ and 14,854,000 GJ respectively; in addition, the energy produced by diesel in material transportation reaches 11,624,256 GJ. (2) The main energy consumption processes include auxiliary engineering projects, material transportation, papermaking, alkali recovery, pulping and other production workshops. The percentages of energy consumption account for 26%, 18%, 15%, 10% and 6%, respectively. (3) The main sources of carbon include coal and forest biomass, reaching 770,000 tons and 1.39 million tons, respectively. (4) Carbon emissions mainly occur in fuel combustion in combined heating and power (CHP) and diesel combustion in material transportation, reaching 6.78 million tons and 790,000 tons of carbon, respectively. (5) Based on steam and electricity consumption, the indirect carbon emissions of various thermal and electric energy production units were calculated, and the key energy consumption process units and hotspot carbon flow paths were further found. This research established a theoretical and methodological basis for energy conservation and emission reduction.

1. Introduction

In the context of global climate change, reduction of greenhouse gas emissions is a major challenge to mankind [1]. Rapid deep decarbonization requires a profound shift in the social technology system [2,3]. The low-carbon sustainable transformation of social technology systems requires high-energy, high-emission industries such as energy, electricity, transportation, forestry and agriculture to achieve low-carbon transformation and innovation-driven development strategies [4]. According to the International Energy Agency, global energy consumption in 2018 increased at nearly twice the average rate of growth since 2010, driven by a robust global economy and higher heating and cooling needs in some parts of the world, and as a result of higher energy consumption, CO2 emissions rose 1.7% in 2017 and hit a new record [5]. The large-scale raw material industries, such as forestry-based, chemicals, cement and steel industries, accounts for more than two-thirds of total emissions.

The pulp and paper industry converts lignocellulosic materials into pulp and paper products [6,7,8]. The life cycle of forestry-pulp and paper industry products includes multiple process units such as forest tending, wood harvesting, preparation, pulping, papermaking, product distribution and use [9,10], with each value added unit consuming a lot of heat and electricity [11]. As the world’s fourth-largest energy-consuming industry, the pulp and paper industry consumes a large amount of energy, accounting for about 5% of the world’s total industrial energy consumption, and its carbon emissions account for about 2% of global industrial direct carbon emissions [12].

Most of the on-site production of electricity used in the forestry-pulp and paper industry is generated using combined heating and power (CHP) generation units, and a small part is derived from other power generation methods, such as generators that use combustible energy or renewable resources [13,14]. Steam from CHP is used as the main energy source for process heating systems, and electricity is the main source of energy-based machine-driven systems. The forestry industry sector meets a large number of energy needs through on-site power generation (combustion power generation and steam power generation), in addition to fossil fuels such as coal, forestry companies use wood residues (e.g., tree bark) and by-products (e.g., black liquor) to self-produce energy. The biomass resources utilized include black liquor from the kraft pulping processes and wood residues collected in the wood processing and manufacturing, producing steam and electricity to meet a significant portion of the energy needs.

Pulp and paper industry has a variety of different production processes, and energy usage patterns varying from sector to sector [15]. Even in some sectors, the energy requirements may vary depending on the technologies. For example, pulp can be manufactured by chemical pulping, mechanical pulping or a combination of two pulping processes, so that the production process differs greatly from the energy requirements. Depending on the type of process, the energy used in the production processes can be divided into process heating (e.g., furnaces, ovens, furnaces and ribbon heaters), process cooling, machine drives (e.g., motors and pumps associated with process equipment), electrochemical processes (such as reduction processes) and other direct process applications.

The use of high-intensity energy, the burning and leakage of wood raw materials in the process of product conversion make the pulp and paper industry become a highly polluting and high-emission industry [16,17]. The international industrial and business community has also conducted long-term and in-depth research on energy consumption and carbon emissions in the production of forestry, pulp and paper. Technical Association of the Pulp and Paper Industry (TAPPI) promotes the use of emerging materials and technologies such as biomass energy and nanotechnology in pulp and paper to reduce energy consumption and carbon emissions [18]. Confederation of European Paper Industries (CEPI) has begun to develop the 2050 roadmap for moving to a competitive low-carbon economy 2050 [19]. By 2050, CEPI aims to: (1) Reduce CO2 emissions by 80% (compared to 1990 levels); (2) reduce energy requirements by 20% in the wood fiber industry (in 2010 benchmark) and (3) increase product value by 50% (based on 2010). In recent years, many studies are working to reduce energy consumption and carbon emissions in the pulp and paper industry.

Various models of energy consumption and carbon emissions from the forestry-pulp and paper industries were established. The internationally renowned company Fisher proposes to measure the carbon footprint using the “cradle to gate” or “cradle to destination” approach to the carbon footprint and corporate carbon emissions measurement of the pulp and paper industry [20]. It involves energy consumption, factory manufacturing processes, transportation and product consumption. The life cycle method is also important for studying the energy consumption and carbon emission intensity of pulp (chemical pulp, mechanical pulp and waste pulp) and paper [21,22]. A variety of methods have been combined to create and visualize bottom-up integrated logistics, energy efficiency and carbon emissions assessment models [23]. The energy consumption and carbon emissions of the pulp and paper industry in different countries are compared and analyzed and it was found that the carbon emissions of the pulp and paper industry are closely related to various factors such as energy efficiency, carbon intensity of main energy sources and substitution of biomass energy [24]. The American Institute of Chemical Engineers (AIChE) conducted an in-depth research report of the energy bandwidth of the US pulp and paper industry [25]. At present, most of the research on energy consumption and carbon emission of the forestry-pulp paper industry is carried out from the aspects of single equipment, single process, single product and single-stock logistics. In fact, the integrated operation of forestry-pulp and paper is the current mainstream operation mode. Forest tending, pulping, papermaking and other sectors constitute a complete system. Energy flows and carbon footprint are embodied in the production processes [26]. Life cycle assessment (LCA) was used to compare factors such as wood consumption, energy consumption and other environmental impacts of unbleached primary pulp, recycled fiber pulp and chemical preheated mechanical pulp.

This research quantifies the energy flows and carbon footprint of the forestry-pulp and paper industry. Based on the analysis of production processes and product life cycle theory, the energy consumption, carbon flow and carbon emission models of each production process unit were established. The energy consumption and carbon emissions of the main production processes were discussed, and the hot-spot carbon flow paths were found, which established a theoretical and methodological basis for energy conservation and emission reduction.

2. Materials and Methods

2.1. Materials

The forestry industry produces thousands of products based on forestry renewable raw materials for transportation, packaging, consumer goods and construction. Many companies producing pulp and paper are engaged in the integrated business of forest and paper products [27,28]. This research takes Stora Enso Co., Ltd. (Beihai, China) as a typical case study modeling and calculating the energy consumption and carbon emissions in its production and processes. The company’s forest plantations extend by 15 counties of the four cities of Beihai, Fangchenggang, Yulin and Chongzuo in Guangxi Province, as well as Gaofeng, Qipo, Bobai, Liuwan, Qinlian, Dongmen and Payangshan. The total area is 1600 hectares. The main forest species are acacia and eucalypt, and the main rotation period is 6–7 years. The company’s annual production scale is 900,000 tons of bleached eucalypt chemical pulp, of which 450,000 tons are used as raw materials for the production of high-grade cultural paper and packaging paperboard, and 450,000 tons are used as pulp for sale as commercial pulp; one high grade packaging cardboard production line has an annual output of 450,000 tons, producing liquid packaging paperboard and coated white cardboard and one high grade cultural paper production line has an annual output of 450,000 tons of dry electrostatic copying paper, offset printing paper and copper paper.

