Comparison and Optimization of Continuous Flow Reactors for Aerobic Granule Sludge Cultivation from the Perspective of Hydrodynamic Behavior

Abstract

:1. Introduction

2. Materials and Methods

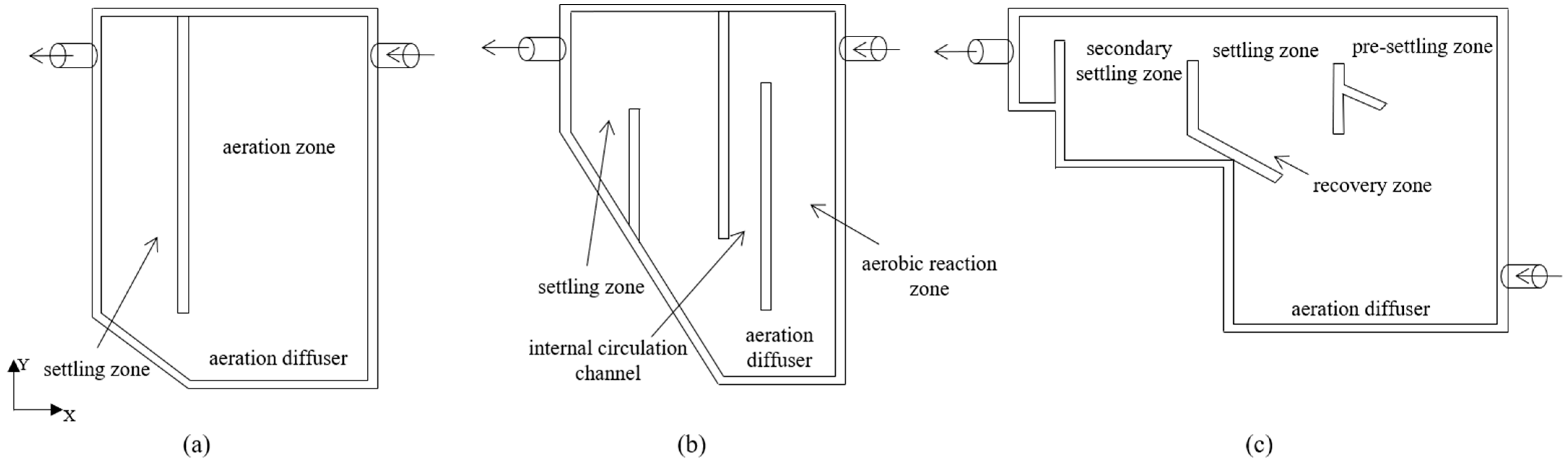

2.1. Bioreactors of CFR

2.2. Model Geometry for CFD Modeling

2.3. Reactor Meshing

2.4. Mathematical Model

2.4.1. General Information

2.4.2. Governing Equations

Equation of Particles Motion

Fluid Phase

Turbulence

Discrete Phase Model

2.5. Boundary Conditions

