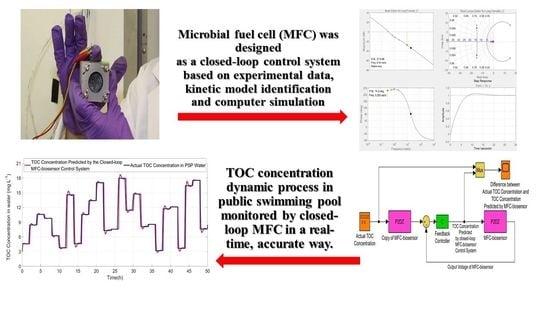

Closed-Loop Microbial Fuel Cell Control System Designed for Online Monitoring of TOC Dynamic Characteristics in Public Swimming Pool

Abstract

1. Introduction

- (1)

- Poor stability. As is known, the open-loop prediction of water pollutants based on output voltages of MFC-biosensors is very sensitive to internal variations and external disturbances, frequently causing the large prediction errors of water pollutants concentration [15].

- (2)

- Transient process of pollutant variation cannot be tracked and captured. According to cybernetics, the open-loop prediction must acquire the steady-state value of water pollutants concentration. However, it often takes quite long time for water pollutants concentration to be stabilized, and concentrations exceeding permissible standards may occur in the transient process of pollutants concentrations variation, which cannot be monitored at all [16].

2. Materials and Methods

2.1. Prototype of MFC-Biosensor for Online Monitoring TOC Concentration

2.2. Construction of Closed-Loop MFC-Biosensor for Online Monitoring TOC Concentration in PSP Water through Digital Simulation