In addition to eucalypt from its own plantations, other raw materials for the company’s production activities come from the market, including bleached softwood pulp, bleached hardwood pulp and various chemicals such as limestone, calcium sulfate, sodium sulfate, starch and latex. The company’s main energy resources are raw coal, heavy oil, liquefied gas, bark and electricity. The forestry-pulp and paper industry consumes a lot of heat and electricity energy in the forest harvesting, preparation, pulping, pulp bleaching, alkali recovery, causticization, lime calcination and waste treatment.

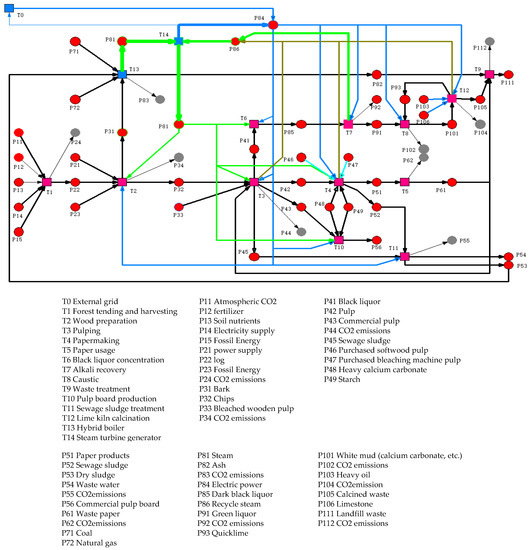

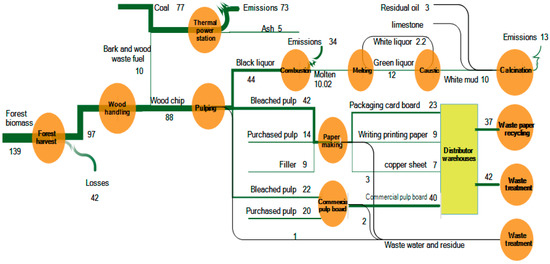

The forestry-pulp and paper industry is composed of a number of sectors, which essentially creates a material circulation network that connects multiple sectors and has multiple levels of characteristics [29,30]. The exchange of products and services between sectors leads to energy consumption and carbon transfer [31]. The forestry-pulp and paper industry production processes and the energy supply network are shown in Figure 1. The figure shows the forestry-pulp and paper industry production units and energy flow network. The squares in the figure represent the transitions, indicating various types of production processes, and corresponding physical and chemical changes are produced in the process; the left and right circles of the transition represent the input and product output of the carbon-containing resources, respectively; the arrows represent the flows of matter; the red circles represent the input and output of materials or energy; the grey circles represent CO2 emissions. The energy network is relatively independent (including energy production nodes, energy transmission paths, energy use nodes, energy conversion and energy recovery processes). The generation, conversion and transportation of energy flows are represented by different colors; the green arrows represent thermal energy flows; the blue arrows represent electrical energy flows; the brown arrows represent thermal energy recovery during production. The main production units and key equipment in the forestry-pulp and paper industry production are shown in Table 1.

Figure 1.

Production processes units and energy supplies.

Table 1.

Main production units and key equipment.

According to the energy consumption profile, the integrated production process of forestry pulp and paper can be classified into multiple sectors, and each sector may be divided into multiple production units [25,32]. External energy (coal, natural gas, electricity and steam) reach the plant boundary and produce on-site energy through CHP, which deliver thermal and electrical energy directly used to meet the power and steam needs of processes and non-process end uses. Another part of the on-site energy comes from a by-product that can be used as a fuel. For example, the black liquor produced in the pulping process is burned to obtain a large amount of heat energy, and a part of this heat energy is transported to each production unit as a process energy source.

Energy flows through various production units, resulting in energy consumption (such as facility energy consumption), energy form conversion (such as conversion of thermal energy into electrical energy and conversion of electrical energy into thermal energy), energy loss (including transport and conversion losses) and by-products that can be further be fueled (black liquor). The energy flows in the energy transportation will fork to generate multiple paths [34]. Different paths will transport energy to different process and non-process terminal energy consumption sites. A complex network is formed between the production units, and there are many energy flow bifurcation paths and cycles. Different energy flows are represented by different colors in Figure 1. In order to avoid double counting energy consumption, it is necessary to carefully distinguish the flow directions and conversion relationships among the energy flows.

2.2. Energy Consumption and Supply Modeling

2.2.1. Energy Consumption Based on Production Processes

The main production process of the forestry pulp-paper industry can be divided into forest tending, forest harvesting, preparation, pulping, bleaching, alkali recovery, slurry drying, papermaking, logistics and other production process units. Based on the supply chain perspective, the “cradle to gate” approach is a new insight to measure the energy consumption to improve energy efficiency and reduce carbon emissions [35,36,37]. The energy consumption equation is as follows:

(1) Energy consumption during forest cultivation and harvesting.

In the equation, is the energy consumption for forest cultivation and harvesting; is the wood volume and is the energy consumption per unit volume wood during forest cultivation and harvesting, taking 0.07 /m3 [38].

(2) Energy consumption of material transportation.

In the equation, is the energy consumption of material transportation, including the energy consumption of the main material and auxiliary materials transportation, GJ; is the material quantity, t; is the transportation distance, km and is the energy consumption per t km, and taking the energy value of unit mass diesel, 0.01922 GJ/t km [33]. The average transportation distance of domestic production materials is set to 100 km, and the average transportation distance of imported materials is set to 500 km.

(3) Energy consumption equation of production process.

The main production processes of pulp and paper companies include preparation, pulping, washing, bleaching, evaporation, alkali recovery, causticization, calcination, slurry preparation, pressing, drying, calendaring, waste treatment, etc. [25]. The total energy consumption model based on the production process is as follows.

where represents the total energy consumption of the production process, GJ; , and represent the steam consumption of process , GJ, power consumption, GJ, and fossil fuel consumption, GJ, respectively.

The energy consumed per unit of the product output in the production process is called energy intensity. Where , and represent the steam consumption intensity of process unit , MMBtu/adt, power consumption intensity, kWh/adt, and direct fossil fuel consumption intensity, MMBtu/adt respectively. , and represent the heat enthalpy value of unit steam, GJ/kg, electricity, GJ/kWh, and fossil fuel, GJ/kWh, respectively. represents the yield of process unit .

2.2.2. Energy Supply and Conversion Processes

(1) Energy supply.

The energy in the forestry-pulp and paper industry comes mainly from electricity and heat, produced by coal and other auxiliary fuels. Energy is present in different forms attached to a certain carrier, including fossil energy, biomass energy and current, water and steam. The thermal enthalpy and conversion parameters are in Table S2. The equations are as follows.

The effective calorific value of coal combustion is:

where, is the coal energy supply, GJ; is the calorific value of the unit mass of coal, GJ/t; is the total coal supply, t; is the boiler combustion efficiency and is the energy conversion ratio.

The effective calorific value produced by bark burning is:

where, is the bark burning energy supply, GJ; is the calorific value of the bark of unit mass, taking 4 GJ/admt; is the total supply of bark, t; is the combustion efficiency of the boiler and is the ratio of energy conversion.

The effective calorific value produced by black liquor combustion is:

where, represents the calorific value of black liquor combustion, GJ; represents the calorific value of black liquor per unit mass, taking 14 GJ/tDS; is the total supply of black liquor, admt; is the combustion efficiency of the boiler and is the ratio of energy conversion.

