Abstract

The United States Department of Energy (DOE) is the lead federal agency for the development and deployment of carbon sequestration technologies. Its mission includes promoting scientific and technological innovations and transfer of knowledge for safe and permanent storage of CO2 in the subsurface. To accomplish its mission, DOE is characterizing and classifying potential geologic storage reservoirs in basins throughout the U.S. and Canada, and developing best practices for project developers, to help ensure the safety of future geologic storage projects. DOE’s Carbon Sequestration Program, Regional Carbon Sequestration Partnership (RCSP) Initiative, administered by the National Energy Technology Laboratory (NETL), is identifying, characterizing, and testing potential injection formations. The RCSP Initiative consists of collaborations among government, industry, universities, and international organizations. Through this collaborative effort, a series of integrated knowledge-based tools have been developed to help potential sequestration project developers. They are the Carbon Sequestration Atlas of the United States and Canada, National Carbon Sequestration Database and Geographic System (NATCARB), and best practice manuals for CCS including Depositional Reservoir Classification for CO2; Public Outreach and Education for Carbon Storage Projects; Monitoring, Verification, and Accounting of CO2 Stored in Deep Geologic Formation; Site Screening, Site Selection, and Initial Characterization of CO2 Storage in Deep Geologic Formations. DOE’s future research will help with refinement of these tools and additional best practice manuals (BPM) which focus on other technical aspects of project development.

1. Introduction

Our modern economy and our associated quality of life—lighting, transportation, communications, heat and air conditioning—rely fundamentally on the consumption of energy, of which approximately 85%, worldwide, comes from the combustion of fossil fuels. One of the byproducts of combustible fuels is carbon dioxide (CO2). Anthropogenic CO2 emissions and resulting increases in CO2 atmospheric concentrations have been generally increasing since the start of the industrial age [1]. Currently, approximately 31 billion metric tons of CO2 are being emitted into the atmosphere annually [2].The concentration of CO2 in the atmosphere is expected to increase at a rate of 1.3% annually between 2007 and 2035 [2].

While the specific links between increasing atmospheric CO2 concentrations and many physical and biological processes remain uncertain, there has been increasing focus over the past decade, by scientists and policymakers alike, on approaches for reducing CO2 emissions. One approach is to capture the CO2 from industrial facilities which are large emission sources. Fossil fueled power plants are prime candidates, but others include refineries, cement plants, gas processing facilities, and other industrial sources. After capture, the CO2 would be compressed, transported, most likely by pipeline, and injected deep in the subsurface into rock formations with the capability of storing the CO2 for thousands of years. This emissions reduction approach is called carbon capture and storage (CCS). DOE’s Office of Fossil Energy manages a Carbon Sequestration Program through NETL which focuses on research and development of CCS technologies to reduce CO2 emissions.

DOE’s Carbon Sequestration Program is focused on geologic storage of captured CO2 that would otherwise be emitted to the atmosphere. Applied research is being conducted to develop and test different approaches to CCS. Technology testing and development through the Regional Carbon Sequestration Partnership (RCSP) Initiative and other entities will be instrumental to the commercial deployment of CCS. DOE’s vision is to fully understand the available CCS options, cost factors, environmental implications, and technological options.

