Comparison of Product Carbon Footprint Protocols: Case Study on Medium-Density Fiberboard in China

Abstract

1. Introduction

2. Methods

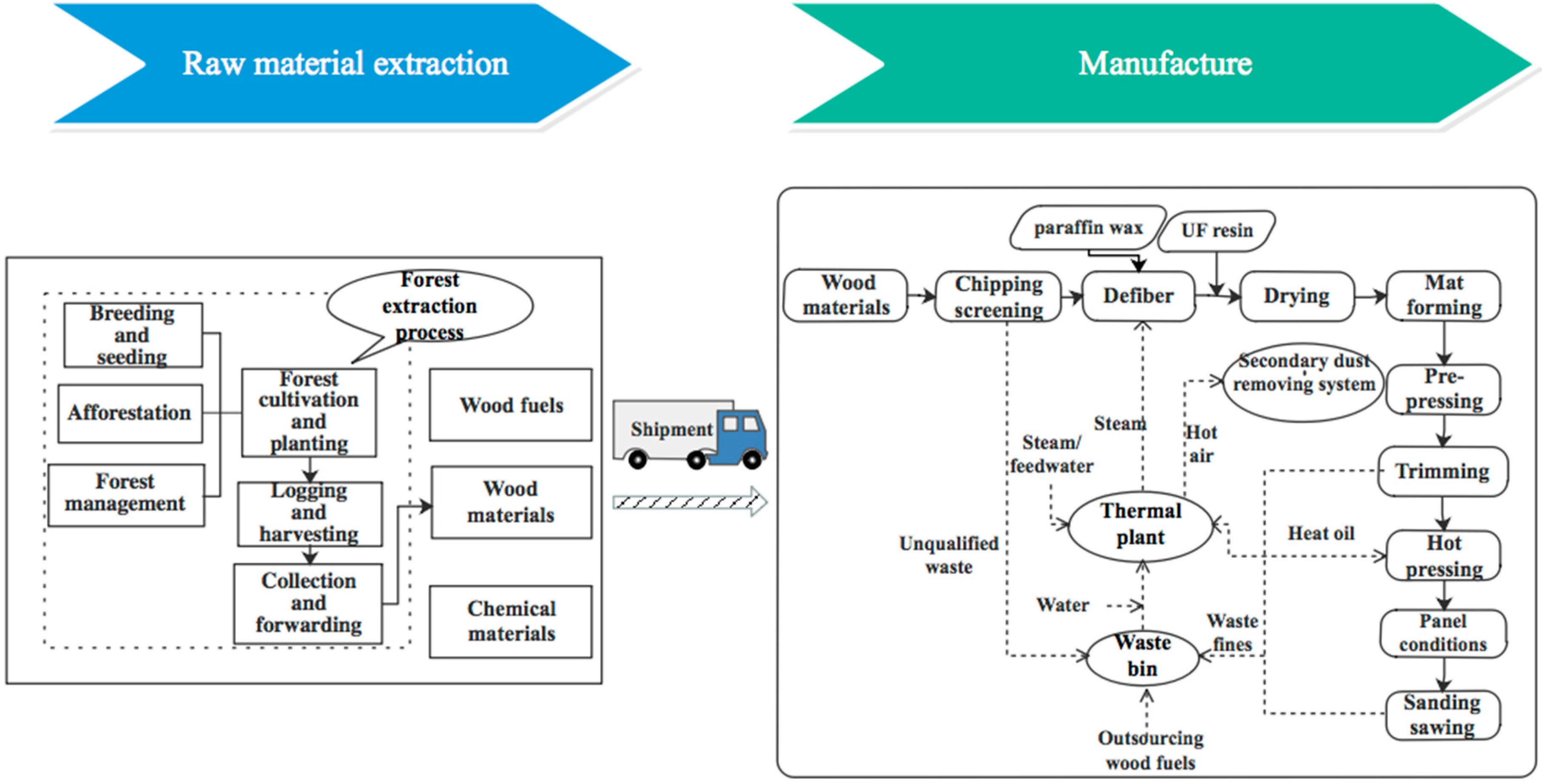

2.1. System Boundary

2.1.1. Life Cycle Stage Inclusion

2.1.2. Cut-Off Criteria

2.1.3. Capital Goods

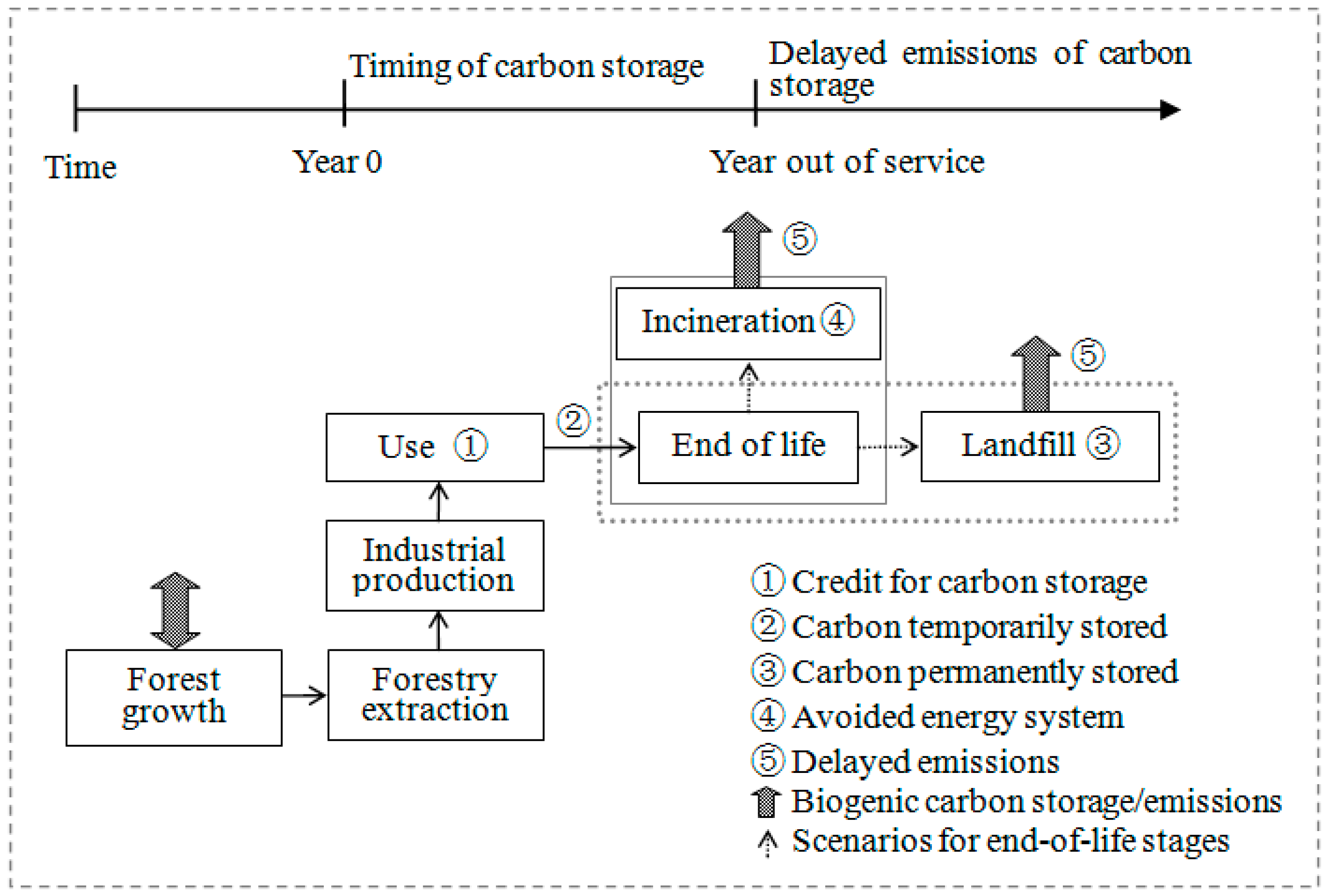

2.1.4. Biogenic Carbon Removals and Emissions

2.1.5. Other System Boundary Exclusions

2.2. Data Collection

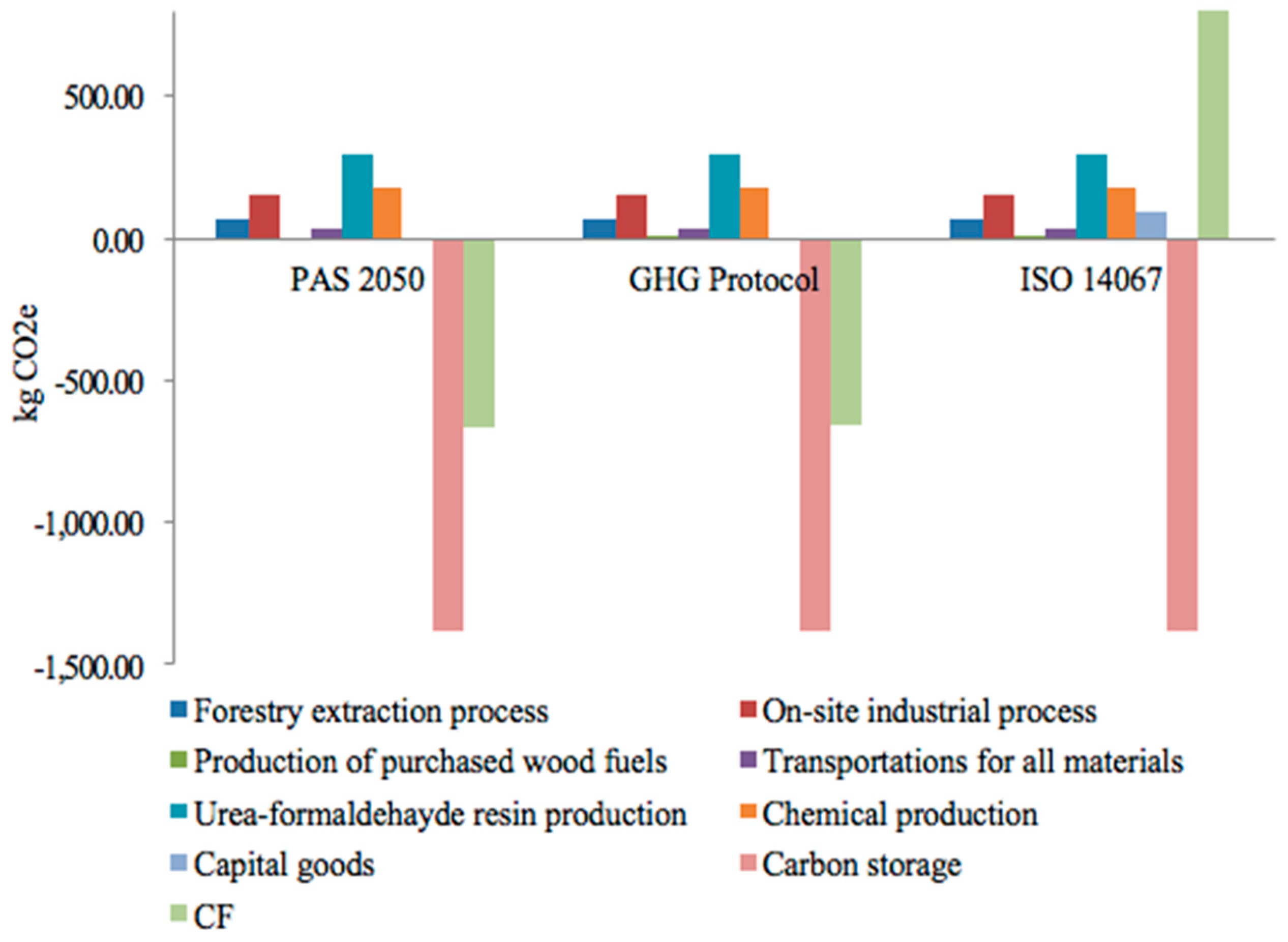

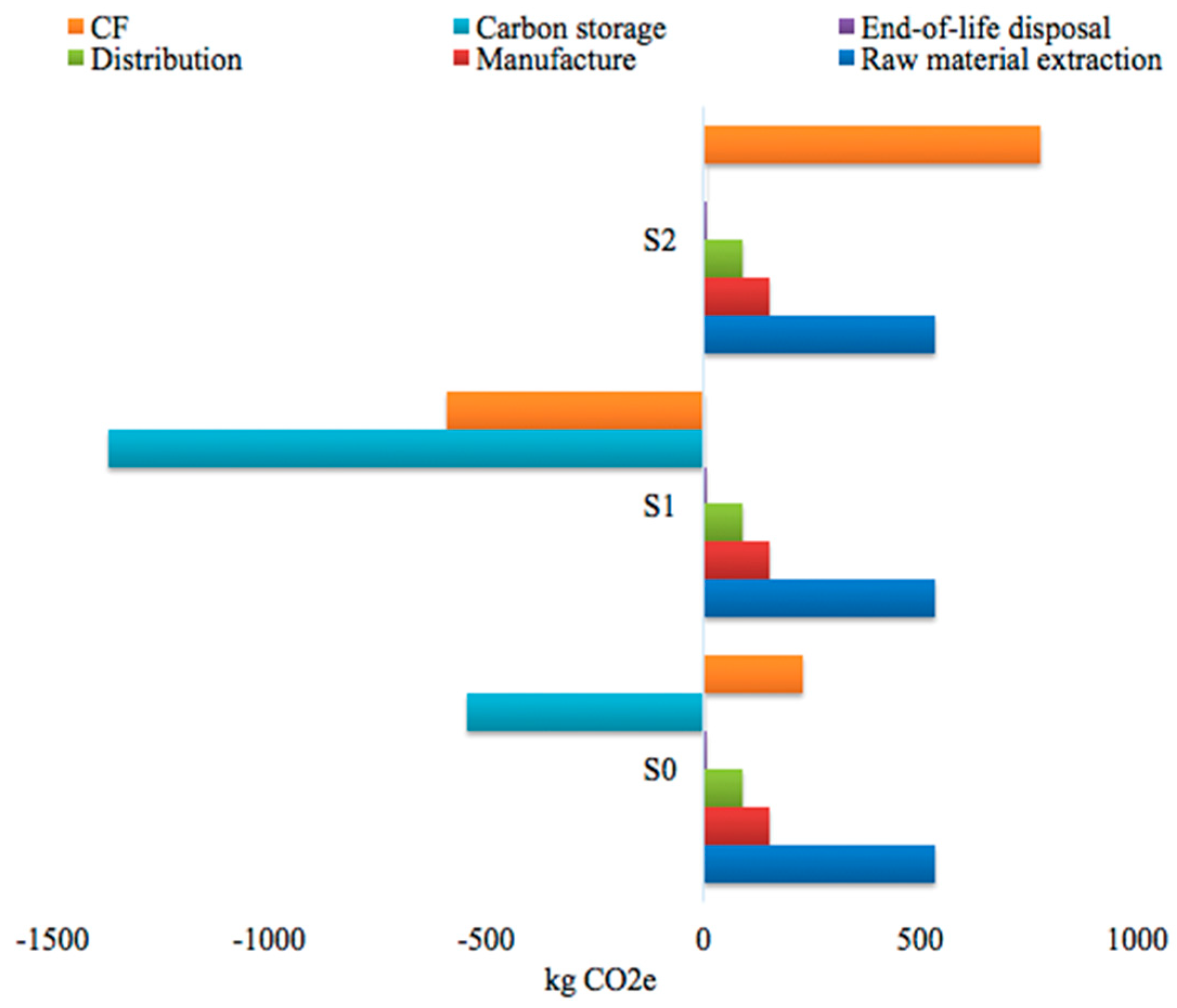

