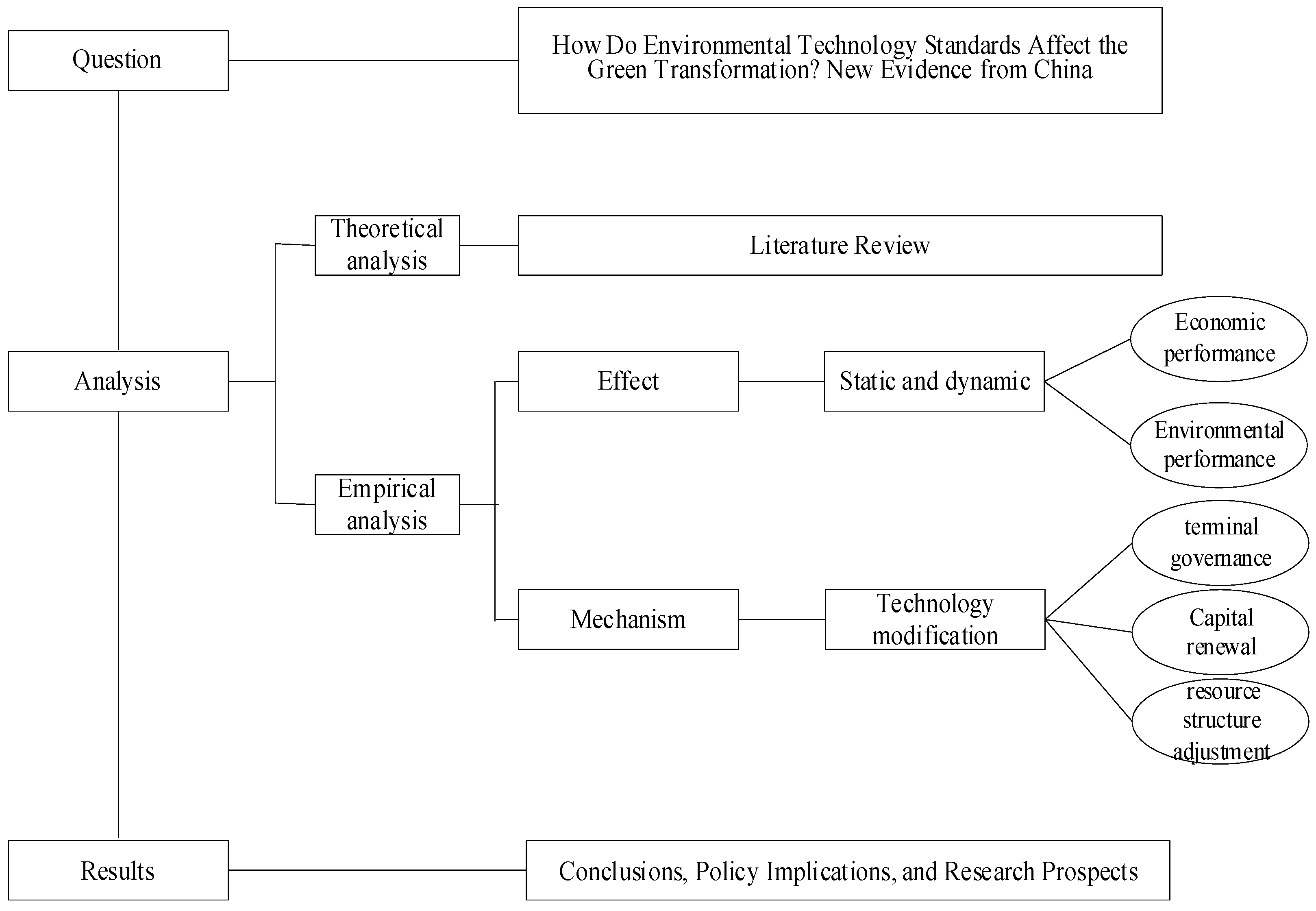

How Do Environmental Technology Standards Affect the Green Transformation? New Evidence from China