2. DOE’s Carbon Sequestration Program

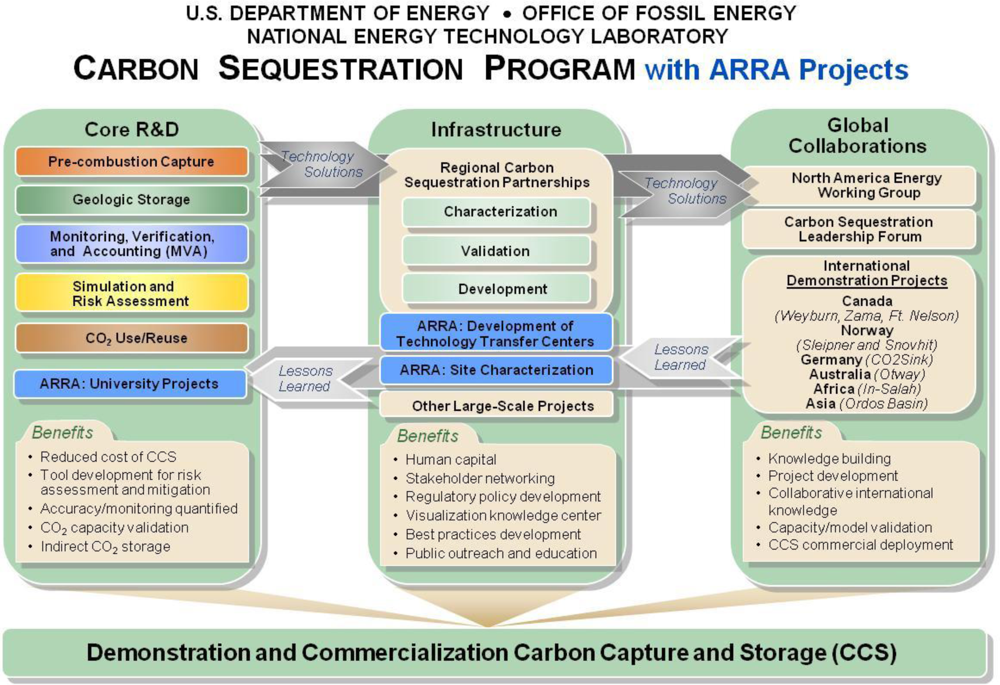

In 1997, DOE established the Carbon Sequestration Program (Program), which is administered by the Office of Fossil Energy and implemented through NETL to move CCS technologies toward commercialization. The Program encompasses all aspects of CCS and has engaged government and private sector partners that have expertise in CCS technology. The Program covers three key elements for technology development (Figure 1): core research and development (R&D), infrastructure, and global collaborations. The R&D element is driven by industry’s technology needs and categorizes those needs into five focal areas to more efficiently obtain solutions that can then be tested and deployed in the field. The infrastructure element includes the RCSPs and other small and large-volume field tests in different geologic formation classes where validation of various CCS technology options and their efficacy are being confirmed. The global collaborations element benefits from technology solutions developed in the R&D and infrastructure elements and, in turn, feeds lessons learned into infrastructure and R&D. Lessons learned from the infrastructure element are also fed back into R&D to guide future applied research and development of CCS technologies. Funds from the American Recovery and Reinvestment Act (ARRA) of 2009 were recently utilized by the program to develop CCS technology training centers, conduct additional site characterization studies and to fund small research projects related to CCS.

Figure 1.

DOE’s Carbon Sequestration Program.

The Program strives to develop fossil fuel conversion systems that offer 90% CO2 capture with a less than 10% increase in the cost of energy services for pre-combustion carbon capture ready for wide scale deployment in the 2020 timeframe. In addition, the Program aims to achieve 99% storage permanence while validating storage potential within +/− 30%. Attaining these goals will require an integrated approach to address CCS challenges through R&D projects, participation in working groups, and the RCSP Initiative. Development of these technologies will help address future challenges to overcome a multitude of economic, social, and technical challenges, including cost-effective CO2 capture through successful integration with fossil fuel conversion systems; effective CO2 monitoring and verification; permanence of underground CO2 storage; and public acceptance.

The commercial deployment of CCS faces many challenges. Technical challenges include the development of lower cost capture technologies, accurate estimates of geologic storage potential, and evaluating the permanence of injected CO2. Legal and social issues include developing a regulatory framework with regards to the permitting and treatment of CO2 once it is injected into a geologic reservoir, developing infrastructure such as pipelines, developing a workforce trained in CCS, and the legal framework for the liability and ownership of the pore space and injected CO2. Additionally, commercial deployment of CCS will require public education on the benefits of CCS. The Program is developing best practice manuals from lessons learned to help transfer knowledge gained to the private sector.

3. Regional Carbon Sequestration Partnerships

The RCSPs are public/private cooperative efforts tasked with developing guidelines and testing the most suitable technologies, regulations, and infrastructure needs for CCS in the United States and Canada. The seven RCSPs that form this initiative currently include more than 400 state agencies, universities, and private companies, spanning 43 states, and four Canadian provinces.

The RCSPs’ initiative consists of three distinct phases of work: (1) Characterization Phase (2003–2005); (2) Validation Phase (2005–2011); and (3) Development Phase (2008–2018+). The Characterization Phase began in September 2003 with the seven RCSPs working to develop the necessary framework to validate and potentially deploy CCS technologies. At the end of the Characterization Phase, the RCSPs had succeeded in establishing a national network of companies and professionals working to support CCS deployments, creating a National Carbon Sequestration Database and Geographic Information System (NATCARB), and raising awareness and support for CCS as a green house gas (GHG) mitigation option. Fact sheets for some of the projects conducted by the RCSPs and NETL are available at http://www.netl.doe.gov/technologies/carbon_seq/refshelf/refshelf.html.

The Validation Phase focuses on validating the most promising regional opportunities to deploy CCS technologies by building upon the accomplishments of the Characterization Phase. Efforts are being conducted to (1) validate and refine current reservoir simulations for CO2 storage projects; (2) collect physical data to confirm CO2 storage potential and injectivity estimates; (3) demonstrate the effectiveness of monitoring, verification, and accounting (MVA) technologies; (4) develop guidelines for well completion, operations, and abandonment; and (5) develop strategies to optimize the CO2 storage potential of various geologic formations. The Validation Phase consists of 20 geologic injection tests.

