Environmental Regulation Intensity, Carbon Footprint and Green Total Factor Productivity of Manufacturing Industries

Abstract

:1. Introduction

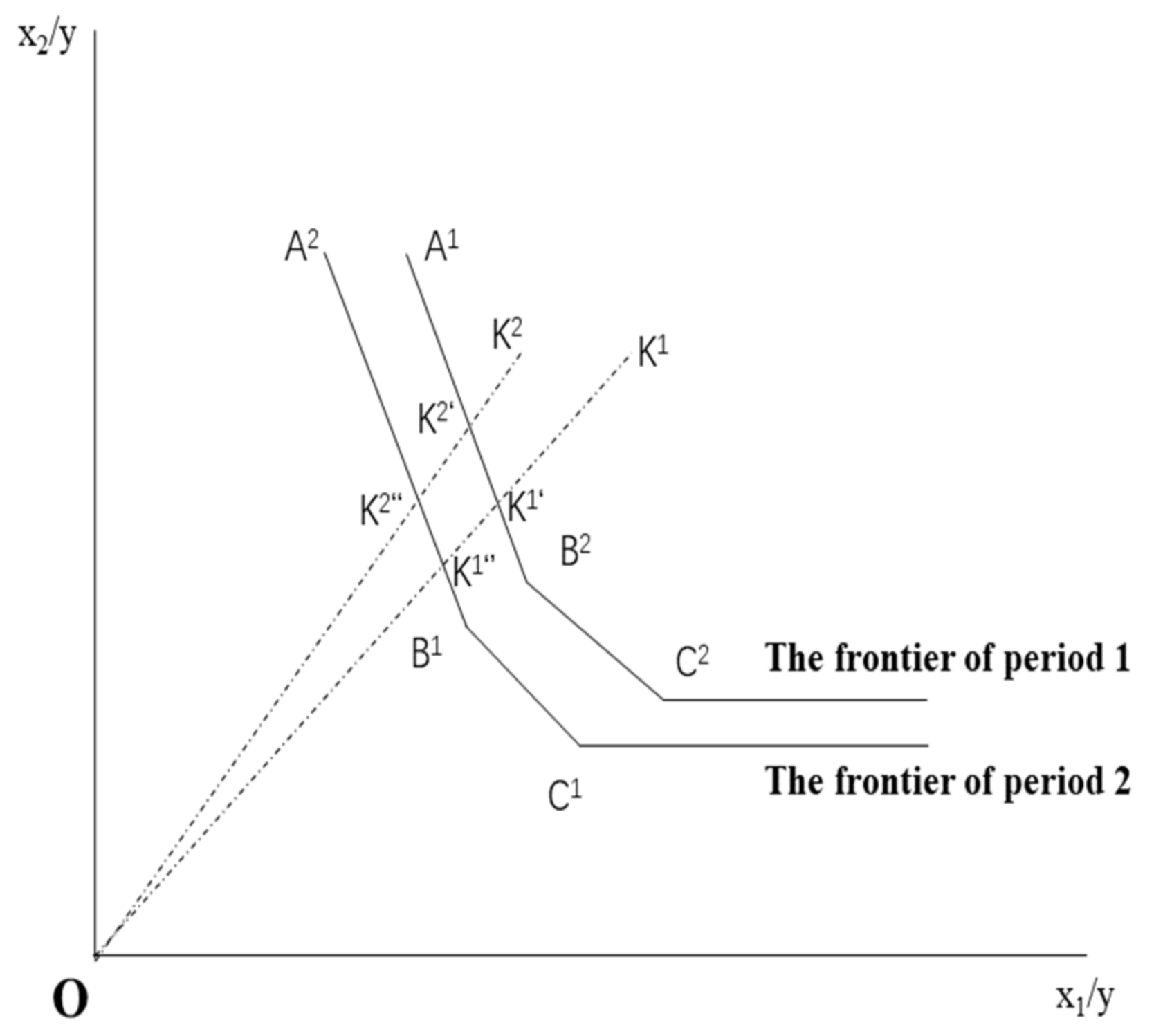

2. GTFP Calculation Based on MAXDEA

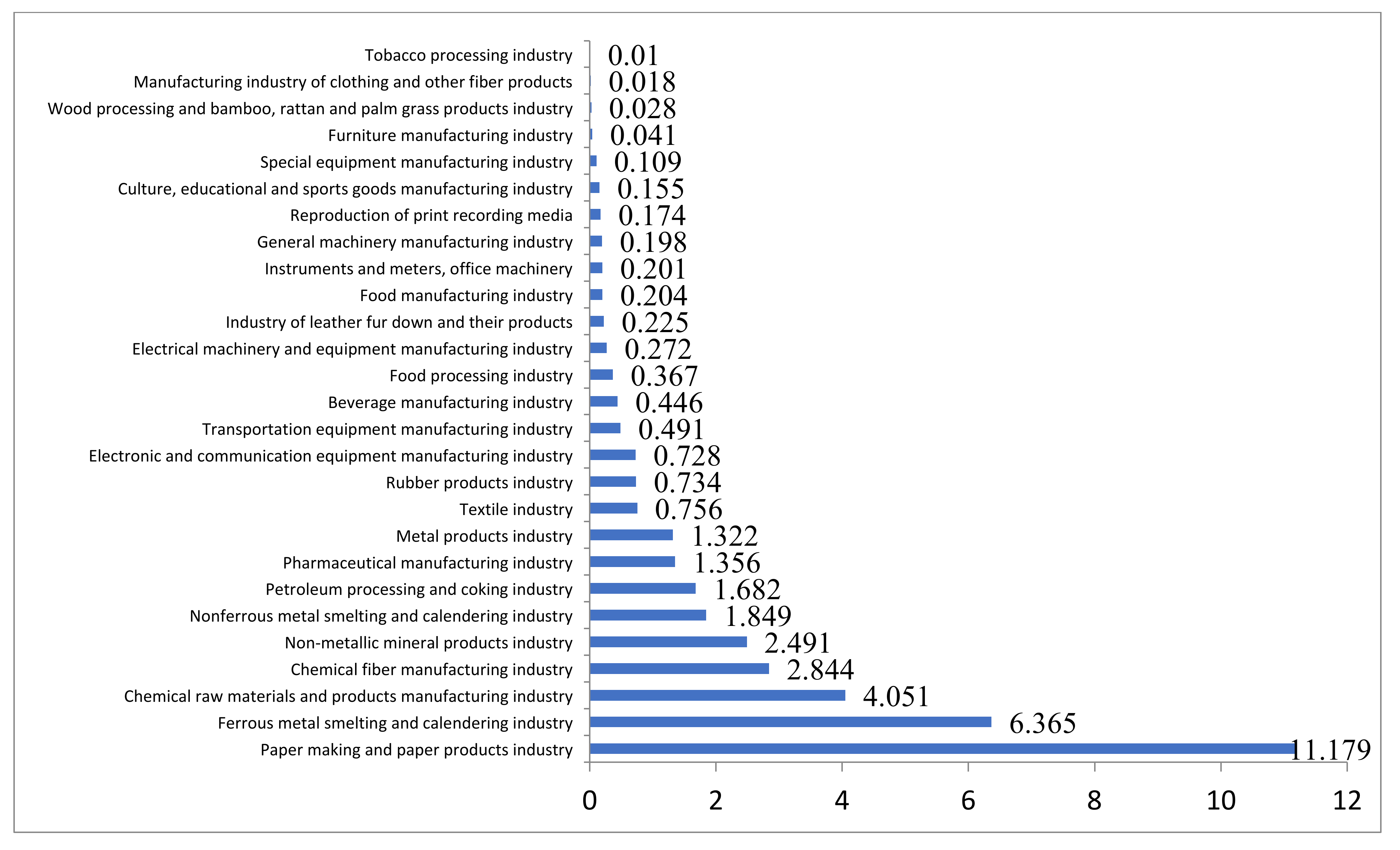

3. Calculation of Environmental Regulation Intensity

- To measure the intensity of environmental regulation by the number of industrial environmental policies. The disadvantage is that the environmental constraints are different between different industries and policies, which cannot be systematically measured, making the method too rough.

- To measure the pollution discharge of each industry. The disadvantage is that it is easy to be affected by the scale of the industry, nor can it reflect the environmental standards set by enterprises in the pollutant discharge treatment. The policy sets different environmental standards for different industries, which affect the cost of pollutant discharge.

- To use the per capita income of each industry as a measure of the intensity of environmental regulation. This view holds that the higher the per capita income in an industry, the higher the requirements for environmental regulation. However, environmental regulation affects the environmental cost of industries with no significant relationship with economic benefits. For high-tech industries with high incomes and low environmental pollution, such a view is one-sided and unconvincing.

