Abstract

Compared with purpose-built units, excavator-based harvesters offer many advantages, but they also face one main limitation: a much higher fuel consumption, which also results in higher CO2 emission levels. The fuel efficiency of excavator-based harvesters can be increased by a better interface between the excavator and the harvester head. This study aimed to determine the performance of a new adaptation kit, specifically designed to improve the communication between these two components. The new kit offers real-time adjustment between the power demand of the harvester head and the power output of the excavator, which should help reducing fuel consumption while stabilizing hydraulic fluid temperature. The test was conducted on 53 excavator-based harvesters purchased and managed by a large Brazilian company. Time use, fuel consumption and production were monitored continuously for one full month, before and after installation of the kit. Overall, the study covered 40,000 h of work, during which the harvesters cut, processed, and debarked 4.5 million trees, or 650,000 m3 of wood, under bark. Fuel consumption amounted to 900,000 liters. After installing the adaptation kit, productivity increased 6%, while fuel consumption per hour decreased 3.5%. Fuel consumption and CO2 emissions per product unit decreased 10%, as an average. The effect of random variability typical of an observational study prevented formulating an accurate figure for the amount of fuel that can be saved by installing the adaptation kit. Yet, one may confidently state that, in most cases, installing the kit results in a reduction of fuel use, and that such reduction is most often in the range from −10 to −20% on a per m3 basis.

1. Introduction

Harvesters are specialized forest machines designed for felling, delimbing, and bucking trees in a continuous sequence. Harvesters accomplish the same tasks performed manually with chainsaws, but they offer better value recovery [1], higher labor productivity [2], and dramatically improved operator safety and comfort [3]. These advantages are so attractive that one can find harvesters in all industrialized countries, especially in Europe, North America, and Russia [4]. In these regions, a growing proportion of all logging work is mechanized, with shares that reach almost 100% in Atlantic, Baltic, and Nordic Europe [5]. Market impacts are remarkable: the estimated demand for new harvesters in the EU between 2010 and 2030 amounts to 18,600 units [6], while the North American market may need additional 14,000–35,000 units in the same period [5]. In fact, the demand for mechanized forestry equipment is increasing on a global scale, and not just in the conifer forests of Europe and North America. Harvester use is now commonplace in close-to-nature forestry [7], mixed hardwood stands [8], and Mediterranean coppice forests [9]. Harvesters and processors are also very popular in plantation forestry worldwide, especially in the Iberian region [10], Italy [11], South Africa [12], and South America [13], where they perform most of the harvesting in the industrial pine, poplar, and eucalypt plantations. The overwhelming popularity of harvesters across widely variable regions is helped by their remarkable adaptability, which allows converting general purpose prime movers into efficient forest machines by installing a detached harvester head [14].

Excavators are often used as a base for building low-cost harvesters and represent a good alternative to purpose-built units [15]. The versatility of excavator-based harvesters improves overall economics when the harvester function is used for a relatively short proportion of the annual work time, which makes them ideal for part-time users [16]. Excavator-based machines are especially suited to tree farms and to stationary tasks (e.g., processing), where the special cross-country mobility of purpose-built harvesters is not required. Furthermore, excavators are robust, relatively inexpensive, and can be bought and serviced almost everywhere in the world. Local manufacturing and service do not only offer a fundamental logistical advantage, but they also result in a much cheaper purchase and maintenance cost in many countries where high trade tariffs are applied to imported products [15]. In fact, this is one of the main reasons for the immense popularity of excavator-based harvesters in much of Asia and South America.

The main disadvantage of excavator-based harvesters is a much higher fuel consumption than incurred by their purpose-built equivalents [17]. The latter incorporate a sophisticated machine control system that is capable of adjusting engine output to harvester power demand in real-time. This system allows substantial fuel economies, which can be further increased by skilful manipulation of machine settings [18]. Theoretically, excavators are equipped with similar systems and should achieve comparable fuel efficiency targets. However, the interface between the harvester head and an excavator that was not originally designed to receive it does not allow the same optimization level as obtained by purpose-built machines. Extending such benefits to excavator-based machines would require that the excavator manufacturers invested time and money into developing specific harvester capability options for one or more of their excavator models, or that the harvester head manufacturers developed effective adaptation kits, comprising both hardware and software. However, the very wide range of possible head and excavator combinations represents a main hurdle, because each combination may require its specific adaptation kit and the number of units produced for most such combinations is generally too small for justifying the effort of developing dedicated adaptation kits.

