A Chance-Constrained Vehicle Routing Problem for Wet Waste Collection and Transportation Considering Carbon Emissions

Abstract

1. Introduction

2. Literature Review

2.1. Research about Waste Collection and Transportation

2.2. Research about Chance-Constrained Programming

2.3. Research about Some Algorithms for Waste Collection and Transportation

3. Model Formulation

3.1. Problem Description

- (1)

- There is only one type of wet waste collection vehicles with limited capacity.

- (2)

- The location of the depot and each smart waste bin are known.

- (3)

- Each waste generation point has its independent stochastic rate of waste generation and obeys normal distribution [24].

- (4)

- All waste collection vehicles must return the depot when collection tasks completed.

- (5)

- Each smart waste bin is only collected by one vehicle once.

3.2. Notation

3.3. Model Construction

3.3.1. Analysis of Objectives Function

3.3.2. Model Setting

3.4. Chance-Constrained Programming

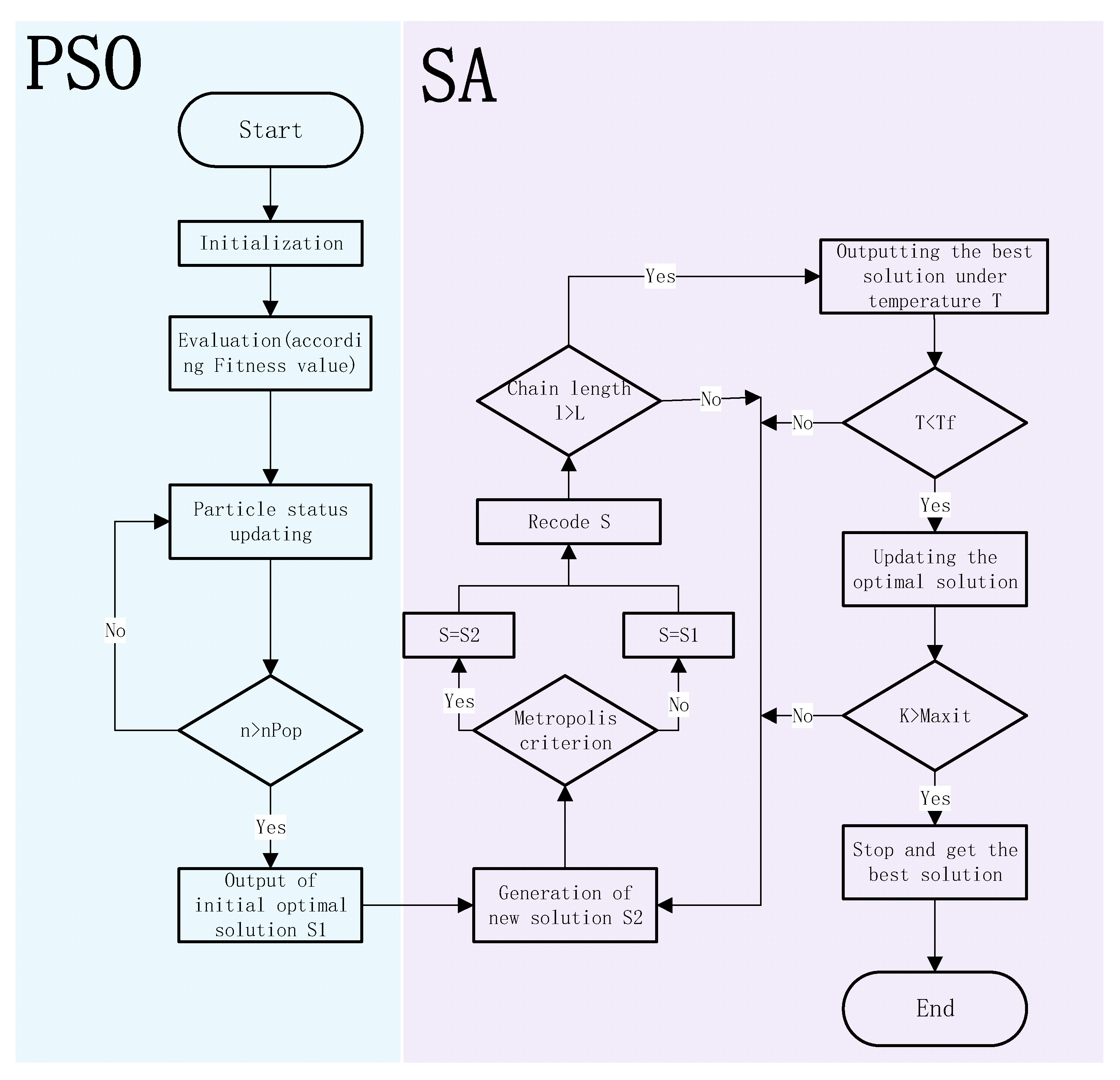

4. Algorithm

4.1. Algorithm Design