Abstract

:1. Introduction

2. Literature Review

2.1. The Effects of Environmental Technology Standards

2.2. The Mechanism of Environmental Technology Standards

3. Methodology

3.1. Selection of Variables

3.1.1. Dependent Variables

3.1.2. Key Explanatory Variables

3.1.3. Control Variables

3.2. Data Sources

3.3. Empirical Model Construction

4. Empirical Results and Analysis

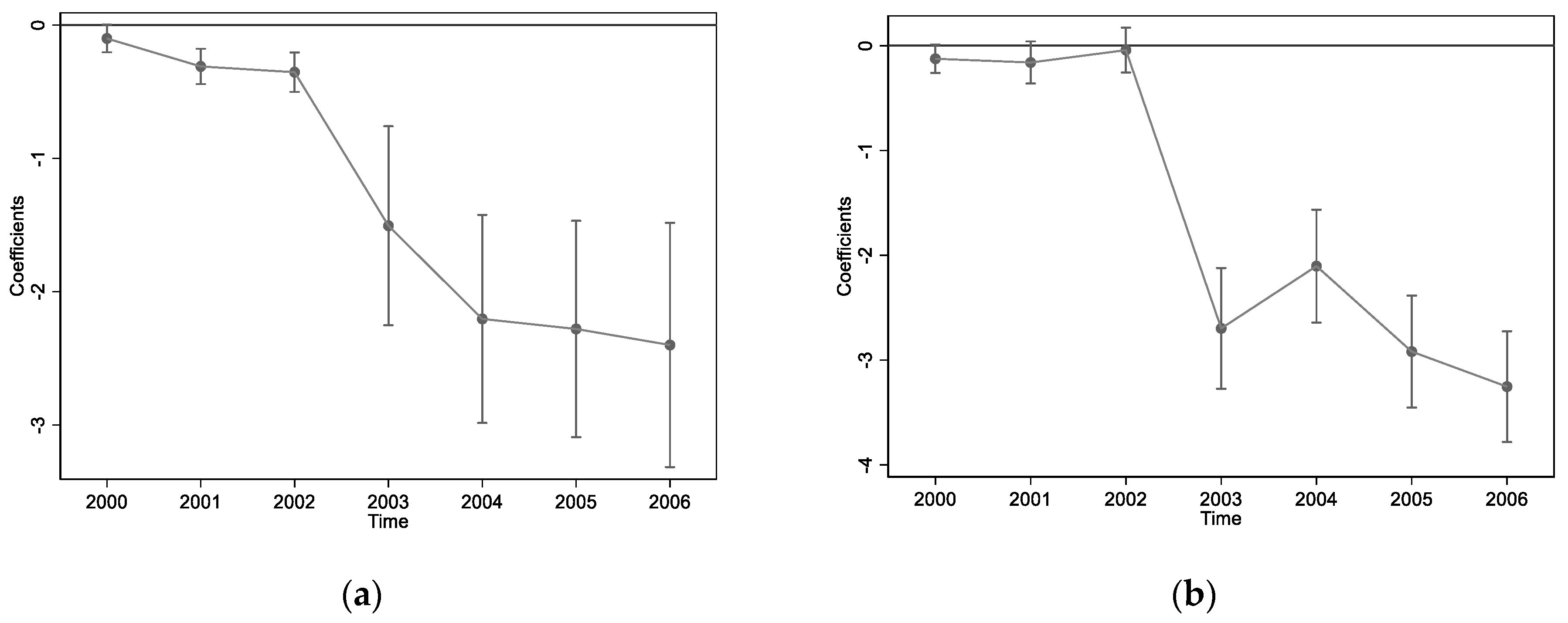

4.1. Parallel Trend Test

4.2. Estimation Results of the Effect Test

4.3. Estimation Results of the Mechanism Test

4.3.1. Terminal Governance

4.3.2. Capital Renewal

4.3.3. Resource Structure Adjustment

5. Conclusions, Policy Implications, and Research Prospects

5.1. Conclusions

5.2. Policy Implications

5.3. Research Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yuan, B.L.; Ren, S.G.; Chen, X.H. Can Environmental Regulation Promote the Coordinated Development of Economy and Environment in China’s Manufacturing Industry?—A Panel Data Analysis of 28 Subsectors. J. Clean. Prod. 2017, 149, 11–24. [Google Scholar] [CrossRef]