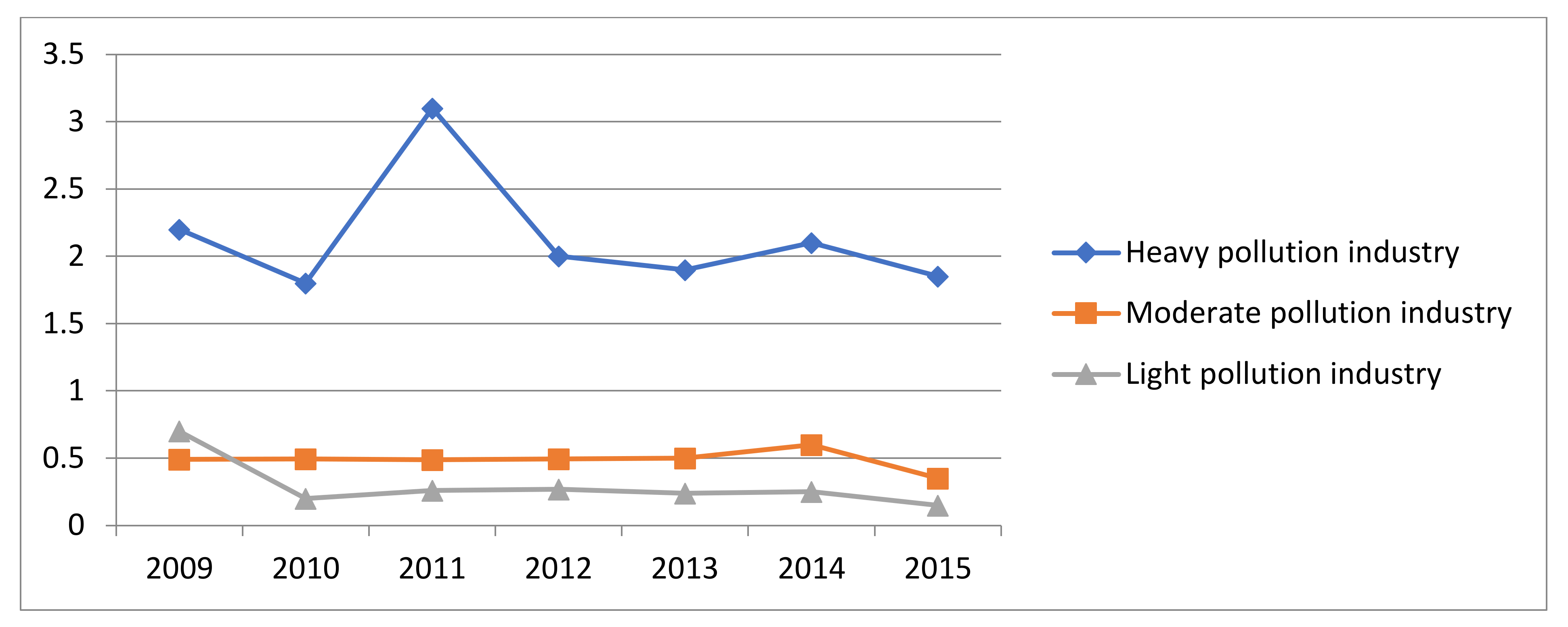

4. Empirical Results

5. Research Conclusions and Policy Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fu, J.; Li, L. An Empirical Study on Environmental Regulation, Factor Endowment and Industrial International Competitiveness. Manag. World 2010, 10, 87–98. (In Chinese) [Google Scholar]

- Song, M.; Wang, S. Environmental Regulation, Technological Progress and Economic Growth. Econ. Res. J. 2013, 3, 122–134. [Google Scholar]

- Zhang, C.; Lu, Y.; Guo, L.; Yu, T. Environmental Regulation Intensity and Production Technology Progress. Econ. Res. J. 2011, 2, 113–124. (In Chinese) [Google Scholar]

- Qi, S.; Lin, S.; Cui, J. Can environmental Rights Trading Market Induce Green Innovation? Econ. Res. 2018, 12, 129–143. (In Chinese) [Google Scholar]

- Tian, C.; Zhang, S. Source decomposition analysis of China’s industrial supply chain carbon footprint. J. Environ. Econ. 2019, 2, 58–75. (In Chinese) [Google Scholar]

- Li, L.; Tao, F. Selection of the optimal environmental Regulation intensity of China’s Manufacturing Industry. China Ind. Econ. 2012, 5, 70–82. (In Chinese) [Google Scholar]

- Chen, S. Rsearch on Energy Conservation and Emission Reduction, Structural Adjustment and Transformation of Industrial Development Mode; Peking University Press: Beijing, China, 2010. (In Chinese) [Google Scholar]

