Greenhouse Gas Emissions and Energy Consumption of Coastal Ecosystem Enhancement Programme through Sustainable Artificial Reefs in Galicia

Abstract

1. Introduction

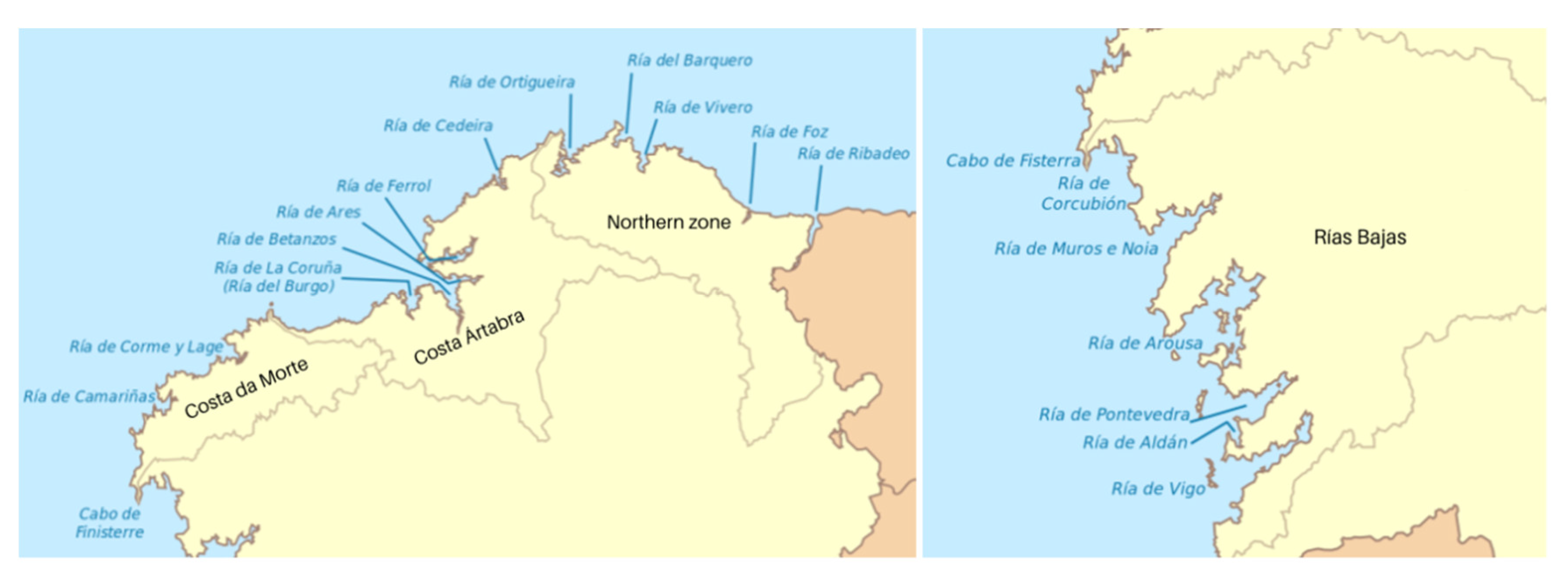

1.1. Coastal Ecosystem Enhancement Programme in Galicia

1.2. Objective

2. Materials and Methods

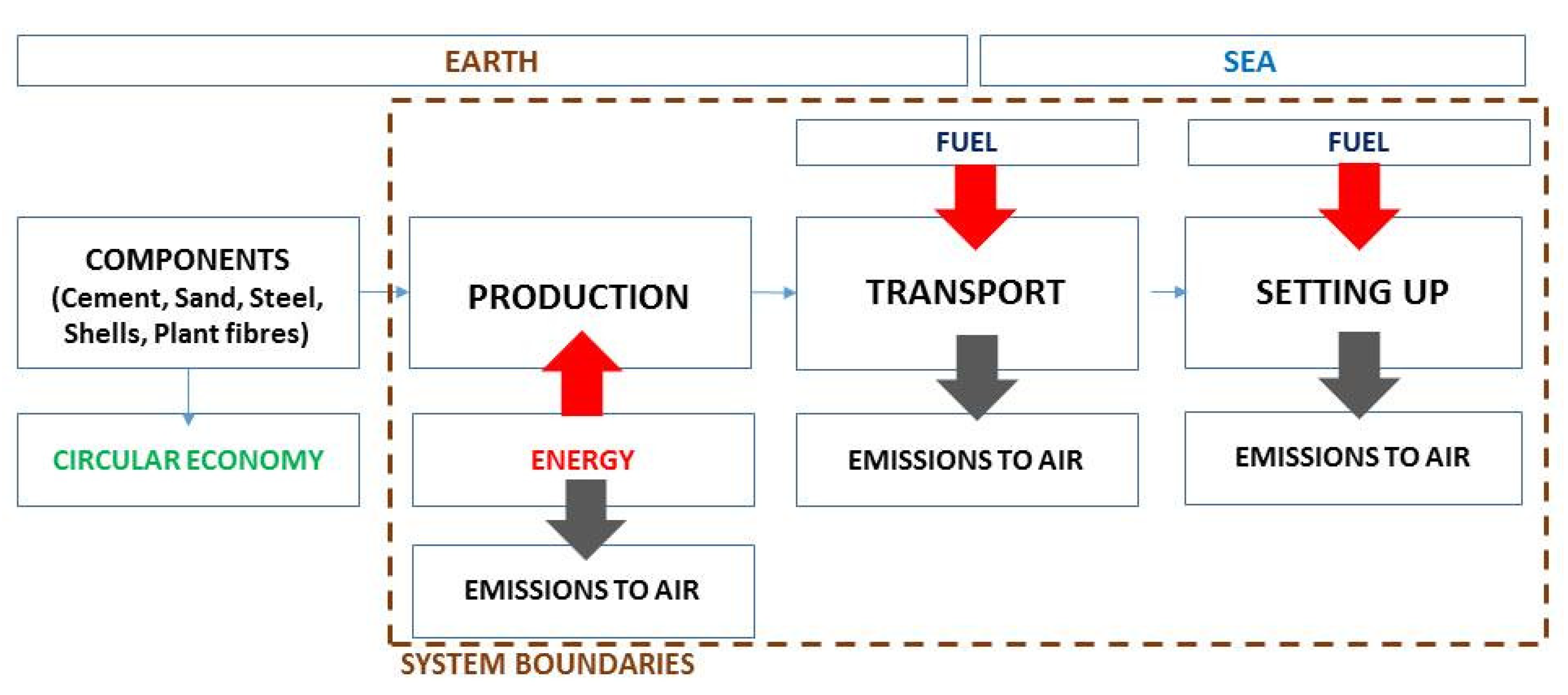

2.1. Environmental Impacts: General Information

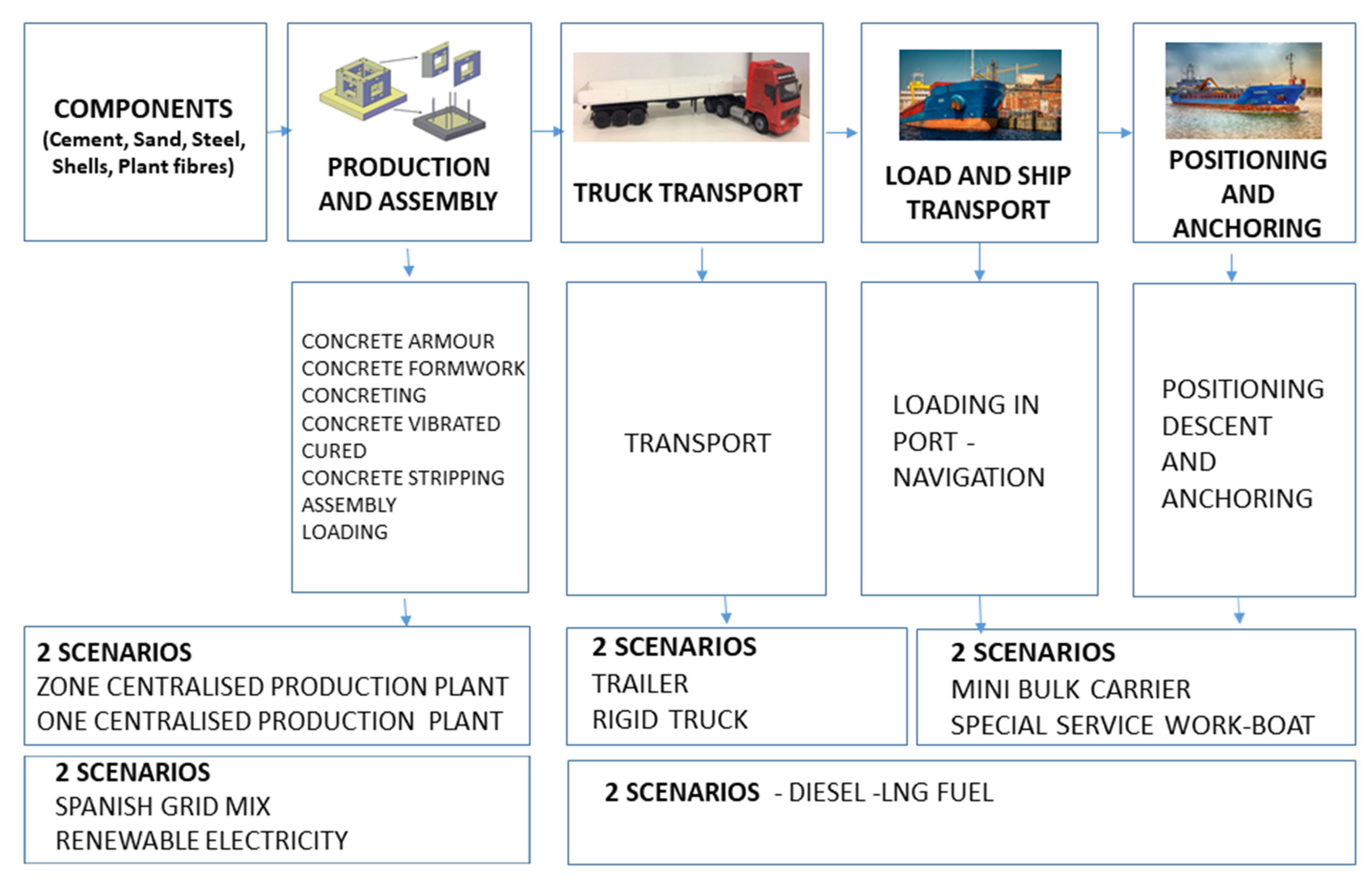

2.2. Manufacturing, Transport and Installation Processes: General Information

2.3. Galician Estuaries and Related Information

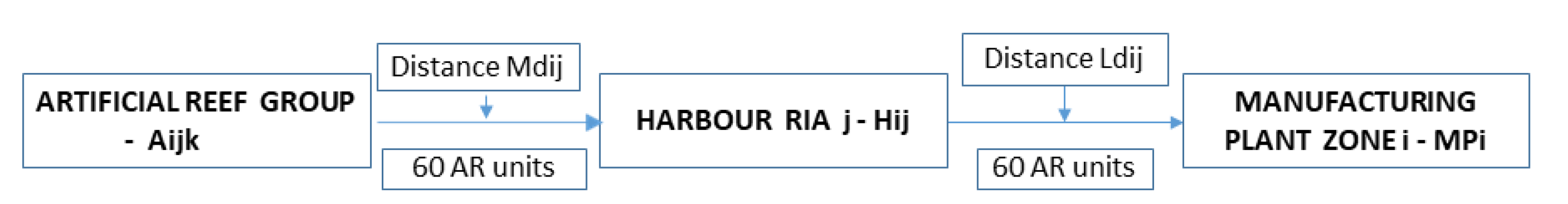

2.4. Determining the Location of the Manufacturing Plant

2.5. Determining GWP and CED

3. Results and Discussion

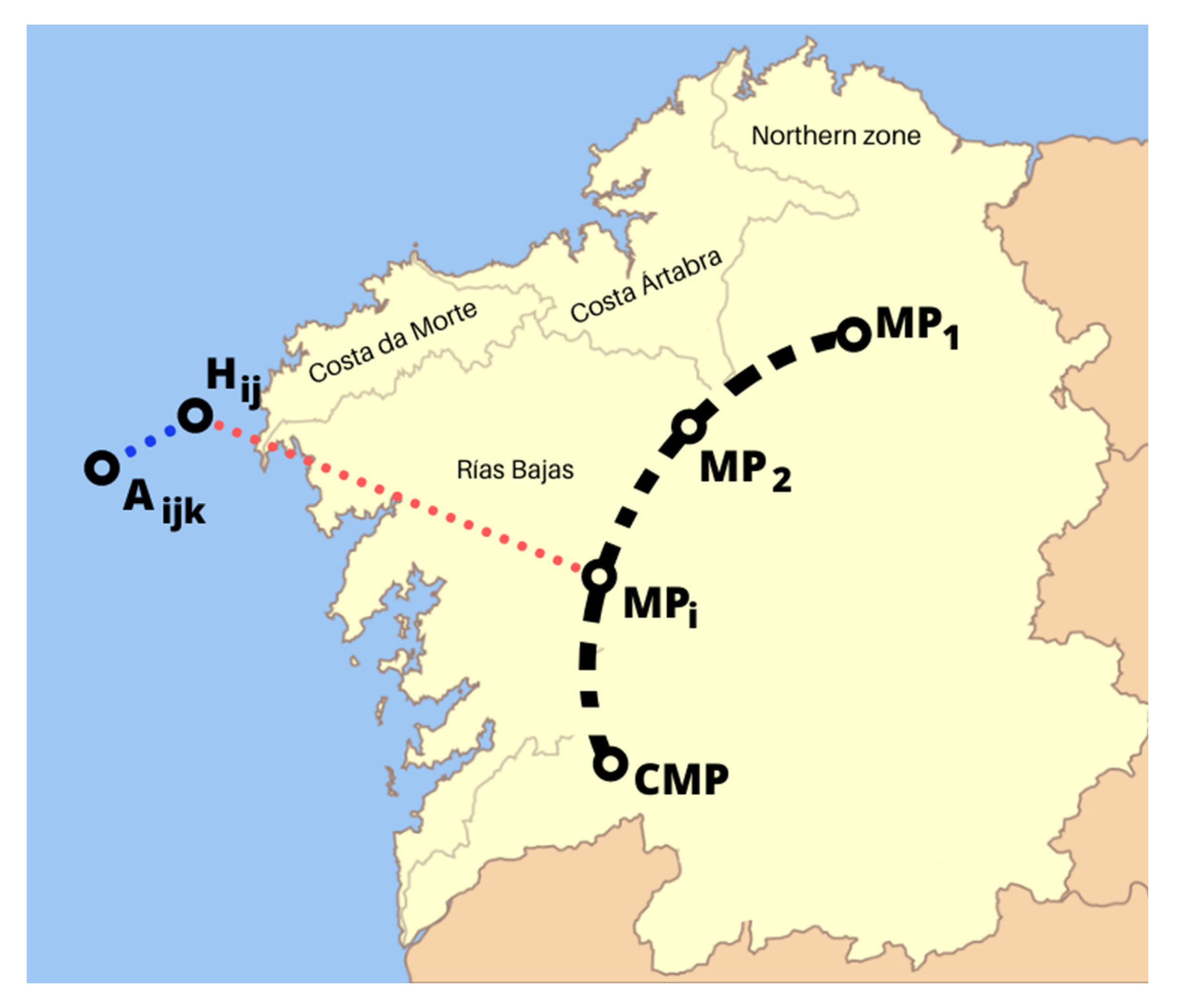

3.1. Location of the Manufacturing Plants

3.2. Results for the Manufacturing Process

3.3. Results for the Transport and Installation Phases

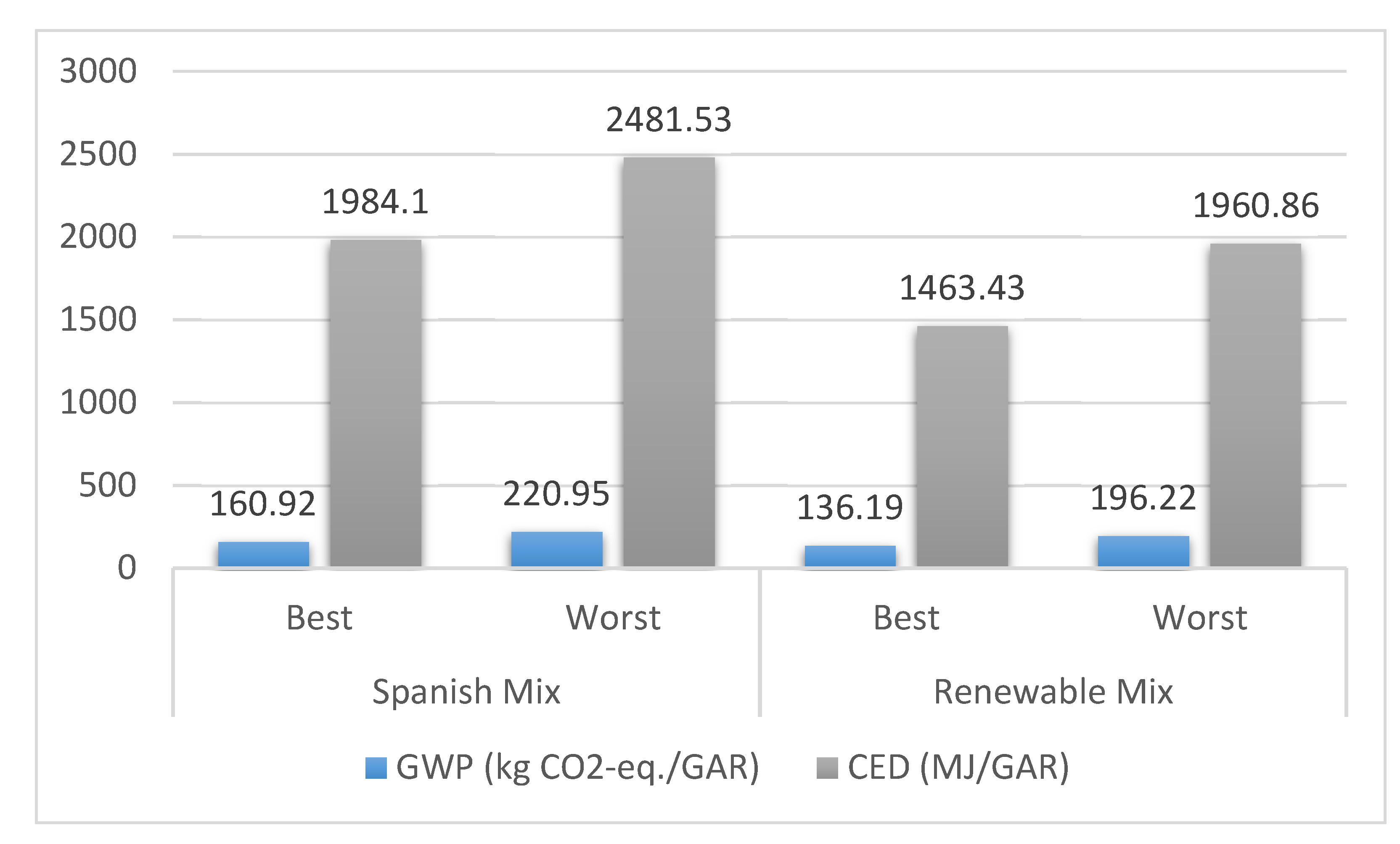

3.4. General Results

4. Conclusions

- The results show that the phase that has the greatest potential impact in contributing to GWP and CED is the maritime one. Road transport presents a considerable variability between the worst and best possible scenarios.

