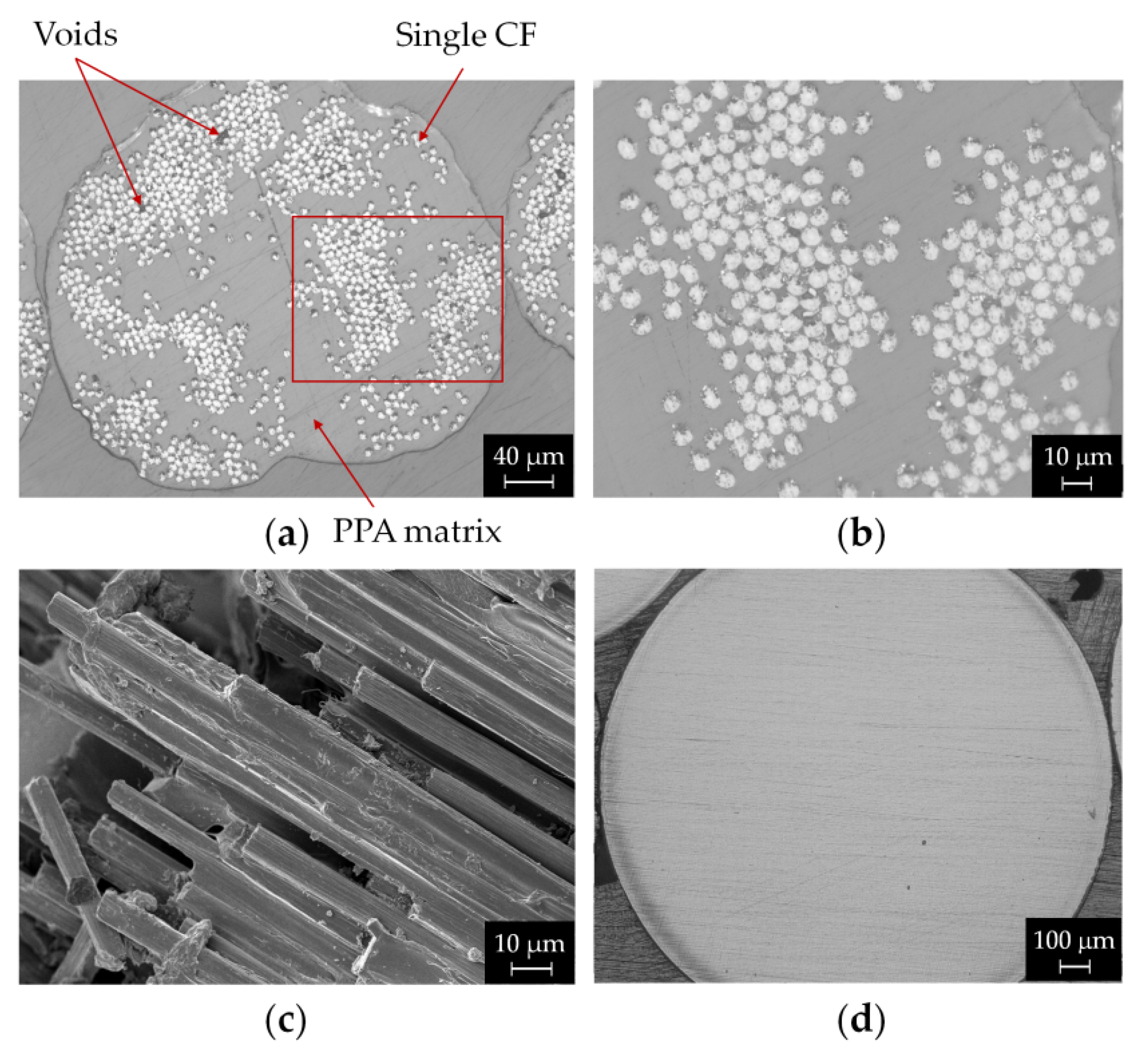

4.2.1. Microstructure and Voids

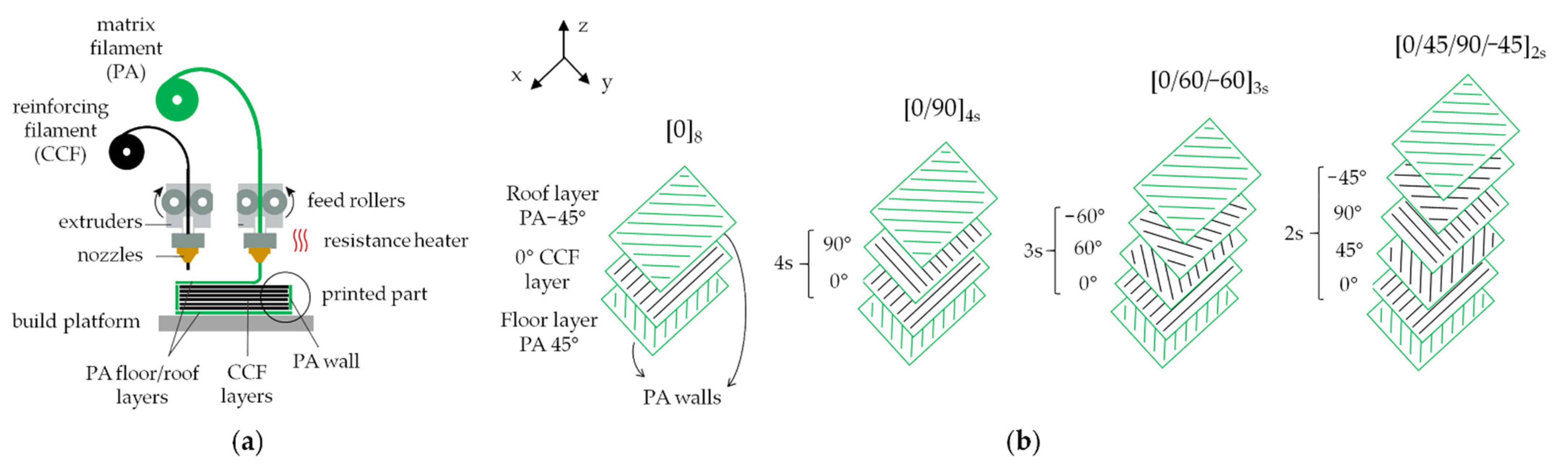

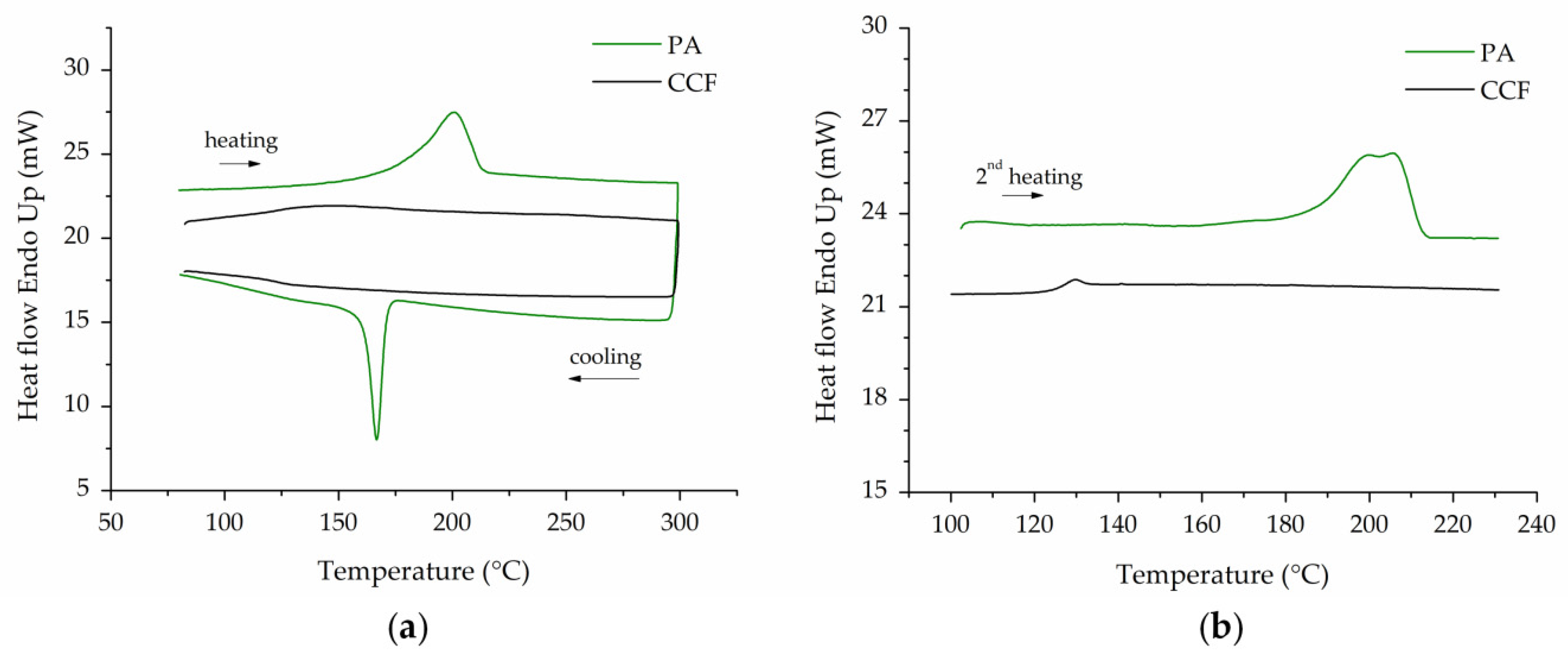

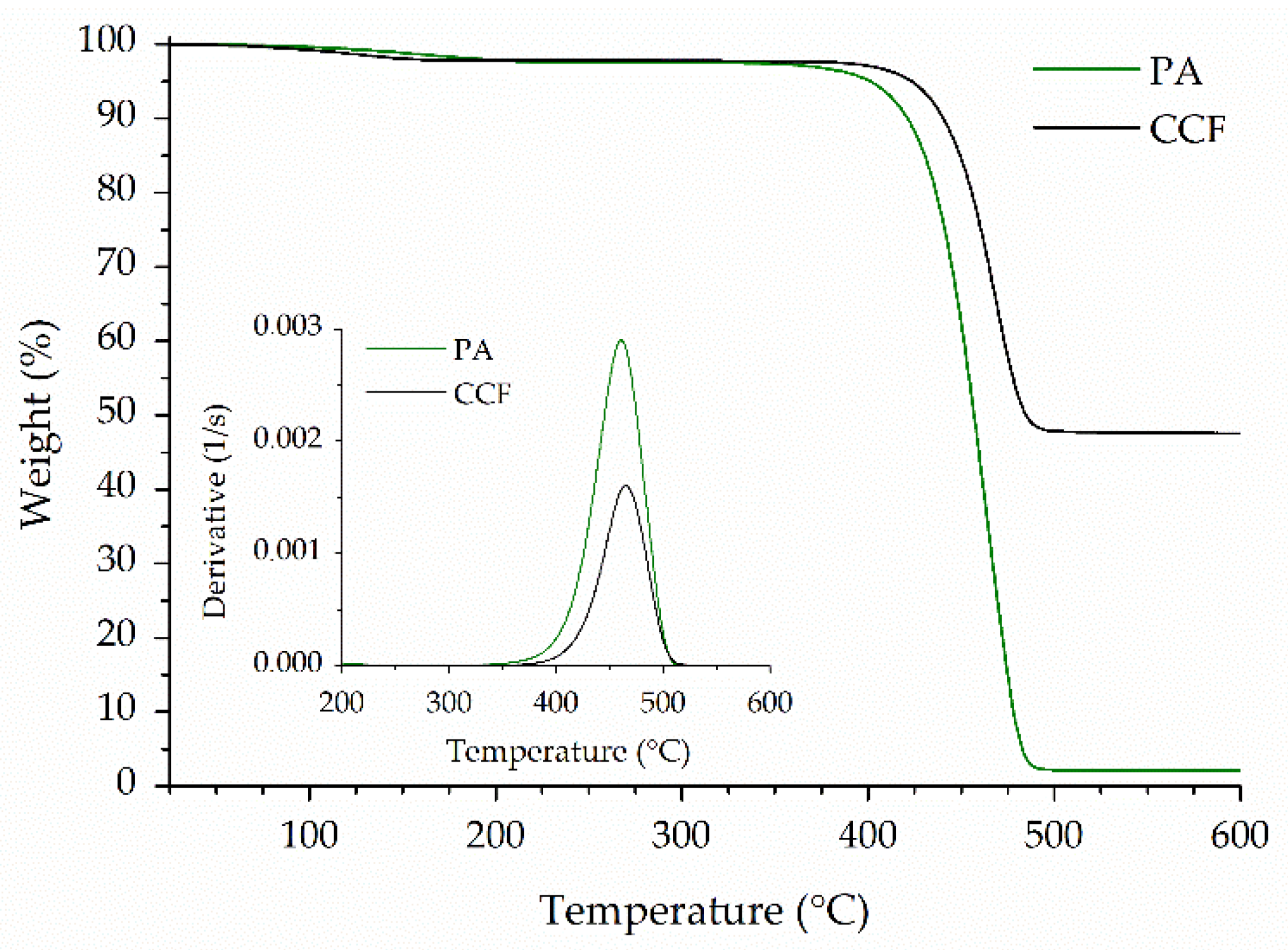

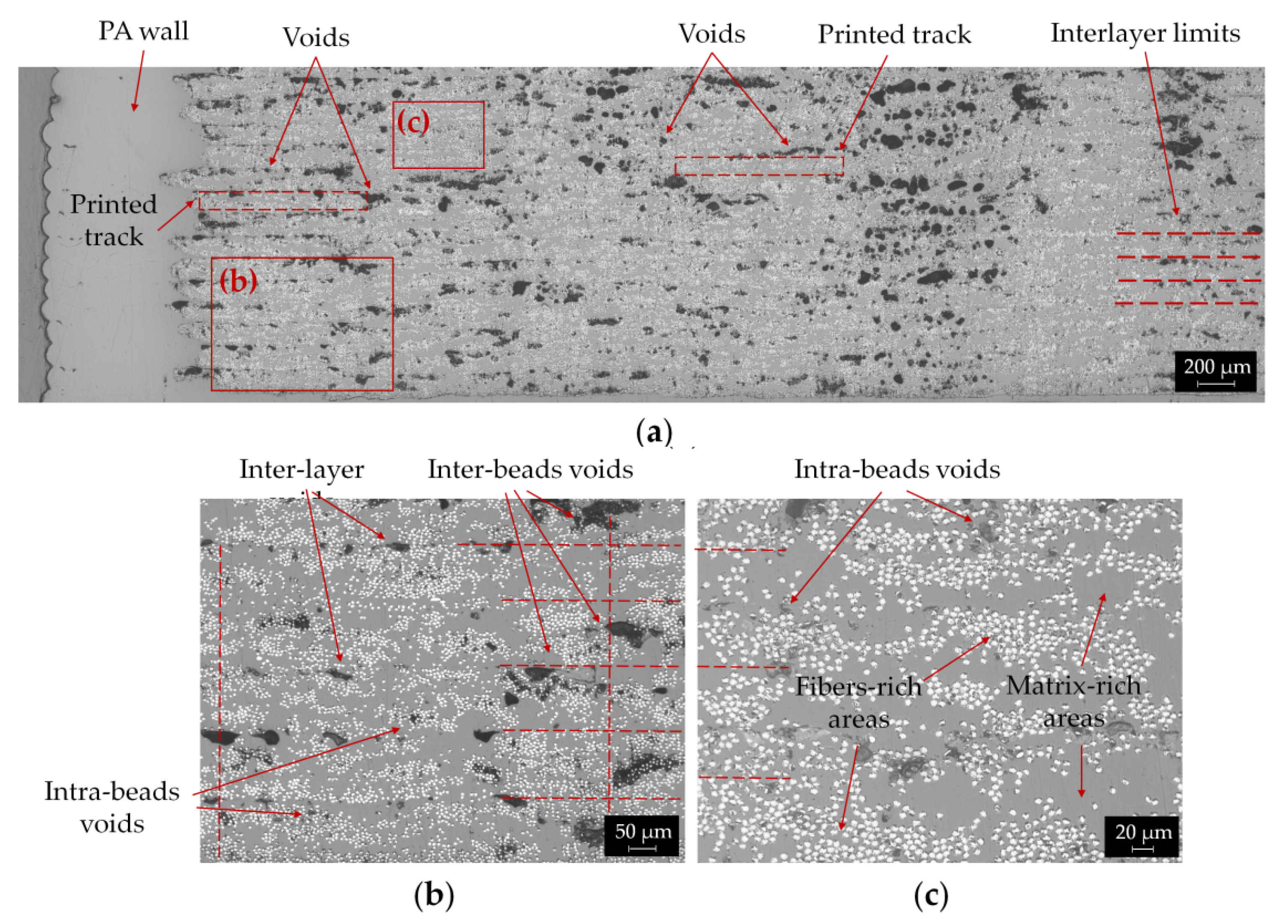

Microstructural analysis of the printed parts was performed using optical microscopy. Images of YZ cross sections of CCF/PA samples with [0] layup at various magnification are presented in

Figure 6.

Figure 6a shows the cross section of longitudinal reinforced composites. The image clearly reveals the typical microstructure of the printed parts produced using the FFF process. Wall and infill of neat PA and CCF materials, respectively, can be distinguished along with the multiple stacked layers through the thickness of the sample. Large voids can also be observed in several regions of the printed part. A high pore content (11.1%) was calculated through ImageJ

® software (Bethesda, MD, USA). Similar values of porosity for the longitudinal composite were reported by other authors by means of optical microscopy [

16,

17,

18] and micro-computer tomography techniques [

25].

Figure 6b shows a magnified area of the entire cross section, where the interfaces between the layers are highlighted with horizontal red lines; in addition, the borders between adjacent printed beads (see vertical red dashed lines) are put in evidence in the image. The interlayer limits can be identified by the presence of nearly elongated voids, referred to as “inter-layer voids” in