The Development Phase builds on the information generated in the Characterization and Validation Phases and involves the injection of 1 million tons or more of CO2 by each RCSP into regionally significant geologic formations. These large-volume injection tests are designed to demonstrate that CO2 storage sites have the potential to store regional volumes of CO2 emissions safely, permanently, and economically for hundreds of years. Development Phase tests will result in a better understanding of commercial scale CCS projects and of regulatory, liability, and ownerships issues associated with these projects. These projects will provide a firm foundation for commercialization of large-scale CCS.

4. Development of the Carbon Sequestration Atlas of the United States and Canada and the NATCARB Database

DOE manages the development of a powerful, user-friendly database that supplies regions of the country with valuable information regarding CCS. The database, called the National Carbon Sequestration Database and Geographic Information System (NATCARB), was originally designed to assess the potential for geologic CO2 storage in five Midwestern states (Indiana, Illinois, Kansas, Kentucky, and Ohio). With the implementation of the RCSP Initiative, the database was expanded to cover the entire U.S. and parts of Canada by linking the seven RCSPs and various public databases. NATCARB provides web-based data access to CO2 stationary sources, potential geologic CO2 storage data, infrastructure information, supporting analytical tools for CO2 storage resource estimation, and CCS cost estimation. NATCARB addresses the broad needs of all users, and includes not only geographical information systems (GIS) and database query tools for the high-end technical user, but also simplified displays for the general public, employing readily available web tools such as Google Earth™ and Google Maps™. Data are generated, maintained, and enhanced locally at the RCSP level, or at specialized data warehouses and public servers. They are assembled, accessed, and analyzed in real-time through a single geoportal. NATCARB is available through the NETL/DOE website at http://www.netl.doe.gov/technologies/carbon_seq/natcarb/index.html.

5. Development of a Depositional Classification Scheme for CO2 Reservoirs

Through NETL, DOE has recently released a comprehensive manual, titled Geologic Storage Formation Classification: Understanding Its Importance and Impact on CCS Opportunities in the United States, to better understand the characteristics of potential geologic storage formations as a component of CCS. This desk reference is intended to:

- Assist with an understanding of basic geological principles and terminology associated with potential CO2 geologic storage in formations.

- Show the importance of geologic depositional systems in determining the internal architecture of such formations, thus making it possible to predict the general behavior of the injected CO2.

- Establish the importance of using the geologic depositional system to assess existing and future research, design, and demonstration needs related to storing CO2 in different depositional environments.

- Focus the efforts of DOE on potential reservoirs in depositional environments that have not been previously investigated.

Three major rock types might be targeted by future developers of CCS projects for storage formations: igneous, metamorphic, and sedimentary. Each major type of rock was formed under different conditions, and their potential for CO2 storage varies based on the necessary criteria of:

- Capacity, based on the porosity or openings within a rock, often called “pore space”.

- Injectivity, dependent on the permeability or the relative ease with which a fluid or gas can move within the pore space(s) of a rock.

- Integrity, the ability to confine a fluid or gas within a geologic unit, is of primary importance, because without impermeable seals, fluids will take the path of least resistance and move to a lower pressure area, including the surface.

The answers to questions concerning capacity, injectivity, and integrity can be learned, in part, by reservoir characterization of the formations in the area of the proposed geologic storage site. Reservoir characterization is an evolving science that integrates many different scientific disciplines (geology, geophysics, mathematical modeling, computational science, seismic interpretation, well log, and core analysis, etc.) in order to build a conceptual model of a formation. The decision to select a particular geologic unit for geologic storage usually depends on a detailed understanding of the reservoir characteristics and the behavior and fate of the injected fluids and their impact on the geologic strata receiving the fluids. Critical factors include economic analysis of the location of the site, distance from the CO2 source to the site, depth of the reservoir (which influences drilling and injectivity of CO2), the volume of CO2 that the site can contain, the trapping mechanism and sealing capacity, and the ultimate fate of the stored CO2. Many of these issues will be affected by the different classes of reservoirs being targeted for injection.

Most CO2 geologic storage targets are sedimentary rocks (clastics and carbonates), where CO2 storage is in the pore space between grains, which are most often filled with undrinkable saline water. Igneous formations, which cover more of the Earth’s surface than sedimentary formations, offer potentially great geologic storage sites because of their total volume both on continents and under the oceans, but are mostly untested. Coal seams are considered both sedimentary and metamorphic and have their own unique properties. The most important storage mechanism for coal is its preferential ability to absorb CO2 directly on its surface. This situation differs from other sedimentary and igneous formations where the CO2 occupies the pore space.

One major goal of the Program is to classify the depositional environments of various formations that are known to have excellent reservoir properties and are amenable to geologic CO2 storage. This is being accomplished through the implementation of 28 CO2 injection field projects in collaboration with the RCSP Initiative and ten American Recovery and Reinvestment Act of 2009 (Recovery Act) projects focused on the characterization of geologic formations as sites for possible commercial CCS development. DOE proposes a geologic depositional classification system for CO2 storage to better understand how the field work being conducted fulfills the need to test these different classes of depositional systems and determine what future R&D projects are still needed.