In addition to the energy consumption of the on-site production process, there are certain energy consumption and losses in the non-process primary energy production outside the factory, secondary energy production at the plant site, energy transportation, energy use, energy recovery and auxiliary facilities and lighting.

(2) Energy conversion processes.

In the production process, energy is constantly undergoing formal transformation and interaction, such as conversion of chemical energy into heat energy, conversion of heat energy into electrical energy, and conversion of electrical energy into kinetic energy. To analyze the transfer and transformation of energy from the perspective of energy flow, it is necessary to define the source and sink of the energy flow. Fossil energy and biomass energy are burned in boilers, converting energy into heat and using hot water and steam to transfer heat. An important carrier of energy flow in the pulp and paper industry is water, which enables heat transfer and thermal energy utilization through heat exchange between two forms of water (water and steam) [33]. Important nodes in the energy flow network include fuel supplies, steam boilers, alkali recovery boilers, steam turbine generator sets and energy-consuming production and living units. In different production processes, energy transfer will cause loss, conversion and emissions. Energy efficiency analysis needs to consider the energy loss, heat recovery and heat dissipated in hot waste water and flue gas during the exchange of different energy forms.

After a certain conversion, the energy is transferred from the source to the sink through a certain carrier, such as hot water, steam, electric wire and the like [33]. Energy can cause some loss and consumption during the conversion and transmission processes, depending on the efficiency of the process such as boiler and heat exchange. The energy conversion rate is calculated as:

where represents the energy conversion rate; represents the loss generated during the combustion of high-pressure steam for energy combustion; represents the loss of high-pressure steam converted to medium-low pressure steam; indicates the energy loss in the interaction between steam and heat sink and indicates the energy that fuel combustion can provide for the production process. The rest of the energy is discharged with the waste water and flue gas.

For process unit , its energy use efficiency equation is:

where represents the energy use efficiency of the production unit ; represents the steam mass, kg; represents the thermal enthalpy value of the unit steam mass, KJ/kg·°C; represents the intake air temperature; represents the extraction steam temperature and represents the energy supply of the production unit .

2.3. Carbon Footprint Modeling

2.3.1. Framework of the Carbon Footprint

The life cycle processes of the forestry-pulp and paper industry include various stages such as forest tending, wood harvesting, preparation, pulping, papermaking, product distribution and use [39]. From the perspective of the supply chain, carbon will undergo spatial and morphological changes at different stages of the supply chain [40]. Spatially, carbon sinks from company’s forest plantation will go through different sectors in the supply chain, including wood chip processing plants, pulp mills, paper mills and finally to dealer warehouses around the world. A range of processes from forest breeding to final paper product consumption will also bring about a variety of carbon morphological changes.

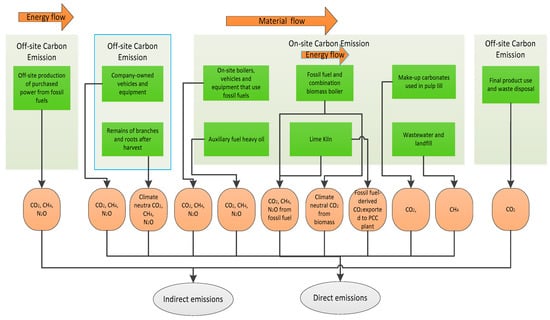

In general, carbon comes mainly from three major parts: Electricity consumption, fossil fuels and pulp and paper raw materials. The forestry-pulp and paper industry consists of a number of different production sectors, essentially creating a material distribution network with multiple levels of characteristics that connects multiple sectors. Each sector generates carbon emissions based on energy consumption and physical and chemical changes in materials. Carbon flows are generated due to the transfer of materials [41,42,43,44]. According to the Greenhouse Gas Protocol: Guidelines for Enterprise Accounting and Reporting [43], the carbon emissions of forestry-pulp paper companies mainly comes from the inner CHP which include: Indirect carbon emissions from external thermal power supply, direct carbon emissions from combustion of thermal power plants, direct carbon emissions from biomass energy combustion, carbon emissions from direct fuel combustion in the production process and non-process, carbon emissions from the biological treatment process of wastewater, and carbon emissions generated by the volatilization of the production processes. The carbon emissions generated by the on-site and off-site primary and secondary energy supply and transportation losses can be mapped to the production units and transportation links of the plant. The framework of the carbon footprint is shown in Figure 2.

Figure 2.

Framework of the carbon footprint.

Six important greenhouse gases are specified in the Kyoto Protocol, namely carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), hydrofluorocarbons, perfluorocarbons and sulfur hexafluoride. Different greenhouse gases have different radiation characteristics, so the effect of a temperature increase caused by their emission into the atmosphere is also different. The global warming effects of various other greenhouse gases in 100 years, namely global warming potential (GWP), were converted to a CO2 equivalent, according to the method of the lifecycle assessment of greenhouse gas given in PAS 2050 [45]. The first three types of greenhouse gases account for a large proportion of global greenhouse gas emissions, and are more common in various industrial production sectors, of which CO2 and CH4 has accounted for 86% of the greenhouse effect.

2.3.2. Direct Carbon Emissions from Fossil and Biomass Fuel Combustion

The coal, natural gas, bark and wood residual, black liquor and auxiliary fuels (heavy oil) are burned in boilers to generate secondary thermoelectric energy, while emitting a large amount of carbon dioxide. Although measurements of biomass burning are not prescribed in the Kyoto Protocol, a large amount of methane and nitrous oxide released in this industry still play an important role in climate impact [46,47,48]. A direct carbon emission model for fossil and biomass fuels is established based on the Equations (7)–(9).

The carbon emission equivalent equation is as follows:

where, is the CO2 equivalent produced by fuel combustion; is the energy value of the fuel, GJ; is the emission factor of greenhouse gas for fuel combustion and is the 100-year global warming of greenhouse gas . It is assumed that the fuel is fully combusted, that is, the combustion rate is 100%.

Fossil and biomass fuels produce steam and electricity through CHP, one part being used in the production process and the other being lost. The carbon emissions from energy consumption are concentrated when the fuel is burned. In order to express the carbon emission effect caused by the energy consumption of each production process, the CO2 released is distributed according to the energy consumption of each process unit, which is called the embodied carbon emission. In the process of fuel combustion into thermoelectric energy and transportation, certain losses will occur, especially in steam transportation. The carbon emission equivalent of fuel combustion can be mapped to each production and auxiliary process unit in embodied carbon flow and carbon emissions.

2.3.3. Direct Carbon Emissions from Forest Tending, Harvesting and Transportation

Carbon emissions from forest tending and harvesting come from the burning of non-road mobile facilities using diesel as fuel [38]. According to the forest tending and harvesting energy consumption Equation (1), a direct carbon emission model for forest tending and harvesting is obtained.

where, is the CO2 equivalent of diesel consumed by the facility; is the energy consumed by diesel for non-road forestry operations, GJ; is the emission equivalent factor of greenhouse gas for diesel and is the 100-year global warming potential of greenhouse gas .

