Occupational Health Risk Assessment for Wastewater Treatment and Reuse in Kanpur, India

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Background

2.2. Case Study Area

2.3. Pavitra Ganga Technologies

2.4. E. coli Measurements

2.5. System Mapping and Health Risk Assessments

3. Results and Discussion

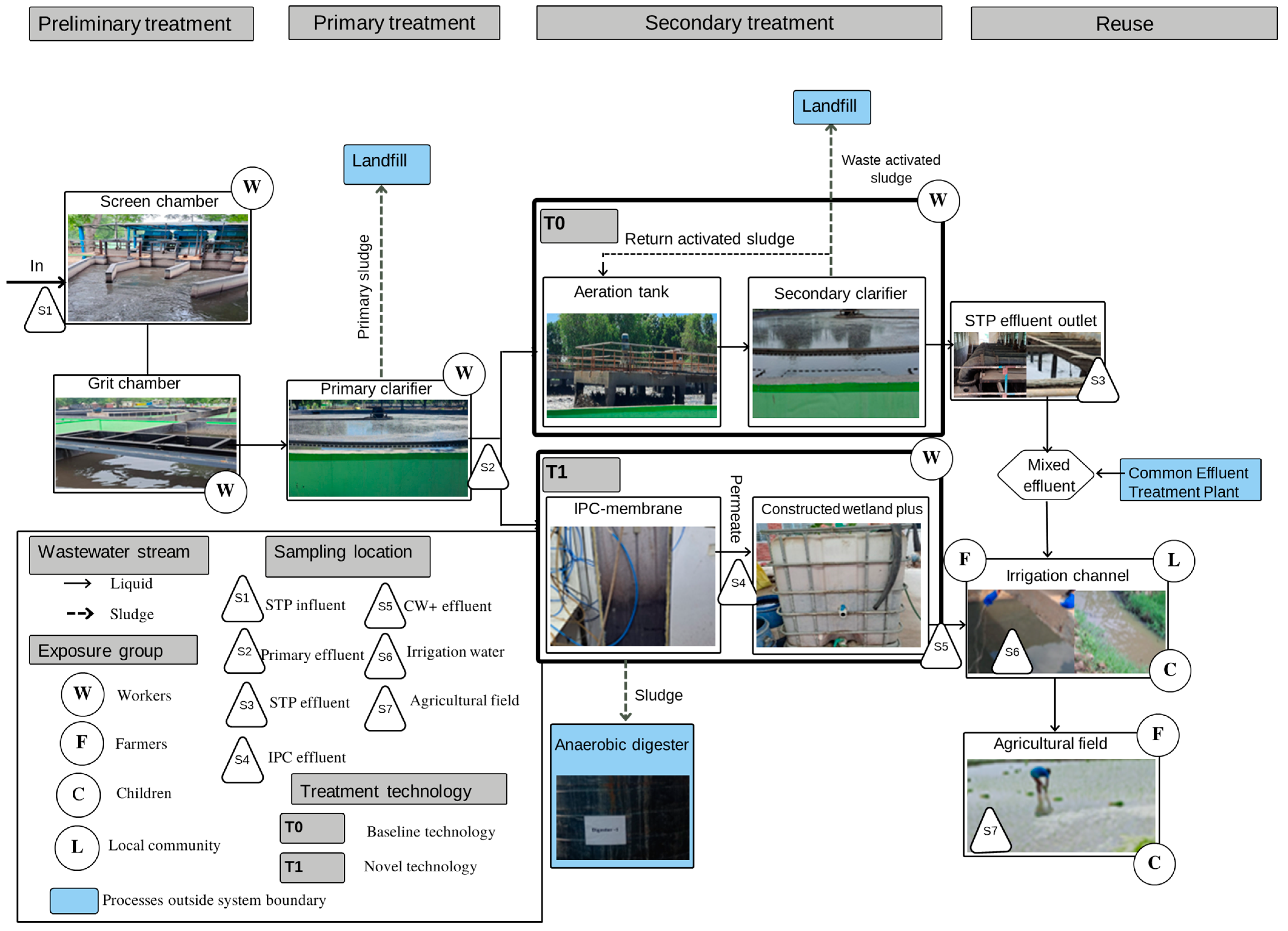

3.1. Mapping of the Wastewater Treatment and Reuse System

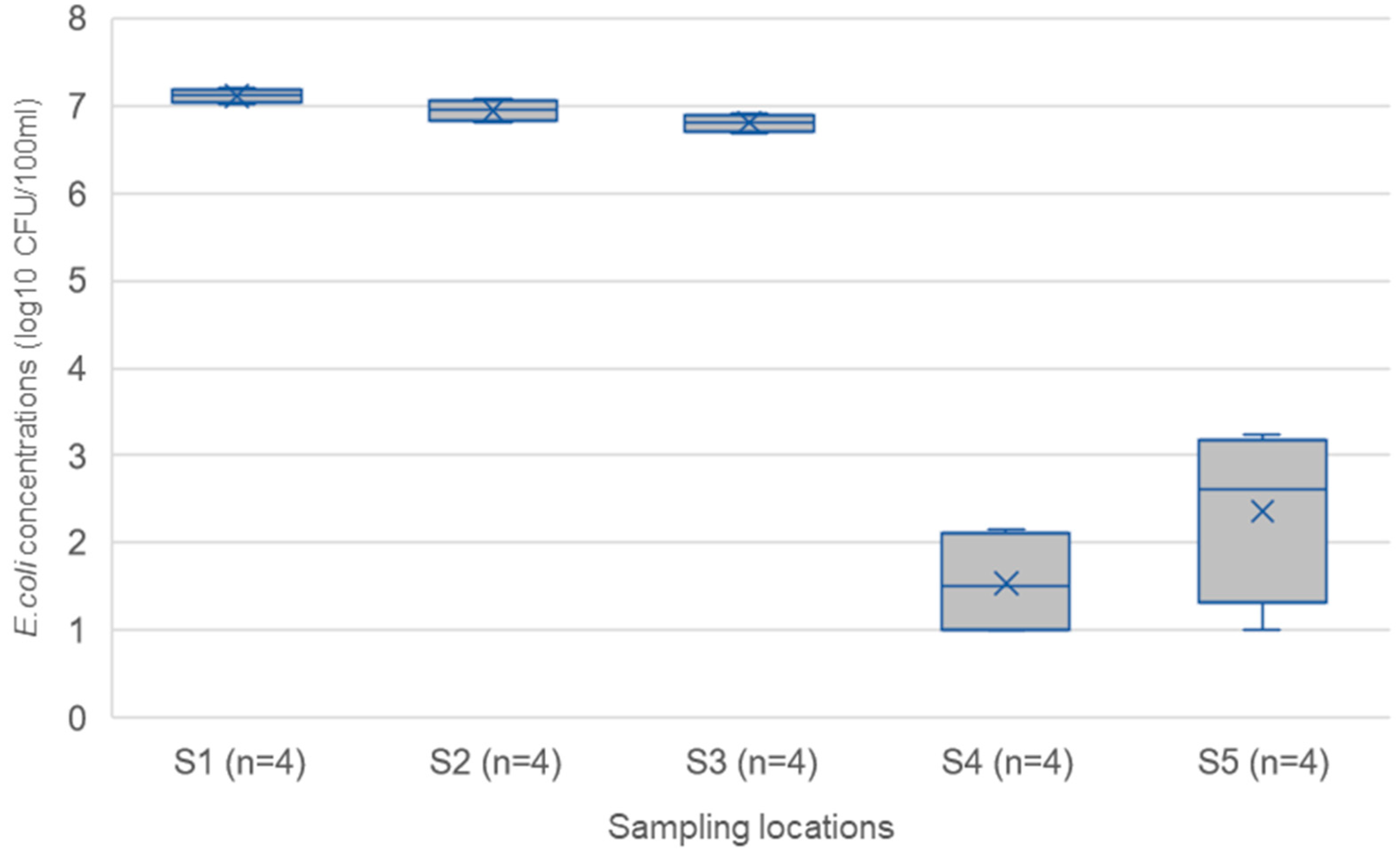