3. Results

4. Discussion

4.1. PAS 2050: The Most Suitable Protocol for Quantifying the CF of MDF

4.2. Implications to Fiberboard Industry

4.3. Limitations of the Present Study

5. Conclusions and Recommendations

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| BSI | British Standards Institution |

| CF | carbon footprint |

| CLCD | Chinese Life Cycle Database |

| CO2 | carbon dioxide |

| CO2e | carbon dioxide equivalent |

| GHG | greenhouse gas |

| GHG | Protocol: GHG Protocol Product Standard |

| GWP | global warming potential |

| IPCC | Intergovernmental Panel on Climate Change |

| ISO | International Organization for Standardization |

| ISO 14067 | ISO 14067 Carbon Footprint of Products |

| MDF | medium–density fiberboard |

| PAS 2050 | Publicly Available Specification 2050 |

| m3 | cubic meter |

| UF resin | urea-formaldehyde resin |

| WBCSD | World Business Council for Sustainable Development |

| WSI | World Resources Institute |

References

- Wiedmann, T.; Minx, J. A definition of carbon footprint. J. R. Soc. Med. 2009, 92, 193–195. [Google Scholar]

- Garcia, R.; Freire, F. Carbon footprint of particleboard: A comparison between ISO/TS 14067, GHG Protocol, PAS 2050 and Climate Declaration. J. Clean. Prod. 2014, 66, 199–209. [Google Scholar] [CrossRef]

- Hussain, M.; Malik, R.N.; Taylor, A. Carbon footprint as an environmental sustainability indicator for the particleboard produced in Pakistan. Environ. Res. 2017, 155, 385–393. [Google Scholar] [CrossRef] [PubMed]

