Using Improved Principal Component Analysis to Explore Construction Accident Situations from the Multi-Dimensional Perspective: A Chinese Study

Abstract

1. Introduction

2. Materials and Methods

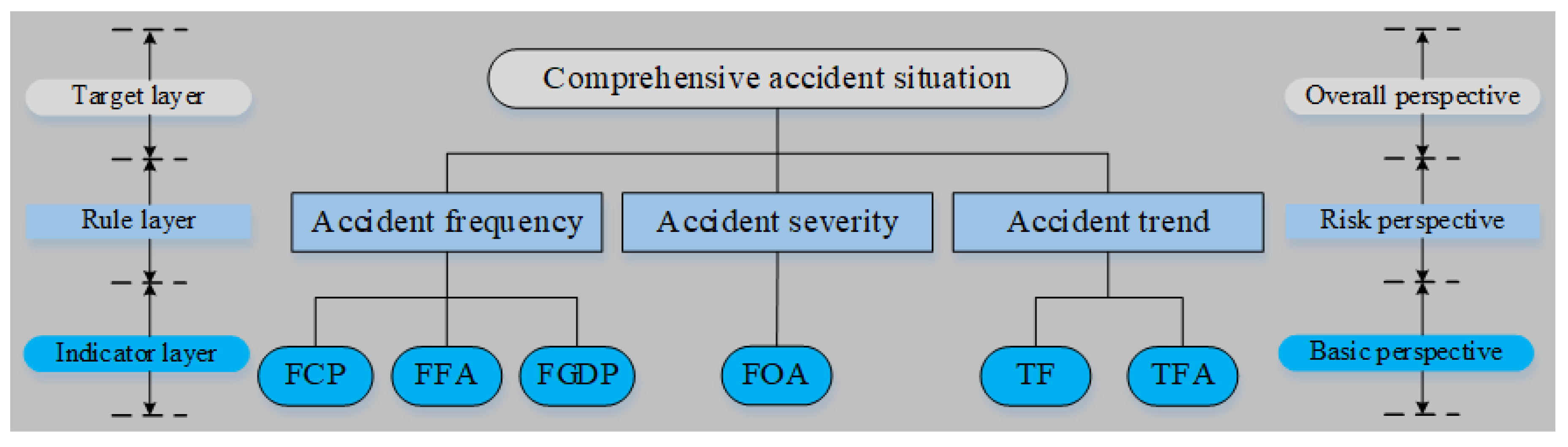

2.1. Selection of CASIs

2.2. Data Collection

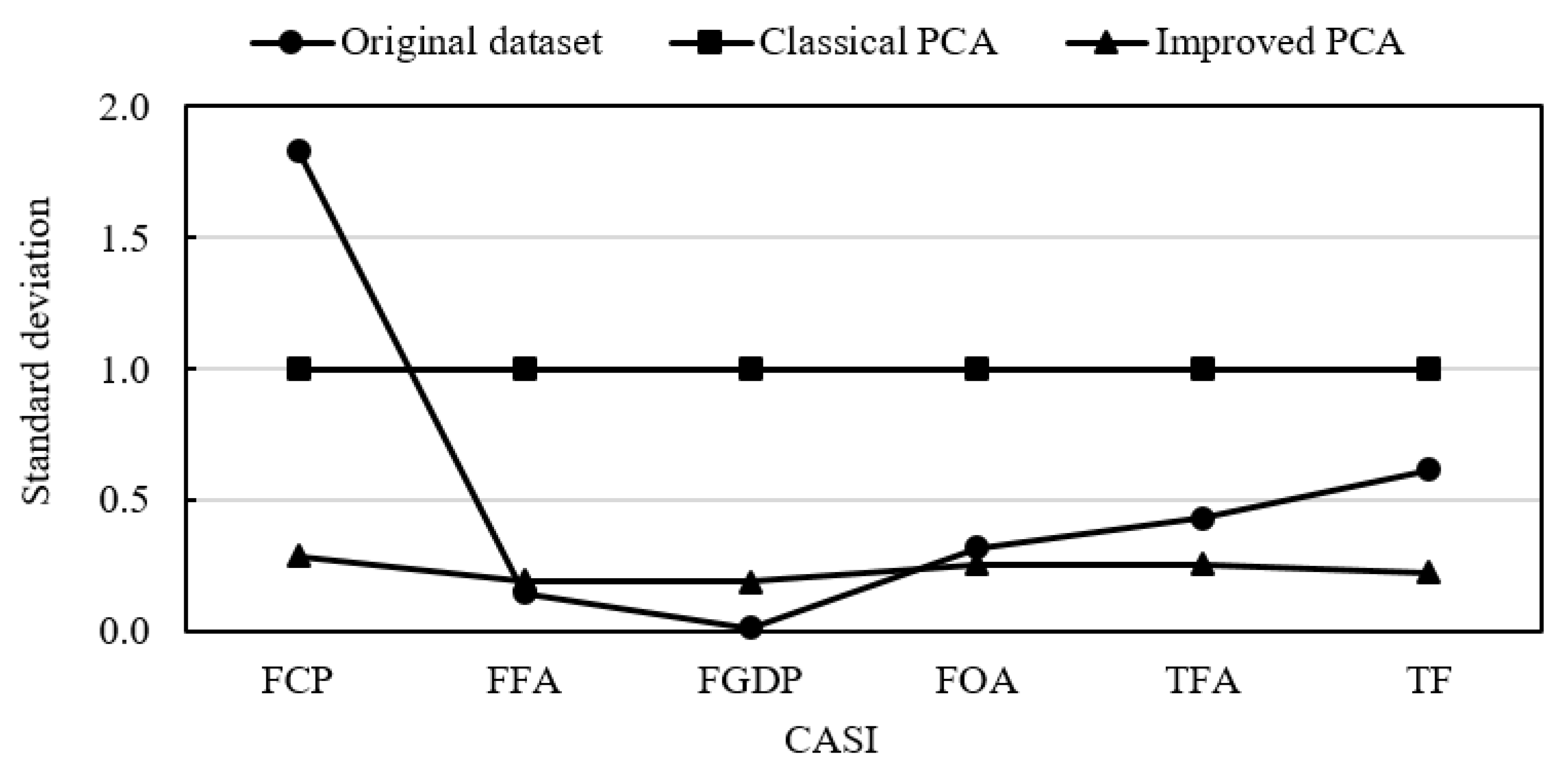

2.3. Improved PCA

3. Results

3.1. Determination of Principal Components

3.2. Connotation of Principal Components

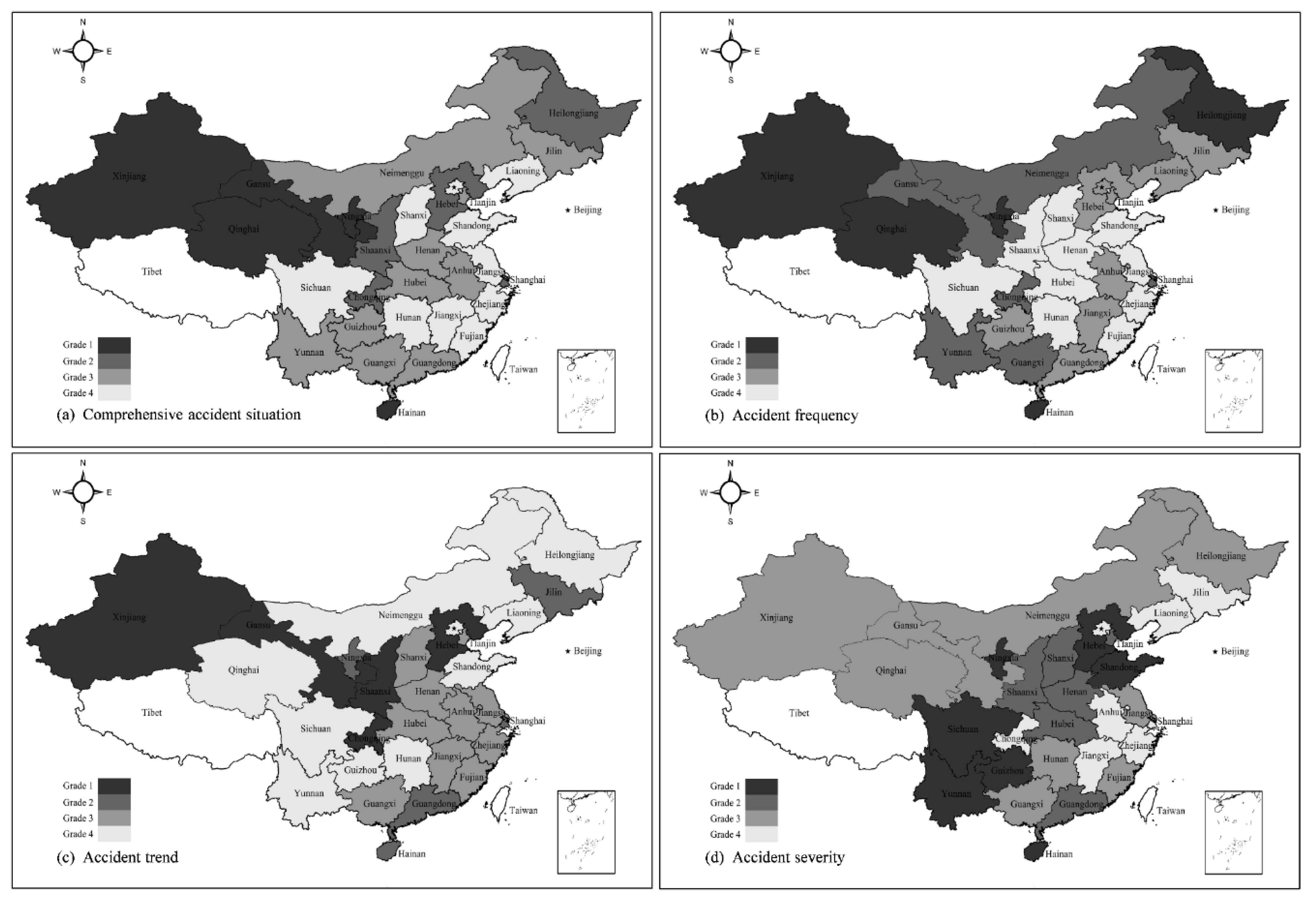

3.3. AS in China Provinces

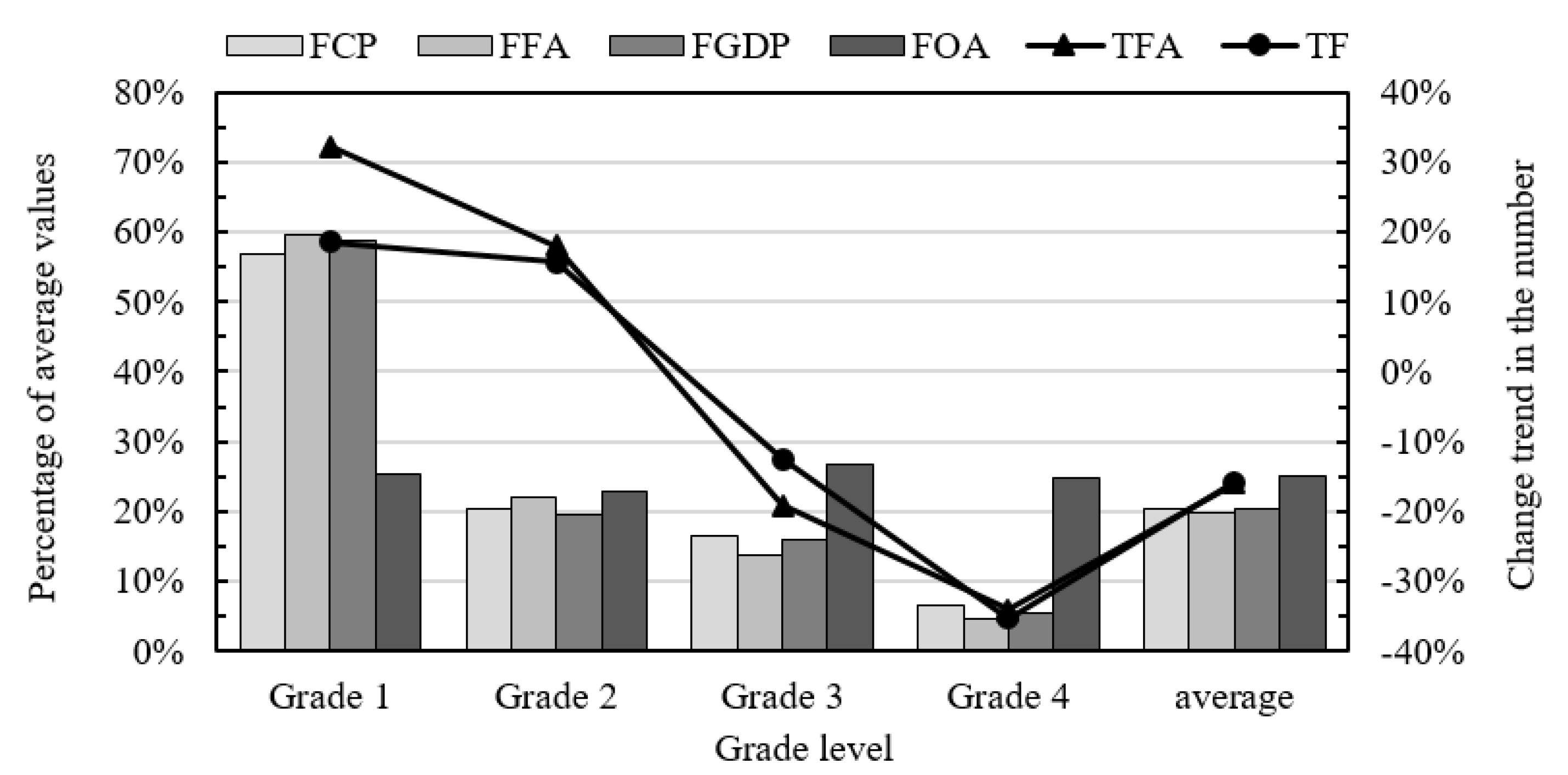

3.3.1. AS from the Risk Perspective

3.3.2. AS from the Basic Perspective

3.3.3. AS from the Regional Perspective

4. Discussion

4.1. Analysis of Improved PCA

4.2. AS Analysis from the Multi-Dimensional Perspective

4.3. Theoretical and Practical Implications

4.4. Limitations and Future Research

