Improvement of Interlayer Adhesion and Heat Resistance of Biodegradable Ternary Blend Composite 3D Printing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Compounding and Preparation of 3D Printing Filaments

2.3. Preparation of 3D-Printing Products

2.4. Characterization

2.4.1. Thermal Properties and Heat Resistance

2.4.2. Mechanical Properties

2.4.3. Morphology

2.4.4. Rheological Behavior

2.4.5. Surface Roughness

2.4.6. Dimensional Accuracy

3. Results and Discussion

3.1. Thermal Properties and Heat Resistance of PLA/PBAT/PBS/nano talc Composites 3D Prints

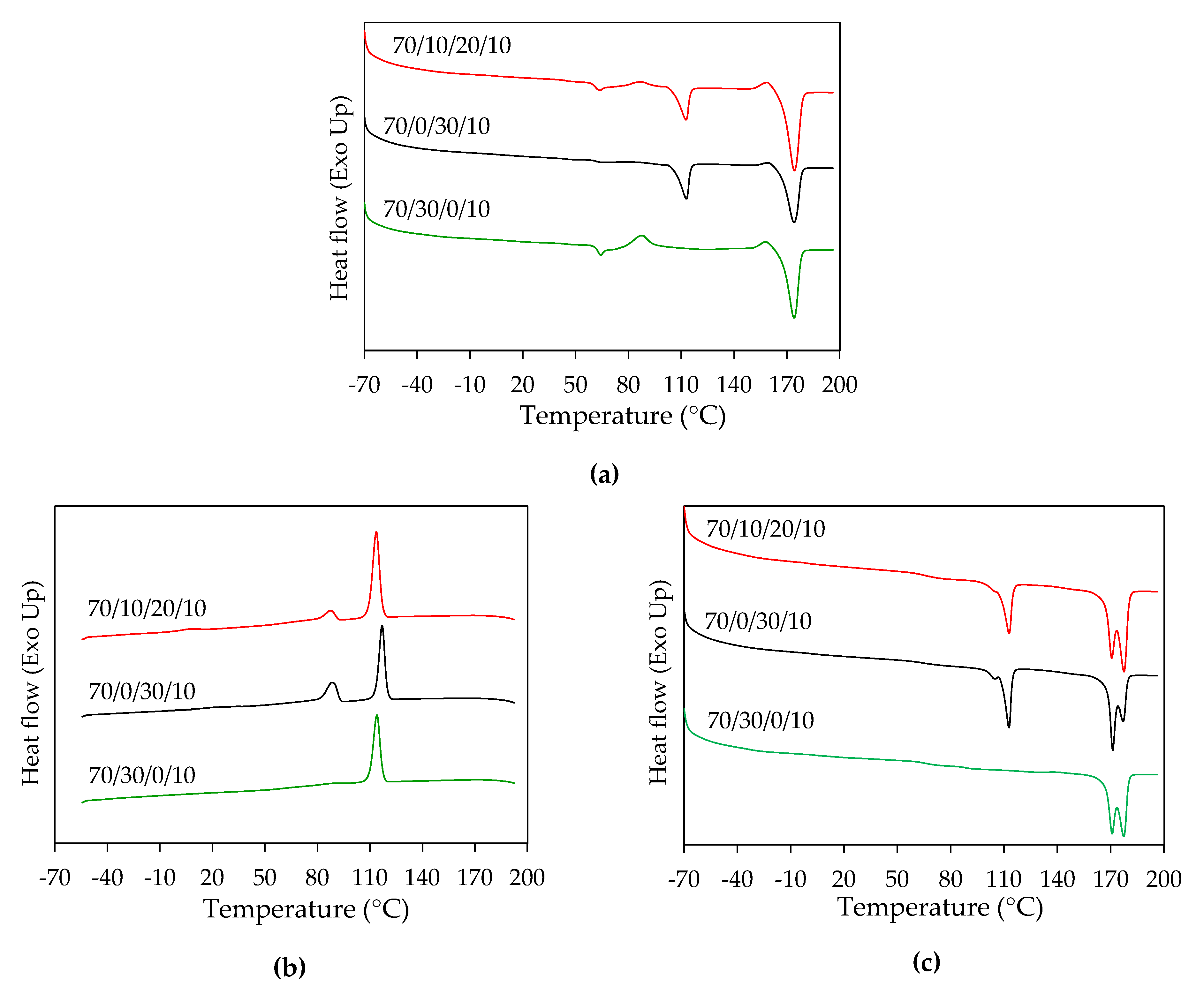

3.1.1. Thermal Properties and Crystallization Behavior

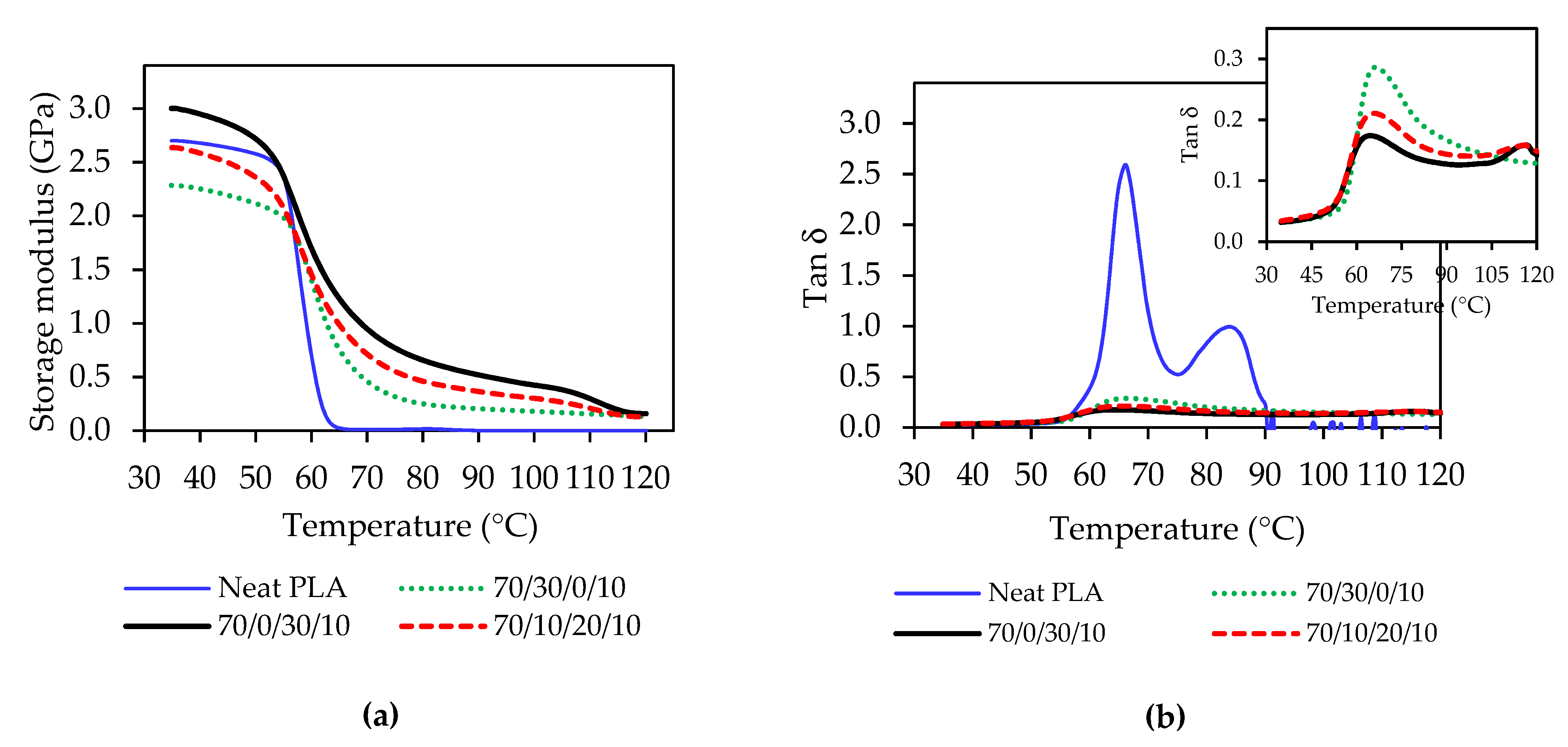

3.1.2. Dynamic Mechanical Properties and Heat Resistance

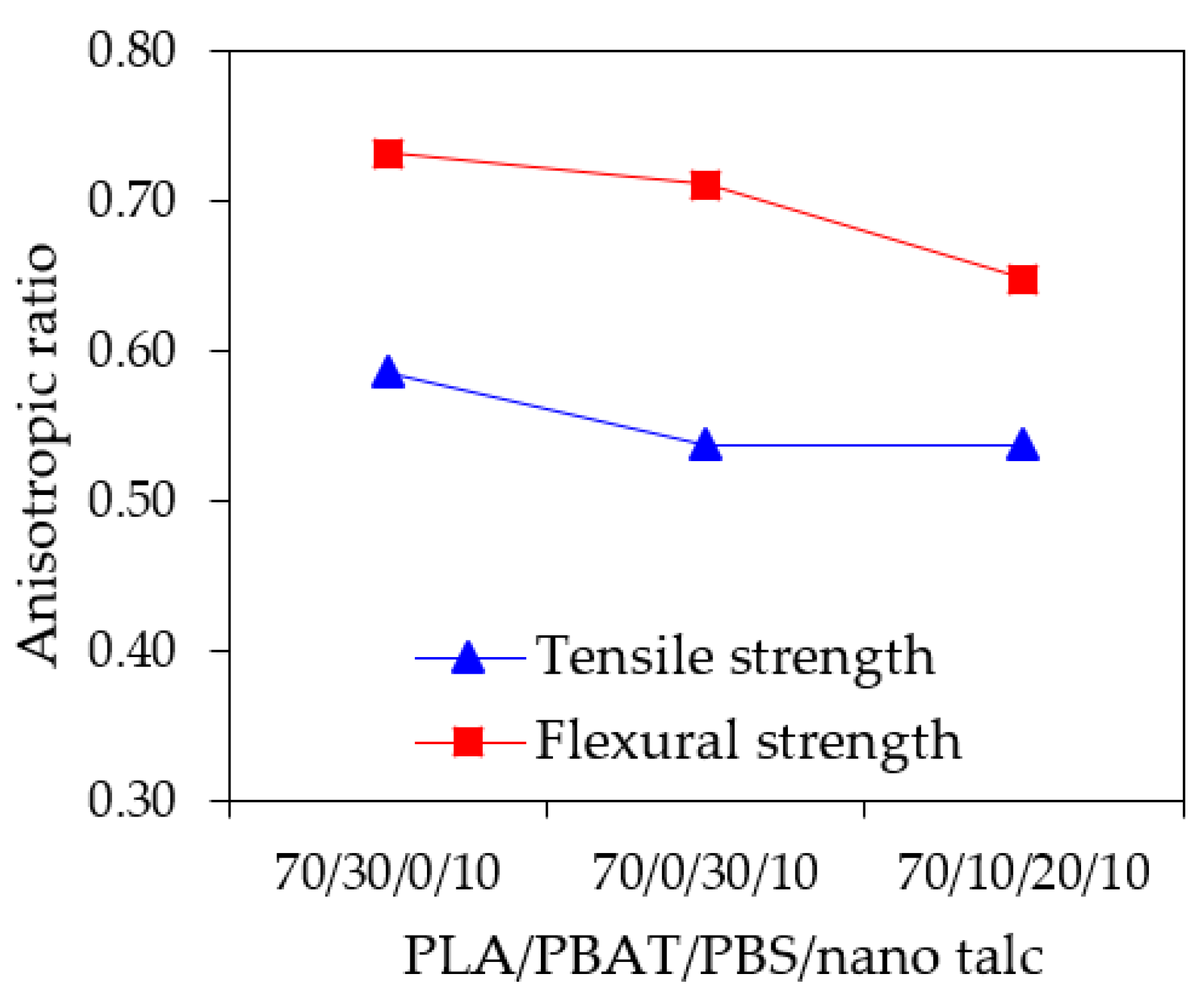

