Air Quality Dispersion Modelling to Evaluate CIPP Installation Styrene Emissions

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Locations

2.2. AERMOD Modelling System

2.3. Model Parameters and Setup

- 101.32 is the standard pressure (kPa)

- 273.15 is the standard temperature K

- 104.15 is the molecular weight of styrene,

- 8.3144 is the gas constant,

2.4. Model Calibration

2.5. Model Simulations& Health Impacts

3. Results

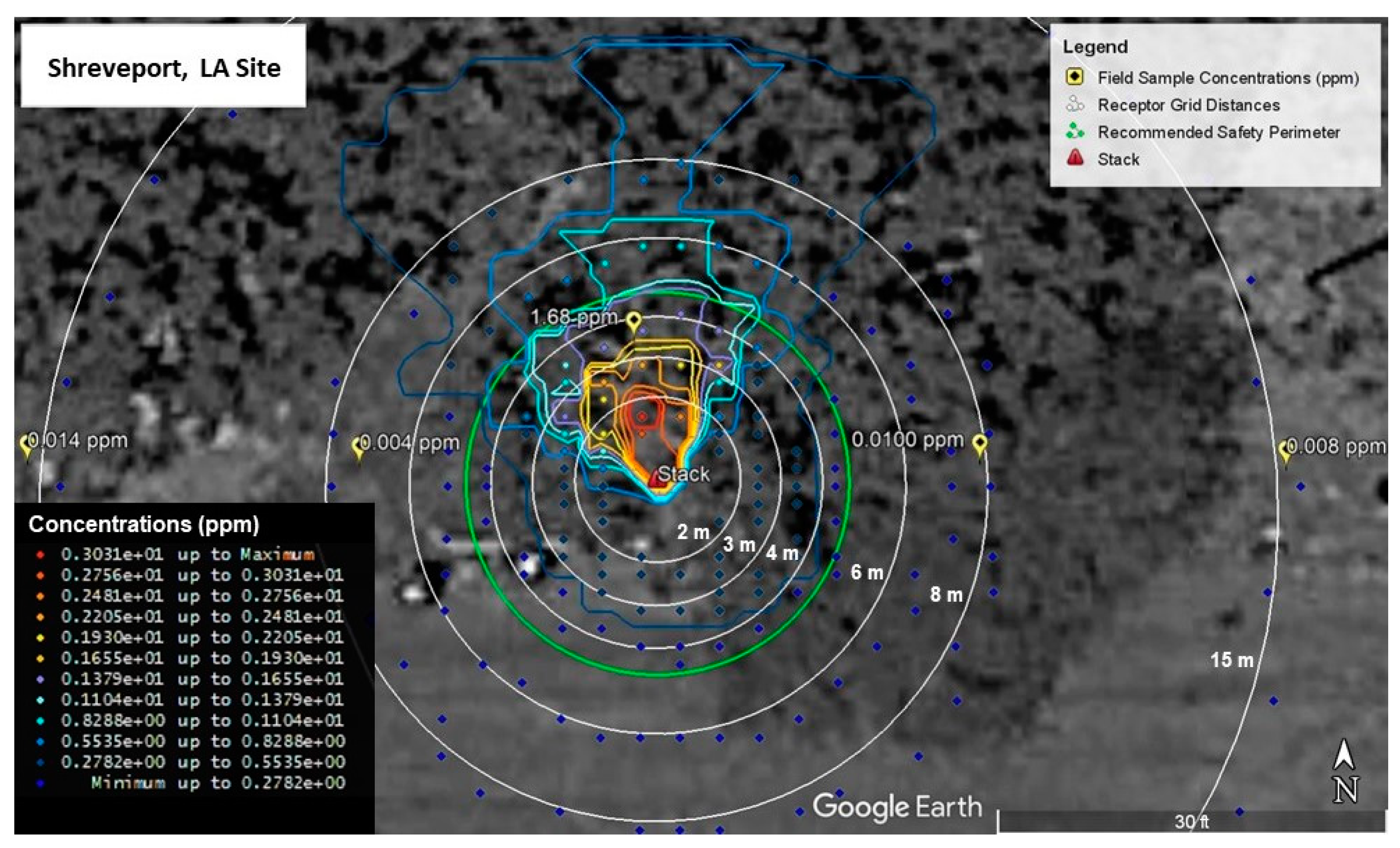

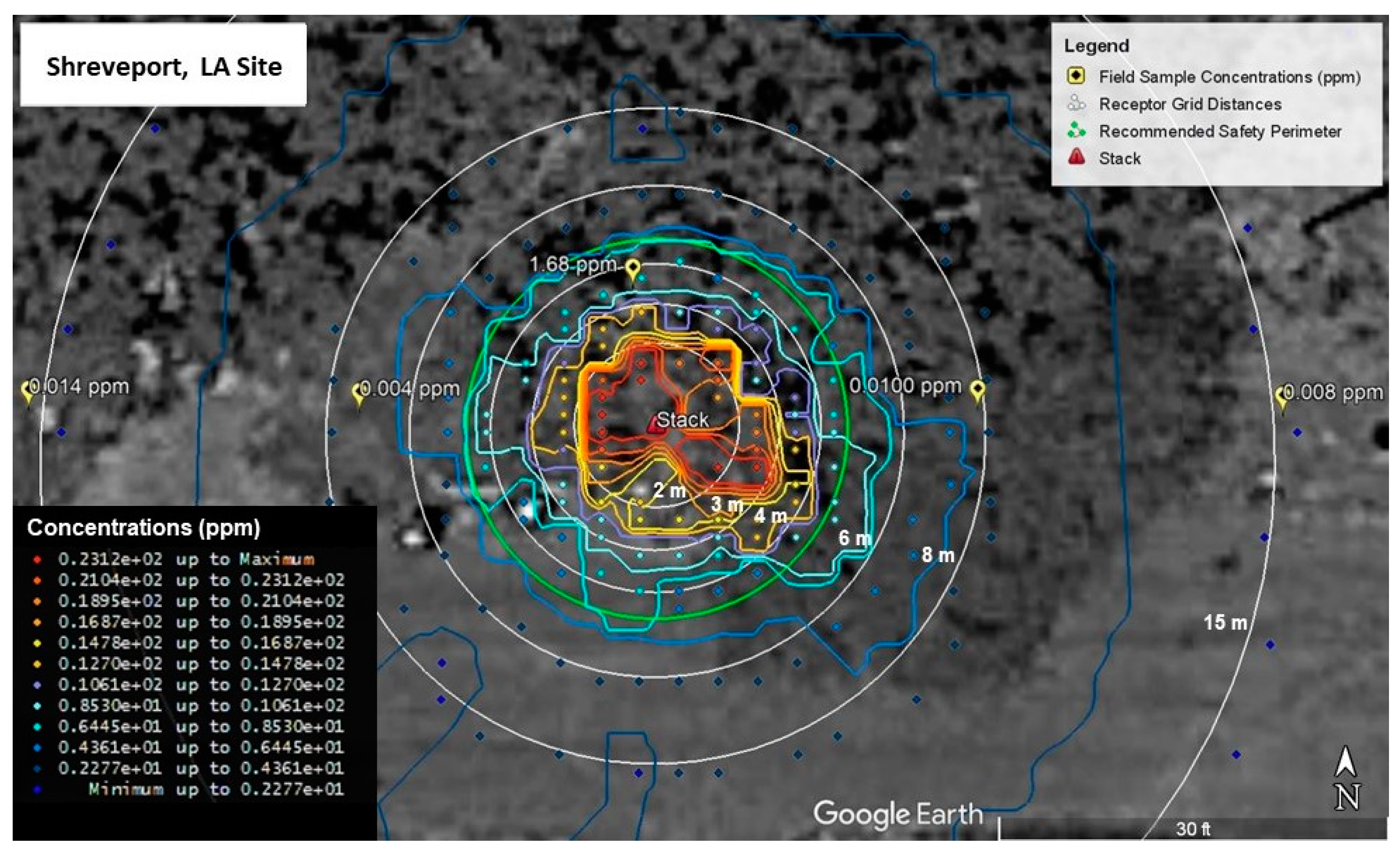

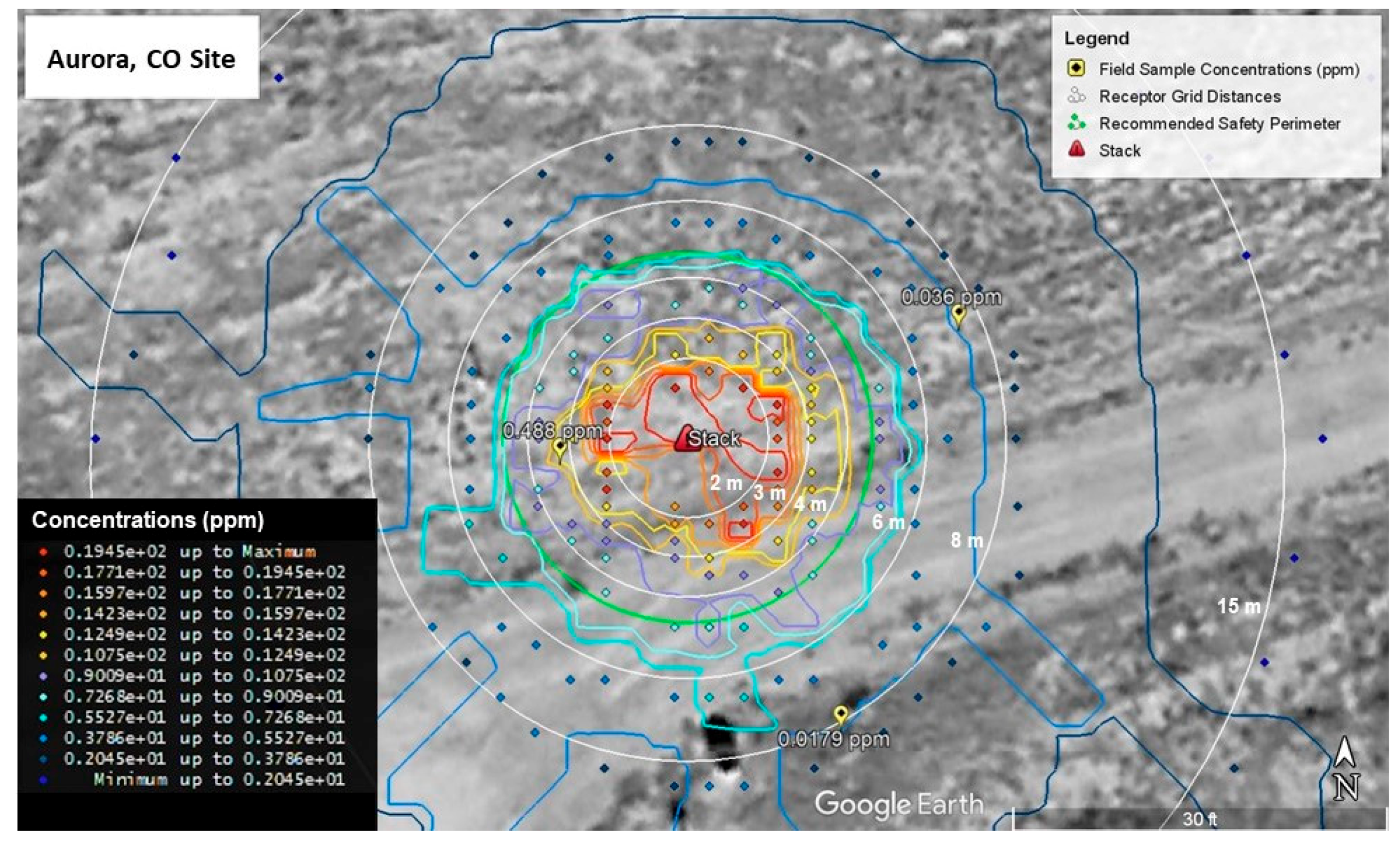

3.1. Model Calibration

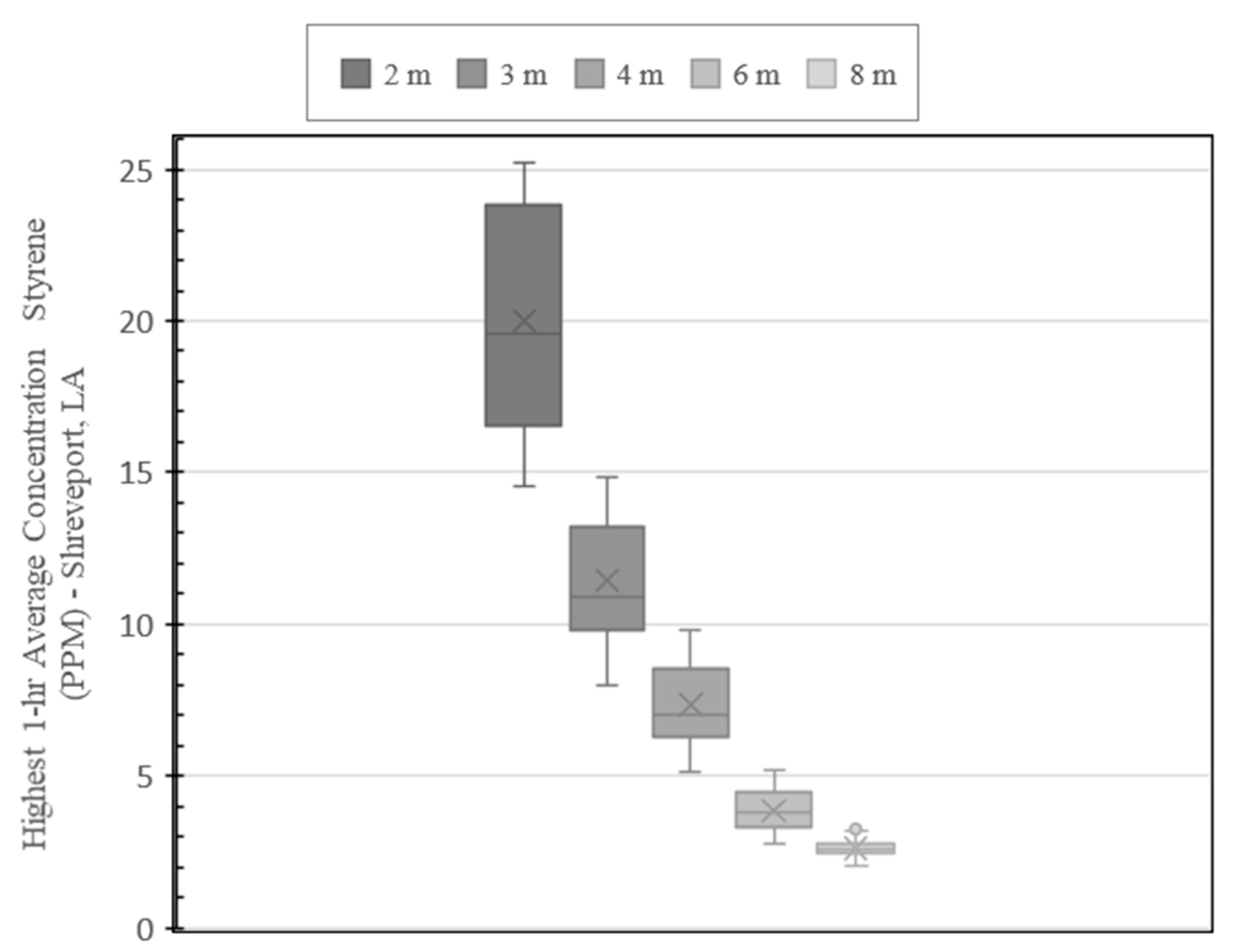

3.2. Model Simulations& Health Impacts

4. Discussion

5. Conclusions