- Ren, S.G.; Li, X.L.; Yuan, B.L.; Li, D.Y.; Chen, X.H. The Effects of Three Types of Environmental Regulation on Eco-efficiency: A Cross-region Analysis in China. J. Clean. Prod. 2018, 173, 245–255. [Google Scholar] [CrossRef]

- Guo, Q.; Zhou, M.; Liu, N.N.; Wang, Y.Y. Spatial Effects of Environmental Regulation and Green Credits on Green Technology Innovation Under Low-carbon Economy Background Conditions. Int. J. Environ. Res. Pub. Health 2019, 16, 3027. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Feng, Y.C.; Wang, X.H.; Hu, S.L. Accountability Audit of Natural Resource, Air Pollution Reduction and Political Promotion in China: Empirical Evidence from a Quasi-natural Experiment. J. Clean. Prod. 2021, 287, 125002. [Google Scholar] [CrossRef]

- Liu, Y.L.; Li, Z.H.; Yin, X.M. The Effects of Three Types of Environmental Regulation on Energy Consumption—Evidence from China. Environ. Sci. Pollut. Res. 2018, 25, 27334–27351. [Google Scholar] [CrossRef]

- Peng, X. Strategic Interaction of Environmental Regulation and Green Productivity Growth in China: Green Innovation or Pollution Refuge? Sci. Total Environ. 2020, 732, 139200. [Google Scholar] [CrossRef]

- Chung, Y.H.; Färe, R.; Grosskopf, S. Productivity and Undesirable Outputs: A Directional Distance Function Approach. J. Environ. Manag. 1997, 51, 229–240. [Google Scholar] [CrossRef] [Green Version]

- Long, X.L.; Zhao, X.C.; Cheng, F.X. The Comparison Analysis of Total Productivity and Eco-efficiency in China’s Cement Manufactures. Energy Policy 2015, 81, 61–66. [Google Scholar] [CrossRef]

- Porter, M. America’s Green Strategy. Sci. Am. 1991, 264, 168. [Google Scholar] [CrossRef]

- Yi, M.; Wang, Y.Q.; Yan, M.D.; Fu, L.N.; Zhang, Y. Government R&D Subsidies, Environmental Regulations, and Their Effect on Green Innovation Efficiency of Manufacturing Industry: Evidence from the Yangtze River Economic Belt of China. Int. J. Environ. Res. Public Health 2020, 17, 1330. [Google Scholar]

- Xie, R.H.; Yuan, Y.J.; Huang, J.J. Different Types of Environmental Regulations and Heterogeneous Influence on “Green” Productivity: Evidence from China. Ecol. Econ. 2017, 132, 104–112. [Google Scholar] [CrossRef]

- Feng, Z.; Chen, W. Environmental Regulation, Green Innovation, and Industrial Green Development: An Empirical Analysis Based on the Spatial Durbin Model. Sustainability 2018, 10, 223. [Google Scholar] [CrossRef] [Green Version]

- Fan, H.J.; Zivin, S.G.; Kou, Z.; Liu, X.; Wang, H. Going Green in China: Firms’ Responses to Stricter Environmental Regulation. NBER Work. Pap. 2019, 26540. [Google Scholar] [CrossRef]

- Shi, D.; Li, P. Quality Evolution and Assessment of China’s Industry over the Past Seven Decades. China Ind. Econ. 2019, 35, 5–23. [Google Scholar]