- British Standard Institute. Publicly Available Specification 2050:2008. Specification for the Assessment of the Life Cycle Greenhouse Gas Emissions of Goods and Services; British Standard Institute: London, UK, 2008. [Google Scholar]

- British Standard Institute. Publicly Available Specification 2050:2011. Specification for the Assessment of the Life Cycle Greenhouse Gas Emissions of Goods and Services; British Standard Institute: London, UK, 2011. [Google Scholar]

- World Resources Institute and the World Business Council for Sustainable Development. Product Life Cycle Accounting and Reporting Standard; World Resources Institute and the World Business Council for Sustainable Development: Washington, DC, USA, 2011. [Google Scholar]

- International Organization for Standardization. ISO 14067: Greenhouse Gases–Carbon Footprint of Products–Requirements and Guidelines for Quantification and Communication (Technical Specifications); International Organization for Standardization: Geneva, Switzerland, 2013. [Google Scholar]

- International Organization for Standardization. ISO14040: Environmental Management–Life Cycle Assessment–Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization. ISO 14044: Environmental Management–Life Cycle Assessment–Requirements and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Liu, T.; Wang, Q.; Su, B. A review of carbon labeling: Standards, implementation, and impact. Renew. Sustain. Energy Rev. 2016, 53, 68–79. [Google Scholar] [CrossRef]

- Pandey, D.; Agrawal, M.; Pandey, J.S. Carbon footprint: Current methods of estimation. Environ. Monit. Assess. 2011, 178, 135–160. [Google Scholar] [CrossRef] [PubMed]

- Whittaker, C.; Mcmanus, M.C.; Hammond, G.P. Greenhouse gas reporting for biofuels: A comparison between the RED, RTFO and PAS 2050 methodologies. Energy Policy 2011, 39, 5950–5960. [Google Scholar] [CrossRef]

- Pattara, C.; Russo, C.; Antrodicchia, V.; Cichelli, A. Carbon footprint as an instrument for enhancing food quality: Overview of the wine, olive oil and cereals sectors. J. Sci. Food Agric. 2016, 97, 396–410. [Google Scholar] [CrossRef] [PubMed]

- Peter, C.; Fiore, A.; Hagemann, U.; Nendel, C.; Xiloyannis, C. Improving the accounting of field emissions in the carbon footprint of agricultural products: A comparison of default IPCC methods with readily available medium-effort modeling approaches. Int. J. Life Cycle Assess. 2016, 21, 791–805. [Google Scholar] [CrossRef]

- Dias, A.C.; Arroja, L. Comparison of methodologies for estimating the carbon footprint–case study of office paper. J. Clean. Prod. 2012, 24, 30–35. [Google Scholar] [CrossRef]

- Soode, E.; Weber-Blaschke, G.; Richter, K. Comparison of product carbon footprint standards with a case study on poinsettia (euphorbia pulcherrima). Int. J. Life Cycle Assess. 2013, 18, 1280–1290. [Google Scholar] [CrossRef]

- An, J.; Xue, X. Life cycle carbon footprint analysis of magnesia products. Resour. Conserv. Recycl. 2016, 119, 4–11. [Google Scholar] [CrossRef]

- Kutnar, A.; Hill, C. Assessment of Carbon Footprint in Different Industrial Sectors; Springer: Singapore, 2014; pp. 135–172. [Google Scholar]

- Intergovernmental Panel on Climate Change. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Intergovernmental Panel on Climate Change: Hayama, Japan, 2006. Available online: http://www.ipcc-nggip.iges.or.jp/public/2006gl/index.htm (accessed on 10 October 2017).

- FAOSTAT. FAOSTAT–FAO’s Online Statistical Database. 2018. Available online: http://www.fao.org/faostat/en/#data/FO/visualize (accessed on 12 April 2018).