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kang, Y.; Siddiqui, S.; Suk, S.J.; Chi, S.; Kim, C. Trends of Fall Accidents in the US Construction Industry. J. Constr. Eng. Manag. 2017, 143, 04017043. [Google Scholar] [CrossRef]

- Liu, P.; Li, Q.M.; Bian, J.; Song, L.L.; Xiahou, X.E. Using Interpretative Structural Modeling to Identify Critical Success Factors for Safety Management in Subway Construction: A China Study. Int. J. Environ. Res. Public Health 2018, 15, 1359. [Google Scholar] [CrossRef] [PubMed]

- Zahoor, H.; Chan, A.P.; Utama, W.P.; Gao, R.; Zafar, I. Modeling the Relationship between Safety Climate and Safety Performance in a Developing Construction Industry: A Cross-Cultural Validation Study. Int. J. Environ. Res. Public Health 2017, 14, 351. [Google Scholar] [CrossRef] [PubMed]

- Hausken, K.; Zhuang, J. The strategic interaction between a company and the government surrounding disasters. Ann. Oper. Res. 2016, 237, 27–40. [Google Scholar] [CrossRef]

- Gao, Y.; Fan, Y.; Wang, J.; Duan, Z. Evaluation of governmental safety regulatory functions in preventing major accidents in China. Saf. Sci. 2019, 120, 299–311. [Google Scholar] [CrossRef]

- Ma, Y.H.; Zhao, Q.H. Decision-making in safety efforts: Role of the government in reducing the probability of workplace accidents in China. Saf. Sci. 2018, 104, 81–90. [Google Scholar] [CrossRef]

- State Council of China. The 13th Five-Year Plan for Safety Production in China; State Council of China: Beijing, China, 2017.

- MHURD. The 13th Five-Year Plan for the Development of Construction Industry in China. 2017. Available online: http://www.mohurd.gov.cn/wjfb/201705/t20170503_231715.html (accessed on 15 April 2019).

- State Council of China. Suggestions on Promoting the Sustainable and Healthy Development of the Construction Industry. 2017. Available online: http://www.gov.cn/zhengce/content/2017-02/24/content_5170625.htm (accessed on 15 April 2019).

- MHURD. Guidances on Cultivating the Team of Construction Workers in the New Era (draft for comment). 2017. Available online: http://www.mohurd.gov.cn/wjfb/201711/t20171113_233935.html (accessed on 15 April 2019).

- State Council of China. Implementation of Information Management System for Workers’ Real-Name Registration in Hainan’s Construction Industry. 2018. Available online: http://www.gov.cn/xinwen/2018-07/02/content_5302725.htm (accessed on 15April 2019).

- Shao, B.; Hu, Z.; Liu, Q.; Chen, S.; He, W. Fatal accident patterns of building construction activities in China. Saf. Sci. 2019, 111, 253–263. [Google Scholar] [CrossRef]

- MHURD. The Short Reports of Fatal Accidents in China Building Construction Activities. 2019. Available online: http://sgxxxt.mohurd.gov.cn/Public/AccidentList.aspx (accessed on 15 April 2019).

