Residual Inequity: Assessing the Unintended Consequences of New York City’s Clean Heat Transition

Abstract

:1. Introduction

2. Background and Literature Review

3. Methods

4. Results

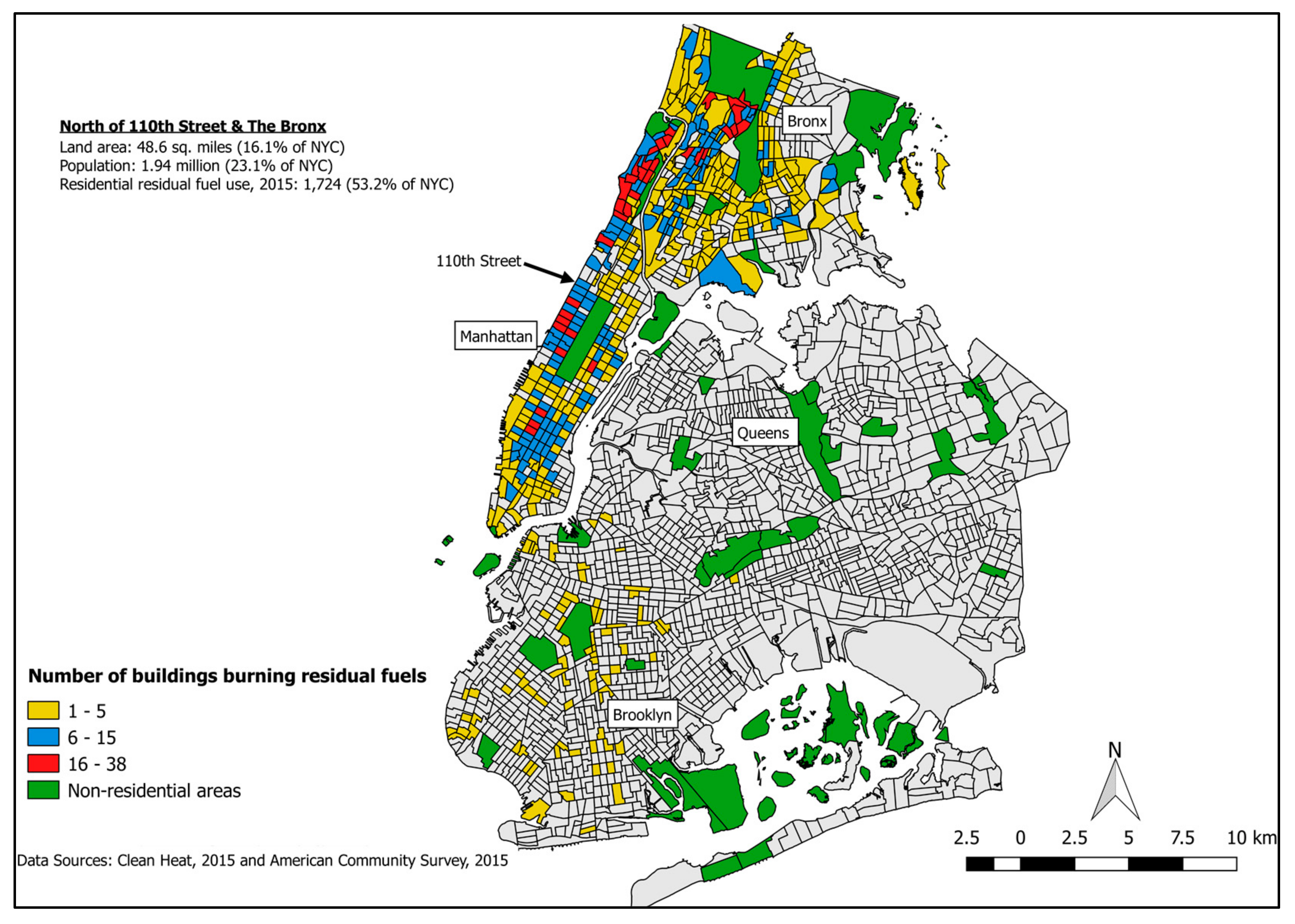

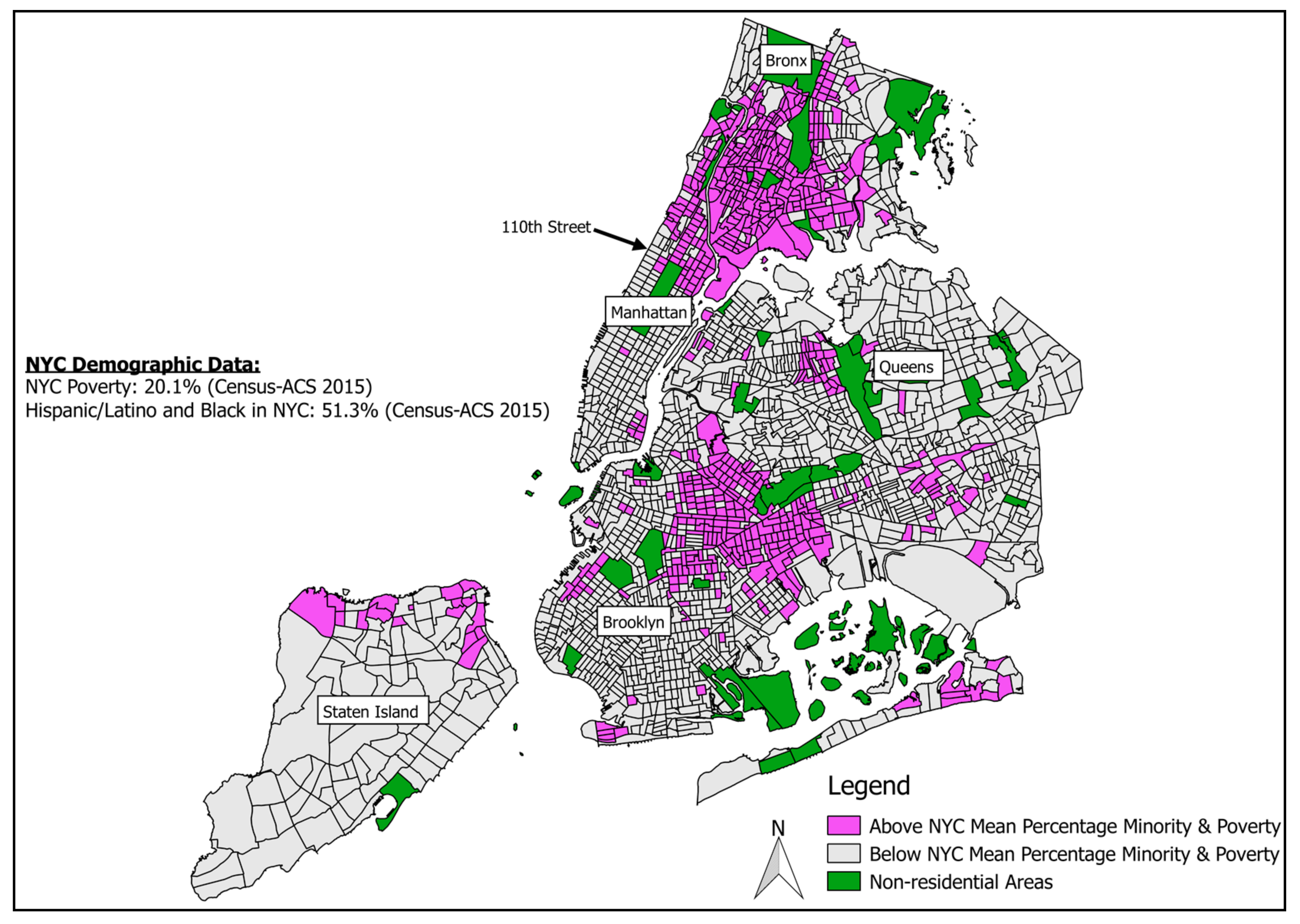

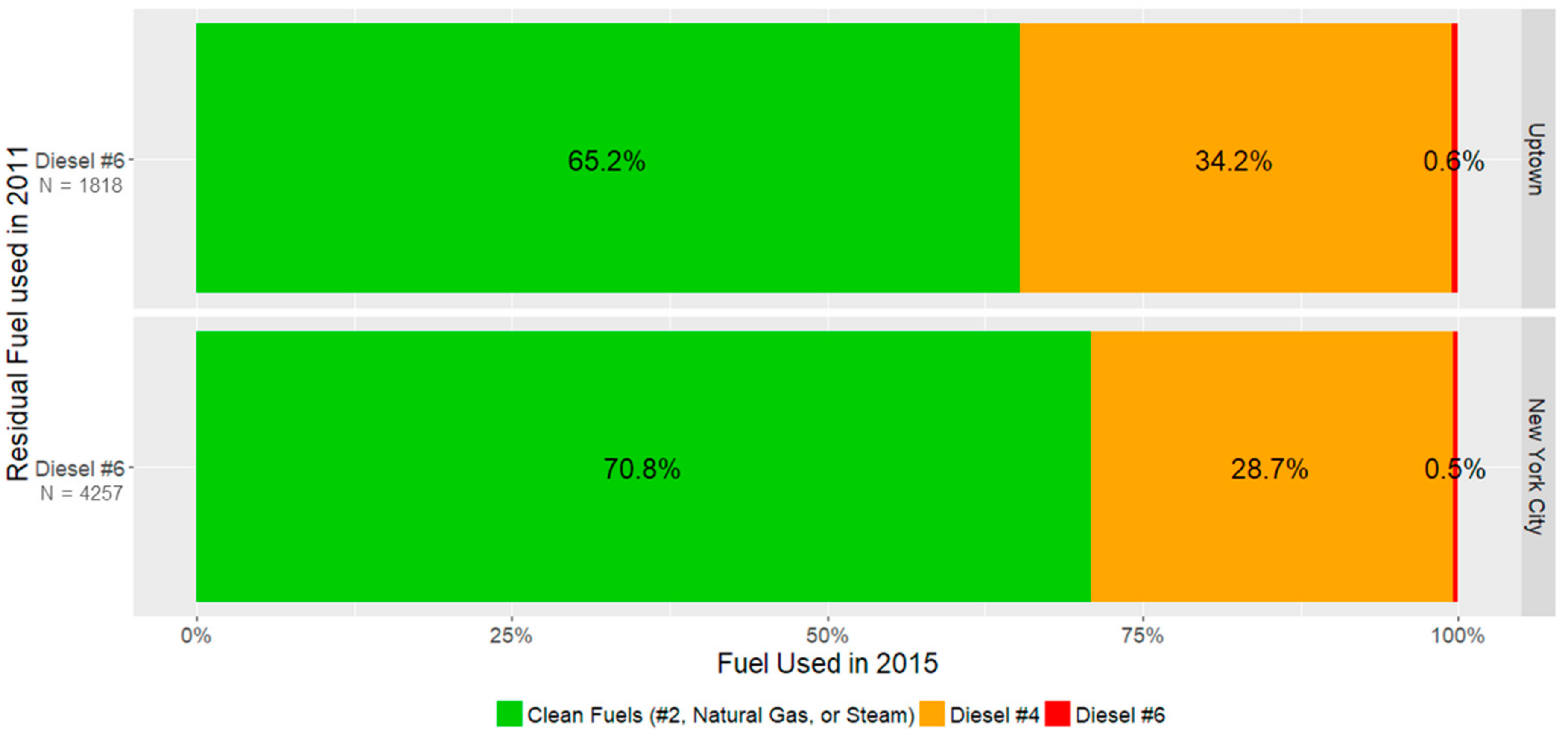

4.1. Unequal Implementation—Geographic and Demographic Trends

4.2. Key Informant Interviews and Document Data

4.2.1. Awareness

“…I’m on the top floor. I’d never seen emissions before, and March 2006 were the first emissions that I saw. And there was huge, it was like a volcano of black smoke that came directly into my kitchen window… I realized immediately when it smelled like a city bus, like I was standing behind a city bus that we needed to get the heck out of the apartment… I shut the window but it was too late… I developed asthma in the same year, 2006. And I was 43 years old. I’d never had asthma in my life.”(Resident-advocate)