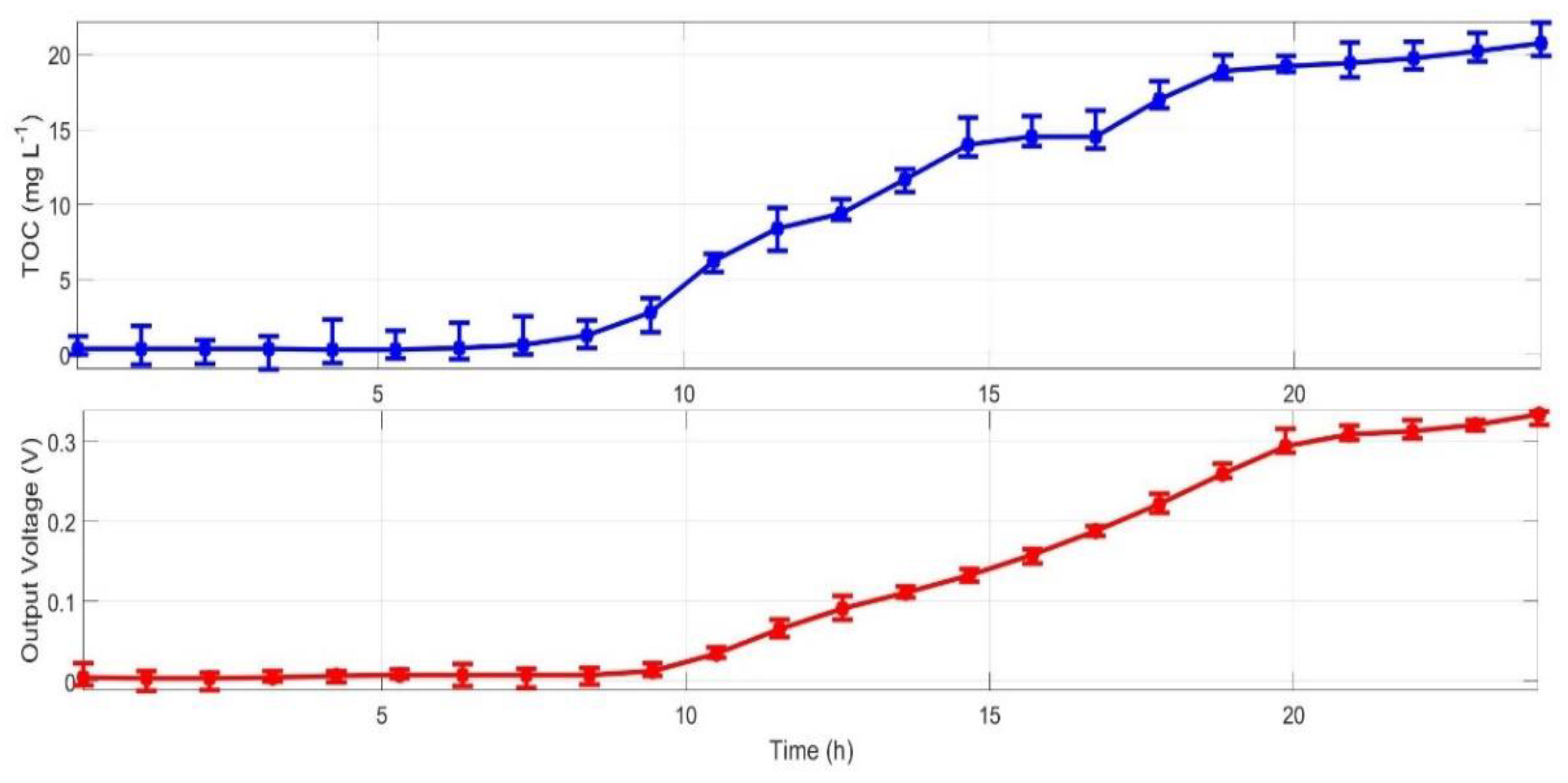

2.2.1. Data Acquisition

2.2.2. Model Identification and Construction of Closed-Loop MFC-Biosensor Control System

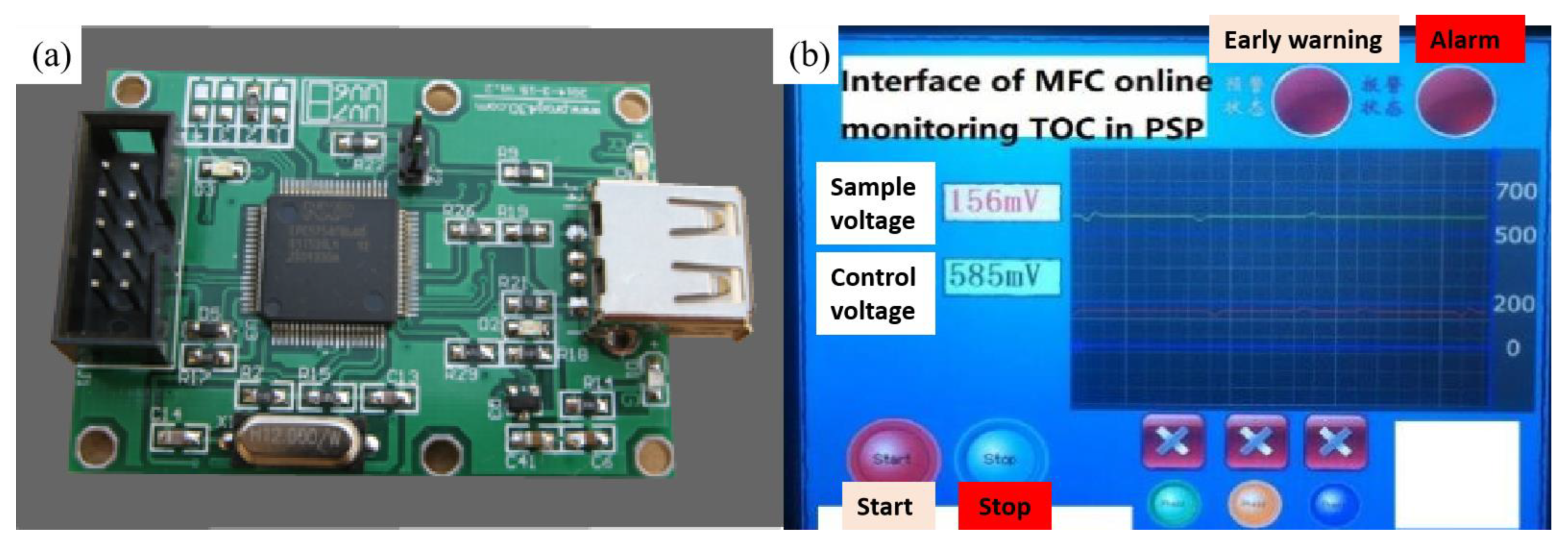

2.3. Rapid Prototyping of the Closed-Loop MFC-Biosensor Control System for Monitoring TOC Concentration in PSP Water by Real-Time Simulation