Figure 6b. The interface between adjacent beads is frequently delimited by large intra-layer pores with irregular shape (“inter-bead voids”) that represent almost 80% of the total porosity content (

Figure 6a,b). However, the beads overlap is not uniform since the regions where the filaments join alternately exhibits more or less pores (

Figure 6a,b). The dimensions of printed beads reveal that the filament experiences a considerable flattening during the printing process, from the tow diameter of 380 μm to a layer thickness of 125 μm and a width of 0.9 mm (i.e., equal to the diameter of the extrusion nozzle). Small round pores also appear in areas within the printed beads (“intra-bead voids”) (

Figure 6b). These areas are shown in detail in

Figure 6c. Within each printed bead, distinct regions of the matrix, fibers and voids can be observed. As a result, the composite parts revealed an uneven fibers distribution with polymer rich areas alternated to high fibers density regions (

Figure 6c). The same microstructural features were found in [

16,

19,

20], where the dimensions of the printed beads, the interlayer limits and the overlapping area between adjacent beads were described.

It is important to notice that in the CCF filament cross section large polymer rich areas also appear, although the amount of porosity is significantly lower compared to the printed parts (

Figure 4a and

Figure 6). This indicates that the FFF process is unable to completely promote adequate bonding between the printed beads, both layer by layer and side by side. In fact, the absence of pressure, the anisotropic thermal properties of the carbon fibers and the typical thermal history of the printing process prevent the coalescence of the contact surfaces between the beads, thus promoting the formation of inter-layer and inter-bead voids. Iragi et al. [

20] found that almost three layers underneath the newly deposited filament keep experiencing heating above T

g of the amorphous PPA matrix (

Table 4). However, the printed beads cooled rather quickly, thus hindering the molecular diffusion of the polymer chains across the contact surfaces. These heating/cooling cycles, which repeatedly occur during printing, strongly influence the bond quality between the adjacent beads, as well as the degree of interlayer consolidation. Regarding the “intra-bead voids”, some authors suggest that an incomplete matrix impregnation, possibly occurring in fibers rich areas of the as received filament (

Figure 4b) and the relaxation of CF bundles during extrusion, could explain the presence of these small voids [

19,

20,

25].