- The use of renewables in the electricity grid mix has a positive impact on the manufacturing of GAR units in terms of both GWP and CED indicators.

- In terms of road transport, the key factor is to reduce the distance. Consequently, production by zones and the articulated trailer resulted to be the best options (GWP and CED), since they imply the shortest distance transport.

- Manoeuvrability resulted to be more important than distance in terms of maritime transport and operations. Consequently, the special work boat obtained better results than mini bulk carrier for GWP and CED indicators.

- The use of LNG as fuel for vessel and truck engines lead to reductions in GHG emissions and energy consumption.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- González-Garcés, A.; Vila Martín, F.; Álvarez Salgado, X.A. La ría de Vigo. Una Aproximación Integral al Ecosistema Marino de la Ría de Vigo; Instituto de Estudios Vigueses: Pontevedra, Spain, 2008. [Google Scholar]

- Carral, L.; Rodriguez-Guerreiro, M.; Tarrio-Saavedra, J.; Alvarez-Feal, J.C.; Fraguela Formoso, J. Social interest in developing a Green modular artificial reef structure in concrete for the ecosystems of the Galician rías. J. Clean. Prod. 2018, 172, 1881–1898. [Google Scholar] [CrossRef]

- Carral, L.; Rodríguez-Guerreiro, M.J.; Vargas, A.; Arean, N.; Carballo, R.; Alvarez-Feal, C. Methology for positioning a group of green artificial reef based on a database management system, applied in the Estuary of Ares-Betanzos (NW Iberian Peninsula). J. Clean. Prod. 2019, 233, 1047–1060. [Google Scholar] [CrossRef]

- Ramos-Esplá, A.A.; Guillén, J.E.; Bayle, J.T.; Sánchez-Jerez, P. Artificial Anti-trawling Reefs off Alicante. In Artifical Reefs in European Seas; Jensen, A., Collins, K.J., Lockwood, A.P.M., Eds.; Kluber Academic Publishers: Southampton, UK, 2000; pp. 195–218. [Google Scholar]

- Carral, L.; Camba-Fabal, C.; Lamas-Galdo, I.; Rodriguez-Guerreiro, M.; Cartelle Barros, J.J. Assessment of the Materials Employed in Green Artificial Reefs for the Galician Estuaries in Terms of Circular Economy. Int. J. Environ. Res. Public Health 2020, 17, 8850. [Google Scholar] [CrossRef] [PubMed]

- Carral Couce, L.; Rodríguez Guerreiro, M.J.; Fraguela Formoso, J.A.; Álvarez-Feal, J.C.; Filgueira-Vizoso, A. Green artificial reef PROARR: Repopulation of coastal ecosystems and waste recycler of the maritime industries. In Proceedings of the 25th Pan-American Conference of Naval Engineering—COPINAVAL, Cartagena, Colombia, 16–19 October 2017; Springer International Publishing: Cham, Switzerland, 2019. [Google Scholar]