3. Results and Discussion

3.1. Model Identification between TOC Concentration and MFC-Biosensor Output Voltage

3.1.1. Data Preprocessing

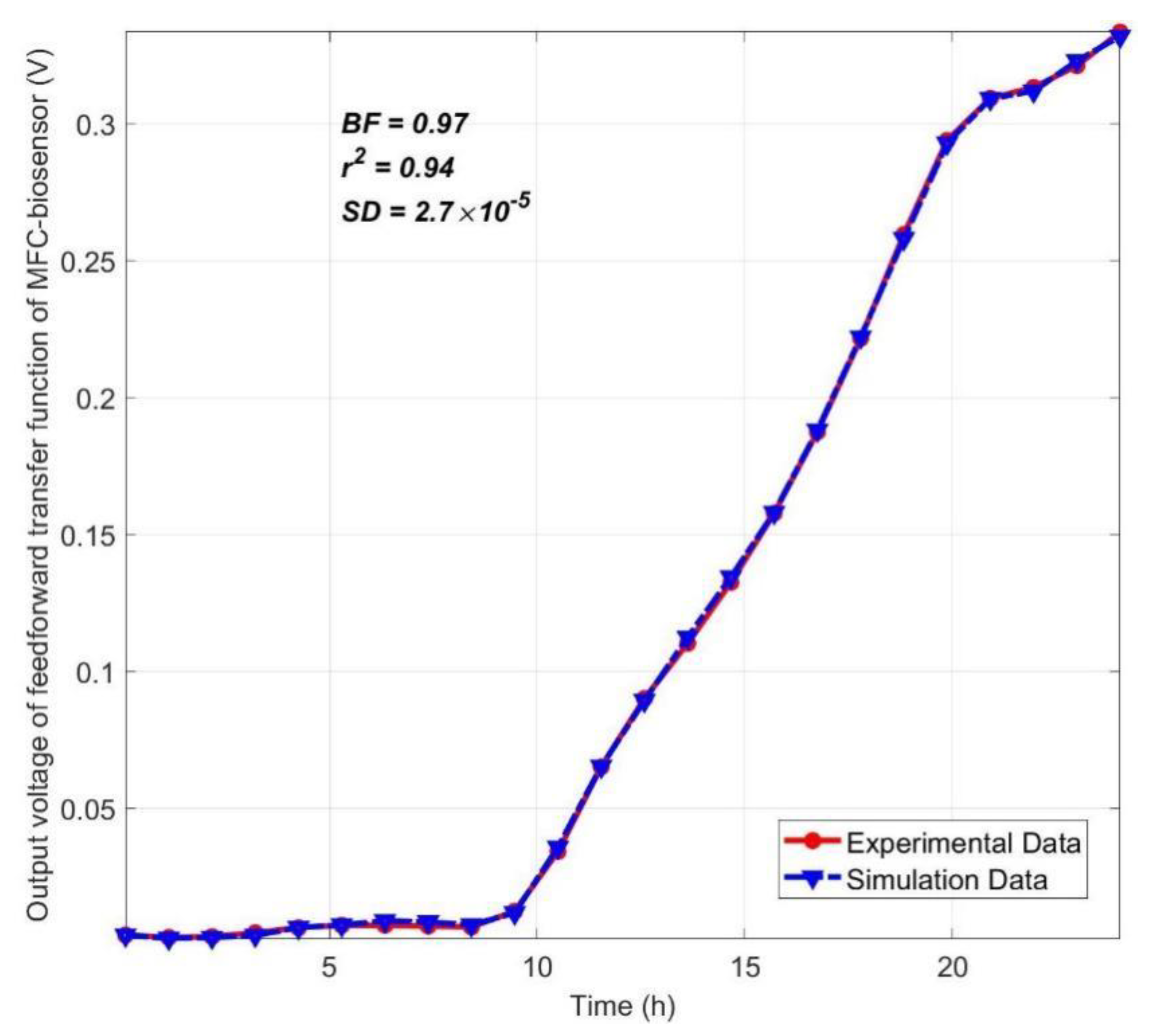

3.1.2. Model Identification and Validation from Time-Series IO Data

- (1)

- Model identification

- (2)