- Shao, S.; Hu, Z.G.; Cao, J.H.; Yang, L.L.; Guan, D.B. Environmental Regulation and Enterprise Innovation: A Review. Bus Strategy Environ. 2020, 29, 1465–1478. [Google Scholar] [CrossRef]

- Cole, M.A.; Elliott, R.J.; Kubo, T.O. Trade, Environmental Regulations and Imobility: An Industry-level Study of Japan. Ecol. Econ. 2010, 69, 1995–2002. [Google Scholar] [CrossRef] [Green Version]

- Korhonen, J.; Pätäri, S.; Toppinen, A.; Tuppura, A. The Role of Environmental Regulation in the Future Competitiveness of the Pulp and Paper Industry: The Case of the Sulfur Emissions Directive in Northern Europe. J. Clean. Prod. 2015, 108, 864–872. [Google Scholar] [CrossRef]

- Guo, Y.Y.; Xia, X.N.; Zhang, S.; Zhang, D.P. Environmental Regulation, Government R & D Funding and Green Technology Innovation: Evidence from China Provincial Data. Sustainability 2018, 10, 940. [Google Scholar]

- Boyd, G.A.; McClelland, J.D. The Impact of Environmental Constraints on Productivity Improvement in Integrated Paper Plants. J. Environ. Econ. Manag. 1999, 38, 121–142. [Google Scholar] [CrossRef]

- Zhao, X.K. Lead to Green Innovation: Research of Innovation-Oriented Environmental Policy; Economic Science Press: Beijing, China, 2006. [Google Scholar]

- Zhao, X.; Zhao, Y.; Zeng, S.; Zhang, S. Corporate Behavior and Competitiveness: Impact of Environmental Regulation on Chinese Firms. J. Clean. Prod. 2015, 86, 311–322. [Google Scholar] [CrossRef]

- Yuan, B.L.; Xiang, Q.L. Environmental Regulation, Industrial Innovation and Green Development of Chinese Manufacturing: Based on An Extended CDM Model. J. Clean. Prod. 2018, 176, 895–908. [Google Scholar] [CrossRef]

- Desrochers, P.; Haight, C.E. Squandered Profit Opportunities? Some Historical Perspective on Industrial Waste and the Porter Hypothesis. Resour. Conserv. Recycl. 2014, 92, 179–189. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Dong, L.; Luan, J.; Wang, P. Do Environmental Regulations Affect Investors? Evidence from China’s Action Plan for Air Pollution Prevention. J. Clean. Prod. 2020, 244, 118817. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Zhu, J.L.; Li, E.Y.; Meng, Z.Y.; Song, Y. Environmental Regulation, Green Technological Innovation, and Eco-efficiency: The Case of Yangtze River Economic Belt in China. Technol. Forecast. Soc. Chang. 2020, 155, 119993. [Google Scholar] [CrossRef]

- Shen, N.; Liao, H.L.; Deng, R.M.; Wang, Q.W. Different Types of Environmental Regulations and the Heterogeneous Influence on the Environmental Total Factor Productivity: Empirical Analysis of China’s industry. J. Clean. Prod. 2019, 211, 171–184. [Google Scholar] [CrossRef]

- Zhang, H.; Wei, X.P. Green Paradox or Forced Emission-reduction: Dual Effect of Environmental Regulation on Carbon Emissions. China Popul. Resour. Environ. 2014, 24, 21–29. [Google Scholar]

- Wang, Y.; Shen, N. Environmental Regulation and Environmental Productivity: The Case of China. Renew. Sustain. Energy Rev. 2016, 62, 758–766. [Google Scholar] [CrossRef]

- Lin, Y.F.; Liu, M.X.; Zhang, Q. Policy Burden and Enterprise’s Soft Budgetary Binding: A Case Study from China. Manag. World 2004, 36, 81–89. [Google Scholar]