- Lamas-Galdo, I.; Townsed, P.; Rodriguez, M.; Castro-Santos, L.; Carral, L. Numerical model to analyze an artificial reef. In Proceedings of the VI International Ship Design & Naval Engineering Congress (CIDIN) and XXVI Pan-American Congress of Naval Engineering, Maritime Transportation and Port Engineering (COPINAVAL), Cartagena, Colombia, 13–15 March 2019; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar]

- Stenico de Campos, R.; Tadeu Simon, A.; de Campos Martins, F. Assessing the impacts of road freight transport on sustainability: A case study in the sugar-energy sector. J. Clean. Prod. 2019, 220, 995–1004. [Google Scholar] [CrossRef]

- Hong, J.; Gu, J.; Liang, X.; Liu, G.; Shen, G.; Qiping, G. Characterizing embodied energy accounting with a multi-dimensional framework: A study of China’s building sector. J. Clean. Prod. 2019, 215, 154–164. [Google Scholar] [CrossRef]

- European Environment Agency (EEA). Transporte. 2020. Available online: https://www.eea.europa.eu/es/themes/transport/intro (accessed on 9 March 2020).

- European Commission (EC). Cambio Climático: Qué Está Haciendo la UE. 2019. Available online: https://www.consilium.europa.eu/es/policies/climate-change/# (accessed on 17 December 2019).