- Model validation

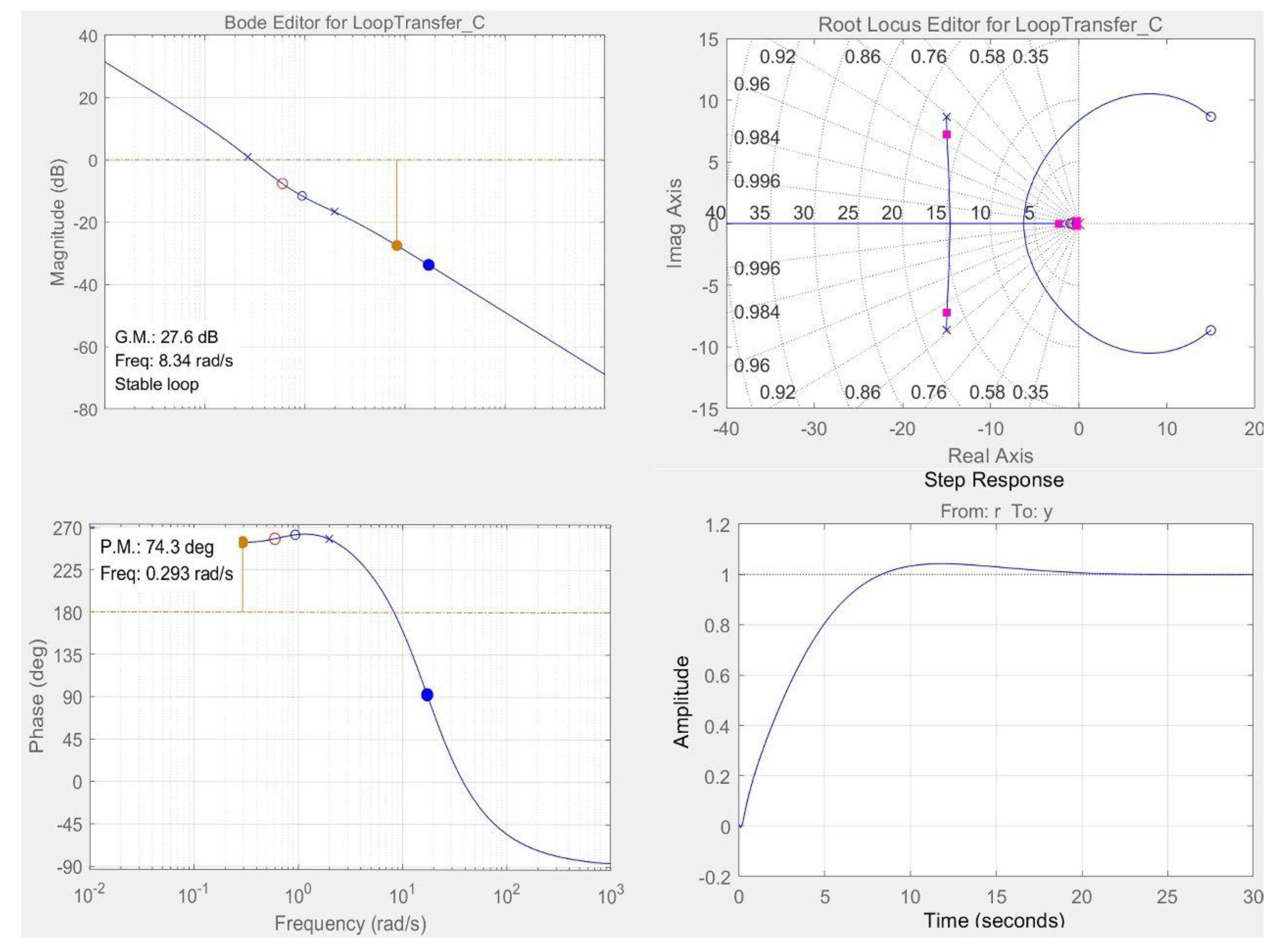

3.2. Design and Optimization of the Closed-Loop MFC-Biosensor Control System

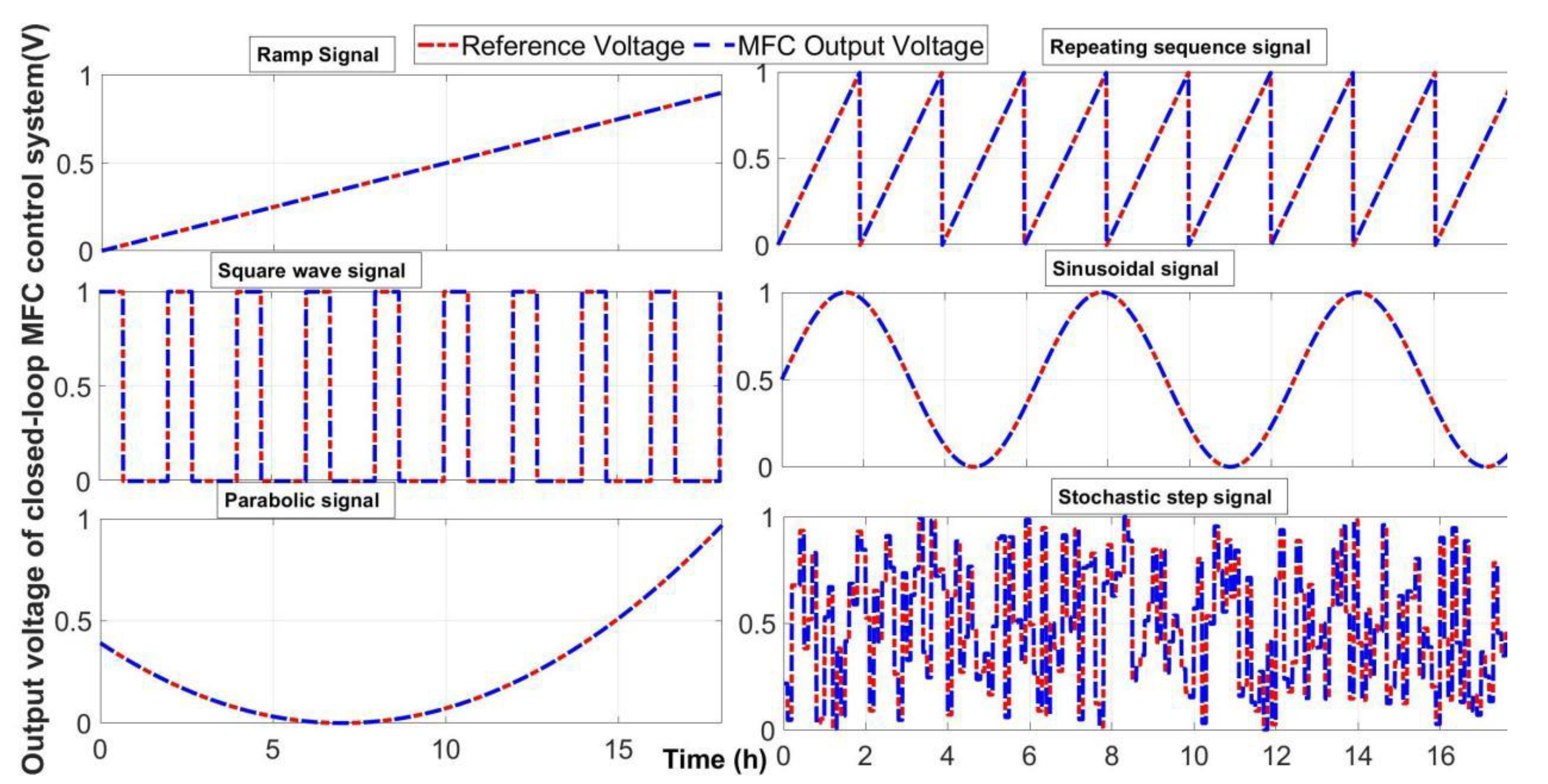

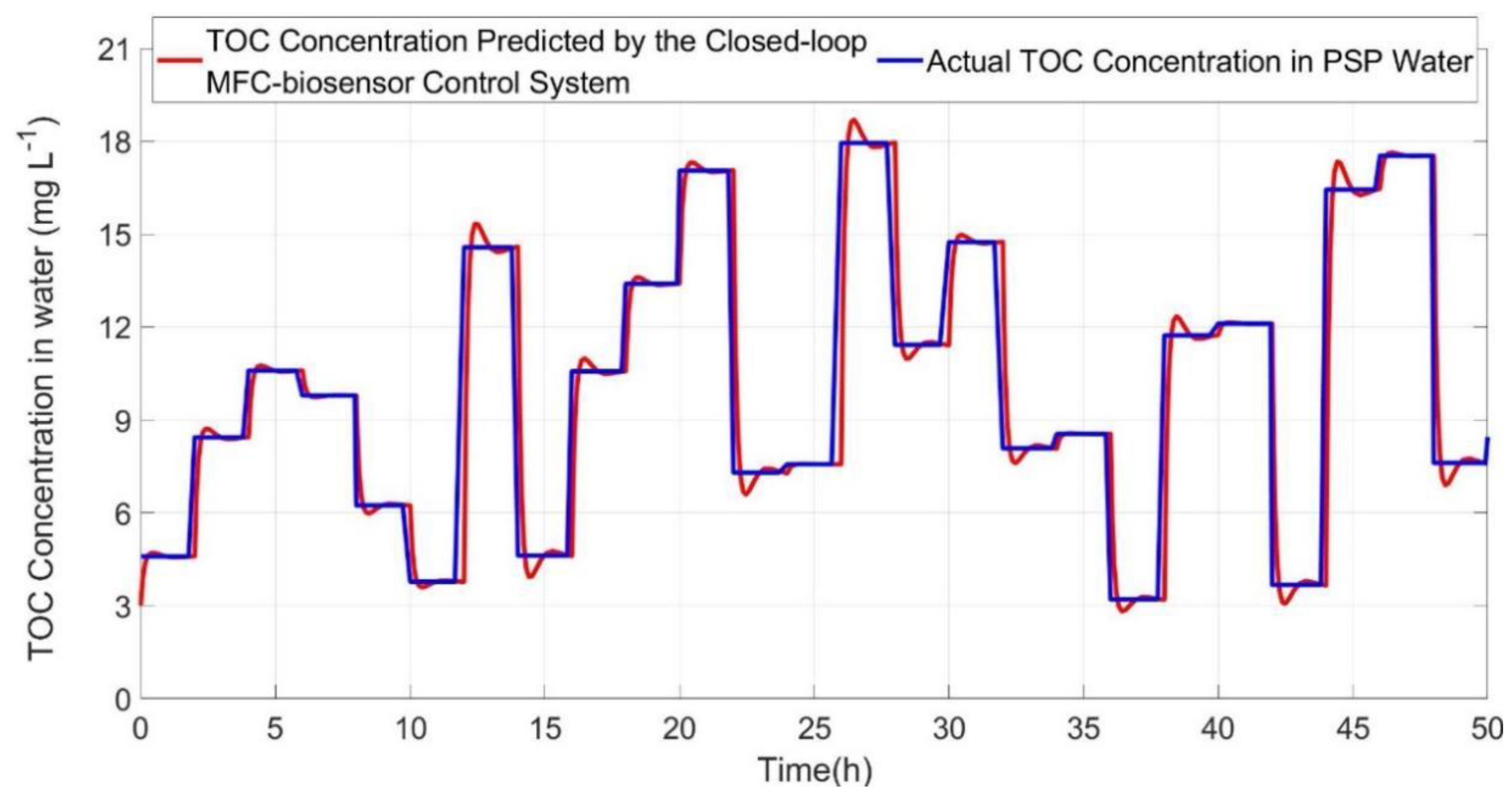

3.3. Real-Time Simulation of the Closed-Loop MFC-Biosensor Control System for Online Monitoring TOC Concentration in PSP Water

- (1)

- Delay time (td) is the time needed for the response to reach half the final value, i.e., state-steady value (Sv), which is the prediction of closed-loop MFC-biosensor control system behaves as time approaches infinity.

- (2)

- Rise time (tr) is the time required for the response to rise from 5% to 95% of Sv.

