1. Introduction

Water is essential to the beginning and continued existence of humanity. Because it covers almost three-quarters of the earth’s surface, water is one of the most abundant resources on the planet. The oceans contain approximately 97% of the water on Earth, which is salt water. The remaining 3% of the water on Earth is fresh water, which can be found at the poles (in the form of ice), in ground water, lakes, and rivers. Fresh water supplies the majority of the water that is needed by humans and animals. Glaciers, areas with permanent snow cover, ice, and permafrost are home to over 70% of the world’s tiny 3% fresh water supply, respectively. Thirty per cent of the world’s fresh water is found underground, most of which is located in very deep aquifers and difficult to access. Rivers, lakes, and underground water reserves have traditionally served as man’s primary sources of water for domestic, agricultural, and industrial uses. Around 70% of the world’s fresh water is used for agricultural purposes, whereas only 20% is used for industrial purposes and only 10% for residential uses [

1].

According to the UN-Water Annual Report 2021, published in June 2022, 2 billion people in underdeveloped nations lack access to clean drinking water. Additionally, 3.6 billion people (46% of the world population) lack access to appropriate sanitation [

2]. According to some recent forecasts, about half of the world’s population will experience genuine water supply problems [

3]. Around 3 billion of the world’s population lack access to adequate quality and/or quantity of fresh water, and 107 countries are not on track to have sustainability-managed water resources by 2030 [

2]. Currently, one-fifth of the world’s population lives in places with insufficient fresh water supply. In many developing nations, 80% of the population lives in rural areas with much poorer access to fresh water than in metropolitan areas [

4]. By 2025, it is anticipated that up to two-thirds of the world’s population will live in nations with water scarcity [

5].

However, increased industrialisation and the global population boom have significantly increased the need for fresh water for home use and crops to generate sufficient food. Additionally, there is the issue of river and lake contamination caused by industrial pollutants and vast volumes of sewage released. Water demand doubles every 20 years on average, making the water problem all the more alarming [

1,

2]. The seas are the only essentially limitless supply of water. Their primary disadvantage is their excessive salinity. As a result, it would be desirable to address the water scarcity issue by desalination this water. Salinity in water is limited to 500 parts per million (ppm) and up to 1000 ppm in rare instances, but most of the accessible water on Earth has a salinity of up to 10,000 ppm and salt water typically has a salinity of 35,000–45,000 ppm in the form of total dissolved salts [

1,

6].

Excessive water salinity results in a loss of flavour, gastrointestinal discomfort, and laxative effects. A desalination system’s objective is to clean or purify brackish or salt water and deliver drinkable and irrigation water with TDS of less than 500 ppm or from 500–1500 ppm for irrigation [

7]. This is performed via a variety of desalination procedures that will be investigated; as a result, desalination operations use a large amount of energy to separate salts from salt water. Renewable energy systems produce energy from renewable sources such as geothermal energy, solar energy, low-grade energy sources, photovoltaic thermal (PV/T) panels, and power plant waste heat. Their primary feature is that they are environmentally friendly. The production of fresh water using desalination technology powered by renewable energy systems is considered a possible solution to the problem of water scarcity in distant places that lack access to potable water and traditional energy sources such as heat and electricity. Numerous renewable energy desalination pilot plants have been erected worldwide, with the majority operating effectively for several years. Almost the majority of them are custom-designed for particular locales and generate fresh water by solar or geothermal energy [

8]. Although renewable energy-powered desalination systems cannot compete with traditional desalination systems in terms of the cost of water produced, they are appropriate in specific places and are projected to shortly become more broadly practicable. El-Ghonemy [

9] analysed water desalination systems driven by renewable energy sources, highlighting current advances in the area of renewable energy-based desalination, with a concentration on technology and economics. Some broad recommendations for the selection of desalination and renewable energy systems, as well as the factors for examination, were provided.

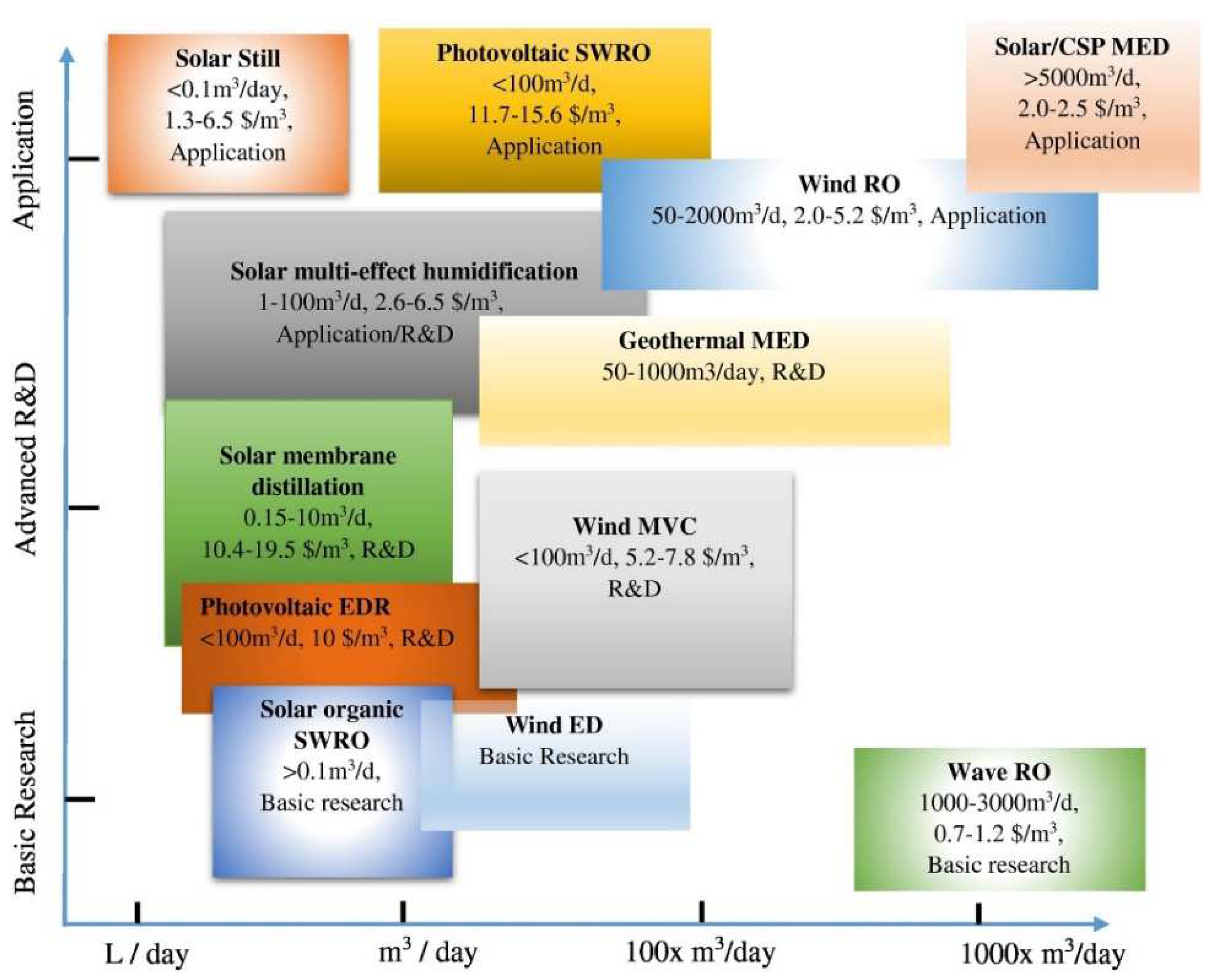

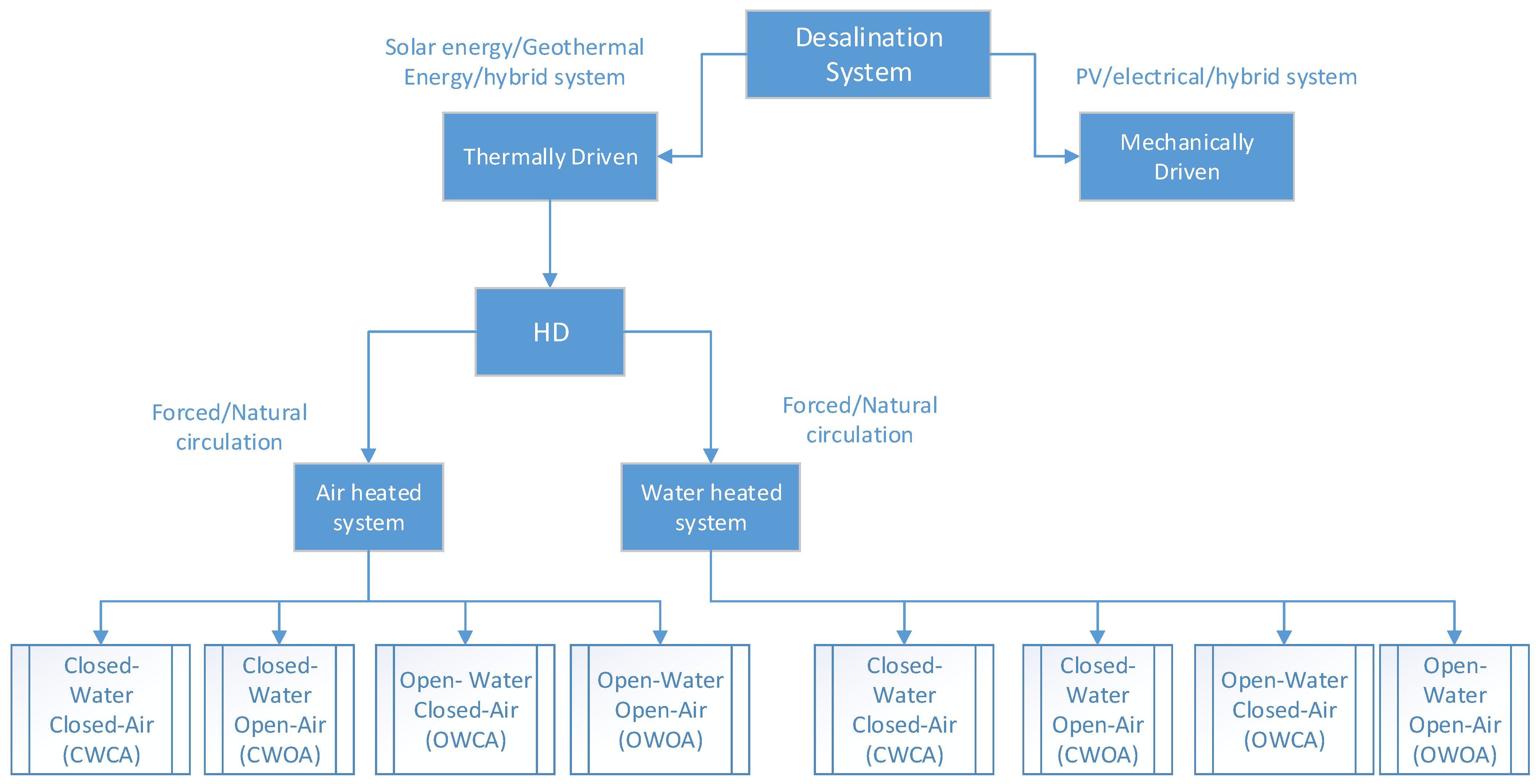

Figure 1 depicts the technical state of renewable energy desalination methods [

10].

Desalination methods available today are mostly classified into two categories: thermal and membrane approaches. The former is prohibitively expensive, has corrosion issues, and requires large, difficult-to-maintain installations (e.g., multi-stage flash (MSF)), while the latter suffers from membrane fouling and demands water pre-treatment before being delivered into the desalination modules, as well as post-treatment. Other less prevalent desalination systems are less established, and each has its own set of advantages and disadvantages.

Desalination is characterised by fast technological advancements. Each year, several new desalination facilities are tested and implemented globally. Desalination methods have matured technologically and economically, enabling them to play a larger part in the future water supply. These installations may be built using a variety of different technological approaches and provide a great deal of versatility in terms of size and energy use (a function of energy resources and the situation). MSF is the most often thermal-based utilised method. This approach is used in about 50% of all installations worldwide. On the other hand, when production scales down, the efficiency of conventional distillers falls due to the difficulty of implementing a given number of effects in small installations. For these smaller installations (in rural areas, for example), conventional distillers are unsuitable: the installation costs, energy usage, and hence water costs, are too expensive.

Several well-established desalination techniques exist, including reverse osmosis (RO), MSF, and multi-effect distillation (MED); however, these technologies are often inappropriate for developing countries because of their high infrastructure requirements, reliance on fossil fuels as a source of energy, and cost-effectiveness on very large scales.