- Li, B.; Peng, X.; Ouyang, M. Environmental regulation, green total factor productivity and the transformation of China’s industrial development pattern: An empirical study based on the data of 36 industrial sectors. China Ind. Econ. 2013, 4, 56–68. (In Chinese) [Google Scholar]

- Li, L.; Tao, F. GTFP of pollution-intensive Industries and its influencing Factors. Economist 2011, 12, 70–82. (In Chinese) [Google Scholar]

- Wang, B.; Zhu, N. Study on efficiency and Total factor Productivity of China’s listed Commercial Banks under the constraint of Non-performing Loans. Financ. Res. 2011, 1, 110–130. (In Chinese) [Google Scholar]

- Wang, B.; Wu, Y.; Yan, P. Regiona Environmental Efficiency and Environmental Total Factor Productivity Growth in China. Econ. Res. J. 2010, 5, 95–109. (In Chinese) [Google Scholar]

- Zhou, J.; Zhao, X. Research on China’s Total Factor Productivity and Sustainable Economic Growth. New Econ. J. 2006, 5, 90–93. (In Chinese) [Google Scholar]

- Zhang, C. The relationship between environmental pollution and economic growth. Stat. Res. 2011, 28, 59–67. (In Chinese) [Google Scholar] [CrossRef]

- Wang, X.; Liu, Q. Research on the impact of environmental regulation and industrial cluster on firms’ innovation input. Technol. Innov. Manag. 2019, 40, 320–325. (In Chinese) [Google Scholar]

- Zhao, H. The Impact of Environmental Regulation on Industrial Technology Innovation in China. Econ. Manag. 2007, 21, 57–61. (In Chinese) [Google Scholar]

- Li, Q.; Nie. Environmental regulation and regional technological innovation: An empirical analysis based on China’s provincial panel data. Econ. Manag. 2009, 4, 18–23. [Google Scholar]

- Wu, G. An empirical analysis of the impact of China’s environmental protection intensity on industrial competitiveness—Taking China’s paper industry as an example. East China Econ. Manag. 2007, 11, 34–38. (In Chinese) [Google Scholar]

- Wang, B.; Wu, Y.; Yan, P. Environmental Regulation and Total Factor Productivity Growth: An Empirical Study of APEC. Econ. Res. J. 2008, 5, 19–33. (In Chinese) [Google Scholar]

- Song, M.; Yang, J. China’s energy efficiency total factor Productivity decomposition and its influencing factors: An empirical study based on China’s provincial panel data. J. Guangdong Univ. Adm. 2010, 22, 73–78. [Google Scholar]

- Marconi, D. Environmental Regulation and Revealed Comparative Advantages in Europe: Is China a Pollution Haven? Rev. Int. Econ. 2012, 20, 616–635. [Google Scholar] [CrossRef]

- Antweiler, W.; Copeland, B.R.; Taylor, M.S. Is Free Trade Good for the Environment? Am. Econ. Rev. 2001, 91, 877–908. [Google Scholar] [CrossRef] [Green Version]

- Berman, E.; Bui, L.T.M. Environmental Regulation and Productivity: Evidence from Oil Refineries. Rev. Econ. Stat. 2001, 83, 498–510. [Google Scholar] [CrossRef] [Green Version]

- Campbell, N. Does Trade Liberalization Make the Porter Hypothesis Less Relevent? Int. J. Bus. Econ. 2003, 2, 129. [Google Scholar]

- Chambers, R.G.; Chung, Y. Benefie and Distance Functions. J. Econ. Theory 1996, 70, 407–419. [Google Scholar] [CrossRef]

- Cole, M.A.; Elliott, R.J.R. Determining the Trade Environment Composition Effect:The Role of Capital, Labor and Environment Regulation. J. Environ. Econ. Manag. 2003, 46, 363–383. [Google Scholar] [CrossRef]

- Stanwick, P.A.; Stanwick, S.D. The relationship between corporate social performance and organizational size financial performance and environmental performance: An empirical examination. J. Bus. Ethics 1998, 17, 195–204. [Google Scholar] [CrossRef]

- Stiel, B.; Victor, D.G.; Nelson, R.R. Technological Innovation and Economic Performance; Princeton University Press: Princeton, NJ, USA, 2002; pp. 347–366. [Google Scholar]