3.2. Microbiological Quality of Wastewater

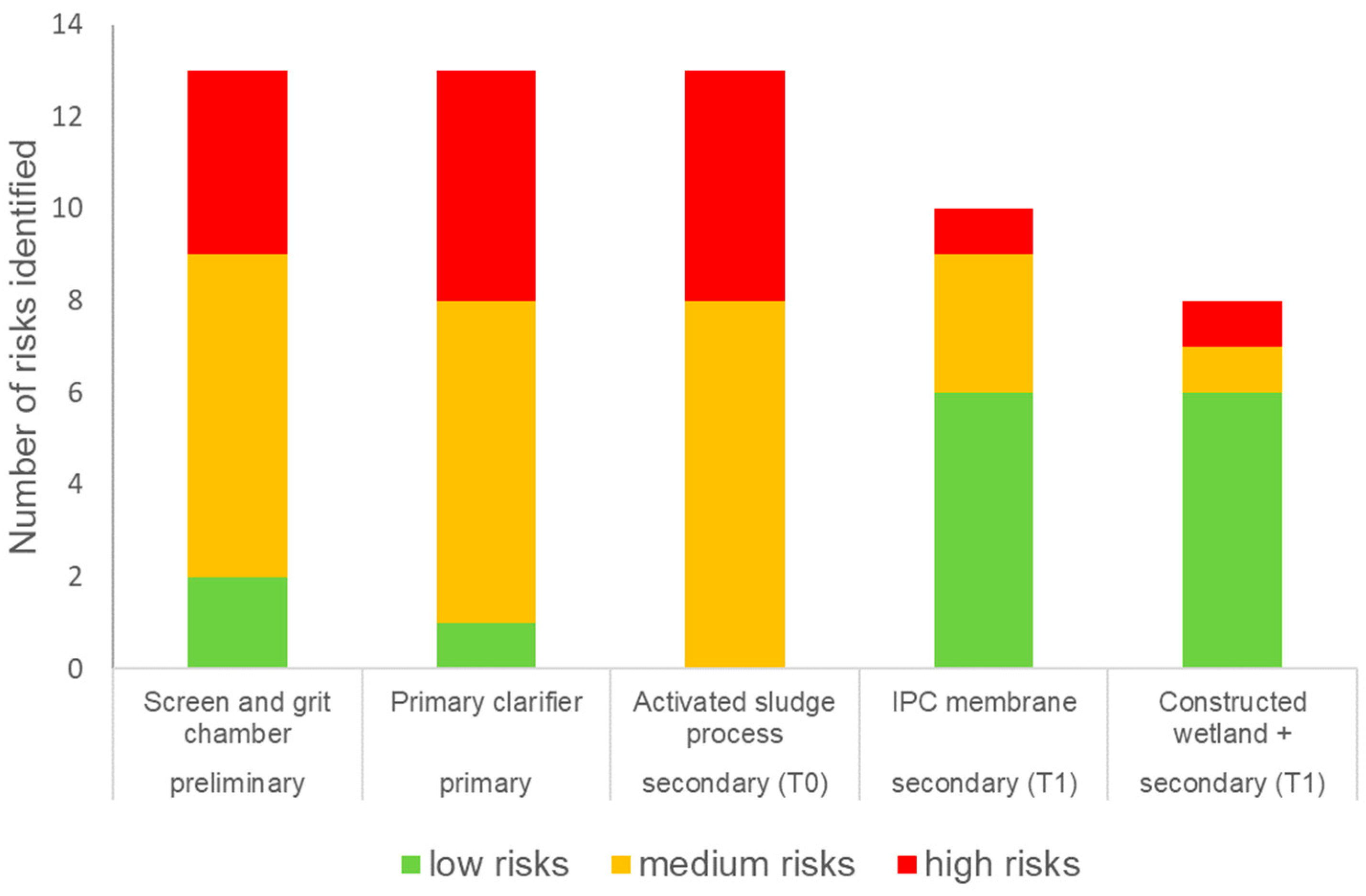

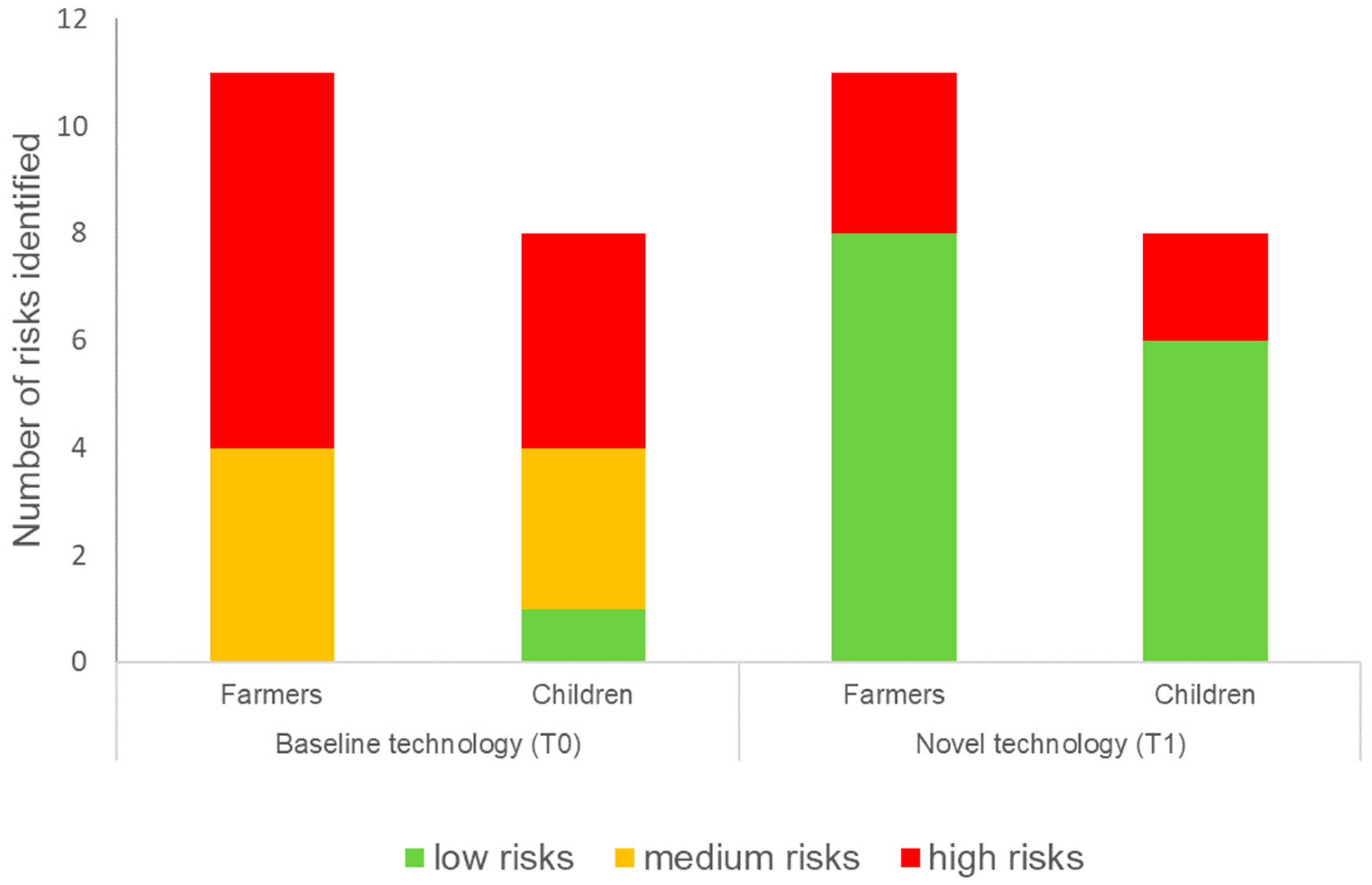

3.3. Health Risks Assessments

4. Study Limitations

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jain, S.K.; Agarwal, P.K.; Singh, V.P. Problems related to water resources management in India. In Hydrology and Water Resources of India; Springer: Berlin, Germany, 2007; pp. 871–936. [Google Scholar]