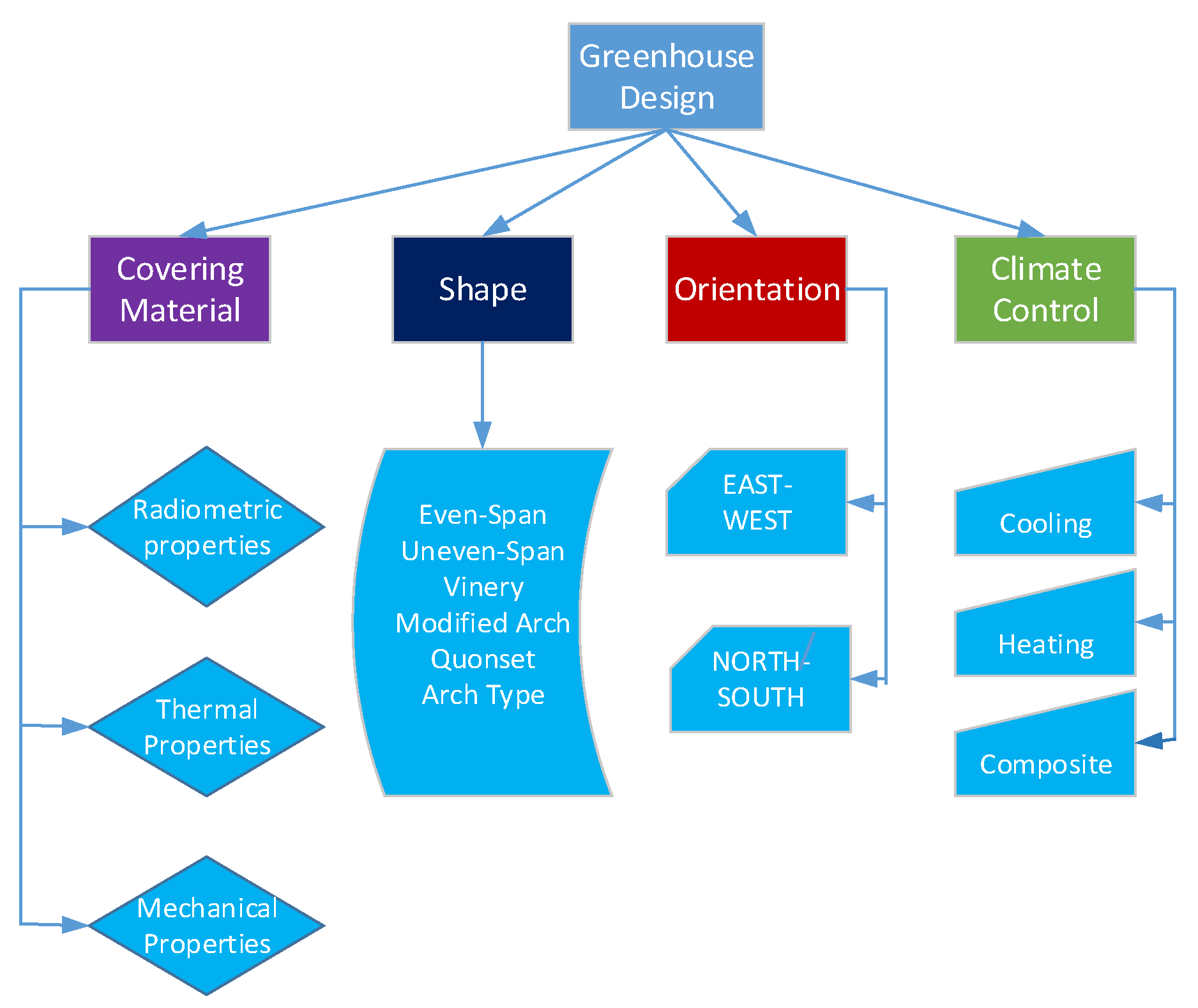

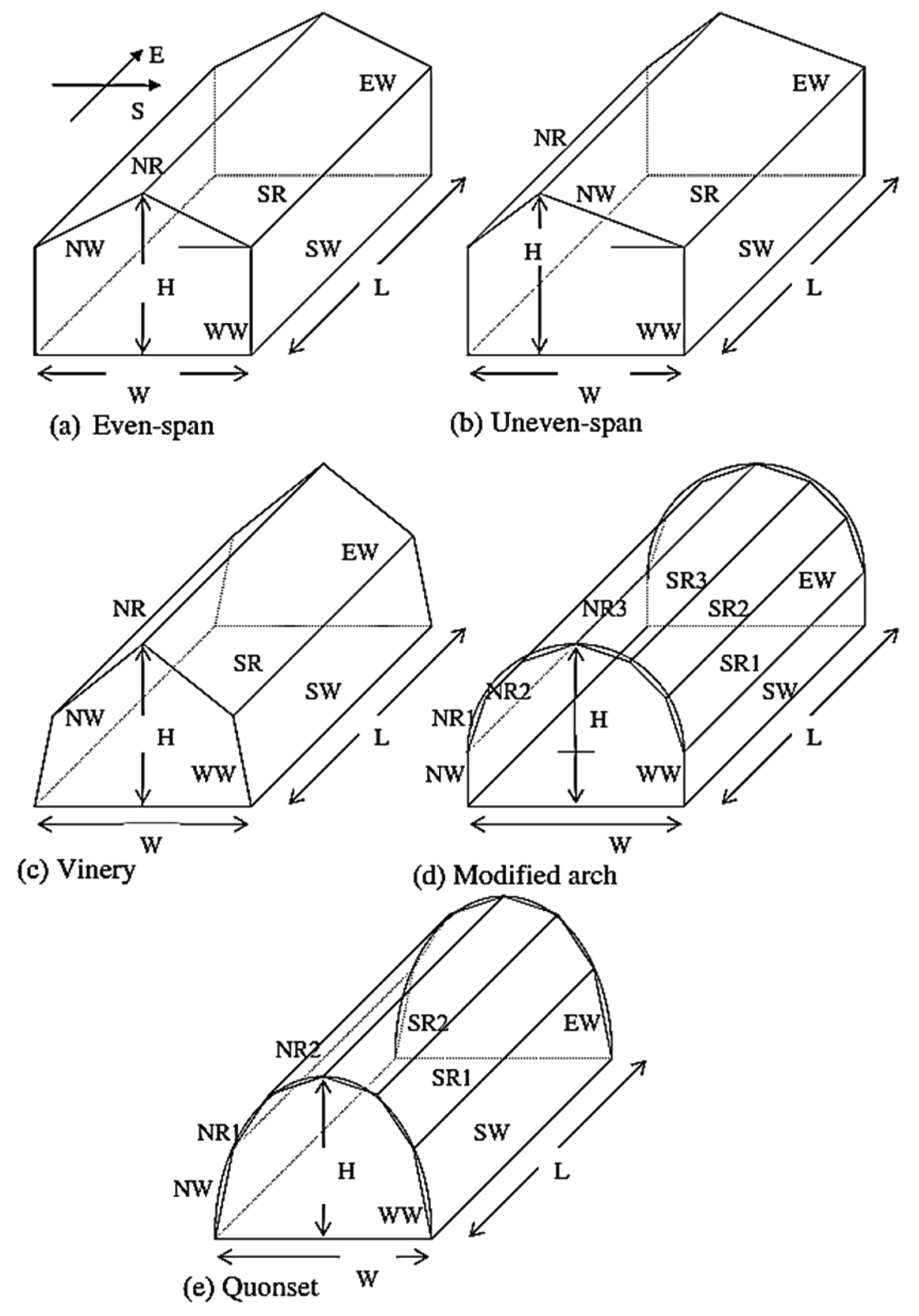

Greenhouses (GHs) are a critical component of the food supply chain as they increase crop yield [

11]. The productivity of GHs is commonly known to be 7–10 times that of an open field. Furthermore, it only uses 10% of the water required for open field agriculture [

12]. They protect the plants while conserving resources such as electricity and water [

13]. GHs are utilised to chill or heat the air within the GH depending on their geographical location and season [

14]. The grown crop’s production is heavily reliant on the GH environment, namely, the GH temperature and relative humidity (RH) [

15]. Plant photosynthesis has a diverse spectral profile; however, in vitro, most photosynthesis chemicals exhibit narrow spectral absorbance maxima in the blue (400–500 nm) and red (600–700 nm) wavelength bands, which account for less than 30% of the incoming solar spectrum [

16]. The remaining 70% of solar energy is in the near-infrared (NIR) band (700–2500 nm), where photons do not drive photosynthesis but do raise the ambient temperature within a GH. Temperature is recognised to have a crucial role in regulating plant development [

17]. However, the transfer of NIR radiation into greenhouses often leads to excessive solar heating and increased water demand for evaporative cooling, particularly in hot and dry locations. Heat stress occurs when plants are exposed to high temperatures for an extended length of time, resulting in decreased output [

18]. Similarly, high RH promotes the growth of pathogens such as fungi, whereas low RH causes plants to lose too much water to the GH air, resulting in wilting [

19]. As a result, it is critical to maintaining an optimal temperature and relative humidity within the GH for growing high-quality produce. Additionally, year-round crop production is required to make the GH commercially viable in dry locations. However, in desert areas, high temperatures and a scarcity of water restrict crop production to a few months, making agriculture economically unviable and difficult. Due to the paucity of fresh water, farmers are sometimes obliged to utilise salty ground water for agriculture to satisfy irrigation needs [

20]. Additionally, the cooling burden rises dramatically during the summer, resulting in temperatures that exceed the optimal range, which is harmful to plant growth. As a result, numerous methods have been developed to control the GH microclimate and meet irrigation needs in dry places [

21,

22]. However, the microclimate of the greenhouse is reliant on dynamic, non-linear, and uncertain parameters such as solar irradiation, outside temperature, air speed, and inside conditions [

23].

In dry areas, natural ventilation alone is inadequate to manage the temperature within the GH during the summer season, when solar gains and outside temperatures are high [

24]. While coupling natural ventilation with shade screens may help reduce cooling loads, restricting solar irradiance entering the GH canopy affects plant growth since sunlight is necessary for photosynthesis [

25]. Evaporative or fan and pad cooling is another way of lowering the temperature of the air passing through the GH and converting it to latent heat. However, evaporative cooling is temperature and relative humidity dependent; in dry climates, when temperature and relative humidity rise, the air’s wet-bulb temperature increases as well, resulting in inefficient cooling within the GH [

26]. As a result of these considerations, active mechanical heating, ventilation, and air conditioning (HVAC) systems scheduling and decision-making may be improved by anticipating factors many hours in advance. In addition, the link between the GH’s cooling load and water demand in an environment with high temperatures and a scarcity of fresh water is evaluated. Crops yield and output are greatly reliant on the microclimate created by the HVAC system in the GH. Maintaining optimal conditions in the greenhouse necessitates monitoring and managing temperature and relative humidity, as well as identifying potential scenarios/techniques to decrease energy and water usage. In the summer, when sun irradiance and temperature reach 1000 W/m

2 and 45 °C, respectively, it is difficult to maintain optimum growth conditions while minimising energy and water use. In order to operate a GH efficiently, it is required to calculate the cooling and water requirements under various climatic conditions/seasons [

27]. HVAC systems are the most effective technique for controlling the GH microclimate, but they use a significant amount of energy. The majority of energy is generated by fossil fuels, which contribute to damaging greenhouse gas (GHG) emissions. As a result, GHs powered by renewable energy and equipped with active mechanical cooling systems provide a viable option for sustainable agriculture in comparison to traditional food production systems fuelled by fossil fuels.