- Fleishman, L.J.; Leal, M.; Persons, M.H. Habitat light and dewlap color diversity in four species of Puerto Rican anoline lizards. J. Comp. Physiol. A 2009, 195, 1043–1060. [Google Scholar] [CrossRef]

- Kolstad, A. Imprisonment as rehabilitation: Offenders assessment of why it does not work. J. Crim. Justice 1996, 24, 323–335. [Google Scholar] [CrossRef]

- Wang, M.; Liao, G.; Li, Y. The Relationship between Environmental Regulation, Pollution and Corporate Environmental Responsibility. Int. J. Environ. Res. Public Health 2021, 18, 8018. [Google Scholar] [CrossRef]

- Li, T.; Ma, J.; Mo, B. Does Environmental Policy Affect Green Total Factor Productivity? Quasi-Natural Experiment Based on China’s Air Pollution Control and Prevention Action Plan. Int. J. Environ. Res. Public Health 2021, 18, 8216. [Google Scholar] [CrossRef]

- Hoang, E.C.; Hoxha, I. A tale of two emerging market economies: Evidence from payout smoothing in China and Taiwan. Int. J. Manag. Financ. 2021, 17, 361–376. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, Y.; Zhang, L. Opportunity Cost of Environmental Regulation in China’s Industrial Sector. Int. J. Environ. Res. Public Health 2021, 18, 8579. [Google Scholar] [CrossRef]

- Fakher, H.A. Investigating the determinant factors of environmental quality (based on ecological carbon footprint index). Env. Sci. Pollut. Res. 2019, 26, 10276–10291. [Google Scholar] [CrossRef]

- Hoang, E.; Hoxha, I. An international study of the response of corporate payout policy. Int. J. Manag. Financ. 2019, 15, 335–349. [Google Scholar] [CrossRef]

- Aşıcı, A.A.; Acar, S. How does environmental regulation affect production location of non-carbon ecological footprint? J. Clean. Prod. 2018, 178, 927–936. [Google Scholar] [CrossRef]

- Brandt, L.; van Biesebroeck, J.; Zhang, Y. Creative accounting or creative destruction? Firm-level productivity growth (In Chinese) manufacturing. J. Dev. Econ. 2012, 97, 339–351. [Google Scholar] [CrossRef] [Green Version]

| Model | Data | Variable | Source and Interpretation |

|---|---|---|---|

| SBM-MALMQUIST | Expected output | Desirable output | Using the total industrial output value of 27 manufacturing industries in 2009–2015. The basic data comes from China Industrial Statistical Yearbook, which have been converted into the constant price in 2000 according to the price index. |

| Unexpected output | Undesired output | In order to measure the green economy efficiency of manufacturing industry more reasonably, this paper selects 27 items of manufacturing wastewater, solid waste and waste gas (carbon dioxide, sulfur dioxide) as the undesirable outputs. (In MAXDEA, data can not be identified as unexpected output, so the above three types of data are counted into the expected output in a negative way, equivalent to the unexpected output). The above data are obtained from China Industrial Statistical Yearbook. | |

| SBM-MALMQUIST | Investment | Input | Previous scholars set the input variables as capital input and labor input but lack consideration for environmental resource consumption. Therefore, this paper puts the consumption of environmental resources in manufacturing industry into the category of efficiency measure, that is, adding the data of energy input. |

| Capital stock | Capital stock | As an important variable in studying GTFP, there is no direct data. Estimate is required. As an important variable in the study of GTFP, there is no direct data, which requires estimate. This paper adopts the perpetual inventory method, taking 2008 as the base year of capital stock, referring to the calculation data of Brandt [37]. The depreciation rate is calculated according to the data of China Industrial Statistical Yearbook in 2009 to 2015. The constant price of current year investment is obtained using the difference between the original value of fixed assets to construct the sequence of investment amount, and converting it into the constant price of 2008 according to the price index of investment goods of the year as the investment amount of that year. | |

| Regression model | Green total factor productivity | GTFP | According to the SBM-MALMQUIST model, GTFP of 27 manufacturing industries in 2010 to 2015 is obtained by MAXDEA. |

| Direct carbon footprint | CF | According to the energy consumption data in the China Energy Statistical Yearbook, the main energy consumption of various industries in China is selected. Using a unified conversion standard, the energy consumption is converted into standard coal consumption, which is the direct carbon footprint discussed in this paper. | |

| Regression model | Environmental regulation intensity | ER | The accurate measurement of environmental regulation intensity is the basis of empirical research on environmental regulation and GTFP. This paper establishes a measurement index system, and the environmental regulation intensity of each industry is obtained by weighted average of the data indicators such as the standard rate of wastewater discharge, the removal rate of waste gas and the comprehensive utilization rate of solid waste. |