- (3)

- Peak time (tp) is the time required for the response to reach the first peak of the overshoot.

- (4)

- Maximum overshoot (Mp) is the maximum peak value of the response curve, the amount of the Mp directly indicates the relative stability of the dynamic system.

- (5)

- Settling time (ts) is the time required for the response curve to reach and stay within 2% of the final value, i.e., state-steady value.

- (6)

- Best fit (BF) between actual TOC concentration and Sv.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Furtado, C.; Adak, G.; Stuart, J.; Wall, P.; Evans, H.; Casemore, D. Outbreaks of Waterborne Infectious Intestinal Disease in England and Wales, 1992–1995. Epidemiol. Infect. 1998, 121, 109–119. [Google Scholar] [CrossRef] [PubMed]

- Bell, A.; Guasparini, R.; Meeds, D.; Mathias, R.G.; Farley, J.D. A Swimming Pool-Associated Outbreak of Cryptosporidiosis in British Columbia. Can. J. Public Health Rev. Can. Sante Publique 1993, 84, 334–337. [Google Scholar]

- Blackburn, B.G.; Craun, G.F.; Yoder, J.S.; Hill, V.; Calderon, R.L.; Chen, N.; Lee, S.H.; Levy, D.A.; Beach, M.J. Surveillance for Waterborne-Disease Outbreaks Associated with Drinking Water–United States, 2001-2002. MMWR Surveill. Summ. 2004, 53, 23. [Google Scholar]