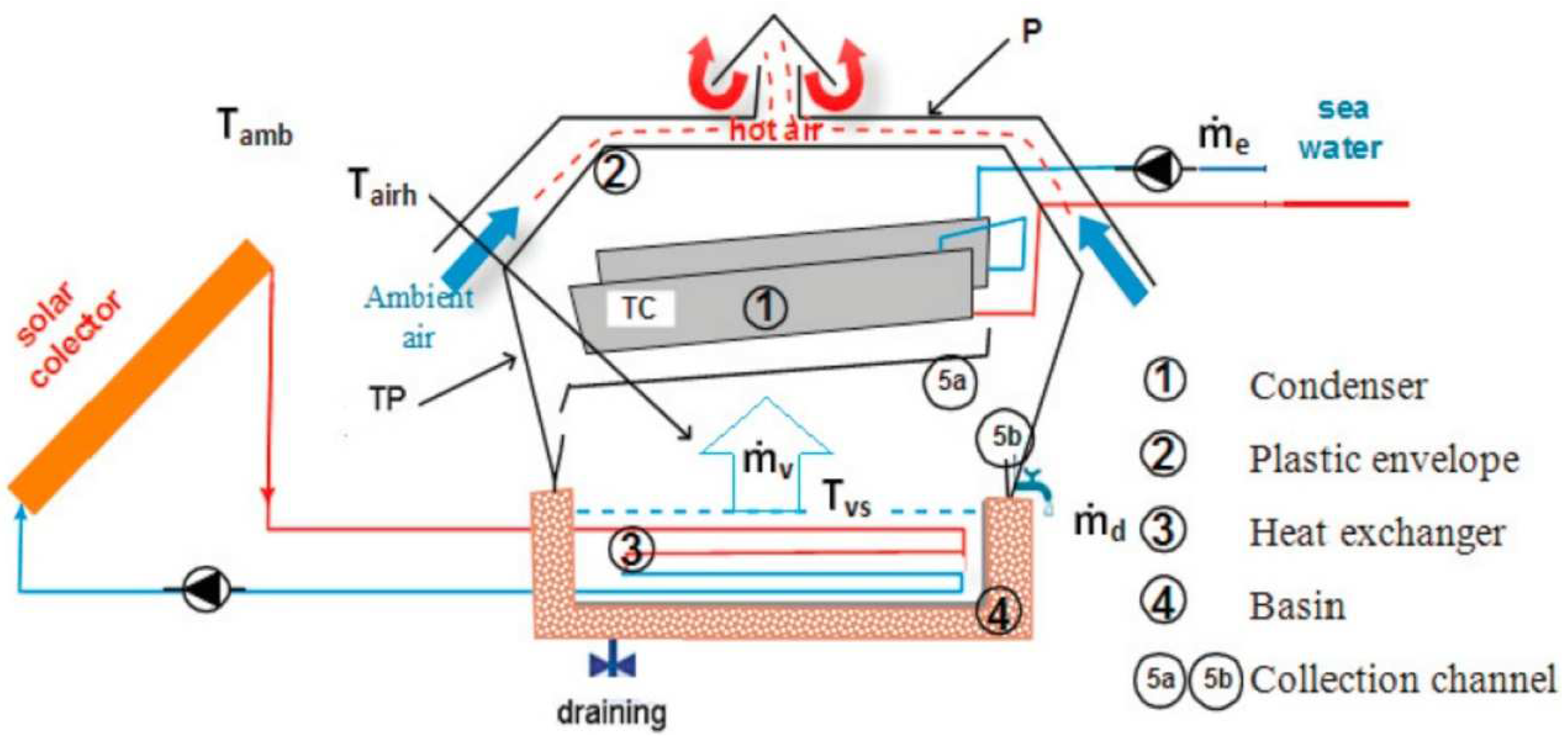

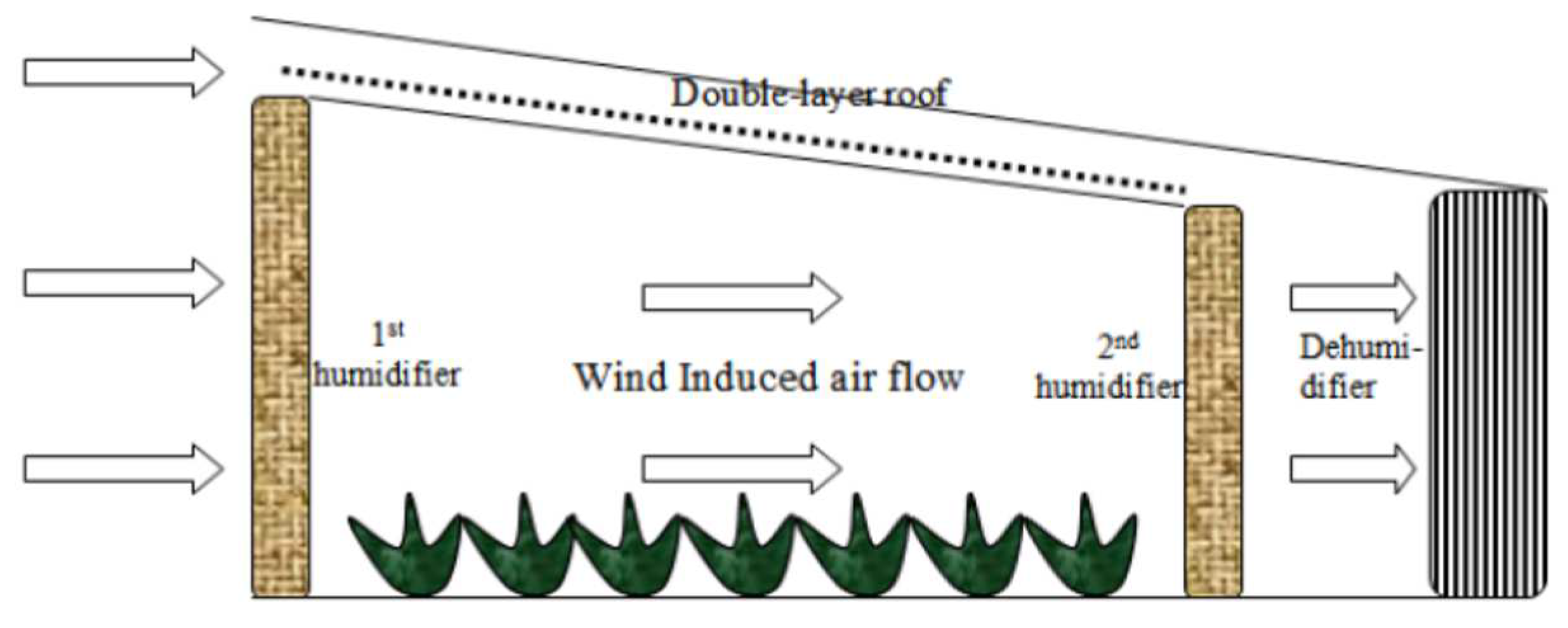

The sun, the sea, and the environment are used to generate fresh water and cool air in a seawater greenhouse. Within a controlled setting, the procedure recreates the natural hydrological cycle. The building’s front wall is a salt water evaporator. It is made of a honeycomb lattice and confronts the wind. Air movement is controlled by fans. Seawater drips down the lattice, cooling and humidifying the air that passes through into the planting area. The sun is diffused by a specifically designed roof. The roof absorbs infrared heat while allowing visible light to pass through to encourage photosynthesis. This results in ideal growing conditions, which are cold and humid with high light intensity. Seawater heated in the roof goes through a second evaporator, producing hot, saturated air that flows through a condenser. Incoming salt water cools the condenser. Because of the temperature differential, fresh water condenses out of the air stream. Air temperature, relative humidity, solar radiation, and airflow rate all influence the amount of fresh water. With adequate meteorological data, these circumstances may be modelled, allowing the design and procedure to be optimised for any acceptable site [

28,

29,

30].

In a salt water greenhouse, substantially more water evaporates than condenses back into fresh water. Because of the high rates of ventilation used to keep the crops cool and supplied with CO2, this humid air is ‘lost.’ The greater humidity of the exhaust air aids in the development of more hardy crops downwind of the greenhouse. This phenomenon may allow biofuel crops to be grown in the region around the seawater greenhouse.

A seawater GH is a GH structure that permits the cultivation of crops and the generation of fresh water in approximately one-third of the planet’s dry areas. This is in reaction to the worldwide water shortage, peak water, and soil salinisation. The system is powered by solar energy. It employs a construction similar to the pad-and-fan GH, but with added evaporators and condensers. The salt water is pumped into the GH to generate the best circumstances for the development of temperate crops: a chilly and damp atmosphere. [

31] Using the idea of solar desalination, which eliminates salt and contaminants, fresh water is generated in a concentrated form. The residual humidified air is then removed from the GH and utilised to enhance outside plant growth conditions.

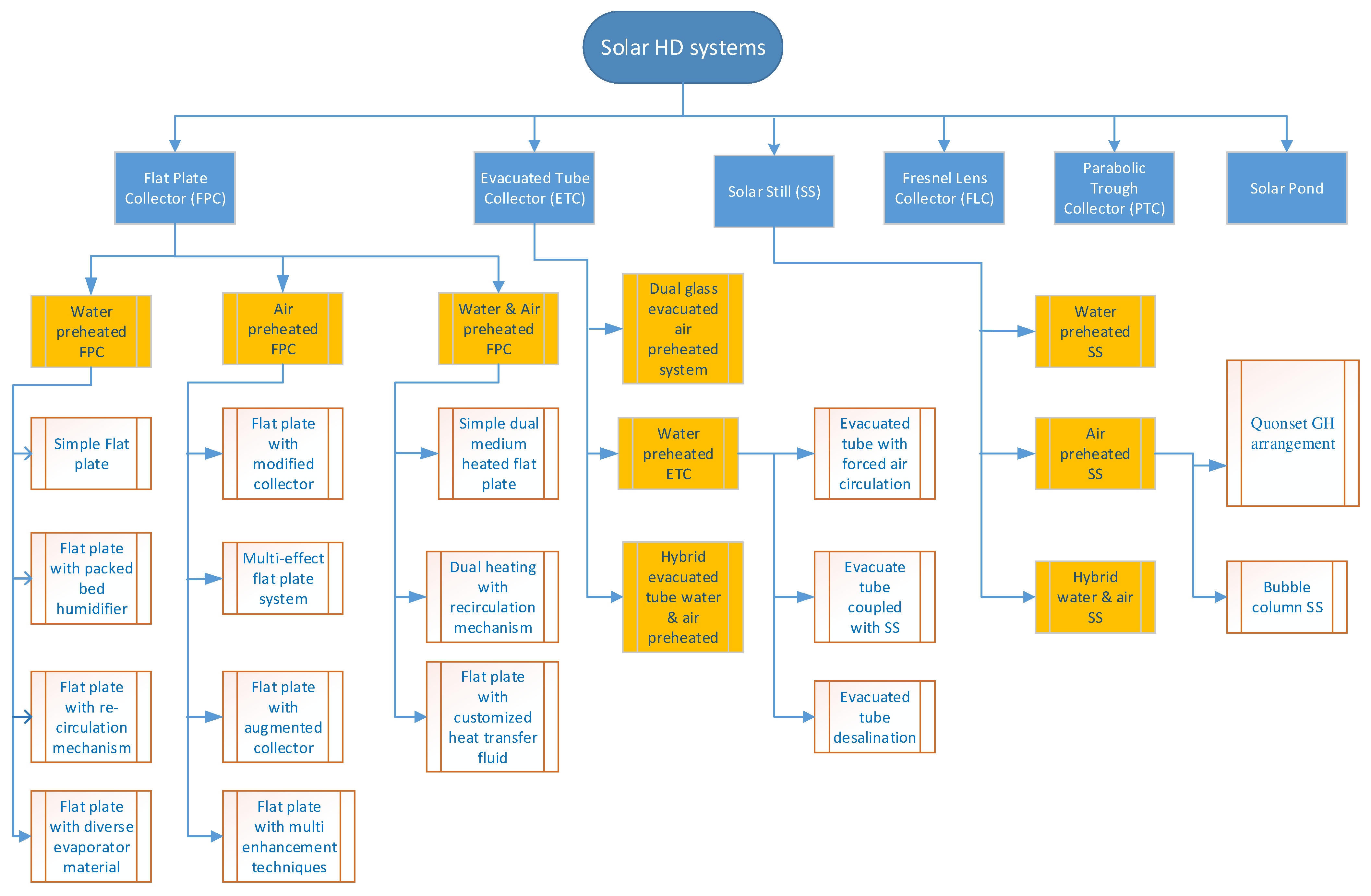

The current article classifies and discusses recent technical advancements in the area of solar HD based on the technique used in the research endeavour. This strategy is adopted to better understand the field’s research gaps and to arrange the results. Throughout the document, the article identifies and analyses the gaps, as well as the existing and future state of each area. The present review included flat plate collectors, evacuated tube collectors, bubble columns, concentrating collectors, photovoltaic modules, solar ponds, and hybrid systems. Following that, current improvements in HD desalination systems and subsystems for by-product treatment are analysed and addressed. The concluding part makes recommendations for further study.

2. Solar Desalination Technologies

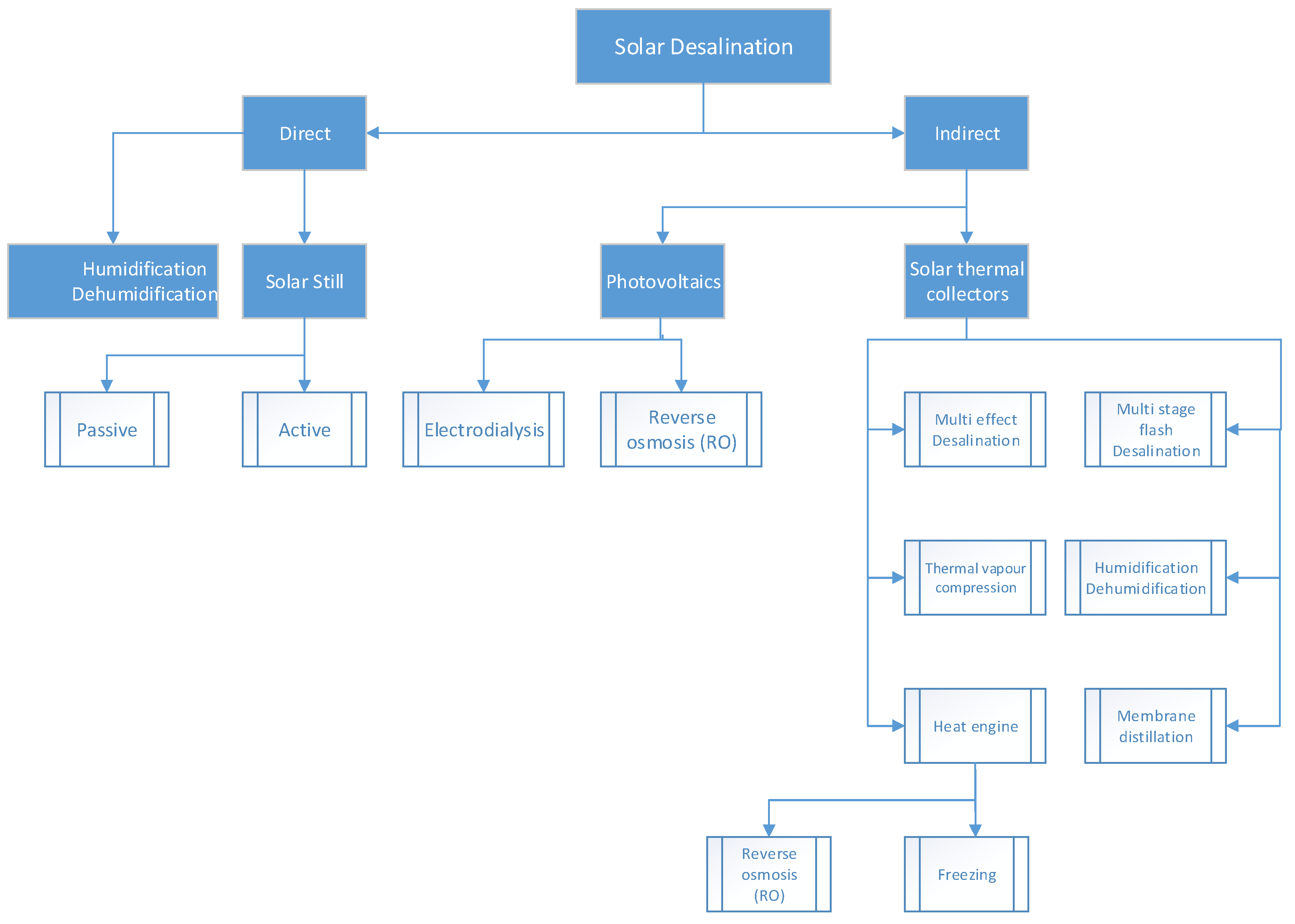

As previously stated, the majority of desalination procedures use a significant quantity of energy. The bulk of desalination facilities now operating on a global scale is powered by fossil fuels. However, the majority of places that face increased fresh water demand also obtain significant quantities of solar energy. Thus, solar energy might be an excellent source for this purpose since it is plentiful and emits few pollutants. Solar desalination methods are divided into direct and indirect categories across the literature. In this context, if solar radiation is absorbed directly by the desalination plant’s input feed water, the plant is regarded to be of the direct kind. Solar energy is collected by solar thermal collectors and then transmitted to the salty water in indirect plants, or it is converted to electricity and then utilised to power the plant. In both scenarios, solar energy might be utilised to power the plant using a heat engine. Adapted from [

32],

Figure 2 displays this categorisation of solar desalination modules. However, this reference classifies HD as a straight drive. This is because, in an HD system, saline water may absorb sun energy directly or via solar thermal collectors. It might be either direct or indirect in this sense.

Numerous aspects must be considered while selecting technology for a desalination project. It is highly dependent on the demand side, available resources, economic considerations, maintenance concerns, and the projected lifespan of the project, among other factors. For example, the simultaneous need for fresh water and energy may necessitate the use of poly-generation plant technology. Additionally, surplus heat generated by solar thermal collectors in the desalination plant might be used to meet heating needs. The magnitude of the demand sector may have a significant impact on the design process since certain technologies are incapable of meeting large demand levels. The operation and maintenance sectors are also important to examine since certain technologies are capable of working for an extended period without requiring significant upkeep. Another factor to consider is the amount of available land and the potential market. Additionally, environmental concerns should not be overlooked since they may be addressed in economic calculations. The benefits and disadvantages of various methods of solar desalination are listed in

Table 1 in terms of environmental, economic, energy consumption, construction, material availability, efficiency, and distilled water quality, among other aspects. This table may provide relevant information on the comparison of several desalination systems.

To create a drinkable water product, three processes are required: pre-treatment, treatment, and post-treatment. Different desalination systems need varying degrees of pre-or post-treatment. In comparison to thermal desalination, membrane-based desalination techniques may be more susceptible to the presence of unwanted organic or inorganic chemicals or pathogens in the product water. Specifically, higher temperature desalination facilities with water temperatures more than 70 °C are considered to be rather safe in terms of the safety and quality of the generated water. This is because at high temperatures, any extant microbes are killed and dangerous inorganic compounds such as Boron products are eliminated by the distillation process, resulting in water with an acceptable purity. On the contrary, RO is unable to successfully remove Boron from seawater and other salty water sources. Additionally, ED cannot ensure pathogen elimination. In these circumstances, extensive post-treatment and water quality testing are necessary, increasing the plant’s capital cost. However, further measures should be employed in thermal plants operating at temperatures below 50 °C, since this temperature is insufficient for reliable pathogen elimination. Additionally, it should be emphasised that water quality problems may be highly dependent on the quality and circumstances of the water supply.