However, this general picture may suddenly change in the case of industrial purchases, as it actually occurred when a large Brazilian forest company acquired over 50 excavator-based units consisting of the same excavator and head combination. These numbers were large enough to justify ad-hoc developments, and that is exactly what happened. The technology provider developed an adaptation kit for the specific combination, which was fine-tuned on a handful of test units and eventually installed on the whole fleet. Data from this case allowed gauging the effectiveness of adaptation kits and their fuel-saving potential. Therefore, the goal of this study was to determine: (1) if installation of a dedicated adaptation kit reduced the fuel consumption and CO2 emissions of excavator-based harvesters; (2) how large was the fuel-saving potential; and (3) if productivity was affected by the installation of the adaptation kit (e.g., if productivity decreased due to a lower fuel flow, or increased due to more stable fluid temperature, among others). The study compared two treatments—before and after installing the adaptation kit. The null hypothesis was that fuel consumption per unit product and productivity were not significantly different between the two treatments.

2. Materials and Methods

The experiment was conducted on 53 excavator-based harvesters owned and managed by the Brazilian company Fibria (Figure 1). These machines were all the same model combination, and namely: a Komatsu PC200-8 excavator (20 t, 116 kW) and a Komatsu Forest 370 harvester head (1.6 t weight, 700 mm cut capacity). All machines were used for harvesting eucalypt trees grown in dedicated short-rotation plantations and normally cut at the age of four to six years, depending on stand productivity. The stands were planted with different clones of Eucalyptus Urograndis, a hybrid between E. urophylla (ST Blake) and E. grandis (W Hill ex Maiden). At the time of harvest, tree size ranged most commonly from 0.1 to 0.2 m3, but few compartments were harvested at the age of 11 years and yielded trees larger than 0.4 m3. All study plantations had been established on firm sandy soils, with an average slope gradient below 10%. Steeper sites would be harvested with purpose-built wheeled harvesters.

Figure 1.

One of the excavator-based harvesters at work (left); the adaptation kit (right).

In May 2012, six months after initial deployment, four machines were equipped with the HookUp adaptation kit, specifically designed to reduce fuel consumption by optimizing the interface between the excavator and the harvester head. This kit is developed in Brazil by Komatsu Forest for their own harvester head model 370, and is controlled by the on-board computer (OBC) through the Maxi Explorer software normally installed on Komatsu Forest harvesters. The system responds to a load-sensing device and adjusts the angle of the pump plates in order to deliver just the flow necessary for operating the machine at any given moment, instead of sending out the full flow and diverting back to the tank any surplus. This system prevents the pumps from generating more flow than necessary, to the benefits of reduced fuel consumption and of lower risk for overheating the hydraulic fluid, which is an additional source of inefficiency, especially in hot tropical climates.

Tests with the adaptation kit were successful, and by October 2012, all 53 machines had been equipped with the HookUp device. Since Fibria keeps accurate performance records for all their machines, it was possible to run a comprehensive validation test about the production and fuel saving impacts of the new adaptation kit. To that purpose, researchers pulled out the monthly records for all 53 machines under the two treatments: Before and after installing the adaptation kit. In particular, the before treatment was represented by the records for April 2012, which was the month immediately before installing the four test kits. Conversely, the after treatment was represented by the records for November 2012, which was the month immediately after all machines had received the adaptation kit. This way, it was possible to limit the effects of operator learning curve and of gradual availability of the kit, which was being installed on machines shortly after May, when the preliminary tests recorded their early success. Defining exactly when each machine was being fitted with the adaptation kit was difficult and selecting different dates risked generating attribution errors. On the other hand, seasonal variations are very small in Northeastern Brazil, where it is relatively warm and humid all year round. That is one of the reasons for the exceptionally fast growth of local plantations. Therefore, seasonal bias was considered to have negligible effects on the comparison study.