- Sandhu, C.; Grischek, T.; Kumar, P.; Ray, C. Potential for riverbank filtration in India. Clean Technol. Environ. Policy 2011, 13, 295–316. [Google Scholar] [CrossRef]

- Dangar, S.; Asoka, A.; Mishra, V. Causes and implications of groundwater depletion in India: A review. J. Hydrol. 2021, 596, 126103. [Google Scholar] [CrossRef]

- Breitenmoser, L.; Quesada, G.C.; Anshuman, N.; Bassi, N.; Dkhar, N.B.; Phukan, M.; Kumar, S.; Babu, A.N.; Kierstein, A.; Campling, P.; et al. Perceived drivers and barriers in the governance of wastewater treatment and reuse in India: Insights from a two-round Delphi study. Resour. Conserv. Recycl. 2022, 182, 106285. [Google Scholar] [CrossRef]

- CPCB. National Inventory of Sewage Treatment Plants; CPCB: New Delhi, India, 2021. [Google Scholar]

- MoEF&CC Government of India. Notification on STP Discharge Standards; The Gazette of India: New Delhi, India, 2017. [Google Scholar]

- Scheierling, S.M.; Bartone, C.; Mara, D.D.; Drechsel, P. Improving wastewater use in agriculture: An emerging priority. In World Bank Policy Research Working Paper; The World Bank: Washington, DC, USA, 2010; p. 5412. [Google Scholar]

- Fuhrimann, S.; Pham-Duc, P.; Cissé, G.; Tram, N.T.; Ha, H.T.; Ngoc, P.; Nguyen-Viet, H.; Vuong, T.A.; Utzinger, J.; Schindler, C.; et al. Microbial contamination along the main open wastewater and storm water channel of Hanoi, Vietnam, and potential health risks for urban farmers. Sci. Total Environ. 2016, 566, 1014–1022. [Google Scholar] [CrossRef] [PubMed]

- Dickin, S.K.; Schuster-Wallace, C.J.; Qadir, M.; Pizzacalla, K. A review of health risks and pathways for exposure to wastewater use in agriculture. Environ. Health Perspect. 2016, 124, 900–909. [Google Scholar] [CrossRef]

- Frattarola, A.; Domini, M.; Sorlini, S. The use of a risk assessment tool based on the Sanitation Safety Planning approach for the improvement of O&M procedures of a wastewater treatment plant in Tanzania. Hum. Ecol. Risk Assess. Int. J. 2019, 25, 1463–1472. [Google Scholar]

- WHO. WHO Guidelines for the Safe Use of Wasterwater Excreta and Greywater; World Health Organization: Geneva, Switzerland, 2006; Volume 1. [Google Scholar]

- WHO. Sanitation Safety Planning: Manual for SAFE Use and Disposal of Wastewater Greywater and Excreta; World Health Organization: Geneva, Switzerland, 2015. [Google Scholar]

- ILO. Occupational Hazard Datasheets—Water Treatment Plant Operator. Available online: https://www.ilo.org/safework/cis/WCMS_190172/lang--en/index.htm (accessed on 10 June 2022).

- Domini, M.; Langergraber, G.; Rondi, L.; Sorlini, S.; Maswaga, S. Development of a Sanitation Safety Plan for improving the sanitation system in peri-urban areas of Iringa, Tanzania. J. Water Sanit. Hyg. Dev. 2017, 7, 340–348. [Google Scholar] [CrossRef]

- WHO. World Health Statistics 2022: Monitoring Health for the SDGs, Sustainable Development Goals; World Health Organization: Geneva, Switzerland, 2022. [Google Scholar]

- Clavijo, A.; Iribarnegaray, M.A.; Rodriguez-Alvarez, M.S.; Seghezzo, L. Closing the cycle? Potential and limitations of Water and Sanitation Safety Plans (WSSPs) for Latin American metropolitan areas. J. Water Sanit. Hyg. Dev. 2020, 10, 490–501. [Google Scholar] [CrossRef]