In comparison to other desalination systems, HD has a smaller capacity. However, it also takes very little care throughout the plant’s life. While the generated water is more expensive than that produced by other technologies such as reverse osmosis, other aspects make solar HD a viable option for distant places with low-to-moderate demand levels. It is not dependent on electricity or other energy sources, and solar energy can generate the necessary thermal energy. Solar HD plants might be an excellent alternative for tiny locations that lack enough access to potable water networks. Additionally, as solar collector technology advances, the total cost of the generated water decreases, making it a viable choice for small-scale applications.

Global Water Intelligence (GWI DesalData) desalination and reuse markets [

59] classified desalination technologies according to

Table 2.

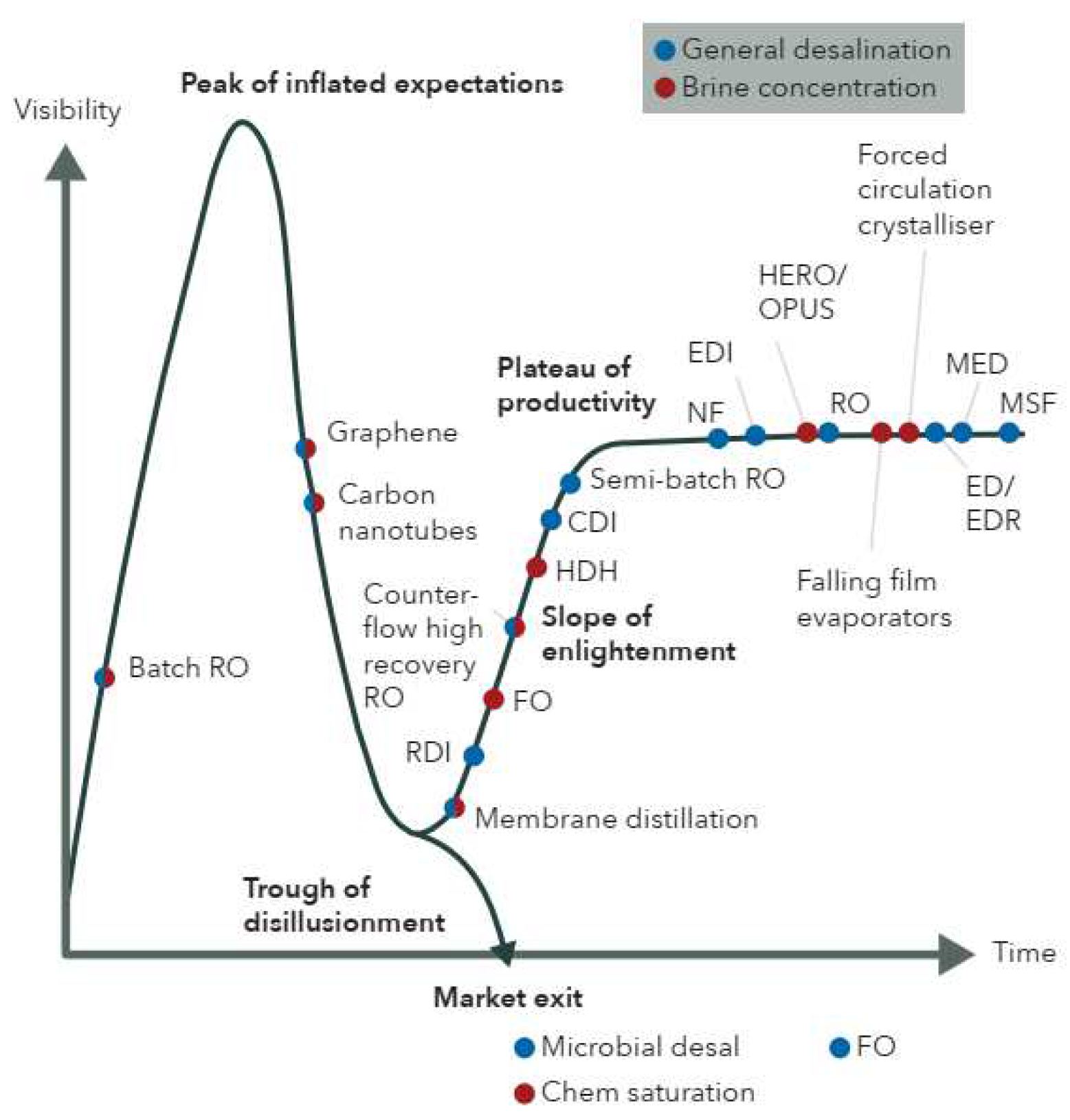

Figure 3 illustrates a technology’s path to commercialisation depicting the early enthusiasm around a new idea, followed by disappointment when practical challenges arise, and then the last push for commercialisation and widespread adoption.

Management of brine is now a major driver of adoption. Except for semi-batch RO, almost all the methods undergoing the gradual march to widespread usage are largely utilised for brine concentration.

Materials such as graphene and carbon nanotubes are among the slowest-maturing technologies due to the time required to develop dependable and cost-effective production processes.

‘Operational R&D’ designs, such as semi-batch or counter-flow RO systems, are expected to gain traction considerably more swiftly.

Despite the capabilities of thermal desalination methods to use waste heat, research undertaken by MIT into primary energy usage demonstrates that even when waste heat is utilised, thermal procedures are less energy efficient than membrane processes. These primary energy values represent the value of the energy in the source, including generating losses and are based on the energy produced by a combined cycle gas turbine.

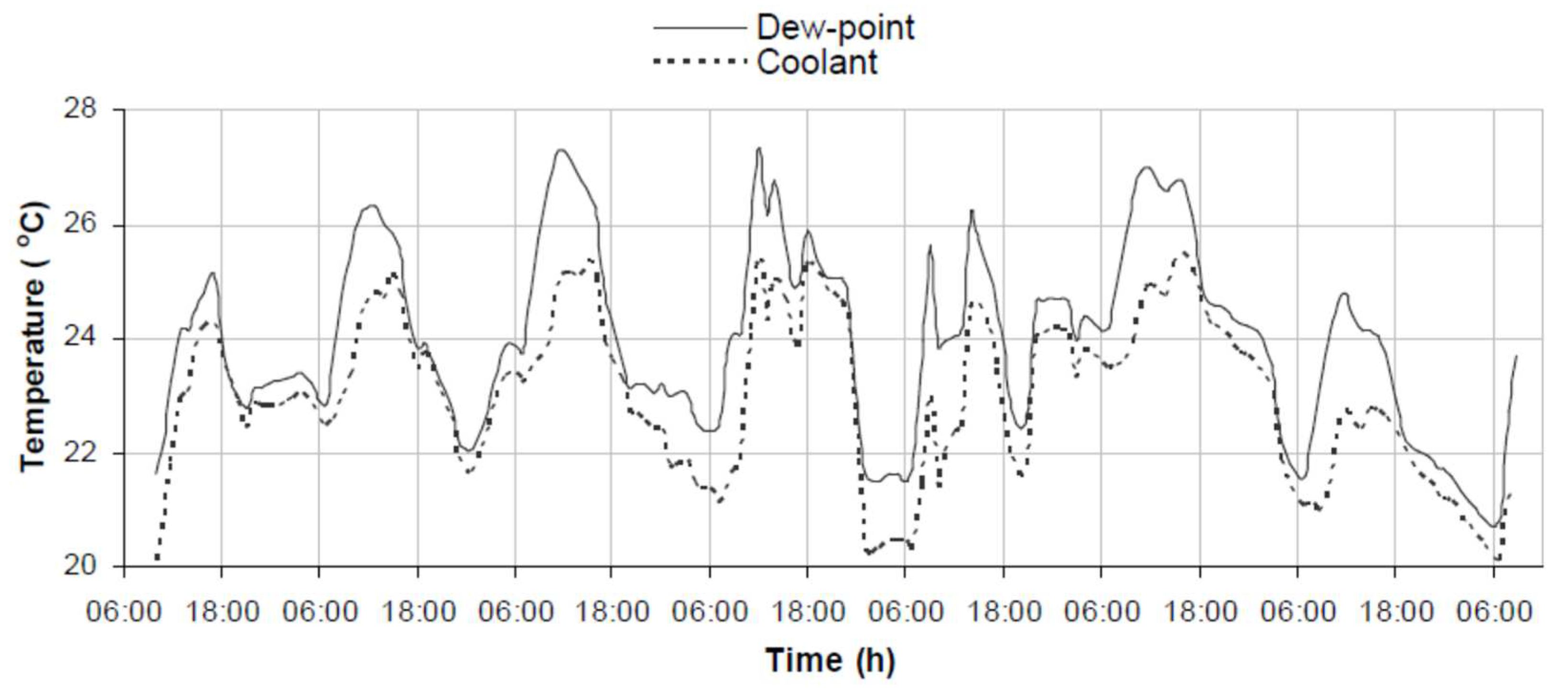

3. Humidification–Dehumidification of Air

The HD desalination method is based on converting salt water to water vapour in the humidifier and then condensing it over the condensing coils in the dehumidifier at a surface temperature lower than the dew point of the air. To boost HD’s fresh water production, the evaporation process is accelerated by heating either the water or the air, or both, to enhance the air’s capacity to transport more water vapour as the temperature rises. In theory, 1 kg of dry air may transport 0.5 kg of vapour with an energy cost of 2814 kJ when the temperature is increased from 30 to 80 °C. [

60]. A defined quantity of water vapour is removed throughout the humidification process by flowing air that is maintained in contact with salt water. When humid air comes into touch with a cold surface, water vapour condensation occurs, providing the necessary fresh water. The condensation method uses the latent heat of condensation to pre-heat the salt water going through the condensing coils [

35,

60,

61,

62,

63]. The seawater cycle may be either open or closed in the HD desalination technology. The evaporation of 1 kg of water leads to a 60 °C fall in the temperature of 10 kg of salt water in the open cycle. The amount of fresh water recovered varies between 5% and 20% of the volume of salt water cycled. This indicates that a little amount of fresh water is produced at a high rate of heat loss. In a closed-cycle system, increased fresh water output is maintained at a low energy cost [

60,

62].

