Implementation of Kinetic and Kinematic Variables in Ergonomic Risk Assessment Using Motion Capture Simulation: A Review

Abstract

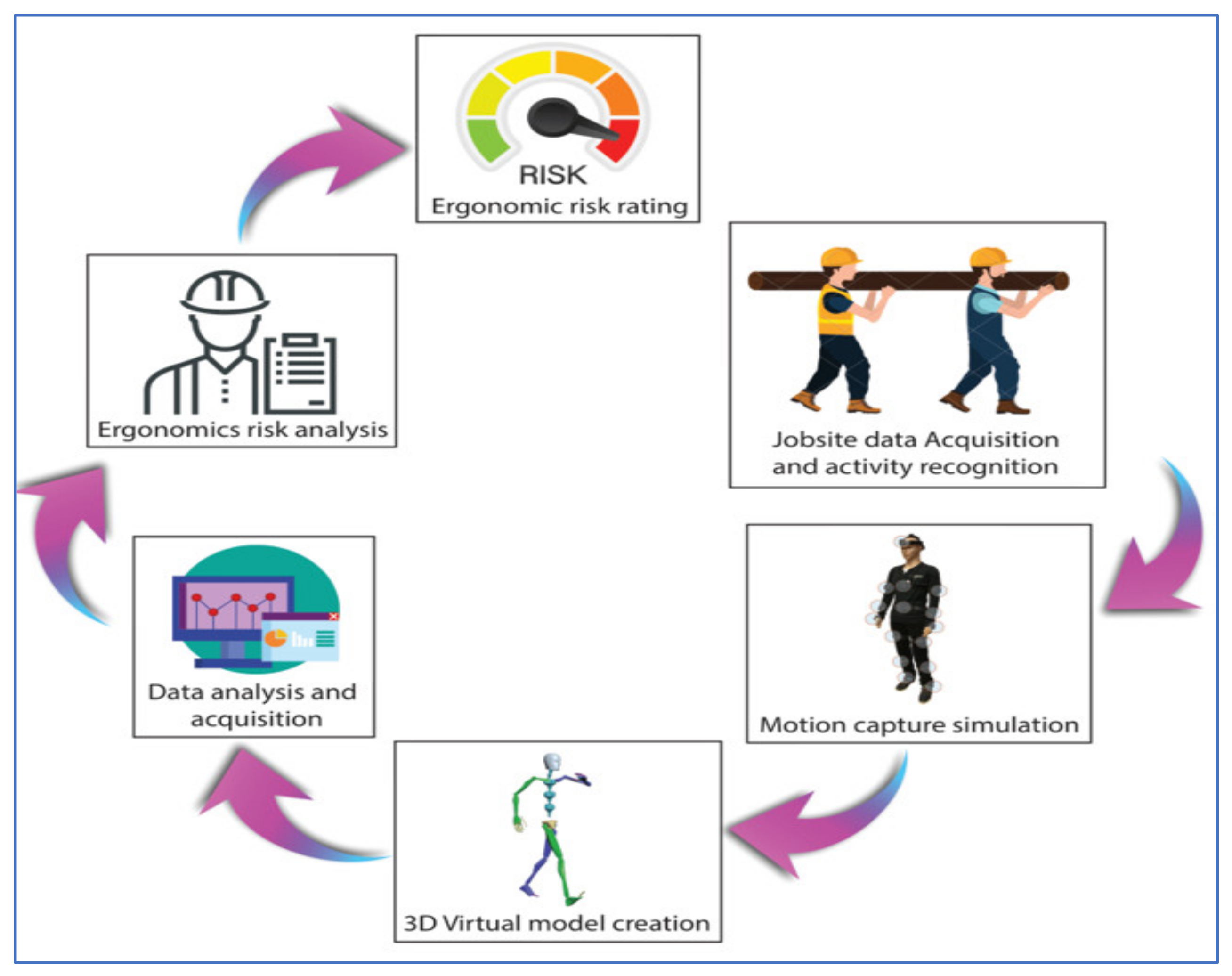

1. Introduction

2. Motion Capture Simulation

3. Ergonomic Risk Assessment

4. Kinetic and Kinematic Variable

- (a)

- Newton’s first law: object will remain at rest or constant velocity unless an external force acts on it;

- (b)

- Newton’s second law: the force is equal to the product of mass and acceleration; and

- (c)

- Newton’s third law: when a body exerts a force on another body, the body will have equal force with the first body.