- Fuhrimann, S.; Winkler, M.S.; Stalder, M.; Niwagaba, C.B.; Babu, M.; Kabatereine, N.B.; Halage, A.A.; Utzinger, J.; Cissé, G.; Nauta, M.; et al. Disease burden due to gastrointestinal pathogens in a wastewater system in Kampala, Uganda. Microb. Risk Anal. 2016, 4, 16–28. [Google Scholar] [CrossRef]

- WHO. Sanitation Safety Planning Applying the WHO Methodology to SOIL’s Operations in Northern Haiti Microsoft Word; World Health Organization: Geneva, Switzerland, 2019. [Google Scholar]

- Ganga, P. Available online: www.pavitra-ganga.eu/en/demonstration-sites/kanpur-jajmau-wastewater-treatment-plant (accessed on 2 March 2023).

- Australian Government; Australian High Commission New Delhi; Victorian Government; Indian Institute of Technology—Kanpur; National Mission for Clean Ganga; World Bank. Jajmau Tannery Industry. Roadmap to sustainable waste management. In A Model for the Ganga Basin; Earth Systems: Belmar, NJ, USA, 2013; 108p. [Google Scholar]

- Haque, I.; Patel, P.P. Growth of metro cities in India: Trends, patterns and determinants. Urban Res. Pract. 2018, 11, 338–377. [Google Scholar] [CrossRef]

- Bassi, N.; Babu, S.S.; Kumar, M.D. Water accounting for Kanpur metropolitan area in Ganges river basin. In Current Directions in Water Scarcity Research; Elsevier: Amsterdam, The Netherlands, 2019; Volume 1, pp. 245–274. [Google Scholar]

- SFD. Shit Flow Diagram Kanpur, India; CSE India: New Delhi, India, 2020. [Google Scholar]

- CPCB. Performance Evaluation of Sewage Treatment Plants under NRCD. Available online: https://cpcb.nic.in/openpdffile.php?id=UmVwb3J0RmlsZXMvMjlfMTQ1ODExMDk5Ml9OZXdJdGVtXzE5NV9TVFBfUkVQT1JULnBkZg== (accessed on 8 May 2022).

- Singh, P. Bridging the ganga action plan: Monitoring failure at Kanpur. Econ. Political Wkly. 2006, 41, 590–592. [Google Scholar]

- Breitenmoser, L.; Furlong, C.; Babalola, F.M.; Anshuman; Campling, P.; Hooijmans, C.M.; Parihar, I.; Hugi, C.; Bose, P.; Maurya, K. Wastewater Safety Planning in Kanpur, Uttar Pradesh: Approach and Learnings from the Eu-India Pavitra Ganga Project. In Proceedings of the 13th IWA International Conference, Chennai, India, 15–19 January 2023. [Google Scholar]

- INDION. Integrated Permeate Channel Membranes (IPC), Ion Exchange (India) LTD. Refreshing the Planet. Product Details. Available online: https://ionexchangeglobal.com/wp/wp-includes/PDfs/IPC%20MBR.pdf (accessed on 28 April 2022).

- Kim, D.-G.; Ko, S.-O. A Dual Media Filter using Zeolite and Mortar for the Efficient Removal of Heavy Metals in Stormwater Runoff. Water 2022, 14, 3567. [Google Scholar] [CrossRef]

- Stefanakis, A.I. Introduction to Constructed Wetland Technology; John Wiley & Sons, Ltd.: Chichester, UK, 2018; Available online: https://www.hende-i-medio-ambiente.org/wp-content/uploads/2020/04/Ch0IntroductiontoConstructedWetlandTechnology_Stefanakis.pdf (accessed on 2 June 2022).

- Lin, J.; Ganesh, A. Water quality indicators: Bacteria, coliphages, enteric viruses. Int. J. Environ. Health Res. 2013, 23, 484–506. [Google Scholar] [CrossRef] [PubMed]

- Mbanga, J.; Abia, A.L.K.; Amoako, D.G.; Essack, S. Quantitative microbial risk assessment for waterborne pathogens in a wastewater treatment plant and its receiving surface water body. BMC Microbiol. 2020, 20, 1–12. [Google Scholar] [CrossRef]

- Diagniastics, H. Available online: https://catalog.hardydiagnostics.com/cp_prod/Content/hugo/CompactDryEC.pdf (accessed on 10 June 2022).