4.2. Encoding and Decoding

4.3. Constructing Initial Optimal Solution Based on PSO Algorithm

4.3.1. Initialization and Fitness Evaluation

4.3.2. Determining Optimal Solution

4.3.3. Particle Status Update

4.3.4. Terminating Condition

4.4. Structure Global Optimal Solution Based on SA

4.4.1. Initialization and Initial Solution

4.4.2. Generation of New Solution

4.4.3. Cooling Operation

4.4.4. Terminating Condition

5. Numerical Experiments and Analysis

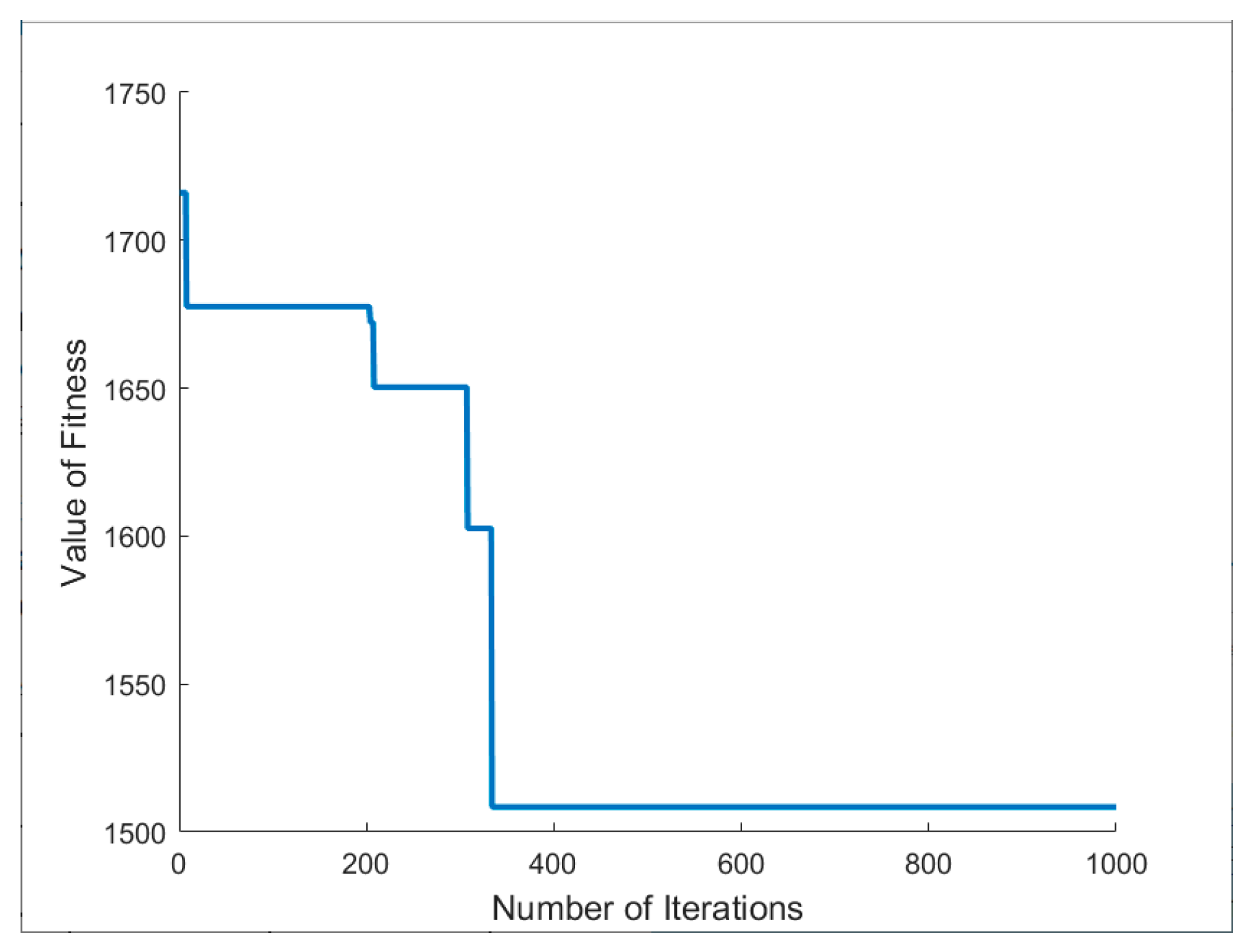

5.1. Algorithm Experiment

