A Quantitative Study on Crucial Food Supplies after the 2011 Tohoku Earthquake Based on Time Series Analysis

Abstract

1. Introduction

2. Literature Review

2.1. Emergency Supplies Management

2.1.1. What Is Demanded in Terms of Timing, Type and Size

2.1.2. Quantitative Estimation of Supplies in Urgent Situations after Disasters Hit

2.1.3. Emergency Response of Supply Requests Based on Concrete Situations

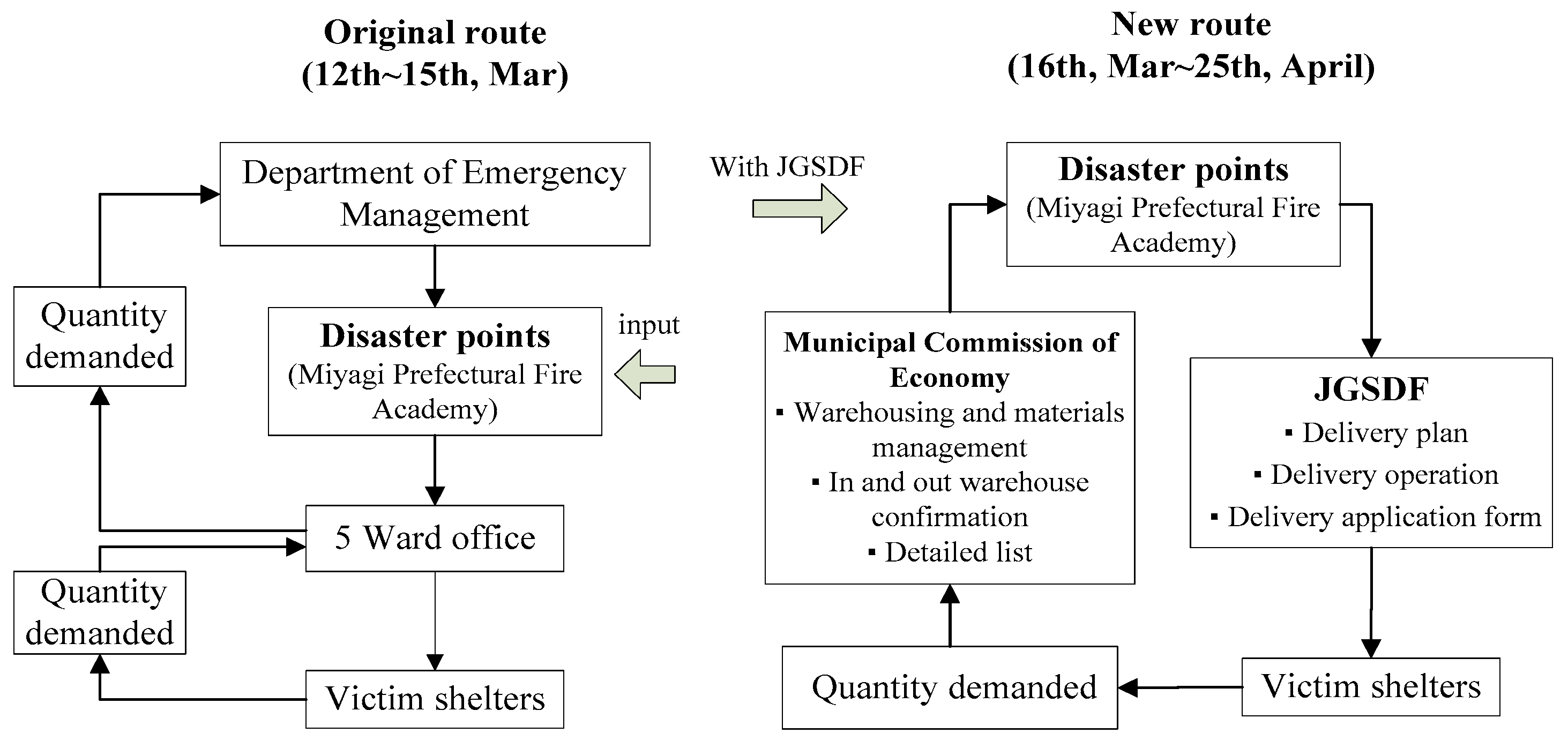

2.2. Response Processes of Supply Management in Sendai City in the 2011 Tohoku Earthquake

3. Models and Method

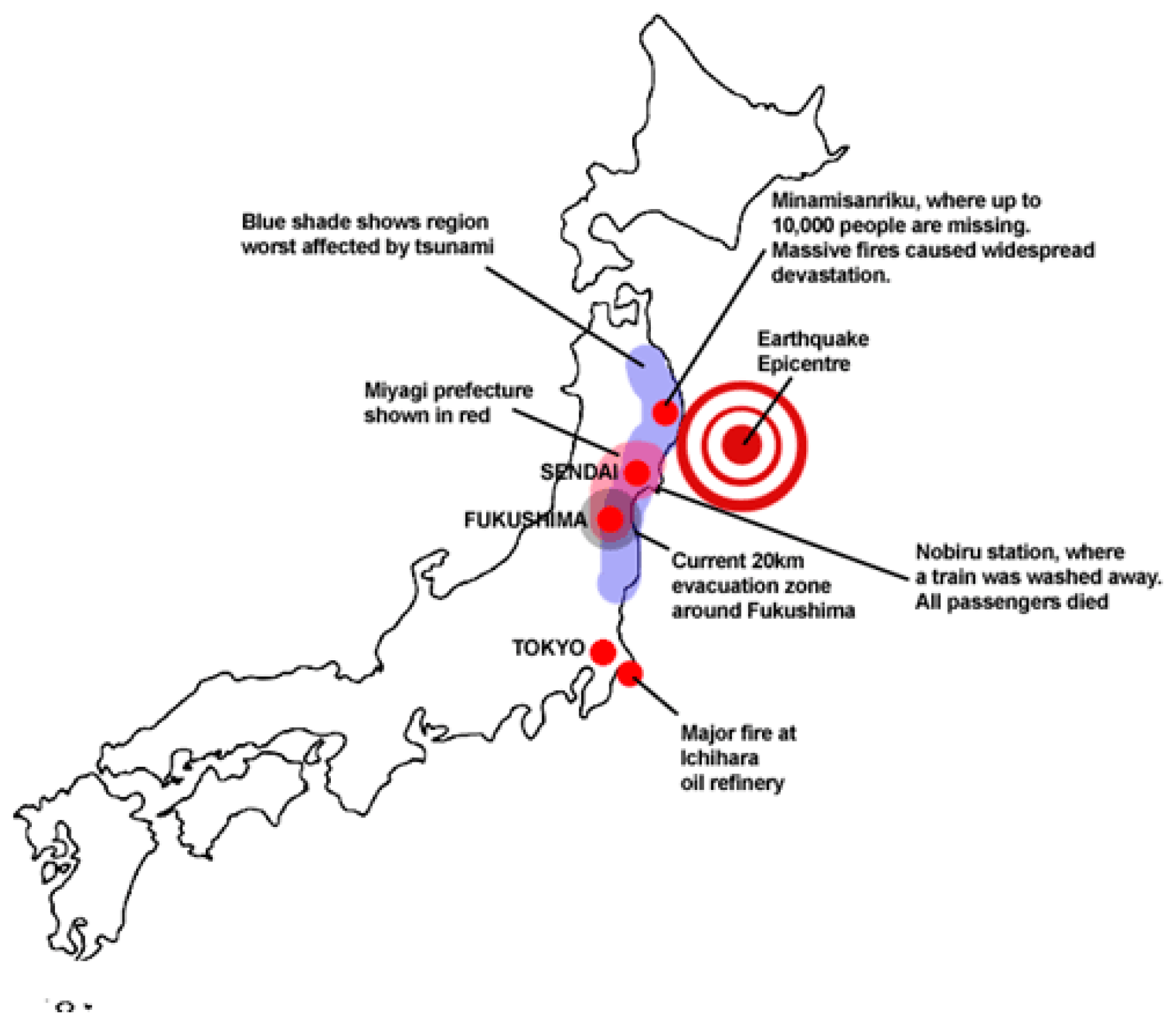

3.1. Region of Study

3.2. Data Gathering

3.3. Time Series Analysis