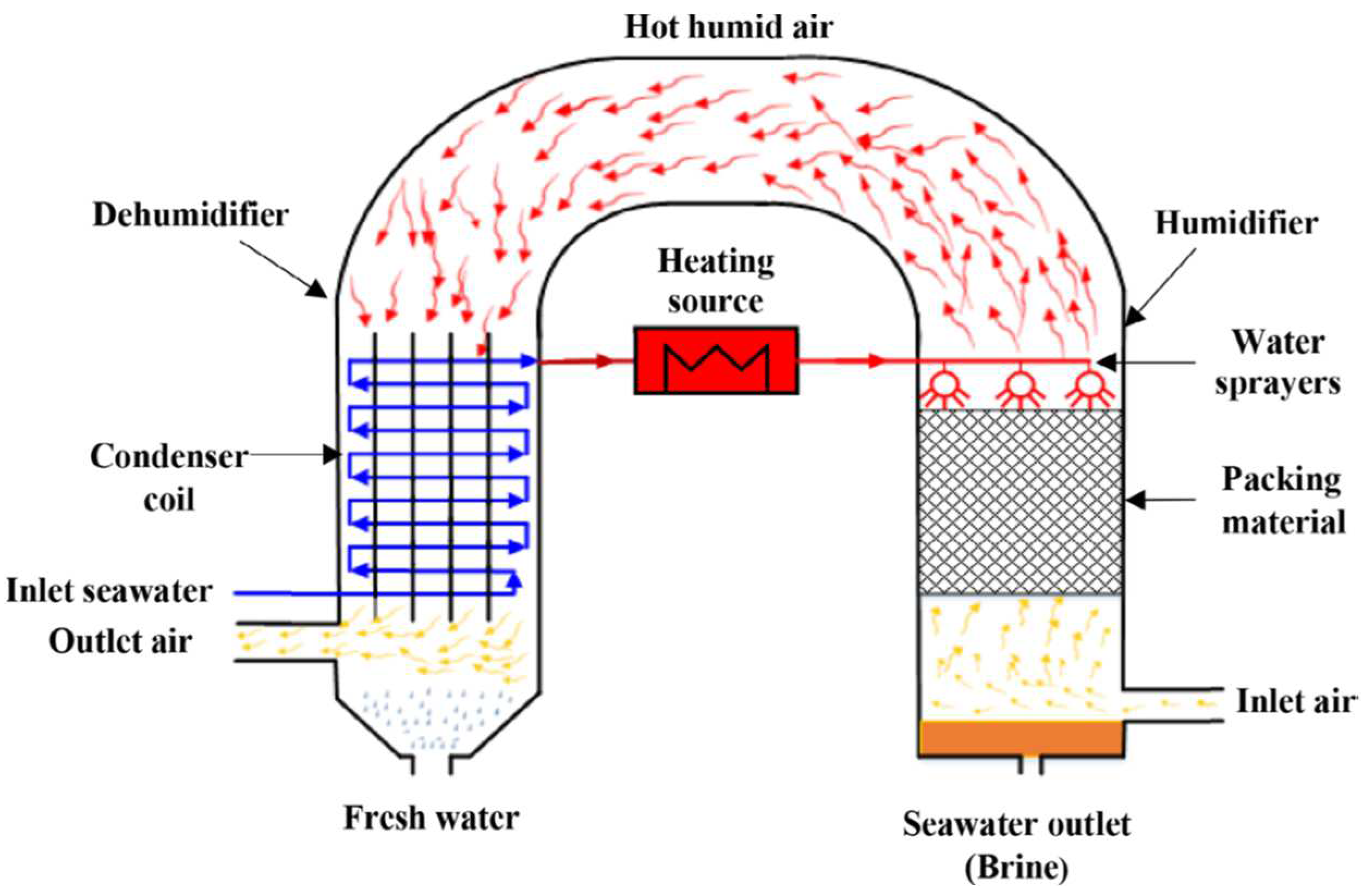

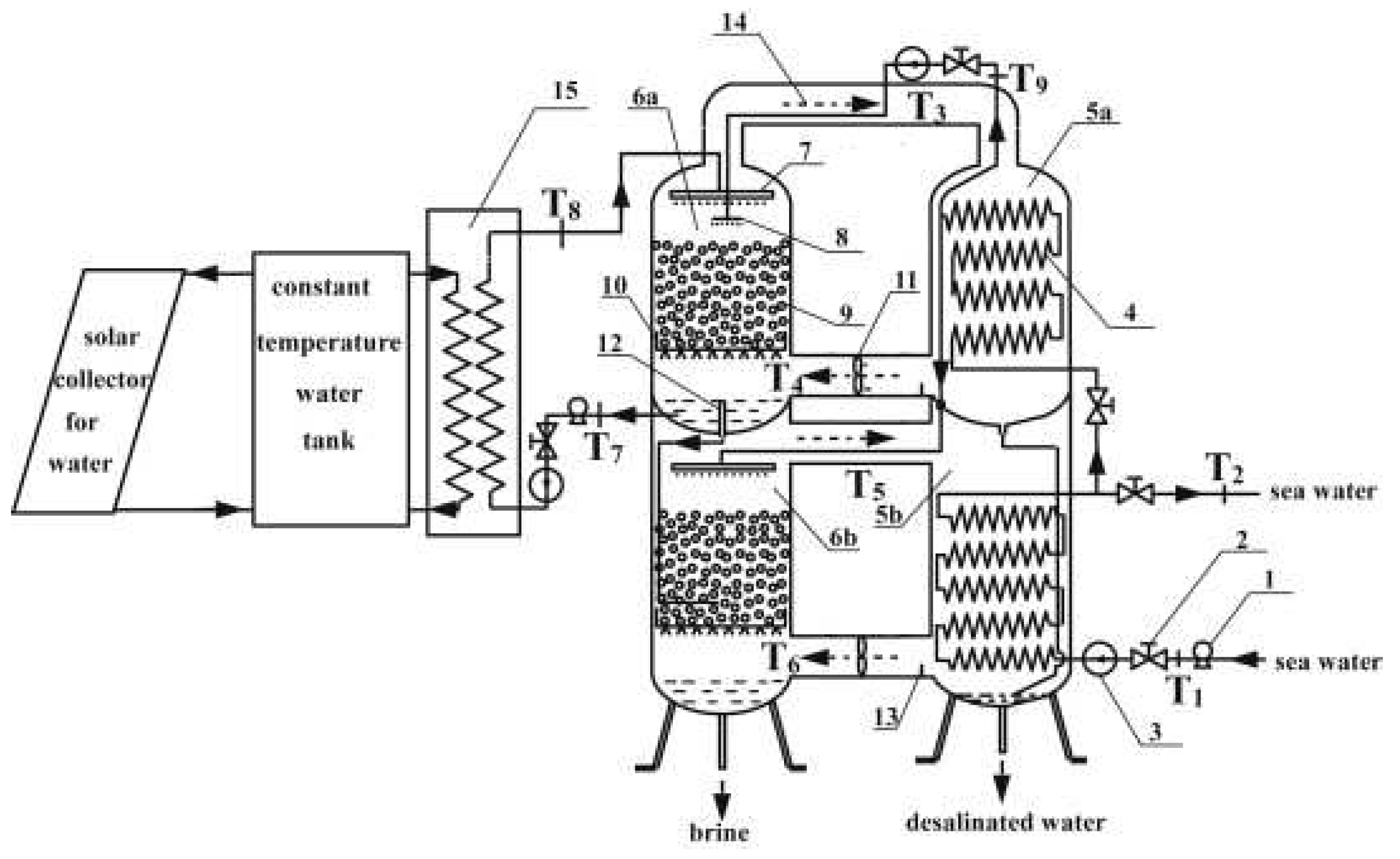

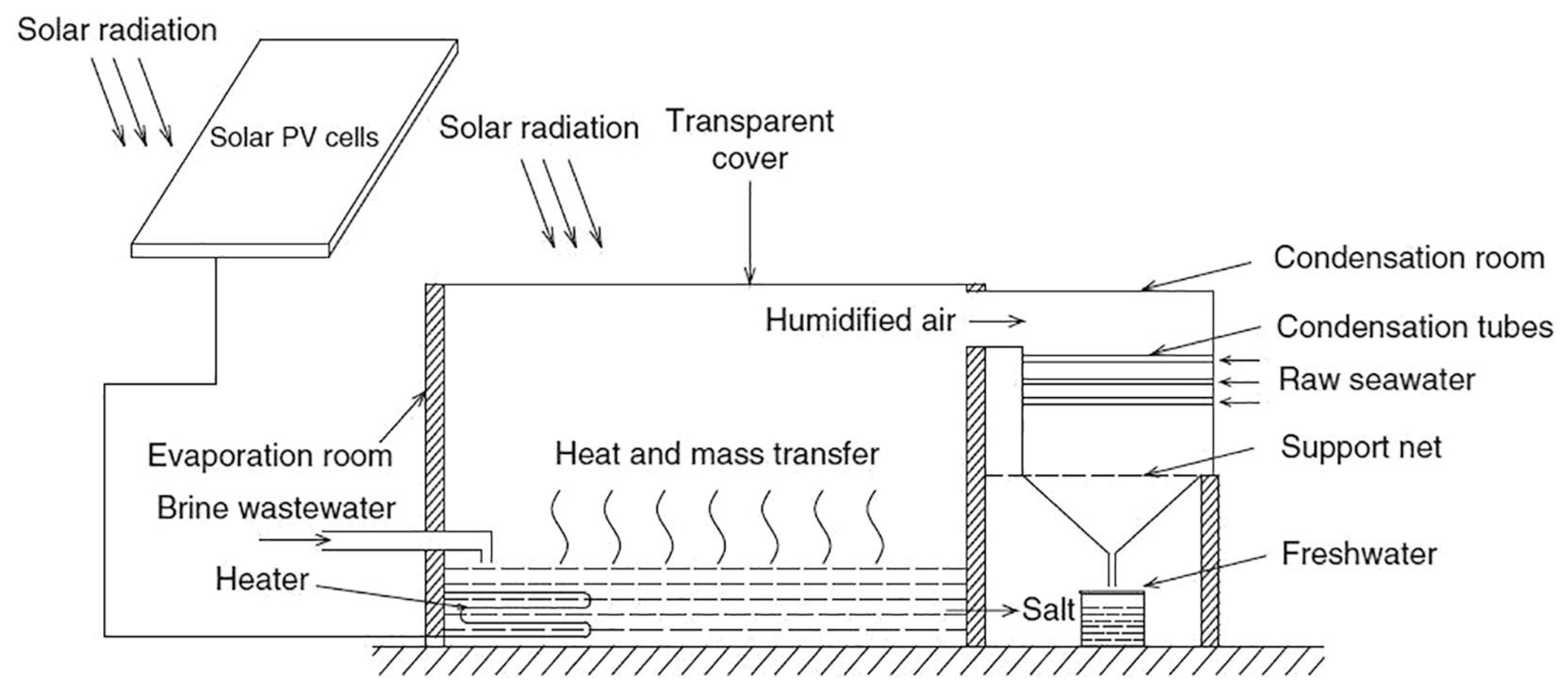

Figure 4 illustrates a basic form of the HD water desalination method. The HD system is simply a pair of vertical/horizontal ducts joined at the top to circulate the air [

64]. The HD desalination system may be operated in natural or forced draught mode, depending on the air circulation. The dehumidifier is comprised of a single duct that includes the condenser that generates the unsaturated air. An atomiser is used to flash salt water within the humidifier, resulting in small droplets. This maximises the surface area of contact between the flashed salt water and the surrounding air [

65]. A packing material used in the other duct to effectively humidify the air is referred to as a humidifier delivering saturated air. To maximise system efficiency, the air and/or water are heated utilising a variety of energy sources, including thermal, solar, geothermal, and hybrid energy. HD systems are categorised according to their energy source, their air and water circulation cycles, and their water and/or air heating sources [

66]. No high temperatures are required for the revolutionary HD of air technology [

67]. Solar energy can provide all of the thermal energy necessary in these systems [

68]. Solar HD desalination systems are well-known for their efficiency in delivering clean water to isolated areas [

68]. HD systems are straightforward in design and operation, but their poor thermal energy efficiency is a major disadvantage. Typically, the poor thermal efficiency of HD systems is attributable to the limited thermodynamic availability of low-grade heat. Moreover, HD systems often use natural draught to circulate air inside the system, which is linked with lower heat and mass transfer coefficients than forced draught air flow. Typically, film condensation over metallic tubes is used to condense airborne water vapour and recover the latent of condensation. Due to the poor rate of heat transmission, often a large metallic surface area is needed, which raises the cost of the system. Solar HD technologies have considerable potential for decentralised small-scale water production applications, but more system efficiency improvements are required to minimise the capital cost [

69].

3.1. Parameters Impacting the HD System’s Performance

The HD’s performance is quantified using a variety of indicators, including GOR, specific water production, recovery ratio (RR), mass flow rate ratio (MR), energy reuse factor (F), and specific entropy generation (Sgen).

3.1.1. Gain Output Ratio (GOR)

The gain output ratio (GOR) is one of the primary performance measures used to evaluate HD’s performance. It may be computed as the ratio of the latent heat of vaporisation of generated fresh water to the total energy input to HD [

71]:

where

is the mass flow rate of fresh water;

λ is the latent heat of vaporisation, and

is the total energy input.

A high GOR value indicates that a low heat input per unit quantity of fresh water is wanted. As a result, employing fossil fuels as a source of heat and reaching a higher GOR value results in cheaper fuel costs, whereas, when solar energy is used as a heat source, sustaining a greater GOR needs a smaller solar collector, lowering initial expenses [

60].

3.1.2. Specific Water Production

The daily amount of fresh water obtained per square metre of collector area is referred to as the specific water production. This indicator is mostly used to determine the efficiency of the HD when it is powered by solar energy. Additionally, a capital cost evaluation of HD is necessary if the cost of solar collectors varies between 40% and 45% for air heating systems [

34,

60] and between 20% and 35% for water heating systems [

34,

60,

72].

3.1.3. Recovery Ratio (RR)

The recovery ratio (RR), defined as the quantity of fresh water recovered per kilogram of input salt water, is greatly increased as a consequence of the improved salt rejection. The recovery ratio (RR) for seawater desalination with a salinity of 35 g/L was about 25% in the 1980s but increased to over 35% in the 1990s. Recently, the recovery ratio (RR) has reached about 45% and may reach 60% when combined with a second stage system [

73]. It is computed using the formula [

74]:

where

is the mass flow rate of feed seawater.

3.1.4. Mass Flow Rate Ratio (MR)

The mass flow rate ratio (MR), which is defined as the ratio of the intake seawater mass flow rate to the dry air mass flow rate supplied to the system, has a significant influence on the performance of HD [

75]. It is approximated by [

76]:

where

is the flow rate of dry air.

3.1.5. Energy Reuse Factor (F)

In the water desalination system powered thermally by HDH, there have been several efforts made to recover heat in order to reduce the amount of money spent on energy. The energy reuse factor, denoted by the letter ‘F’ is the ratio of the energy that is obtained from the heated working fluid to the energy that it provides [

77]. It is an essential indication of the HD system’s ability to reclaim lost heat. There is a range of possibilities for the economic value of the energy reuse factor in the HD system, from 6 to 12 [

34]. The energy reuse factor, denoted by the letter ‘F’ may be calculated as follows [

77]:

where

V is the vapour loading in moles of water vapour per moles of carrier gas.

3.1.6. Specific Entropy Generation

The total specific entropy generation (

Sgen,total) of the humidification–dehumidification desalination cycle is equal to the sum of the entropies created by each component of the HD system divided by the produced water flow rate.

Sgen,total may be computed using the least work of separation and classical thermodynamic concepts as follows [

78]:

where

Sgen,total is the total specific entropy generation for each system component.

3.2. Humidifier and Dehumidifier

As a result, HD technology is a viable desalination approach for small-scale potable water needs [

34,

79]. In comparison to the thermal and membrane desalination processes described previously, HD systems are relatively insensitive to high feed salinity and can operate efficiently at low operating pressures (1 bar) and temperatures, making them suitable for decentralised production of potable water from high salinity seawater [

80]. The HD process is analogous to the rain cycle, in which salt water evaporates into the air or other carrier gases such as Ar, He, or CO

2 [

81,

82] when heated by solar radiation; air transports water vapour at higher altitudes and condenses at very low pressures and temperatures. Similarly, water vapour is removed from a humidifier by air interaction with the hot feed, followed by condensation of water vapour in a condenser or dehumidifier, where humid air interacts with a cold surface to generate distillate/fresh water [

83].

The HD desalination method utilises packing materials in the humidifier to increase the amount of time that air has contact with the water [

66,

84,

85]. This increases heat and mass transfer efficiency (which is the foundation of the HD desalination process) and humidification efficiency. In other words, the humidifier’s packing material has a significant effect on HD efficiency. Numerous research has been undertaken to determine the efficacy of various humidifier packing materials in improving HD processes [

86,

87,

88]. Yuan et al. [

89] employed honeycomb paper in an HD solar desalination unit’s humidifier tower. A mathematical model was constructed to investigate the system’s behaviour, and the findings indicated that closed air and water circulation contributed to the system’s superior performance when compared to open circulation. Yamali et al. [

90] investigated the impacts of different operating conditions on solar-powered HD desalination machines by incorporating four plastic honeycomb structures into the humidifier unit and developing a mathematical model. Increased feed and coolant flow rates were shown to boost system productivity. The air flow rate, on the other hand, had a negligible influence on the system’s performance. Amer et al. [

91] conducted a similar investigation, comparing HD performance with three different kinds of humidifier packings (wooden slats, gunny bag cloth, and polyvinyl chloride). The influence of operational parameters on system performance revealed that forced air circulation increased system productivity considerably only at lower feed temperatures; however, the effect was minor at higher feed temperatures.

Hermosillo et al. [

92] evaluated the possibility of condensation enthalpy recovery throughout the dehumidifier unit using a cellulose paper humidifier. It was discovered that by reducing the input flow rate, a maximum latent heat recovery of roughly 100% could be attained while maintaining better yields. Muthusamy et al. [

93] analysed the energy and exergy consumption of an HD system loaded with sawdust and gunny bag humidifier packing materials. The performance of the system was improved by installing inserts in the air heater and dehumidifier units. The findings indicated that the gunny bag humidifier improved energy and exergy efficiency by 44% and 38%, respectively when compared to the sawdust humidifier. Al. Hallaj et al. [

94] incorporated wooden slats into a wooden-framed humidifier tower. Experiments with the closed-air cycle solar HD process showed that yield was heavily reliant on feed flow rate and that air velocity had an influence only at lower intake water temperatures. Nematollahi et al. [

95] conducted an in-depth investigation of the exergy consumption of an HD system integrated with a pall rings humidifier. It was discovered that when the diameter of the humidifier unit rose, its length and incoming air temperature declined, and the exergy efficiency improved. Nafey et al. [

96] investigated the performance of a solar HD unit equipped with a canvas humidifier in an experimental setting. The distillation rate was found to be predominantly dependent on system characteristics (e.g., feed and air input temperatures/flow rates), with wind speed and ambient temperature having a minimal influence. Ben Bacha et al. [

97] demonstrated a solar multiple condensation evaporation cycle (SMCEC) desalination method using a thorn tree humidifier. In comparison to other aspects, it was discovered that fresh water productivity was significantly dependent on the water entry temperature of the humidifier and dehumidifier units.