The materials transported in the forestry-pulp and paper industry mainly include logs, pulp boards, paper, coal, coal slag ash, sludge and chemical raw materials. According to factory surveys, the total annual transportation volume was 6.048 million t/a, of which the import volume was 3.782 million t/a, and the shipment volume was 2.266 million t/a. Material transportation is often in the form of trucks. Distance-based emission factor methods are often used because of the difficulty in obtaining accurate fossil fuel consumption data for carbon emissions calculations in vehicle transportation. According to the equation of material transportation energy consumption (2), the direct carbon emission model of material transportation is obtained.

where is the CO2 equivalent of diesel consumed by the facility, is the energy consumed by the diesel, GJ; is the emission equivalent factor of the greenhouse gas produced by diesel and is the 100-year global warming potential of greenhouse gas i.

2.3.4. Indirect Carbon Emissions from Energy Consumption in the Production Process

The total carbon equivalent of the production process unit is equal to the sum of the direct carbon emission equivalent of the process unit and the indirect carbon emission equivalent of the process unit. Direct carbon emissions from the process unit are due to fuel combustion or waste leakage within the unit; indirect carbon emissions from the process unit are those that are produced by upstream authorities in the supply chain to meet the production needs of a downstream sector. When accounting for indirect carbon emissions, the principle of consumer territoriality is often used to allocate the total amount of upstream carbon emissions to various consumer units. The forms of energy consumed by the process unit are primarily electricity, heat and auxiliary fuel. Based on the energy consumption analysis of the production process, the calculation model of the indirect carbon emission equivalent of the production process unit based on energy consumption is as follows.

(1) Indirect carbon emissions from electricity use.

The greenhouse gas (GHG) emission model generated by electricity use is:

where, is the CO2 emission equivalent caused by electricity; is the electricity consumption, kWh; is the grid greenhouse gas emission equivalent factor of greenhouse gas i and is the 100-year global warming potential of greenhouse gas .

(2) Indirect carbon emissions from thermal use.

The thermal use carbon emission equivalent calculation equation is:

where is the CO2 emission equivalent caused by thermal use; is the steam consumption, kg; is the thermal enthalpy of steam under the pressure ; indicates the emission coefficient of greenhouse gas caused by heat and is the 100-year global warming potential of greenhouse gas .

2.3.5. Embodied Carbon Flows Based on Production Materials

Embodied carbon flow refers to the carbon flow that is embodied in material in the form of a carbon element and enters a certain sector in order to meet the demands for the product. The size of the embodied carbon flow depends on the amount of material the sector receives and its carbon content. When the embodied carbon flow of a certain sector flows downstream, it may also flow to different paths. The proportion of each tributary depends on the actual situation of production activities. Based on the supply chain network structure and the input–output relationship matrix of each level, it can be traced back to the carbon resources of the upstream relevant sectors from the downstream product demands [49].

The calculation of the embodied carbon flow and carbon emissions in the forestry-pulp and paper supply chain is mainly based on the material balance of input and output at all levels in the supply chain [26,50]. First, based on the input–output mapping matrix among the various sectors, the loss rate is fully considered, and the resource consumption of each sector is calculated. Secondly, based on the carbon content of each resource, the embodied carbon flow of each sector is further calculated. The measurement of embodied carbon flows and carbon emissions require full consideration of the complex physical and chemical changes in the supply chain. In the forestry-pulp and paper supply chain, due to consumer demands for downstream paper products, the embodied carbon stream flows from upstream to downstream, and carbon emissions are generated in the production activities of relevant sectors at each level. Thus, based on the market demands for final paper products, input and output of various materials at all levels in the supply chain can be obtained, including paper products, pulp, excipients, wood chips, logs, coal, bark and the fossils such as black liquor and biomass fuel.

The input–output method is used to calculate the embodied carbon flows in the material [31]. By the Leontief equation, there is:

where is the final products demand vector; is the total output vector; is the matrix of consumption coefficients and the element of represents the input–output coefficient between sector and sector .

where is the inverse matrix of the Leontief matrix and its element represents the total output (direct and indirect) from sector to meet one unit of demand of sector .

Using the power approximation of the Leontief inverse matrix [51], we can get:

where . It is assumed that the various levels of the supply chain have the relationship among different levels, that is, the previous level of each sector inputs resources for production, whose output will be reinvested as raw materials to the next level of production activities. The multi-level input-output model of the supply chain can be established based on the Leontief inverse matrix [31].

From Equation (19) we can get:

The power expansion of the Leontief inverse matrix is understood as the input–output relationship at multiple levels of the supply chain. Assuming is the final product demands vector, to meet the market demands for the product, the embodied carbon flow of sector in level is:

where represents the carbon content of the resource of sector s at level ; A represents the matrix of consumption coefficients and is a vector indicating the input–output coefficients matrix among sector s and other sectors.

3. Results

3.1. Energy Consumption and Energy Flows

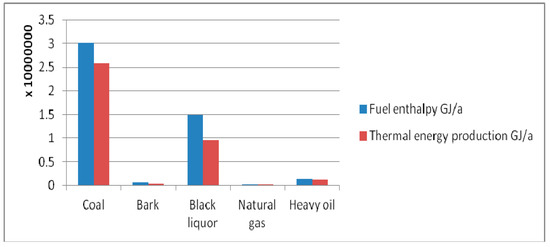

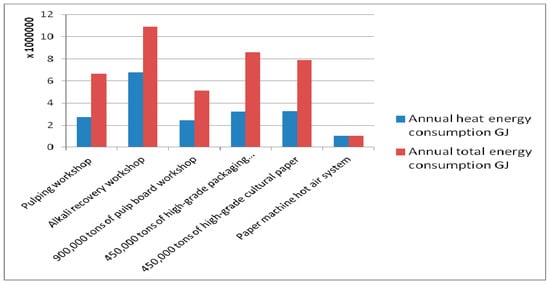

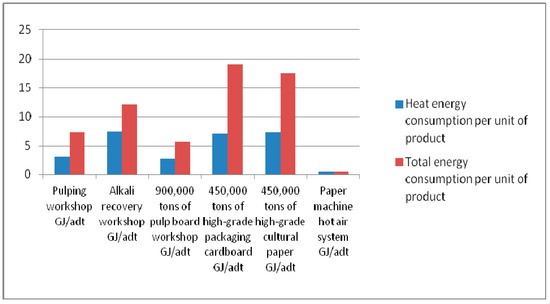

Based on Equations (7)–(9), Table S1 and Table S2, the total thermal enthalpies and energy production of different fuels were calculated, as shown in Figure 3. Based on the energy consumption parameters of major production processes in Table S1, we calculated the thermal energy consumption and comprehensive energy consumption (heat energy, electric energy and water treatment) of the main production units. The results are shown in Figure 4 and Figure 5.

Figure 3.

Main fuel thermal enthalpy and thermal energy production.

Figure 4.

Annual energy consumptions of the major production units.

Figure 5.

Energy consumptions of the main production units.