2.6. Simulation

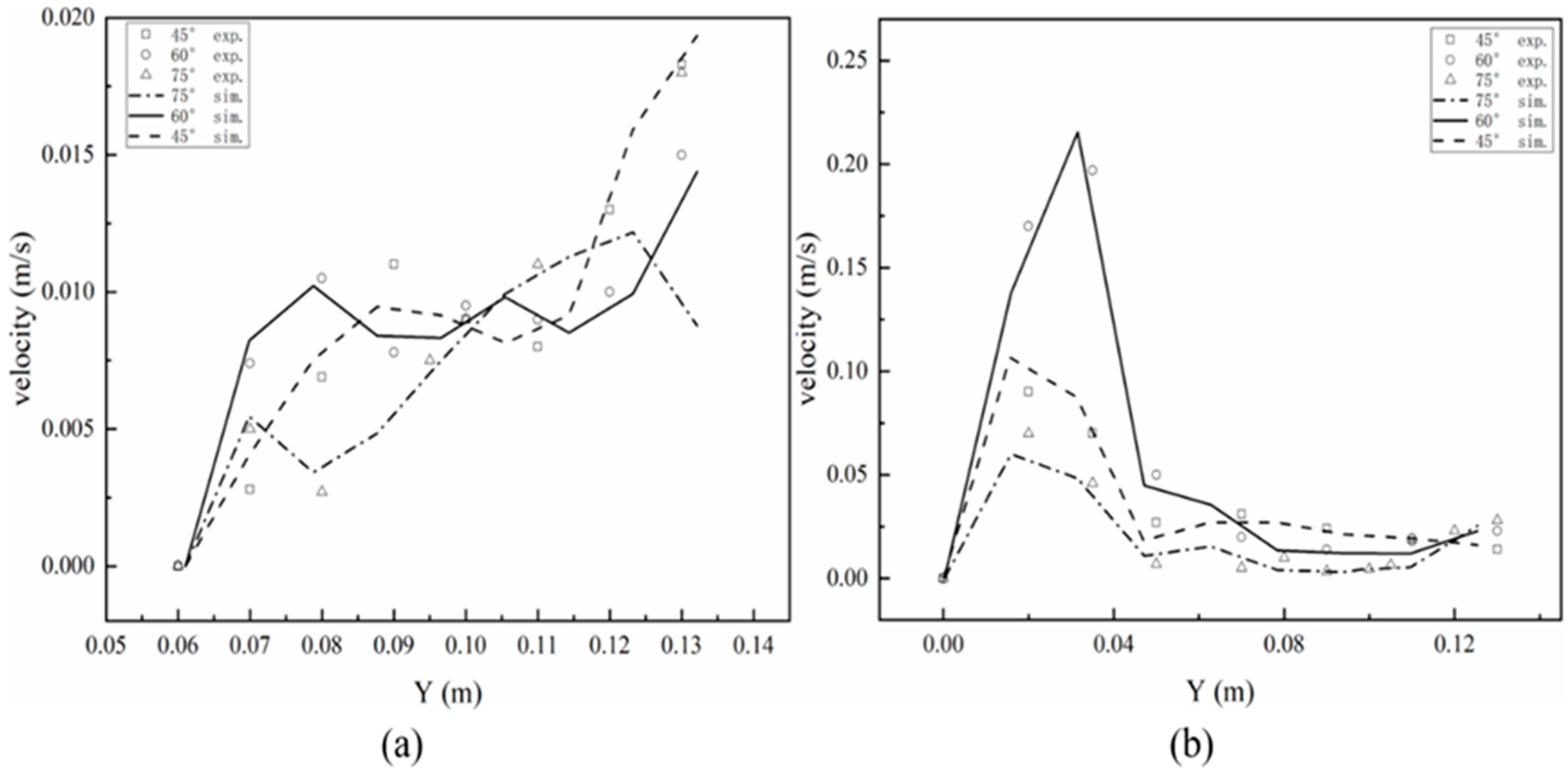

2.7. CFD Model Validation

2.8. Retention Time Distribution Analysis

3. Results and Discussions

3.1. Validation of CFD Model

3.2. Comparison of Hydrodynamic Behavior in Three CFRs

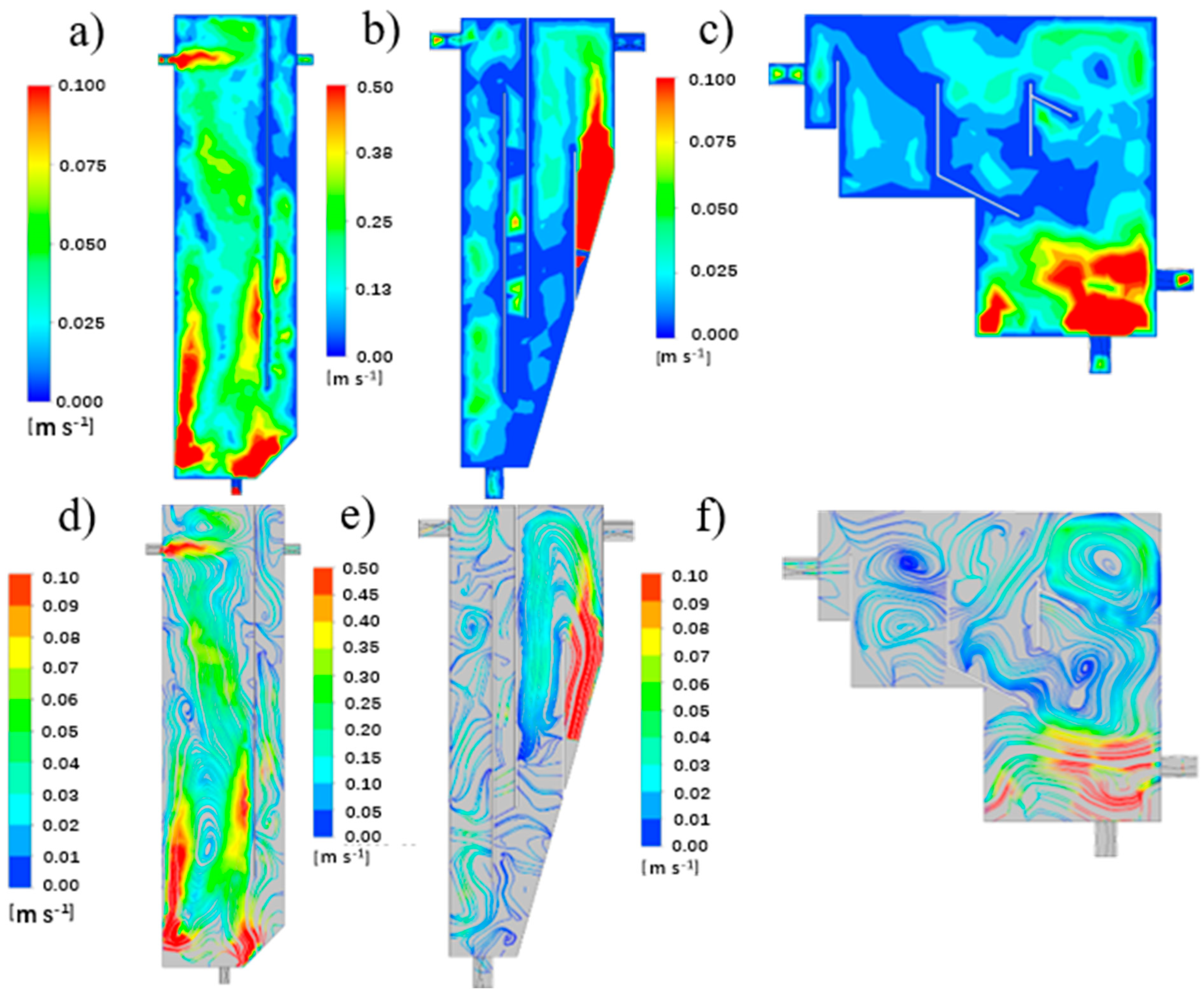

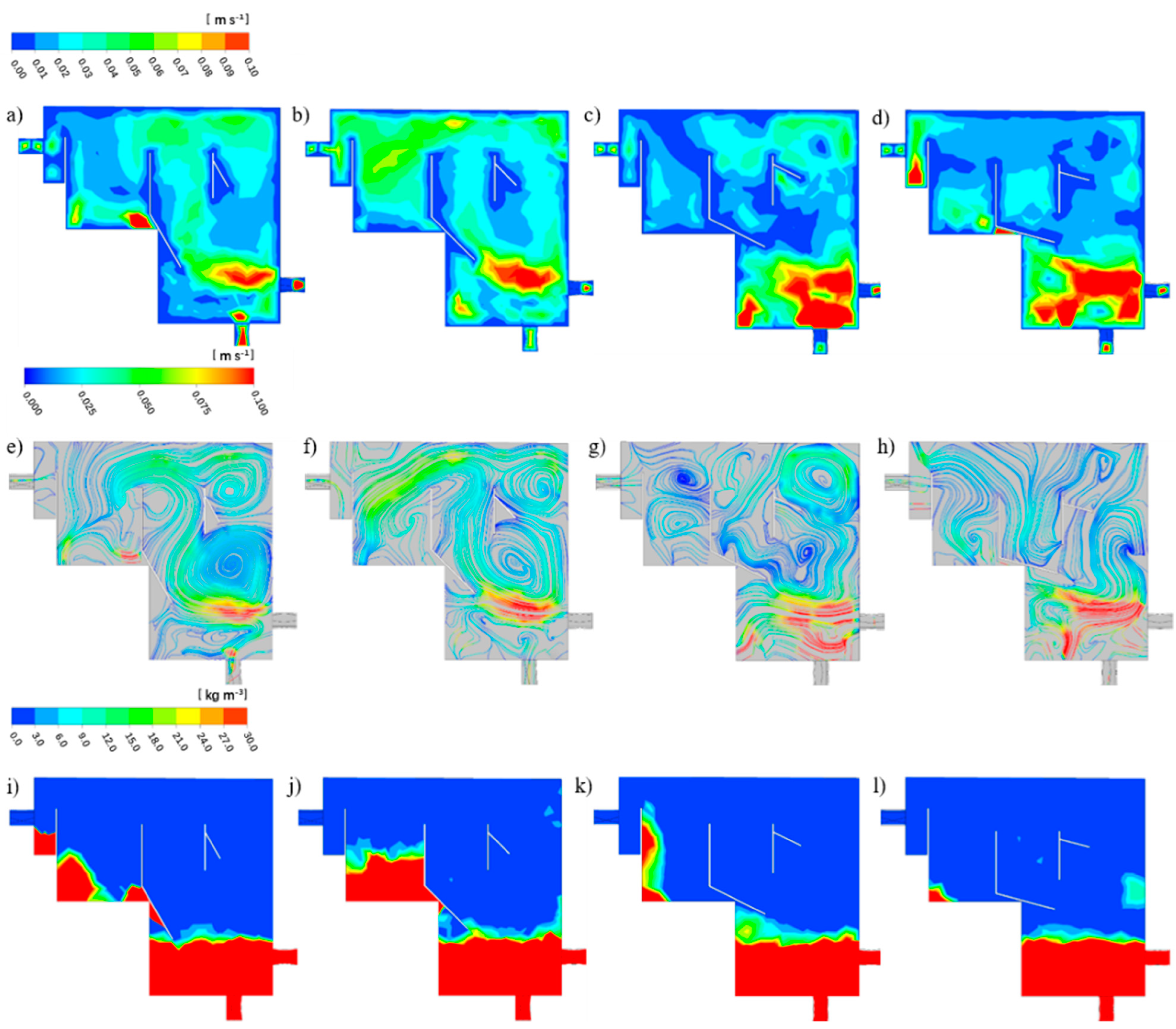

3.2.1. Fluid Behavior

3.2.2. Granular Separation

3.3. Structural Optimization of R3

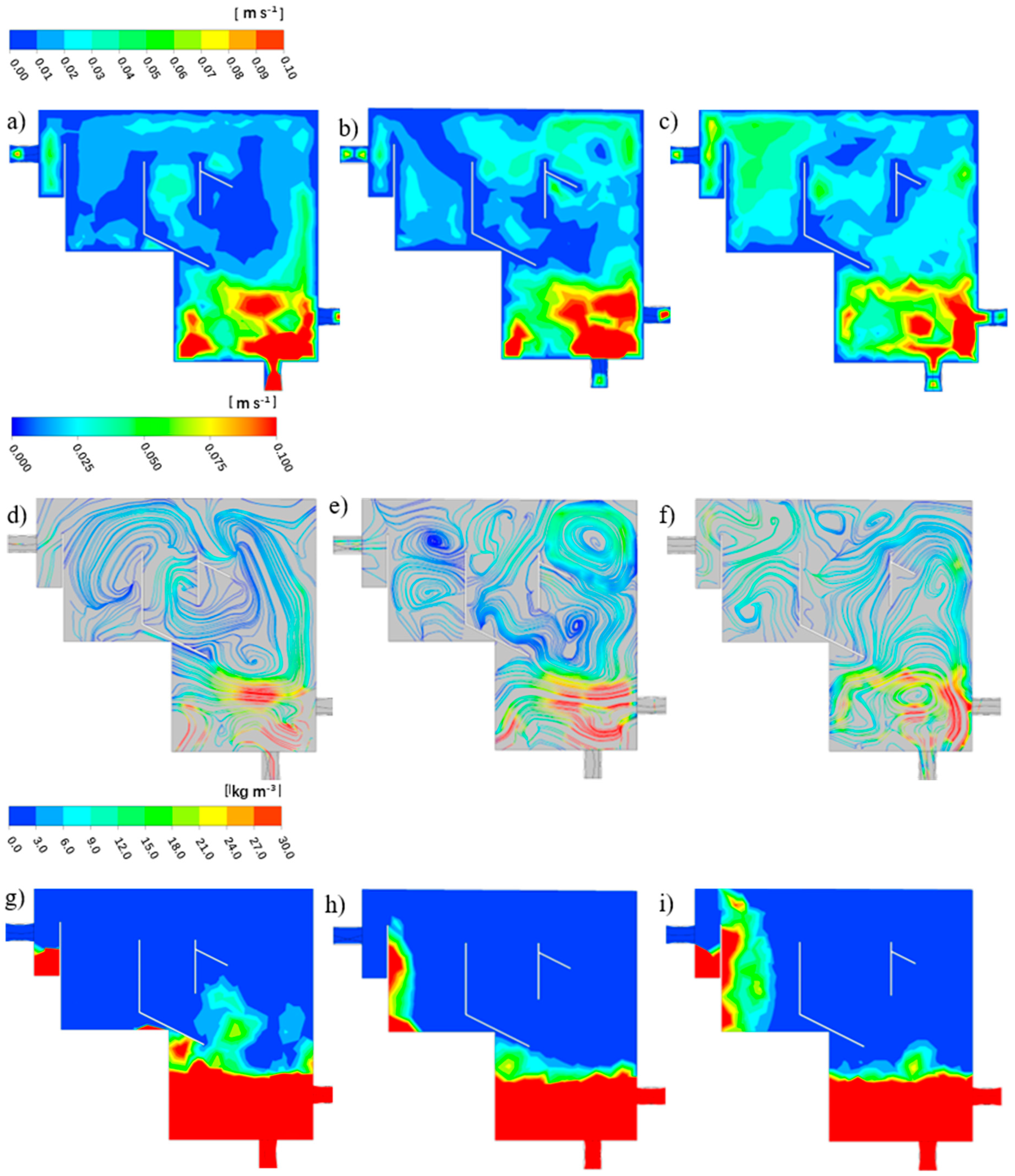

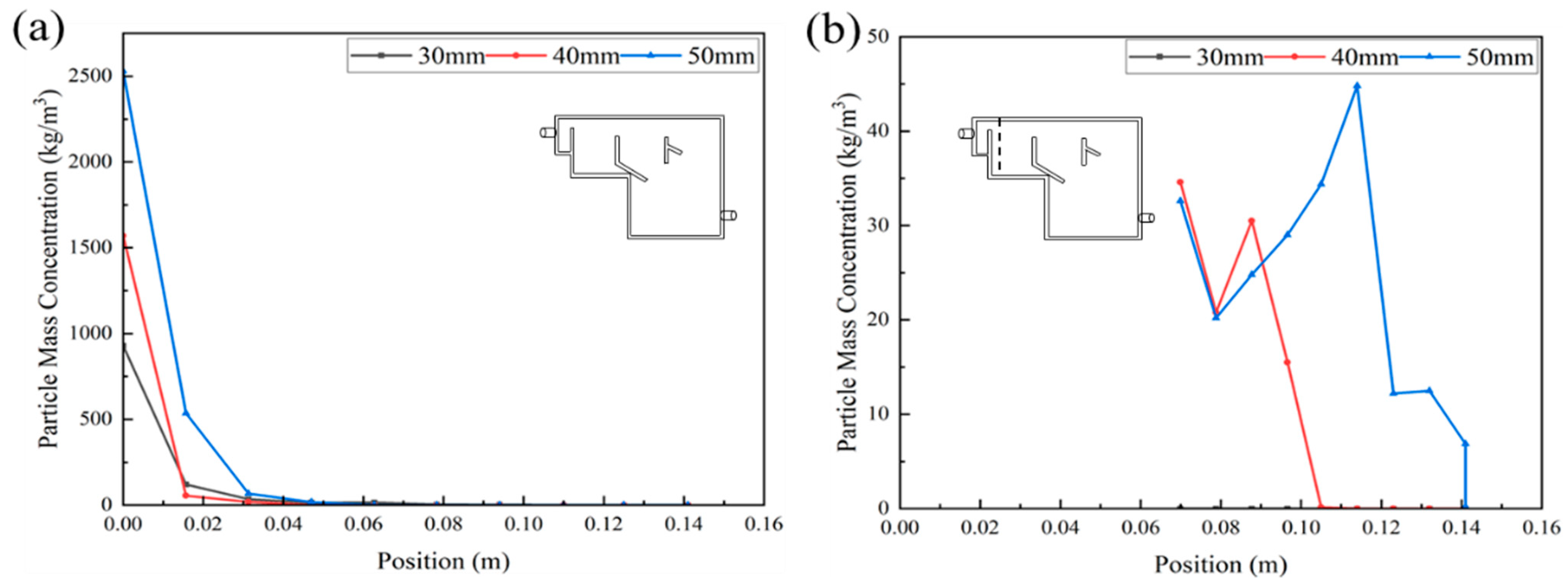