3.2. Mechanical Properties of PLA/PBAT/PBS/nano talc Composites 3D Prints

3.3. Complex Viscosity of PLA/PBAT/PBS/nano talc Composite 3D Prints

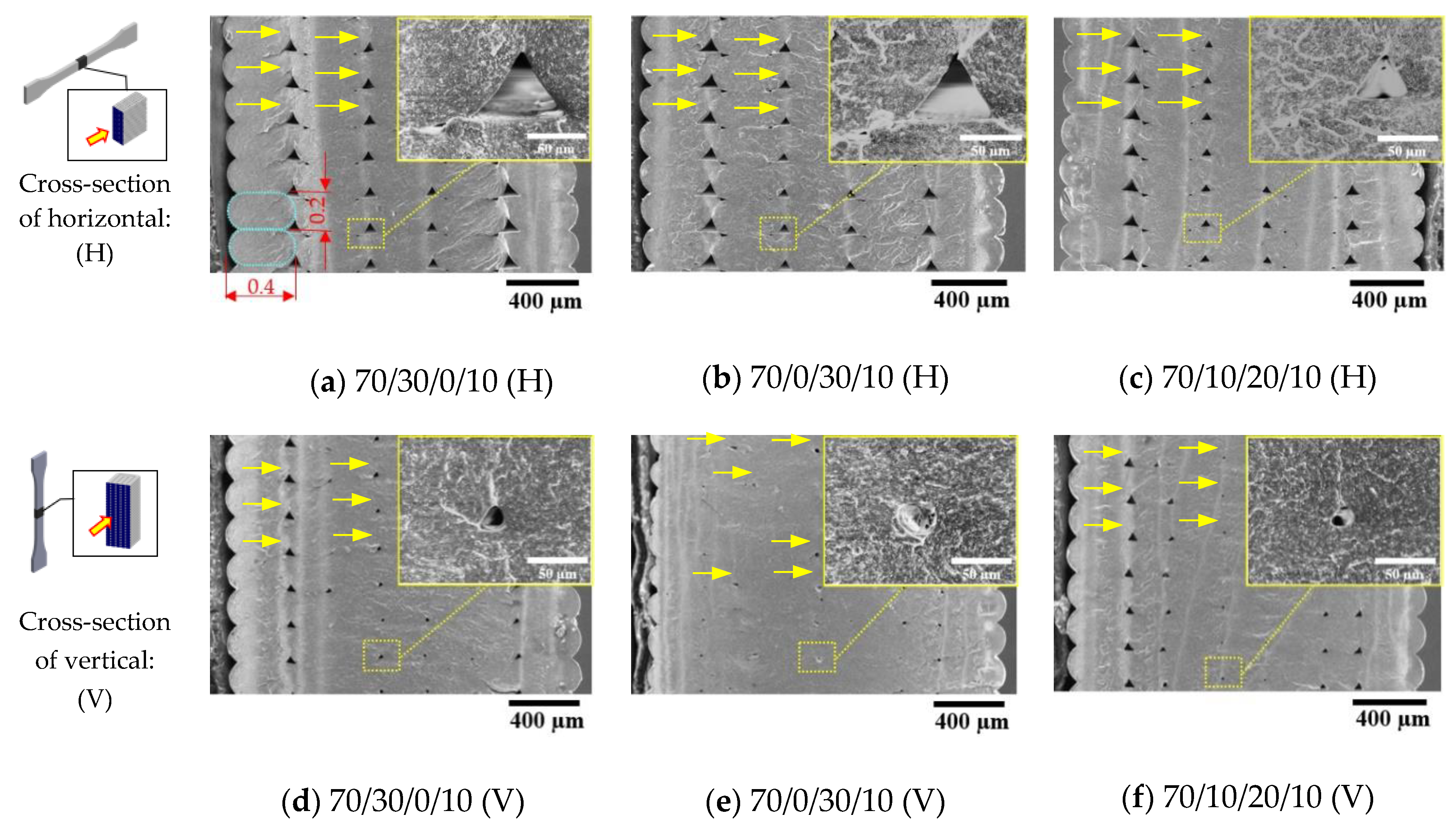

3.4. Interlayer Adhesion and Morphology of PLA/PBAT/PBS/nano talc Composite 3D Prints

3.4.1. Interlayer Adhesion of PLA/PBAT/PBS/nano talc Composite 3D Prints

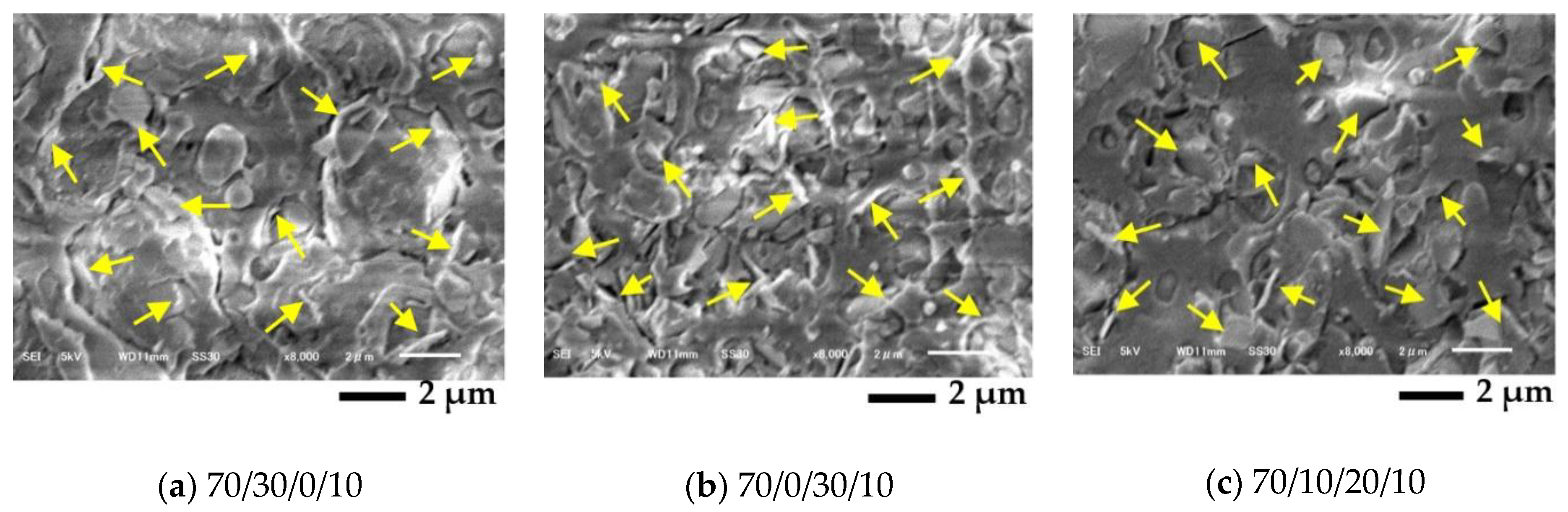

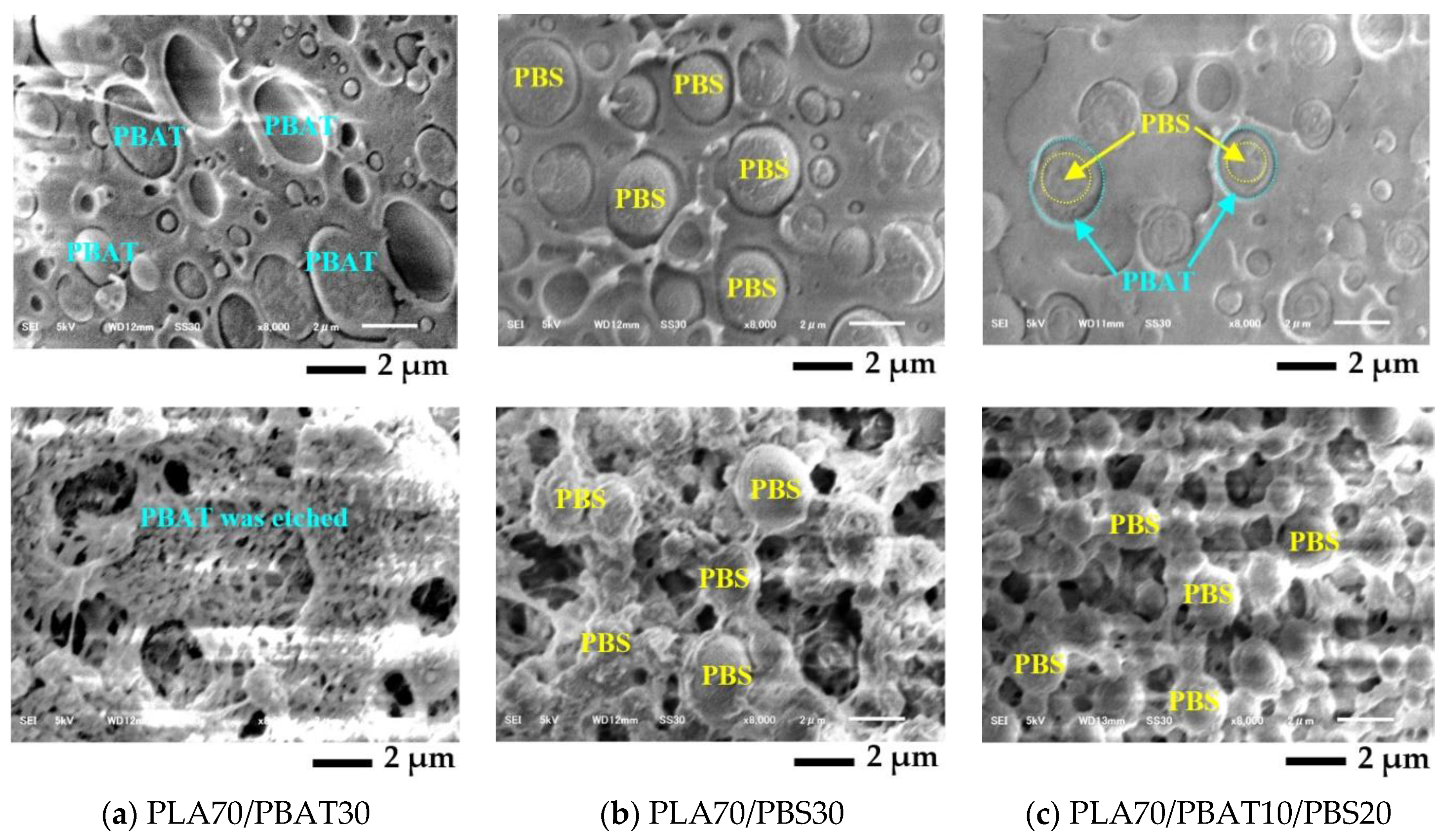

3.4.2. Morphology of PLA/PBAT/PBS/nano talc Composites

3.5. Surface Roughness and Dimensional Accuracy of PLA/PBAT/PBS/nano talc Composite 3D Prints

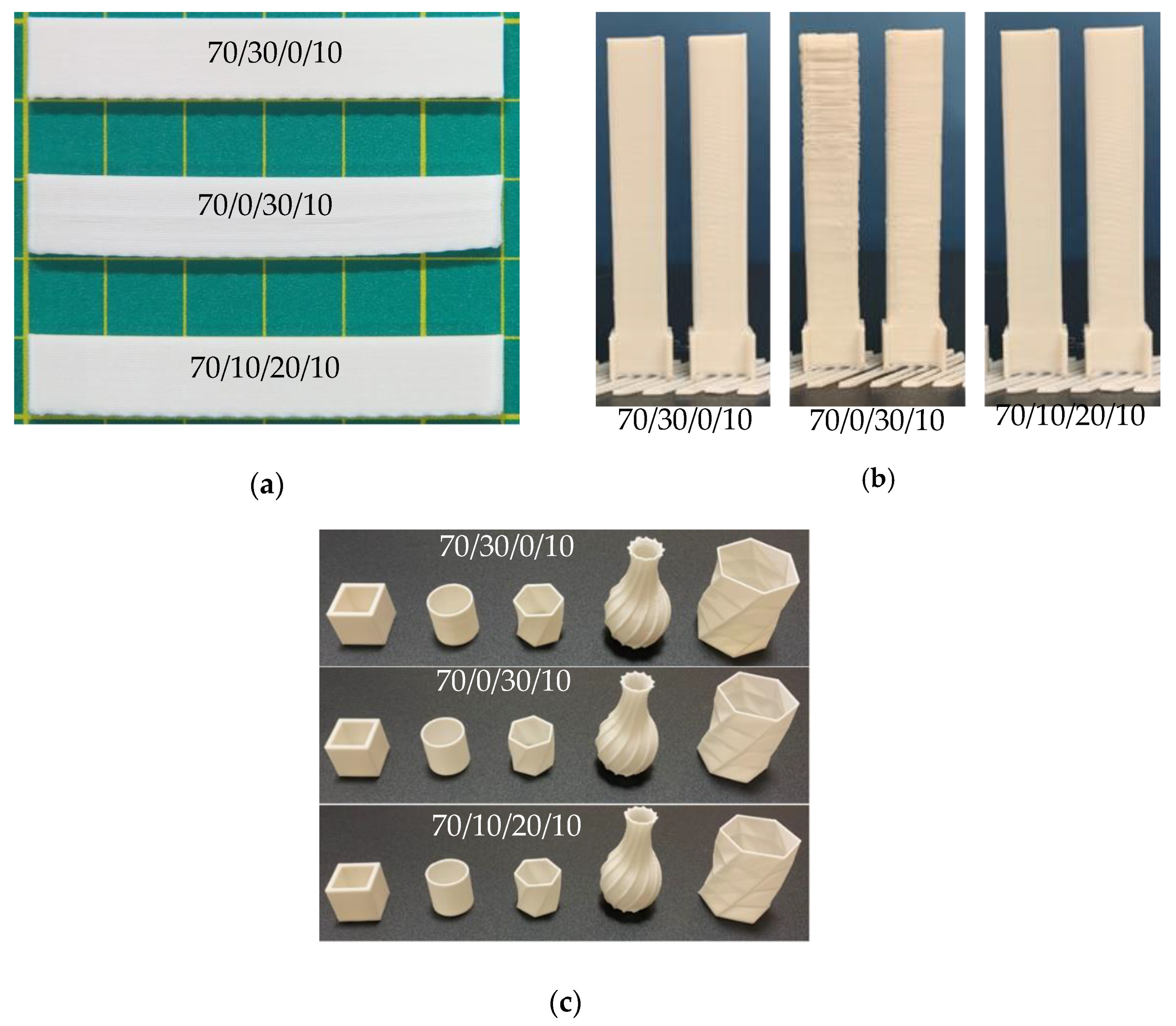

3.5.1. Surface Roughness

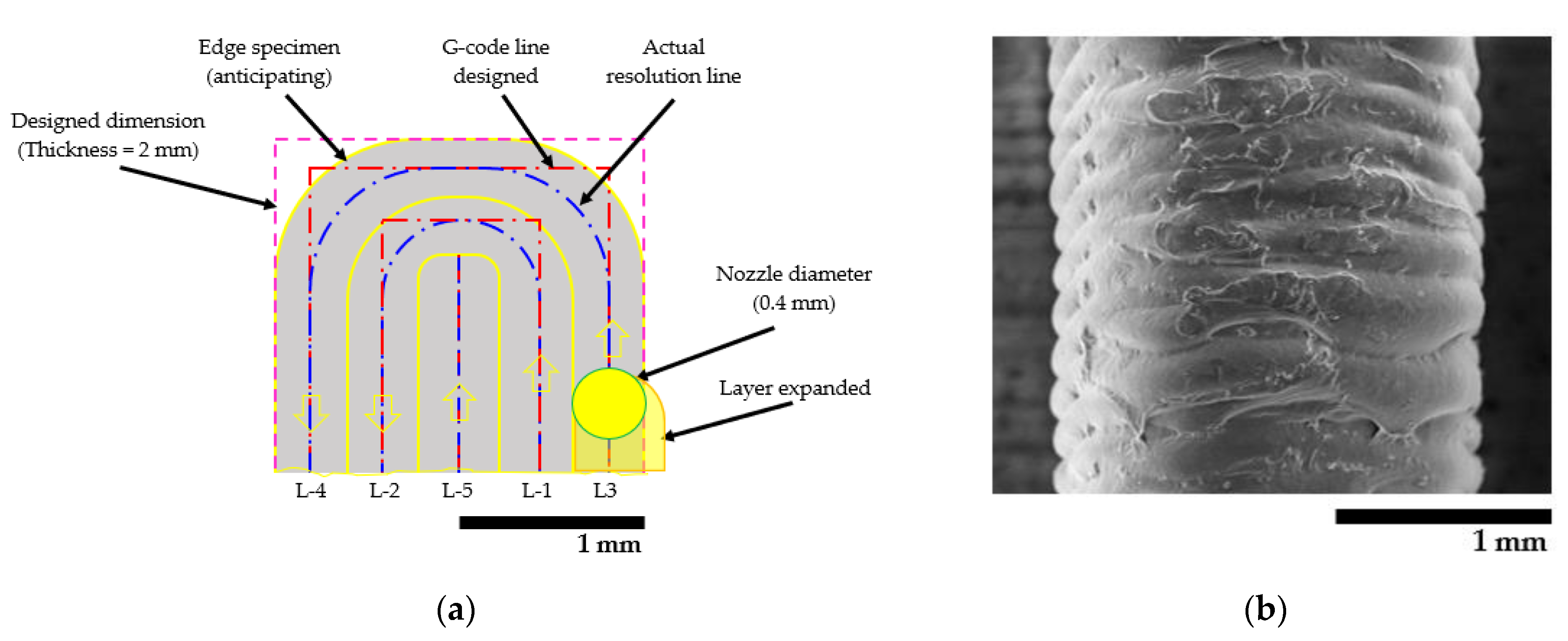

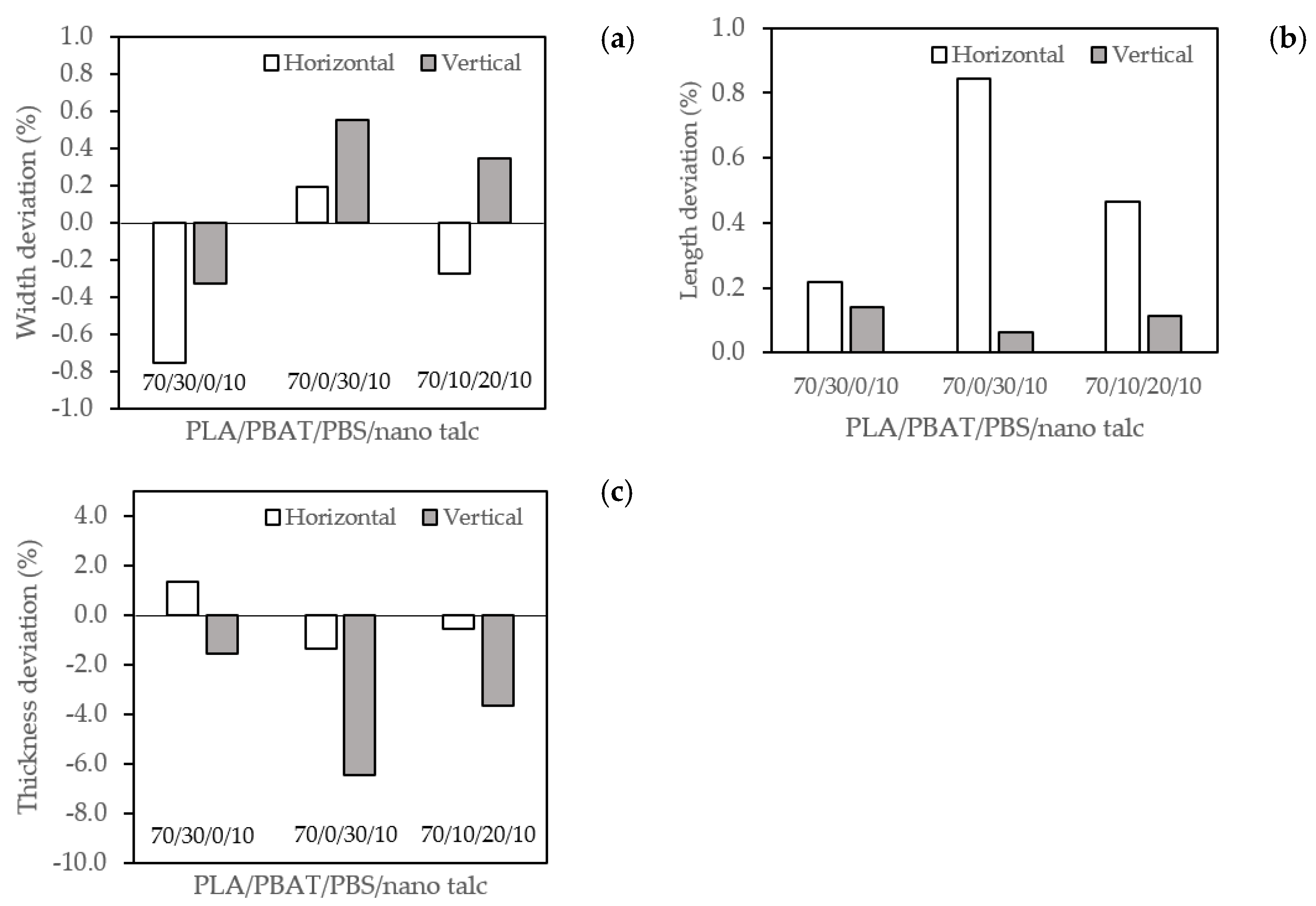

3.5.2. Dimensional Accuracy