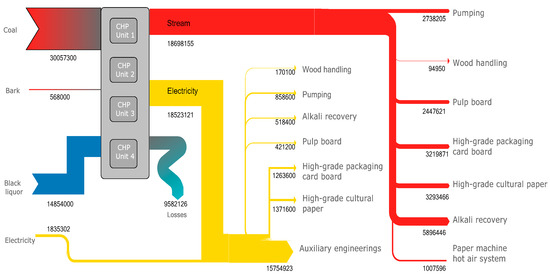

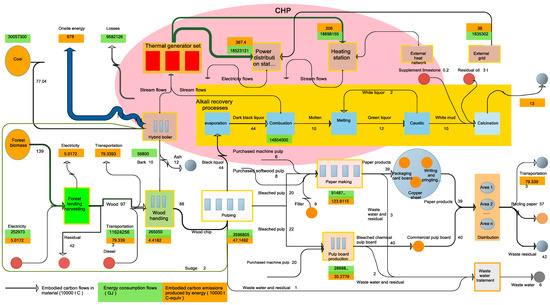

Each production unit needs to consume different types of energy such as electricity, steam, fossil fuel, etc., and the by-product black liquor in the alkali recovery process is an important fuel source. The energy flowchart of the pulping and papermaking processes is shown in Figure 6. The basic parameters are in Tables S3–S6. The software package e!Sankey 4 was used when making the flowcharts [1]. As we can see from Figure 6, the two main sources of energy were external coal and internal black liquor, which supplied 30,057,300 GJ and 14,854,000 GJ, respectively. It can be seen that black liquor played an extremely important role in energy recycling. External electricity and internal bark provided a small amount of energy for the system. As auxiliary fuels, the energy flows of natural gas and heavy oil are not shown in Figure 6. The CHP system has four units, corresponding to the actual “four furnace three machines”, namely an alkali recovery boiler, three sets of fluidized bed boilers and steam turbine generator sets. The parameters are in Tables S8 and S9. Most of the steam and electric energy were produced from the CHP, and a small part was supplied from outside the company. The energy produced by CHP was used in various production plants and auxiliary works. Heat energy was mainly used for alkali recovery, pulping, pulp board, high grade packaging paperboard, high grade cultural paper and the paper machine hot air system. The power output was mainly used for auxiliary projects (including water supply engineering, circulating water engineering, sewage process engineering, compressed air stations, oxygen plants, thermal power plants, etc.) and machine drives in various production plants. The steam energy output accounted for the majority of energy production, and the electricity energy output was smaller than the steam energy output. Losses in heat exchange and transportation (including energy generation, energy transmission and direct end uses) accounted for about 20% of the total energy. In different production units, due to different ways of using energy, the ratios of final energy applications and thermal energy consumption were significantly different.

Figure 6.

Energy flows in pulping and papermaking workshops (unit: GJ).

3.2. Carbon Flows and Emissions

3.2.1. Carbon Emissions from Production Processes

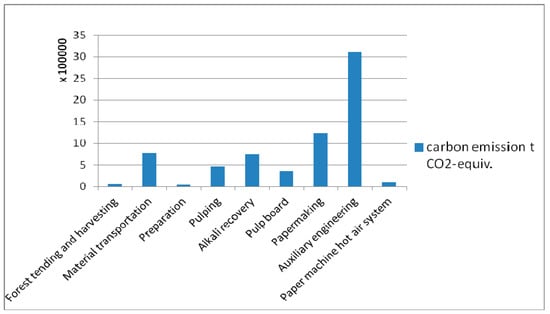

According to the calculation results, the company needed about 3,397,100 m3 log one year (debarked), and it was about 3,613,900 m3 before debarking. The energy consumed during the cultivation and harvesting of the forest was 252,973 GJ/a. The carbon equivalent produced by cultivation and harvesting was 16,899 t CO2-equiv/a. The energy consumption of material transportation was 11,624,256 GJ/a. The energy equivalent of the energy consumption of material transportation was 776,500 t CO2-equiv/a. The statistical average transport distance was 100 km. The total requirement of the coal of the thermal power station was about 110.912 million tons one year. If the carbon content was set to 70% as shown in Table S7, then the carbon content was 770,400 tons. According to the boiler combustion efficiency parameters in Table S2, the coal and bark combustion conversion rates were set to 86% and 69%, respectively, and the black liquor combustion boiler efficiency was set to 64%, allowing for calculations of direct carbon emissions from fuel burning. Based on the energy flow and the carbon emission equivalent value per unit of energy consumption in Figure 7, we calculated the carbon equivalent of energy consumption. According to the Kyoto Protocol, carbon emission equivalents from biomass burning are negligible. Based on the carbon content of the materials, the conversion ratio parameters and the carbon emission factors, with 900,000 tons of pulp and 900,000 tons of paper as the final output basis, the embodied carbon flows and carbon emissions from energy consumption could be calculated.

Figure 7.

Carbon emission from energy consumption in production processes.

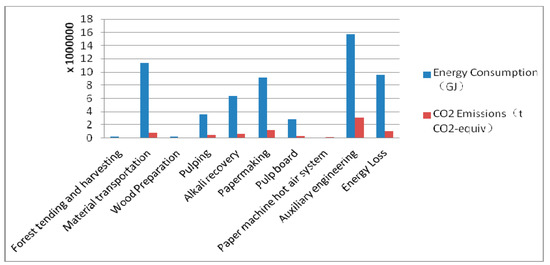

A large part of the carbon emissions from the forestry-pulp and paper industry was generated by energy consumption from different sectors including forest tending and harvesting, material transportation, wood preparation, pulping, alkali recovery, pulp board manufacturing, papermaking and auxiliary engineering. The energy consumption of the pulping and papermaking workshops came mainly from the steam and electricity generated by the combustion of coal, bark and other fuels in CHP. Based on Tables S8–S10, the carbon emission equivalent histogram generated by the energy consumption of each main workshop is shown in Figure 7.

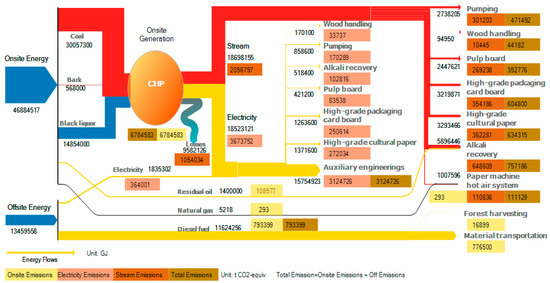

3.2.2. Carbon Footprint of Energy Supply

The carbon footprint of the forestry-pulp and paper industry energy supply is shown in Figure 8. The arrows in Figure 8 represent the energy flow, and the numbers under the arrows represent their energy values. Energy was divided into onsite energy and offsite energy. Onsite energy came mainly from coal, bark and black liquor. They generated heat and electricity through CHP. In addition, natural gas and heavy oil were used for auxiliary fuel. Offsite energy came mainly from external electricity and diesel. The total carbon emission of the annual energy supply of the case company was about 8.03 million tons, mainly from the internal CHP, external electricity supply, heavy oil and the diesel using for transportation vehicles. The sources of fuels included fossil energy (coal), biomass fuel (bark) and black liquor. The carbon emissions from the energy consumption of each process are marked in a brown box. The thermoelectric power boiler used a fluidized bed boiler that burned coal and bark wood chips for heating and power generation; the alkali recovery boiler burned black liquor to generate high-pressure superheated steam, which was still supplied to the production workshop after power generation. The thermal power station also provided thermoelectric energy for the operation of public facilities such as water treatment and living lighting. As can be seen from Figure 8, the largest source of carbon emissions was the indirect carbon emissions generated by auxiliary engineering power consumption, reaching 3,124,726 tons of CO2 equivalent followed by diesel used in vehicle transportation, and its carbon emissions reached 793,399 t CO2 equivalent. In the pulp and paper workshops, the alkali recovery, pulping and papermaking processes indirectly generated large amounts of carbon emissions due to the consumption of large amounts of heat and electricity.

Figure 8.

Carbon footprint of energy supply.