5.2. Model Experiment

5.2.1. Experimental Design

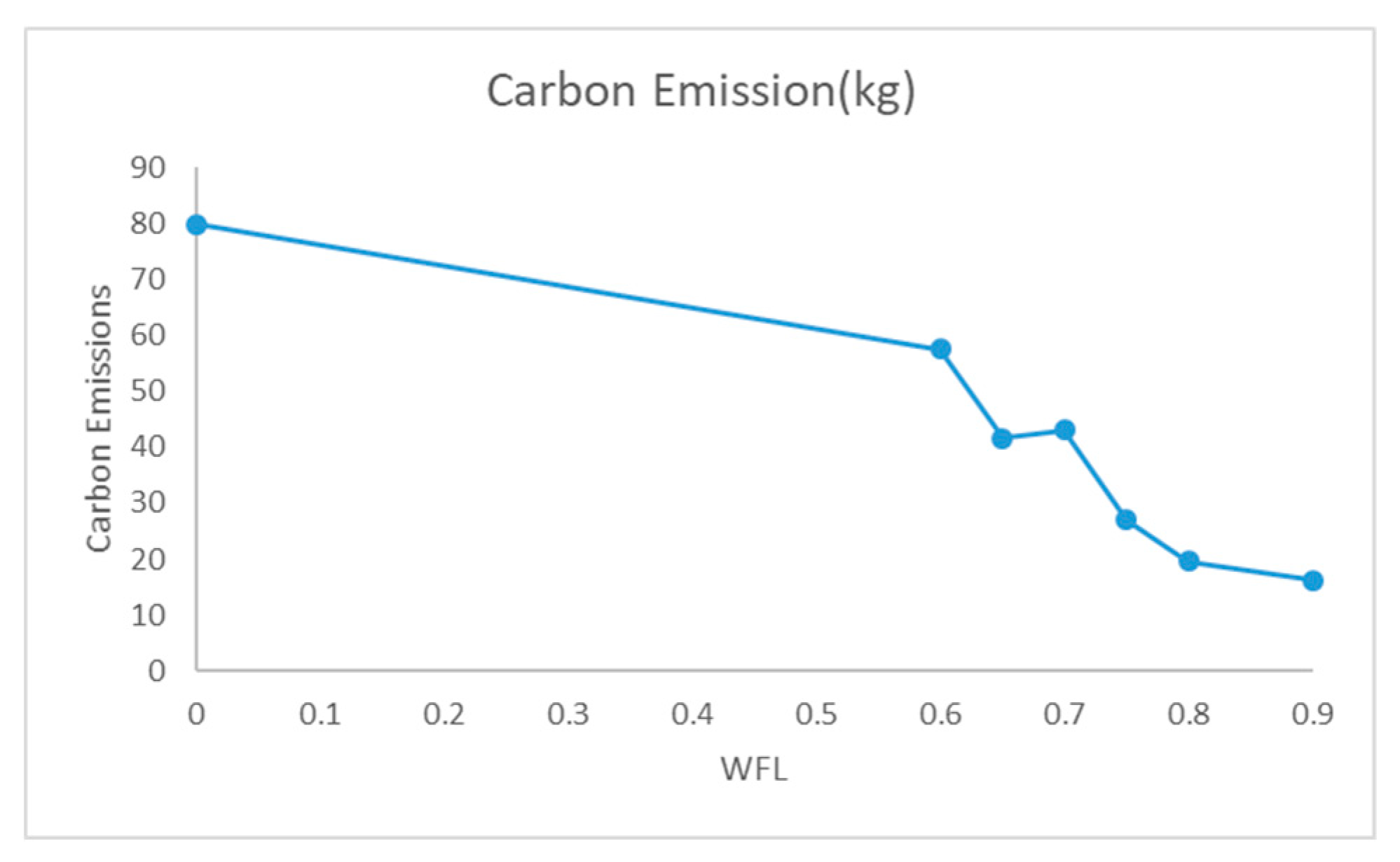

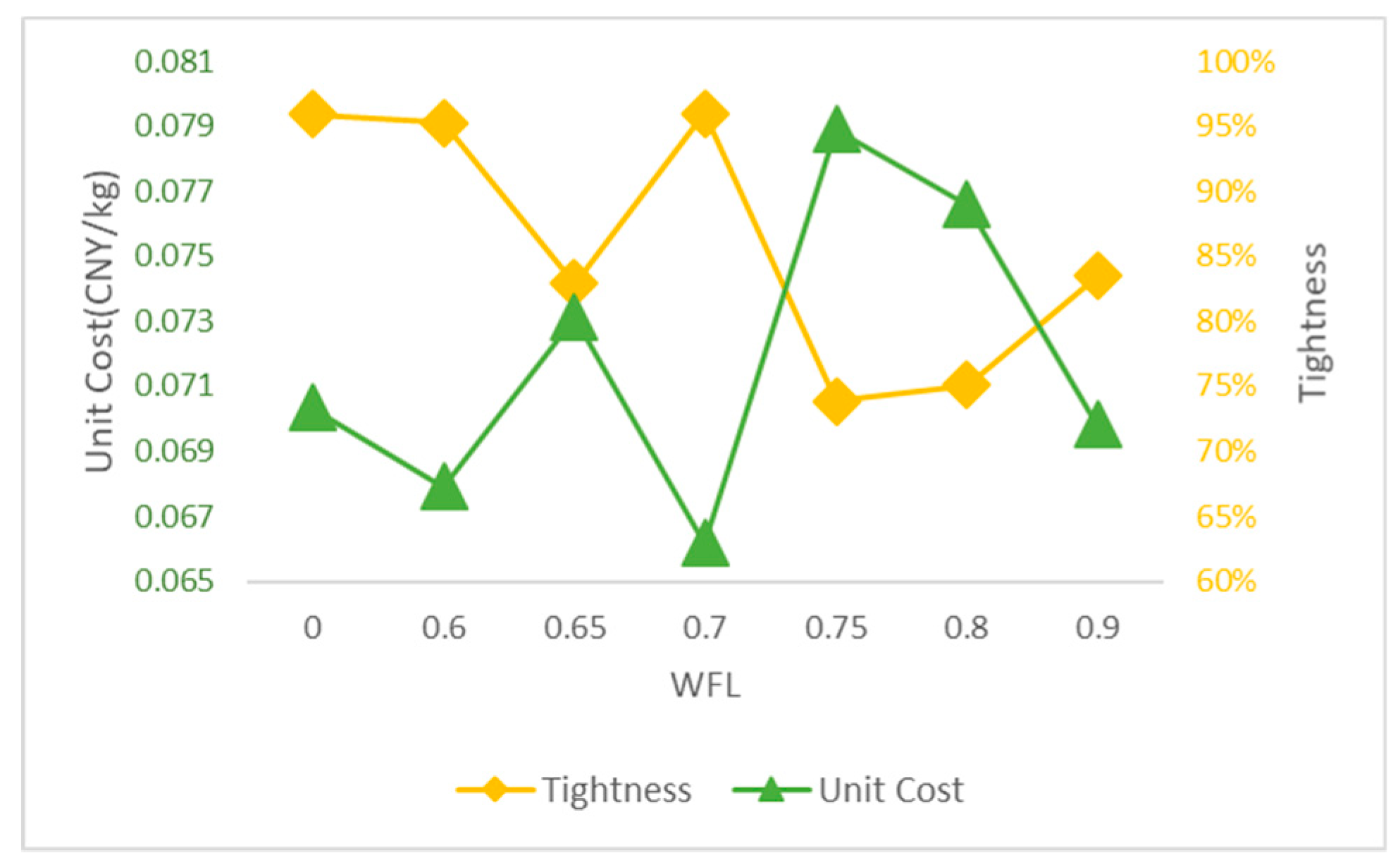

5.2.2. Experimental Results

5.3. Analysis of Results

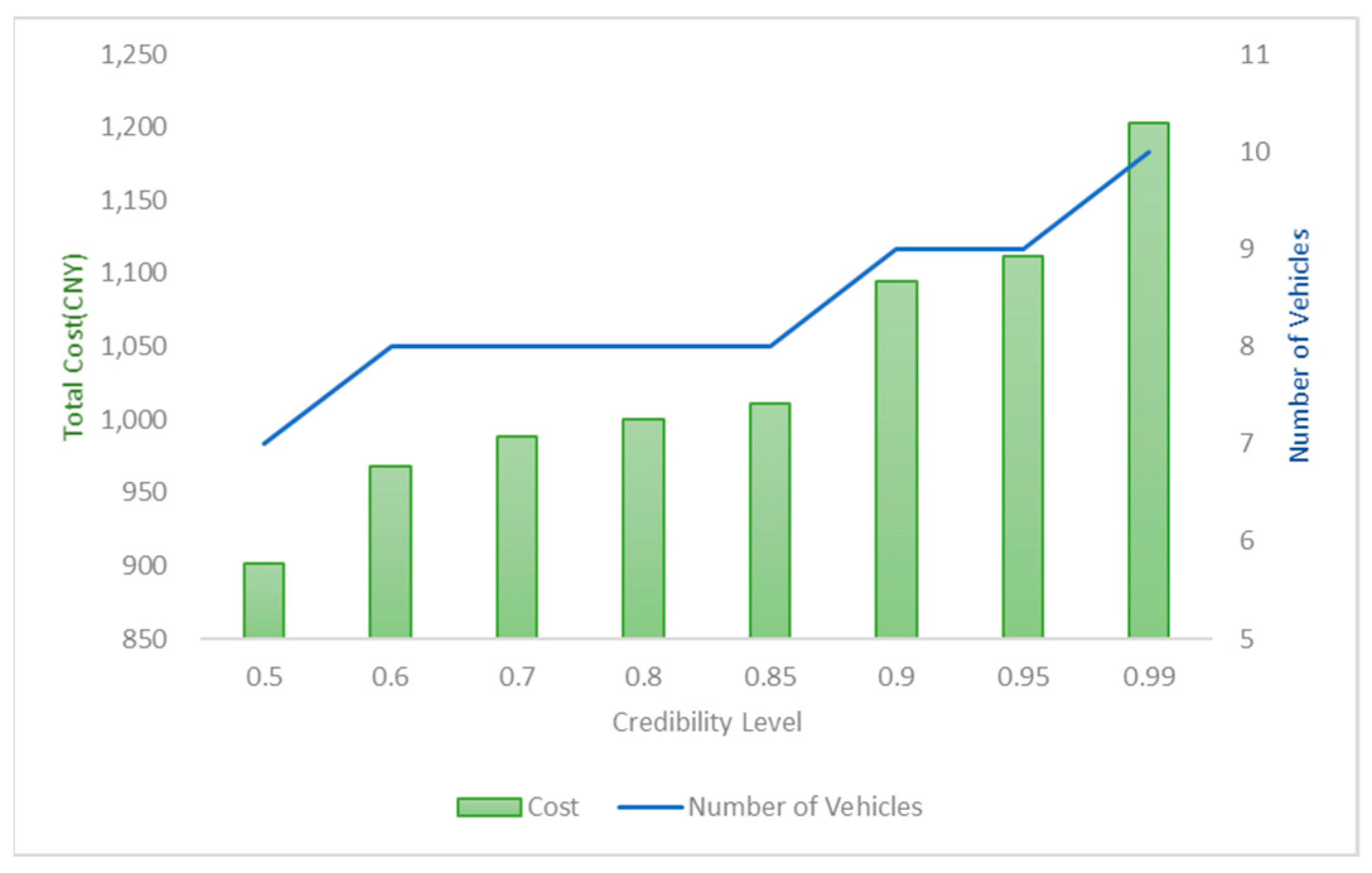

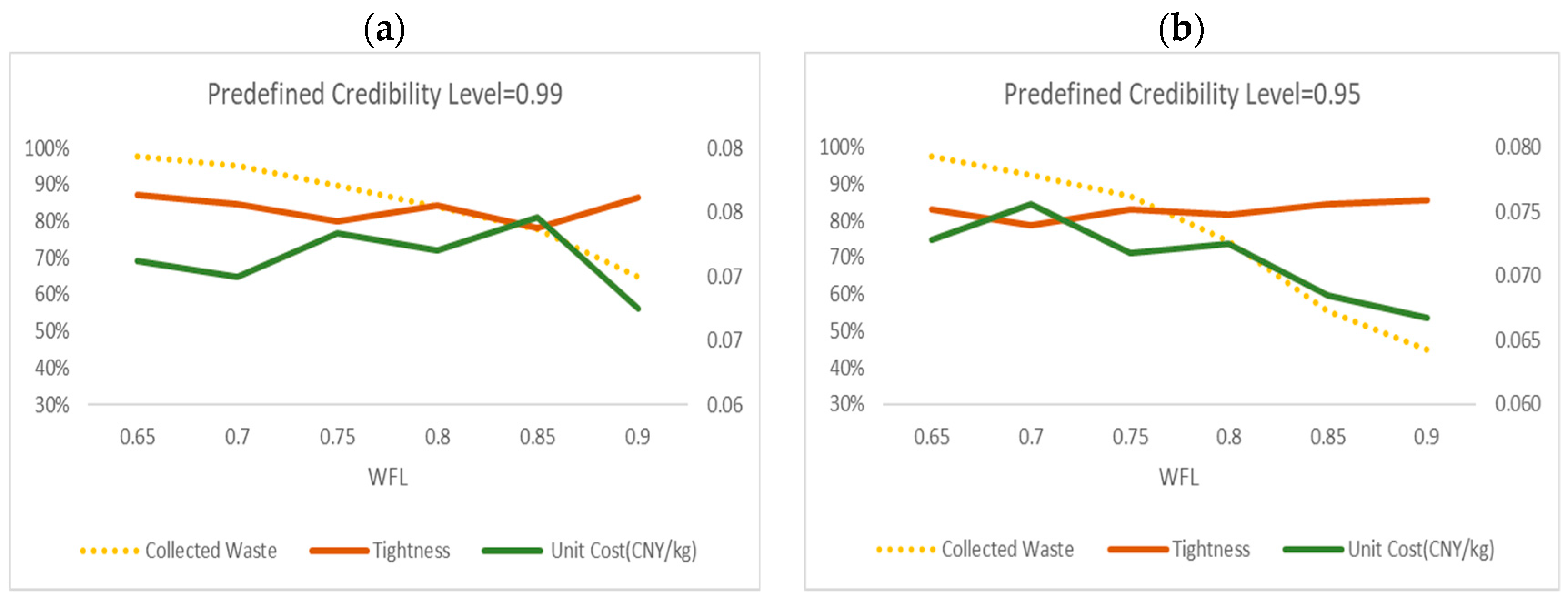

- (1)

- For experiment 1, when the WFL is increasing, all of the total cost, carbon emissions and route length decrease, and the unit cost and tightness fluctuate. In the static environment, there is a certain WFL of 0.75 with the minimum unit cost and the highest tightness.