- Albritton, D.L.; Meira-Filho, L.G. Climate Change 2001: The Scientific Basis—Contribution of Working Group I to the Third Assessment; Report of the Intergovernmental Panel on Climate Change (IPCC), Houghton, J.T., Ding, Y., Griggs, D.J., Noguer, M., van der Linden, P.J., Xiaosu, D., Eds.; Cambridge University Press: Cambridge, UK, 2001. [Google Scholar]

- Huijbregts, M.A.J.; Rombouts, L.J.A.; Hellweg, S.; Frischknecht, R.; Hendriks, J.A.; Van de Meent, D.; Ragas, A.J.; Reijnders, L.; Struijs, J. Is cumulative fossil energy demand a useful indicator for the environmental performance of Products? Environ. Sci Technol. 2006, 40, 641–648. [Google Scholar] [CrossRef] [PubMed]

- Boustead, I.; Hancock, G.F. Handbook of Industrial Energy Analysis; John Wiley & Sons: New York, NY, USA, 1979. [Google Scholar]

- Pimentel, D.; Hurd, L.E.; Bellotti, A.C.; Forster, M.J.; Oka, I.N.; Sholes, O.D.; Whitman, R.J. Food Production and the Energy Crisis. Science 1973, 182, 443–449. [Google Scholar] [CrossRef] [PubMed]

- Boschiero, M.; Zanotelli, D.; Ciarapica, F.; Fadanelli, L.; Tagliavini, M. Greenhouse gas emissions and energy consumption during the post-harvest life of apples as affected by storage type, packaging and transport. J. Clean. Prod. 2019, 220, 45–56. [Google Scholar] [CrossRef]

- Gayo Romero, J.L. Arrecifes artificiales: Estructuras llenas de vida. Inf. Construcción 1998, 50, 5–16. [Google Scholar] [CrossRef]

- Gobierno de España. Ministerio del Interior. Reglamento sobre vehículos pesados, prioritarios, especiales, de transporte de persona y mercancías y tramitación administrativa. 2015. Available online: http://www.dgt.es/es/ (accessed on 12 March 2020).

- López-Davalillo, J. Geografía Regional de España; UNED: Madrid, Spain, 2014; pp. 91–93. [Google Scholar]

- Carro-Paz, R.; González-Gómez, D. Localización de Instalaciones; Universidad Nacional del Mar del Plata: Buenos Aires, Argentina, 2013. [Google Scholar]

- Ballou, R.H. Logística: Administración de la Cadena de Suministro, 5th ed.; Pearson Educación: México, Mexico, 2004. [Google Scholar]

- International Energy Agency (IEA). Spain—Energy System Overview. 2018. Available online: https://www.iea.org/countries/spain (accessed on 28 February 2020).

- Cartelle Barros, J.J.; Lara Coira, M.; de la Cruz López, M.; del Caño Gochi, A.; Soares, I. Probabilistic multicriteria environmental assessment of power plants: A global approach. Applied Energy 2020, 260, 114344. [Google Scholar] [CrossRef]

- Raugei, M.; Leccisi, E. A comprehensive assessment of the energy performance of the full range of electricity generation technologies deployed in the United Kingdom. Energy Policy 2016, 90, 46–59. [Google Scholar] [CrossRef]

- Corona, B.; San Miguel, G. Environmental analysis of a Concentrated Solar Power (CSP) plant hybridised with different fossil and renewable fuels. Fuel 2015, 145, 63–69. [Google Scholar] [CrossRef]

- García, R.; Marques, P.; Freire, F. Life-cycle assessment of electricity in Portugal. Appl. Energy 2014, 134, 563–572. [Google Scholar] [CrossRef]

- Corona, B.; San Miguel, G.; Cerrajero, E. Life cycle assessment of concentrated solar power (CSP) and the influence of hybridising with natural gas. Int. J. Life Cycle Assess. 2014, 19, 1264–1275. [Google Scholar] [CrossRef]

- Lechón, Y.; De la Rua, C.; Sáez, R. Life Cycle Environmental Impacts of Electricity Production by Solar thermal Power Plants in Spain. J. Sol. Energy Eng. 2008, 130, 021012-1. [Google Scholar] [CrossRef]

- Carral, L.; Fernández-Garrido, C.; Vega, A.; Sabonge, R. Importance of the Panama canal in the reduction of CO2 emissions from maritime transport. Int. J. Sustain. Transp. 2019, 14, 819–832. [Google Scholar] [CrossRef]

- Puig, R.; Fullana-i-Palmer, P.; Baquero, G.; Riba, J.-R.; Bala, A. A Cumulative Energy Demand indicator (CED), life cycle based, for industrial waste management decision making. Waste Manag. 2013, 33, 2789–2797. [Google Scholar] [CrossRef] [PubMed]

- Barber, A. New Zealand Fuel and Electricity Total Primary Energy and Life Cycle Greenhouse Gas Emission Factors 2010. 2011. Available online: http://agrilink.co.nz/wp-content/uploads/2016/08/Fuel-LCA-emission-factors.pdf (accessed on 27 September 2019).

- Bengtsson, S.; Andersson, K.; Fridell, K. Life Cycle Assessment of Marine Fuels-A Comparative Study of Four Fossil Fuels for Marine Propulsion; Chalmers University of Techonology: Gothenburgm, Sweden, 2011. [Google Scholar]

- Bengtsson, S.; Andersson, K.; Fridell, K. A comparative life cycle assessment of marine fuels: Liquefied natural gas and three other fossil fuels. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2011, 225, 97–110. [Google Scholar] [CrossRef]

- Bengtsson, S.; Andersson, K.; Fridell, K. Fuels for short sea shipping: A comparative assessment with focus on environmental impact. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2014, 228, 44–54. [Google Scholar] [CrossRef]