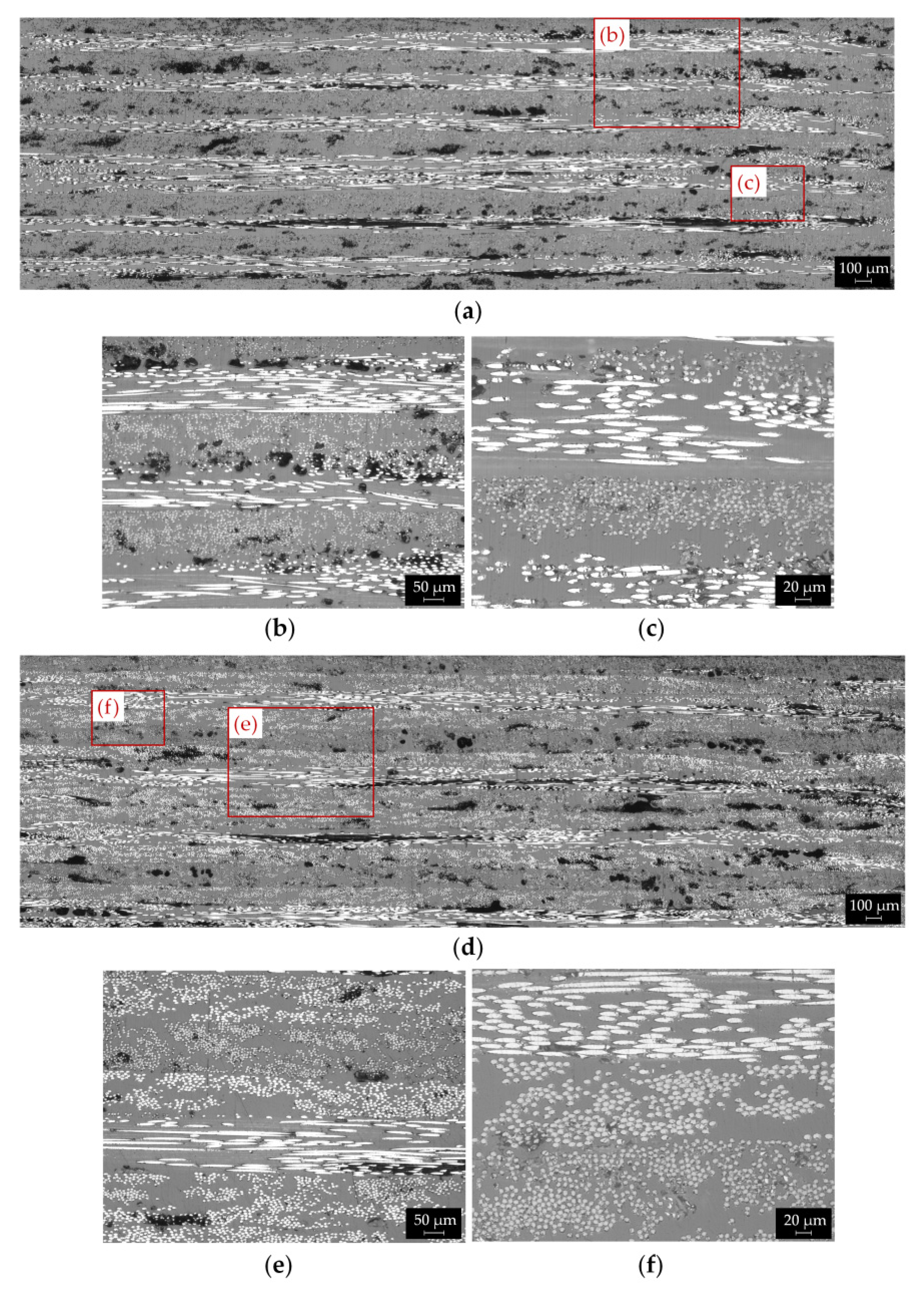

Figure 7a,d show some panoramic micrographs of the YZ cross sections of [0/90]

s and [0/45/90/−45]

s printed parts, obtained by stitching together several 50x images.

Large void areas are clearly visible in these images. The porosity content is comparable to that observed in longitudinal composite and reaches values of 11.1%, 11.3% and 11.6% for the [0/90]

s, [0/±60]

s and [0/45/90/−45]

s layups, respectively. However, the voids shape and distribution differ from that of the longitudinal laminates (

Figure 6) as the porosities are more elongated (“crack-like void”) and are mainly located in the interlayer areas (

Figure 7). These type of pores represent the largest portion of the voids for the cross-ply and quasi-isotropic composites.

The panoramic cross-sectional images are magnified in

Figure 7b,c,e,f for [0/90]

s, [0/45/90/−45]

s composites, respectively. The interlayer voids can be easily observed in the images, while the laminate layup sequence can be identified by the different cross-sectional shape of the fibers (

Figure 7b,e). Moreover, the magnified micrographs of

Figure 7c,g reveals regions with high fibers content alternated to large polymer-dominated areas, as already observed in the longitudinal sample. Smaller voids within the layers, probably related to incomplete sintering between beads or inherent porosity of the pre-impregnated feedstock filament, can also be noticed (

Figure 7c,f).

It is important to outline that the void shape and distribution significantly change for the different laminate layup from irregular gaps in the inter-bead limits for [0] samples (

Figure 6) to elongated voids located at the interface between layers for the other laminate layups (

Figure 7). In fact, the laminate layup strongly influences the temperature profiles developed during the FFF process, as observed by Kousiatza et al. [

52] through in-situ monitoring of the temperature variations during printing of CCF/PA composites. The authors found that longitudinal composites (0°) exhibited a uniform temperature profile with a gradual decreasing during the building process. By contrast, composites with a biaxial layup (±45°) displayed non-uniform temperature variations in one layer to the next one. Higher temperatures are recorded in the first layers, followed by a quick decreasing trend as the printing process progresses [

52]. Therefore, it can be assumed that cross-ply and quasi-isotropic samples experience lower temperatures for a longer period during processing if compared with the longitudinal composites. This leads to the reduction in inter-diffusion efficiency of the polymer chains between consecutive layers. Consequently, large voids are formed in the interlaminar areas (

Figure 7), resulting in poor adhesion. On the other hand, the smaller distance travelled by the printing head to deposit contiguous fiber bundles at an angle of 45°, 60° or 90° compared to 0° results in higher initial temperatures [

52]. This promotes the softening of the adjacent bead once it is in contact with the newly deposited raster, thus leading to improved bonding and smaller interbeads voids compared to the longitudinal composites (

Figure 6 and

Figure 7).

Unfortunately, the above discussed defects are intrinsically associated to the FFF technique and the void content of the printed parts is significantly higher compared to laminates produced by conventional techniques (<1%) [

53]. However, a method to improve the consolidation of the part is to perform a post-process treatment of hot compression molding. Several authors observed a reduction in void content between 50% [

25,

53] and 87% [

54] by hot pressing the printed parts. As a result, a great improvement of mechanical properties was achieved [

25,

53,

54]. On the other hand, this post-processing step requires the adoption of molds, which limits the main advantage of 3D printing (i.e., the ability to produce near-net-shape parts with complex geometry) and increases the manufacturing costs and time. Finally, it is worth noting that other approaches could be implemented to reduce the void content, such as printing inside at low pressure conditions inside a vacuum chamber [

55], using a material preheating system [

56], a layer post-compaction stage [

57,

58] or a combination of the two [

59,

60]. This last method is usually adopted in Automated Fiber Placement (AFP) to improve material consolidation [

61].