While geologic formations are infinitely variable in detail, they have been classified by geologists and engineers in the petroleum industry by their trapping mechanism, the hydrodynamic conditions (mechanical forces that produce), lithology (physical characteristics), and more recently by their depositional environment (how they were formed). The depositional environment influences how formation fluids are held in place, how they move, and how they interact with other formation fluids and solids (minerals). For the purposes of geologic storage, the geologic formation/reservoir classification system has been expanded to include unconventional reservoirs, such as coal seams, and igneous formations, like stacked basalts. The reservoir classification scheme developed for CO2 storage, based on depositional environments, is presented as Table 1.

Table 1.

Proposed depositional environments classification scheme.

For fluid flow in porous media, knowledge of how depositional systems formed and directional tendencies imposed by the depositional environment can influence how fluids flow within these systems and how CO2 in geologic storage would be anticipated to flow in the future. Although diagenesis has modified fluid flow paths in the intervening millions of years, the basic architectural framework created during deposition remains; geologic processes that exist today also existed when the sediments were initially deposited. Analysis of modern day depositional analogs and evaluation of core, outcrops, and well logs from ancient subsurface formations provide an indication of how formations were deposited and how fluid flow within the formation is anticipated to flow.

The DOE is gathering data and developing a database of regional reservoirs and associated properties for each type of depositional environment. This data could be utilized by site developers and property owners to develop risk assessments and business models for CCS and to better define costs for geologic storage and determine the type and quality of geologic reservoirs in a region. DOE’s goal is to characterize the different depositional environments with drilling, subsurface geophysics, chemical analysis, geomechanical analysis of the rocks, and conducting both small- and large-scale CO2 injection tests.

The results of DOE’s initial evaluation indicate that reservoir characterization (with the ability to store >30 million tons of CO2) has not been completed for shelf clastic, reef, and coal environments. Small-scale injection tests have not been performed on fluvial deltaic, eolian, and turbidite sedimentary environments. Large-scale injection tests have not been performed on deltaic, strandplain, shelf carbonate, eolian, turbidite, basalt large igneous providences (LIP), and coal. Three highly experimental reservoirs (fractured shales, basalts mid-oceanic ridge [MOR], and offshore turbidites) have not been evaluated. The evaluated projects are in various states of completion—some investigations are completed and some just started. Understanding the impacts of different reservoir classes on CO2 storage supports DOE’s efforts to develop the knowledge and tools necessary for commercialization of CCS technologies throughout the United States. Using lessons learned from the behavior of CO2 in reservoirs from these geologic investigations and their known depositional environments is important in developing an understanding for similar depositional environments being considered for storage (Table 2).

Table 2.

Matrix of NETL CO2 geologic storage projects and geologic formation classes.

6. Technology Transfer and the Development of Best Practice Manuals

Through the various projects in the Program, lessons learned have been documented in a series of best practice manuals (BPMs) that serve as the basis for the design and implementation of commercial CCS projects. As of August 2010, DOE has released three BPMs: (1) “Public Outreach and Education for Carbon Storage Projects,” (2) “Site Screening, Selection, and Characterization for Storage of CO2 in Deep Geologic Formations,” and (3) “Monitoring, Verification, and Accounting of CO2 Stored in Deep Geologic Formations.”

Public Outreach and Education for Carbon Storage Projects

The objective of the Public Outreach and Education for Carbon Storage Projects Best Practices Manual is to communicate lessons learned and to recommend best practices emerging from the public outreach conducted by the seven RCSPs. The manual is intended to assist project developers in understanding and adopting best practices in outreach to support CO2 storage projects. Although project developers are the primary audience for this document, other stakeholders may find the contents useful. Early CO2 storage projects have been highly visible, and their success will likely impact future CO2 storage projects.

The primary lesson learned from the RCSPs’ experience is that public outreach should be an integrated component of project management. Conducting effective public outreach will not necessarily ensure project success, but underestimating its importance can contribute to delays, increased costs, and community ill will. Effective public outreach involves listening, sharing information, and addressing concerns through proactive community engagement. Public outreach begins at the onset of the project, continues through the close of the project, and involves each individual on the project team.

The RCSPs’ concept of public outreach involves efforts to understand, anticipate, and address public perceptions and concerns about CO2 storage in a community being considered for a project. Ideally, public outreach can lead to a mutually beneficial outcome where project developers move ahead with the support of well-informed stakeholders who are comfortable with the project benefits and potential risks and trust the project team. As described in this BPM and shown in Table 3, the RCSPs have proposed the 10 best practices for CCS public outreach.

Table 3.

Ten best practices for public outreach.