- China National Forest Products Industry Association. China’s Wood-Based Panel Industry Report (Compact Edition); China National Forest Products Industry Association: Beijing, China, 2015. (In Chinese) [Google Scholar]

- Wang, S.S.; Zhang, H.; Nie, Y.; Yang, H.Q. Contributions of China’s wood-based panels to CO2 emission and removal implied by the energy consumption standards. Forests 2017, 8, 273. [Google Scholar] [CrossRef]

- Kouchaki-Penchah, H.; Sharifi, M.; Mousazadeh, H.; Zarea-Hosseinabada, H. Life cycle assessment of medium-density fiberboard manufacturing process in Islamic Republic of Iran. J. Clean. Prod. 2015, 112, 351–358. [Google Scholar] [CrossRef]

- Nakano, K.; Ando, K.; Takigawa, M.; Hattori, N. Life cycle assessment of wood-based boards produced in Japan and impact of formaldehyde emissions during the use stage. Int. J. Life Cycle Assess. 2018, 23, 957–969. [Google Scholar] [CrossRef]

- Piekarski, C.M.; Francisco, A.C.D.; Luz, L.M.D.; Kovaleski, J.L.; Silva, D.A.L. Life cycle assessment of medium-density fiberboard (MDF) manufacturing process in Brazil. Sci. Total Environ. 2017, 575, 103–111. [Google Scholar] [CrossRef] [PubMed]

- Puettmann, M.; Oneil, E.; Wilson, J. Cradle to Gate Life Cycle Assessment of U.S. Medium Density Fiberboard Production; Final Report to the Consortium for Research on Renewable Industrial Materials; Consortium for Research on Renewable Industrial Materials: Corvallis, OR, USA, 2013. [Google Scholar]

- Rivela, B.; Ma, T.M.; Feijoo, G. Life cycle inventory of medium density fiberboard. Int. J. Life Cycle Assess. 2007, 12, 143–150. [Google Scholar] [CrossRef]

- Wilson, J.B. Medium Density Fiberboard (MDF): A Life-Cycle Inventory of Manufacturing Panels from Resource through Products; Final Report to the Consortium for Research on Renewable Industrial Materials; Consortium for Research on Renewable Industrial Materials: Corvallis, OR, USA, 2008. [Google Scholar]

- Wilson, J.B. Life-cycle inventory of medium density fiberboard in terms of resources, emissions, energy and carbon. Wood Fiber Sci. 2010, 42, 90–106. [Google Scholar]

- Tártaro, A.S.; Mata, T.M.; Martins, A.A.; Silva, J.C.G.E.D. Carbon footprint of the insulation cork board. J. Clean. Prod. 2017, 143, 925–932. [Google Scholar] [CrossRef]

- Bergman, R.; Puettmann, M.E.; Taylor, A.; Skog, K.E. The carbon impacts of wood products. For. Prod. J. 2014, 64, 220–231. [Google Scholar] [CrossRef]

- Čuček, L.; Klemeš, J.J.; Kravanja, Z. A review of footprint analysis tools for monitoring impacts on sustainability. J. Clean. Prod. 2012, 34, 9–20. [Google Scholar] [CrossRef]

- Jungmeier, G.; Werner, F.; Jarnehammar, A.; Richter, K. Allocation in LCA of wood-based products: Experiences of Cost Action E9. Int. J. Life Cycle Assess. 2002, 7, 369–375. [Google Scholar] [CrossRef]

- Wu, P.; Xia, B.; Wang, X. The contribution of ISO 14067 to the evolution of global greenhouse gas standards—A review. Renew. Sustain. Energy Rev. 2015, 47, 142–150. [Google Scholar] [CrossRef]

- Lun, F.; Liu, M.C.; Zhang, D.; Li, W.H.; Liu, J.G. Life cycle analysis of carbon flow and carbon footprint of harvested wood products of larix principis-rupprechtii in China. Sustainability 2016, 8, 247. [Google Scholar] [CrossRef]

- European Commission. Analysis of Existing Environmental Footprint Methodologies for Products and Organizations: Recommendations, Rationale, and Alignment; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- Frischknecht, R.; Althaus, H.J.; Bauer, C.; Doka, G.; Heck, T.; Jungbluth, N.; Kellemberger, D.; Nemecek, T. The environmental relevance of capital goods in life cycle assessments of products and services. Int. J. Life Cycle Assess. 2007, 12, 7–17. [Google Scholar]

- Garcia, R.; Freire, F. Environmental assessment of wood-based panels: A comparison of life-cycle-based tools. Int. J. Sustain. Constr. 2012, 1, 63–71. [Google Scholar]

- Athena Sustainable Materials Institute. A Cradle-to-Gate Life Cycle Assessment of Canadian Medium Density Fiberboard (MDF)–2013 Update; Final Report to Canadian Wood Council; Athena Sustainable Materials Institute: Ottawa, ON, Canada, 2013. [Google Scholar]