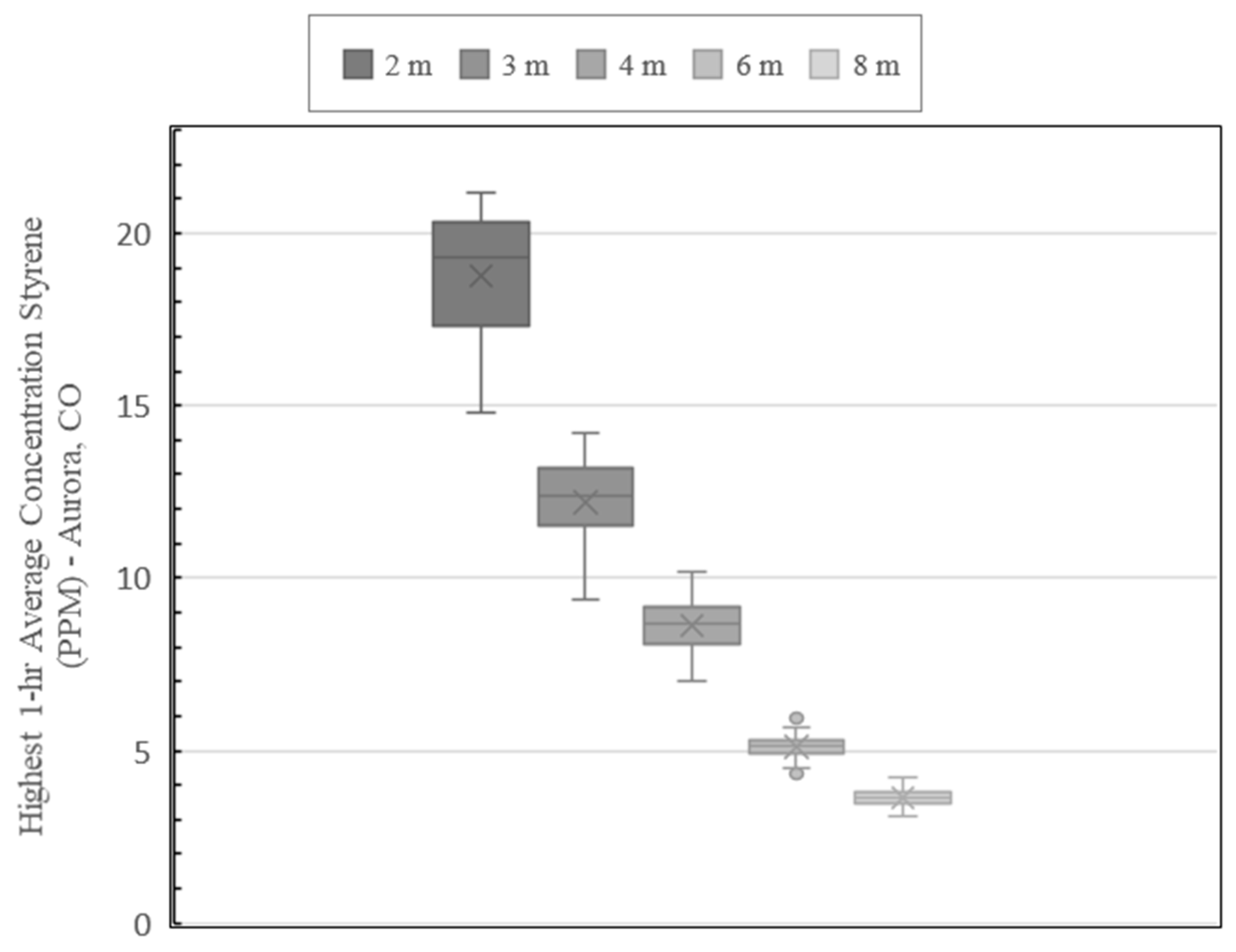

- Styrene dissipates rapidly with concentrations only exceeding minimum health and safety threshold levels (AEGL-1) at distances close to the emissions stack (2 m or less).

- Significant and lasting health impacts are unlikely to occur outside of the currently recommended 4.6-m (15-ft) safety perimeter for stack emission points on CIPP sites.

- Styrene concentration values predicted by the model for both sites are comparable to field measured styrene concentrations from other studies. The modeled values of 18.8 ppm and 20 ppm fall within a range of instantaneous field measure values reported in previous literature

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AEGL | Acute Exposure Guideline Level |