3.3.1. Optimizing Baffle Distances

Judging from Fluid Behavior

Judging from Granular Separation

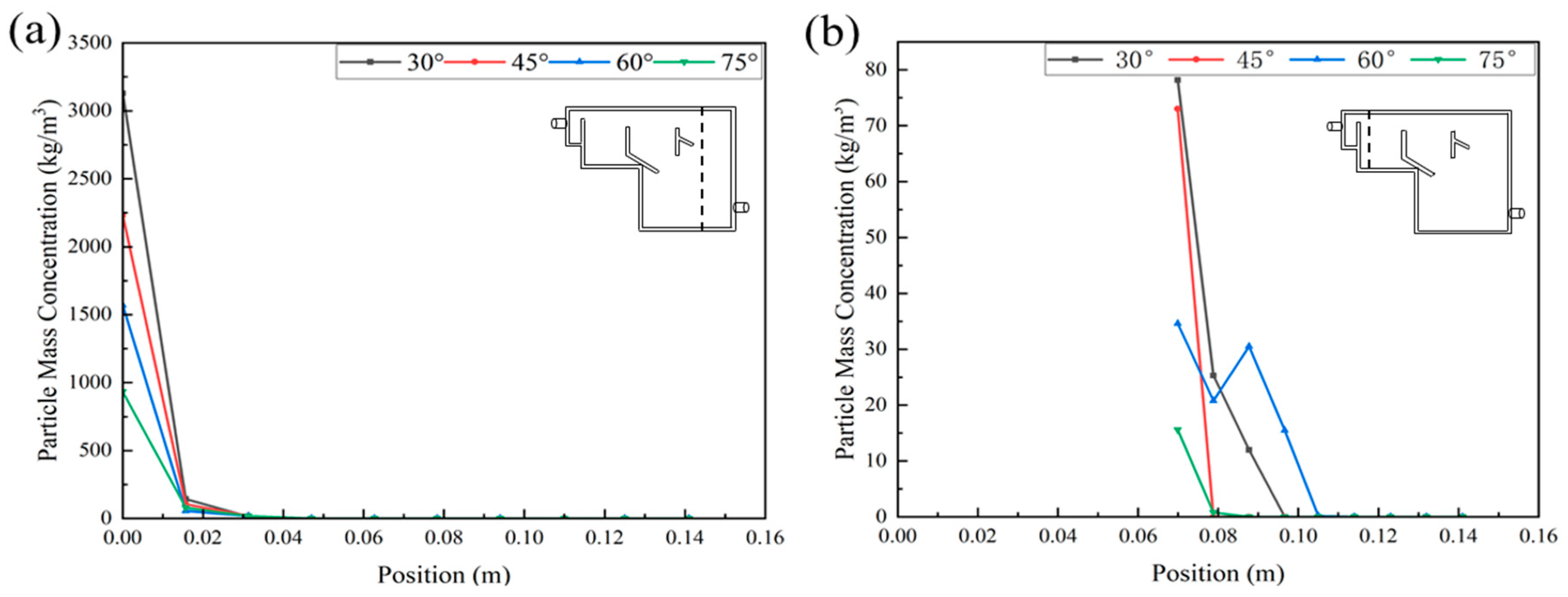

3.3.2. Optimizing Baffle Angles

Judging from Fluid Behavior

Judging from Granular Separation

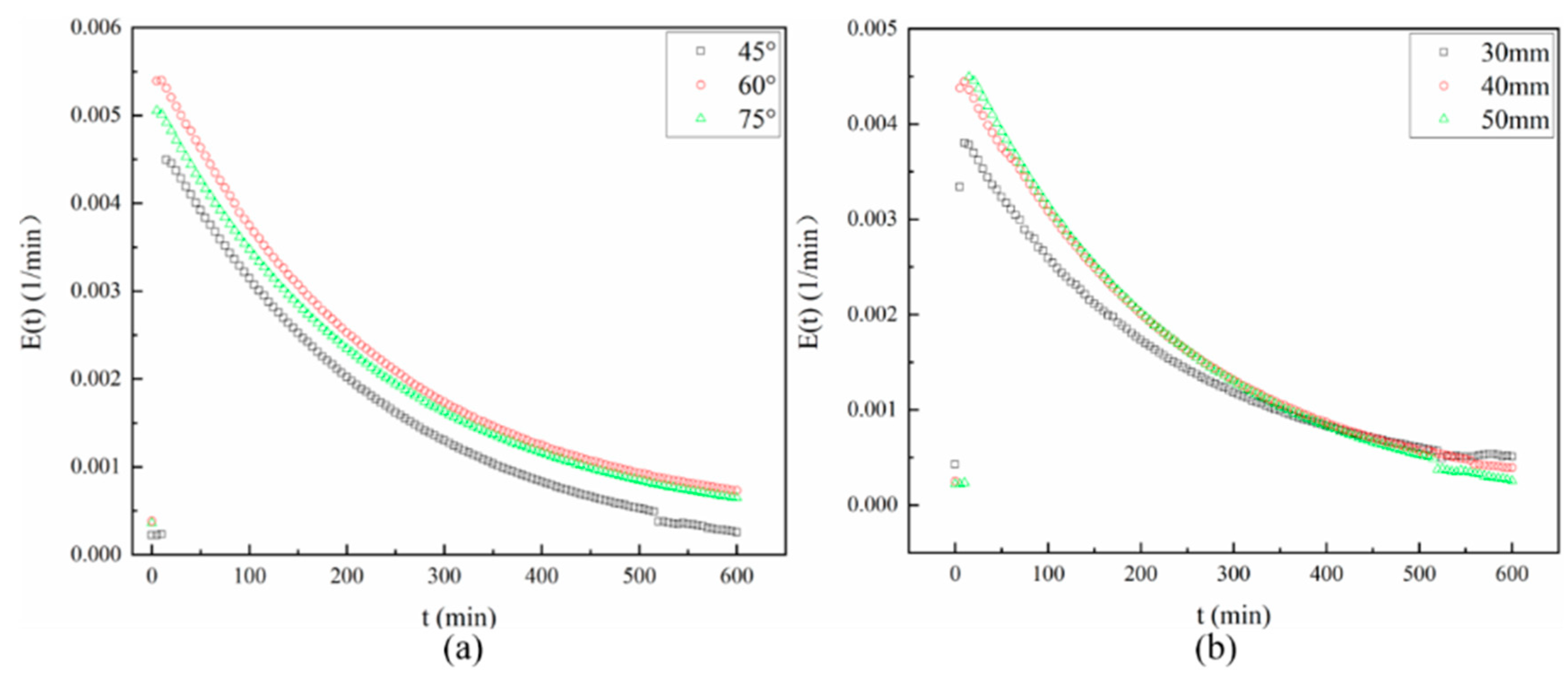

3.4. Hydraulic Parameters by RTD Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| density of the fluid | |

| p | static pressure |

| v | kinematic viscosity |

| ui | the instantaneous velocity associated with the coordinate direction |