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef] [PubMed]

- Chung, M.; Radacsi, N.; Robert, C.; McCarthy, E.D.; Callanan, A.; Conlisk, N.; Hoskins, P.R.; Koutsos, V. On the optimization of low-cost FDM 3D printers for accurate replication of patient-specific abdominal aortic aneurysm geometry. 3D Print. Med. 2018, 4, 2. [Google Scholar] [CrossRef] [Green Version]

- Mohan, N.; Senthil, P.; Vinodh, S.; Jayanth, N. A review on composite materials and process parameters optimisation for the fused deposition modelling process. Virtual Phys. Prototyp. 2017, 12, 47–59. [Google Scholar] [CrossRef]

- Yadav, D.; Chhabra, D.; Gupta, R.K.; Phogat, A.; Ahlawat, A. Modeling and analysis of significant process parameters of FDM 3D printer using ANFIS. Mater. Today Proc. 2020, 21, 1592–1604. [Google Scholar] [CrossRef]

- Li, H.; Fan, W.; Zhu, X. Three-dimensional printing: The potential technology widely used in medical fields. J. Biomed. Mater. Res. Part A 2020, 108, 2217–2229. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, R. 3D printing of food materials: A state of art review and future applications. Mater. Today Proc. 2020, 33, 1463–1467. [Google Scholar]

- Chakraborty, S.; Biswas, M.C. 3D printing technology of polymer-fiber composites in textile and fashion industry: A potential roadmap of concept to consumer. Compos. Struct. 2020, 248, 112562. [Google Scholar] [CrossRef]

- Shi, S.; Peng, Z.; Jing, J.; Yang, L.; Chen, Y.; Kotsilkova, R.; Ivanov, E. Preparation of Highly Efficient Electromagnetic Interference Shielding Polylactic Acid/Graphene Nanocomposites for FDM 3D Printing. Ind. Eng. Chem. Res. 2020, 35, 15565–15575. [Google Scholar] [CrossRef]