| Ratio of cost-profit | RCP | It reflects the ratio of cost input and profit of each industry, and the cost of each industry can be obtained in the statistical yearbook. | |

| Full-staff labor productivity | LP | The ratio of industrial added value to all employees in the corresponding industry reflects the average value created in each industry per capita every year. The data are all from China Industrial Statistical Yearbook. | |

| Energy productivity | EP | The ratio of industrial added value to the energy consumption of the corresponding industry. The data are all from China Industrial Statistical Yearbook. |

| Industry/Year | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|---|---|

| Food processing industry | 1.000 | 1.000 | 1.000 | 0.627 | 0.771 | 0.797 |

| Food manufacturing industry | 0.519 | 0.550 | 0.532 | 0.458 | 0.479 | 1.000 |

| Beverage manufacturing industry | 1.000 | 1.000 | 1.000 | 0.566 | 0.618 | 0.660 |

| Tobacco processing industry | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Textile industry | 0.386 | 0.354 | 0.366 | 0.294 | 0.347 | 0.432 |

| Manufacturing industry of clothing and other fiber products | 0.304 | 0.309 | 0.179 | 0.121 | 0.199 | 0.186 |

| Industry of leather fur down and their products | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Wood processing and bamboo, rattan and palm grass products industry | 0.158 | 0.146 | 0.170 | 0.096 | 0.298 | 0.373 |

| Furniture manufacturing industry | 0.246 | 1.000 | 0.162 | 0.089 | 0.075 | 0.085 |

| Paper making and paper products industry | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Reproduction of print recording media | 0.065 | 0.079 | 0.076 | 0.058 | 0.097 | 0.146 |

| Culture, educational and sports goods manufacturing industry | 0.117 | 0.154 | 0.047 | 0.042 | 0.037 | 1.000 |

| Petroleum processing and coking industry | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Chemical raw materials and products manufacturing industry | 0.625 | 1.000 | 1.000 | 0.514 | 0.703 | 1.000 |

| Pharmaceutical manufacturing industry | 0.450 | 0.439 | 0.453 | 0.321 | 0.377 | 0.387 |

| Chemical fiber manufacturing industry | 0.706 | 0.622 | 0.577 | 0.437 | 0.561 | 0.575 |

| Rubber products industry | 0.141 | 0.158 | 0.171 | 0.201 | 0.211 | 0.306 |

| Non-metallic mineral products industry | 1.000 | 0.172 | 0.214 | 0.243 | 0.460 | 1.000 |

| Ferrous metal smelting and calendering industry | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Nonferrous metal smelting and calendering industry | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Metal products industry | 0.191 | 0.238 | 0.242 | 0.269 | 0.240 | 0.330 |

| General machinery manufacturing industry | 0.145 | 0.095 | 0.080 | 0.064 | 0.086 | 0.085 |

| Special equipment manufacturing industry | 0.169 | 0.113 | 0.134 | 0.096 | 0.125 | 0.115 |

| Transportation equipment manufacturing industry | 0.289 | 0.138 | 0.148 | 0.133 | 0.161 | 0.181 |

| Electrical machinery and equipment manufacturing industry | 1.000 | 0.216 | 0.104 | 0.078 | 0.149 | 0.142 |

| Electronic and communication equipment manufacturing industry | 0.207 | 1.000 | 0.209 | 0.083 | 0.136 | 0.114 |

| Instruments and meters, office machinery | 0.205 | 0.118 | 0.068 | 0.040 | 0.093 | 0.070 |

| Target Level | Criterion Level | Scheme Level |

|---|---|---|

| Environmental regulation intensity | Wastewater | Discharge amount of wastewater |

| Amount of wastewater that reaches the standard | ||

| Solid waste | Discharge amount of solid waste | |

| Utilization of solid waste | ||

| Waste gas | Amount of waste gas treatment equipment | |

| Amount of waste gas emission |

| Industry/Year | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|---|---|---|

| Food processing industry | 0.423 | 0.319 | 0.423 | 0.422 | 0.479 | 0.497 | 0.154 |

| Food manufacturing industry | 0.147 | 0.413 | 0.396 | 0.261 | 0.280 | 0.347 | 0.205 |

| Beverage manufacturing industry | 0.389 | 0.384 | 0.792 | 0.503 | 0.530 | 0.650 | 0.140 |