- Kofod, M.; Stephenson, T. Well-to Wheel Greenhouse Gas Emissions of LNG Used as a Fuel for Long Haul Trucks in a European Scenario. In Proceedings of the 11th International Conference on Engines and Vehicles, Capri, Italy, 19 September 2013. [Google Scholar] [CrossRef]

| GAR | Conventional Materials | Dosage kg/m3 | Substitution Materials (waste) | Percentage of Substitution (mass) |

|---|---|---|---|---|

| Option 1 | Cement | 350 | Oyster and mussel shells | 10% |

| Sand | 750 | - | - | |

| Gravel | 1300 | - | - | |

| Frames | 45 | Eucalyptus vegetable fibres | 25% | |

| Option 2 | Cement | 350 | - | - |

| Sand | 750 | Oyster and mussel shells | 20% | |

| Gravel | 1300 | - | - | |

| Frames | 45 | Eucalyptus vegetable fibres | 25% | |

| Option 3 | Cement | 350 | Oyster and mussel shells | 5% |

| Sand | 750 | Oyster and mussel shells | 10% | |

| Gravel | 1300 | - | - | |

| Frames | 45 | Eucalyptus vegetable fibres | 25% | |

| Option 4 2 | Cement | 350 | Oyster and mussel shells | 5% |

| Sand | 750 | Oyster and mussel shells | 10% | |

| Gravel | 1300 | - | - | |

| Frames | 45 | Eucalyptus vegetable fibres | 100% |

| Type | Dwt 1 | Vol (m3) | Hold/Deck Area (m2) | Lpp (m) 2 | Propulsion Power (Kw) and Speed (Kn) | Cranes Safe Working Load (SWL) Scope | Useful Cargo |

|---|---|---|---|---|---|---|---|

| Mini bulk carrier | 3600 | 4600 | 577 | 81 | 1470-12Kn | 2x12t 18 m | 3000 t 3 |

| Special service work boat | 500 | 0 | 180 1 | 24.2 | 1310-10Kn | 2x12t 12 m | 115 t 4 |

| Zone, i | Estuary, j | Harbour, Hi,j | GAR Groups, Ai,j,k | Total Number of GAR Units |

|---|---|---|---|---|

| Northern, i = 1 | Ribadeo, j = 1 | Ribadeo, H1,1 | A1,1,1, A1,1,2, A1,1,3 | 180 |

| Foz, j = 2 | Foz, H1,2 | A1,2,1, A1,2,2, A1,2,3 | 180 | |

| Vivero, j = 3 | Celeiro, H1,3 | A1,3,1, A1,3,2, A1,3,3 | 180 | |

| Barquero, j = 4 | Barquero, H1,4 | A1,4,1, A1,4,2, A1,4,3 | 180 | |

| Ortigueira, j = 5 | Cariño, H1,5 | A1,5,1, A1,5,2, A1,5,3 | 180 | |

| Cedeira, j = 6 | Cedeira, H1,6 | A1,6,1, A1,6,2, A1,6,3 | 180 | |

| Costa Ártabra, i = 2 | Ferrol, j = 1 | Lorbé, H2,1 | A2,1,1, A2,1,2, A2,1,3, A2,1,4 | 240 |

| Ares, j = 2 | Lorbé, H2,2 | A2,2,1, A2,2,2, A2,2,3 | 180 | |

| Betanzos, j = 3 | Lorbé, H2,3 | A2,3,1, A2,3,2, A2,3,3, A2,3,4 | 240 | |

| La Coruña, j = 4 | Lorbé, H2,4 | A2,4,1, A2,4,2, A2,4,3 | 180 | |

| Costa da Morte, i = 3 | Corme y Lage, j = 1 | Corme, H3,1 | A3,1,1, A3,1,2, A3,1,3 | 180 |

| Camariñas, j = 2 | Muxía, H3,2 | A3,2,1, A3,2,2, A3,2,3 | 180 | |

| Corcubión, j = 3 | Corcubión, H3,3 | A3,3,1, A3,3,2, A3,3,3 | 180 | |

| Muros, j = 4 | Muros, H3,4 | A3,4,1, A3,4,2, A3,4,3, A3,4,4 | 240 | |

| Noya, j = 5 | O Freixo, H3,5 | A3,5,1, A3,5,2, A3,5,3, A3,5,4 | 240 | |

| Rías Bajas, i = 4 | Arosa, j = 1 | Villanueva de Arosa, H4,1 | A4,1,1, A4,1,2, A4,1,3, A4,1,4, A4,1,5 | 360 |

| Pontevedra, j = 2 | Portonovo, H4,2 | A4,2,1, A4,2,2, A4,2,3, A4,2,4, A4,2,5 | 360 | |

| Aldán, j = 3 | Cangas, H4,3 | A4,3,1, A4,3,2, A4,3, | 180 | |

| Vigo, j = 4 | Cangas, H4,4 | A4,4,1, A4,4,2, A4,4,3, A4,4,4 | 240 |

| Supply Chain Number, t | Processes | Electricity Input (EIt) (kWh/FU) | Other Inputs | Other Inputs (kg) |