- Tilley, E.; Ulrich, L.; Luethi, C.; Reymond, P.H.; Schertenleib, R.; Zurbruegg, C. Compendium of Sanitation Systems and Technologies, 2nd ed.; Swiss Federal Institute of Aquatic Science and Technology (Eawag): Dübendorf, Switzerland, 2014. [Google Scholar]

- Rose, J.B.; Farrah, S.R.; Harwood, V.J.; Levine, A.D.; Lukasik, J.; Scott, T.M. Reduction of Pathogens, Indicator Bacteria, and Alternative Indicators by Wastewater Treatment and Reclamation Processes; Final Report; Water Environment Research Foundation: Alexandria, VA, USA, 2004. [Google Scholar]

- Tribunal, N.G. NGT Orders Stricter Norms for Effluent Discharge from Sewage Treatment Plants. Available online: https://www.theweek.in/wire-updates/national/2019/05/03/lgd11-green-stps.html (accessed on 6 December 2020).

- Fairbrother, J.; Nadeau, E. Escherichia coli: On-farm contamination of animals. Rev. Sci. Technol. 2006, 25, 555–569. [Google Scholar] [CrossRef]

- Austigard, Å.D.; Svendsen, K.; Heldal, K.K. Hydrogen sulphide exposure in waste water treatment. J. Occup. Med. Toxicol. 2018, 13, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Kataki, S.; Patowary, R.; Chatterjee, S.; Vairale, M.G.; Sharma, S.; Dwivedi, S.K.; Kamboj, D.V. Bioaerosolization and pathogen transmission in wastewater treatment plants: Microbial composition, emission rate, factors affecting and control measures. Chemosphere 2022, 287, 132180. [Google Scholar] [CrossRef]

- Malakahmad, A.; Downe, A.G.; Fadzil, S.D.M. Application of Occupational Health and Safety Management System at Sewage Treatment Plants. In Proceedings of the 2012 IEEE Business, Engineering & Industrial Applications Colloquium (BEIAC), Kuala Lumpur, Malaysia, 7–8 April 2012; pp. 347–350. [Google Scholar]

- WHO. Guidelines on Sanitation and Health; World Health Organization: Geneva, Switzerland, 2018. [Google Scholar]

- Gupta, G.; Tarique, J. Prevalence of Musculoskeletal Disorders in Farmers of Kanpur-Rural, India. J. Community Med. Health Educ. 2013, 3, 249. [Google Scholar] [CrossRef]

- Amerasinghe, P.; Bhardwaj, R.M.; Scott, C.; Jella, K.; Marshall, F. Urban Wastewater and Agricultural Reuse Challenges in India; IWMI: Colombo, Sri Lanka, 2013; Volume 147. [Google Scholar]

- Yadla, S.; Sen, H.; Hotez, P. An epidemiological study of ancylostomiasis in a rural area of Kanpur district Uttar Pradesh, India. Indian J. Public Health 2003, 47, 53–60. [Google Scholar]

- Ganguly, S.; Barkataki, S.; Karmakar, S.; Sanga, P.; Boopathi, K.; Kanagasabai, K.; Kamaraj, P.; Chowdhury, P.; Sarkar, R.; Raj, D.; et al. High prevalence of soil-transmitted helminth infections among primary school children, Uttar Pradesh, India, 2015. Infect. Dis. Poverty 2017, 6, 1–9. [Google Scholar] [CrossRef]

- Garg, A.; Garg, J.; Rao, Y.; Upadhyay, G.; Sakhuja, S. Prevalence of dengue among clinically suspected febrile episodes at a teaching hospital in North India. J. Infect. Dis. Immun. 2011, 3, 85–89. [Google Scholar]

- Verma, R.K.; Giri, R.; Singh, N.; Gupta, C.; Jain, A. A study on clinical presentation and outcome of concurrent malaria and dengue infection from a malaria endemic zone of North India. J. Med. Sci. Clin. Res. 2016, 4, 15116–15127. [Google Scholar] [CrossRef]