| ASCE | American Society of Civil Engineers |

| ASOS | Automatic Surface Observing Systems |

| CDC | Centers for Disease Control |

| CIPP | Cured-In-Place Pipe |

| EPA | US Environmental Protection Agency |

| GC/MS | Gas Chromatography/Mass Spectrometry |

| GIS | Geographic Information System |

| GPS | Global Positioning System |

| HHS | US Department of Health and Human Services |

| IKT | Institute for Underground Infrastructure |

| LIDAR | Light Detection and Ranging |

| MRLC | Multi-Resolution Land Characteristics |

| NASSCO | National Association of Sewer Service Companies |

| NED | National Elevation Dataset |

| NOAA | US National Oceanic and Atmospheric Administration |

| PPM | Parts Per Million |

| USGS | United States Geological Survey |

| VOC | Volatile Organic Compound |

References

- American Society of Civil Engineers (ASCE). 2021 Report Card for America’s Infrastructure; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2021; Available online: https://infrastructurereportcard.org/ (accessed on 10 August 2022).

- Matthews, J.C.; Allouche, E.N.; Sterling, R.L. Social cost impact assessment of pipeline infrastructure projects. Environ. Impact Assess. Rev. 2015, 50, 196–202. [Google Scholar] [CrossRef]

- Alam, S.; Manzur, T.; Matthews, J.; Bartlett, C.; Allouche, E.N. Experimental Evaluation of Deteriorated CMPs Retrofitted by Different Non-invasive Approaches. KSCE J. Civ. Eng. 2021, 25, 4335–4347. [Google Scholar] [CrossRef]

- Alsadi, A.A.; Matthews, J.C. Evaluation of carbon footprint of pipeline materials during installation, operation, and disposal phases. J. Pipeline Syst. Eng. Pract. 2020, 11. [Google Scholar] [CrossRef]

- Matthews, E.; Matthews, J.; Alam, S.; Eklund, S.; Banjara, A.; Hashm, H.; Kraft, J. NASSCO CIPP Emissions Phase 2: Evaluation of Air Emissions from Polyester Resin CIPP with Steam Cure, National Association of Sewer Service Companies. 2020. Available online: https://live-nassco.pantheonsite.io/wp-content/uploads/2021/04/NASSCO_CIPP_Phase_II_Final-Report-Feb-2020-1.pdf (accessed on 29 September 2022).