“…People should know about this [residential boiler fuel type], I doubt they know when they buy, they don’t know when they rent. There’s no way for people to know what they’re stepping into. And once you’re there, like I said, almost like blackmail. If you make noise you might lose your apartment…”(Resident-advocate)

4.2.2. Process

“I had one [natural gas hookup] that was more than twelve months late.”(Building owner)

“I would never recommend any building sticking with one fuel, because no one ever has been right. The cost of fuel, the cost of gas is going to [fluctuate] over the next 20 years, so I always advocate for full convertibility.”(Green lender)

“So if those interruptibles come on, and those 4000 accounts cost me 2 million gallons, which I did not know I was going to have to use…the [oil] price spikes.”(Heating oil supplier)

“…ultra-low Sulfur #2 has close to zero soot emissions, the lowest of all conventional heating fuels.”(Heating oil supplier)

“Not everybody is a fan of natural gas, ultra-low Sulfur diesel #2 is certainly even a cleaner source of energy than natural gas, without the implications that bother people about fracking.”(Green lender)

“…as we increase our biodiesel level we will in fact be cleaner than natural gas at all levels.”(City subcontractor supporting the Clean Heat Program)

“Going from 6 to 4 is relatively inexpensive, I can say around $5000. Going from 6 to 2, more expensive, could be as much as 15 to 20 thousand depending on the equipment.”(Building owner)

“…last year at this time you were paying maybe $3.50 a gallon of oil, converting to gas you’re paying $2, you know, $1.70, $1.80.”(Heating oil supplier)

“When we do a loan we try to put energy efficiency or retrofits into every loan. We’re not a government program so we can’t force it, but we benchmark the building before we loan them the money…so we approach owners with common sense money saving approaches.”(Green lender)

“…the majority of our buildings were in conjunction with weatherizing the building with [weatherization organizations]… replacing windows, boilers, [etc.] can get very expensive, so having the help of [nonprofits] enabled us to do all of the work we wanted to do…”[Traditional lender]

“There are very few building owners of multifamily buildings that are environmentalists. They are capitalists, they want to make money.”(Building owner)

4.2.3. Problems

“…one of the biggest challenges is that buildings [owners] just didn’t quite understand, they understood that they needed to convert but they didn’t understand what their options were.”(City subcontractor supporting the Clean Heat Program)

“…one of the things that we’ve also discovered is that nobody knows how a boiler works, and nobody knows what it actually takes to convert your boiler, if it even takes anything.”(Representative from elected official’s office)

“So the good news is I think at this point, hopefully nobody doesn’t know about the local law 43, because their boiler maintenance group, that service the boilers and the oil services groups who deliver the fuel have certainly, I think, been keeping people abreast of what they need to do… They generally will talk to a contractor about what their options are, [such as] is there gas availability?”(Community-based non-profit outreach staffer)

“And one [property management] company, the guy told me that he gets confused by all of the different companies that are contacting him with services that are supposedly gonna help them meet or comply with these local laws, and at the same time save them money on their energy bills. So that was one of the things, he’s like ‘I got all these people sending me messages via email, via regular mail, and I don’t know which ones are actually trying to scam me, which ones are the real deal. I wish they could provide us a list of which companies are actually worth my time and energy as opposed to having to figure it out by trial and error.’”(Community-based non-profit outreach staffer)