- Zhou, Z.P.; Goh, Y.M.; Li, Q.M. Overview and analysis of safety management studies in the construction industry. Saf. Sci. 2015, 72, 337–350. [Google Scholar] [CrossRef]

- Zheng, X.; Zhou, J.; Wang, F.; Chen, Y. Routes to failure and prevention recommendations in work systems of hydropower construction. J. Civ. Eng. Manag. 2018, 24, 206–222. [Google Scholar] [CrossRef]

- Hola, B.; Szostak, M. Modeling of the Accidentality Phenomenon in the Construction Industry. Appl. Sci. 2019, 9, 1878. [Google Scholar] [CrossRef]

- Xue, Y.J.Y.; Fu, G. A modified accident analysis and investigation model for the general aviation industry: Emphasizing on human and organizational factors. J. Saf. Res. 2018, 67, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Jamot, D.G.C.; Park, J.Y. System theory based hazard analysis for construction site safety: A case study from Cameroon. Saf. Sci. 2019, 118, 783–794. [Google Scholar] [CrossRef]

- Zheng, X.Z.; Wang, F.; Zhou, J.L. A Hybrid Approach for Evaluating Faulty Behavior Risk of High-Risk Operations Using ANP and Evidence Theory. Math. Probl. Eng. 2017, 2017, 1–16. [Google Scholar] [CrossRef]

- Hernandez-Arriaza, F.A.; Perez-Alonso, J.; Gomez-Galan, M.; Salata, F. The Guatemalan Construction Industry: Approach of Knowledge Regarding Work Risks Prevention. Int. J. Environ. Res. Public Health 2018, 15, 2252. [Google Scholar] [CrossRef] [PubMed]

- Hola, B.; Nowobilski, T. Classification of Economic Regions with Regards to Selected Factors Characterizing the Construction Industry. Sustainability 2018, 10, 1637. [Google Scholar] [CrossRef]

- Chen, F.; Wang, J.J.; Deng, Y.J. Road safety risk evaluation by means of improved entropy TOPSIS-RSR. Saf. Sci. 2015, 79, 39–54. [Google Scholar] [CrossRef]

- Coates, W.C. Analysis of the Causes of Construction Fatalities from 2007 to 2009. Available online: http://ufdc.ufl.edu/UFE0042920/00001 (accessed on 18 September 2019).

- Hola, B. Methodology of estimation of accident situation in building industry. Arch. Civ. Mech. Eng. 2009, 9, 29–46. [Google Scholar] [CrossRef]

- Marsh, S.M.; Fosbroke, D.E. Trends of occupational fatalities involving machines, United States, 1992–2010. Am. J. Ind. Med. 2015, 58, 1160–1173. [Google Scholar] [CrossRef]

- Mendeloff, J.; Burns, R. States with low non-fatal injury rates have high fatality rates and vice-versa. Am. J. Ind. Med. 2013, 56, 509–519. [Google Scholar] [CrossRef]

- Liu, A.; Wu, C. Correlation Analysis between Death Rate Per Hundred Million GDP and Regional Development Level. China Saf. Sci. J. 2011, 21, 3–9. (In Chinese) [Google Scholar]

- Eteifa, S.O.; El-adaway, I.H. Using Social Network Analysis to Model the Interaction between Root Causes of Fatalities in the Construction Industry. J. Manag. Eng. 2018, 34, 1–15. [Google Scholar] [CrossRef]

- Doorsamy, W.; Cronje, W.A. A Method for Fault Detection on Synchronous Generators Using Modified Principal Component Analysis. In Proceedings of the 2015 IEEE International Conference on Industrial Technology (ICIT), Seville, Spain, 17–19 March 2015; pp. 586–591. [Google Scholar]

- Shirali, G.A.; Shekari, M.; Angali, K.A. Quantitative assessment of resilience safety culture using principal components analysis and numerical taxonomy: A case study in a petrochemical plant. J. Loss Prev. Process Ind. 2016, 40, 277–284. [Google Scholar] [CrossRef]

- Jolliffe, I.T. Principal Component Analysis, 2nd ed.; Springer: New York, NY, USA, 2002. [Google Scholar]

- Azadeh, A.; Roudi, E.; Salehi, V. Optimum design approach based on integrated macro-ergonomics and resilience engineering in a tile and ceramic factory. Saf. Sci. 2017, 96, 62–74. [Google Scholar] [CrossRef]

- Coussement, A.; Isaac, B.J.; Gicquel, O.; Parente, A. Assessment of different chemistry reduction methods based on principal component analysis: Comparison of the MG-PCA and score-PCA approaches. Combust. Flame 2016, 168, 83–97. [Google Scholar] [CrossRef]

- Liu, B.S.; Chen, Y.; Shen, Y.H.; Sun, H.; Xu, X.H. A complex multi-attribute large-group decision making method based on the interval-valued intuitionistic fuzzy principal component analysis model. Soft Comput. 2014, 18, 2149–2160. [Google Scholar] [CrossRef]