In order to meet the demands for the final product, each process in the upstream of the supply chain invested a certain amount of resources and energy for production, resulting in embodied carbon flows. The conversion ratios of various materials in the production processes and the raw material ratio of the main products are shown in Tables S11–S14. Based on the product life cycle perspective and input–output model, we calculated the embodied carbon flows in the production processes in the reverse direction of the supply chain. The results are shown in Figure 9. As can be seen from the figure, the system involved a total amount of biomass carbon of about 1.39 million tons, including roots and branches. These carbon sinks were embodied in the biomass material and flowed along the supply chain of the production system to the final product. In the wood handling workshop, a part of carbon was embodied in the bark, about 100,000 tons, and was sent to the power boiler to burn with the coal to generate thermoelectric power. About 880,000 tons of carbon was embodied in the wood chips for pulping. In the carbon pulp and paper workshop, 440,000 tons were sent to the recovery boiler and burned in the black liquor. The slurry purchased from the external market contains about 440,000 tons of carbon. Waste paper recycling and landfill disposal had important impacts on the carbon cycle. If the proportion of waste paper recycling is higher, the carbon emissions from landfill and combustion will be less. There is still considerable uncertainty and potential in this area.

Figure 9.

Embodied carbon flows based on product life cycle (unit: 10,000 t C).

3.3. Flowchart of Material, Energy and Carbon Flows

Based on the above calculation and analysis, the whole flowchart of the energy flows, embodied carbon flows and emissions in the forestry-pulp and paper industry were obtained and depicted in Figure 10. The arrows represent the directions of the embodied carbon flows and energy flows. The flowchart consisted of two major sections, the forestry-pulp and paper system and the CHP system. The thermal and electrical energy produced by CHP was supplied to various production process units in the pulp and paper mills. From Figure 10, we can observe the carbon flows embodied in the material input and product output, the thermoelectric energy consumption of each process unit and the carbon emissions from the energy consumption from the perspective of the overall landscape. For example, for forest tending and harvesting, involving 1.39 million tons of biomass carbon sinks, electricity use contained 252,973 GJ of energy, and electricity consumption indirectly produced about 50,000 tons of CO2 equivalent emissions. About 970,000 tons of carbon were embodied in the harvested logs and transported to the wood preparation plant. The remaining branches and roots contained about 420,000 tons of carbon. Due to the complexity of the system, multiple processes in the production supply chain involved the circulation of materials and energy. For example, sludge produced by pulping was sent to a power boiler for combustion, and white liquor was reused in alkali recovery. Accurately estimating energy consumption and carbon emissions from various production processes is a huge challenge.

Figure 10.

Flowchart of energy flows, embodied carbon flows and emissions in the forestry-pulp and paper industry (Units: Energy, GJ; embodied carbon flows, 10,000 t C; carbon emissions, t CO2-equiv).

4. Discussion

The key to the overall energy conservation and emission reduction of the forestry-pulp and paper industry system is to find the hot-spot energy consumption units. On-site energy consumption is mainly in the form of heat and electricity. Different production materials and equipment technologies produce different carbon emissions, and the amount of steam and electric energy consumed is different. From Figure 6, Figure 7 and Figure 8, the total thermal energy consumption and the embodied carbon emissions of the main production processes could be calculated, as shown in Figure 11. It can be seen from Figure 11 that the processes with large energy consumption mainly included auxiliary engineering, material transportation, energy loss, paper making, alkali recovery and pulping.

Figure 11.

Energy consumption and embodied carbon emissions from major production processes.

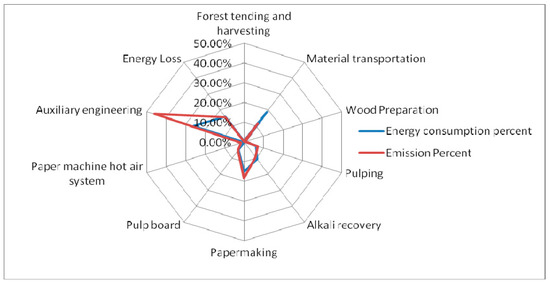

Figure 12 is a comparison between the percentage of total energy consumption and the percentage of total carbon emissions in each production process. As can be seen from the figure, the proportion of carbon emissions in each production process was not completely linearly related to the proportion of energy consumption. Lower energy efficiency processes were linked to higher carbon emissions. For example, the auxiliary projects consumed about 26% of the total energy consumption, and accounted for about 46% of the total emissions. Papermaking consumed about 15% of the total energy consumption with 18% of the total emissions. Material transportation accounted for nearly 19%, and the percentage of the carbon emissions was 11%. This was due to the fact that electricity production came from coal combustion, and the efficiency of coal combustion was much lower than diesel.

Figure 12.

Comparison of energy consumption and carbon emissions in major production processes.

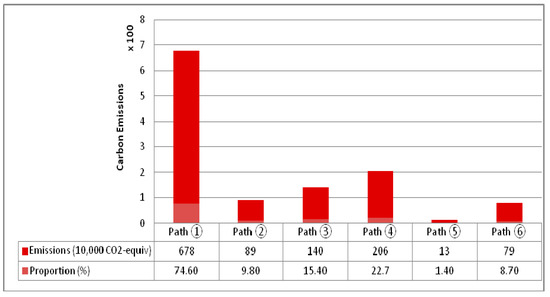

A plurality of hot-spot carbon flow paths can be obtained from Figure 9 and Figure 10. A hot-spot carbon flow path refers to a path consisting of a series of adjacent production processes with high embodied carbon flows and large emissions. In consideration of the main production process units, the total number of carbon flow paths in the forestry-pulp and paper industry supply chain may be thousands or even tens of thousands, and detailed calculations need to be processed by means of network modeling and analysis tools [52,53]. In fact, in a carbon flow path, people are most concerned about a section with the largest carbon emissions, rather than the entire path, in order to accurately implement equipment technology upgrades or process modification measures to effectively reduce carbon emissions. Table 2 lists the key sections of the hot-spot carbon flow paths and their proportions. Among them, the path ① is one of the energy supply paths, and the rest are the production side paths. Figure 13 visually compares the amount of carbon emissions from each hotspot path and its proportion in the form of a histogram. As can be seen from the figure, the carbon emissions generated by path ① accounted for 74.6% of the total emissions generated by the energy supplies, and the carbon emissions generated by path 4 accounted for 22.7% of the total emissions generated by the energy consumption processes. Referring to Figure 11, we also know that one hot-spot carbon flow path usually contains hot-spot energy consumption units linked with major energy location processes.

Table 2.

Hot-spot paths of carbon flows unit: Ton.

Figure 13.

Hot-spot carbon flow paths.

5. Conclusions

The forestry-pulp and paper industry is a typical high energy consumption and high emission industry. We conducted an in-depth research on the energy flows and carbon footprint of the forestry-pulp paper industry. The results show that: (1) The main sources of energy supply included external fossil fuel coal and internal biomass fuel black liquor, which supplied 30,057,300 GJ and 14,854,000 GJ respectively; external electricity and internal bark provided a small amount of energy to the system; in addition, the energy produced by diesel in material transportation reached 11,624,256 GJ. (2) The main energy consumption processes included auxiliary engineering projects, material transportation, papermaking, alkali recovery, pulping and other production workshops. The percentages of energy consumption accounted for 26%, 18%, 15%, 10% and 6%, respectively. (3) The main sources of carbon included coal and forest biomass, reaching 770,000 tons and 1.39 million tons, respectively. (4) Carbon emissions mainly occurred in fuel combustion in CHP and diesel combustion in material transportation, reaching 6.78 million tons and 790,000 tons of carbon, respectively. (5) Based on steam and electricity consumption, the indirect carbon emissions of various thermal and electric energy production units were calculated, and the key energy consumption process units and hotspot carbon flow paths were further found, which established a theoretical and methodological basis for energy conservation and emission reduction.