| Ui | mean flow velocity |

| ui′ | turbulent velocity fluctuation |

| ui | Ui+ ui′ |

| determined with a turbulence closure model | |

| u | velocity of the fluid phase |

| up | velocity of the particle phase |

| μ | hydrodynamic viscosity |

| ρp | density of the particles |

| dP | diameter of the particles |

| Re | relative Reynolds number |

| Gk | the generation rate of turbulence kinetic energy due to mean velocity gradients |

| Gb | the generation rate of turbulence kinetic energy due to buoyancy |

| ak | the inverse effective Prandtl numbers for k |

| aε | the inverse effective Prandtl numbers for ε |

| µeff | effective viscosity |

| C1ε, C2ε and C3ε | turbulence model constants |

References

- de Kreuk, M.K.; Kishida, N.; van Loosdrecht, M.C. Aerobic granular sludge—State of the art. Water Sci. Technol. 2007, 55, 75–81. [Google Scholar] [CrossRef] [PubMed]

- Adav, S.S.; Lee, D.J.; Show, K.Y.; Tay, J.H. Aerobic granular sludge: Recent advances. Biotechnol. Adv. 2008, 26, 411–423. [Google Scholar] [CrossRef] [PubMed]

- Giesen, A.; Niermans, R.; Loosdrecht, M. Aerobic granular biomass: The new standard for domestic and industrial wastewater treatment. Water 2012, 21, 28–30. [Google Scholar]

- Moy, B.Y.; Tay, J.H.; Toh, S.K.; Liu, Y.; Tay, S.T. High organic loading influences the physical characteristics of aerobic sludge granules. Lett. Appl. Microbiol. 2010, 34, 407–412. [Google Scholar] [CrossRef] [PubMed]