A spray tower is the second form of humidifier. It is a cylindrical structure in which water is disseminated downward by spray nozzles while air flows upward. The pressure drop is minimal on the air side, but the humidifier can hold a large amount of water and air. The humidifier’s effectiveness is limited due to the short contact time between the air and the water stream [

65]. As a result, the length of a humidifier may enhance its efficiency [

98,

99]. The upward hot-water injection [

100] increased humidifier efficiency and fresh water production. As a result, increasing the humidifier’s length may boost its efficiency. Numerous heat and mass transport characteristics must be determined in order to determine the humidifier’s efficiency. Kreith and Boehm [

101] discussed several empirical correlations and design methods. Other researchers [

102,

103,

104] discovered that when the flow of sprayed water rises, the absolute outlet humidity increases as well. As a result, multi-stage humidification is necessary to optimise the generation of fresh water.

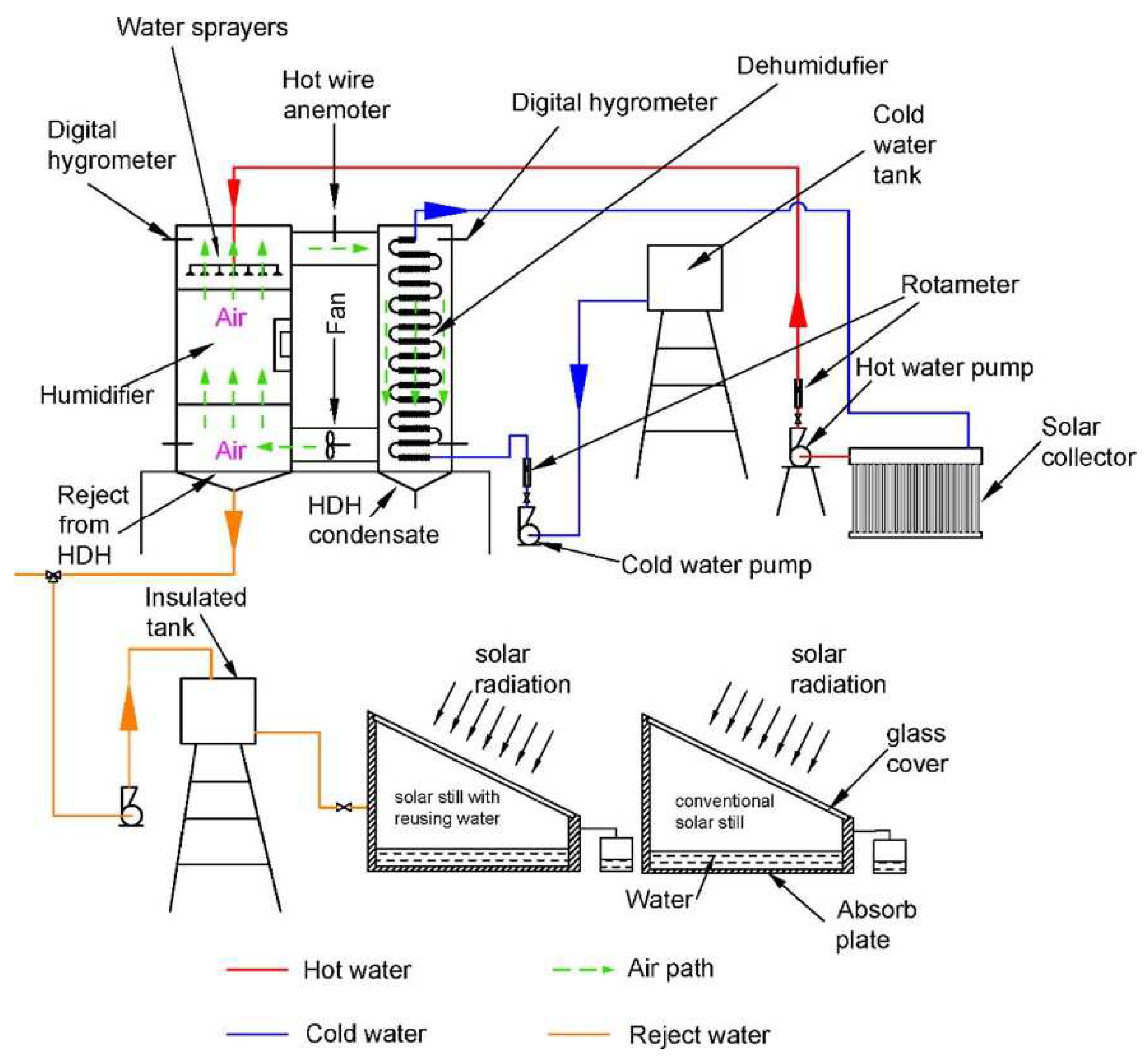

A bubble column represents the third type of tower that is characterised by the injection of a light gas or fluid into its base at the same time that it produces bubbles. The movement of fluid is extremely intricate in this column, even though its structure is quite straightforward. There have been some experimental investigations carried out on the flow of fluid through bubble columns. Computational fluid dynamics techniques are used for the majority of the work involved in conducting numerical evaluations. Schmack et al. [

105] offered a new bubble column-HD module that could be scaled down to a small size and connected with a straightforward flat plate condenser for use in distant areas. The proposed desalination method using a condenser measuring 1 m

2 could produce roughly 19 litres of water distillate on a daily basis and was effective at temperatures lower than the point at which water boils. In another attempt, Rajaseenivasan et al. [

106] analysed a bubble column-HD unit integrated with solar collectors in three different configurations. These configurations included a conventional solar air heater, a solar air heater containing turbulators, and a dual-purpose solar collector containing turbulators. The conventional solar air heater was found to be the most efficient of the three. In the three situations that were discussed, the highest daily productivity reached was determined to be 16.32, 20.61, and 23.92 L, respectively. In the case of solar air heaters featuring turbulators, the maximum possible overall efficiency reached up to 78%. Abd-ur-Rehman et al. [

107] designed and improved an innovative bubble column humidifier that could be combined with an HD module. They studied the relationship that existed between the fluctuations in air pressure and air superficial velocity and the height of the water column. Additionally, they looked into the impact that the temperature of the water had on the vapour density. According to the findings, there was a correlation between the rise in water temperature and the increase in the air’s surface velocity, which led to a higher vapour density. In addition, the least amount of pressure decrease was seen at air superficial velocities that were lower, as was the case for the height of the water column. In a different attempt, Srithar et al. [

108] evaluated the functionality of an HD module that had been improved by the addition of a solar collector and a bubble column humidifier. It was discovered that the performance may be improved by preheating the air supply, increasing the air mass flow, reducing the water depth, and including turbulators within the absorber plate. The design of concave-shaped turbulators produced the highest daily productivity, which amounted to 20.61 L per day. El-Agouz and Abugderah [

109] demonstrated the performance of a bubble column employing air bubbles travelling through heated seawater for the HD. They discovered that the air vapour content difference was 222 g/kg of dry air at both water and air temperatures of 75 °C. Additionally, Khalil et al. [

110] discovered that increasing both the water temperature and the airflow rate increases the plant’s production and efficiency, whereas increasing the water height in the humidifier had a negligible impact.

Wetted-wall towers as the fourth form of humidifier were employed by [

104,

111]. In a wetted-wall tower, a thin film of water is created as it flows downhill within a vertical pipe, either co-currently or counter-currently. Additionally, Zamen et al. [

112] used vertical polypropylene fleeces to slow the downward flow of water. On the other hand, Orfi et al. [

104] used a cotton wick to cover the tower walls to aid in the evaporation process.

There are several different varieties of heat exchangers that may be used in HD settings as dehumidifiers. For instance, Müller-Holst et al. [

111] made use of heat exchangers that consisted of flat plates. Others used finned-tube heat exchangers [

72,

109,

113]. One research [

114] employed a horizontal falling film-type condenser that consisted of a long tube with longitudinal fins. In contrast, another studies [

115,

116] used a stack of plates with copper tubes placed on them to create the same effect. In some additional investigations [

117], direct contact heat exchangers were also employed as a condenser. These heat exchangers were used in conjunction with a shell-and-tube heat exchanger to give better condensation and improved heat recovery for the cycle. The humidifier exits humid air and enters the dehumidifier to be cooled. Different forms of heat exchangers are employed, including plate–fin tubes, bubble columns, and desiccants. While the humid air cools, the salty water somewhat warms up before reaching the heater. As the temperature of the air lowers, its specific humidity decreases as well. This ejects moisture carried by the humid air.

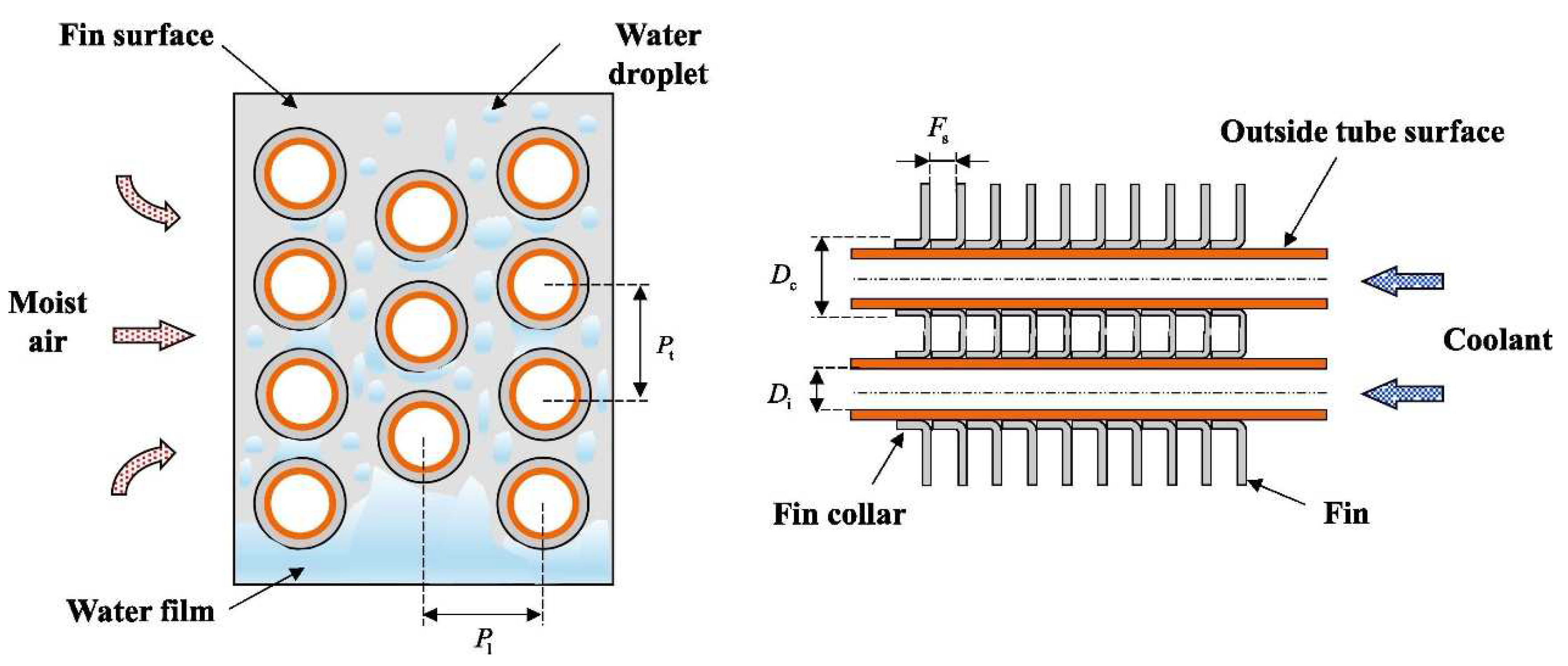

The vast majority of the publications that were evaluated [

34] make reference to plate–fin tube heat exchangers (FTHE) (

Figure 5), which are the form of heat exchanger that is the most cost-effective for HVAC dehumidification. This kind is often used for HD procedures as well as other kinds. While salty water travels down the tubes, air flows around them and along the plate fins in the direction of gravity. Either salty water may be pumped through all of the tubes at once using a port manifold, or alternatively, the tubes can be arranged in a multi-pass design. Equal mass-flow rates may be achieved in all tubes of an HVAC system or a process sector HVAC system by the use of a z-configuration and the modification of the flow cross-section. In a heat exchanger with many passes, the return bends directly the salty water to go through several tubes. The outcome is either a crossflow setup with a single pass or several passes.

Plain louvre fins [

119,

120,

121,

122,

123,

124], plain fins [

125,

126,

127], slit fins [

121,

125,

128], and wavy fins [

120,

128,

129,

130] have all had their effect on thermal performance studied in order to investigate the cooling and dehumidifying capabilities of FTHEs. The influence of the number of tube rows on thermal performance has been studied [

120,

125,

126,

128], whereas the effect of the fin spacing on thermal performance has been addressed [

121,

122,

125,

131]. Additionally, FTHEs with a tiny diameter have been investigated in [

119,

128,

132]. The papers referenced in [

122,

128,

133] discuss the transverse tube spacing as well as the longitudinal tube space, also known as row space.

Plate–fins increase the amount of surface area that is exposed to the air, which results in improved air-side heat transfer. They might have a smooth surface, or they can be perforated or corrugated to create turbulence. Commonly used standardised geometries for air-cooling and dehumidifying heat exchangers include the following, according to [

134]: outside tube diameters of 8.0, 10.0, 12.5, 16.0, 20.0, and 25.0 mm; longitudinal and transverse tube spacing ranging from 15 to 75 mm; fin spacing ranging from 1.4 to 6.4 mm; and according to [

135] fin thickness ranging from 0.005 to 0.008 inches (0.127 to 0.203 mm). In modern refrigeration applications, outer tube diameters that are no more than 10 mm are often used. It is advised that seawater velocities be between 1.5 and 2.4 m/s [

134] in order to minimise severe fouling and erosion.