Supplementary Materials

The following are available online at https://www.mdpi.com/1999-4907/10/9/725/s1, Table S1: Energy consumption intensity table of major production processes, Table S2: Energy supply and conversion parameters in the forestry pulp and paper industry, Table S3: Carbon content of materials, Table S4: Conversion ratio parameters of materials in the supply chain, Table S5: Proportions of raw materials for high-grade packaging cardboard, Table S6: Main raw materials of high-grade writing paper, Table S7: Main raw materials of coated paper, Table S8: Boiler performance parameters, Table S9: Turbine generator set performance parameters, Table S10: Main production workshop heat load parameters, Table S11: Energy value and boiler combustion efficiency, Table S12: Carbon emissions parameters of raw materials, Table S13: Global warming potential of greenhouse gases for 100 years, Table S14: Emission Factors.

Author Contributions

Conceptualization, Q.Z.; methodology, Q.Z. and S.D.; investigation, Q.Z., Z.W. and A.T.; resources, Z.W.; writing—original draft preparation, Q.Z.; All authors contributed with ideas and discussion.

Funding

This research was funded by National Natural Science Foundation of China, grant number 71373125; Project of International Cooperation and Exchanges of National Natural Science Foundation NSFC, grant number 3136113034 and Academy of Finland, Grant number 265593.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Liu, Z.; Guan, D.; Wei, W.; Davis, S.J.; Ciais, P.; Bai, J.; Peng, S.; Zhang, Q.; Hubacek, K.; Marland, G.; et al. Reduced carbon emission estimates from fossil fuel combustion and cement production in China. Nature 2015, 524, 335–338. [Google Scholar] [CrossRef] [PubMed]

- Geels, F.W.; Sovacool, B.K.; Schwanen, T.; Sorrell, S. Sociotechnical transitions for deep decarbonization. Science 2017, 357, 1242–1244. [Google Scholar] [CrossRef] [PubMed]

- Geels, F.W.; Schwanen, T.; Sorrell, S.; Jenkins, K.; Sovacool, B.K. Reducing energy demand through low carbon innovation: A sociotechnical transitions perspective and thirteen research debates. Energy Res. Soc. Sci. 2018, 40, 23–35. [Google Scholar] [CrossRef]

- Wesseling, J.H.; Lechtenböhmer, S.; Åhman, M.; Nilsson, L.J.; Worrell, E.; Coenen, L. The transition of energy intensive processing industries towards deep decarbonization: Characteristics and implications for future research. Renew. Sustain. Energy Rev. 2017, 79, 1303–1313. [Google Scholar] [CrossRef]

- IEA (International Energy Agency). Global Energy and CO2 Status Report. 2019. Available online: https://webstore.iea.org/global-energy-CO2-status-report-2018 (accessed on 5 March 2019).

- He, Z.X.; Shen, W.X.; Li, Q.B.; Xu, S.C.; Zhao, B.; Long, R.Y.; Chen, H. Investigating external and internal pressures on corporate environmental behavior in papermaking enterprises of China. J. Clean. Prod. 2018, 172, 1193–1211. [Google Scholar] [CrossRef]

- Chen, J.; Ter-Mikaelian, M.T.; Yang, H.; Colombo, S.J. Assessing the greenhouse gas effects of harvested wood products manufactured from managed forests in Canada. For. Int. J. For. Res. 2018, 91, 193–205. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, H.; Chen, J. Life-cycle carbon budget of China’s harvested wood products in 1900–2015. For. Policy Econ. 2018, 92, 181–192. [Google Scholar] [CrossRef]

- Cotea, W.A.; Younga, R.J.; Risseb, K.B. A carbon balance method for paper and wood products. Environ. Pollut. 2002, 116, 1–6. [Google Scholar] [CrossRef]

- Shabbir, I.; Mirzaeian, M. Carbon emissions reduction potentials in pulp and paper mills by applying cogeneration technologies. Energy Procedia 2017, 112, 142–149. [Google Scholar] [CrossRef]

- Korhonen, J.; Wihersaari, M.; Savolainen, I. Industrial ecosystem in the Finnish forest industry: Using the material and energy flow model of a forest ecosystem in a forest industry system. Ecol. Econ. 2001, 39, 145–161. [Google Scholar] [CrossRef]

- Trudeau, N.; Tam, C.; Graczyk, D.; Taylor, P. Energy Transition for Industry: India and the Global Context; IEA (International Energy Agency): Paris, France, 2011. [Google Scholar]

- Kong, L.; Hasanbeigi, A.; Price, L. Assessment of emerging energy-efficiency technologies for the pulp and paper industry: A technical review. J. Clean. Prod. 2016, 122, 5–28. [Google Scholar] [CrossRef]

- Kong, L.; Price, L.; Hasanbeigi, A.; Liu, H.; Li, J. Potential for reducing paper mill energy use and carbon dioxide emissions through plant-wide energy audits: A case study in China. Appl. Energy 2013, 102, 1334–1342. [Google Scholar] [CrossRef]

- Bieler, P.S.; Fischer, U.; Hungerbühler, K. Modeling the Energy Consumption of Chemical Batch Plants: Bottom-Up Approach. Ind. Eng. Chem. Res. 2004, 42, 6135–6144. [Google Scholar] [CrossRef]

- Chen, H.W.; Hsu, C.H.; Hong, G.B. The case study of energy flow analysis and strategy in pulp and paper industry. Energy Policy 2012, 43, 448–455. [Google Scholar] [CrossRef]

- Hong, G.B.; Ma, C.M.; Chen, H.W.; Chuang, K.J.; Chang, C.T.; Su, T.L. Energy flow analysis in pulp and paper industry. Energy 2011, 36, 3063–3068. [Google Scholar] [CrossRef]

- TAPPI. Available online: https://www.tappi.org/industries/bioenergy/ (accessed on 8 May 2019).

- CEPI (Confederation of European Paper Industries). Unfold the Future: The Forest Fibre Industry—2050 Roadmap to a Low-Carbon Bio-Economy; Confederation of European Paper Industries: Brussels, Belgium, 2011. [Google Scholar]

- Fisher, R. Analyzing Carbon Emissions in the Pulp and Paper Industry. 2014. Available online: http://www.tappi.org (accessed on 10 August 2018).