4.1. Velocity and Acceleration

4.2. Force

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Delice, E.K.; Can, G.F. A new approach for ergonomic risk assessment integrating KEMIRA, best worst and MCDM methods. Soft Comput. 2020, 24, 15093–15110. [Google Scholar] [CrossRef]

- Samaei, S.E.; Tirgar, A.; Khanjani, N.; Mostafaee, M.; Hosseinabadi, M.B. Effect of personal risk factors on the prevalence rate of musculoskeletal disorders among workers of an Iranian rubber factory. Work 2017, 57, 547–553. [Google Scholar] [CrossRef] [PubMed]

- Penkala, S.; El-Debal, H.; Coxon, K. Work-related musculoskeletal problems related to laboratory training in university medical science students: A cross sectional survey. BMC Public Health 2018, 18, 1205. [Google Scholar] [CrossRef]

- Álvarez, D.; Alvarez, J.C.; González, R.C.; López, A.M. Upper limb joint angle measurement in occupational health. Comput. Methods Biomech. Biomed. Eng. 2016, 19, 159–170. [Google Scholar] [CrossRef] [PubMed]

- Antwi-Afari, M.F.; Li, H.; Edwards, D.J.; Pärn, E.A.; Seo, J.; Wong AY, L. Biomechanical analysis of risk factors for work-related musculoskeletal disorders during repetitive lifting task in construction workers. Autom. Constr. 2017, 83, 41–47. [Google Scholar] [CrossRef]

- Hossain, M.D.; Aftab, A.; Hassan, M.; Imam, A.; Mahmud, I.; Chowdhury, I.A.; Kabir, R.I.; Sarker, M. Prevalence of work-related musculoskeletal disorders (WMSDs) and ergonomic risk assessment among readymade garment workers of Bangladesh: A cross sectional study. PLoS ONE 2018, 13, e0200122. [Google Scholar] [CrossRef] [PubMed]

- Enez, K.; Nalbantoğlu, S.S. Comparison of ergonomic risk assessment outputs from OWAS and REBA in forestry timber harvesting. Int. J. Ind. Ergon. 2019, 70, 51–57. [Google Scholar] [CrossRef]

- Isusi, I. Work-Related Musculoskeletal Disorders—Facts and Figures (Syntesis of 10 National Reports); European Agency for Safety and Health at Work: Luxembourg, 2020; pp. 1–80. [Google Scholar]

- Pal, A.; Dhara, P. Evaluation of Work-Related Musculoskeletal Disorders and Postural Stress of Female “Jari” Workers. Indian J. Occup. Environ. Med. 2017, 21, 132. [Google Scholar]

- Fletcher, S.R.; Johnson, T.L.; Thrower, J. A study to trial the use of inertial non-optical motion capture for ergonomic analysis of manufacturing work. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 90–98. [Google Scholar] [CrossRef]

- Merino, G.; da Silva, L.; Mattos, D.; Guimarães, B.; Merino, E. Ergonomic evaluation of the musculoskeletal risks in a banana harvesting activity through qualitative and quantitative measures, with emphasis on motion capture (Xsens) and EMG. Int. J. Ind. Ergon. 2019, 69, 80–89. [Google Scholar] [CrossRef]

- Petrosyan, T.; Dunoyan, A.; Mkrtchyan, H. Application of Motion Capture Systems in Ergonomic Analysis. Armen. J. Spec. Educ. 2020, 1, 107–117. [Google Scholar] [CrossRef]

- Schmitz, A.; Ye, M.; Boggess, G.; Shapiro, R.; Yang, R.; Noehren, B. The measurement of in vivo joint angles during a squat using a single camera markerless motion capture system as compared to a marker-based system. Gait Posture 2015, 41, 694–698. [Google Scholar] [CrossRef] [PubMed]

- Bortolini, M.; Faccio, M.; Gamberi, M.; Pilati, F. Motion Analysis System (MAS) for production and ergonomics assessment in the manufacturing processes. Comput. Ind. Eng. 2020, 139, 105485. [Google Scholar] [CrossRef]

- Akhavian, R.; Behzadan, A.H. Smartphone-based construction workers’ activity recognition and classification. Autom. Constr. 2016, 71, 198–209. [Google Scholar] [CrossRef]

- Ide, D.; Tokcalar, O.; Gunduz, T. The effect of joint forces and torques on speed variation in automobile assembly lines. Work 2018, 61, 211–224. [Google Scholar] [CrossRef]