3.3.1. ARIMA

3.3.2. The Method of Least Squares

4. Results

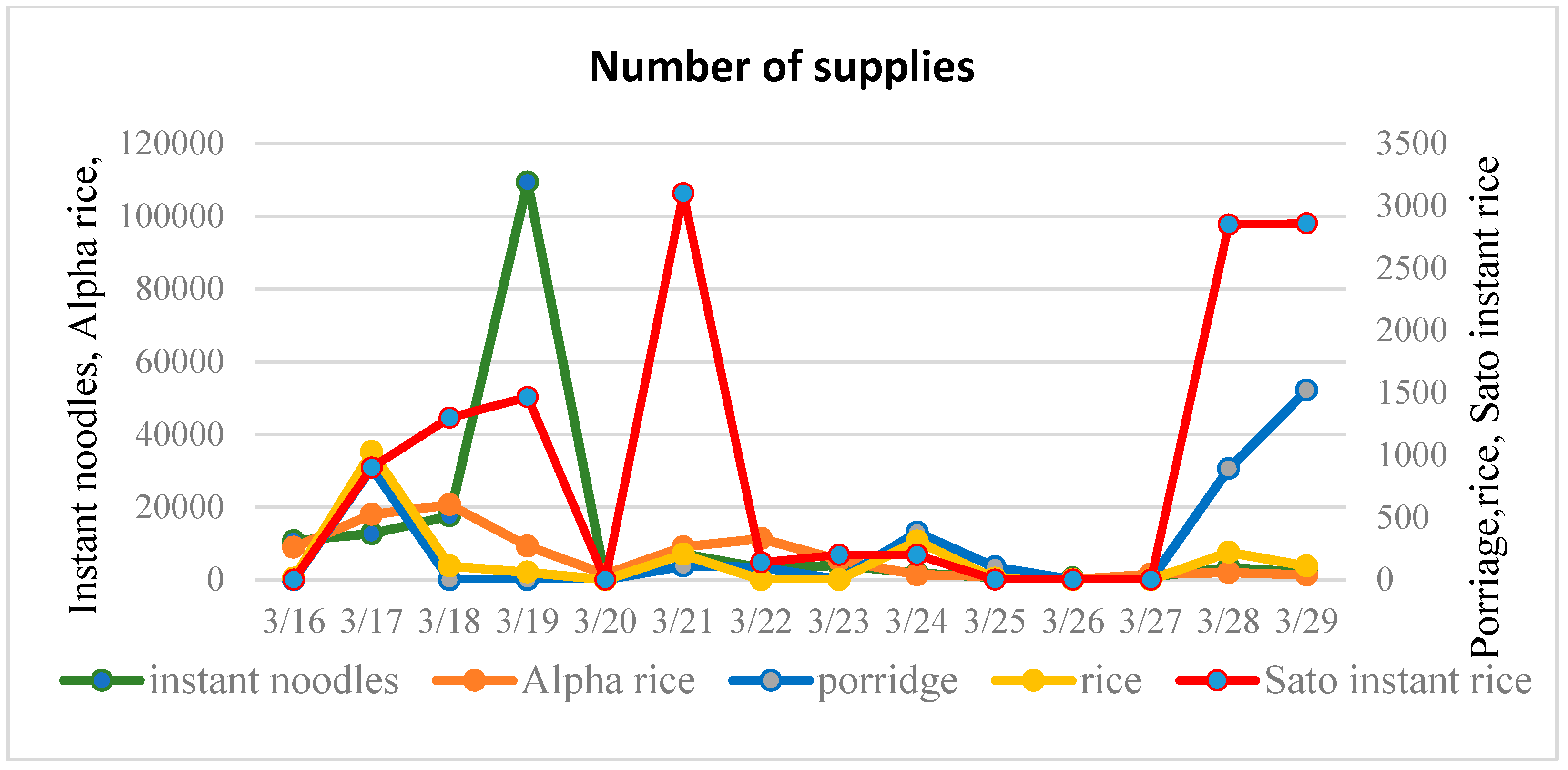

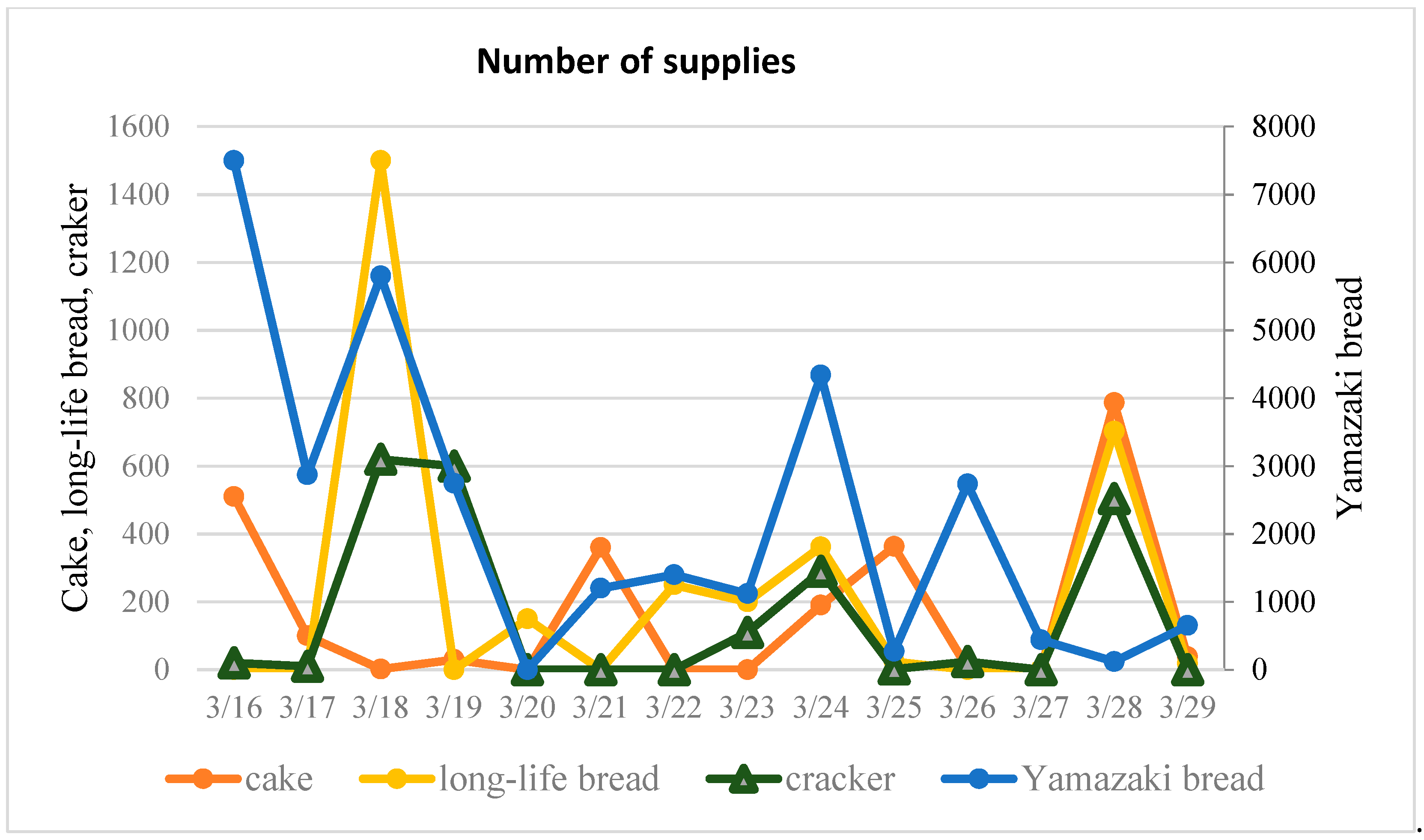

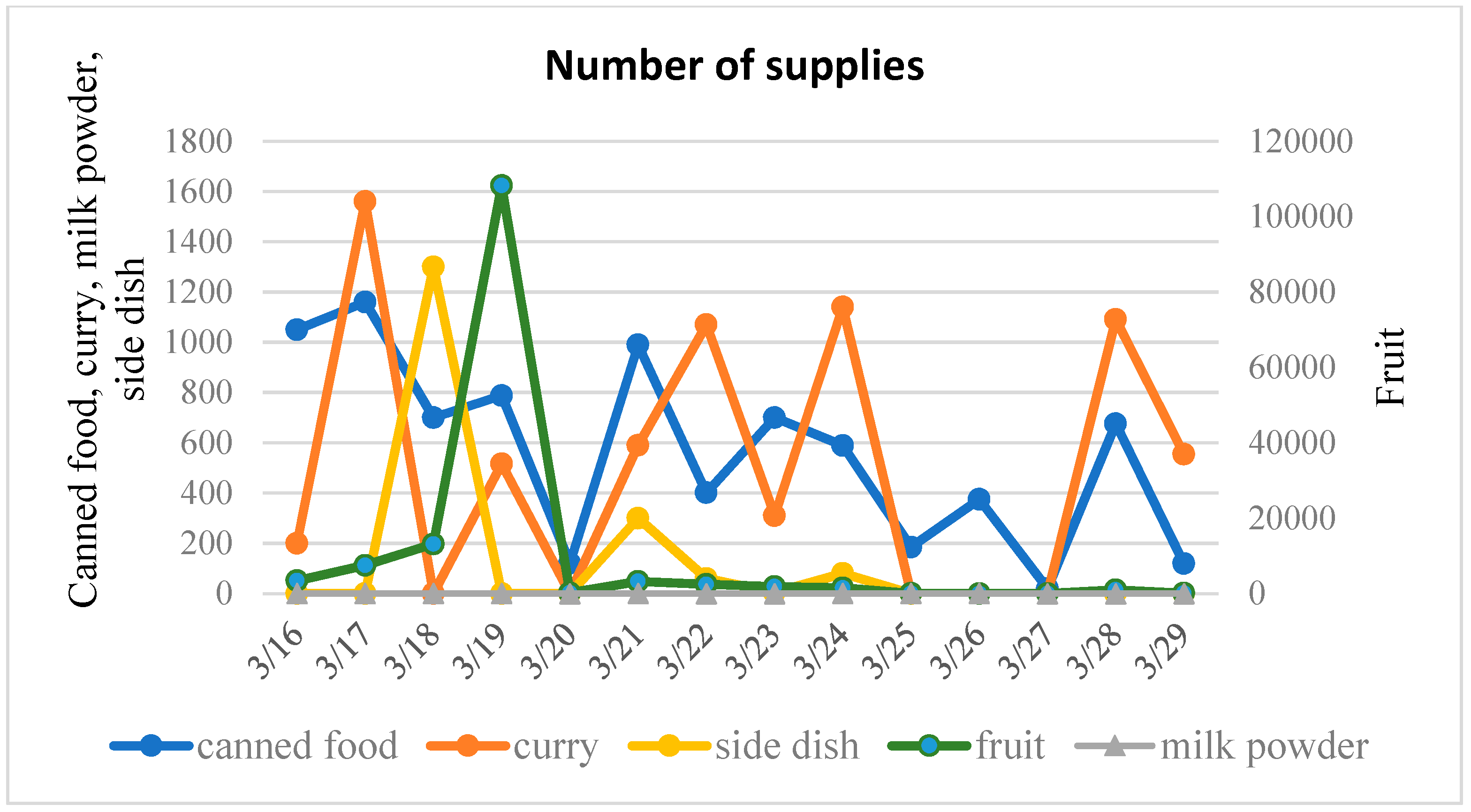

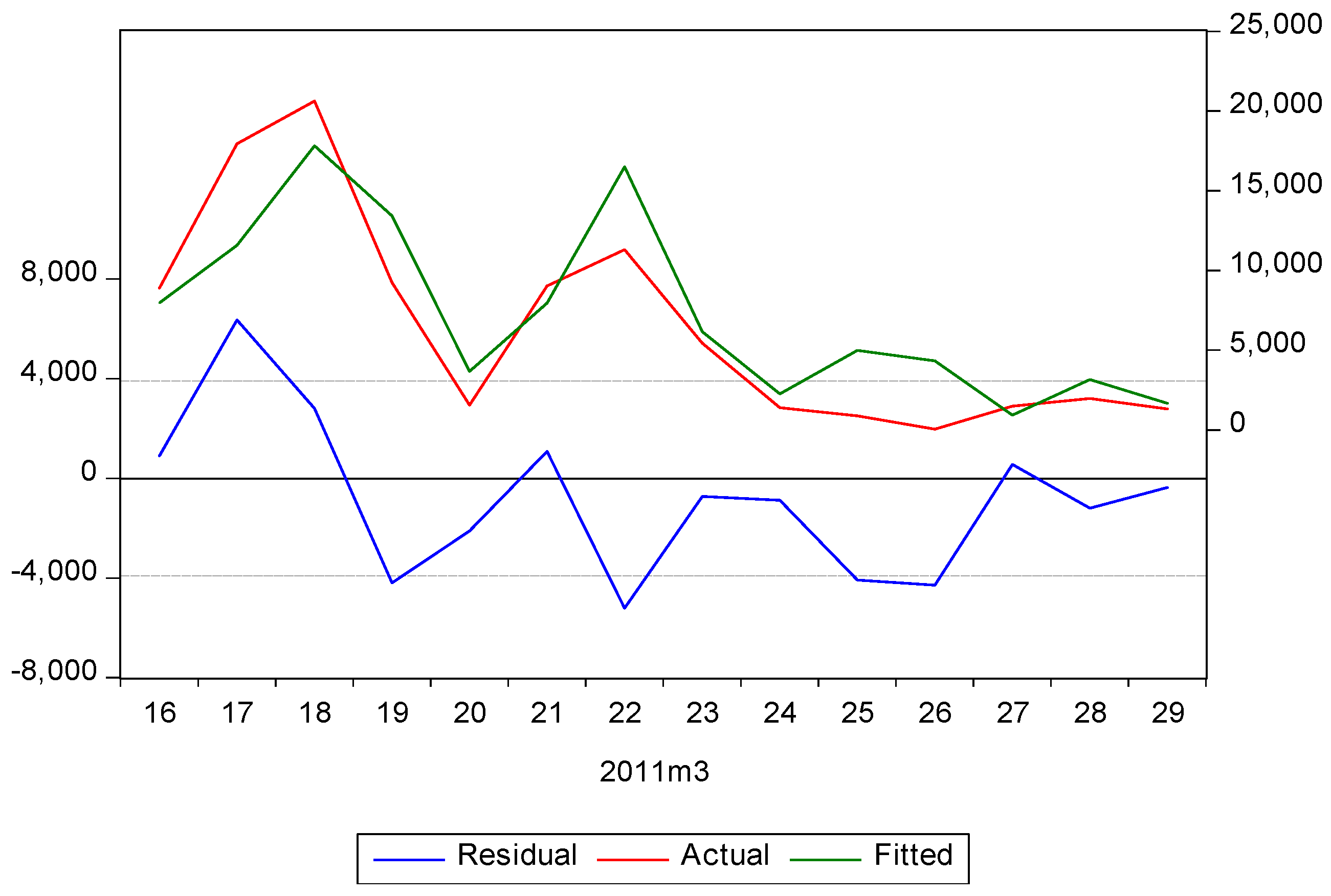

4.1. ARIMA Model of Food Supplies

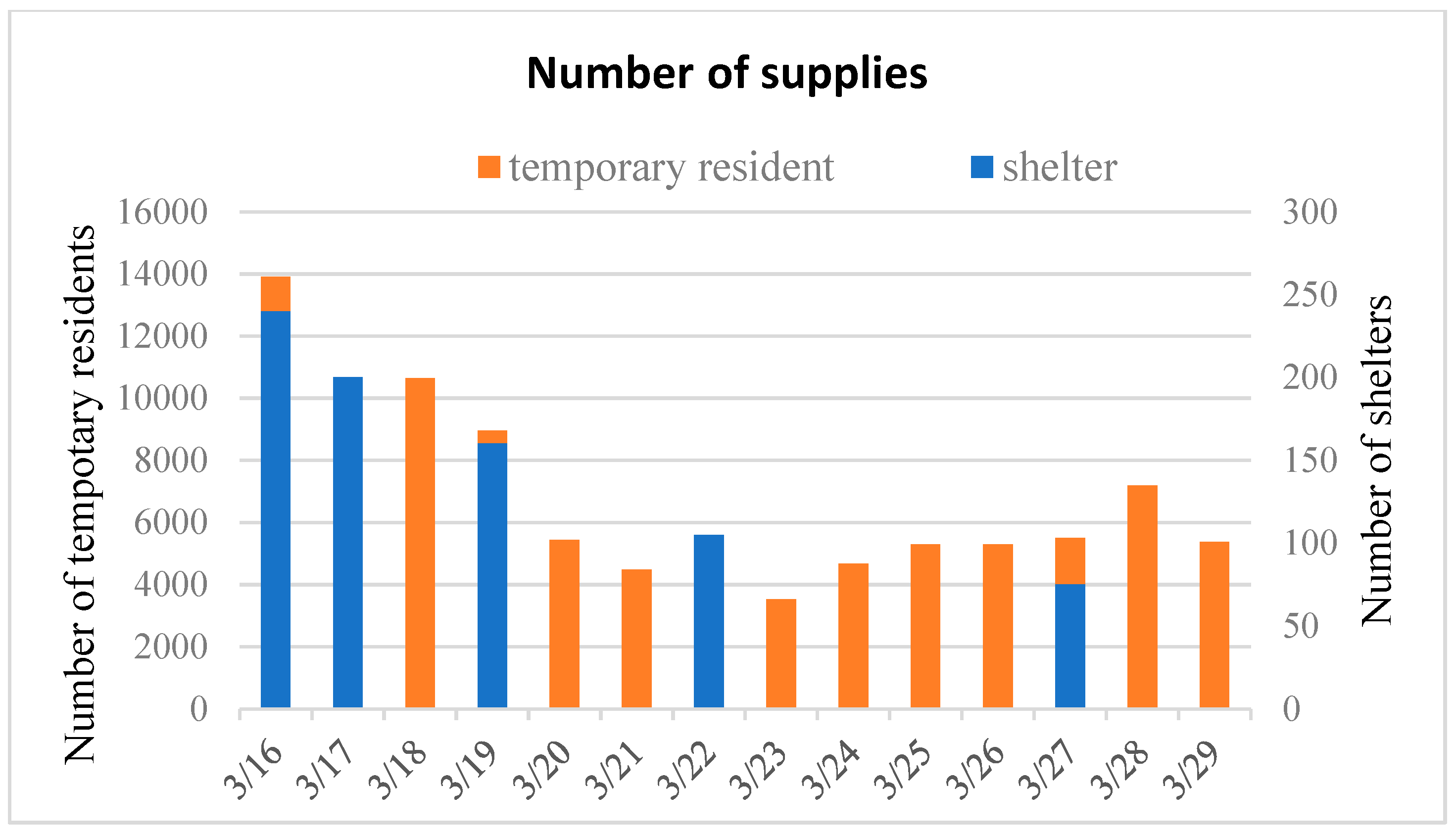

4.2. The Relation between Residents and Food Supplies

5. Discussion

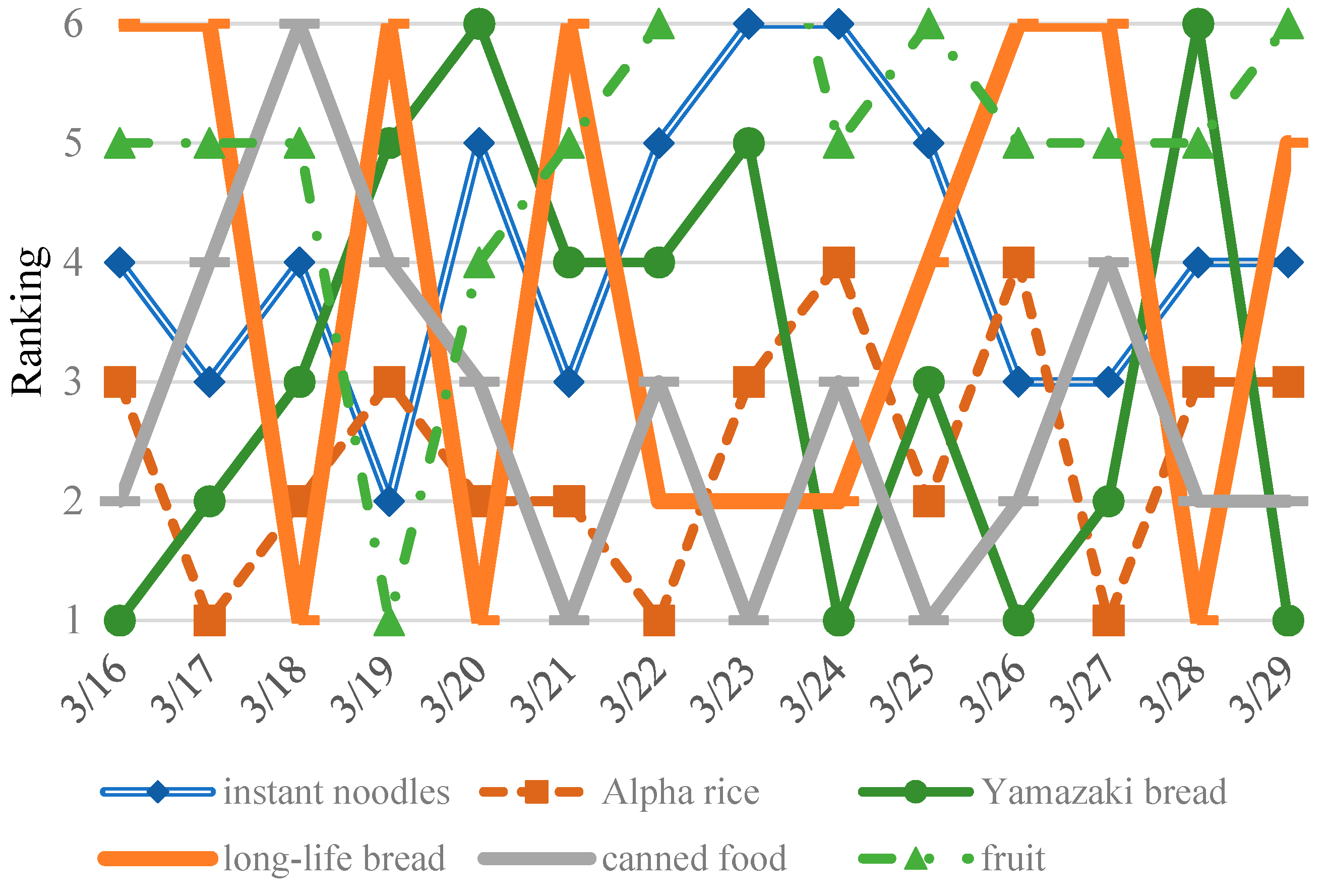

5.1. Temporal Evolution of Supplies Demanded in the Tohoku Earthquake

5.2. Estimated Time Series of Food Supplies

5.3. Crucial Commodities of Food Supplies