- Wang, D.; Liang, P.; Jiang, Y.; Liu, P.; Miao, B.; Hao, W.; Huang, X. Open External Circuit for Microbial Fuel Cell Sensor to Monitor the Nitrate in Aquatic Environment. Biosens. Bioelectron. 2018, 111, 97–101. [Google Scholar] [CrossRef]

- Kim, M.; Hyun, M.S.; Gadd, G.M.; Kim, H.J. A Novel Biomonitoring System Using Microbial Fuel Cells. J. Environ. Monit. 2007, 9, 1323–1328. [Google Scholar] [CrossRef] [PubMed]

- Prévotea, A.; Rabaey, K. Electroactive Biofilms for Sensing: Reflections and Perspectives. ACS Sens. 2017, 2, 1072–1085. [Google Scholar] [CrossRef]

- Logan, B.E. Exoelectrogenic Bacteria That Power Microbial Fuel Cells. Nat. Rev. Microbiol. 2009, 7, 375–381. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, H.; Wang, X.; Gao, Y.; Su, X.; Qin, Y.; Xing, L. Multi-Sub-Inlets at Cathode Flow-Field Plate for Current Density Homogenization and Enhancement of PEM Fuel Cells in Low Relative Humidity. Energy Convers. Manag. 2022, 252, 115069. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.D.; Qi, Y.Z.; Zhang, L.; Wang, Y.L. Three-dimensional numerical study of a cathode gas diffusion layer with a through/in plane synergetic gradient porosity distribution for PEM fuel cells. Int. J. Heat Mass Trans. 2022, 188, 122661. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, H.; Zhang, Z.; Li, H.; Wang, X. Lattice Boltzmann simulation of a gas diffusion layer with a gradient polytetrafluoroethylene distribution for a proton exchange membrane fuel cell. Appl. Energy 2022, 320, 119248. [Google Scholar] [CrossRef]

- Nimje, V.R.; Chen, C.Y.; Chen, H.R.; Chen, C.C.; Huang, Y.M.; Tseng, M.J.; Cheng, K.C.; Chang, Y.F. Comparative Bioelectricity Production from Various Wastewaters in Microbial Fuel Cells Using Mixed Cultures and a Pure Strain of Shewanella Oneidensis. Bioresour. Technol. 2012, 104, 315–323. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.; Youn, S.M.; Shin, S.H.; Jang, J.G.; Han, S.H.; Hyun, M.S.; Gadd, G.M.; Kim, H.J. Practical Field Application of a Novel BOD Monitoring System. J. Environ. Monit. 2003, 5, 640–643. [Google Scholar] [CrossRef] [PubMed]

- Modin, O.; Wilen, B.M. A Novel Bioelectrochemical BOD Sensor Operating with Voltage Input. Water Res. J. Int. Water Assoc. 2012, 46, 6113–6120. [Google Scholar] [CrossRef]

- Di Lorenzo, M.; Thomson, A.R.; Schneider, K.; Cameron, P.J.; Ieropoulos, I. A Small-Scale Air-Cathode Microbial Fuel Cell for on-Line Monitoring of Water Quality. Biosens. Bioelectron. 2014, 62, 182–188. [Google Scholar] [CrossRef]

- Jiang, Y.; Yang, X.; Liang, P.; Liu, P.; Huang, X. Microbial Fuel Cell Sensors for Water Quality Early Warning Systems: Fundamentals, Signal Resolution, Optimization and Future Challenges. Renew. Sustain. Energy Rev. 2018, 81, 292–305. [Google Scholar] [CrossRef]

- Yu, D.; Bai, L.; Zhai, J.; Wang, Y.; Dong, S. Toxicity Detection in Water Containing Heavy Metal Ions with a Self-Powered Microbial Fuel Cell-Based Biosensor. Talanta 2017, 168, 210–216. [Google Scholar] [CrossRef] [PubMed]

- Balch, W.E.; Fox, G.E.; Magrum, L.J.; Woese, C.R.; Wolfe, R. Methanogens: Reevaluation of a unique biological group. Microbiol. Rev. 1979, 43, 260–296. [Google Scholar] [CrossRef] [PubMed]

- Yi, Y.; Xie, B.; Zhao, T.; Li, Z.; Stom, D.; Liu, H. Effect of external resistance on the sensitivity of microbial fuel cell biosensor for detection of different types of pollutants. Bioelectrochemistry 2018, 125, 71–78. [Google Scholar] [CrossRef]

- Chalabi, Z.; Bailey, B.; Wilkinson, D. A Real-Time Optimal Control Algorithm for Greenhouse Heating. Comput. Electron. Agric. 1996, 15, 1–13. [Google Scholar] [CrossRef]

- Mathworks, Inc. MATLAB/Control System Toolbox & System Identification Toolbox & Simulink Real-Time Workshop. Available online: https://www.mathworks.com (accessed on 21 June 2020).