The following data was collected for each machine and month: work time (productive machine hours), total production (m3 under bark), average tree size (m3 under bark), and total diesel fuel consumption (l). In particular, work time was obtained from the machine hour meter, total production (m3) from mill delivery tickets, average tree size from the preharvest compartment inventory, and fuel consumption from the fleet management records. Relying on these sources, rather than on the machine onboard computers, established records independent of machine calibration accuracy. These data allowed calculating productivity and fuel consumption, per hour and per product unit. The database represented over 120 professional operators. All operators fulfilled company standards for skills, training and motivation, but had variable levels of experience and proficiency, which constituted an additional source of variability. No attempt was made to normalize individual performances by means of productivity ratings, and operator effect was considered as part of the random variability that was widely spread due to the very large number of operators included in the survey. All machines were run triple shifts.

Based on diesel fuel consumption, direct emissions were estimated using the following equation [19]:

where:

E = FC × CC × FO × CF

- E = CO2 emissions (kg m−3 solid volume of wood)

- FC = Diesel fuel consumption (l m−3 solid volume of wood)

- CC = Carbon content of diesel fuel = 0.732 kg l−1

- FO = Fraction of diesel actually oxidized = 1

- CF = Conversion factor of C into CO2 = 3.67

The dataset was analyzed with the SAS Statview advanced statistics software in order to extract descriptive statistics and to check the statistical significance of any differences between treatments. Before analysis, the data distribution plots were observed for normality. Minor deviations from the classic bell-shaped distribution were detected, and for this reason a robust general linear model and non-parametric techniques were used for the analysis. Since data were available for each individual machine before and after installation, paired analysis was applied to the dataset using the Wilcoxon Signed Rank test. Regression analysis was used to test the relationship between machine productivity and stem size. The regression analysis included an indicator variable for the adaptation kit treatment, which was tested for both separate effect and interaction effect (i.e., in combination with stem size). In all analyses, the elected significance level was α < 0.05.

Results were scaled up to company level by multiplying the eventual fuel and CO2 saving per m3 with the annual production of the entire fleet (53 units).

3. Results

Overall, the study included over 40,000 h of productive work, during which 4.5 million trees were harvested, accounting for 650,000 m3 under bark. Fuel consumption amounted to 900,000 liters. The grand means for tree size, productivity, and fuel consumption were, respectively: 0.145 m3, 15.8 m3 hour−1, 22 l hour−1 or 1.39 l m−3. Direct CO2 emissions averaged 3.8 kg m−3.

Descriptive statistics showed a general better performance for the after treatment: productivity increased 6%, while fuel consumption per hour decreased 3.5%. Fuel consumption and CO2 emissions per product unit decreased 10% (Table 1). That was true despite an 11% drop in mean tree size, from 0.164 to 0.145 m3. Conducted with the Wilcoxon Signed Rank test, pairwise comparisons indicated significant between-treatment differences for stem size (tied p-Value = 0.0404), productivity (tied p-Value = 0.0013), fuel consumption per hour (tied p-Value < 0.0001), fuel consumption per product unit (tied p-Value = 0.0040), and direct CO2 emissions per product unit (tied p-Value = 0.0040). Since direct emissions were calculated based on fuel consumption per product unit, analytical results were the same for both variables and the following paragraphs report the trends for fuel consumption only, in order to avoid repetition.

Table 1.

Main results of the experiment.

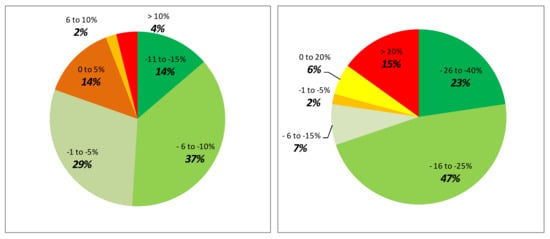

Given the observational character of the study, random variability still had a strong effect. Therefore, the fuel use reduction records were far from homogeneous. Fuel use reduction varied widely and was not achieved in all cases. In fact, 20% of the machines on test did not show any reduction of fuel consumption after installing the kit. Some even showed an increase of fuel consumption, which was occasionally high (Figure 2). For the remaining 80%, the reduction of fuel use obtained through the installation of the adaptation kit was quite variable, and ranged from −5% to −40%, when reported on a per m3 basis.

Figure 2.

Distribution of the number of units according to the percent variation in fuel use after installing the adaptation kit. The variation calculated in l hour−1 (left) and in l m−3 (right).