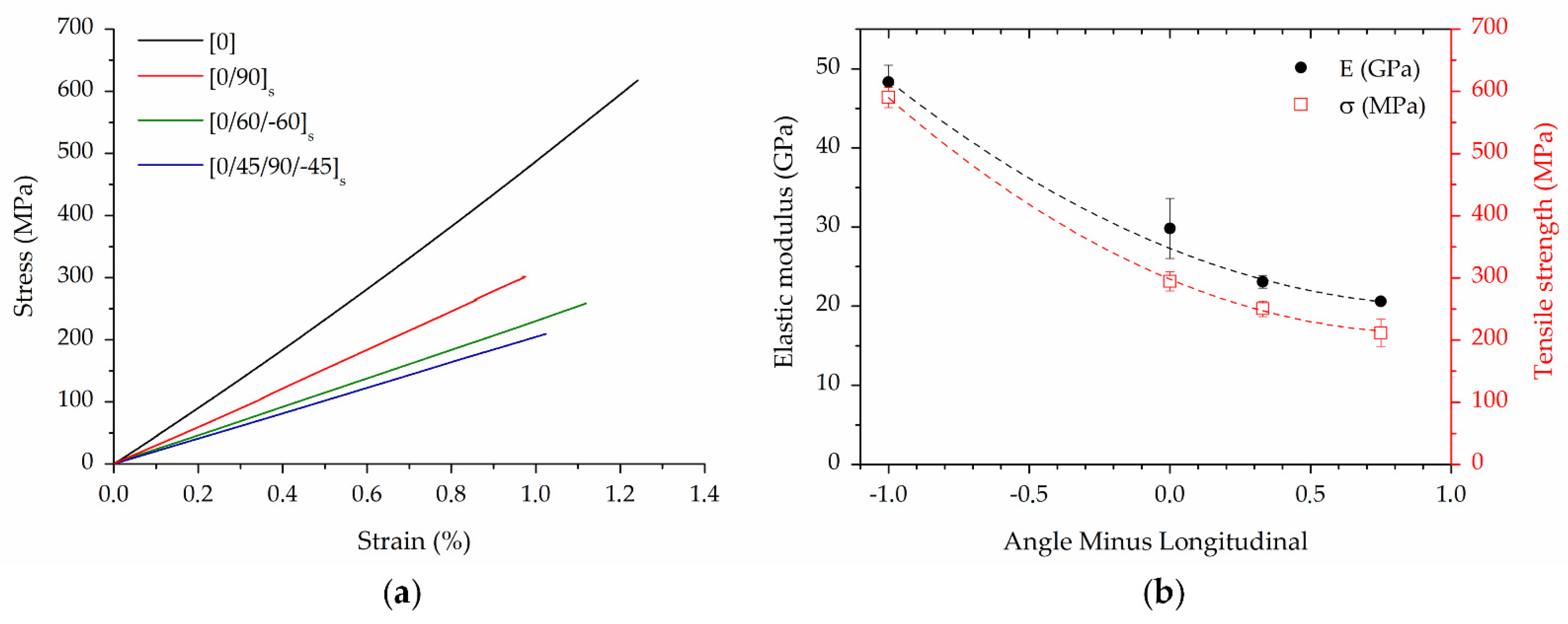

4.2.2. Tensile Properties and Fracture Surfaces

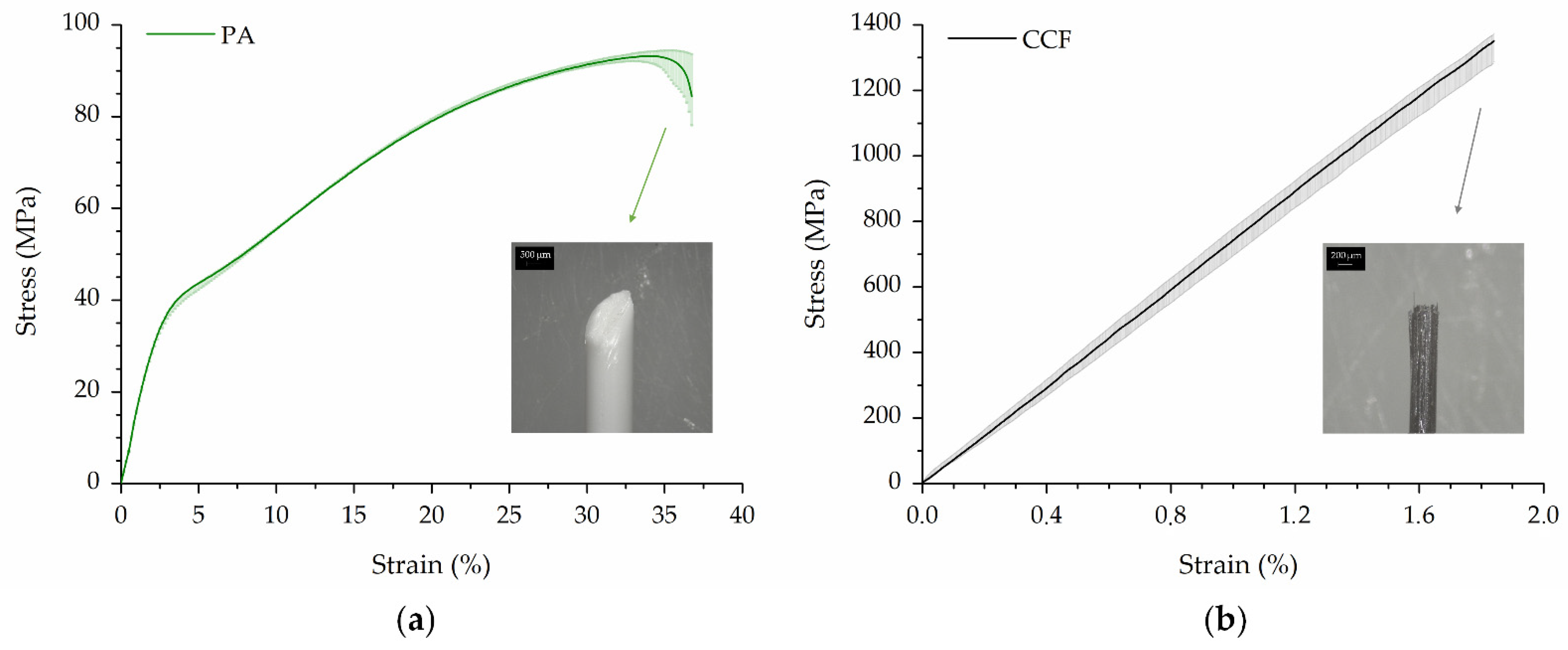

The typical stress–strain curves of CCF/PA samples with different layups are reported in

Figure 8a. The composites display a linear elastic behavior until failure (

Figure 8a). This behavior is comparable to that observed in single CCF filaments (

Figure 5b) and indicates that the fibers effectively withstand most of the applied stresses. Very low strain at break (in the range of 1–1.2%) was recorded, which is typical of brittle materials (

Figure 8a). A slight stiffening effect was observed in the tensile curves as a result of fibers straightening under increasing load. This behavior was also reported in the literature for CFRPA composites produced by FFF [

20].