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Holguín-Veras, J.; Pérez, N.; Ukkusuri, S.; Wachtendorf, T.; Brown, B. Emergency logistics issues affecting the response to katrina: A synthesis and preliminary suggestions for improvement. Transp. Res. Rec. J. Transp. Res. Board 2007, 2022, 76–82. [Google Scholar] [CrossRef]

- Haghani, A.; Oh, S.-C. Formulation and solution of a multi-commodity, multi-modal network flow model for disaster relief operations. Transp. Res. Part A Policy Pract. 1996, 30, 231–250. [Google Scholar] [CrossRef]

- Ma, J. Coronavirus: China Red Cross under Fire over Poor Distribution of Masks, Medical Supplies. Available online: https://www.scmp.com/news/china/society/article/3048512/china-red-cross-under-fire-poor-delivery-coronavirus-supplies (accessed on 19 September 2020).

- Shao, J.; Liang, C.; Wang, X. Relief demand calculation in humanitarian logistics using material classification. Int. J. Environ. Res. Public Health 2020, 17, 582. [Google Scholar] [CrossRef]

- Tufekci, S.; Wallace, W.A. The emerging area of emergency management and engineering. Ieee Trans. Eng. Manag. 1998, 45, 103–105. [Google Scholar] [CrossRef]

- Rawls, C.G.; Turnquist, M.A. Pre-positioning of emergency supplies for disaster response. Transp. Res. Part B 2010, 44, 521–534. [Google Scholar] [CrossRef]

- Holguín-Veras, J.; Jalle, M. Immediate resource requirements after hurricane katrina. Nat. Hazards Rev. 2012, 13, 117–131. [Google Scholar] [CrossRef]