“…a lot of buildings that didn’t have the resources, or didn’t somehow get the message that they had to do something, or have realized that #4 is a short term solution that is not ideal.”(City subcontractor supporting the Clean Heat Program)

“…property managers really appreciate it when we go to co-op and condo boards since they have to vote on everything and it can be really difficult to get them to move. … they said they will not do it [transition heating fuel], it costs too much money… It’s difficult to get people to realize that it costs less to use grade 2 oil than to maintain a boiler using grade 6.”(City subcontractor supporting the Clean Heat Program)

“…there were about 10 panelists from various non-profits and government agencies that do provide services for buildings. And that’s when a lot of property management companies and also coop shareholders came out…”(Community-based non-profit outreach staffer)

“…we’ve been tracking the data and seeing that buildings were converting and we saw that particularly rent stabilized buildings were converting more slowly.”(City subcontractor supporting the Clean Heat Program)

“Clean Heat resources that the city put together has been fantastic. I mean they’ve done a really good job just getting out there with outreach and education and targeting building owners…”(Representative from elected official’s office)

5. Discussion

5.1. Policy Implications and Future Directions

5.2. Strengths and Limitations

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- PlaNYC, N. PlaNYC: A Greener, Greater New York. 2007. Available online: www.nyc.gov/html/planyc/html/publications/publications.shtml (accessed on 10 November 2015).

- American Lung Association. State of the Air. Available online: http:// www.stateoftheair.org/2011/assets/SOTA2011.pdf (accessed on 15 December 2015).

- American Lung Association. State of the Air, 2017. Available online: http://www.lung.org/assets/documents/healthy-air/state-of-the-air/state-of-the-air-2017.pdf (accessed on 2 November 2017).

- NYC Clean Heat. Available online: https://www.nyccleanheat.org/ (accessed on 10 November 2015).

- Warman, K.; Silver, E.J.; Wood, P.R. Modifiable risk factors for asthma morbidity in Bronx versus other inner-city children. J. Asthma 2009, 46, 995–1000. [Google Scholar] [CrossRef] [PubMed]

- U.S. Census Bureau American Community Survey, 5-Year Estimates. Available online: htttps://factfinder.census.gov (accessed on 13 May 2017).

- EIA Petroleum & Other Liquids. Available online: https://www.eia.gov/petroleum/ (accessed on 14 November 2014).

- Winnes, H.; Fridell, E. Particle emissions from ships: Dependence on fuel type. J. Air Waste Manag. Assoc. 2009, 59, 1391–1398. [Google Scholar] [CrossRef] [PubMed]

- New York City Department of Health and Mental Hygiene. The New York City Community Air Survey: Results from Year One Monitoring 2008–2009; New York City Department of Health and Mental Hygiene: New York, NY, USA, 2011.

- EIA Residual Fuel Oil. Available online: https://www.eia.gov/tools/glossary/ (accessed on 14 November 2014).

- Gregory, K. Cost among Hurdles Slowing New York City’s Plan to Phase out Dirty Heating Oil. NY Times. 2014. Available online: https://www.nytimes.com/2014/04/07/nyregion/cost-among-hurdles-slowing-new-yorks-plan-to-phase-out-dirty-heating-oil.html (accessed on 12 November 2015).

- Lewtas, J. Air pollution combustion emissions: Characterization of causative agents and mechanisms associated with cancer, reproductive, and cardiovascular effects. Mutat. Res./Rev. Mutat. Res. 2007, 636, 95–133. [Google Scholar] [CrossRef] [PubMed]

- EPA Six Common Air Pollutants. Available online: http://epa.gov/airquality/urbanair (accessed on 1 December 2014).