- (2)

- For experiment 2, when , the dispatcher is the risk aversion type, expecting to plan more vehicles to obtain higher path reliability; when , the manager is the risk preference type, thinking that the overloading risk caused by uncertain environment can be accepted.

- (3)

- For experiment 3, in the range between 0.65 and 0.75 of WFL, the waste transportation obtains the overall optimality under different credibility levels.

- (4)

- Through setting different value of WFLs and credibility levels, it is proved that the CCLCVRP model is applicable for waste collection and transportation.

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hemidat, S.; Oelgemöller, D.; Nassour, A.; Nelles, M. Evaluation of Key Indicators of Waste Collection Using GIS Techniques as a Planning and Control Tool for Route Optimization. Waste Biomass Valorization 2017, 8, 1533–1554. [Google Scholar] [CrossRef]

- Erfan, B.T.; Alireza, G.; Maryam, P.; Ramina, M.K. A robust bi-objective multi-trip periodic capacitated arc routing problem for urban waste collection using a multi-objective invasive weed optimization. Waste Manag. Res. 2019, 37, 1089–1101. [Google Scholar]

- Assaf, R.; Saleh, Y. Vehicle-Routing Optimization for Municipal Solid Waste Collection Using Genetic Algorithm: The Case of Southern Nablus City. Civ. Environ. Eng. Rep. 2017, 26, 43–57. [Google Scholar] [CrossRef]

- Christopher, C.J.; Mondal, M.M.; Weichgrebe, D. Evaluation of compositional characteristics of organic waste shares in municipal solid waste in fast-growing metropolitan cities of India. J. Mater. Cycles Waste Manag. 2018, 20, 2150–2162. [Google Scholar]

- Akhtar, M.; Hannan, M.A.; Begum, R.A.; Basri, H.; Scavino, E. Backtracking search algorithm in CVRP models for efficient solid waste collection and route optimization. Waste Manag. 2017, 61, 117–128. [Google Scholar] [CrossRef]

- Ding, Z.; Zhu, M.; Tam, V.W.Y.; Yi, G.; Tran, C.N.N. Asystem dynamics based environmental benefit assessment model of construction waste reduction management at the design and construction stages. J. Clean. Prod. 2018, 176, 676–692. [Google Scholar] [CrossRef]

- Ghose, M.K.; Dikshit, A.K.; Sharma, S.K. A GIS based transportation model for solid waste disposal—A case study on Asansol municipality. Waste Manag. 2005, 26, 1287–1293. [Google Scholar] [CrossRef]

- Zhou, M.; Shen, S.; Xu, Y.; Zhou, A. New Policy and Implementation of Municipal Solid Waste Classification in Shanghai, China. Int. J. Environ. Res. Public Health 2019, 16, 3099. [Google Scholar] [CrossRef]

- Expósito-Márquez, A.; Expósito-Izquierdo, C.; Brito-Santana, J.; Moreno-Pérez, J.A. Greedy randomized adaptive search procedure to design waste collection routes in La Palma. Comput. Ind. Eng. 2019, 137, 106047. [Google Scholar] [CrossRef]

- Kwon, Y.-J.; Choi, Y.-J.; Lee, D.-H. Heterogeneous fixed fleet vehicle routing considering carbon emission. Transp. Res. Part D Transp. Environ. 2013, 23, 81–89. [Google Scholar] [CrossRef]

- Maurizio, F.; Alessandro, P.; Giorgia, Z. Waste collection multi objective model with real time traceability data. Waste Manag. 2011, 31, 2391–2405. [Google Scholar]

- Zsigraiova, Z.; Semiao, V.; Beijoco, F. Operation costs and pollutant emissions reduction by definition of new collection scheduling and optimization of MSW collection routes using GIS. The case study of Barreiro, Portugal. Waste Manag. 2013, 33, 793–806. [Google Scholar] [CrossRef] [PubMed]

- Arebey, M.; Hannan, M.A.; Begum, R.A.; Basri, H. Solid waste bin level detection using gray level co-occurrence matrix feature extraction approach. J. Environ. Manag. 2012, 104, 9–18. [Google Scholar] [CrossRef] [PubMed]

- Hannan, M.A.; Al Mamun, M.A.; Hussain, A.; Basri, H.; Begum, R.A. A review on technologies and their usage in solid waste monitoring and management systems: Issues and challenges. Waste Manag. 2015, 43, 509–523. [Google Scholar] [CrossRef]

- Hannan, M.A.; Arebey, M.; Begum, R.A.; Basri, H. Radio Frequency Identification (RFID) and communication technologies for solid waste bin and truck monitoring system. Waste Manag. 2011, 31, 2406–2413. [Google Scholar] [CrossRef]

- Kim, B.I.; Kim, S.; Sahoo, S. Waste collection vehicle routing problem with time windows. Comput. Oper. Res. 2005, 33, 3624–3642. [Google Scholar] [CrossRef]

- Asefi, H.; Shahparvari, S.; Chettri, P.; Lim, S. Variable fleet size and mix VRP with fleet heterogeneity in Integrated Solid Waste Management. J. Clean. Prod. 2019, 230, 1376–1395. [Google Scholar] [CrossRef]

- Markov, I.; Bierlaire, M.; Cordeau, J.F.; Maknoon, Y.; Varone, S. Waste Collection Inventory Routing with Non-Stationary Stochastic Demands. Comput. Oper. Res. 2019, 113, 104798. [Google Scholar] [CrossRef]

- Singh, A. Solid waste management through the applications of mathematical models. Resour. Conserv. Recycl. 2019, 151, 104503. [Google Scholar] [CrossRef]

- Abdallah, M.; Adghim, M.; Maraqa, M.; Aldahab, E. Simulation and optimization of dynamic waste collection routes. Waste Manag. Res. 2019, 37, 793–802. [Google Scholar] [CrossRef]

- Jabbarzadeh, A.; Darbaniyan, F.; Jabalameli, M.S. A multi-objective model for location of transfer stations: Case study in waste management system of Tehran. J. Ind. Syst. Eng. 2016, 9, 109–125. [Google Scholar]

- Herold, D.M.; Lee, K.-H. The influence of internal and external pressures on carbon management practices and disclosure strategies. Australas. J. Environ. Manag. 2019, 26, 63–81. [Google Scholar] [CrossRef]