- Abaeian, H.; Moselhi, O.; Al-hussein, M. System Dynamics Model Application for Ergonomic Assessment of Manual Material Handling Tasks; Modular and Offsite Construction: Edmonton, AB, Canada, 2016. [Google Scholar]

- Bortolini, M.; Gamberi, M.; Pilati, F.; Regattieri, A. Automatic assessment of the ergonomic risk for manual manufacturing and assembly activities through optical motion capture technology. Procedia CIRP 2018, 72, 81–86. [Google Scholar] [CrossRef]

- Kaharuddin, M.Z.; Khairu Razak, S.B.; Kushairi, M.I.; Abd Rahman, M.S.; An, W.C.; Ngali, Z.; Siswanto, W.A.; Salleh, S.M.; Yusup, E.M. Biomechanics Analysis of Combat Sport (Silat) by Using Motion Capture System. IOP Conf. Ser. Mater. Sci. Eng. 2017, 166, 012028. [Google Scholar] [CrossRef]

- Ray, P.K.; Parida, R.; Sarkar, S. Ergonomic Analysis of Construction Jobs in India: A Biomechanical Modelling Approach. Procedia Manuf. 2015, 3, 4606–4612. [Google Scholar] [CrossRef][Green Version]

- Agethen, P.; Otto, M.; Mengel, S.; Rukzio, E. Using Marker-less Motion Capture Systems for Walk Path Analysis in Paced Assembly Flow Lines. Procedia CIRP 2016, 54, 152–157. [Google Scholar] [CrossRef]

- Kim, J.H.; Hwang, J.; Jung, M.; Mo, S. The Kinematic Evaluation of Shoulder and Elbow Joints for Different Walking Speeds. Int. J. Eng. Technol. 2019, 11, 169–172. [Google Scholar] [CrossRef]

- Soh, A.A.S.A.; Jafri, M.Z.; Azraai, N.Z. Power estimation of martial arts movement with different physical, mood, and behavior using motion capture camera. In Optics for Arts, Architecture, and Archaeology VI; International Society for Optics and Photonics: Bellingham, WA, USA, 2017; Volume 10331, p. 103310X. [Google Scholar]

- Maurice, P.; Malaisé, A.; Amiot, C.; Paris, N.; Richard, G.J.; Rochel, O.; Ivaldi, S. Human movement and ergonomics: An industry-oriented dataset for collaborative robotics. Int. J. Robot. Res. 2019, 38, 1529–1537. [Google Scholar] [CrossRef]

- Eldar, R.; Fisher-Gewirtzman, D. Ergonomic design visualization mapping-developing an assistive model for design activities. Int. J. Ind. Ergon. 2019, 74, 102859. [Google Scholar] [CrossRef]

- Antwi-Afari, M.F.; Li, H.; Luo, X.E.; Edwards, D.J.; Owusu-Manu, D.; Darko, A. Overexertion-related construction workers’ activity recognition and ergonomic risk assessment based on wearable insole pressure system. In Proceedings of the West Africa Built Environment Research Conference, Accra, Ghana, 5–7 August 2019; pp. 788–796. [Google Scholar]

- Scalise, L.; Paone, N. Pressure sensor matrix for indirect measurement of grip and push forces exerted on a handle. Measurement J. Int. Meas. Confed. 2015, 73, 419–428. [Google Scholar] [CrossRef]

- Nath, N.D.; Akhavian, R.; Behzadan, A.H. Ergonomic analysis of construction worker’s body postures using wearable mobile sensors. Appl. Ergon. 2017, 62, 107–117. [Google Scholar] [CrossRef]

- Jahanbanifar, S.; Akhavian, R. Evaluation of wearable sensors to quantify construction workers muscle force: An ergonomic analysis. In Proceedings of the Winter Simulation Conference, Gothenburg, Sweeden, 9–12 December 2018; pp. 3921–3929. [Google Scholar]

- Waddell, M.L.; Amazeen, E.L. Lift speed moderates the effects of muscle activity on perceived heaviness. Q. J. Exp. Psychol. 2016, 71, 2174–2185. [Google Scholar] [CrossRef] [PubMed]