- Lim, C.W.J.; Le, K.Q.; Lu, Q.; Wong, C.H. An overview of 3-D printing in manufacturing, aerospace, and automotive industries. IEEE Potentials 2016, 35, 18–22. [Google Scholar] [CrossRef]

- Lin, A.; Tan, Y.K.; Wang, C.-H.; Kua, H.W.; Taylor, H. Utilization of waste materials in a novel mortar–polymer laminar composite to be applied in construction 3D-printing. Compos. Struct. 2020, 253, 112764. [Google Scholar] [CrossRef]

- Sang, L.; Han, S.; Li, Z.; Yang, X.; Hou, W. Development of short basalt fiber reinforced polylactide composites and their feasible evaluation for 3D printing applications. Compos. Part B Eng. 2019, 164, 629–639. [Google Scholar] [CrossRef]

- Penumakala, P.K.; Santo, J.; Thomas, A. A critical review on the fused deposition modeling of thermoplastic polymer composites. Compos. Part B Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Sabyrov, N.; Abilgaziyev, A.; Ali, M.H. Enhancing interlayer bonding strength of FDM 3D printing technology by diode laser-assisted system. Int. J. Adv. Manuf. Technol. 2020, 108, 603–611. [Google Scholar] [CrossRef]

- Garzon-Hernandez, S.; Arias, A.; Garcia-Gonzalez, D. A continuum constitutive model for FDM 3D printed thermoplastics. Compos. Part B Eng. 2020, 201, 108373. [Google Scholar] [CrossRef]

- Cuiffo, M.A.; Snyder, J.; Elliott, A.M.; Romero, N.; Kannan, S.; Halada, G.P. Impact of the fused deposition (FDM) printing process on polylactic acid (PLA) chemistry and structure. Appl. Sci. 2017, 7, 579. [Google Scholar] [CrossRef] [Green Version]