- Peltier, R.E.; Lippmann, M. Residual oil combustion: 2. Distributions of airborne nickel and vanadium within New York City. J. Expo. Sci. Environ. Epidemiol. 2010, 20, 342–350. [Google Scholar] [CrossRef] [PubMed]

- Lippmann, M.; Ito, K.; Hwang, J.-S.; Maciejczyk, P.; Chen, L.-C. Cardiovascular effects of nickel in ambient air. Environ. Health Perspect. 2006, 114, 1662–1669. [Google Scholar] [PubMed]

- Jacobson, M.Z. Strong radiative heating due to the mixing state of black carbon in atmospheric aerosols. Nature 2001, 409, 695–697. [Google Scholar] [CrossRef] [PubMed]

- Ramanathan, V.; Carmichael, G. Global and regional climate changes due to black carbon. Nat. Geosci. 2008, 1, 221–227. [Google Scholar] [CrossRef]

- Kheirbek, I.; Haney, J.; Douglas, S.; Ito, K.; Caputo, S., Jr.; Matte, T. The Public Health Benefits of Reducing Fine Particulate Matter through Conversion to Cleaner Heating Fuels in New York City. Environ. Sci. Technol. 2014, 48, 13573–13582. [Google Scholar] [CrossRef] [PubMed]

- Loeser, S.; Passalacqua, L. Mayor Bloomberg Announces More than $100 million in Financing and New Resources to Help Buildings Convert to Clean Heating Fuels and Improve New York City Air Quality. Available online: http://www1.nyc.gov/office-of-the-mayor/news/212-12/mayor-bloomberg-more-100-million-financing-new-resources-help-buildings (accessed on 9 January 2018).

- Calgary, O. Oil Boilers—Detailed Fuel Consumption and Building Data | NYC Open Data. Available online: https://data.cityofnewyork.us/Housing-Development/Oil-Boilers-Detailed-Fuel-Consumption-and-Building/jfzu-yy6n (accessed on 16 December 2017).

- PLUTO and MapPLUTO. Available online: https://www1.nyc.gov/site/planning/data-maps/open-data/dwn-pluto-mappluto.page (accessed on 16 December 2017).

- Creswell, J.W. Qualitative Inquiry and Research Design: Choosing among Five Approaches; Sage: Thousand Oaks, CA, USA, 2013; ISBN 1-4129-9531-0. [Google Scholar]

- Jacquemin, B.; Siroux, V.; Sanchez, M.; Carsin, A.-E.; Schikowski, T.; Adam, M.; Bellisario, V.; Buschka, A.; Bono, R.; Brunekreef, B. Ambient air pollution and adult asthma incidence in six European cohorts (ESCAPE). Environ. Health Perspect. 2015, 123, 613–621. [Google Scholar] [CrossRef] [PubMed]

- Künzli, N.; Bridevaux, P.-O.; Liu, S.; Garcia-Esteban, R.; Schindler, C.; Gerbase, M.; Sunyer, J.; Rochat, T. Traffic-related air pollution correlates with adult-onset asthma among never-smokers. Thorax 2009, 64, 664–670. [Google Scholar] [CrossRef] [PubMed]

- Calgary, O. 311 Service Requests for 2009 | NYC Open Data. Available online: https://data.cityofnewyork.us/Social-Services/311-Service-Requests-for-2009/3rfa-3xsf (accessed on 17 December 2017).

- Transcript of the Minutes; New York City Council. 2010. Available online: legistar.council.nyc.gov/legislation.aspx (accessed on 20 October 2014).

- Calgary, O. 311 Service Requests 2015. Available online: https://data.cityofnewyork.us/Social-Services/311-Service-Requests-2015/hemm-82xw (accessed on 17 December 2017).

- ConED Knowledge Center: FAQ’s. Available online: http://www.coned.com/steam/kc_faqs.asp (accessed on 25 June 2016).