The longitudinal laminate exhibits the highest load bearing capacity as the fibers are aligned in the tensile loading direction. As expected, the mechanical performances gradually decrease for the cross-ply and quasi-isotropic composites (

Figure 8a). In fact, the laminate layup strongly affects the mechanical response of the material as fibers in angled plies could not well withstand the axial tensile loads. As shown in

Figure 8b, the elastic modulus and ultimate tensile strength of the composites decrease with a quadratic function of the Angle Minus Longitudinal (AML). AML is the difference between the fraction of angled plies and the fraction of longitudinal (0°) plies [

33]. This metric shows if a layup is dominated by off axis plies or not. Therefore, the four layup can be classified in terms of tensile properties as follows: longitudinal > cross-ply > quasi-isotropic [0/±60]

s > quasi-isotropic [0/45/90/−45]

s. The elastic modulus declines by 38% and 57% for [0/90]

4s and [0/45/90/−45]

2s layup, respectively, compared to the longitudinal samples (

Figure 8b). A high reduction in strength was also reported due to the low transverse and interlaminar properties of the composites (

Figure 8b) [

19,

20,

25].

The stiffness and strength in other orthotropic directions are also important to define the ply elastic and strength properties of a laminate. Several literature studies addressed in detail the mechanical behavior of additively manufactured PA/CCF composites with [90] and [±45] layups, thus determining their transverse and in-plane shear properties, respectively [

20,

31,

32,

33]. Laminates with [90] layup exhibit poor mechanical properties (E = 4.0 GPa and σ = 19 MPa) [

32] and very low elongation break (ε = 0.5%) [

20,

31,

32]. Brittle fracture in the plane perpendicular to the applied load and parallel to the fibers is commonly observed [

20,

32]. Angle-ply [±45] laminates shows low modulus (E = 2.3 GPa) and moderate fracture strength (σ = 90.4 MPa) [

32]. However, the stress-strain response is non-linear and high plastic strains are achieved owing to the ductile nature of the polyamide matrix [

20,

31,

32,

33].

A comparison between the experimental results and these literature data is useful to better explain the mechanical behavior of the different layups. Longitudinal laminates provide the highest axial strength and stiffness (

Figure 8a). Laminates with [±45] and [90] layup exhibit low strength and stiffness due to the mechanical response of the material depending on the matrix properties and manufacturing defects [

20]. Cross-ply and quasi-isotropic laminates display an intermediate behavior between the longitudinal composite and the other layups. In fact, it has been found that the ratio between 0° plies and off-axis plies has a great role in determining the stiffness and strength of the laminate (

Figure 8b). Moreover, these layups differ from those previously described as they are balanced and symmetric, resulting in nearly constant strength and stiffness regardless of the direction in which they are loaded. This quality is highly relevant for structural applications. Accordingly, cross-ply laminates are widely used in industry. However, if the loading condition are complex (i.e., off-axis bending and tension), quasi-isotropic composites offer superior performance.

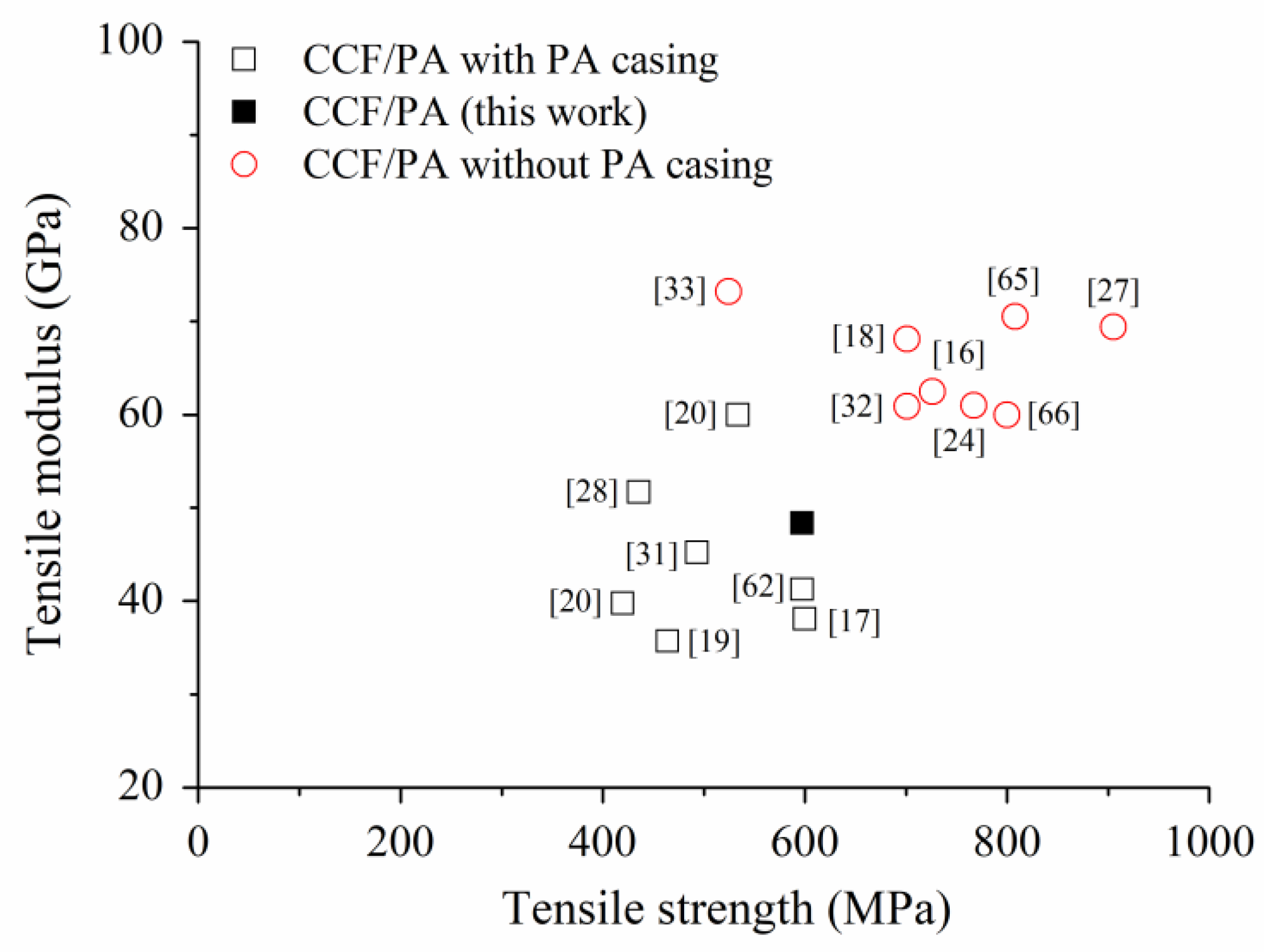

As reported in

Table 2, the longitudinal laminate has 27 vol.% of carbon fibers. This layup reaches an average elastic modulus and strength of 48.3 GPa and 597.8 MPa. These values are comparable to those reported in the literature [

17,

19,

21,

22,

31,

62] for CFRPA composites produced by FFF with sandwich configuration (i.e., outer layers and walls of neat PA) and similar volume fraction of carbon fibers (

Figure 9). Higher stiffness and strength were achieved in [

18,

20,

25,

32,

33,

63,

64] by eliminating the neat PA contours and outer layers before testing (

Figure 9), thus obtaining laminates with higher fibers content (up to 35 vol.%). It is worth noting that the CCF/PA composites exhibit a tremendous enhancement of the mechanical properties compared to those of the neat PA matrix [

39]. The printed parts also show a great improvement (greater than 4x) of elastic modulus and strength with respect to short fiber reinforced polymer composites produced by FFF [

12,

65].