- Picciano, J. Responding to the Unexpected–Identifying Potential Technologies, Research and Development; National Science Foundation’s “Responding to the Unexpected” Workshop: New York, NY, USA, 2002. [Google Scholar]

- Balcik, B.; Beamon, B.M. Facility location in humanitarian relief. Int. J. Logist. 2008, 11, 101–121. [Google Scholar] [CrossRef]

- Ozdamar, L.; Ekinci, E.; Kücükyazici, B. Emergency logistics planning in natural disasters. Ann. Oper. Res. 2004, 129, 217–245. [Google Scholar] [CrossRef]

- Rivera-Royeroa, D.; Galindob, G.; Yie-Pinedoa, R. Planning the delivery of relief supplies upon the occurrence of a natural disaster while considering the assembly process of the relief kits. Socio-Econ. Plan. Sci. 2020. [Google Scholar] [CrossRef]

- Zhao, L.; Li, H.; Sun, Y. Planning emergency shelters for urban disaster resilience: An integrated location-allocation modeling approach. Sustainability 2017, 9, 2098. [Google Scholar] [CrossRef]

- Kemball-Cook, D.; Stephenson, R. Lessons in logistics from somalia. Disasters 1984, 8, 57–66. [Google Scholar] [CrossRef] [PubMed]

- Barbarosoglu, G.; Arda, Y. A two-stage stochastic programming framework for transportation planning in disaster response. J. Oper. Res. Soc. 2004, 55, 43–53. [Google Scholar] [CrossRef]