| Tobacco processing industry | 0.151 | 0.053 | 0.128 | 0.059 | 0.047 | 0.066 | 0.054 |

| Textile industry | 1.389 | 1.472 | 1.002 | 1.072 | 1.179 | 1.295 | 0.256 |

| Manufacturing industry of clothing and other fiber products | 2.600 | 0.044 | 0.075 | 0.060 | 0.057 | 0.057 | 0.035 |

| Industry of leather fur down and their products | 0.366 | 0.476 | 0.245 | 0.296 | 0.269 | 0.241 | 0.195 |

| Wood processing and bamboo, rattan and palm grass products industry | 0.109 | 0.038 | 0.089 | 0.069 | 0.056 | 0.075 | 0.035 |

| Furniture manufacturing industry | 0.780 | 0.128 | 0.076 | 0.050 | 0.040 | 0.062 | 0.090 |

| Paper making and paper products industry | 7.456 | 8.700 | 20.040 | 10.614 | 8.741 | 8.733 | 2.695 |

| Reproduction of print recording media | 0.322 | 0.500 | 0.104 | 0.149 | 0.118 | 0.132 | 0.248 |

| Culture, educational and sports goods manufacturing industry | 0.085 | 0.090 | 0.211 | 0.334 | 0.073 | 0.151 | 0.039 |

| Petroleum processing and coking industry | 2.351 | 1.710 | 0.832 | 0.569 | 0.709 | 1.783 | 2.039 |

| Chemical raw materials and products manufacturing industry | 3.485 | 2.656 | 1.964 | 2.438 | 2.668 | 3.546 | 2.155 |

| Pharmaceutical manufacturing industry | 1.509 | 1.154 | 0.827 | 1.522 | 1.552 | 1.268 | 1.618 |

| Chemical fiber manufacturing industry | 3.830 | 0.894 | 3.257 | 0.888 | 1.523 | 1.558 | 6.378 |

| Rubber products industry | 0.213 | 0.154 | 0.636 | 0.694 | 0.656 | 1.001 | 1.066 |

| Non-metallic mineral products industry | 0.483 | 0.366 | 0.596 | 0.833 | 0.598 | 0.432 | 0.407 |

| Ferrous metal smelting and calendering industry | 0.536 | 0.832 | 0.659 | 0.693 | 0.721 | 1.095 | 1.199 |

| Nonferrous metal smelting and calendering industry | 0.198 | 0.131 | 1.749 | 0.267 | 0.138 | 0.325 | 0.331 |

| Metal products industry | 1.456 | 1.352 | 0.156 | 0.904 | 1.438 | 2.000 | 1.172 |

| General machinery manufacturing industry | 0.214 | 0.156 | 0.090 | 0.163 | 0.183 | 0.173 | 0.195 |

| Special equipment manufacturing industry | 0.112 | 0.104 | 0.051 | 0.114 | 0.104 | 0.148 | 0.129 |

| Transportation equipment manufacturing industry | 0.358 | 0.370 | 0.267 | 0.429 | 0.595 | 0.528 | 0.467 |

| Electrical machinery and equipment manufacturing industry | 0.175 | 0.181 | 0.176 | 0.258 | 0.339 | 0.337 | 0.229 |

| Electronic and communication equipment manufacturing industry | 0.524 | 0.461 | 0.588 | 1.015 | 0.397 | 0.103 | 0.031 |

| Instruments and meters, office machinery | 0.343 | 0.015 | 0.149 | 0.263 | 0.175 | 0.263 | 0.107 |

| CF (14) | GTFP (15) | GTFP (16) | GTFP (17) | GTFP (18) | GTFP (19) | |

|---|---|---|---|---|---|---|

| C. | 6.323 *** (40.302) | 0.460 *** (14.858) | 0.009 (0.919) | 0.162 (1.156) | 0.189 (1.345) | 0.144 (1.060) |

| ER. | 0.302 *** (2.649) | 0.050 *** (3.864) | 0.031 *** (2.449) | 0.031 *** (2.479) | 0.029 ** (2.278) | 0.019 * (1.628) |

| CF. | 0.073 *** (5.329) | 0.067 *** (4.651) | 0.065 *** (4.577) | 0.079 *** (5.544) | ||

| RCP. | −0.015 * (1.411) | −0.011 (−0.981) | −0.007 (−0.700) | |||

| LP. | −0.007 * (−1.762) | −0.006 (−1.569) | ||||

| EP. | −0.020 *** (−3.617) |

| Industry Category | Variable | Number of Observations | Average | Standard Deviation | Minimum Value | Maximum Value |