However, the tensile strength and in most cases the elastic modulus of CCF/PA composites produced by FFF are still lower compared to hot compression molded counterparts, irrespective of the layup adopted (

Table 7). Moreover, it is worth noting that epoxy-based laminates currently used for primary load-bearing structures in aerospace applications are made by autoclave curing processes and exhibit significantly higher mechanical performances (E = 141 GPa and σ = 2205 MPa for HexPly

® 8552/AS4 unidirectional prepreg [

66]). Poly (ether ether ketone) (PEEK)/carbon fibers laminates display better tensile properties too (E = 138 GPa and σ = 2070 MPa for Cytec APC-2/AS4 unidirectional prepreg [

67]).

These differences can be explained by considering the current shortcomings of the MarkForged® dual extrusion FFF process for continuous fiber reinforced laminates:

high void contents, poor interlayer bonding and uneven fiber distribution due to the manufacturing process itself. In fact, the absence of pressure and the thermal conditions typical of the FFF process does not allow a proper thermo-mechanical consolidation between layers and adjacent filaments. These defects create stress concentration, thus causing the composite failure at lower stresses. This observation is confirmed by the experimental results reported in different studies, where a great enhancement of mechanical properties (22%, 36% and 145% for elastic modulus, tensile strength [

25,

73] and interlaminar shear strength [

54], respectively) was achieved by reducing the void content via hot compression molding.

low volume fraction of fibers (about 30%) compared to conventional laminates made from prepregs (>50%). In fact, the use of pre-impregnated filaments (those supplied by MarkForged® have 37 vol.% of continuous fibers) limits the fiber content in the printed parts and does not give the flexibility to modify it.

low properties of raw materials. The polyamide matrix (i.e., PA6I/6T) used in the pre-impregnated filaments has lower mechanical performances compared to PEEK and epoxy resins. Moreover, low modulus carbon fibers (i.e., Toray T300) are used [

18,

21].

process parameters cannot be modified by the user. For example, the extrusion temperatures are too low (270 °C and 255 °C for the neat polymer and pre-impregnated fiber filament, respectively) to print filaments based on high performance thermoplastics such as PEEK.

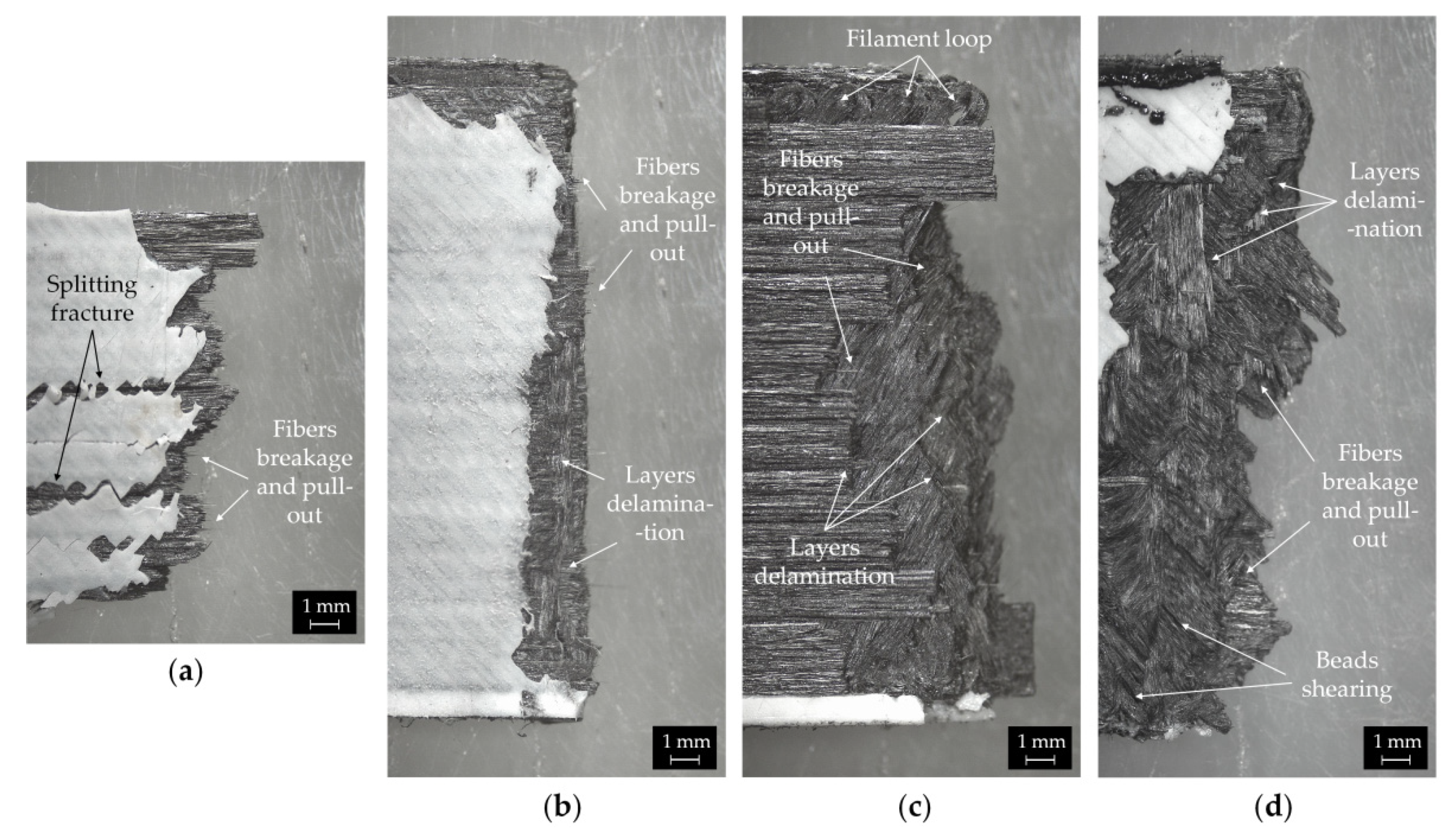

Figure 10 shows the macroscopic images of the surface fracture of the printed composites, obtained by stitching four low magnification micrographs recorded using a stereomicroscope. From these micrographs, the different failure mechanism can be clearly detected. The longitudinal laminate fails with a step-like fracture mode without necking. Both vertical and horizontal cracks are observed indicating tensile rupture due to fibers breakage and pull-out (

Figure 10a). This fracture mode is frequently reported for longitudinal fibers reinforced laminates produced both by traditional and additive technologies [

17,

32,

70]. The fracture surface of the cross-ply composite is perpendicular to the tensile load direction and exhibits a relatively smooth profile (

Figure 10b). The poor adhesion between 0° and 90° layers promotes nucleation of cracks and delamination (

Figure 10b). The cracks propagate at the 0° layer with fiber rupture and pull-out until catastrophic failure (

Figure 10b). The failure behaviors of the quasi-isotropic layups reflect the complex structure of these laminates. The fracture surfaces are very irregular (

Figure 10c,d).