- Herold, D.M.; Farr, B.; Lee, K.-H.; Groschopf, W. The interaction between institutional and stakeholder pressures: Advancing a framework for categorising carbon disclosure strategies. Bus. Strategy Dev. 2018, 2, 77–90. [Google Scholar] [CrossRef]

- Edalatpour, M.A.; Al-e-hashem, S.M.J.M.; Karimi, B.; Bahli, B. Investigation on a novel sustainable model for waste management in megacities: A case study in tehran municipality. Sustain. Cities Soc. 2018, 36, 286–301. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, A.A. Chance-Constrained Programming. Manag. Sci. 1959, 6, 73–79. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, G.; He, L. A multi-echelon supply chain model for municipal solid waste management system. Waste Manag. 2014, 34, 553–561. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, X.; Hu, X.; Huang, G.; Meng, N. A genetic-algorithm-aided fuzzy chance-constrained programming model for municipal solid waste management. Eng. Optimiz. 2019, 1–17. [Google Scholar] [CrossRef]

- Men, J.; Jiang, P.; Xu, H. A chance constrained programming approach for HazMat capacitated vehicle routing problem in Type-2 fuzzy environment. J. Clean. Prod. 2019, 237, 117754. [Google Scholar] [CrossRef]

- Kundu, P.; Majumder, S.; Kar, S.; Maiti, M. A method to solve linear programming problem with interval type-2 fuzzy parameters. Fuzzy Optim. Decis. Mak. 2019, 18, 109–130. [Google Scholar] [CrossRef]

- Kundu, P.; Kar, S.; Maiti, M. Multi-objective solid transportation problems with budget constraint in uncertain environment. Int. J. Syst. Sci. 2014, 45, 1668–1682. [Google Scholar] [CrossRef]

- Braekers, K.; Ramaekers, K.; Nieuwenhuyse, I.V. The vehicle routing problem: State of the art classification and review. Comput. Ind. Eng. 2016, 99, 300–313. [Google Scholar] [CrossRef]

- Buhrkal, K.; Larsen, A.; Ropke, S. The Waste Collection Vehicle Routing Problem with Time Windows in a City Logistics Context. Procedia Soc. Behav. Sci. 2012, 39, 241–254. [Google Scholar] [CrossRef]

- Yassen, E.T.; Ayob, M.; Nazri, M.Z.A.; Sabar, N.R. An adaptive hybrid algorithm for vehicle routing problems with time windows. Comput. Ind. Eng. 2017, 113, 382–391. [Google Scholar] [CrossRef]

- Luo, Z.; Qin, H.; Zhang, D.; Lim, A. Adaptive large neighborhood search heuristics for the vehicle routing problem with stochastic demands and weight-related cost. Transp. Res. Part E Logist. Transp. Rev. 2016, 85, 15–29. [Google Scholar] [CrossRef]

- Nucamendi-Guillén, S.; Angel-Bello, F.; Martínez-Salazar, I.; Cordero-Franco, A.E. The cumulative capacitated vehicle routing problem: New formulations and iterated greedy algorithms. Expert Syst. Appl. 2018, 113, 315–327. [Google Scholar] [CrossRef]

- Tohidifard, M.; Tavakkoli-Moghaddam, R.; Navazi, F.; Partovi, M. A Multi-Depot Home Care Routing Problem with Time Windows and Fuzzy Demands Solving by Particle Swarm Optimization and Genetic Algorithm. IFAC PapersOnLine 2018, 51, 358–363. [Google Scholar] [CrossRef]

- Xu, Y.; Qu, R.; Li, R. A simulated annealing based genetic local search algorithm for multi—Objective multicastrouting problems. Ann. Oper. Res. 2013, 206, 527–555. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Goli, A.; Hematian, M.; Sangaiah, A.H.; Han, T. Multi-objective multi-mode resource constrained project scheduling problem using Pareto-based algorithms. Computing 2019, 101, 547–570. [Google Scholar] [CrossRef]

- Jacobsen, R.; Buysse, J.; Gellynck, X. Cost comparison between private and public collection of residual household waste: Multiple case studies in the Flemish region of Belgium. Waste Manag. 2013, 33, 3–11. [Google Scholar] [CrossRef]

- Hemmelmayr, V.; Doerner, K.F.; Hartl, R.F.; Rath, S. A heuristic solution method for node routing based solid waste collection problems. J. Heuristics 2013, 19, 129–156. [Google Scholar] [CrossRef]

- Schneider, M.; Stenger, A.; Hof, J. An adaptive VNS algorithm for vehicle routing problems with intermediate stops. Or Spectr. 2015, 37, 353–387. [Google Scholar] [CrossRef]

- Groot, J.; Bing, X.; Bos-Brouwers, H.; Bloemhof-Ruwaard, J. A comprehensive waste collection cost model applied to post-consumer plastic packaging waste. Resour. Conserv. Recycl. 2014, 85, 79–87. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhao, Q.; Kaku, I.; Xu, Y. Development of a fuel consumption optimization model for the capacitated vehicle routing problem. Comput. Oper. Res. 2012, 39, 1419–1431. [Google Scholar] [CrossRef]

- Shen, L.; Tao, F.; Wang, S. Multi-Depot Open Vehicle Routing Problem with Time Windows Based on Carbon Trading. Int. J. Environ. Res. Public Health. 2018, 15, 2025. [Google Scholar] [CrossRef]

- Jiang, R.; Guan, Y. Data-driven chance constrained stochastic program. Math. Program. 2016, 158, 291–327. [Google Scholar] [CrossRef]

- Heidari, R.; Yazdanparast, R.; Jabbarzadeh, A. Sustainable design of a municipal solid waste management system considering waste separators: A real-world application. Sustain. Cities Soc. 2019, 47, 101457. [Google Scholar] [CrossRef]

- Coelho, L.C.; Laporte, G. Optimal joint replenishment, delivery and inventory management policies for perishable products. Comput. Oper. Res. 2014, 47, 42–52. [Google Scholar] [CrossRef]