7. Site Screening, Site Selection, and Initial Characterization for Storage of CO2 in Deep Geologic Formations

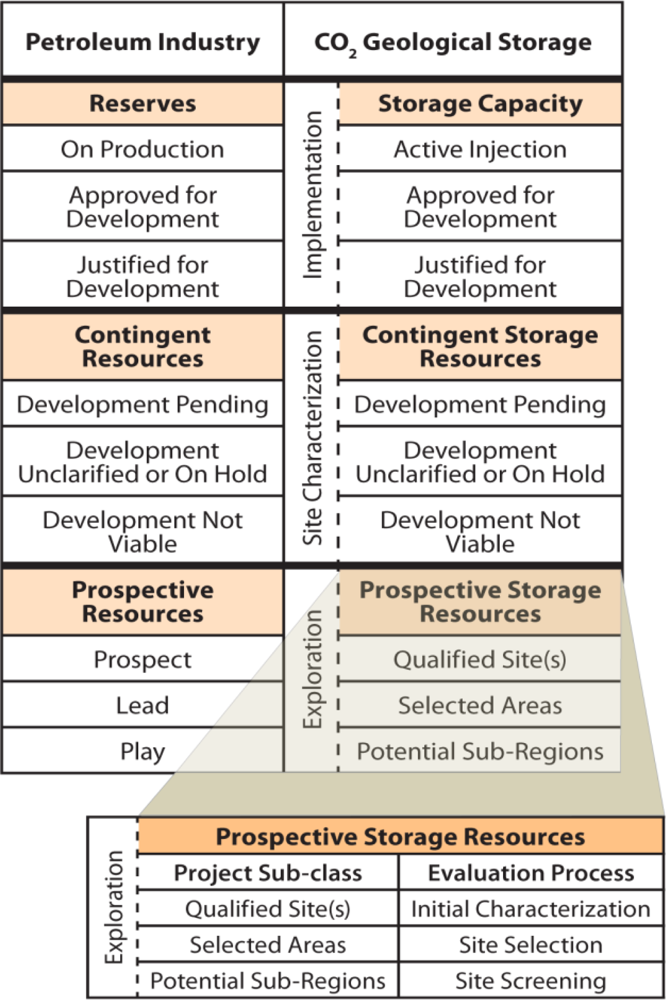

Another in the series of BPMs developed is the “Site Screening, Site Selection, and Initial Characterization for Storage of CO2 in Deep Geologic Formations,” which includes a series of process diagrams and guidelines for site screening, site selection, and initial characterization. This document is based on the lessons learned from the RCSPs through the Validation Phase and integrates the analyses into a proposed geologic storage framework. The proposed classification framework is divided into three phases: Exploration Phase, Site Characterization Phase, and Implementation Phase. The Exploration Phase classifies storage estimates for prospective storage and classifies the site based on the level of analyses conducted. The Exploration Phase has three project sub-classes: Potential Sub-Regions, Selected Areas, and Qualified Site(s). These sub-classes correspond to three stages of evaluation during the Exploration Phase: site screening, site selection, and initial characterization (Figure 2). The most important objectives of the Exploration Phase are to lay the groundwork to ensure safe storage of CO2 and compliance with the Underground Injection Control (UIC) program requirements.

Figure 2.

Comparison of Petroleum Industry Classification and Proposed CO2 Geologic Storage Classification. Adapted from SPE/WPC/AAPG/SPEE Resource Classification System. (© 2007 Society of Petroleum Engineers, Petroleum Resource Management System).