- Rajesh, S.; Jain, S.; Sharma, P. Inherent vulnerability assessment of rural households based on socio-economic indicators using categorical principal component analysis: A case study of Kimsar region, Uttarakhand. Ecol. Indic. 2018, 85, 93–104. [Google Scholar] [CrossRef]

- Shang, L.; Wang, S. Application of improved principal component analysis in comprehensive assessment on thermal power generation units. Power Syst. Technol. 2014, 38, 1928–1933. (In Chinese) [Google Scholar]

- Hao, R.X.; Li, S.M.; Li, J.B.; Zhang, Q.K.; Liu, F. Water Quality Assessment for Wastewater Reclamation Using Principal Component Analysis. J. Environ. Inform. 2013, 21, 45–54. [Google Scholar] [CrossRef]

- Hosseini, H.M.; Kaneko, S. Dynamic sustainability assessment of countries at the macro level: A principal component analysis. Ecol. Indic. 2011, 11, 811–823. [Google Scholar] [CrossRef]

- Hola, B.; Szostak, M. Analysis of the State of the Accident Rate in the Construction Industry in European Union Countries. Arch. Civ. Eng. 2015, 61, 19–34. [Google Scholar] [CrossRef]

- Irumba, R. Spatial analysis of construction accidents in Kampala, Uganda. Saf. Sci. 2014, 64, 109–120. [Google Scholar] [CrossRef]

- Tam, C.M.; Zeng, S.X.; Deng, Z.M. Identifying elements of poor construction safety management in China. Saf. Sci. 2004, 42, 569–586. [Google Scholar] [CrossRef]

- Ma, J.; Chen, X.; Liu, W. Suggestions on the supervision and assessment of safety production in the construction industry. Constr. Archit. 2015, 17, 34–37. (In Chinese) [Google Scholar]

- Wang, B.; Wu, C.; Kang, L.; Reniers, G.; Huang, L. Work safety in China’s Thirteenth Five-Year plan period (2016–2020): Current status, new challenges and future tasks. Saf. Sci. 2018, 104, 164–178. [Google Scholar] [CrossRef]

- Tupe, H.V. Analyzing the Mortality Rate in the U.S. Construction Industry (2004—2014). Master’s Thesis, Texas A & M University, College Station, TX, USA, 2017. [Google Scholar]

- Dong, X.W.S.; Fujimoto, A.; Ringen, K.; Stafford, E.; Platner, J.W.; Gittleman, J.L.; Wang, X.W. Injury Underreporting Among Small Establishments in the Construction Industry. Am. J. Ind. Med. 2011, 54, 339–349. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Huang, X.; Duan, J.; Zhang, H. The assessment of traffic accident risk based on grey relational analysis and fuzzy comprehensive evaluation method. Nat. Hazards 2017, 88, 1409–1422. [Google Scholar] [CrossRef]

- NBS. National Data. Available online: http://data.stats.gov.cn/easyquery.htm?cn=C01 (accessed on 15 April 2019).

- Cai, W.; Dou, L.M.; Si, G.Y.; Cao, A.Y.; He, J.; Liu, S. A principal component analysis/fuzzy comprehensive evaluation model for coal burst liability assessment. Int. J. Rock Mech. Min. Sci. 2016, 81, 62–69. [Google Scholar] [CrossRef]

- Deng, X.P.; Low, S.P.; Li, Q.M.; Zhao, X.B. Developing Competitive Advantages in Political Risk Management for International Construction Enterprises. J. Constr. Eng. Manag. 2014, 140, 04014040. [Google Scholar] [CrossRef]

- Bellamy, L.J. Exploring the relationship between major hazard, fatal and non-fatal accidents through outcomes and causes. Saf. Sci. 2015, 71, 93–103. [Google Scholar] [CrossRef]

- Baradan, S.; Usmen, M.A. Comparative injury and fatality risk analysis of building trades. J. Constr. Eng. Manag. 2006, 132, 533–539. [Google Scholar] [CrossRef]

- Sun, Y.; Fang, D.P.; Wang, S.Q.; Dai, M.D.; Lv, X.Q. Safety risk identification and assessment for Beijing Olympic venues construction. J. Manag. Eng. 2008, 24, 40–47. [Google Scholar] [CrossRef]

- Long, H.L.; Zou, J.; Pykett, J.; Li, Y.R. Analysis of rural transformation development in China since the turn of the new millennium. Appl. Geogr. 2011, 31, 1094–1105. [Google Scholar] [CrossRef]