- Ra, K.; Sendesi, S.M.T.; Nuruddin, M.; Zyaykina, N.N.; Conkling, E.N.; Boor, B.E.; Jafvert, C.T.; Howarter, J.A.; Youngblood, J.P.; Whelton, A.J. Considerations for emission monitoring and liner analysis of thermally manufactured sewer cured-in-place-pipes (CIPP). J. Hazard. Mater. 2019, 371, 540–549. [Google Scholar] [CrossRef] [PubMed]

- Sendesi, S.M.T.; Ra, K.; Conkling, E.N.; Boor, B.E.; Nuruddin, M.; Howarter, J.A.; Youngblood, J.P.; Kobos, L.M.; Shannahan, J.H.; Jafvert, C.T.; et al. Worksite chemical air emissions and worker exposure during sanitary sewer and stormwater pipe rehabilitation using cured-in-place-pipe (CIPP). Environ. Sci. Technol. Lett. 2017, 4, 325–333. [Google Scholar] [CrossRef]

- Ajdari, E. Volatile Organic Compound (VOC) Emission during Cured-in-Place-Pipe (CIPP) Sewer Pipe Rehabilitation (Publication No. 10291102). Doctoral Dissertation, University of New Orleans, New Orleans, LA, USA, 2016. [Google Scholar]

- U.S Department of Health and Human Services. Toxicological Profile for Styrene. 2010. Available online: https://www.atsdr.cdc.gov/toxprofiles/tp53.pdf (accessed on 30 September 2022).

- Murata, K.; Araki, S.; Yokoyama, K. Assessment of the peripheral, central, and autonomic nervous system function in styrene workers. Am. J. Ind. Med. 1991, 20, 775–784. [Google Scholar] [CrossRef]

- Matikainen, E.; Forsman-Grönholm, L.; Pfäffli, P.; Juntunen, J. Nervous system effects of occupational exposure to styrene: A clinical and neurophysiological study. Environ. Res. 1993, 61, 84–92. [Google Scholar] [CrossRef]

- Welp, E.; Kogevinas, M.; Andersen, A.; Bellander, T.; Biocca, M.; Coggon, D.; Esteve, J.; Gennaro, V.; Kolstad, H.; Lundberg, I.; et al. Exposure to styrene and mortality from nervous system diseases and mental disorders. Am. J. Epidemiol. 1996, 144, 623–633. [Google Scholar] [CrossRef][Green Version]

- Werder, E.J.; Engel, L.S.; Richardson, D.B.; Emch, M.E.; Gerr, F.E.; Kwok, R.K.; Sandler, D.P. Environmental styrene exposure and neurologic symptoms in U.S. Gulf coast residents. Environ. Int. 2018, 121 Pt 1, 480–490. [Google Scholar] [CrossRef]

- Werder, E.J.; Sandler, D.P.; Richardson, D.B.; Emch, M.E.; Kwok, R.K.; Gerr, F.E.; Engel, L.S. Environmental Styrene Exposure and Sensory and Motor Function in Gulf Coast Residents. Environ. Health Perspect. 2019, 127, 47006. [Google Scholar] [CrossRef]

- Najafi, M.; Sattler, M.; Schug, K.; Kaushal, V.; Habibzadeh, S.; Korky, S.; Iyer, G.; Kakkera, S.; Habibzadek, S. Evaluation of Potential Release of Organic Chemicals in the Steam Exhaust and Other Release Points during Pipe Rehabilitation Using the Trenchless Cured-In-Place Pipe (CIPP) Method, National Association of Sewer Service Companies. 2018. Available online: https://live-nassco.pantheonsite.io/wp-content/uploads/2021/06/NASSCO-CUIRE-Final-Report-04-30-2018-1.pdf (accessed on 10 August 2022).

- Howell, J.M.; Matthews, E.; Matthews, J.; Alam, S.; Bednar, A.; Laber, C.; Eklund, S. Styrene Emissions in Steam-Cured CIPP: A Review and Comparison of Multiple Studies. J. Pipeline Syst. Eng. Pract. 2022, 13, 04021071. [Google Scholar] [CrossRef]

- National Association of Sewer Service Companies (NASSCO). Guideline for the Safe Use and Handling of Styrene-Based Resins in Cured-in-Place Pipe; NASSCO: Frederick, MD, USA, 2020; Available online: https://www.nassco.org/wp-content/uploads/2021/02/Safe-Handling-and-Use-of-Styrene_Specification-Guideline-_-2020-2.pdf (accessed on 30 September 2022).

- Rood, A.S. Performance evaluation of AERMOD, CALPUFF, and legacy air dispersion models using the Winter Validation Tracer Study dataset. Atmos. Environ. 2014, 89, 707–720. [Google Scholar] [CrossRef]

- Environmental Protection Agency (EPA). Support Center for Regulatory Atmospheric Modeling (SCRAM): Air Quality Dispersion Modelling—Preferred and Recommended Models; Environmental Protection Agency: Washington, DC, USA. Available online: https://www.epa.gov/scram/air-quality-dispersion-modeling-preferred-and-recommended-models (accessed on 6 October 2022).