- Fleron, M.K.; Ubbesen, N.C.H.; Battistella, F.; Dejtiar, D.L.; Oliveira, A.S. Accuracy between optical and inertial motion capture systems for assessing trunk speed during preferred gait and transition periods. Sports Biomech. 2019, 18, 366–377. [Google Scholar] [CrossRef]

- White, S.C.; Hostler, D. The effect of firefighter protective garments, self-contained breathing apparatus and exertion in the heat on postural sway. Ergonomics 2017, 60, 1137–1145. [Google Scholar] [CrossRef]

- Nelson-Wong, E.; Gallagher, K.; Johnson, E.; Antonioli, C.; Ferguson, A.; Harris, S.; Johnson, H.; Miller, J.B. Increasing standing tolerance in office workers with standing-induced back pain. Ergonomics 2020, 63, 804–817. [Google Scholar] [CrossRef]

- Jun, D.; Johnston, V.; McPhail, S.M.; O’Leary, S. Are Measures of Postural Behavior Using Motion Sensors in Seated Office Workers Reliable? Hum. Factors 2019, 61, 1141–1161. [Google Scholar] [CrossRef]

- Aurand, A.M.; Dufour, J.S.; Marras, W.S. Accuracy map of an optical motion capture system with 42 or 21 cameras in a large measurement volume. J. Biomech. 2017, 58, 237–240. [Google Scholar] [CrossRef] [PubMed]

- Arendra, A.; Akhmad, S.; Lumintu, I. Working tool redesign to reduce ergonomic risk of salt evaporation field workers based on RULA and REBA assessments using esMOCA Instrument. J. Phys. Conf. Ser. 2020, 1477, 022034. [Google Scholar] [CrossRef]

- Dhyani, M.; Roll, S.C.; Gilbertson, M.W.; Orlowski, M.; Anvari, A.; Li, Q.; Anthony, B.; Samir, A.E. A pilot study to precisely quantify forces applied by sonographers while scanning: A step toward reducing ergonomic injury. Work 2017, 58, 241–247. [Google Scholar] [CrossRef] [PubMed]

- Yu, K.; Barmaki, R.; Unberath, M.; Mears, A.; Brey, J.; Hwan, T.; Chung, M.D.; Navab, N. On the Accuracy of Low-Cost Motion Capture Systems for Range of Motion Measurements; SPIE Medical Imaging: Houston, TX, USA, 2018; p. 10579. [Google Scholar]

- Patrizi, A.; Pennestrì, E.; Valentini, P.P. Comparison between low-cost marker-less and high-end marker-based motion capture systems for the computer-aided assessment of working ergonomics. Ergonomics 2016, 59, 155–162. [Google Scholar] [CrossRef] [PubMed]

- Perrott, M.A.; Pizzari, T.; Cook, J.; McClelland, J.A. Comparison of lower limb and trunk kinematics between markerless and marker-based motion capture systems. Gait Posture 2017, 52, 57–61. [Google Scholar] [CrossRef]

- Karatsidis, A.; Bellusci, G.; Schepers, H.M.; de Zee, M.; Andersen, M.S.; Veltink, P.H. Estimation of ground reaction forces and moments during gait using only inertial motion capture. Sensors 2017, 17, 75. [Google Scholar] [CrossRef] [PubMed]

- Humadi, A.; Nazarahari, M.; Ahmad, R.; Rouhani, H. In-field instrumented ergonomic risk assessment: Inertial measurement units versus Kinect V2. Int. J. Ind. Ergon. 2021, 84, 103147. [Google Scholar] [CrossRef]

- Brunner, O.; Mertens, A.; Nitsch, V.; Brandl, C. Accuracy of a Markerless Motion Capture System for Postural Ergonomic Risk Assessment in Occupational Practice. Int. J. Occup. Saf. Ergon. 2021, in press. [Google Scholar] [CrossRef]

- Huang, C.; Kim, W.; Zhang, Y.; Xiong, S. Development and Validation of a Wearable Inertial Sensors-Based Automated System for Assessing Work-Related Musculoskeletal Disorders in the Workspace. Int. J. Environ. Res. Public Health 2020, 17, 6050. [Google Scholar] [CrossRef] [PubMed]

- Abedi, M.; Ghanbary, A.; Habibi, E.; Palyzban, F.; Ghasemi, H.; Hasani, A.A. Back Compressive Force (BCF) assessment using UTAH method in manual handling tasks among workers of a chemical manufacturing company. J. Occup. Health Epidemiol. 2018, 7, 222–226. [Google Scholar] [CrossRef]