- Ogata, K. Discrete-Time Control System; China Machine Press: Beijing, China, 2018. [Google Scholar]

- Ogata, K. Modern Control Engineering; China Machine Press: Beijing, China, 2012. [Google Scholar]

- Forcato, D.O.; Pécora, R.P.; Kivatinitz, S.C. On-Line Biomass Monitoring in Bench-Scale Stirred Bioreactors Using Parts of a Liquid Chromatography System. Biotechnol. Lett. 2002, 24, 1999–2003. [Google Scholar] [CrossRef]

- Zhao, T.; Xie, B.; Yi, Y.; Liu, H. Sequential flowing membrane-less microbial fuel cell using bioanode and biocathode as sensing elements for toxicity monitoring. Bioresour. Technol. 2019, 276, 276–280. [Google Scholar] [CrossRef] [PubMed]

- Zang, Y.; Zhao, T.; Xie, B.; Feng, Y.; Yi, Y.; Liu, H. A bio-electrochemical sensor based on suspended Shewanella oneidensis MR-1 for the sensitive assessment of water biotoxicity. Sens. Actuators B Chem. 2021, 341, 130004. [Google Scholar] [CrossRef]

- Zang, Y.; Zhao, H.; Cao, B.; Xie, B.; Yi, Y.; Liu, H. Enhancing the sensitivity of water toxicity detection based on suspended Shewanella oneidensis MR-1 by reversing extracellular electron transfer direction. Anal. Bioanal. Chem. 2022, 414, 3057–3066. [Google Scholar] [CrossRef] [PubMed]

- Hu, D.; Zhang, H.; Zhou, R.; Li, M.; Sun, Y. Controller Development of Photo Bioreactor for Closed-Loop Regulation of O2 Production Based on ANN Model Reference Control and Computer Simulation. Acta Astronaut. 2013, 83, 232–238. [Google Scholar] [CrossRef]

- Hu, D.; Wang, K.; Hu, J.; Xu, X.; Long, Y. Robust Stability of Closed Artificial Ecosystem Cultivating Cabbage Realized by Ecological Thermodynamics and Dissipative Structure System. Ecol. Model. 2018, 380, 1–7. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Meng, X.; Liu, D.; Wang, W.; Xing, X.; Zhang, Z.; Dong, C. Closed-Loop Microbial Fuel Cell Control System Designed for Online Monitoring of TOC Dynamic Characteristics in Public Swimming Pool. Int. J. Environ. Res. Public Health 2022, 19, 13024. https://doi.org/10.3390/ijerph192013024

Chen H, Meng X, Liu D, Wang W, Xing X, Zhang Z, Dong C. Closed-Loop Microbial Fuel Cell Control System Designed for Online Monitoring of TOC Dynamic Characteristics in Public Swimming Pool. International Journal of Environmental Research and Public Health. 2022; 19(20):13024. https://doi.org/10.3390/ijerph192013024

Chicago/Turabian StyleChen, Haishan, Xiaoping Meng, Dianlei Liu, Wei Wang, Xiaodong Xing, Zhiyong Zhang, and Chen Dong. 2022. "Closed-Loop Microbial Fuel Cell Control System Designed for Online Monitoring of TOC Dynamic Characteristics in Public Swimming Pool" International Journal of Environmental Research and Public Health 19, no. 20: 13024. https://doi.org/10.3390/ijerph192013024

APA StyleChen, H., Meng, X., Liu, D., Wang, W., Xing, X., Zhang, Z., & Dong, C. (2022). Closed-Loop Microbial Fuel Cell Control System Designed for Online Monitoring of TOC Dynamic Characteristics in Public Swimming Pool. International Journal of Environmental Research and Public Health, 19(20), 13024. https://doi.org/10.3390/ijerph192013024