|---|---|---|---|---|---|---|

| Light pollution industry | TFP | 54 | 0.480 | 0.376 | 0.040 | 1.000 |

| ER | 54 | 0.263 | 0.380 | 0.040 | 2.600 | |

| CF | 54 | 5.519 | 1.349 | 3.020 | 7.720 | |

| RCP | 54 | 5.885 | 7.506 | 1.010 | 33.830 | |

| EP | 54 | 2.813 | 1.159 | 1.280 | 5.91 | |

| LP | 54 | 10.709 | 7.775 | 4.770 | 34.73 | |

| Moderate pollution industry | TFP | 60 | 0.362 | 0.348 | 0.040 | 1 |

| ER | 60 | 0.446 | 0.337 | 0.020 | 1.470 | |

| CF | 60 | 6.062 | 1.914 | 3.290 | 10.900 | |

| RCP | 60 | 3.126 | 1.957 | 0.210 | 7.94 | |

| EP | 60 | 14.001 | 7.157 | 3.170 | 31.5 | |

| LP | 60 | 8.101 | 2.176 | 2.360 | 13.78 | |

| Heavy pollution industry | TFP | 54 | 0.704 | 0.335 | 0.080 | 1 |

| ER | 54 | 2.343 | 3.436 | 0.100 | 20.040 | |

| CF | 54 | 7.764 | 1.91 | 4.900 | 11.090 | |

| RCP | 54 | 1.337 | 1.641 | 0.110 | 5.96 | |

| EP | 54 | 3.057 | 0.544 | 2.200 | 4.33 | |

| LP | 54 | 6.079 | 2.762 | 0.810 | 13.15 |

| Light Pollution Industry | Moderate Pollution Industry | Heavy Pollution Industry | ||||||

|---|---|---|---|---|---|---|---|---|

| ER | TFP (1) | TFP (2) | ER | TFP (1) | TFP (2) | ER | TFP | |

| C | 5.351 (26.442) | −0.165 (−1.209) | −0.424 ** (−2.310) | 4.927 (13.332) | −0.199 (−0.844) | −1.451 *** (−3.088) | 7.6 (25.352) | −0.024 (−0.114) |

| CF | 1.309 * (1.613) | 0.090 ** (2.035) | 0.388 *** (3.755) | 0.144 *** (3.015) | 1.471 (0.894) | 0.055 ** (1.898) | ||

| ER | 1.188 *** (4.062) | 1.170 *** (4.091) | 1.208 ** (2.461) | 0.824 * (1.734) | 0.046 *** (3.503) | |||

| ER2 | −0.430 *** (−3.548) | −0.434 *** (−3.692) | −0.722 ** (−2.106) | −0.466 (−1.410) | −0.054 *** (−2.520) | |||

| RCP | 0.014 (0.768) | 0.025 (1.357) | 0.044 * (1.838) | 0.099 *** (3.434) | −0.001 (−0.051) | |||

| LP | 0.090 (0.375) | −0.072 (−0.573) | −0.010 (−1.347) | −0.033 *** (−3.169) | 0.113 (1.428) | |||

| EP | 0.003 (0.247) | 0.021 (1.358) | 0.012 (0.423) | 0.119 *** (2.714) | −0.096 *** (−4.038) | |||

| Inflection point | 1.381 | 1.348 | 0.837 | 0.884 | 0.426 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Yan, Y. Environmental Regulation Intensity, Carbon Footprint and Green Total Factor Productivity of Manufacturing Industries. Int. J. Environ. Res. Public Health 2022, 19, 553. https://doi.org/10.3390/ijerph19010553

Wang L, Yan Y. Environmental Regulation Intensity, Carbon Footprint and Green Total Factor Productivity of Manufacturing Industries. International Journal of Environmental Research and Public Health. 2022; 19(1):553. https://doi.org/10.3390/ijerph19010553

Chicago/Turabian StyleWang, Lei, and Yu Yan. 2022. "Environmental Regulation Intensity, Carbon Footprint and Green Total Factor Productivity of Manufacturing Industries" International Journal of Environmental Research and Public Health 19, no. 1: 553. https://doi.org/10.3390/ijerph19010553

APA StyleWang, L., & Yan, Y. (2022). Environmental Regulation Intensity, Carbon Footprint and Green Total Factor Productivity of Manufacturing Industries. International Journal of Environmental Research and Public Health, 19(1), 553. https://doi.org/10.3390/ijerph19010553