- Figueroa, M.; Val del Rio, A.; Campos, J.L.; Mosquera-Corral, A.; Mendez, R. Treatment of high loaded swine slurry in an aerobic granular reactor. Water Sci. Technol. 2011, 63, 1808–1814. [Google Scholar] [CrossRef] [Green Version]

- Bumbac, C.; Ionescu, I.A.; Tiron, O.; Badescu, V.R. Continuous flow aerobic granular sludge reactor for dairy wastewater treatment. Water Sci. Technol. 2015, 71, 440–445. [Google Scholar] [CrossRef]

- Othman, I.; Anuar, A.N.; Ujang, Z.; Rosman, N.H.; Harun, H.; Chelliapan, S. Livestock wastewater treatment using aerobic granular sludge. Bioresour. Technol. 2013, 133, 630–634. [Google Scholar] [CrossRef]

- Xin, X.; Lu, H.; Yao, L.; Leng, L.; Guan, L. Rapid Formation of Aerobic Granular Sludge and Its Mechanism in a Continuous-Flow Bioreactor. Appl. Biochem. Biotechnol. 2017, 181, 424–433. [Google Scholar] [CrossRef]

- Liu, H.; Xiao, H.; Huang, S.; Ma, H.; Liu, H. Aerobic granules cultivated and operated in continuous-flow bioreactor under particle-size selective pressure. J. Environ. Sci. 2014, 11, 79–85. [Google Scholar] [CrossRef]

- Kent, T.R.; Bott, C.B.; Wang, Z.W. State of the art of aerobic granulation in continuous flow bioreactors. Biotechnol. Adv. 2018, 36, 1139–1166. [Google Scholar] [CrossRef]

- Figueroa, M.; Mosquera-Corral, A.; Campos, J.L.; Méndez, R. Aerobic granular-type biomass development in a continuous stirred tank reactor. Sep. Purif. Technol. 2012, 89, 199–205. [Google Scholar]

- Ferng, Y.M.; Su, A. A three-dimensional full-cell CFD model used to investigate the effects of different flow channel designs on PEMFC performance. Int. J. Hydrogen Energy 2007, 32, 4466–4476. [Google Scholar] [CrossRef]

- Rismanchi, B.; Akbari, M.H. Performance prediction of proton exchange membrane fuel cells using a three-dimensional model. Int. J. Hydrogen Energy 2008, 33, 439–448. [Google Scholar] [CrossRef]

- Nagarajan, V.; Ponyavin, V.; Chen, Y.; Vernon, M.E.; Pickard, P.; Hechanova, A.E. CFD modeling and experimental validation of sulfur trioxide decomposition in bayonet type heat exchanger and chemical decomposer for different packed bed designs. Int. J. Hydrogen Energy 2009, 34, 2543–2557. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, J.; Zuo, J.; Ye, L.; He, S.; Xiao, Y.; Zhang, K. Study on two operating conditions of a full-scale oxidation ditch for optimization of energy consumption and effluent quality by using CFD model. Water Res. 2011, 45, 3439–3452. [Google Scholar] [CrossRef]

- Yang, J.; Zhong, T.; Xiao, G.; Chen, Y.; Liu, J.; Xia, C.; Du, H.; Kang, X.; Lin, Y.; Guan, R. Polymorphisms and haplotypes of the TGF-β1 gene are associated with risk of polycystic ovary syndrome in Chinese Han women. Eur. J. Obstet. Gynecol. Reprod. Biol. 2015, 186, 1–7. [Google Scholar] [CrossRef]

- Mutharasu, L.C.; Kalaga, D.V.; Sathe, M.; Turney, D.E.; Griffin, D.; Li, X.; Kawaji, M.; Nandakumar, K.; Joshi, J.B. Experimental study and CFD simulation of the multiphase flow conditions encountered in a Novel Down-flow Bubble Colum. Chem. Eng. J. 2018, 350, 507–522. [Google Scholar]

- Wang, H.; Ding, J.; Liu, X.S.; Ren, N.Q. The Impact of Water Distribution System on the Internal Flow Field of EGSB by Using CFD Simulation. Appl. Mech. Mater. 2014, 614, 596–604. [Google Scholar] [CrossRef]

- Pan, H.; Hu, Y.f.; Pu, W.h.; Dan, J.f.; Yang, J.k. CFD optimization of the baffle angle of an expanded granular sludge bed reactor. J. Environ. Chem. Eng. 2017, 5, 4531–4538. [Google Scholar] [CrossRef]

- Qian, F.; Wang, J.; Shen, Y.; Wang, Y.; Wang, S.; Chen, X. Achieving high performance completely autotrophic nitrogen removal in a continuous granular sludge reactor. Biochem. Eng. J. 2017, 118, 97–104. [Google Scholar] [CrossRef]

- Tarpagkou, R.; Pantokratoras, A. CFD methodology for sedimentation tanks: The effect of secondary phase on fluid phase using DPM coupled calculations. Appl. Math. Model. 2013, 37, 3478–3494. [Google Scholar] [CrossRef]