- Liu, C.; Kou, G.; Peng, Y.; Alsaadi, F. Location-routing problem for relief distribution in the early post-earthquake stage from the perspective of fairness. Sustainability 2019, 11, 3420. [Google Scholar] [CrossRef]

- Barreto, S.; Ferreira, C.; Paixao, J.; Sousa Santos, B. Using clustering analysis location-routing in a capacitated problem. Eur. J. Oper. Res. 2007, 179, 968–977. [Google Scholar] [CrossRef]

- Zhang, S.; Ma, H.; Lei, Y.; Fu, J. Optimization of Municipal Solid Waste Collection and Transportation Routes Considering Residents’ Satisfaction. J. Syst. Manag. 2019, 28, 545–551. [Google Scholar]

- Li, L.; Qin, G.; Yang, Y. Optimization of Integrated Inventory Routing Problem for Cold Chain Logistics Considering Carbon Footprint and Carbon Regulations. Sustainability 2019, 11, 4628. [Google Scholar] [CrossRef]

- Qin, G.; Tao, F.; Li, L. A Vehicle Routing Optimization Problem for Cold Chain Logistics Considering Customer Satisfaction and Carbon Emissions. Int. J. Environ. Res. Public Health 2019, 16, 576. [Google Scholar] [CrossRef] [PubMed]

- Huang, M.; Ren, L.; Wang, X. Fourth party logistics routing optimization problem with stochastic transportation time and cost. J. Syst. Eng. 2019, 34, 82–90. [Google Scholar]

- Hannan, M.A.; Akhtar, M.; Begum, R.A.; Basri, H.; Hussain, A.; Scavino, E. Capacitated vehicle-routing problem model for scheduled solid waste collection and route optimization using PSO algorithm. Waste Manag. 2018, 71, 31–41. [Google Scholar] [CrossRef] [PubMed]

- Ran, L.; Wu, D.; Jiao, Z.; Wang, S.; Yuan, S. Distributionally robust chance-constrained vehicle scheduling with uncertain demand. Syst. Eng. Theory Pract. 2018, 38, 1792–1801. [Google Scholar]

| Notation | Explanation |

|---|---|

| Set of smart waste bins () | |

| Set of vehicles () | |

| Longest length of each route | |

| Initial waste of bin | |

| Incremental waste of bin , | |

| Weight of vehicle itself | |

| Load weight of vehicle | |

| Maximum load capacity of vehicle | |

| Fuel consumption rate per unit distance while vehicle is empty () | |

| Fuel consumption rate per unit distance () | |

| Fuel consumption rate per unit distance while vehicle is at full load () | |

| Fuel consumption rate per unit time while vehicle idling | |

| Total amount of fuel consumption () | |

| Total amount of carbon emissions from fuel consumption. | |

| Conversion factor value of fuel consumption and carbon dioxide | |

| Cost of per unit carbon emission | |

| Distance between smart waste bin and | |

| Service time of smart waste bin | |

| Fixed cost of per unit vehicle | |

| If the vehicle visits bin from , is 1. Otherwise, is 0 | |

| Price of per unit fuel consumption |

| 3 | 2 | 1 | 1 | 2 | 3 | 2 | 3 | 1 | 1 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 0.7358 | 0.4398 | 0.6832 | 0.3605 | 0.0735 | 0.0884 | 0.9307 | 0.3978 | 0.3530 | 0.7460 |