- Lee, J.; Veloso, F.M.; Hounshell, D.A.; Edward, S.R. Forcing Technological Change: A Case of Automobile Emissions Control Technology Development in the US. Technovation 2010, 30, 249–264. [Google Scholar] [CrossRef]

- Greenstone, M.; List, J.; Syverson, C. The Effects of Environmental Regulation on the Competitiveness of U.S. Manufacturing. NBER Work. Pap. Ser. 2012, 18392. [Google Scholar] [CrossRef]

- Rubashkina, Y.; Galeotti, M.; Verdolini, E. Environmental Regulation and Competitiveness: Empirical Evidence on the Porter Hypothesis from European Manufacturing Sectors. Energy Policy 2015, 83, 288–300. [Google Scholar] [CrossRef] [Green Version]

- Lanoie, P.; Laurent-Lucchetti, J.; Johnstone, N.; Ambec, S. Environmental Policy, Innovation and Performance: New Insights on the Porter Hypothesis. J. Econ. Manag. Strategy 2011, 20, 803–842. [Google Scholar] [CrossRef] [Green Version]

- Franco, C.; Marin, G. The Effect of Within-sector, Upstream and Downstream Environmental Taxes on Innovation and Productivity. Environ. Resour. Econ. 2017, 66, 261–291. [Google Scholar] [CrossRef]

- Guo, L.; Qu, Y.; Tseng, M.L. The Interaction Effects of Environmental Regulation and Technological Innovation on Regional Green Growth Performance. J. Clean. Prod. 2017, 162, 894–902. [Google Scholar] [CrossRef]

- Ren, S.G.; Zheng, J.J.; Liu, D.H.; Chen, X.H. Does Emission Trading System Improve Firm’s Total Factor Productivity-evidence from Chinese Listed Companies. China Ind. Econ. 2019, 5, 5–23. [Google Scholar]

- Deng, Y.P.; Wang, L.; Zhou, W.J. Does Environmental Regulation Promote Green Innovation Capability?—Evidence from China. Static. Res. 2021, 38, 76–86. [Google Scholar]

- Ashford, N.A. Government Strategies and Policies for Cleaner Production. United Nations Environment Program: Industry and Environment. 1994. Available online: https://dspace.mit.edu/handle/1721.1/1560 (accessed on 24 March 2022).

- Renning, K.; Ziegler, A.; Ankele, K.; Hoffman, E. The Influence of Different Characteristics of the EU Environmental Management and Auditing Scheme on Technical Environmental Innovations and Economic Performance. Ecol. Econ. 2006, 57, 45–59. [Google Scholar] [CrossRef]

- Liu, W.M. The Path of Environmental Pollution Control and Sustainable Growth: Terminal Control or Source Control. Econ. Rev. 2014, 6, 41–53. [Google Scholar]

- Olley, G.S.; Pakes, A. The Dynamics of Productivity in the Telecommunications Equipment Industry. Econometrica 1996, 64, 1263–1297. [Google Scholar] [CrossRef]

- Levinsohn, J.; Petrin, A. Estimating Production Functions Using Inputs to Control for Unobservables. Rev. Econ. Stud. 2003, 70, 317–341. [Google Scholar] [CrossRef]

- Han, C.; Chen, Z.; Wang, Z. Study on the Mechanism of Firm’s Pollution Reduction under the Constraint of Energy-saving Target. China Ind. Econ. 2020, 10, 43–61. [Google Scholar]

- Brandt, L.; Van Biesebroeck, J.; Zhang, Y. Creative Accounting or Creative Destruction? Firm-level Productivity Growth in Chinese Manufacturing. J. Dev. Econ. 2012, 97, 339–351. [Google Scholar] [CrossRef] [Green Version]