- Hsu, C.-Y.; Wu, R.-M. Hot Zone in a Hydrocyclone for Particles Escape from Overflow. Dry. Technol. 2008, 26, 1011–1017. [Google Scholar] [CrossRef]

- Villermaux, J. Génie de la Réaction Chimique: Conception et Fonctionnement des Réacteurs; Jacques Villermaux: Paris, France, 1982. [Google Scholar]

- Geropp, D.; Odenthal, H.J. Drag reduction of motor vehicles by active flow control using the Coanda effect. Exp. Fluids 2000, 28, 74–85. [Google Scholar] [CrossRef]

- Tao, C.; Zhang, Y.; Hottinger, D.G.; Jiang, J.J. Asymmetric airflow and vibration induced by the Coanda effect in a symmetric model of the vocal folds. J. Acoust. Soc. Am. 2007, 122, 2270–2278. [Google Scholar] [CrossRef]

- French, J.W.; Guntheroth, W.G. An Explanation of Asymmetric Upper Extremity Blood Pressures in Supravalvular Aortic Stenosis: The Coanda Effect. Circulation 1970, 42, 31–36. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stokes, L.J.B.J.; West, J.R. Evaluation of different analytical methods for tracer studies in aeration lanes of activated sludge plants. Water Res. 1999, 33, 367–374. [Google Scholar]

- Climent, J.; Martínez-Cuenca, R.; Carratalà, P.; González-Ortega, M.J.; Abellán, M.; Monrós, G.; Chiva, S. A comprehensive hydrodynamic analysis of a full-scale oxidation ditch using Population Balance Modelling in CFD simulation. Chem. Eng. J. 2019, 374, 760–775. [Google Scholar] [CrossRef]

| V | HRT | Baffle Number | Qwater | Qgas | Granulation Time | SVI5 | Granular Diameter | Ref. | |

|---|---|---|---|---|---|---|---|---|---|

| (L) | (hour) | (L/h) | (L/min) | (days) | (mL/g) | (mm) | |||

| R1 | 4.3 | 0.55 | 1 | 7.8 | 0.3 | 40 | 44–61 | 0.5–2.0 | [8] |

| R2 | 1.5 | 0.9 | 3 | 1.7 | 0.9 | 33 | 87 | 1.2 | [20] |

| R3 | 10 | 10 | 3 | 1 | 6–8 | 14 | / | 2 | [6] |

| Case | tactual | τ | eV | σ2 | t10 | t90 | MDI |

|---|---|---|---|---|---|---|---|

| min | min | g | g | ||||

| Distance 30 mm | 118 | 210 | 0.56 | 10,140 | 1.29 | 0.22 | 0.17 |

| Distance 40 mm | 134 | 210 | 0.64 | 10,519 | 1.52 | 0.21 | 0.14 |

| Distance 50 mm | 133 | 210 | 0.64 | 9979 | 1.56 | 0.15 | 0.1 |

| Angle 45° | 134 | 210 | 0.64 | 10,519 | 1.52 | 0.21 | 0.14 |

| Angle 60° | 172 | 2108 | 0.82 | 20,026 | 1.85 | 0.35 | 0.19 |

| Angle 75° | 160 | 210 | 0.77 | 18,659 | 1.7 | 0.31 | 0.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, X.; Li, H.; Zhao, Q.; Yang, P.; Zeng, M.; Guo, D.; Fu, Z.; Hao, L.; Wu, N. Comparison and Optimization of Continuous Flow Reactors for Aerobic Granule Sludge Cultivation from the Perspective of Hydrodynamic Behavior. Int. J. Environ. Res. Public Health 2022, 19, 8306. https://doi.org/10.3390/ijerph19148306

Jiang X, Li H, Zhao Q, Yang P, Zeng M, Guo D, Fu Z, Hao L, Wu N. Comparison and Optimization of Continuous Flow Reactors for Aerobic Granule Sludge Cultivation from the Perspective of Hydrodynamic Behavior. International Journal of Environmental Research and Public Health. 2022; 19(14):8306. https://doi.org/10.3390/ijerph19148306

Chicago/Turabian StyleJiang, Xinye, Hongli Li, Qingyu Zhao, Peng Yang, Ming Zeng, Du Guo, Zhiqiang Fu, Linlin Hao, and Nan Wu. 2022. "Comparison and Optimization of Continuous Flow Reactors for Aerobic Granule Sludge Cultivation from the Perspective of Hydrodynamic Behavior" International Journal of Environmental Research and Public Health 19, no. 14: 8306. https://doi.org/10.3390/ijerph19148306

APA StyleJiang, X., Li, H., Zhao, Q., Yang, P., Zeng, M., Guo, D., Fu, Z., Hao, L., & Wu, N. (2022). Comparison and Optimization of Continuous Flow Reactors for Aerobic Granule Sludge Cultivation from the Perspective of Hydrodynamic Behavior. International Journal of Environmental Research and Public Health, 19(14), 8306. https://doi.org/10.3390/ijerph19148306