Despite the strong confounding effect of random variability, the analysis of covariance showed that fuel consumption was significantly affected by treatment, tree size, and the treatment per tree size interaction (Table 2). The effects of treatment and of tree size were equally strong when fuel consumption per hour was considered. In contrast, the effect of tree size on fuel consumption per product unit was three times as strong as that of treatment, because tree size also impacted productivity per hour, generating a multiplier effect. The strong impact of the interaction variable tree size x treatment on fuel consumption per hour and per unit product indicated that the benefit offered from the adaptation kit was proportional to tree size. In that regard, regression analysis allowed establishing that the proportional effect was direct, and that the fuel savings accrued with the installation of the adaptation kit increased with increasing tree size (Table 3). That explains why the equation for fuel consumption per hour is reported in the table. Although the low explanatory power (R2 < 0.1) denies any practical use of this equation, the equation itself shows that fuel savings increase with tree size, even when they are calculated on a per hour basis. That is quite relevant, because it suggests that fuel consumption is especially high when handling larger trees, and that the fuel saving potential is highest with them.

Table 2.

Results of the ANCOVA analysis for fuel use per hour and per product unit.

Table 3.

Regression equations for fuel use and productivity.

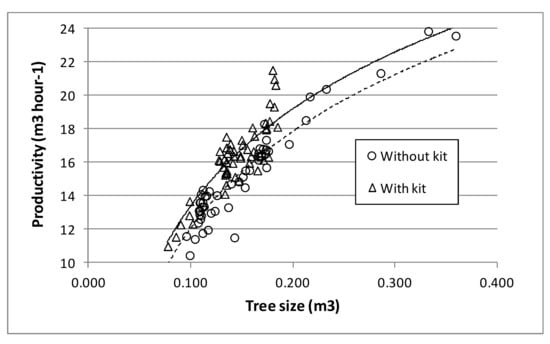

Regression analysis also allowed gauging the effects of tree size and of the adaptation kit on productivity. These two variables alone explained over 80% of the variability in the dataset, and the equation had a very strong predictive power (Table 3).

Moreover, the equation indicated that installing the adaptation kit had small, but positive, effect on productivity. Therefore, fuel savings were not gained at the cost of lower productivity. Fuel consumption was reduced not by crudely restricting fuel flow, but also by optimizing the excavator-head interface. The equation had a typical logarithm shape that described the law of diminishing returns, whereby the productivity increases associated with increasing stem size became progressively smaller as stem size kept increasing (Figure 3).

Figure 3.

Relationship between productivity in m3 under bark per work hour (excluding all major delays) and tree size (m3 under bark).

Scaling up unit results to company size indicated that the introduction of the adaptation kit allowed saving 612,900 liters of diesel per year and avoided the emission of 1650 t of CO2 per year.

4. Discussion

First, readers must be reminded that this study was observational and did not follow a strictly controlled experimental plan. That entailed specific limitations and advantages: on one hand, the absence of a controlled experimental layout made it very difficult to dampen the effect of casual error and resulted in the strong intrusion of random variability. One possible source of unaccounted variability was the inclusion in the records of the time and fuel spent for machine relocation. However, this effect was likely very small, and for at least two reasons. First, the rational layout of these plantations implied that compartments were generally large, and relocation was infrequent. Second, tracked machines are always relocated on low-bed trucks, unless travel distance is minimal and no paved roads have to be traversed. In any case, the effect of random variability made it hard to determine the exact value of any fuel saving effects. The mean values reported in the tables were strongly affected by the wide variability in the dataset, which included extreme figures possibly derived from measurement errors, improper installation of the kit or poor handling of the machine. In the absence of more detail that may point at specific errors, these extreme values were not removed from the dataset as outliers, and therefore their effect remains. A more accurate estimate of the potential saving could be gleaned from the medians, which were higher than the means and indicated a general skew in the data distribution, which was compatible with the effect of potential outliers indicating minimum fuel savings or even an increase of fuel consumption. Overall, the effect of random variability prevented formulating an accurate figure for the fuel saving effect of the adaptation kit. At present, one can only state that in most cases installing the kit will result in a reduction of fuel use, and that such reduction is most likely to be in the range from −10 to −20% on a per m3 basis.

On the other hand, this study seized all the advantages typical of observational studies, and namely: the possibility of including many machines (i.e., 53 units) and of covering relatively long observation periods (one month per machine and treatment). That offered the benefit of very robust results, which was demonstrated by the high statistical significance returned by most of the analyses. Therefore, if one cannot say exactly how large is the fuel saving obtained after installing the adaptation kit, one can be confident that the adaptation kit allows saving some fuel and that the amounts saved are most likely included within the bracket described in the study.