| 5 | 6 | 9 | 4 | 8 | 2 | 3 | 1 | 10 | 7 |

| Sub-path1 | 0 | 4 | 10 | 3 | 9 | 0 | |||

| Sub-path 2 | 0 | 7 | 2 | 5 | 0 | ||||

| Sub-path 3 | 0 | 8 | 6 | 1 | 0 |

| Case | Node | Capacity |

|---|---|---|

| A-n32-k5 | 31 | 100 |

| A-n36-k5 | 35 | 100 |

| A-n46-k7 | 45 | 100 |

| A-n53-k7 | 52 | 100 |

| A-n62-k8 | 61 | 100 |

| A-n80-k10 | 79 | 100 |

| B-n51-k7 | 50 | 100 |

| F-n135-k7 | 134 | 2210 |

| P-n76-k5 | 75 | 280 |

| P-n101-k4 | 100 | 400 |

| Description | Parameter | Value |

|---|---|---|

| Number of the population | 20 | |

| Inertia weight | 0.7 | |

| Inertia weight damping ratio | 0.99 | |

| Personal learning coefficient | 1.5 | |

| Global learning coefficient | 1.5 | |

| Evolution terminate generation | 1000 | |

| Initial temperature | 1000 | |

| Cooling coefficient | 0.9 | |

| Final temperature | 1 |

| Database | PSO | PSOSA | ||||

|---|---|---|---|---|---|---|

| Cost | Length | Carbon Emissions | Cost | Length | Carbon Emissions | |

| A-n32-k5 | 3889 | 1628 | 1628 | 3587 | 1543 | 974 |

| A-n36-k5 | 6005 | 1623 | 1127 | 5256 | 1454 | 1005 |

| A-n46-k7 | 5039 | 2075 | 1419 | 4771 | 1893 | 1382 |

| A-n53-k7 | 6982 | 2925 | 2090 | 3856 | 2463 | 1918 |

| A-n62-k8 | 10,449 | 3043 | 2367 | 9035 | 2766 | 2053 |

| A-n80-k10 | 15,103 | 4531 | 2836 | 9997 | 4471 | 2641 |

| B-n51-k7 | 8552 | 2864 | 1905 | 6203 | 2648 | 1697 |

| F-n135-k7 | 14,645 | 5946 | 5876 | 12,906 | 5671 | 4052 |

| P-n76-k5 | 10,227 | 2573 | 1390 | 9576 | 2369 | 1237 |

| P-n101-k4 | 7091 | 2865 | 1762 | 6739 | 2680 | 1628 |

| Point | X Coordinate | Y Coordinate | Amount of Waste |

|---|---|---|---|

| Depot | 2.3 | 2.12 | — |

| 1 | 0.98 | 0.08 | 376.122 |

| 2 | 3.6 | 1.05 | 339.786 |

| 3 | 3.35 | 2.68 | 463.5 |

| 4 | 1.92 | 4.27 | 548.34 |

| 5 | 2.46 | 4.55 | 551.1 |

| 6 | 3.87 | 1.67 | 550.002 |

| 7 | 0.74 | 2.35 | 361.116 |

| 8 | 2.43 | 0.01 | 463.326 |

| 9 | 0.36 | 1.55 | 562.482 |

| 10 | 3.94 | 2.43 | 336.3 |

| 11 | 1.97 | 1.31 | 556.908 |

| 12 | 1.18 | 3.42 | 569.934 |

| 13 | 0.4 | 4.56 | 365.358 |

| 14 | 0.4 | 2.85 | 323.094 |

| 15 | 4.64 | 1.33 | 442.266 |

| 16 | 1.02 | 4.64 | 550.506 |

| 17 | 4.78 | 0.32 | 440.82 |

| 18 | 1.7 | 3.13 | 424.128 |

| 19 | 0.3 | 0.54 | 450.822 |

| 20 | 1.72 | 2.58 | 337.632 |

| 21 | 3.02 | 4.78 | 339.684 |

| 22 | 3.06 | 1.36 | 561.144 |

| 23 | 2.78 | 2.63 | 480.888 |

| 24 | 2.73 | 3.56 | 379.59 |

| 25 | 1.01 | 1.07 | 559.44 |

| 26 | 3.94 | 4.13 | 317.43 |

| 27 | 1.74 | 0.69 | 437.328 |

| 28 | 4.86 | 2.19 | 516.66 |

| 29 | 0.58 | 3.88 | 401.7 |

| 30 | 3.56 | 3.52 | 420.366 |

| Parameters | Value |

|---|---|

| 100 CNY | |

| 8 CNY//L | |

| 0.165 L/km | |

| 0.377 L/km | |

| 0.05 L/min | |

| 2.63 kg/L | |

| 0.025 CNY/kg |

| Results | EVM | |||||

|---|---|---|---|---|---|---|

| 0.6 | 0.7 | 0.8 | 0.9 | 0.99 | ||

| Robustness | 45% | 55% | 75% | 80% | 90% | 97% |

| WFL | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| WFL = 0 | 945 | 80 | 91 | 0% | 30 | 7 | (0,11,3,29,4,0) | 13,428 | 100% | 96% | 0.07035 |

| (0,23,26,9,5,0) | |||||||||||

| (0,20,17,18,14,8,0) | |||||||||||

| (0,12,24,25,30,0) | |||||||||||

| (0,7,28,10,6,0) | |||||||||||

| (0,16,22,15,2,0) | |||||||||||

| (0,27,19,21,1,13,0) | |||||||||||

| WFL = 0.9 | 350 | 16 | 18 | 63% | 9 | 3 | (0,7,1,2,0) | 5010 | 37% | 83% | 0.06983 |

| (0,9,4,6,0) | |||||||||||

| (0,3,8,5,0) | |||||||||||

| WFL = 0.8 | 460 | 20 | 23 | 51% | 11 | 4 | (0,4,10,5,0) | 6007 | 45% | 75% | 0.07659 |

| (0,2,6,0) | |||||||||||

| (0,1,7,9,0) | |||||||||||

| (0,11,3,8,0) | |||||||||||

| WFL = 0.75 | 583 | 27 | 31 | 38% | 14 | 5 | (0,6,9,8,0) | 7385 | 55% | 74% | 0.07889 |

| (0,5,1,0) | |||||||||||

| (0,10,13,7,0) | |||||||||||

| (0,12,2,3,0) | |||||||||||

| (0,11,14,4,0) | |||||||||||

| WFL = 0.7 | 632 | 43 | 47 | 33% | 19 | 5 | (0,18,16,17,5,0) | 9550 | 71% | 96% | 0.06618 |

| (0,6,2,3,0) | |||||||||||

| (0,4,9,7,13,0) | |||||||||||

| (0,12,15,1,14,0) | |||||||||||

| (0,19,10,8,11,0) | |||||||||||

| WFL = 0.65 | 728 | 42 | 48 | 23% | 20 | 6 | (0,1,15,20,4,0) | 9952 | 74% | 83% | 0.07312 |

| (0,8,18,11,9,0) | |||||||||||

| ([0,2,16,14,0) | |||||||||||

| (0,5,17,13,6,0) | |||||||||||

| (0,19,3,7,0) | |||||||||||

| (0,10,12,0) | |||||||||||

| WFL = 0.6 | 776 | 58 | 67 | 18% | 24 | 6 | (0,23,11,10,17,0) | 11,434 | 85% | 95% | 0.06791 |

| (0,6,15,22,20,0) | |||||||||||

| ([0,19,9,8,18,0) | |||||||||||

| (0,13,1,16,12,0) | |||||||||||

| (0,14,7,21,3,0) | |||||||||||

| (0,24,5,4,2,0) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Tao, F.; Qiao, Q.; Zhang, M. A Chance-Constrained Vehicle Routing Problem for Wet Waste Collection and Transportation Considering Carbon Emissions. Int. J. Environ. Res. Public Health 2020, 17, 458. https://doi.org/10.3390/ijerph17020458

Wu H, Tao F, Qiao Q, Zhang M. A Chance-Constrained Vehicle Routing Problem for Wet Waste Collection and Transportation Considering Carbon Emissions. International Journal of Environmental Research and Public Health. 2020; 17(2):458. https://doi.org/10.3390/ijerph17020458

Chicago/Turabian StyleWu, Hailin, Fengming Tao, Qingqing Qiao, and Mengjun Zhang. 2020. "A Chance-Constrained Vehicle Routing Problem for Wet Waste Collection and Transportation Considering Carbon Emissions" International Journal of Environmental Research and Public Health 17, no. 2: 458. https://doi.org/10.3390/ijerph17020458

APA StyleWu, H., Tao, F., Qiao, Q., & Zhang, M. (2020). A Chance-Constrained Vehicle Routing Problem for Wet Waste Collection and Transportation Considering Carbon Emissions. International Journal of Environmental Research and Public Health, 17(2), 458. https://doi.org/10.3390/ijerph17020458