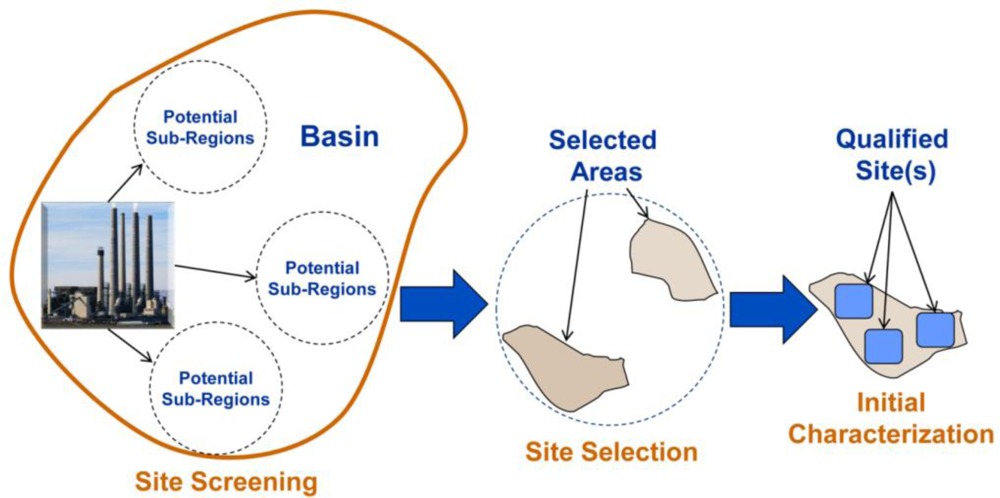

The primary goal of the Exploration Phase is to pare down a large region into a select few sites as seen in Figure 3 below. The ultimate goal of this process is to identify sites with highest potential for storage, and help eliminate from consideration those that are less preferable. The site screening stage evaluates existing data and resources from sub-regional data thorough a series of analyses on critical components to assess storage potential within a potential sub-region. These results in a set of selected areas that are then ranked based on criteria established during project definition, and the highest ranking selected areas advance to the site selection stage. The selected areas are then further analyzed through the site selection components, and the most promising qualified sites proceed to the final stage in the Exploration Phase—initial characterization.

Figure 3.

CCS screening process.

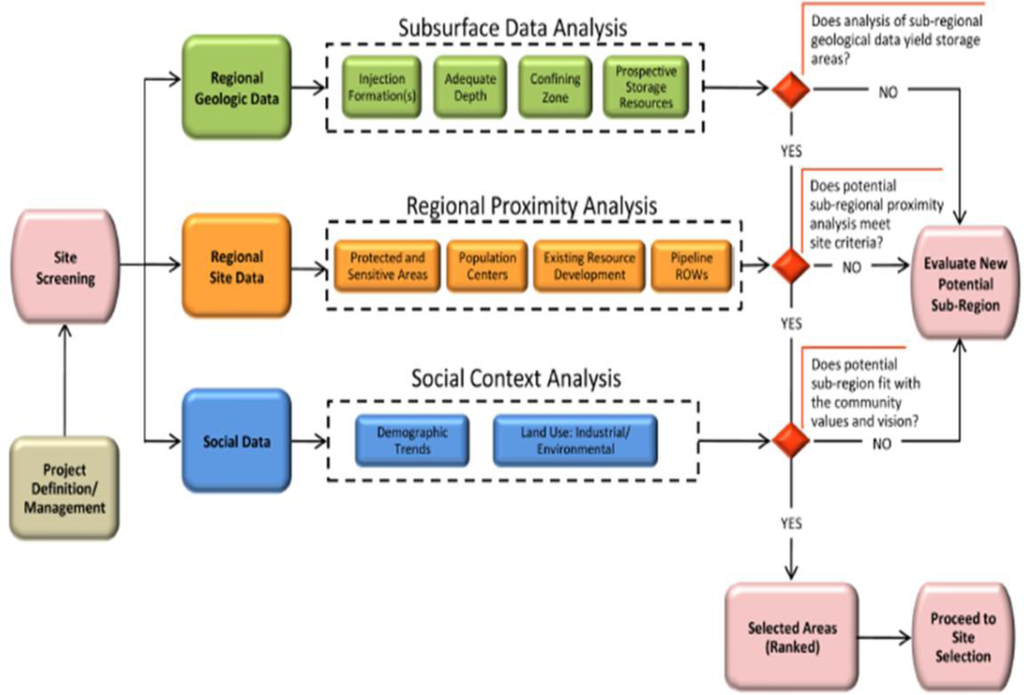

The Site Screening process diagram in Figure 4 describes analyses that should be conducted on elements within each of the three components—regional geologic data, regional site data, and social data. Once the analysis is completed for each of the three components, a decision gate is reached. A “yes” response to all three analyses advances a selected area within the potential sub-region to the next stage and a “no” response at any decision gate will result in a new potential sub-region being selected with the process beginning over again. The selected area will then proceed through the next series of analyses in the site selection evaluation stage.

Figure 4.

Process flow chart for site screening and initial characterization.

In order to assist future project developers, a set of guidelines (Table 4) has been developed for each of the elements within the component being analyzed for all three stages of evaluation. The guidelines presented in the manual are not intended to be prescriptive but provide future project developers with an understanding of the level of work necessary to further mature a project. Table 4 includes the guidelines for site screening.

Table 4.

Guidelines for site screening.

Upon completion of the site screening process, a selected area will be further evaluated during the site selection process. During site selection, five components will be analyzed. Existing data and analyses from site screening will be augmented with proprietary or other purchased data to evaluate both technical and nontechnical components, subsurface geologic data, regulatory requirements, model data, site data, and social data. Completion of each analysis will lead to a decision gate. A “yes” response will result in a list of qualified sites that will then be evaluated based on an economic feasibility plan. A “no” response at any decision gate will result in an alternative selected area being selected, and the analysis will begin again. Once it successfully proceeds through the decision gates, the selected area will be included on a list of qualified sites to be prioritized based on criteria developed during project definition, and the highest priority qualified site will proceed to the next evaluation stage—initial characterization. Process maps and site selection guidelines can be found on the NETL/DOE website: http://www.netl.doe.gov/technologies/carbon_seq/refshelf/BPM-SiteScreening.pdf.