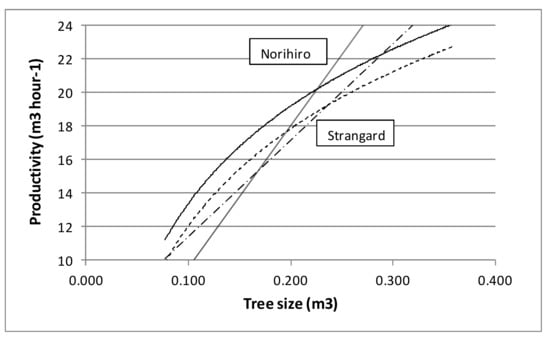

This same character applies to the results of the productivity study, as well. In that case, the prediction may also be rather accurate, because the productivity model obtained from the regression analysis is able to explain most of the variability in the dataset. So, the model is both robust and accurate. This statement is corroborated by the comparison with other similar studies, and in particular, by the good match with the productivity models recently published by Strandgard et al. [20] and by Norihiro et al. [21] for plantation eucalypt, respectively in Australia (E. globulus) and South Africa (E. grandis × camaldulensis, E. grandis × urophylla, E. smitthii, and E. dunnii) (Figure 4). Although these models represent different curve shapes—linear instead of logarithmic—the graphs are quite near to each other and represent very similar trends. What is more, the estimates obtained from this study are also in agreement with the figures reported in many other studies concerned with the productivity of CTL harvesters in eucalypt plantations, which span a period of 20 years [10,12,22,23,24,25,26,27,28]. Of course, agreement is not universal, and four short-term time studies conducted in Brazil report productivity figures that are approximately 50% higher than those indicated here [29,30,31,32]. However, an overwhelming majority within the relevant literature supports the model estimated in this study, offering a strong independent validation of its general accuracy and reliability.

Figure 4.

Comparison between the productivity models developed in this study and the productivity models published by Strandgard et al. [20] and Norihiro et al. [21].

It is also worth noticing that agreement is obtained between productivity studies with very different characteristics: A long-term observational study as presented here; a collection of over 40 short-term studies, lasting one or few hours each [20]; a compilation of five different time studies with widely variable sampling intensity [21]; and nine individual studies, lasting few days each [10,12,22,23,24,25,26,27,28]. Apparently, different techniques are capable of returning similar figures, all representing viable alternatives to reach the same goal: one may then select one, rather than the others, based on convenience and opportunity. If at all, the only dissonant notes come from single short-term time studies, which recommends special caution when generalizing the results of this type of studies.

If the study results were accurate enough for productivity, they might also prove reasonably accurate for fuel consumption, despite the limitations derived from the observational character of the study. After all, random variability is a fact of life, and while an observational study may not accurately gauge the potential of the adaptation kit, it likely offers a reasonably good estimate of its performance under real life conditions. In that case, the results point at a marked reduction of fuel consumption, of the same order obtained in other cases where machine settings were manipulated on harvesters [18] as well as on chippers [33,34]. Taken together, these studies suggest that the fuel savings reasonably achieved by setting adjustments or retrofit modifications are around −10%, or −20% in the best case. Further reduction of fuel use may require more radical interventions.

On the same note, one may want to know if these modifications are enough to fill the gap between excavator-base and purpose-built harvesters. The answer is yes and no. On one hand, fuel consumption per m3 is getting closer to that reported for dedicated harvesters in previous studies, since the post-intervention figure of 1.35 l m−3 is a good match for the 1.32 l m−3 reported by Klvac and Skoupy [35]—although still substantially higher than the 1.17 l m−3 indicated by Athanassiadis [36] in his seminal work on the subject. On the other hand, per-hour consumption is still in the 20 l h−1 range, which is substantially higher than reported for purpose-built harvesters [37]. A possible explanation may come from the different operational conditions explored by different studies: the current study covers plantation forests, while previous comparison studies were conducted in natural forests [17], characterized by a relatively difficult work environment where purpose-built harvesters can get all the benefit from their superior agility. In those forests, purpose-built harvesters offer a substantial productivity margin over excavator-based harvesters, and that clearly shows when it comes to calculating fuel consumption per m3. Such margin becomes much smaller when operating in plantation forests [38], and that tends to reduce the fuel efficiency gap, especially after specific fuel saving interventions, such as setting adjustments or the installation of a specifically-designed adaptation kit. However, the fact remains that all previous comparison studies between excavator-based and purpose-built harvesters have been conducted in natural forests, not in plantations. Therefore, new comparison studies are required before one can give a clear answer about any productivity and fuel efficiency differences between these two machine types when used under the more favorable conditions of plantation forestry.