- Wang, X.; Padgett, J.M.; Cruz, F.B.D.L.; Barlaz, M.A. Wood biodegradation in laboratory-scale landfills. Environ. Sci. Technol. 2011, 45, 6864–6871. [Google Scholar] [CrossRef] [PubMed]

- Bolwig, S.; Gibbon, P. Emerging Product Carbon Footprint Standards and Schemes and Their Possible Trade Impacts; Risø National Laboratory for Sustainable Energy, Technical University of Denmark: Lyngby, Denmark, 2009. [Google Scholar]

- Gao, T.; Liu, Q.; Wang, J. A comparative study of carbon footprint and assessment standards. Int. J. Low Carbon Technol. 2014, 9, 237–243. [Google Scholar] [CrossRef]

- Zhang, Y.M. Comprehensive energy consumption analysis of UF resins prepared via different processes. China’s Wood-Based Panel 2013, 20, 12–13. (In Chinese) [Google Scholar]

- CLCD. Chinese Life Cycle Database Version 0.8, Sichuan University; IKE Environmental Technology Co., Ltd.: Sichuan, China, 2010. [Google Scholar]

- Ecoinvent 3.0. Ecoinvent System Processes; Swiss Centre for Life Cycle Inventories: Zurich, Switzerland, 2013. [Google Scholar]

- West, T.; Marland, G.A. Synthesis of carbon sequestration, carbon emissions, and net carbon flux in agriculture: Comparing tillage practices in the United States. Agric. Ecosyst. Environ. 2002, 91, 217–232. [Google Scholar] [CrossRef]

- ELCD. European Reference Life Cycle Database; Joint Research Center (JRC) of the European Commission: Brussels, Belgium, 2013. [Google Scholar]

- Demertzi, M.; Dias, A.C.; Matos, A.; Arroja, L.M. Evaluation of different end-of-life management alternatives for used natural cork stoppers through life cycle assessment. Waste Manag. 2015, 46, 668–680. [Google Scholar] [CrossRef] [PubMed]

- Murphy, F.; Devlin, G.; McDonnell, K. Greenhouse gas and energy based life cycle analysis of products from the Irish wood processing industry. J. Clean. Prod. 2015, 92, 134–141. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change. 2013 Revised Supplementary Methods and Good Practice Guidance Arising from the Kyoto Protocol; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2014. Available online: http://www.ipcc-nggip.iges.or.jp/public/kpsg/index.html (accessed on 10 October 2017).

- Bushi, L.; Salazar, J.; Meil, J. A PAS 2050:2008 Carbon Footprint of Four Canadian Wood Products Delivered to the UK. In Proceedings of the ACLCA LCA XI Conference, Chicago, IL, USA, 20 November 2010. [Google Scholar]

- Huang, S. Study on carbon footprint assessment of furniture. Furniture 2013, 34, 36–39. (In Chinese) [Google Scholar]

- Lazzerini, G.; Lucchetti, S.; Nicese, F.P. Analysis of greenhouse gas emissions from ornamental plant production: A nursery level approach. Urban For. Urban Green. 2014, 13, 517–525. [Google Scholar] [CrossRef]

- Martínez-Alonso, C.; Berdasco, L. Carbon footprint of sawn timber products of Castanea sativa mill in the north of Spain. J. Clean. Prod. 2015, 102, 127–135. [Google Scholar] [CrossRef]

- Wu, P.; Low, S.P.; Xia, B.; Zuo, J. Achieving transparency in carbon labeling for construction materials—Lessons from current assessment standards and carbon labels. Environ. Sci. Policy 2014, 44, 11–25. [Google Scholar] [CrossRef]

- Wilson, J.B. Life-cycle inventory of formaldehyde-based resins used in wood composites in terms of resources, emissions, energy and carbon. Wood Fiber Sci. 2010, 42, 125–143. [Google Scholar]

| Specifications and Requirements | PAS 2050 | GHG Protocol | ISO 14067 | ||

|---|---|---|---|---|---|

| Goals | To provide a uniform specifications for GHG emissions of goods and services | To provide detailed guidelines on accounting and reporting | To standardize the quantification process and the communication of GHG emissions | ||

| Life cycle stage included | Cradle-to-grave | Cradle-to-grave | Cradle-to-grave | ||