The final stage of evaluation in the Exploration Phase is initial characterization. The distinction between the initial characterization stage within the Exploration Phase and within the Site Characterization Phase is based on the level of additional funding and detailed analyses needed for the site to prepare an evaluation for potential implementation. During initial characterization, sites identified in site selection will be evaluated using five technical and nontechnical elements, including (1) baseline data, (2) regulatory requirements, (3) model data, (4) social data, and (5) site development plan. The site would be evaluated according to the evaluation criteria and a determination would be made to either collect additional data and elevate the site to the Site Characterization Phase or leave it ranked as a qualified site. If the qualified site advances to the Site Characterization Phase, then the storage estimates would be considered contingent storage resource. Initial characterization process maps and guidelines can be found on the NETL/DOE website.

The site screening, site selection, and initial characterization manual will be periodically updated based on new lessons learned from the Development Phase of DOE projects. The geologic storage classification framework will also be updated as definitions and project status guidelines are further developed and refined for the Site Characterization and Implementation Phases.

8. Monitoring, Verification, and Accounting of CO2 Stored in Deep Geologic Formations

Reliable and cost-effective MVA techniques are an important part of making CO2 geologic storage a safe, effective, and acceptable method for GHG control. MVA of geologic storage sites is expected to serve several purposes, including addressing safety and environmental concerns; inventory verification; project and national accounting of GHG emissions reductions at geologic storage sites; and evaluating potential regional, national, and international GHG reduction goals.

Each geologic storage site varies significantly in risk profile and overall site geology, including target formation depth, formation porosity, permeability, temperature, pressure, and seal formation. MVA packages selected for commercial-scale projects should be tailored to site-specific characteristics and geologic features. In general, the goals of an MVA best practice manual for geologic storage are to:

- Improve understanding of storage processes and confirm their effectiveness.

- Evaluate the interactions of CO2 with formation of solids and fluids.

- Assess environmental, safety, and health impacts in the event of a leak to the atmosphere.

- Evaluate and monitor any required remediation efforts should a leak occur.

- Provide a technical basis to assist in legal disputes resulting from any impact of sequestration technology (groundwater impacts, seismic events, crop losses, etc.).

The life cycle of a geologic storage project involves four phases. Monitoring activities will vary among these phases:

- Pre-Operation Phase: Project design is carried out, baseline conditions are established, geology is characterized, and risks are identified.

- Operation Phase: Period of time during which CO2 is injected into the storage reservoir.

- Closure Phase: Period after injection has stopped (wells are abandoned and plugged, equipment and facilities are removed, and previously determined site restoration is accomplished). Only necessary monitoring equipment is retained.

- Post-Closure Phase: Period when ongoing monitoring is used to demonstrate that the storage project is performing as expected until it is safe to discontinue further monitoring. Once it is satisfactorily demonstrated that the site is stable, monitoring will no longer be required except in the unlikely event of release, regulatory requirements, or other matters that may require new information about the status of the storage project.

This BPM evaluated the different available technologies for use in MVA. The technologies were evaluated for their effectiveness of monitoring atmospheric concentrations of CO2, near surface CO2, and subsurface CO2. The evaluated technologies were subdivided as primary technologies, secondary technologies, and potential additional MVA technologies.

- Primary technologies are considered proven technologies capable of satisfying the monitoring requirements under the United States Environmental Protection Agencies underground injection control (UIC) regulations for Class I (non-hazardous), Class II(enhanced oil recovery operations), and Class V (experimental) injection wells and meet a goal of 99 percent containment by 2015. These technologies have been utilized in the petroleum industry and for geologic characterization.

- Secondary technologies are technologies that show promise but would need to demonstrate that they are sufficiently precise and quantitative to detect, locate, and quantify emissions as part of a CCS monitoring program.

- Potential additional MVA technologies are promising additional technologies being developed to better understand the long-term behavior of CO2 in a broad portfolio of potential reservoirs types. This also includes improvements of existing technologies to allow for detailed monitoring of CO2 in GS.

In order to implement effective controls on injection well completion, injection rates, and well head and formation pressures, specific monitoring objectives were recommended by Benson et al. (2004) [3], including:

- Establishing baseline conditions from which the impacts of CO2 storage can be assessed.

- Assessing the integrity of shut-in, plugged, or abandoned wells.

- Monitoring to ensure injection effectiveness.

- Monitoring to detect the location of the injected CO2 plume.

- Comparing model predictions to monitoring data.

- Detecting and quantifying leakage from the storage formation to other strata or the surface.

- Assessing health, safety, and environmental impacts of leakage.

- Monitoring to detect micro-seismicity associated with CO2 injection.

- Monitoring to aid in the design and evaluation of remediation efforts, if needed.