When choosing a material for a heat exchanger, it is important to consider factors such as cost, mass, resistance to corrosion, thermal conductivity, and the ability to be machined. Plate–fin tube heat exchangers are often used in HVAC systems [

134]. These heat exchangers are generally made of copper tubes with aluminium fins, which enables great thermal conductivity at a reasonable cost. The round tubes are extended so that they may press-fit into the plates that surround them.

This common Cu-Al combination, on the other hand, will create an electrochemical cell in an environment where corrosion is present, which will cause corrosion to occur. CuNi alloys, which have stronger corrosion resistance, are often used for the tubes of plate–fin tube heat exchangers used in maritime applications. Chafik [

72] suggests using CuNi 90/10 for the tubes, Al or Cu for the fins, and stainless steel 304 L for the frames, casing, and collecting basin in HD dehumidifiers that are powered by salt water. After just six months of use, Houcine et al. [

136] found that the materials of these dehumidifiers started to corrode. By adding a little percentage of iron, or Fe, to the tube alloy, improved corrosion resistance may be accomplished. Happ [

137] suggests using CuNiFe 90/10 tubes with copper fins on the basis of more than 20 years of expertise gained at a salt water corrosion testing centre located in Helgoland, which is located in the North Sea in Germany. It is helpful to have a coating layer on the air side of the dehumidifier, as this will slow down or even prevent the corrosion of the fins and lengthen the life of the device. The design of the system must exclude any possibility of salty water droplets being transferred from the humidifier to the dehumidifier. The analyses of modified fundamental HDH desalination systems are included in

Table 3.

In summary, the above presentation of published literature demonstrates a strong interest in increasing the efficiency and fresh water production of HD desalination, as well as the progress made via the use of packing-bed materials inside the humidifier. As a result, it has been determined that regardless of the system or fluid preheated, the following humidifiers have the highest utilisation: cellulose (34%), plastic packed bed (14%), fibre (12%), polyethylene balls and rings (10%), wood-based (10%), bubble column (8%), metal-based (4%), thorn trees (4%), ceramic packed bed (2%), and aspen pads (2%). Similar to dehumidifiers, finned tube heat exchangers (FTHE) (56%), shell and tube heat exchangers (STHE) (38%), plate heat exchangers (4%), and bubble column heat exchangers (2%) are used [

148].

3.3. HD System Classification Based on Cycle Configurations

HD systems function below the boiling point, providing an operational advantage over other technologies, since they may be powered by thermal energy supplied at a temperature of 30 °C. Additionally, unlike MSF and MED, this system may be linked with a thermosiphon system because of its ability to function at low flow rates and low temperatures, obviating the need for pumps to assure the circulation of hot fluid. It is easy to use and maintain, requiring no specialist technical expertise or automation. Its mobility is proportional to the system’s size, taking into account that the available prototypes is suited for small-scale applications [

149,

150].

Regarding its environmental effect, it is worth noting that HD is a new technology that has emerged as a means of mitigating the environmental harm caused by traditional technologies. HD consumes less thermal energy than MSF and MED [

149], owing to the system’s current capacity, which concentrates on small-scale systems [

151]. Additionally, it generates less brine [

149] and is a simple technology that can be constructed, maintained, and operated using local resources in urban and remote places [

152].

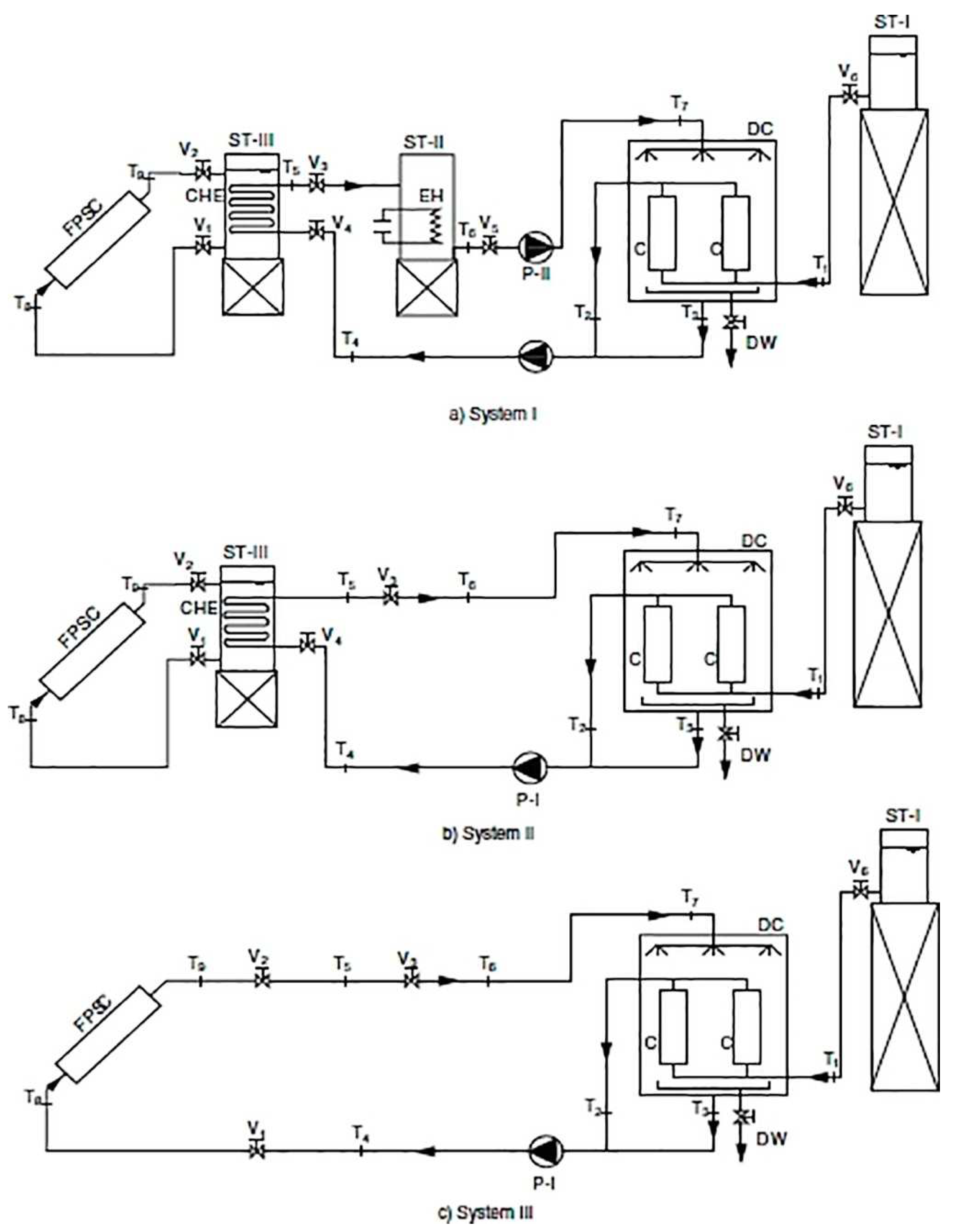

There are three primary categories of HD systems. One categorisation is based on the source of energy, which may be solar, heating, geothermal, or hybrid. This classification emphasises a positive feature of the HD concept: the prospect of obtaining water with less energy, most notably industrial waste heat or renewable energy sources such as solar or biomass. The second categorisation is determined by the configuration of the cycle (

Figure 6). A closed-water open-air (CWOA) cycle is one in which ambient air is drawn into the humidifier, heated, and humidified, and then transported to the dehumidifier, where it is partly dehumidified and drained in an open circuit to create a closed circuit. Air circulates in a closed circuit between the humidifier and the dehumidifier. This procedure is repeated until the brine reaches the required level of recovery. Mechanical or natural convection fans may circulate the air in these systems, and a pump is often used to circulate the feed water. It is vital to understand the technical advantages of each of these circuits and to choose the design that optimises efficiency while minimising water production expenses. The third kind of HD system is classified according to the type of heating used (water or air). The temperature of the fluid being heated has a considerable effect on the system’s performance [

153].

The HD has attracted particular attention from thermal-driven desalination cycles because of its simplicity, operational stability, cheap cost, low-grade thermally driven, and integration flexibility with other systems such as heat pumps, adsorption, and absorption cycles [

154,

155,

156]. Therefore, extensive research has been undertaken to optimise the HD cycle’s performance via different configurations and integrations (i.e., fresh water productivity and efficiency). In terms of mixing HD with another cycle, He et al. [

147] generated both electricity and fresh water by combining an organic Rankine cycle with an air-heated HD cycle. At its peak, the combined system generated 19.53 kg/h of fresh water at a GOR of 2.82. Fouda et al. [

157] evaluated the transient performance of single-stage, double-stage, and modified double-stage HDH systems that were driven by solar energy. The improved two-stage HD cycle generated 350 kg/d of fresh water with a GOR of 1.63.

By combining the HD cycle with a silica gel adsorption cooling cycle, Qasem and Zubair [

158] showed that the HD cycle may be used in conjunction with a silica gel adsorption cooling cycle. For USD 6.4/m

3, this system could produce 20–30 kg/h and may provide GOR levels that are higher than 7.5. Elbassoussi et al. [

156] evaluated the effectiveness of combining water-heated HD with an adsorption cycle to provide fresh water and cooling. Fresh water was generated for USD 11.5/m

3 with a GOR of 2.5. Ali et al. [

154] established a connection between HD, two ejectors, and the desalination cycle through adsorption. Theoretical studies indicated that the system could produce 98.41 m

3/ton of silica gel daily at a GOR of 2.75. Rostamzadeh et al. [

159] studied and optimised an HD system driven by an absorption–compression heat pump. With a GOR of 9, the hybrid cycle produced fresh water at a rate of 2329 kg/h.

The configuration of the water and air routes in the HD desalination cycle significantly affects its performance [

160]. Ettouney [

161] conducted research in this regard by examining the performance of different HD cycle topologies. For each arrangement, different governing equations were devised. According to studies, configurations must be tuned for maximum efficiency and the lowest possible water cost. Closed-air and closed-water HD cycles function equally well, according to Narayan et al. [

34]. Sharqawy et al. [

74] assessed the performance of a single humidifier equipped with a water- and air-heated HD cycle. The two cycles were compared in detail. It was found that increasing GOR might be accomplished by employing a more efficient humidifier and dehumidifier.

Zubair et al. [

162] investigated an open-water open-air (OWOA) and a modified closed-water open-air (CWOA) HD desalination cycle using experimental and computational methods. The modified cycle outperforms the original cycle by a factor of 10, according to some sources. Garg et al. [

163] developed a thorough heat and mass transport model for an open-water closed-air (OWCA) and water-heated desalination cycle using HD. The humidifier and dehumidifier were sized optimally to provide the required thermal cycle performance, as measured by GOR and recovery ratio. With parametric analysis, it was discovered that there was always a maximum GOR value and that the thermal performance of the system was more dependent on the dehumidifier’s performance than on the humidifier’s performance. Wu et al. [

164] explored a single-effect OWCA-WH heated HD cycle that was driven by solar energy. The findings indicate that raising the operational temperature (i.e., the driving temperature) decreases the amount of effort needed. Muthusamy and Sridhar [

165] presented an enhanced HD cycle that would boost fresh water production while using less energy. A 40% decrease in input power was obtained when compared to the traditional HD cycle. Müller-Holst [

166] presented a multi-effect HD cycle for system performance optimisation. The OWCA water-heated system with multiple effects was claimed to have the maximum energy efficiency and the lowest water cost of around USD 3–7/m

3 [

166]. Dave et al. [

167] proposed and investigated a direct absorption solar humidifier in conjunction with the OWCA HD desalination system, characterising the effects of seawater and air flow rates on the HD desalination system’s performance in order to determine the optimal operating state for solar thermal conditions. The suggested system outperformed the traditional system by 18.4%, and the anticipated cost of water production was between 0.007 and 0.035 USD/L. Additional past research is summarised in

Table 4 [

168].

As previously indicated, the HD performance is mostly controlled by the arrangement of the water and air flow circuits. The presented investigations centred on a specific kind of HD system to be studied: thermodynamically balanced or hybrid systems. In addition, the research evaluated single humidifier air-heated vs. water-heated HD systems. There has not yet been a complete comparison and evaluation of alternative HD system configurations for single, double, and triple humidifier (water-heated and air-heated) HD systems. In the water-heated HD cycle, a higher amount of water is heated and sprayed into the humidifier. More hot water sprays from the humidifier result in higher water vapour and, therefore, more fresh water production. However, this large output does not suggest that the system GOR is high because of the considerable energy spent to increase the water temperature. As a consequence, the power consumption in the air-heated HD cycle is reduced, which may result in a higher GOR value.

6. By-Product Treatment Subsystem

During the desalination process, a by-product known as brine is created [

358]. This concentrated solution contains seawater with salt levels 1.6 to 2 times greater than seawater (36 g/L NaCl), as well as any chemicals employed in the pre-treatment and post-treatment stages (NaOCl, FeCl

3, AlCl

3, H

2SO

4, HCl, NaHSO

3, and scale inhibitors). Even though all desalination methods have a negative environmental effect, brine saltiness tends to be greater with the MSF and MED techniques. In MSF and MED, brine is blended with cool water before discharge to minimise salt concentrations [

359]. In addition, the temperature of the ejected liquid must be taken into account as well. A rise in discharge temperature of up to 1.82 times greater than the MD technology may be achieved with the MSF and MED procedures by contacting the brine with the surrounding environment.

According to a United Nations-sponsored study, Jones et al. [

360] published a report in 2019 titled ‘The state of desalination and brine production: a global outlook,’ in which they highlight the advantages of providing drinking water from desalination plants while also pointing out the numerous drawbacks. Economic and technological challenges in brine management are also highlighted in the report. Most desalination facilities (80% of them globally) dump untreated concentrate straight into nature. According to Jones and colleagues, there are several ways to overcome these difficulties, such as using brine to grow fish that are resistant to salinity, as well as commercially recovering salt and metals from brine. Using any of the aforementioned treatment procedures may generate revenue from these ancillary activities.

Brine removal is a major source of environmental concern since it raises soil salinity, affects marine life at its discharge point, and contains chemical products and corrosion metals including Copper (Cu), Nickel (Ni), Chromium (Cr), Ferrous (Fe), and molybdenum (Mo). In contrast to saline from a single desalination plant, which would have little influence on the marine ecosystem, brine from several plants running nearby for extended periods might have negative effects [

361]. It was for this reason that research conducted in 2015 [

361] by Gall and Thompson, and more recently in 2018 [

362] by Al-Shammari and Ali, proved the negative impact seawater salinity increases have on marine life. Brine discharge into the ocean is avoided by copious marine currents and is of an acceptable magnitude, resulting in little consequences on marine animals [

363].