- Choi, W.J.; Hwang, K.S.; Kwon, H.J.; Lee, C.; Kim, C.H.; Kim, T.H.; Heo, S.W.; Kim, J.-H.; Lee, J.-Y. Rapid development of dual porous poly (lactic acid) foam using fused deposition modeling (FDM) 3D printing for medical scaffold application. Mater. Sci. Eng. C 2020, 110, 110693. [Google Scholar] [CrossRef] [PubMed]

- Benwood, C.; Anstey, A.; Andrzejewski, J.; Misra, M.; Mohanty, A.K. Improving the impact strength and heat resistance of 3D printed models: Structure, property, and processing correlationships during fused deposition modeling (FDM) of poly (lactic acid). ACS Omega 2018, 3, 4400–4411. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Cheng, J.; Anstey, A.; Mohanty, A.K.; Misra, M. Development of Toughened Blends of Poly (lactic acid) and Poly (butylene adipate-co-terephthalate) for 3D Printing Applications: Compatibilization Methods and Material Performance Evaluation. ACS Sustain. Chem. Eng. 2020, 8, 6576–6589. [Google Scholar] [CrossRef]

- Qahtani, M.; Wu, F.; Misra, M.; Gregori, S.; Mielewski, D.F.; Mohanty, A.K. Experimental design of sustainable 3D-printed poly (lactic acid)/biobased poly (butylene succinate) blends via fused deposition modeling. ACS Sustain. Chem. Eng. 2019, 7, 14460–14470. [Google Scholar] [CrossRef] [Green Version]

- Zhang, K.; Mohanty, A.K.; Misra, M. Fully biodegradable and biorenewable ternary blends from polylactide, poly(3-hydroxybutyrate-co-hydroxyvalerate) and poly (butylene succinate) with balanced properties. ACS Appl. Mater. Interfaces 2012, 4, 3091–3101. [Google Scholar] [CrossRef] [PubMed]

- Wu, F.; Misra, M.; Mohanty, A.K. Super Toughened Poly (lactic acid)-Based Ternary Blends via Enhancing Interfacial Compatibility. ACS Omega 2019, 4, 1955–1968. [Google Scholar] [CrossRef]

- Jiang, L.; Wolcott, M.P.; Zhang, J. Study of biodegradable polylactide/poly(butylene adipate-co-terephthalate) blends. Biomacromolecules 2006, 7, 199–207. [Google Scholar] [CrossRef]

- Ravati, S.; Favis, B.D. Tunable morphologies for ternary blends with poly (butylene succinate): Partial and complete wetting phenomena. Polymer 2013, 54, 3271–3281. [Google Scholar] [CrossRef]

- Ravati, S.; Beaulieu, C.; Zolali, A.M.; Favis, B.D. High performance materials based on a self-assembled multiple-percolated ternary blend. AIChE J. 2014, 60, 3005–3012. [Google Scholar] [CrossRef]

- Nakayama, D.; Wu, F.; Mohanty, A.K.; Hirai, S.; Misra, M. Biodegradable composites developed from PBAT/PLA binary blends and silk powder: Compatibilization and performance evaluation. ACS Omega 2018, 3, 12412–12421. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tri, P.; Domenek, S.; Guinault, A.; Sollogoub, C. Crystallization behavior of poly(lactide)/poly(β-hydroxybutyrate)/talc composites. J. Appl. Polym. Sci. 2013, 129, 3355–3364. [Google Scholar] [CrossRef] [Green Version]

- Jain, S.; Misra, M.; Mohanty, A.K. Thermal, mechanical and rheological behavior of poly (lactic acid)/talc composites. J. Polym. Environ. 2012, 20, 1027–1037. [Google Scholar] [CrossRef]

- Prasong, W.; Muanchan, P.; Ishigami, A.; Thumsorn, S.; Kurose, T.; Ito, H. Properties of 3D Printable Poly (lactic acid)/Poly (butylene adipate-co-terephthalate) Blends and Nano Talc Composites. J. Nanomater. 2020, 2020, 1–16. [Google Scholar] [CrossRef]

- Wootthikanokkhan, J.; Cheachun, T.; Sombatsompop, N.; Thumsorn, S.; Kaabbuathong, N.; Wongta, N.; Wong-On, J.; Na Ayutthaya, S.I.; Kositchaiyong, A. Crystallization and thermomechanical properties of PLA composites: Effects of additive types and heat treatment. J. Appl. Polym. Sci. 2013, 129, 215–223. [Google Scholar] [CrossRef]

- Mazière, A.; Prinsen, P.; García, A.; Luque, R.; Len, C. A review of progress in (bio) catalytic routes from/to renewable succinic acid. Biofuels Bioprod. Biorefining 2017, 11, 908–931. [Google Scholar] [CrossRef]

- Ostrowska, J.; Sadurski, W.; Paluch, M.; Tyński, P.; Bogusz, J. The effect of poly (butylene succinate) content on the structure and thermal and mechanical properties of its blends with polylactide. Polym. Int. 2019, 68, 1271–1279. [Google Scholar] [CrossRef]

- Su, S.; Kopitzky, R.; Tolga, S.; Kabasci, S. Polylactide (PLA) and its blends with poly (butylene succinate) (PBS): A brief review. Polymers 2019, 11, 1193. [Google Scholar] [CrossRef] [Green Version]

- Wu, D.; Yuan, L.; Laredo, E.; Zhang, M.; Zhou, W. Interfacial properties, viscoelasticity, and thermal behaviors of poly (butylene succinate)/polylactide blend. Ind. Eng. Chem. Res. 2012, 51, 2290–2298. [Google Scholar] [CrossRef]

- Ou-Yang, Q.; Guo, B.; Xu, J. Preparation and characterization of poly (butylene succinate)/polylactide blends for fused deposition modeling 3D printing. ACS Omega 2018, 3, 14309–14317. [Google Scholar] [CrossRef]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Biodegradable Poly (butylene succinate) and Poly (butylene adipate-co-terephthalate) Blends: Reactive Extrusion and Performance Evaluation. J. Polym. Environ. 2014, 22, 336–349. [Google Scholar] [CrossRef]