The rupture mode drastically changes to an interlaminar fracture (i.e., delamination between layers instead of fiber breakage). In fact, the weak intra- and interlayer bonding of the composites result in shear rupture between beads and delamination under mechanical loading (

Figure 10c,d). Fiber breakage and pull-out can be also observed (

Figure 10c,d). Moreover, filament loops on the top edge of the samples are clearly visible in

Figure 10c. These loops are an inherent defect of the printing process, resulting from the sharp turn of the printed head at the perimeter of the part [

16,

19].

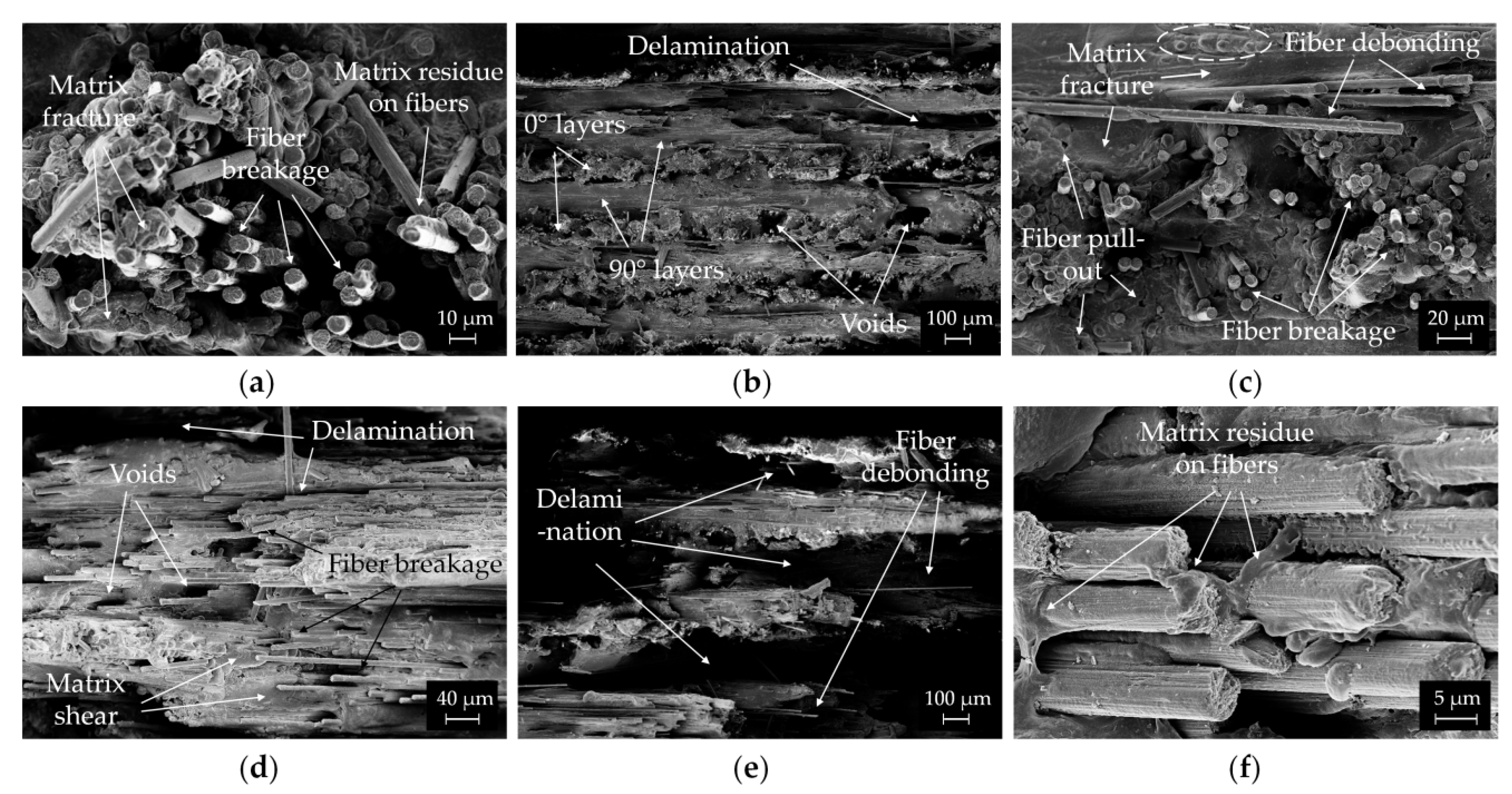

The micro-scale morphologies of the fracture surfaces of the CCF/PA composites were observed in detail by FESEM (

Figure 11).

Extensive fiber breakage can be noticed in the fracture surface of the longitudinal composites (

Figure 11a), suggesting that the tensile failure mode is fiber dominant. This may indicate that the stresses are effectively transferred from the matrix to the fibers. Polymer residues on the surface of the pull-out fibers were also observed, revealing good fiber/matrix interfacial adhesion inside the beads (

Figure 11a). Matrix fracture can be also detected in the FESEM image (

Figure 11a).

Figure 11b displays the fracture surface of [0/90]

s composites. The periodic and symmetric structure typical of the cross-ply laminates, with an alternating distribution of 0° and 90° oriented layers, can be easily detected. The fracture surface is relatively smooth. Few voids and delamination zones are visible at the interface between layers (

Figure 11b). The different fracture behavior for 0° and 90° layers can be appreciated at higher magnification (

Figure 11c). The longitudinal layers reveal an irregular fracture surface where most of the carbon fibers are embedded by the matrix material. A few pores created by fibers pull-out also appears after rupture (

Figure 11c). The layer fails by fiber breakage and pull-out, indicating their ability of carrying high mechanical stresses before failure. By contrast, the fracture surface of the 90° layers is relatively smooth and shows localized matrix fracture zones, fibers breakage and extended debonding (

Figure 11c). The debonded fibers have little polymer residue on the surface. Some micro-hills also appear in matrix rich areas (dashed circle in

Figure 11c) as a result of the plastic deformation of the polymer.

FESEM micrographs of the tensile fractured surface of [0/45/90/−45]

s and [0/±60]

s composites are shown in

Figure 11d,e. Large delamination zones in the interlayer areas, fiber debonding and matrix shear are present in both samples. These microscopic features could explain the macroscopic interlaminar fracture mode of the quasi-isotropic composites observed in

Figure 10c,d. Moreover, matrix deformation in polymer rich regions, fiber breakage and few voids are clearly visible in the fractured surfaces (

Figure 11d). At higher magnification (

Figure 11f), protruding fibers coated by matrix material were also observed. The polymer adheres well on the fiber surface, indicating good interfacial bonding with the matrix in off axis plies too.