- Jacobson, L.S.; Lalonde, R.J.; Sullivan, D.G. Earnings losses of displaced workers. Am. Econ. Rev. 1993, 83, 685–709. [Google Scholar]

| Variables | Observations | Mean | S.D. | Min | Max |

|---|---|---|---|---|---|

| DID | 177,505 | 0.017 | 0.129 | 0 | 1 |

| COD | 177,505 | 1.233 | 4.281 | 0 | 28.133 |

| 177,505 | 2.448 | 5.929 | 0 | 40.259 | |

| TFP_OP | 177,505 | 1.593 | 1.058 | −7.700 | 7.779 |

| TFP_LP | 177,505 | 6.399 | 1.207 | −2.859 | 12.617 |

| GEQ | 177,505 | 0.847 | 0.789 | 0 | 7.171 |

| SEQ | 177,505 | 0.166 | 0.413 | 0 | 4.454 |

| GCA | 177,505 | 6.234 | 4.449 | 0 | 21.172 |

| SCA | 177,505 | 0.515 | 1.375 | 0 | 14.815 |

| WEQ | 177,505 | 0.522 | 0.494 | 0 | 7.601 |

| WCA | 177,505 | 3.218 | 3.215 | 0 | 15.113 |

| INV | 177,505 | 7.635 | 1.931 | −4.224 | 16.812 |

| DEP | 177,505 | 6.819 | 1.805 | −0.121 | 15.144 |

| DEP_R | 177,505 | 5.999 | 5.231 | 0 | 33.246 |

| EFF | 177,505 | −7.152 | 1.579 | −14.756 | 2.478 |

| CLE | 177,505 | 2.113 | 13.669 | 0 | 100 |

| REC | 177,505 | 27.721 | 31.384 | 0 | 100 |

| EO | 177,505 | 0.166 | 0.372 | 0 | 1 |

| SZ | 177,505 | 9.360 | 1.679 | −0.121 | 16.957 |

| ES | 177,505 | 0.201 | 0.400 | 0 | 1 |

| DAR | 177,505 | 0.646 | 0.292 | 0.025 | 1.577 |

| DC | 177,505 | 3.088 | 3.445 | 0.140 | 38.382 |

| Variables | COD | TFP_OP | TFP_LP | |

|---|---|---|---|---|

| (1) | (2) | (3) | (4) | |

| DID | −1.705 *** | −0.340 *** | 0.242 *** | 0.267 *** |

| (0.040) | (0.073) | (0.008) | (0.010) | |

| EO | 0.030 | 0.064 | −0.042 *** | −0.013 |

| (0.049) | (0.056) | (0.014) | (0.014) | |

| SZ | −0.115 *** | −0.250 *** | −0.235 *** | 0.019 |

| (0.043) | (0.040) | (0.017) | (0.018) | |

| ES | −0.051 * | −0.086 ** | 0.015 * | 0.036 *** |

| (0.027) | (0.039) | (0.009) | (0.009) | |

| DAR | 0.071 | 0.193 * | −0.233 *** | −0.238 *** |

| (0.062) | (0.108) | (0.020) | (0.021) | |

| DC | 0.002 | 0.004 | −0.002 | −0.003 ** |

| (0.005) | (0.009) | (0.001) | (0.002) | |

| Fixed variables | Yes | Yes | Yes | Yes |

| Observations | 150,195 | 151,118 | 153,237 | 153,237 |

| R-squared | 0.712 | 0.612 | 0.664 | 0.747 |

| Variables | GEQ | SEQ | WEQ | GCA | SCA | WCA |

|---|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | (5) | (6) | |

| DID | 0.097 *** | 0.016 *** | −0.033 *** | 1.034 *** | 0.029 ** | 0.729 *** |

| (0.006) | (0.005) | (0.007) | (0.020) | (0.014) | (0.057) | |

| EO | 0.009 | 0.005 | −0.001 | 0.010 | 0.006 | −0.029 |

| (0.007) | (0.006) | (0.005) | (0.050) | (0.022) | (0.030) | |

| SZ | 0.034 *** | 0.011 *** | 0.015 *** | 0.112 *** | 0.021 *** | 0.096 *** |

| (0.006) | (0.002) | (0.002) | (0.021) | (0.007) | (0.012) | |

| ES | 0.007 | 0.001 | 0.005 | 0.022 | −0.013 | 0.062 *** |

| (0.005) | (0.004) | (0.003) | (0.041) | (0.013) | (0.016) | |