- Antony, G.M.; Rao, K.V. A composite index to explain variations in poverty, health, nutritional status and standard of living: Use of multivariate statistical methods. Public Health 2007, 121, 578–587. [Google Scholar] [CrossRef]

- Brewer, C.A.; Pickle, L. Evaluation of methods for classifying epidemiological data on choropleth maps in series. Ann. Assoc. Am. Geogr. 2002, 92, 662–681. [Google Scholar] [CrossRef]

- Yung, P. Institutional arrangements and construction safety in China: An empirical examination. Constr. Manag. Econ. 2009, 27, 439–450. [Google Scholar] [CrossRef]

- Jia, G. There were 159 accidents and 195 fatalities in ten housing companies in 8 years: The “supervisory unspoken rules” behind the frequent occurrence of well-known housing companies. China Econ. Wkly. 2018, 34, 26–29. [Google Scholar]

- Ge, J.; Xu, K.; Zheng, X.; Yao, X.; Xu, Q.; Zhang, B. The main challenges of safety science. Saf. Sci. 2019, 118, 119–125. [Google Scholar] [CrossRef]

| CASI | Abbr. | Description | Computing Formula |

|---|---|---|---|

| Fatality rate per 100,000 construction practitioners | FCP | Reflecting the average fatality rate of construction practitioners. | (a) |

| Fatality rate per 1,000,000 m2 of floor area | FFA | Reflecting the average fatality rate of accomplishing a certain floor area. | (b) |

| Fatality rate per 100,000,000 yuan of GDP | FGDP | Reflecting the harmonious level between construction industry and economic development in one region. | (c) |

| Fatality rate per one accident | FOA | Reflecting the average lethality of fatal accidents. | (d) |

| Trend of the number of fatal accidents | TFA | Reflecting changes in the number of fatal accidents during given periods. | (e) |

| Trend of the number of fatalities | TF | Reflecting changes in the number of fatalities during given periods. | (f) |

| Pearson (Correlation) | CASI | ||||||

|---|---|---|---|---|---|---|---|

| FCP | FFA | FGDP | FOA | TFA | TF | ||

| CASI | FCP | 1.000 | 0.788 ** | 0.800 ** | −0.077 | 0.168 | 0.025 |

| FFA | 0.788 ** | 1.000 | 0.992 ** | −0.200 | 0.058 | −0.063 | |

| FGDP | 0.800 ** | 0.992 ** | 1.000 | −0.177 | 0.045 | −0.064 | |

| FOA | −0.077 | −0.200 | −0.177 | 1.000 | −0.156 | 0.185 | |

| TFA | 0.168 | 0.058 | 0.045 | −0.156 | 1.000 | 0.841 ** | |

| TF | 0.025 | −0.063 | −0.064 | 0.185 | 0.841 ** | 1.000 | |

| Component | Initial Eigenvalue | Extraction Sums of Squared Loadings | ||||

|---|---|---|---|---|---|---|

| Total | % of Variance | Cumulative % | Total | % of Variance | Cumulative% | |

| 1 | 2.781 | 46.348 | 46.348 | 2.781 | 46.348 | 46.348 |

| 2 | 1.848 | 30.794 | 77.142 | 1.848 | 30.794 | 77.142 |

| 3 | 1.018 | 16.972 | 94.114 | 1.018 | 16.972 | 94.114 |

| 4 | 0.263 | 4.377 | 98.491 | |||

| 5 | 0.083 | 1.386 | 99.878 | |||

| 6 | 0.007 | 0.122 | 100.000 | |||

| CASI | Eigenvector | Factor Loading | ||||

|---|---|---|---|---|---|---|

| P1 | P2 | P3 | P1 | P2 | P3 | |

| FCP | 0.536 | 0.035 | 0.167 | 0.893 | 0.048 | 0.168 |

| FFA | 0.583 | −0.061 | 0.054 | 0.972 | −0.083 | 0.055 |

| FGDP | 0.583 | −0.066 | 0.081 | 0.973 | −0.089 | 0.081 |

| FOA | −0.156 | 0.052 | 0.951 | −0.260 | 0.071 | 0.960 |

| TFA | 0.096 | 0.695 | −0.201 | 0.160 | 0.944 | −0.203 |

| TF | −0.005 | 0.711 | 0.131 | −0.008 | 0.966 | 0.132 |

| Principal Component | Including CASIs | Connotation | Weight |

|---|---|---|---|

| P1 | FCP, FFA, FGDP | Accident frequency | 0.493 |

| P2 | TFA, TF | Accident trend | 0.327 |

| P3 | FOA | Accident severity | 0.180 |

| Province | P1 Score | P2 Score | P3 Score | Comprehensive Score | Classification | Ranking | |