The more favorable working conditions offered by plantations forestry and the ensuing higher productivity may help explaining the lower emission levels shown in this study, compared with those reported in previous studies conducted in natural forests. After installing the adaptation kit, the mean emission levels estimated here amount to 3.6 kg CO2 m−3, which is substantially lower than the 4.2 kg CO2 m−3 reported by Athanassiadis [36] or the 4.6 to 4.9 kg CO2 m−3 indicated by Klvac and Skoupy [35] in Europe for the same operation (felling and processing) and emission type (direct emissions only). In fact, the values reported in this study also account for debarking, which is not included in the European studies and normally requires multiple passes through the head, leading to additional time and energy consumption. Therefore, the emission cut varies from 14% to 27%, which is quite substantial, although it is likely that part of the merit goes to the technological progress in engine design occurred over the past decades, since available references on the subject are quite old and emission reduction has been one of the primary drivers of development in engine technology.

One final remark should be made about the conditions leading to the development of the adaptation kit. Although it was designed to solve the interface problems afflicting excavator-base harvesters, the kit presented in the study was not developed for universal use, but it fits one specific harvester head model to one specific excavator model. Incidentally, both are produced by the same company, and the kit was designed because this company sold a large number of units of this very combination. Therefore, the study does not actually cover the case of a universal adaptation kit that allows full flexibility in harvester head and excavator choice. The problem of adapting a whole range of harvester head models to several excavator types is not solved yet, especially for those combinations that are least popular and cannot count on large sale numbers. Nevertheless, this case demonstrated that suitable adaptation kits can be developed and that they work efficiently: designing a new and more flexible version is just the next step.

5. Conclusions

Installing a dedicated adaptation kit on excavator-based harvesters allowed reducing fuel consumption and emission levels by at least 10%. That was achieved without any productivity losses: in fact, productivity increased after installing the kit, due to improved machine handling characteristics, possibly related with a more stable temperature of the hydraulic fluid. The study also produced a very robust productivity model, and demonstrated the remarkable potential of automated long-term observational studies. The model obtained from this study is quite accurate, and is corroborated by a large corpus of literature available on the same subject.

Author Contributions

Conceptualization, R.S. and A.C.d.A.M.; Data curation, R.S. and A.C.d.A.M.; Formal analysis, R.S. and A.C.d.A.M.; Methodology, R.S. and A.C.d.A.M.; Supervision, A.C.d.A.M.; Writing—original draft, R.S. and A.C.d.A.M.; Writing—review & editing, R.S.

Acknowledgments

Special thank are due to the Fibria Technical Development Team for their support with logistics, supervision and field data collection: without their help this study could not have been performed. This research was partly funded by the Bio Based Industries Joint Undertaking under the European Union’s Horizon 2020 research and innovation program under grant agreement No 720757 Tech4Effect.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Spinelli, R.; Magagnotti, N.; Nati, C. Work quality and veneer value recovery of mechanised and manual log-making in Italian poplar plantations. Eur. J. For. Res. 2011, 130, 737–744. [Google Scholar] [CrossRef]

- Chiorescu, S.; Grönlund, A. Assessing the role of the harvester within the forestry-wood chain. For. Prod. J. 2001, 51, 77–84. [Google Scholar]

- Bell, J. Changes in logging injury rates associated with use of feller-bunchers in West Virginia. J. Saf. Res. 2002, 33, 436–471. [Google Scholar] [CrossRef]

- Eurostat. Roundwood Production. Dataset Code: TAG 00072. 2016. Available online: http://ec.europa.eu/eurostat/web/forestry/data/main-tables (accessed on 12 February 2018).