|---|---|---|---|---|

| 1 | Concrete armour | 2 | Iron–AR reinforcement | 280.5 |

| 2 | Concrete formwork 1 | 0.5 | Wood | 360 |

| 3 | Concreting | 7.5 | Aggregates | |

| 4 | Transport | 4.1 | - | - |

| 5 | Concrete vibrating | 1 | - | - |

| 6 | Curing | - | - | - |

| 7 | Concrete stripping | 1 | - | - |

| 8 | Assembly | 50 | - | - |

| 9 | Loading | 16.5 | - | - |

| Total | - | 82.6 | - | - |

| Sources | Sharesource (%) | Emission Factors (Electricity) | |

|---|---|---|---|

| GWPsource6 (kgCO2-eq./kWh) | CEDsource7 (MJ/kWh) | ||

| Natural gas | 20.859 | 0.5 1 | 7.75 3 |

| Nuclear | 20.312 | 0.005 1 | 12.024 5 |

| Wind | 18.565 | 0.008 1 | 0.04 3 |

| Coal | 14.363 | 1.1 1 | 11.26 3 |

| Hydropower | 13.427 | 0.007 1 | 0.043 3 |

| Oil | 5.276 | 0.9 1 | 13.16 3 |

| Solar photovoltaic | 2.745 | 0.07 1 | 0.65 3 |

| Biofuels | 2.004 | 0.1 1 | 0.75 3 |

| Solar thermal | 1.897 | 0.203 2 | 1.15 4 |

| Waste | 0.552 | 0.147 1 | 1.71 3 |

| Total | 100 | GWPelectricity = 0.3218 | CEDelectricity = 6.4478 |

| Sources | Sharesource (%) | Emission Factors (Electricity) | |

|---|---|---|---|

| GWPsource6 (kgCO2-eq./kWh) | CEDsource7 (MJ/kWh) | ||

| Wind | 50.677 | 0.008 1 | 0.04 3 |

| Hydropower | 36.652 | 0.007 1 | 0.043 3 |

| Solar photovoltaic | 7.493 | 0.07 1 | 0.65 3 |

| Solar thermal | 5.178 | 0.203 2 | 1.15 4 |

| Total | 100 | GWPelectricity−ideal = 0.0224 | CEDelectricity−ideal = 0.1443 |

| Type of Vehicle | GWPkm1 (kg CO2-eq./km) | CEDkm2 (MJ/km) |

|---|---|---|

| Articulated truck (trailer), diesel | 1.43 | 12.46 |

| Rigid truck, diesel | 1.37 | 10.24 |

| Articulated truck (trailer), LNG | 1.16 | 10.09 |

| Rigid truck, LNG | 1.11 | 8.29 |

| Table 2. | GWPNm1 (kg CO2-eq./Nm) | CEDNm2 (MJ/Nm) | GWPh1 (kg CO2-eq./h) | CEDh2 (MJ/h) |

|---|---|---|---|---|

| Mini bulk carrier (diesel) | 314.65 | 3592.68 | 297.88 | 3401.26 |

| Special service work boat (diesel) | 139.07 | 1587.85 | 253.20 | 2891.10 |

| Mini bulk carrier (LNG) | 303.29 | 3414.48 | 287.13 | 3232.88 |

| Special service work boat (LNG) | 134.05 | 1509.09 | 244.06 | 2747.70 |

| Zone, i | Estuary, j | Harbour, Hi,j | Coordinates, MPi | Distances Ldi,j (km), MPi | Coordinates, CMP | Distances Ldi,j (km), CMP |

|---|---|---|---|---|---|---|

| Northern, i = 1 | Ribadeo, j = 1 | Ribadeo, H1,1 | MP1 −7.536441; 43.688121 (Xove) | Ld1,1 = 53 | CMP −8.791827; 43.026543 (Santa Comba) | Ld1,1 = 204 |

| Foz, j = 2 | Foz, H1,2 | Ld1,2 = 29 | Ld1,2 = 192 | |||

| Vivero, j = 3 | Celeiro, H1,3 | Ld1,3 = 10 | Ld1,3 = 188 | |||

| Barquero, j = 4 | Barquero, H1,4 | Ld1,4 = 26 | Ld1,4 = 168 | |||

| Ortigueira, j = 5 | Cariño, H1,5 | Ld1.5 = 61 | Ld1.5 = 144 | |||

| Cedeira, j = 6 | Cedeira, H1,6 | Ld1,6 = 70 | Ld1,6 = 130 | |||

| Costa Ártabra, i = 2 | Ferrol, j = 1 | Lorbé, H2,1 | MP2 −8.29608; 43.305471 (Espíritu Santo) | Ld2,1 = 12 | Ld2,1 = 73 | |

| Ares, j = 2 | Lorbé, H2,2 | Ld2,2 = 12 | Ld2,2 = 73 | |||

| Betanzos, j = 3 | Lorbé, H2,3 | Ld2,3 = 12 | Ld2,3 = 73 | |||

| La Coruña, j = 4 | Lorbé, H2,4 | Ld2,4 = 12 | Ld2,4 = 73 | |||

| Costa da Morte, i = 3 | Corme y Lage, j = 1 | Corme, H3,1 | MP3 −9.191713; 42.976406 (Cee) | Ld3,1 = 52 | Ld3,1 = 43 | |

| Camariñas, j = 2 | Muxía, H3,2 | Ld3,2 = 17 | Ld3,2 = 46 | |||

| Corcubión, j = 3 | Corcubión, H3,3 | Ld3,3 = 4 | Ld3,3 = 47 | |||

| Muros, j = 4 | Muros, H3,4 | Ld3,4 = 42 | Ld3,4 = 43 | |||

| Noya, j = 5 | O Freixo, H3,5 | Ld3,5 = 48 | Ld3,5 = 41 | |||

| Rías Bajas, i = 4 | Arosa, j = 1 | Villanueva de Arosa, H4,1 | MP4 −8.8078; 42.429693 (Nantes) | Ld4,1 = 21 | Ld4,1 = 85 | |

| Pontevedra, j = 2 | Portonovo, H4,2 | Ld4,2 = 6 | Ld4,2 = 100 | |||

| Aldán, j = 3 | Cangas, H4,3 | Ld4,3 = 62 | Ld4,3 = 122 | |||

| Vigo, j = 4 | Cangas, H4,4 | Ld4,4 = 62 | Ld4,4 = 122 |

| Results | Spanish Electricity Grid Mix | Alternative Electricity Grid Mix |

|---|---|---|

| GWPManufacturing (kg CO2-eq./GAR) | 26.58 | 1.85 |

| CEDManufacturing (MJ/GAR) | 532.59 | 11.92 |

| Total − GWPManufacturing (kg CO2-eq.) | 108,446.4 | 7548 |

| Total − CEDManufacturing (MJ) | 2,172,967.2 | 48,633.6 |

| Supply Chain Number, t | Processes | GWPManufacturing (kg CO2-eq./GAR) | CEDManufacturing (MJ/GAR) | Total − GWPManufacturing (kg CO2-eq.) | Total − CEDManufacturing (MJ) |

|---|---|---|---|---|---|

| 1 | Concrete Armour | 0.6436 | 12.8956 | 2625.89 | 52,614.05 |

| 2 | Concrete Formwork | 0.1609 | 3.2239 | 656.47 | 13,153.51 |

| 3 | Concreting | 2.4135 | 48.3585 | 9847.08 | 197,302.68 |

| 4 | Transport | 1.3194 | 26.4360 | 5383.15 | 107,858.88 |

| 5 | Concrete Vibrating | 0.3218 | 6.4478 | 1312.94 | 26,307.02 |

| 6 | Curing | - | - | - | - |

| 7 | Concrete Stripping | 0.3218 | 6.4478 | 1312.94 | 26,307.02 |

| 8 | Assembly | 16.09 | 322.39 | 65,647.2 | 1,315,351.2 |

| 9 | Loading | 5.3097 | 106.39 | 21,663.58 | 434,071.2 |

| Supply Chain Number, t | Processes | GWPManufacturing (kg CO2-eq./GAR) | CEDManufacturing (MJ/GAR) | Total − GWPManufacturing (kg CO2-eq.) | Total − CEDManufacturing (MJ) |