- Kamat, S.R.; Zula, N.M.; Rayme, N.S.; Shamsuddin, S.; Husain, K. The ergonomics body posture on repetitive and heavy lifting activities of workers in aerospace manufacturing warehouse. IOP Conf. Ser. Mater. Sci. Eng. 2017, 210, 012079. [Google Scholar] [CrossRef]

- Namnik, N.; Negahban, H.; Salehi, R.; Shafizadeh, R.; Tabib, M.S. Validity and reliability of Persian version of the Specific Nordic questionnaire in Iranian industrial workers. Work 2016, 54, 35–41. [Google Scholar] [CrossRef] [PubMed]

- Kahraman, T.; Genç, A.; Göz, E. The Nordic Musculoskeletal Questionnaire: Cross-cultural adaptation into Turkish assessing its psychometric properties. Disabil. Rehabil. 2016, 38, 2153–2160. [Google Scholar] [CrossRef]

- Cremasco, M.M.; Giustetto, A.; Caffaro, F.; Colantoni, A.; Cavallo, E.; Grigolato, S. Risk assessment for musculoskeletal disorders in forestry: A comparison between RULA and REBA in the manual feeding of a wood-chipper. Int. J. Environ. Res. Public Health 2019, 16, 793. [Google Scholar] [CrossRef] [PubMed]

- Bidiawati, J.R.; Suryani, E. Improving the Work Position of Worker’s Based on Quick Exposure Check Method to Reduce the Risk of Work-Related Musculoskeletal Disorders. Procedia Manuf. 2015, 4, 496–503. [Google Scholar] [CrossRef][Green Version]

- Gómez-Galán, M.; Callejón-Ferre, Á.J.; Pérez-Alonso, J.; Díaz-Pérez, M.; Carrillo-Castrillo, J.A. Musculoskeletal risks: RULA bibliometric review. Int. J. Environ. Res. Public Health 2020, 17, 4354. [Google Scholar] [CrossRef] [PubMed]

- Hita-Gutiérrez, M.; Gómez-Galán, M.; Díaz-Pérez, M.; Callejón-Ferre, Á.J. An overview of reba method applications in the world. Int. J. Environ. Res. Public Health 2020, 17, 2635. [Google Scholar] [CrossRef]

- Abd Rahman, M.K.; Shahriman, A.B.; Desa, H.; Daud, R.; Razlan, Z.M.; Wan, K.; Cheng, E.M.; Afendi, M. Comparative Study of Rapid Upper Limb Assessment (RULA) and Rapid Entire Body Assessment (REBA) between Conventional and Machine Assisted Napier Grass Harvest Works. Appl. Mech. Mater. 2015, 786, 275–280. [Google Scholar] [CrossRef]

- Plantard, P.; Auvinet, E.; Le Pierres, A.S.; Multon, F. Pose estimation with a kinect for ergonomic studies: Evaluation of the accuracy using a virtual mannequin. Sensors 2015, 15, 1785–1803. [Google Scholar] [CrossRef]

- Lowe, B.D.; Dempsey, P.G.; Jones, E.M. Ergonomics assessment methods used by ergonomics professionals. Appl. Ergon. 2019, 81, 102882. [Google Scholar] [CrossRef]

- Zare, M.; Biau, S.; Brunet, R.; Roquelaure, Y. Comparison of three methods for evaluation of work postures in a truck assembly plant. Ergonomics 2017, 60, 1551–1563. [Google Scholar] [CrossRef]

- Kim, W.; Sung, J.; Saakes, D.; Huang, C.; Xiong, S. Ergonomic postural assessment using a new open-source human pose estimation technology (OpenPose). Int. J. Ind. Ergon. 2021, 84, 103164. [Google Scholar] [CrossRef]

- Ansari, N.A.; Sheikh, D.M.J. Evaluation of work Posture by RULA and REBA: A Case Study. IOSR J. Mech. Civ. Eng. 2014, 11, 18–23. [Google Scholar] [CrossRef]

- Rizkya, I.; Syahputri, K.; Sari, R.M.; Siregar, I. Evaluation of work posture and quantification of fatigue by Rapid Entire Body Assessment (REBA). IOP Conf. Ser. Mater. Sci. Eng. 2018, 309, 012051. [Google Scholar] [CrossRef]