| DAR | −0.004 | 0.002 | −0.007 | 0.033 | 0.013 | −0.058 |

| (0.013) | (0.006) | (0.007) | (0.092) | (0.026) | (0.040) | |

| DC | −0.001 | −0.000 | −0.001 | −0.008 | 0.000 | −0.014 ** |

| (0.001) | (0.001) | (0.001) | (0.006) | (0.002) | (0.005) | |

| Observations | 148,071 | 118,090 | 147,416 | 128,160 | 117,840 | 147,492 |

| R-squared | 0.783 | 0.684 | 0.769 | 0.722 | 0.605 | 0.800 |

| Variables | INV | DEP | DEP_R | EFF |

|---|---|---|---|---|

| (1) | (2) | (3) | (4) | |

| DID | 0.282 *** | 0.283 *** | 1.853 *** | 0.029 *** |

| (0.016) | (0.011) | (0.039) | (0.001) | |

| EO | −0.069 ** | −0.045 *** | −0.307 *** | 0.001 |

| (0.029) | (0.015) | (0.083) | (0.002) | |

| SZ | 0.854 *** | 0.550 *** | −0.669 *** | −0.980 *** |

| (0.018) | (0.011) | (0.059) | (0.002) | |

| ES | 0.027 ** | 0.066 *** | 0.155 *** | 0.005 *** |

| (0.013) | (0.011) | (0.045) | (0.001) | |

| DAR | −0.216 *** | 0.030 | 0.079 | −0.029 *** |

| (0.039) | (0.021) | (0.104) | (0.003) | |

| DC | −0.002 | −0.004 ** | −0.010 | −0.001 *** |

| (0.003) | (0.002) | (0.010) | (0.000) | |

| Observations | 91,883 | 145,870 | 156,576 | 153,352 |

| R-squared | 0.704 | 0.821 | 0.268 | 0.997 |

| Variables | CLE | REC |

|---|---|---|

| (1) | (2) | |

| DID | 0.570 *** | 2.547 *** |

| (0.089) | (0.239) | |

| EO | 0.128 | 0.593 |

| (0.158) | (0.434) | |

| SZ | 0.057 | 0.379 * |

| (0.048) | (0.226) | |

| ES | −0.045 | 0.533 *** |

| (0.111) | (0.194) | |

| DAR | 0.027 | 0.239 |

| (0.156) | (0.373) | |

| DC | −0.015 | 0.106 *** |

| (0.029) | (0.033) | |

| Observations | 91,634 | 141,008 |

| R-squared | 0.781 | 0.728 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Li, Y.; Shi, K.; Feng, Y. How Do Environmental Technology Standards Affect the Green Transformation? New Evidence from China. Int. J. Environ. Res. Public Health 2022, 19, 5883. https://doi.org/10.3390/ijerph19105883

Zhang X, Li Y, Shi K, Feng Y. How Do Environmental Technology Standards Affect the Green Transformation? New Evidence from China. International Journal of Environmental Research and Public Health. 2022; 19(10):5883. https://doi.org/10.3390/ijerph19105883

Chicago/Turabian StyleZhang, Xiufeng, Yan Li, Ke Shi, and Yanchao Feng. 2022. "How Do Environmental Technology Standards Affect the Green Transformation? New Evidence from China" International Journal of Environmental Research and Public Health 19, no. 10: 5883. https://doi.org/10.3390/ijerph19105883

APA StyleZhang, X., Li, Y., Shi, K., & Feng, Y. (2022). How Do Environmental Technology Standards Affect the Green Transformation? New Evidence from China. International Journal of Environmental Research and Public Health, 19(10), 5883. https://doi.org/10.3390/ijerph19105883