- Cimorelli, A.J.; Perry, S.G.; Venkatram, A.; Weil, J.C.; Paine, R.J.; Wilson, R.B.; Lee, R.F.; Peters, W.D.; Brode, R.W.; Paumier, J.O. AERMOD: Description of Model Formulation (Report No. EPA-454/R-03–004); USA Environmental Protection Agency: Washington, DC, USA, 2004. Available online: https://nepis.epa.gov/Exe/ZyPURL.cgi?Dockey=P1009OXW.TXT (accessed on 30 September 2022).

- Chen, Y.; Liang, D. Quantitative Assessment of Construction Site Pollutant Emission and Dispersion. In Proceedings of the AEI 2019: Integrated Building Solutions—The National Agenda, Tysons, VA, USA, 3–6 April 2019. [Google Scholar] [CrossRef]

- Jung, S.; Kang, H.; Sung, S.; Hong, T. Health risk assessment for occupants as a decision-making tool to quantify the environmental effects of particulate matter in construction projects. Build. Environ. 2019, 161, 106267. [Google Scholar] [CrossRef]

- Truong, S.C.; Lee, M.I.; Kim, G.; Kim, D.; Park, J.H.; Choi, S.D.; Cho, G.H. Accidental benzene release risk assessment in an urban area using an atmospheric dispersion model. Atmos. Environ. 2016, 144, 146–159. [Google Scholar] [CrossRef]

- Seangkiatiyuth, K.; Surapipith, V.; Tantrakarnapa, K.; Lothongkum, A.W. Application of the AERMOD modeling system for environmental impact assessment of NO2 emissions from a cement complex. J. Environ. Sci. 2011, 23, 931–940. [Google Scholar] [CrossRef]

- Hadlocon, L.S.; Zhao, L.Y.; Bohrer, G.; Kenny, W.; Garrity, S.R.; Wang, J.; Wyslouzil, B.; Upadhyay, J. Modeling of particulate matter dispersion from a poultry facility using AERMOD. J. Air Waste Manag. Assoc. 2015, 65, 206–217. [Google Scholar] [CrossRef]

- Heist, D.; Isakov, V.; Perry, S.; Snyder, M.; Venkatram, A.; Hood, C.; Stocker, J.; Carruthers, D.; Arunachalam, S.; Owen, R.C. Estimating near-road pollutant dispersion: A model inter-comparison. Transp. Res. Part D Transp. Environ. 2013, 25, 93–105. [Google Scholar] [CrossRef]

- Arani, M.H.; Jaafarzadeh, N.; Moslemzadeh, M.; Ghalhari, M.R.; Arani, S.B.; Mohammadzadeh, M. Dispersion of NO2 and SO2 pollutants in the rolling industry with AERMOD model: A case study to assess human health risk. J. Environ. Health Sci. Eng. 2021, 19, 1287–1298. [Google Scholar] [CrossRef]

- Mousavi, S.S.; Goudarzi, G.; Sabzalipour, S.; Rouzbahani, M.M.; Mobarak Hassan, E. An evaluation of CO, CO2, and SO2 emissions during continuous and non-continuous operation in a gas refinery using the AERMOD. Environ. Sci. Pollut. Res. 2021, 28, 56996–57008. [Google Scholar] [CrossRef]

- Kalhor, M.; Bajoghli, M. Comparison of AERMOD, ADMS and ISC3 for incomplete upper air meteorological data (case study: Steel plant). Atmos. Pollut. Res. 2017, 8, 1203–1208. [Google Scholar] [CrossRef]

- Environmental Protection Agency (EPA). Support Center for Regulatory Atmospheric Modeling (SCRAM): Meteorological Processors and Accessory Programs; Environmental Protection Agency: Washington, DC, USA. Available online: https://www.epa.gov/scram/meteorological-processors-and-accessory-programs#aermet (accessed on 5 July 2022).

- Environmental Protection Agency (EPA). Support Center for Regulatory Atmospheric Modeling (SCRAM): Air Quality Dispersion Modelling—Related Model Support Programs; Environmental Protection Agency: Washington, DC, USA. Available online: https://www.epa.gov/scram/air-quality-dispersion-modeling-related-model-support-programs (accessed on 27 June 2022).

- Environmental Protection Agency (EPA). User’s Guide for the AMS/EPA Regulatory Model (AERMOD); Environmental Protection Agency (EPA): Washington, DC, USA, 2022. Available online: https://gaftp.epa.gov/Air/aqmg/SCRAM/models/preferred/aermod/aermod_userguide.pdf (accessed on 29 September 2022).