- Streibel, T.; Schnelle-Kreis, J.; Czech, H.; Harndorf, H.; Jakobi, G.; Jokiniemi, J.; Karg, E.; Lintelmann, J.; Matuschek, G.; Michalke, B. Aerosol emissions of a ship diesel engine operated with diesel fuel or heavy fuel oil. Environ. Sci. Pollut. Res. 2017, 24, 10976–10991. [Google Scholar] [CrossRef] [PubMed]

- Hernández, D. Sacrifice along the energy continuum: A call for energy justice. Environ. Justice 2015, 8, 151–156. [Google Scholar] [CrossRef] [PubMed]

- Hernández, D. Clean Heat: A Technical Response to a Policy Innovation. Cityscape 2016, 18, 277–282. [Google Scholar]

- Wong, M.R.; McKelvey, W.; Ito, K.; Schiff, C.; Jacobson, J.B.; Kass, D. Impact of a letter-grade program on restaurant sanitary conditions and diner behavior in New York City. J. Inf. 2015, 105, e81–e87. [Google Scholar] [CrossRef] [PubMed]

- 1.5 Climate Action Plan—Mayor’s Office of Sustainability. Available online: https://www1.nyc.gov/site/sustainability/codes/1.5-climate-action-plan.page (accessed on 17 December 2017).

| 2007 | 2017 | |||||

|---|---|---|---|---|---|---|

| County (Borough) | Ozone Grade (A–F) | 24-h Particle Grade (A–F) | Annual Particle Grade (Pass/Fail) | Ozone Grade (A–F) | 24-h Particle Grade (A–F) | Annual Particle Grade (Pass/Fail) |

| Bronx | C | F | F | F | A | P |

| Kings (Brooklyn) | Data Not Available | F | P | Data Not Available | A | P |

| New York (Manhattan) | Data Not Available | F | F | D | A | P |

| Queens | D | F | P | F | A | P |

| Richmond (Staten Island) | F | F | P | F | A | Data Not Available |

| Name | Year | Government Level | Policy Type | Intent |

|---|---|---|---|---|

| New York State S.1145-C | 2010 | State | Law | Reduction #2 diesel oil sulfur limits: 2000 to 15 ppm |

| NYC Local Law 43-2010 | 2010 | City | Law | Requirement of ≥2% biodiesel in home heating oils and reduction of #4 diesel oil sulfur limits: 3000 to 1500 ppm |

| Amendments to Title 15, Chapter 12 of the Rules of the City of New York | 2011 | City | Regulation | Ban of #6 diesel oil by 2015 and #4 by 2030 |

| Year | Uptown | Rest of NYC | Total |

|---|---|---|---|

| 2011 | 47.9% | 52.1% | 7170 |

| (N = 3434) | (N = 3736) | ||

| 2015 | 53.2% | 46.8% | 3242 |

| (N = 1724) | (N = 1518) |

| Process | Problems | Successes |

|---|---|---|

| Compliance triggered by boiler permit renewals | Unsuccessful outreach efforts to building owners | Public-private partnerships were effectively executed |

| Public surveillance via “spot the soot” | High cost and delays with transition to cleanest fuels | Near universal compliance with the #6 ban |

| Financial support for building owners often coupled with weatherization efforts | Perception of a volatile energy market for clean fuels |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carrión, D.; Lee, W.V.; Hernández, D. Residual Inequity: Assessing the Unintended Consequences of New York City’s Clean Heat Transition. Int. J. Environ. Res. Public Health 2018, 15, 117. https://doi.org/10.3390/ijerph15010117

Carrión D, Lee WV, Hernández D. Residual Inequity: Assessing the Unintended Consequences of New York City’s Clean Heat Transition. International Journal of Environmental Research and Public Health. 2018; 15(1):117. https://doi.org/10.3390/ijerph15010117

Chicago/Turabian StyleCarrión, Daniel, W. Victoria Lee, and Diana Hernández. 2018. "Residual Inequity: Assessing the Unintended Consequences of New York City’s Clean Heat Transition" International Journal of Environmental Research and Public Health 15, no. 1: 117. https://doi.org/10.3390/ijerph15010117

APA StyleCarrión, D., Lee, W. V., & Hernández, D. (2018). Residual Inequity: Assessing the Unintended Consequences of New York City’s Clean Heat Transition. International Journal of Environmental Research and Public Health, 15(1), 117. https://doi.org/10.3390/ijerph15010117