| Cradle-to-gate | |||||

| Gate-to-gate | |||||

| Cradle-to-gate | Cradle-to-gate | Partial life cycle | |||

| Cut-off criteria | Exclusion based on materiality (<1%); at least 95% of the complete product life cycle must be included; no scale-up requirement to account for 100% | No cut-off criteria exist, because 100% completeness is necessary | No specific criteria available | ||

| Capital goods | Excluded | Excluded, but encouraged to be included when relevant | Excluded if they do not significantly affect the overall conclusions | ||

| Biogenic carbon | Carbon storage | Stored carbon within 100 years shall be recorded and accounted for in the CF calculations | For cradle-to-gate system, credit is given to biogenic carbon storage | If carbon storage is calculated, then it shall be separately reported but not included in the CF result | |

| Delayed emissions | A weighting factor is included and proposed | Shall a not be included | Shall not be included | ||

| Other exclusions | Land-use change | Specific procedure and provides default soil emissions per country | Provides guidance for determining attributable impacts | Direct land-use change shall be separately documented; indirect land-use change should be considered | |

| Others | Other exclusions include the transport of workers to their workplace and consumers to purchase sites, human energy inputs to the process, and animals providing transport services | ||||

| Allocation |

|

| |||

| Global warming potential | 100 years | ||||

| Materials and Energy | Analyzed Protocols | ||

|---|---|---|---|

| PAS 2050 | GHG Protocol a | ISO 14067 b | |

| Chemicals | Ammonium chloride | None | Ammonium chloride |

| Sodium hydroxide | |||

| Herbicide | |||

| Sodium hydroxide | Paraffin wax | ||

| Paraffin wax | K fertilizer | ||

| Energy | Energy for seedling cultivation | None | Gasoline for harvesting |

| Energy for tree plantation | |||

| Energy for total thinning | |||

| Stages | Data Source | |

|---|---|---|

| Activity Data | Emission Factor | |

| On-site industrial process | ||

| Wood fuels for energy | Surveyed company | Ecoinvent 3.0 [45] |

| Electricity | Surveyed company | NDRC a |

| Off-site process | ||

| Capital goods | Frischknecht et al. [37] | Frischknecht et al. [37] |

| Energy for forestry extraction | ||

| Petroleum | Lun et al. [35] | IPCC [19] |

| Gasoline | Lun et al. [35] | IPCC [19] |

| Diesel | Lun et al. [35] | IPCC [19] |

| Electricity | Lun et al. [35] | NDRC |

| Fertilizer and biocide | Lun et al. [35] | West et al. [46] |

| Chemical production | ||

| Formaldehyde | Surveyed company | CLCD [44] |

| Urea | Surveyed company | CLCD [44] |

| Ammonium chloride | Surveyed company | Ecoinvent 3.0 [45] |

| Sodium hydroxide | Surveyed company | ELCD [47] |

| Paraffin wax | Surveyed company | Ecoinvent 3.0 [45] |

| UF resin production | Surveyed company | Zhang [43] |

| Transports | ||

| Distances | Surveyed company and national reports b | CLCD [44] |

| Fossil fuels | Surveyed company | CLCD [44] |

| End-of-life disposal | Demertzi et al. [48] | |

| Energy for landfill | ||

| Electricity | NDRC | |

| Diesel | IPCC [19] | |

| Energy for incineration | Demertzi et al. [48] | |

| Electricity | NDRC | |

| Diesel | IPCC [19] | |

| Natural gas | IPCC [19] | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Wang, W.; Yang, H. Comparison of Product Carbon Footprint Protocols: Case Study on Medium-Density Fiberboard in China. Int. J. Environ. Res. Public Health 2018, 15, 2060. https://doi.org/10.3390/ijerph15102060

Wang S, Wang W, Yang H. Comparison of Product Carbon Footprint Protocols: Case Study on Medium-Density Fiberboard in China. International Journal of Environmental Research and Public Health. 2018; 15(10):2060. https://doi.org/10.3390/ijerph15102060

Chicago/Turabian StyleWang, Shanshan, Weifeng Wang, and Hongqiang Yang. 2018. "Comparison of Product Carbon Footprint Protocols: Case Study on Medium-Density Fiberboard in China" International Journal of Environmental Research and Public Health 15, no. 10: 2060. https://doi.org/10.3390/ijerph15102060

APA StyleWang, S., Wang, W., & Yang, H. (2018). Comparison of Product Carbon Footprint Protocols: Case Study on Medium-Density Fiberboard in China. International Journal of Environmental Research and Public Health, 15(10), 2060. https://doi.org/10.3390/ijerph15102060