- Louisiana State University (LSU). Maps, Downloads, and Web Services: Louisiana Statewide LIDAR, Atlas: Louisiana GIS. Available online: https://atlas.ga.lsu.edu/ (accessed on 30 July 2020).

- Google. Google Earth Pro Elevation Data for N 39°44′54.93″, W 104°47′53.33″. Available online: https://earth.google.com/web/ (accessed on 6 August 2019).

- National Oceanic and Atmospheric Administration (NOAA). Automated Surface/Weather Observing Systems (ASOS/AWOS). [Data Set]. Available online: https://www.ncei.noaa.gov/products/land-based-station/automated-surface-weather-observing-systems (accessed on 30 July 2020).

- Earth System Research Laboratory (ESRL). NOAA/ESRL Radiosonde Database; National Oceanic and Atmospheric Administration: Washington, DC, USA, 2020. Available online: https://ruc.noaa.gov/raobs/ (accessed on 30 July 2020).

- Multi-Resolution Land Characteristics (MRLC) Consortium. 1992 National Land Cover Database (NLCD). [Data Set]. United States Geological Survey. Available online: https://www.mrlc.gov/nlcd-92 (accessed on 15 July 2020).

- United States Geological Survey (USGS). The National Map: Advanced Viewer. [Data Set]. Available online: https://apps.nationalmap.gov/viewer/ (accessed on 15 July 2020).

- Environmental Protection Agency (EPA). Styrene: Interim Acute Exposure Guideline Levels (AEGLs). 2008. Available online: https://www.epa.gov/sites/default/files/2014-08/documents/styrene_interim_feb_2008.v1.pdf (accessed on 29 September 2022).

| City | Location Latitude Longitude | Land Use | Climate | Elevation m (ft) above MSL | Pipe Diameter mm (in) | Pipe Length m (ft) |

|---|---|---|---|---|---|---|

| Shreveport, LA | N 32°29′23.41 W 93°47′57.65″ | Residential | Humid & Wet | 61 (200) | 203 (8) | 185.4 (608) |

| Aurora, CO | N 39°44′54.93″ W 104°47′53.33″ | Rural | Dry | 1646 (5400) | 914 (36) | 106.1 (348) |

| Site (Site Visit Date) | Model Stack Parameters | ||||||

|---|---|---|---|---|---|---|---|

| Velocity (m/s) | Height (m) | Diameter (m) | AVG Temp (K) | Styrene Concentration (ppm) | Calculated Emission Rate (g/s) | Adjusted Emission Rate (g/s) | |

| Shreveport (12 December 2018) | 21.23 * 25 | 1.78 * 0.5 | 0.056 | 287.5 | 0.0500 | 0.00001 | * 0.15 |

| Aurora (14 May 2019) | 23.5 | 1.8 | 0.05 | 298.9 | 25.4 | 0.00621 | * 0.18 |

| AEGL Styrene Exposure Limit | Impact on Health |

|---|---|

Level-1

|

|

Level-2

|

|

Level-3

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matthews, E.; Kraft, J.; Hossain, G.; Bednar, A.; Laber, C.; Alam, S.; Manzur, T.; Matthews, J.; Howell, J.; Eklund, S. Air Quality Dispersion Modelling to Evaluate CIPP Installation Styrene Emissions. Int. J. Environ. Res. Public Health 2022, 19, 13800. https://doi.org/10.3390/ijerph192113800

Matthews E, Kraft J, Hossain G, Bednar A, Laber C, Alam S, Manzur T, Matthews J, Howell J, Eklund S. Air Quality Dispersion Modelling to Evaluate CIPP Installation Styrene Emissions. International Journal of Environmental Research and Public Health. 2022; 19(21):13800. https://doi.org/10.3390/ijerph192113800

Chicago/Turabian StyleMatthews, Elizabeth, John Kraft, Gazi Hossain, Anthony Bednar, Charles Laber, Shaurav Alam, Tanvir Manzur, John Matthews, Jason Howell, and Sven Eklund. 2022. "Air Quality Dispersion Modelling to Evaluate CIPP Installation Styrene Emissions" International Journal of Environmental Research and Public Health 19, no. 21: 13800. https://doi.org/10.3390/ijerph192113800

APA StyleMatthews, E., Kraft, J., Hossain, G., Bednar, A., Laber, C., Alam, S., Manzur, T., Matthews, J., Howell, J., & Eklund, S. (2022). Air Quality Dispersion Modelling to Evaluate CIPP Installation Styrene Emissions. International Journal of Environmental Research and Public Health, 19(21), 13800. https://doi.org/10.3390/ijerph192113800