- Singh, R.; Sengupta, B.; Bali, R.; Shukla, B.; Gurunadharao, V.; Srivatstava, R. Identification and mapping of chromium (VI) plume in groundwater for remediation: A case study at Kanpur, Uttar Pradesh. J. Geol. Soc. India 2009, 74, 49–57. [Google Scholar] [CrossRef]

| Main Hazard Categories Identified | Risk Levels Identified | ||||

|---|---|---|---|---|---|

| Preliminary | Primary | Secondary (T0) | Secondary (T1) | ||

| Screen and Grit Chamber | Primary Clarifier | Activated Sludge Process/Secondary Clarifier | IPC Membrane | Constructed Wetland + | |

| A. Exposure to harmful gases | |||||

| A1. Malodour | medium | medium | medium | low | low |

| A2. Hydrogen sulfide | medium | medium | medium | low | low |

| A3. Aerosols | low | low | medium | none | none |

| B. Accidents | |||||

| B1. Falls, slips | high | high | high | low | low |

| B2. Cuts | high | high | high | low | high |

| B3. Electric shock | high | high | high | high | none |

| B4. Suffocation | medium | medium | medium | none | none |

| B5. Drowning | low | high | high | none | none |

| C. Diseases | |||||

| C1. Through microbial pathogens | medium | medium | medium | medium | low |

| C2. Through mosquito bites | high | high | high | low | medium |

| C3. Skin irritation | medium | medium | medium | medium | low |

| C4. Musculoskeletal disorders | medium | medium | medium | low | low |

| D. Exposure to high noise level | |||||

| D1. Noise | medium | medium | medium | medium | none |

| Main Hazard Categories Identified | Risk Levels Identified | |||

|---|---|---|---|---|

| Baseline Technology (T0) | Novel Technology (T1) | |||

| Farmers | Children | Farmers | Children | |

| A. Exposure to harmful gases | ||||

| A1. Malodour | medium | medium | low | low |

| B. Accidents | ||||

| B1. Falls, slips | high | high | high | high |

| C. Diseases | ||||

| C1. Microbial pathogens | ||||

| During flood irrigation | high | none | low | none |

| During farming activities | high | none | low | none |

| Through playing and helping parents | none | high | none | low |

| During preparation of contaminated crop | medium | medium | low | low |

| C2. Soil helminths | ||||

| During irrigation | high | none | low | none |

| During farming activities | high | none | low | none |

| Through playing and helping parents | none | high | none | low |

| C3. Skin irritation | ||||

| During irrigation | medium | none | low | none |

| During farming activities | medium | none | low | none |

| Through playing and helping parents | none | medium | none | low |

| C4. Vector-related diseases | ||||

| Through mosquito bites | high | high | high | high |

| C5. Musculoskeletal disorders | ||||

| Through farming activities | high | low | high | low |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Babalola, F.M.; Breitenmoser, L.; Furlong, C.; Campling, P.; Hooijmans, C.M. Occupational Health Risk Assessment for Wastewater Treatment and Reuse in Kanpur, India. Int. J. Environ. Res. Public Health 2023, 20, 6072. https://doi.org/10.3390/ijerph20126072

Babalola FM, Breitenmoser L, Furlong C, Campling P, Hooijmans CM. Occupational Health Risk Assessment for Wastewater Treatment and Reuse in Kanpur, India. International Journal of Environmental Research and Public Health. 2023; 20(12):6072. https://doi.org/10.3390/ijerph20126072

Chicago/Turabian StyleBabalola, Folake Monsurat, Lena Breitenmoser, Claire Furlong, Paul Campling, and Christine Maria Hooijmans. 2023. "Occupational Health Risk Assessment for Wastewater Treatment and Reuse in Kanpur, India" International Journal of Environmental Research and Public Health 20, no. 12: 6072. https://doi.org/10.3390/ijerph20126072

APA StyleBabalola, F. M., Breitenmoser, L., Furlong, C., Campling, P., & Hooijmans, C. M. (2023). Occupational Health Risk Assessment for Wastewater Treatment and Reuse in Kanpur, India. International Journal of Environmental Research and Public Health, 20(12), 6072. https://doi.org/10.3390/ijerph20126072