- Balcik, B.; Yanıkoğlu, İ. A robust optimization approach for humanitarian needs assessment planning under travel time uncertainty. Eur. J. Oper. Res. 2020, 282, 40–57. [Google Scholar] [CrossRef]

- Son, C.; Sasangohar, F.; Larsen, E.P. Resilient performance of emergency department: Patterns, models and strategies. Saf. Sci. 2019, 120, 362–373. [Google Scholar] [CrossRef]

- Rodríguez-Espíndola, O.; Albores, P.; Brewster, C. Disaster preparedness in humanitarian logistics: A collaborative approach for resource management in floods. Eur. J. Oper. Res. 2018, 264, 978–993. [Google Scholar] [CrossRef]

- Cavdur, F.; Sebatli, A. A decision support tool for allocating temporary-disaster-response facilities. Decis. Support Syst. 2019, 127, 1–14. [Google Scholar] [CrossRef]

- Kazama, M.; Noda, T. Damage statistics (summary of the 2011 off the pacific coast of tohoku earthquake damage). Soils Found. 2012, 52, 780–792. [Google Scholar] [CrossRef]

- Mori, N.; Takahashi, T.; Yasuda, T.; Yanagisawa, H. Survey of 2011 tohoku earthquake tsunami inundation and run-up. Geophys. Res. Lett. 2011, 38. [Google Scholar] [CrossRef]

- Gideon, M.R. Map Showing Major Areas of Damage in Japan, Including Fukushima & Missing Trains #Prayforjapan. Available online: https://100gf.wordpress.com/2011/03/13/map-showing-major-areas-of-damage-in-japan-including-fukushima-missing-trains-prayforjapan/ (accessed on 19 September 2020).

- Saotome, A.; Numada, M.; Meguro, K. Changes of contents and amount of relief goods during the 2011 off the Pacific coast of Tohoku earthquake--case study of the relief goods distributed in Sendai city. Jsce J. Earthq. Eng. 2012, 68, 1969–1975. [Google Scholar]

- Zhang, X.; Liu, Y.; Yang, M. Comparative study of four time series methods in forecasting typhoid fever incidence in china. PLoS ONE 2013, 8, e23116. [Google Scholar] [CrossRef]

- Ziegel, E.R. Time series: Theory and methods (2nd ed,). Technometrics 1992, 34, 371. [Google Scholar] [CrossRef]

- Gujarati, D.N. Basic Econometrics, 4th ed.; McGraw-Hill: Boston, MA, USA, 2003. [Google Scholar]

- Hahn, H.; Meyer-Nieberg, S.; Pickl, S. Electric load forecasting methods: Tools for decision making. Eur. J. Oper. Res. 2009, 199, 902–907. [Google Scholar] [CrossRef]

- Brandt, S. The Method of Least Squares; Springer: New York, NY, USA, 2014. [Google Scholar]

- Zhu, X.; Zhang, G.; Sun, B. A comprehensive literature review of the demand forecasting methods of emergency resources from the perspective of artificial intelligence. Nat. Hazards 2019, 65–82. [Google Scholar] [CrossRef]

- Xu, X.; Qi, Y.; Hua, Z. Forecasting demand of commodities after natural disasters. Expert Syst. Appl. 2010, 37, 4313–4317. [Google Scholar] [CrossRef]

- Sheu, J.B. Dynamic relief-demand management for emergency logistics operations under large-scale disasters. Transp. Res. Part E: Logist. Transp. Rev. 2010, 46, 1–17. [Google Scholar] [CrossRef]

| Variable | Coefficient | Std. Error | t-Statistic | Prob. |

|---|---|---|---|---|

| C | 6968.511 | 7320.139 | 0.952 | 0.366 |

| AR (1) | 1.184 | 0.205 | 5.763 | 0.000 |

| AR (2) | −1.009 | 0.229 | −4.401 | 0.002 |

| AR (3) | 0.710 | 0.242 | 2.931 | 0.017 |

| SIGMASQ | 9,831,953 | 4,665,112 | 2.108 | 0.064 |

| R-squared | 0.759 | Mean dependent var | 6515.643 | |

| S.E. of regression | 3910.773 | Akaike info criterion | 19.870 | |

| F-statistic | 7.075 | Schwarz criterion | 20.098 | |

| Prob (F-statistic) | 0.007 | Durbin–Watson stat | 1.476 | |

| Item | ARIMA Model | Parameters | ||||

|---|---|---|---|---|---|---|

| Type | Coefficient | t-Statistic | Sig. | |||

| 1 | Instant noodles | (2,2,0) | AR (1) | −1.034 | −3.594 | 0.007 |

| AR (2) | −0.552 | −1.970 | 0.084 | |||

| 2 | Rice | (3,1,0) | AR (1) | −1.008 | −2.734 | 0.026 |

| AR (2) | −0.844 | −2.062 | 0.073 | |||

| AR (3) | −0.589 | −2.146 | 0.064 | |||

| 3 | Alpha rice | (3,2,0) | AR (1) | 1.184 | 5.763 | 0.000 |

| AR (2) | −1.009 | −0.402 | 0.002 | |||

| AR (3) | 0.710 | 2.931 | 0.017 | |||

| 4 | Porridge | (1,2,0) | AR (1) | −0.778 | −4.027 | 0.003 |

| 5 | Sato instant rice | (1,2,0) | AR (1) | −0.729 | −3.046 | 0.014 |

| 6 | Yamazaki bread | (1,1,0) | AR (1) | −0.672 | −3.005 | 0.013 |

| 7 | Long-life bread | (3,1,0) | AR (1) | −0.926 | −2.668 | 0.028 |

| AR (2) | −0.836 | −2.251 | 0.055 | |||

| AR (3) | −0.681 | −2.797 | 0.023 | |||

| 8 | Cake | (2,2,0) | AR (1) | −0.988 | −2.783 | 0.024 |

| AR (2) | −0.758 | −1.919 | 0.091 | |||

| 9 | Canned food | (1,1,0) | AR (1) | −0.779 | −3.810 | 0.003 |

| 10 | Curry | (1,1,0) | AR (1) | −0.711 | −3.304 | 0.008 |

| 11 | Side dish | (2,1,0) | AR (1) | −0.920 | −4.817 | 0.001 |

| AR (2) | −0.870 | −7.246 | 0.000 | |||

| 12 | Fruit | (3,1,0) | AR (1) | −0.802 | −2.586 | 0.032 |

| AR (2) | −0.665 | −1.935 | 0.089 | |||

| AR (3) | −0.566 | −2.114 | 0.067 | |||

| Category | Item | Coeff. | SE | t-Statistic | Prob. | ||

|---|---|---|---|---|---|---|---|

| Number of residents | I Rice and noodle products | 1 | instant noodles | 3.4100 | 2.6454 | 1.2891 | 0.2217 |