- Asikainen, A.; Leskinen, L.; Pasanen, K.; Väätäinen, K.; Anttila, P.; Tahvanainen, T. Metsäkonesektorin nykytila ja tulevaisuus. In Working Papers of the Finnish Forest Research Institute; Metla: Joensuu, Finland, 2009; Volume 125, p. 48. [Google Scholar]

- Asikainen, A.; Anttila, P.; Verkerk, H.; Diaz, O.; Röser, D. Development of forest machinery and labour in the EU in 2010–2030. In Proceedings of the 44th International Symposium on Forestry Mechanisation: “Pushing the Boundaries with Research and Innovation in Forest Engineering”, Graz, Australia, 9–13 October 2011; p. 8. [Google Scholar]

- Suadicani, K.; Fjeld, D. Single-tree and group selection in montane Norway spruce stands: Factors influencing operational efficiency. Scand. J. For. Res. 2001, 16, 79–87. [Google Scholar] [CrossRef]

- Wang, J.; Ledoux, C. Simulating cut-to-length harvesting operations in Appalachian hardwoods. Int. J. For. Eng. 2005, 16, 11–27. [Google Scholar] [CrossRef]

- Spinelli, R.; Hartsough, B.; Magagnotti, N. Productivity standards for harvesters and processors in Italy. For. Prod. J. 2010, 60, 226–235. [Google Scholar] [CrossRef]

- Spinelli, R.; Owende, P.; Ward, S. Productivity and cost of CTL harvesting of Eucalyptus globulus stands using excavator-based harvesters. For. Prod. J. 2002, 52, 67–77. [Google Scholar]

- Spinelli, R.; Magagnotti, N.; Sperandio, G.; Cielo, P.; Verani, S.; Zanuttini, R. Cost and productivity of harvesting high-value hybrid poplar plantations in Italy. For. Prod. J. 2011, 61, 64–70. [Google Scholar] [CrossRef]

- Ramantswana, M.; McEwan, A.; Steenkamp, J. A comparison between excavator based harvester productivity in coppiced and planted Eucalyptus grandis compartments in KwaZulu-Natal, South Africa. South. For. 2013, 75, 239–246. [Google Scholar] [CrossRef]

- Mac Donagh, P.; Botta, G.; Schlichter, T.; Cubbage, F. Harvesting contractor production and costs in forest plantations of Argentina, Brazil, and Uruguay. Int. J. For. Eng. 2017, 28, 157–168. [Google Scholar] [CrossRef]

- Johansson, J. Backhoe loaders as base machines in logging operations. Silva Fennica 1995, 29, 297–309. [Google Scholar] [CrossRef]

- Wang, J.; Haarlaa, R. Production analysis of an excavator-based harvester: A case study in Finnish forest operations. For. Prod. J. 2002, 52, 85–90. [Google Scholar]

- Väätäinen, K.; Sikanen, L.; Asikainen, A. Feasibility of excavator-based harvester in thinnings of peatland forests. Int. J. For. Eng. 2004, 15, 103–111. [Google Scholar] [CrossRef]

- Magagnotti, N.; Pari, L.; Spinelli, R. Use, Utilization, Productivity and Fuel Consumption of Purpose-Built and Excavator-Based Harvesters and Processors in Italy. Forests 2017, 8, 485. [Google Scholar] [CrossRef]

- Prinz, R.; Spinelli, R.; Magagnotti, N.; Routa, J.; Asikainen, A. Modifying the settings of CTL timber harvesting machines to reduce fuel consumption and CO2 emissions. J. Clean. Prod. 2018, 197, 208–217. [Google Scholar] [CrossRef]

- Environmental Protection Agency (EPA). Direct Emissions from Mobile Combustion Sources; US Environmental Protection Agency: Washington, DC, USA, 2008; p. 31.

- Strandgard, M.; Mitchell, R.; Acuna, M. General productivity model for single grip harvesters in Australian eucalypt plantations. Aust. For. 2016, 79, 108–113. [Google Scholar] [CrossRef]

- Norihiro, J.; Ackerman, P.; Spong, B.; Längin, D. Productivity Model for Cut-to-Length Harvester Operation in South African Eucalyptus Pulpwood Plantations. Croat. J. For. Eng. 2018, 39, 1–13. [Google Scholar]

- Tiburcio, V.; Sene, J.M.; Condi, L. Colheita mecanizada: Avaliação do harvester e forwarder. In Simposio Brasileiro sobre Colheta e Transporte Florestal 2; SIF UFV: Campinas, Brazil, 1995; pp. 205–221. [Google Scholar]