- Choi, K.H.; Kim, D.M.; Cho, M.U.; Park, C.W.; Kim, S.Y.; Kim, M.J.; Kong, Y.K. Application of aula risk assessment tool by comparison with other ergonomic risk assessment tools. Int. J. Environ. Res. Public Health 2020, 17, 6479. [Google Scholar] [CrossRef]

- Jones, T.; Kumar, S. Comparison of ergonomic risk assessment output in four sawmill jobs. Int. J. Occup. Saf. Ergon. 2010, 16, 105–111. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.; Xiong, S. Comparison of seven fall risk assessment tools in community-dwelling Korean older women. Ergonomics 2017, 60, 421–429. [Google Scholar] [CrossRef] [PubMed]

- Valero, E.; Sivanathan, A.; Bosché, F.; Abdel-Wahab, M. Musculoskeletal disorders in construction: A review and a novel system for activity tracking with body area network. Appl. Ergon. 2016, 54, 120–130. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.; Seto, E.; Lin, K.Y.; Migliaccio, G.C. An evaluation of wearable sensors and their placements for analyzing construction worker’s trunk posture in laboratory conditions. Appl. Ergon. 2017, 65, 424–436. [Google Scholar] [CrossRef]

- Plantard, P.; Shum, H.P.; Le Pierres, A.S.; Multon, F. Validation of an ergonomic assessment method using Kinect data in real workplace conditions. Appl. Ergon. 2017, 65, 562–569. [Google Scholar] [CrossRef]

- Brandl, C.; Mertens, A.; Schlick, C.M. Effect of sampling interval on the reliability of ergonomic analysis using the Ovako working posture analysing system (OWAS). Int. J. Ind. Ergon. 2017, 57, 68–73. [Google Scholar] [CrossRef]

- Soh, A.A.; Jafri, M.Z.; Azraai, N.Z. Study of human body: Kinematics and kinetics of a martial arts (Silat) performers using 3D-motion capture. AIP Conf. Proc. 2015, 1657, 040009. [Google Scholar]

- Swaminathan, R.; Williams, J.M.; Jones, M.D.; Theobald, P.S. The prediction of neck extensor force using surface electromyography. J. Back Musculoskelet. Rehabil. 2016, 29, 279–285. [Google Scholar] [CrossRef]

- Caputo, F.; Amato, E.D.; Spada, S.; Sessa, F.; Losardo, M. Upper Body Motion Tracking System with Inertial Sensors for Ergonomic Issues in Industrial Environments. Adv. Phys. Ergon. Hum. Factors 2016, 489, 801–812. [Google Scholar]

- Lavender, S.A.; Sommerich, C.M.; Bigelow, S.; Weston, E.B.; Seagren, K.; Pay, N.A.; Sillars, D.; Ramachandran, V.; Sun, C.; Xu, Y.; et al. A biomechanical evaluation of potential ergonomic solutions for use by firefighter and EMS providers when lifting heavy patients in their homes. Appl. Ergon. 2020, 82, 102910. [Google Scholar] [CrossRef]

- Dickerson, C.R.; Alenabi, T.; Martin, B.J.; Chaffin, D.B. Shoulder muscular activity in individuals with low back pain and spinal cord injury during seated manual load transfer tasks. Ergonomics 2018, 61, 1094–1101. [Google Scholar] [CrossRef] [PubMed]

- Greenland, K.O.; Merryweather, A.S.; Bloswick, D.S. The effect of lifting speed on cumulative and peak biomechanical loading for symmetric lifting tasks. Saf. Health Work 2013, 4, 105–110. [Google Scholar] [CrossRef] [PubMed]

- Yoon, J.; Shiekhzadeh, A.; Nordin, M. The effect of load weight vs. pace on muscle recruitment during lifting. Appl. Ergon. 2012, 43, 1044–1050. [Google Scholar] [CrossRef]

- Wang, T.J. A study on utilizing 3D motion-capture analysis to assist in Chinese opera teaching. Res. Danc. Educ. 2020. [Google Scholar] [CrossRef]

- Chen, J.; Qiu, J.; Ahn, C. Construction worker’s awkward posture recognition through supervised motion tensor decomposition. Autom. Constr. 2017, 77, 67–81. [Google Scholar] [CrossRef]