| 2 | rice | −0.0045 | 0.1189 | −0.0375 | 0.9707 | ||

| 3 | Alpha rice | 1.2037 | 0.5599 | 2.1498 | 0.0527 * | ||

| 4 | porridge | −0.0094 | 0.0473 | −0.1997 | 0.8450 | ||

| 5 | Sato instant rice | −0.0045 | 0.1189 | −0.0375 | 0.9707 | ||

| II Wheat-based commodities | 6 | Yamazaki bread | 0.5945 | 0.1490 | 3.9906 | 0.0018 ** | |

| 7 | long-life bread | 0.0367 | 0.0402 | 0.9142 | 0.3786 | ||

| 8 | cracker | 0.0292 | 0.0225 | 1.3004 | 0.2179 | ||

| 9 | cake | 0.0252 | 0.0233 | 1.0790 | 0.3018 | ||

| III Other, etc. | 10 | canned food | 0.0662 | 0.0313 | 2.1114 | 0.0564 * | |

| 11 | curry | −0.0141 | 0.0512 | −0.2751 | 0.7879 | ||

| 12 | side dish | 0.0376 | 0.0329 | 1.1431 | 0.2753 | ||

| 13 | milk powder | 0.0019 | 0.0019 | 1.0030 | 0.3357 | ||

| 14 | fruit | 2.8515 | 2.7086 | 1.0528 | 0.3132 |

| Variable | Coefficient | Std. Error | t-Statistic | Prob. |

|---|---|---|---|---|

| C | 117.6720 | 228.1217 | 0.515830 | 0.6153 |

| X | 0.066177 | 0.031342 | 2.111412 | 0.0564 |

| R-square | 0.270874 | Mean dependent var | 562.3571 | |

| Adjusted R-squared | 0.210113 | S.D. dependent var | 369.0127 | |

| S.E. of regression | 327.9621 | Akaike info criterion | 14.5524 | |

| Log likelihood | −99.88666 | Schwarz criterion | 14.64653 | |

| F-statistic | 4.458061 | Hannan–Quinn criterion | 14.54679 | |

| Prob (F-statistic) | 0.056390 | Durbin–Watson stat | 2.351963 | |

| Variable | Coefficient | Std. Error | t-Statistic | Prob. |

|---|---|---|---|---|

| C | −1572.489 | 4075.014 | −0.385886 | 0.7063 |

| X | 1.203655 | 0.559881 | 2.149840 | 0.0527 |

| R-square | 0.278057 | Mean dependent var | 6515.643 | |

| Adjusted R-squared | 0.217895 | S.D. dependent var | 6624.509 | |

| S.E. of regression | 5858.497 | Akaike info criterion | 20.32074 | |

| Log likelihood | −140.2452 | Schwarz criterion | 20.41203 | |

| F-statistic | 4.621810 | Hannan–Quinn criterion | 20.31229 | |

| Prob (F-statistic) | 0.052658 | Durbin–Watson stat | 1.144110 | |

| Variable | Coefficient | Std. Error | t-Statistic | Prob. |

|---|---|---|---|---|

| C | −1766.724 | 1084.228 | −1.629476 | 0.1292 |

| X | 0.594463 | 0.148966 | 3.990593 | 0.0018 |

| R-square | 0.570275 | Mean dependent var | 2227.857 | |

| Adjusted R-squared | 0.534465 | S.D. dependent var | 2284.554 | |

| S.E. of regression | 1558.755 | Akaike info criterion | 17.67273 | |

| Log likelihood | −121.7091 | Schwarz criterion | 17.76402 | |

| F-statistic | 15.92483 | Hannan–Quinn criterion | 17.66428 | |

| Prob (F-statistic) | 0.01792 | Durbin–Watson stat | 2.094655 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, X.; Wang, Y.; Regan, D.; Sun, B. A Quantitative Study on Crucial Food Supplies after the 2011 Tohoku Earthquake Based on Time Series Analysis. Int. J. Environ. Res. Public Health 2020, 17, 7162. https://doi.org/10.3390/ijerph17197162

Zhu X, Wang Y, Regan D, Sun B. A Quantitative Study on Crucial Food Supplies after the 2011 Tohoku Earthquake Based on Time Series Analysis. International Journal of Environmental Research and Public Health. 2020; 17(19):7162. https://doi.org/10.3390/ijerph17197162

Chicago/Turabian StyleZhu, Xiaoxin, Yanyan Wang, David Regan, and Baiqing Sun. 2020. "A Quantitative Study on Crucial Food Supplies after the 2011 Tohoku Earthquake Based on Time Series Analysis" International Journal of Environmental Research and Public Health 17, no. 19: 7162. https://doi.org/10.3390/ijerph17197162

APA StyleZhu, X., Wang, Y., Regan, D., & Sun, B. (2020). A Quantitative Study on Crucial Food Supplies after the 2011 Tohoku Earthquake Based on Time Series Analysis. International Journal of Environmental Research and Public Health, 17(19), 7162. https://doi.org/10.3390/ijerph17197162