- Salmeron, A.; Ribeiro, R.S. Colheita mecanizada de eucaliptos em regiões acidentadas. In Seminario de Atualizaçao sobre Sistemas de Colheita e Transporte Florestal 10; UFPR, FUPEF: Curitiba, Brazil, 1997; pp. 165–181. [Google Scholar]

- Hartsough, B.R.; Cooper, D.J. Cut-to-length harvesting of short-rotation Eucalyptus. For. Prod. J. 1999, 49, 69–75. [Google Scholar]

- Magagnotti, N.; Nati, C.; Pari, L.; Spinelli, R.; Visser, R. Assessing the cost of stump-site debarking in eucalypt plantations. Biosyst. Eng. 2011, 110, 443–449. [Google Scholar] [CrossRef]

- Da Silva Leite, E.; Minette, L.J.; Fernandes, H.C.; de Souza, A.P.; do Amaral, E.J.; das Graça Lacerda, E. Desempenho do harvester na colheita de eucalipto em diferentes espaçamentos e declividades (Harvester performance on eucalyptus crops in different spacing and slopes). Revista Árvore 2014, 38, 7. [Google Scholar]

- Seixas, F.; Batista, J.L.F. Use of wheeled harvesters and exca vators in Eucalyptus harvesting in Brazil. In Proceedings of the 35th Council on Forest Engineering Annual Meeting: Engineering New Solutions for Energy Supply and Demand. Council on Forest Engineering, New Bern, North Carolina, 9–12 September 2012; p. 7. [Google Scholar]

- McEwan, A.; Magagnotti, N.; Spinelli, R. The effect of number of stems per stool on cutting productivity in coppice Eucalyptus plantations. Silva Fennica 2016, 50, 1–14. [Google Scholar] [CrossRef]

- Dos Santos, S.L.; Machado, C.C. Analise técnico-economica do processamento de madeira de eucalipto em areas planas, utilizando o processador (technical and economical analysis of eucalypt tree processing in flat land, using a mechanical processor). Revista Arvore 1995, 19, 346–357. [Google Scholar]

- Tarnowsky, C.; Schneider, P.; Machado, C. Productivity and costs of processor working in stands of Eucalyptus grandis (Hill. Ex. Maiden). Ciência Florestal 1999, 2, 103–115. [Google Scholar]

- Simoes, D. Avaliação Econômica de dois Sistemas de Colheita Florestal Mecanizada de Eucalipto. Master’s Thesis, Faculty of Agronomy, Campus of Botucatu, State University “Júlio de Mesquita filho”, San Paolo State, Brazil, 2008; p. 105. [Google Scholar]

- Martins, R.; Seixas, F.; Stape, J.L. Technical and economical evaluation of a harvester working under different spacing and planting arrangement conditions in eucalyptus plantations. Sci. For. 2009, 83, 253–263. [Google Scholar]

- Spinelli, R.; de Arruda Moura, A.C.; da Silva, P.M. Decreasing the diesel fuel consumption and CO2 emissions of industrial in-field chipping operations. J. Clean. Prod. 2018, 172, 2174–2181. [Google Scholar] [CrossRef]

- Spinelli, R.; Eliasson, L.; Magagnotti, N. Increasing wood fuel processing efficiency by fine-tuning chipper settings. Fuel Proc. Technol. 2016, 151, 126–130. [Google Scholar] [CrossRef]

- Klvac, R.; Skoupy, A. Characteristic fuel consumption and exhaust emissions in fully mechanized logging operations. J. For. Res. 2009, 14, 328–334. [Google Scholar] [CrossRef]

- Athanassiadis, D. Energy consumption and exhaust emissions in mechanized timber harvesting operations in Sweden. Sci. Tot. Environ. 2000, 255, 135–143. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N. The effects of introducing modern technology on the financial, labour and energy performance of forest operations in the Italian Alps. For. Pol. Econ. 2011, 13, 520–524. [Google Scholar] [CrossRef]

- Ackerman, P.; Williams, C.; Ackerman, S.; Nati, C. Diesel consumption and carbon balance in South African pine clear-felling CTL operations: A preliminary case study. Croat. J. For. Eng. 2017, 38, 65–72. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).