- Laurijssen, J.; Faaij, A.; Worrell, E. Benchmarking energy use in the paper industry: A benchmarking study on process unit level. Energy Effic. 2013, 6, 49–63. [Google Scholar] [CrossRef]

- Manda, B.M.K.; Blok, K.; Patel, M.K. Innovations in papermaking: An LCA of printing and writing paper from conventional and high yield pulp. Sci. Total Environ. 2012, 439, 307–320. [Google Scholar] [CrossRef]

- Mantau, U. Wood flow analysis: Quantification of resource potentials, cascades and carbon effects. Biomass Bioenergy 2015, 79, 28–38. [Google Scholar] [CrossRef]

- Sun, M.; Wang, Y.; Shi, L.; Klemeš, J.J. Uncovering energy use, carbon emissions and environmental burdens of pulp and paper industry: A systematic review and meta-analysis. Renew. Sustain. Energy Rev. 2018, 92, 823–833. [Google Scholar] [CrossRef]

- AIChE (American Institute of Chemical Engineers). Pulp and Paper Industry Energy Bandwidth Study; American Institute of Chemical Engineers: New York, NY, USA, 2006. [Google Scholar]

- Zhao, Q.; Wen, Z.; Toppinen, A. Constructing the embodied Carbon flows and emissions landscape from the perspective of supply chain. Sustainability 2018, 10, 3865. [Google Scholar] [CrossRef]

- Toppinen, A.; Korhonen, K.K. Global Reporting Initiative and social impact in managing corporate responsibility: A case study of three multinationals in the forest industry. Bus. Ethics Eur. Rev. 2013, 22, 202–217. [Google Scholar] [CrossRef]

- D’Amato, D.; Wan, M.; Li, N.; Rekola, M.; Toppinen, A. Managerial Views of Corporate Impacts and Dependencies on Ecosystem Services: A Case of International and Domestic Forestry Companies in China. J. Bus. Ethics 2018, 150, 1–18. [Google Scholar] [CrossRef]

- Xu, T.; Galama, T.; Sathaye, J. Reducing carbon footprint in cement material making: Characterizing costs of conserved energy and reduced carbon emissions. Sustain. Cities Soc. 2013, 9, 54–61. [Google Scholar] [CrossRef]

- Acquaye, A.; Genovese, A.; Barrett, J.; Koh, S.L. Benchmarking carbon emissions performance in supply chains. Supply Chain Manag. Int. J. 2014, 19, 306–321. [Google Scholar] [CrossRef]

- Karali, N. Greenhouse Gas Mitigation Options in ISEEM Global Energy Model: 2010–2050 Scenario Analysis for Least-Cost Carbon Reduction in Iron and Steel Sector; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2014. [Google Scholar]

- Martin, N.; Anglani, N.; Einstein, D. Opportunities to Improve Energy Efficiency and Reduce Greenhouse Gas Emissions in the U.S. Pulp and Paper Industry; Ernest Orlando Lawrence Berkeley National Laboratory (LBNL): Berkeley, CA, USA, 2000. [Google Scholar]

- Mateos-Espejel, E.; Savulescu, L.; Maréchal, F.; Paris, J. Base case process development for energy efficiency improvement, application to a Kraft pulping mill. Part II: Benchmarking analysis. Chem. Eng. Res. Des. 2011, 89, 729–741. [Google Scholar] [CrossRef]

- Chen, C.; Qiu, R.Z. Estimation of energy consumption and carbon emissions of China’s pulp & paper industry. Chung-kuo Tsao Chih/China Pulp Pap. 2014, 33, 50–55. [Google Scholar]

- Brueske, S.; Sabouni, R.; Zach, C.; Andres, H. U.S. Manufacturing Energy Use and Greenhouse Gas Emissions Analysis; Office of Scientific & Technical Information Technical Reports; Office of Energy Efficiency & Renewable Energy: Washington, DC, USA, 2012; Volume 249, pp. 4196–4201. [Google Scholar]

- England, J.; May, B.; Raison, R.; Paul, K. Cradle-to-gate inventory of wood production from Australian softwood plantations and native hardwood forests: Carbon sequestration and greenhouse gas emissions. Forest. Ecol. Manag. 2013, 302, 295–307. [Google Scholar] [CrossRef]

- Wagner, M.; Lippe, M.; Lewandowski, I.; Salzer, M.; Cadisch, G. CO2 footprint of the seeds of rubber (Hevea brasiliensis) as a biodiesel feedstock source. Forests 2018, 9, 548. [Google Scholar] [CrossRef]

- Chen, H.; Chen, G.Q. Energy cost of rapeseed-based biodiesel as alternative energy in China. Renew. Energy 2011, 36, 1374–1378. [Google Scholar] [CrossRef]

- Pineda-Henson, R.; Culaba, A.B.; Mendoza, G.A. Evaluating Environmental Performance of Pulp and Paper Manufacturing Using the Analytic Hierarchy Process and Life-Cycle Assessment. J. Ind. Ecol. 2010, 6, 15–28. [Google Scholar] [CrossRef]

- Leuschner, C.; Moser, G.; Hertel, D.; Erasmi, S.; Leitner, D.; Culmsee, H.; Schuldt, B.; Schwendenmann, L. Conversion of tropical moist forest into cacao agroforest: consequences for carbon pools and annual C sequestration. Agrofor. Syst. 2013, 87, 1173–1187. [Google Scholar] [CrossRef]

- Hu, Y.; Lin, J.; Cui, S.; Khanna, N.Z. Measuring urban carbon footprint from carbon flows in the global supply chain. Environ. Sci. Technol. 2016, 50, 6154–6163. [Google Scholar] [CrossRef] [PubMed]

- Kang, C.; Zhou, T.; Chen, Q.; Wang, J.; Sun, Y.; Xia, Q.; Yan, H. Carbon Emission Flow from Generation to Demand: A Network-Based Model. IEEE Trans. Smart Grid 2017, 6, 2386–2394. [Google Scholar] [CrossRef]

- NCASI (National Council for Air and Stream Improvement, Inc.). Calculation Tools for Estimating Greenhouse Gas Emissions from Pulp and Paper Mills Version 1.1; National Council for Air and Stream Improvement, Inc.: Research Triangle Park, NC, USA, 2005. [Google Scholar]

- Gu, L.; Zhou, Y.; Mei, T.; Zhou, G.; Xu, L. Carbon Footprint Analysis of Bamboo Scrimber Flooring—Implications for Carbon Sequestration of Bamboo Forests and Its Products. Forests 2019, 10, 51. [Google Scholar] [CrossRef]

- BSI (British Standards Institution). PAS 2050: Specification for the Assessment of the Life Cycle Greenhouse Gas Emissions of Goods and Services; British Standards Institution: London, UK, 2011. [Google Scholar]

- Weaver, A.J. Climate change. Toward the second commitment period of the Kyoto Protocol. Science 2011, 332, 795–796. [Google Scholar] [CrossRef] [PubMed]

- Schulze, E.D.; Luyssaert, S.; Ciais, P.; Freibauer, A.; Janssens, I.A.; Soussana, J.F.; Smith, P.; Grace, J.; Levin, I.; Thiruchittampalam, B.; et al. Importance of methane and nitrous oxide for Europe’s terrestrial greenhouse-gas balance. Nat. Geosci. 2009, 4, 1685–1690. [Google Scholar] [CrossRef]

- IPCC (Intergovemmental Panel on Climate Change). Greenhouse Gas Inventory Book—1996 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 1996. [Google Scholar]

- Cheng, H.; Dong, S.; Li, F.; Yang, Y.; Li, S.; Li, Y. Multiregional Input-Output Analysis of Spatial-Temporal Evolution Driving Force for Carbon Emissions Embodied in Interprovincial Trade and Optimization Policies: Case Study of Northeast Industrial District in China. Environ. Sci. Technol. 2018, 52, 346–358. [Google Scholar] [CrossRef]

- Sarkis, J. A boundaries and flows perspective of green supply chain management. Supply Chain Manag. Int. J. 2012, 17, 202–216. [Google Scholar] [CrossRef]

- Tukker, A.; Dietzenbacher, E. Global multiregional input-output frameworks: An introduction and outlook. Econ. Syst. Res. 2013, 25, 1–19. [Google Scholar] [CrossRef]

- Sankey Diagram Software. Available online: https://www.ifu.com/e-sankey/? (accessed on 6 June 2018).

- Ulanowicz, R.E. Identifying the structure of cycling in ecosystems. Math. Biosci. 1983, 65, 219–237. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).