|---|---|---|---|---|---|---|---|

| Improved PCA | Classical PCA | ||||||

| Qinghai | 1.454 | −0.206 | −0.029 | 0.643 | 1 | 1 | |

| Ningxia | 0.468 | 0.221 | 0.390 | 0.373 | 2 | 2 | |

| Hainan | 0.581 | 0.002 | 0.435 | 0.365 | Grade 1 | 3 | 3 |

| Xinjiang | 0.420 | 0.297 | −0.092 | 0.287 | 4 | 4 | |

| Gansu | 0.111 | 0.687 | −0.179 | 0.247 | 5 | 5 | |

| Shaanxi | −0.193 | 0.964 | 0.041 | 0.227 | 6 | 6 | |

| Hebei | −0.175 | 0.758 | 0.286 | 0.214 | 7 | 7 | |

| Heilongjiang | 0.394 | −0.238 | −0.137 | 0.091 | Grade 2 | 8 | 8 |

| Chongqing | 0.125 | 0.246 | −0.287 | 0.090 | 9 | 9 | |

| Shanghai | 0.032 | 0.136 | −0.204 | 0.023 | 10 | 10 | |

| Guangdong | −0.126 | 0.163 | 0.002 | −0.009 | 11 | 11 | |

| Yunnan | 0.007 | −0.205 | 0.258 | −0.017 | 12 | 12 | |

| Guangxi | 0.068 | −0.069 | −0.178 | −0.021 | 13 | 13 | |

| Neimenggu | 0.120 | −0.206 | −0.115 | −0.029 | 14 | 14 | |

| Tianjin | −0.098 | −0.054 | 0.024 | −0.061 | Grade 3 | 15 | 15 |

| Hubei | −0.204 | −0.002 | 0.066 | −0.089 | 16 | 17 | |

| Jilin | −0.081 | 0.013 | −0.295 | −0.089 | 17 | 16 | |

| Guizhou | −0.150 | −0.291 | 0.374 | −0.102 | 18 | 18 | |

| Anhui | −0.072 | −0.108 | −0.200 | −0.107 | 19 | 19 | |

| Henan | −0.249 | −0.016 | 0.054 | −0.118 | 20 | 20 | |

| Jiangxi | −0.172 | −0.001 | −0.249 | −0.130 | 21 | 21 | |

| Fujian | −0.224 | −0.111 | −0.112 | −0.167 | 22 | 22 | |

| Jiangsu | −0.193 | −0.144 | −0.179 | −0.174 | 23 | 23 | |

| Shandong | −0.337 | −0.251 | 0.387 | −0.178 | 24 | 24 | |

| Sichuan | −0.408 | −0.320 | 0.692 | −0.181 | Grade 4 | 25 | 25 |

| Shanxi | −0.278 | −0.205 | 0.081 | −0.189 | 26 | 26 | |

| Hunan | −0.233 | −0.222 | −0.123 | −0.210 | 27 | 27 | |

| Zhejiang | −0.239 | −0.163 | −0.243 | −0.215 | 28 | 28 | |

| Liaoning | −0.190 | −0.275 | −0.202 | −0.220 | 29 | 29 | |

| Beijing | −0.158 | −0.401 | −0.265 | −0.256 | 30 | 30 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, B.; Hu, Z.; Liu, D. Using Improved Principal Component Analysis to Explore Construction Accident Situations from the Multi-Dimensional Perspective: A Chinese Study. Int. J. Environ. Res. Public Health 2019, 16, 3476. https://doi.org/10.3390/ijerph16183476

Shao B, Hu Z, Liu D. Using Improved Principal Component Analysis to Explore Construction Accident Situations from the Multi-Dimensional Perspective: A Chinese Study. International Journal of Environmental Research and Public Health. 2019; 16(18):3476. https://doi.org/10.3390/ijerph16183476

Chicago/Turabian StyleShao, Bo, Zhigen Hu, and Dawei Liu. 2019. "Using Improved Principal Component Analysis to Explore Construction Accident Situations from the Multi-Dimensional Perspective: A Chinese Study" International Journal of Environmental Research and Public Health 16, no. 18: 3476. https://doi.org/10.3390/ijerph16183476

APA StyleShao, B., Hu, Z., & Liu, D. (2019). Using Improved Principal Component Analysis to Explore Construction Accident Situations from the Multi-Dimensional Perspective: A Chinese Study. International Journal of Environmental Research and Public Health, 16(18), 3476. https://doi.org/10.3390/ijerph16183476