|---|---|---|---|---|---|

| 1 | Concrete Armour | 0.0448 | 0.2886 | 182.78 | 1177.49 |

| 2 | Concrete Formwork | 0.0112 | 0.0722 | 45.70 | 294.58 |

| 3 | Concreting | 0.1680 | 1.0823 | 685.44 | 4415.78 |

| 4 | Transport | 0.0918 | 0.5916 | 374.54 | 2413.73 |

| 5 | Concrete Vibrating | 0.0224 | 0.1443 | 91.39 | 588.74 |

| 6 | Curing | - | - | - | - |

| 7 | Concrete Stripping | 0.0224 | 0.1443 | 91.39 | 588.74 |

| 8 | Assembly | 1.12 | 7.215 | 4569.6 | 29,437.2 |

| 9 | Loading | 0.3696 | 2.3810 | 1507.97 | 9714.48 |

| Results | Road Transport Scenarios | |||

|---|---|---|---|---|

| Articulated Truck and MPi | Articulated Truck and CMP | Rigid Truck and MPi | Rigid Truck and CMP | |

| Total− GWPRoad (kg CO2-eq.) | 119,548 | 194,708.8 | 171,798 | 279,808.8 |

| Total− CEDRoad (MJ) | 1,041,656 | 1,696,553.6 | 1,284,096 | 2,091,417.6 |

| Results | Road Transport Scenarios | |||

|---|---|---|---|---|

| Articulated Truck and MPi | Articulated Truck and CMP | Rigid Truck and MPi | Rigid Truck and CMP | |

| Total− GWPRoad (kg CO2-eq.) | 96,976 | 157,945.6 | 139,194 | 226,706.4 |

| Total− CEDRoad (MJ) | 843,524 | 1,373,854.4 | 1,039,566 | 1,693,149.6 |

| Results | Maritime Transport Scenarios | |||

|---|---|---|---|---|

| Mini Bulk Carrier and Diesel | Mini Bulk Carrier and LNG 1 | Service Work Boat and Diesel | Service Work Boat and LNG 1 | |

| Total− GWPMaritime (kg CO2-eq.) | 513,238.16 | 494,714.28 | 468,008.64 | 451,114.72 |

| Total− CEDMaritime (MJ) | 5,860,241.36 | 5,569,988.8 | 5,343,698.4 | 5,078,645.28 |

| Parameters | Best Scenario | Worst Scenario |

|---|---|---|

| Type of truck | Articulated truck | Rigid truck |

| Truck fuel | LNG 1 | Diesel |

| Manufacturing plant model | MPi | CMP |

| Type of vessel | Service work boat | Mini bulk carrier |

| Vessel fuel | LNG 1 | Diesel |

| Results | Spanish Electricity Grid Mix | Alternative or Renewable Electricity Grid Mix | ||

|---|---|---|---|---|

| Best Scenario | Worst Scenario | Best Scenario | Worst Scenario | |

| Total − GWPManufacturing (kg CO2-eq.) | 108,446.4 | 108,446.4 | 7548 | 7548 |

| Total − GWPRoad (kg CO2-eq.) | 96,976 | 279,808.8 | 96,976 | 279,808.8 |

| Total − GWPMaritime (kg CO2-eq.) | 451,114.72 | 513,238.16 | 451,114.72 | 513,238.16 |

| Total − GWPTransport-Installation (kg CO2-eq.) | 548,090.72 | 793,046.96 | 548,090.72 | 793,046.96 |

| Total − GWP (kg CO2-eq.) | 656,537.12 | 901,493.36 | 555,638.72 | 800,594.96 |

| Total − CEDManufacturing (MJ) | 2,172,967.2 | 2,172,967.2 | 48,633.6 | 48,633.6 |

| Total − CEDRoad (MJ) | 843,524 | 2,091,417.6 | 843,524 | 2,091,417.6 |

| Total − CEDMaritime (MJ) | 5,078,645.28 | 5,860,241.36 | 5,078,645.28 | 5,860,241.36 |

| Total − CEDTransport-Installation (MJ) | 5,922,169.28 | 7,951,658.96 | 5,922,169.28 | 7,951,658.96 |

| Total − CED (MJ) | 8,095,136.48 | 10,124,626.16 | 5,970,802.88 | 8,000,292.56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carral, L.; Cartelle Barros, J.J.; Carro Fidalgo, H.; Camba Fabal, C.; Munín Doce, A. Greenhouse Gas Emissions and Energy Consumption of Coastal Ecosystem Enhancement Programme through Sustainable Artificial Reefs in Galicia. Int. J. Environ. Res. Public Health 2021, 18, 1909. https://doi.org/10.3390/ijerph18041909

Carral L, Cartelle Barros JJ, Carro Fidalgo H, Camba Fabal C, Munín Doce A. Greenhouse Gas Emissions and Energy Consumption of Coastal Ecosystem Enhancement Programme through Sustainable Artificial Reefs in Galicia. International Journal of Environmental Research and Public Health. 2021; 18(4):1909. https://doi.org/10.3390/ijerph18041909

Chicago/Turabian StyleCarral, Luis, Juan José Cartelle Barros, Humberto Carro Fidalgo, Carolina Camba Fabal, and Alicia Munín Doce. 2021. "Greenhouse Gas Emissions and Energy Consumption of Coastal Ecosystem Enhancement Programme through Sustainable Artificial Reefs in Galicia" International Journal of Environmental Research and Public Health 18, no. 4: 1909. https://doi.org/10.3390/ijerph18041909

APA StyleCarral, L., Cartelle Barros, J. J., Carro Fidalgo, H., Camba Fabal, C., & Munín Doce, A. (2021). Greenhouse Gas Emissions and Energy Consumption of Coastal Ecosystem Enhancement Programme through Sustainable Artificial Reefs in Galicia. International Journal of Environmental Research and Public Health, 18(4), 1909. https://doi.org/10.3390/ijerph18041909