- Evaluating interactions with, or impacts on, other geologic resources.

- Reassuring the public, where visibility and transparency are of prime importance3.

The monitoring requirements may change through the different phases of the project. This is dependent on the project’s needs and site-specific conditions. The recommended steps in the BPM for selection of suitable geophysical techniques include:

- Developing geologic models for the sequestration site that include the reservoir, the seals, and overlying geology, aquifer(s), vadose zone, and surface.

- Performing reservoir simulations of the sequestration processes of interest, such as prediction of changes and the distribution of fluid phases resulting from CO2 injection.

- Using the geologic model and results of reservoir simulations to perform numerical simulations to predict the response of candidate geophysical and geochemical monitoring techniques.

The goal of this BPM is to provide information to limit unnecessary burden on owners, operators, or permitting agencies and provide a strong foundation for national consistency in permitting and safe operation of geologic storage projects.

Recent regulatory developments through the U.S. EPA have focused on finalizing rules for a new Class of UIC injection well for CO2 storage projects and monitoring requirements under the Clean Air Act. DOE plans to update the MVA BPM to account for additional monitoring requirements once these rules become final ( http://water.epa.gov/type/groundwater/uic/wells_sequestration.cfm).

9. Conclusions

Through NETL’s RCSP Initiative, informational tools are being developed to promote successful deployment of CCS technology as a GHG mitigation option. As part of this effort, the RCSPs provide information from their regional characterization efforts and field projects to support the development of NATCARB and the BPMs. NATCARB is updated in real-time as the RCSPs perform and obtain results from their field tests allow real time access to the most recent data that the RCSPs have available. The Carbon Sequestration Atlas of the U.S. and Canada is updated and published every two years. The BPMs will be updated as results from the RCSP field tests are analyzed and published. It is also anticipated that these BPMs will be updated as the technology and information matures.

This document was developed from several different studies/documents that were sponsored by NETL and the RCSP Initiative. A list of the documents, in addition to the cited references, is included in Appendix.

Acknowledgments

The authors thank the United States Department of Energy and the National Energy Technology Laboratory for their support and permission to publish this paper. This paper is part of a DOE series of publications on Carbon Capture and Storage technologies from anthropogenic sources and is based on DOE’s Best Practice Manuals and field activities conducted by the seven Regional Carbon Sequestration Partnerships.

References

- Climate Change 2007—The Physical Science Basis; Contribution of Working Group I to the Fourth Assessment Report of the IPCC; Cambridge University Press: Cambridge, UK and New York, NY, USA, 2007.

- Energy Information Administration. Outlook for Future Emissions. Available online: http://www.eia.doe.gov/energyexplained/index.cfm?page=environment_outlook_for_emissions (accessed on 2 November 2010).

- Benson, SM; Gasperikova, E; Hoversten, GM. Overview of Monitoring Techniques and Protocols for GS Projects; IEA Greenhouse Gas R&D Program Report PH4/29; International Energy Agency Greenhouse Gas Research and Development Program: Gloucestershire, UK, 2004. [Google Scholar]

Appendix

Source Documents

- Carbon Sequestration Technology Roadmap and Program Plan 2005; United States Department of Energy, National Energy Technology Laboratory: Pittsburgh, PA, USA, May 2005.

- Carbon Sequestration Program Overview; United States Department of Energy, National Energy Technology Laboratory: Pittsburgh, PA, USA, 2010. Available online: http://www.netl.doe.gov/technologies/carbon_seq/overview/index.html (accessed on 2 November 2010).

- Carbon Sequestration Program Goals; United States Department of Energy, National Energy Technology Laboratory: Pittsburgh, PA, USA, 2010. Available online: http://www.netl.doe.gov/technologies/carbon_seq/overview/program_goals.html (accessed on 2 November 2010).

- Carbon Sequestration Atlas of the United States and Canada; United States Department of Energy, National Energy Technology Laboratory: Pittsburgh, PA, USA, November 2010.

- Geologic Storage Formation Classification: Understanding Its Importance and Impacts on CCS Opportunities in the United States; United States Department of Energy, National Energy Technology Laboratory: Pittsburgh, PA, USA, September 2010.

- Best Practices Manual for: Public Outreach and Education for Carbon Storage Projects; United States Department of Energy, National Energy Technology Laboratory: Pittsburgh, PA, USA, December 2009.

- Draft Best Practices Manual for: Site Screening, Site Selection, and Initial Characterization for Storage of CO2 in Deep Geologic Formations; United States Department of Energy, National Energy Technology Laboratory: Pittsburgh, PA, USA, June 2010.

- Best Practices Manual for: Monitoring, Verification, and Accounting of CO2 Stored in Deep Geologic Formations; United States Department of Energy, National Energy Technology Laboratory: Pittsburgh, PA, USA, January 2009.

© 2011 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).