In light of the foregoing, a variety of disposal strategies have been suggested and developed in this research. Desalination’s environmental effect must be minimised, thus it’s critical to figure out the best way to do it. These include the amount, quality and composition of brine in the desalination plant as well as other criteria such as geographic location, the availability of space for discharge, public acceptability, operational costs, and the capability for future expansions [

364]. The dilution approach involves adding another liquid to the brine to dilute its salt content, while the concentration method makes use of direct solar radiation to remove the brine or turn it into another by-product (see

Table 12) [

365].

Costs to remove brine range from 5% to 33% of the entire process cost and rely on a variety of factors, such as the technology used, volume, and properties of brine, treatment level, and disposal location [

366]. The desalination process may employ any kind of water as long as the brine composition is appropriate to prevent pollution of the receiving body of water [

367]. Although the various salt disposal methods minimise their effect, they do not totally solve the issue until the by-product of the brine disposal process can be reintegrated into the economic cycle.

In sum, pumping systems are required to dilute brine in desalination plants, and the size of these systems depends on how much salt they remove from water. The evaporation points concentration systems, on the other hand, use solar radiation as a power source, whereas the zero liquid discharge (ZLD) method has a high energy consumption, ranging from 5.1 kWh/m

3 to 67 kWh/m

3 of treated water depending on the technology used [

368]. Finally,

Table 13 summarises the implementation costs [

369] associated with the various brine treatment procedures.

7. Recent Advancements in HD Desalination Systems

The use of the fogging nozzles technique with a droplet size of 20-μ in an HD desalination system was investigated experimentally by Alrbai et al. [

371]. The technology of fogging nozzles was able to significantly minimise entropy generation and energy consumption. With a minimal entropy generation of 0.235 kJ/kg K, a maximum GOR of 3.4 was achieved. Energy and exergy analyses were used to determine the system’s performance.

El-Said et al. [

372] conducted experiments to explore the integration of solar water desalination using HD methods with a cooling system and a hot air flow rate. Where the relative humidity approached 100%, a porous activated carbon tube was employed as a humidifier, and the cooling system was used as a dehumidifier. The highest daily output of fresh water is 6.12 kg/d. Energy and exergy efficiency, as well as the GOR, were 26.73% and 1.57%, and 1.24, respectively. According to economic calculations, the cost of fresh water is USD 0.01386/L.

An HD-vapour compression refrigeration (HD-VCR) cycle has been combined to fulfil fresh water, space cooling, and hot water requirements while using the least amount of floor space possible [

373]. The intended outputs of the refrigeration and heat pump cycles are heat absorption and heat rejection, respectively. To create the appropriate outputs in the proposed HD-VCR, a water-cooled condenser for humidification and an evaporator for dehumidification are utilised concurrently. Through parametric analysis, the evaporator temperature was tuned to maximise the energy performance ratio (EPR) of the cycle and plant. Maximum cycle EPR requires a lower evaporator temperature than maximum plant EPR. The optimal evaporator temperature increases as the temperature of the hot water, the temperature of the ambient air, and the RH of the ambient air rise. At 100 m

3/h and a hot water supply temperature of 50 °C, the area of the solar PV plant and the area of the SWH are practically identical at 14.23 m

2 and 11.74 m

2, respectively. In these circumstances, the EPR of the HDH-VCR cycle is 1.80.

Rafiei [

374] performed an HD combined with a thermal PV system for the purpose of producing fresh water and power. They developed a novel sort of solar collector: a dish concentrator with a conical cavity receiver as the primary source of heat. Additionally, solar PV thermal was employed as a supplementary thermal energy source to pre-heat salt water. They also investigated the impact of several nanofluids as working fluids for the heating process, including Cu/oil, CuO/oil, Al

2O

3/oil, TiO

2/oil, and MWCNT/oil. Kolahi et al. [

375] combined an organic Rankin cycle with an HD desalination system in a series and parallel arrangement to generate both fresh water and electricity. The hybrid system generated fresh water at a rate of 3.93 L/s and a total work output of 5.72 MW through parallel and series arrangements, respectively.

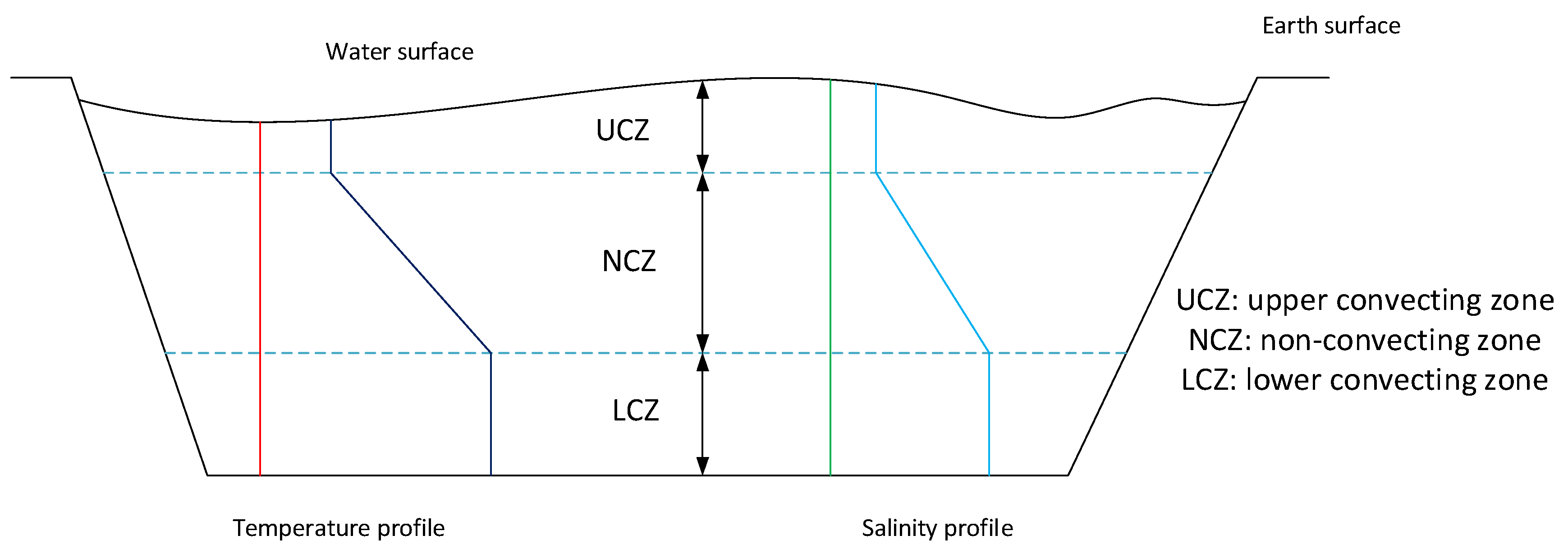

There is a novel arrangement for the cogeneration of electricity and distilled water by using thermal energy stored in the lower convective zone (LCZ) of a solar pond with a salinity gradient (SGSP) [

376]. A Kalina cycle (KC), an HD unit, and two thermoelectric generators (TEGs) are included in the proposed system. The findings of multi-objective optimisation indicate that the energy utilisation factor (EUF), exergy efficiency, and total unit cost of the product (TUCP) may all be increased by 14.09%, 5.5%, and 27.93%, respectively, over the base case. The optimal EUF, exergy efficiency, and TUCP values were 0.756, 27.7%, and 30.54 USD/GJ, respectively, when the proposed power/desalination system was designed with the following design parameters: solar pond area of 15,326 m

2, LCZ thickness of 1.65 m, NCZ thickness of 1.35 m, UCZ thickness of 0.35 m, LCZ temperature of 370 K, figure of merit of 2.45, desalination flow ratio of 2.45 The example study determined that between 20 March and 20 April, the system generates the least amount of fresh water, 0.152 m

3/h. On the contrary, between 21 June and 21 July, the greatest volume of distilled water is available. Additionally, the optimal period to operate the system to create distilled water and power simultaneously is from 21 May to 21 August.

Qasem et al. [

155] investigated the HD in combination with a double-effect absorption refrigeration cycle that was fuelled by a low heat energy source (solar collector and waste heat), while the heat outlet/rejected from this system was utilised to heat the salt water. In comparison to the traditional HD, the hybrid system improved performance by about 2.21 times in terms of fresh water productivity, 2.20 times in terms of GOR, and 8.24 times in terms of fresh water cost reduction. Sachdev et al. [

377] heated the air in their HD using a double-pass solar collector. The system was linked with the wind tower system in this research to generate fresh water and air inside the comfort zone. In comparison to alternative heat sources, employing a heat pump cycle to heat HD desalination systems significantly enhanced GOR (GOR = 4.17) [

378].

9. Conclusions

Green desalination has built a dependable business utilising fewer chemicals and cleaning chemicals. Concerning low-cost renewable energy, solar energy in particular is now accessible to tackle renewable energy-related challenges [

388]. The seawater greenhouse (SWGH) configuration is a novel concept in the agricultural field for the production of fresh water that has recently been developed for irrigation and drinking purposes. The SWGH desalination technology is a sort of desalination plant that reproduces the water cycle through seawater evaporation and condensation into fresh water (the HD concept). The SWGH system is the most suitable technology for arid and remote regions, especially in the coastal zones of the Middle East and Northern Africa.

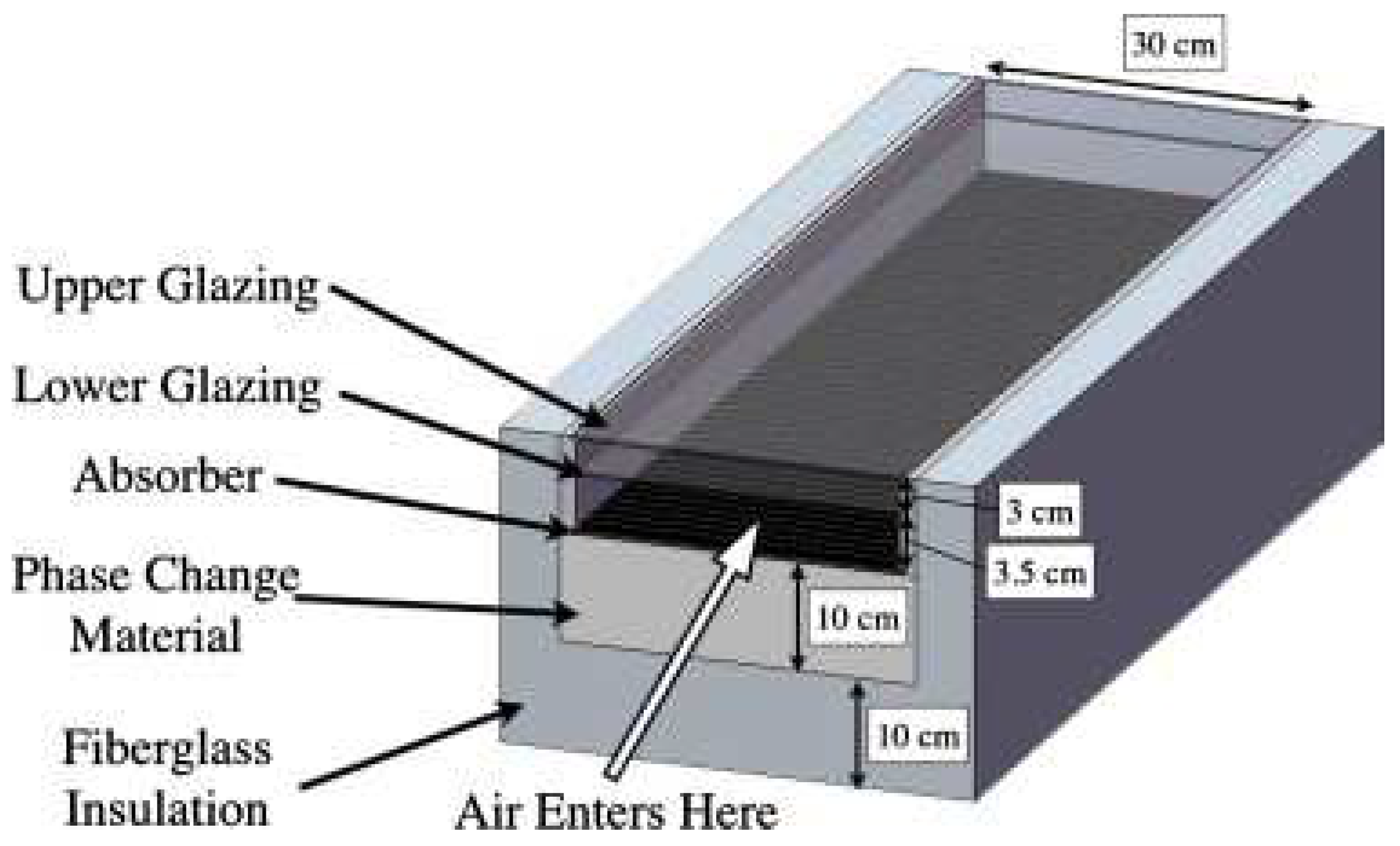

Meanwhile, the FPC for WH is the most often utilised device in the HD system, accounting for 61% of this desalination system [

389]. The FPC’s low temperature may be readily enhanced by employing reflectors [

390], which increase absorbed solar radiation by up to 80% when top, bottom, right, and lift reflectors are utilised.

One of HD’s primary disadvantages is the limited mass and heat transmission between the salty water and the surrounding air. Numerous ways have been explored to address this issue, including the humidifier’s use of wick, treated cellulose paper, corrugated cellulosic material, and wooden slates. Additionally, the air bubble basin humidifier demonstrated effective performance due to its wide surface area for heat transmission between water and air [

391].

HD heated with FPC has the potential to provide an ideal worldwide solution for the disposal of high salinity industrial water. This visibility is based on four HD characteristics: it is capable of operating in excessively salty water, has a basic design, and is free of biological fouling or silt [

309].

There are few active SWGHs around the world, but considering the global climatic conditions, global warming, reduced fresh water resources, and increased world population growth, their applications will be extended.

HD can be used for seawater or brackish water desalination to obtain sustainable GH and can also aid recirculation to partially restore excess moisture in the GH cavity, especially in hot and dry countries. Thus, proper circumstances are critical in guaranteeing a greenhouse’s outstanding functioning.