- Wardoyo, S.; Hutajulu, P.T.; Togibasa, O. A Development of Force Plate for Biomechanics Analysis of Standing and Walking. J. Phys. Conf. Ser. 2016, 739, 012118. [Google Scholar] [CrossRef]

| Motion Capture | Type | Data | Advantage | Disadvantage | References |

|---|---|---|---|---|---|

| Optical | Markerless |

|

|

| [17,18,19,20,21] |

| Marker Based |

|

|

| [22,23,24,25] | |

| Non-Optical | Pressure sensor |

|

|

| [26,27] |

| Inertial |

|

|

| [28,29,30,31] | |

| Force plate |

|

| [32,33] | ||

| Mechanical |

|

|

| [34] |

| Ergonomic Assessment Method | Tools | Advantage | References |

|---|---|---|---|

| Self-report |

|

| [45,46,47,48] |

| Observational |

|

| [49,50,51,52,53] |

| Direct measurement |

|

| [29,54,55,56] |

| Data Input | Motion Capture Type | System | Research Scope/Finding | References |

|---|---|---|---|---|

| Velocity | Optical | Microsoft Kinect V2 | Evaluate the cycle time of worker in the set-up workstation | [18] |

| Kinect based | Compare the martial art performance (Silat) between novice and experienced performer | [19] | ||

| Optitrack | Evaluate the kinematic data of shoulder and elbow during walking with different pace | [22] | ||

| Acceleration | Optical | Ipi soft Motion capture | The maximum back compressive force produced during high acceleration and angle of trunk flexion | [17] |

| Northern Digital Optotrak 3020 motion tracking system | Perceived heaviness is the function of ratio of muscle activity to acceleration | [30] | ||

| Non-Optical | Wearable accelerometer | Predict the angle of deviation for shoulder and trunk flexion using the angular acceleration | [28] | |

| Wearable accelerometer | Proposed low-cost wearable inertial sensor to track the upper body movement | [69] | ||

| Wearable accelerometer | The proposed wearable sensor is potentially acceptable for slow tasks to predict the trunk flexion | [64] | ||

| OpenGo system (Moticon) | Evaluate the risk of overexertion based on acceleration and pressure data | [26] | ||

| Force | Optical | Ariel performance analysis system (APAS) | The musculoskeletal injury happened when normal forces are exerted to abnormally weak tissues or when high forces are exerted to normal tissues | [20] |

| Non-Optical | Electromyogram (EMG) | The higher the trunk flexion angle, the higher the compression force | [70] | |

| Electromyogram (EMG) | Anterior deltoid and upper trapezius are under high demand during load transfer tasks for people with lower back pain and spinal cord injury | [71] | ||

| Baltimore therapeutic equipment (BTE) | Data collected during the study using accelerometer sensor has a correlation with force applied by muscle | [29] | ||

| Force plate | Calculate the ground reaction forces and moment from the walking task with different pace | [41] |

| Variable | Contribution |

|---|---|

| Velocity |

|

| Acceleration |

|

| Force |

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yunus, M.N.H.; Jaafar, M.H.; Mohamed, A.S.A.; Azraai, N.Z.; Hossain, M.S. Implementation of Kinetic and Kinematic Variables in Ergonomic Risk Assessment Using Motion Capture Simulation: A Review. Int. J. Environ. Res. Public Health 2021, 18, 8342. https://doi.org/10.3390/ijerph18168342

Yunus MNH, Jaafar MH, Mohamed ASA, Azraai NZ, Hossain MS. Implementation of Kinetic and Kinematic Variables in Ergonomic Risk Assessment Using Motion Capture Simulation: A Review. International Journal of Environmental Research and Public Health. 2021; 18(16):8342. https://doi.org/10.3390/ijerph18168342

Chicago/Turabian StyleYunus, Muhamad Nurul Hisyam, Mohd Hafiidz Jaafar, Ahmad Sufril Azlan Mohamed, Nur Zaidi Azraai, and Md. Sohrab Hossain. 2021. "Implementation of Kinetic and Kinematic Variables in Ergonomic Risk Assessment Using Motion Capture Simulation: A Review" International Journal of Environmental Research and Public Health 18, no. 16: 8342. https://doi.org/10.3390/ijerph18168342

APA StyleYunus, M. N. H., Jaafar, M. H., Mohamed, A. S. A., Azraai, N. Z., & Hossain, M. S. (2021). Implementation of Kinetic and Kinematic Variables in Ergonomic Risk Assessment Using Motion Capture Simulation: A Review. International Journal of Environmental Research and Public Health, 18(16), 8342. https://doi.org/10.3390/ijerph18168342