- Deng, Y.; Yu, C.; Wongwiwattana, P.; Thomas, N.L. Optimising ductility of poly (lactic acid)/poly (butylene adipate-co-terephthalate) blends through co-continuous phase morphology. J. Polym. Environ. 2018, 26, 3802–3816. [Google Scholar] [CrossRef] [Green Version]

- Virgilio, N.; Desjardins, P.; L′Espérance, G.; Favis, B.F. In situ measure of interfacial tensions in ternary and quaternary immiscible polymer blends demonstrating partial wetting. Macromolecules 2009, 42, 7518–7529. [Google Scholar] [CrossRef]

- Saeb, M.R.; Khonakdar, H.A.; Razban, M.; Jafari, S.H.; Garmibi, H.; Wagenknecht, U. Morphology prediction in HDPE/PA-6/EVOH ternary blends: Defining the role of elasticity. Macromol. Chem. Phys. 2012, 213, 1791–1802. [Google Scholar] [CrossRef]

- Rastin, H.; Jafari, S.H.; Saeb, M.R.; Khonakdar, H.A.; Wagenknecht, U.; Heinrich, G. On the reliability of existing theoretical models in anticipating type of morphology and domain size in HDPE/PA-6/EVOH ternary blends. Eur. Polym. J. 2014, 53, 1–12. [Google Scholar] [CrossRef]

- Jazani, O.M.; Goodarzi, V.; Hemmati, F.; Saeb, M.R. Structure–property relationships in ternary polymer blends with core–shell inclusions: Revisiting the critical role of the viscosity ratio. J. Polym. Res. 2016, 23, 231. [Google Scholar] [CrossRef]

- Hemmati, M.; Nazokdast, H.; Shariat Panahi, H. Study on morphology of ternary polymer blends. I. Effects of melt viscosity and interfacial interaction. J. Appl. Polym. Sci. 2001, 82, 1129–1137. [Google Scholar] [CrossRef]

- Rastin, H.; Ormsby, R.T.; Atkins, G.J.; Losic, D. 3D bioprinting of methylcellulose/gelatin-methacryloyl (MC/GelMA) bioink with high shape integrity. ACS Appl. Bio Mater. 2020, 3, 1815–1826. [Google Scholar] [CrossRef]

- Rastin, H.; Zhang, B.; Mazinani, A.; Hassan, K.; Bi, J.; Tung, T.T.; Losic, D. 3D bioprinting of cell-laden electroconductive MXene nanocomposites bioinks. Nanoscale 2020, 12, 16069–16080. [Google Scholar] [CrossRef]

- Chohan, J.S.; Singh, R.; Boparai, K.S.; Penna, R.; Fraternali, F. Dimensional accuracy analysis of coupled fused deposition modeling and vapour smoothing operations for biomedical applications. Compos. Part B Eng. 2017, 117, 138–149. [Google Scholar] [CrossRef]

- Song, Y.; Li, Y.; Song, W.; Yee, K.; Lee, K.-Y.; Tagarielli, V.L. Measurements of the mechanical response of unidirectional 3D-printed PLA. Mater. Des. 2017, 123, 154–164. [Google Scholar] [CrossRef]

- Arabha, S.; Akbarzadeh, A.; Rajabpour, A. Engineered porous borophene with tunable anisotropic properties. Compos. Part B Eng. 2020, 200, 108260. [Google Scholar] [CrossRef]

- Kuznetsov, V.E.; Solonin, A.N.; Tavitov, A.; Urzhumtsev, O.; Vakulik, A. Increasing strength of FFF three-dimensional printed parts by influencing on temperature-related parameters of the process. Rapid Prototyp. J. 2020, 26, 107–121. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.K.; Mahapatra, S.S. Parametric appraisal of mechanical property of fused deposition modelling processed parts. Mater. Des. 2010, 31, 287–295. [Google Scholar] [CrossRef]

- Gebisa, A.W.; Lemu, H.G. Investigating effects of Fused-Deposition Modeling (FDM) processing parameters on flexural properties of ULTEM 9085 using designed experiment. Materials 2018, 11, 500. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, Y.; Xia, X.; Liu, X.; Huang, B.; Xiao, L.; Qian, Q.; Chen, Q. Preparation and rheological and mechanical properties of poly (butylene succinate)/talc composites for material extrusion additive manufacturing. Macromol. Mater. Eng. 2019, 304, 1900021. [Google Scholar] [CrossRef]

- Akhoundi, B.; Behravesh, A. Effect of filling pattern on the tensile and flexural mechanical properties of FDM 3D printed products. Exp. Mech. 2019, 59, 883–897. [Google Scholar] [CrossRef]

- Alsoufi, M.S.; Elsayed, A.E. How surface roughness performance of printed parts manufactured by desktop FDM 3D printer with PLA+ is influenced by measuring direction. Am. J. Mech. Eng. 2017, 5, 211–222. [Google Scholar]

- Redwood, B.; Schffer, F.; Garret, B. The 3D Printing Handbook: Technologies, Design and Applications; 3D Hubs: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Yasa, E.; Ersoy, K. Dimensional Accuracy and Mechanical Properties of Chopped Carbon Reinforced Polymers Produced by Material Extrusion Additive Manufacturing. Materials 2019, 12, 3885. [Google Scholar] [CrossRef] [Green Version]

- Calderon, A.; Griffin, J.; Zagal, J.C. BeamMaker: An open hardware high-resolution digital fabricator for the masses. Rapid Prototyp. J. 2014, 20, 245–255. [Google Scholar] [CrossRef]

- Jin, Y.; Wan, Y.; Zhang, B.; Liu, Z. Modeling of the chemical finishing process for polylactic acid parts in fused deposition modeling and investigation of its tensile properties. J. Mater. Process. Technol. 2017, 240, 233–239. [Google Scholar] [CrossRef]

- Alsoufi, M.S.; Elsayed, A.E. Surface roughness quality and dimensional accuracy—a comprehensive analysis of 100% infill printed parts fabricated by a personal/desktop cost-effective FDM 3D printer. Mater. Sci. Appl. 2018, 9, 11–40. [Google Scholar] [CrossRef] [Green Version]

- Sirjani, E.; Cragg, P.J.; Dymond, M.K. Glass transition temperatures, melting temperatures, water contact angles and dimensional precision of simple fused deposition model 3D prints and 3D printed channels constructed from a range of commercially available filaments. Chem. Data Collect. 2019, 22, 100244. [Google Scholar] [CrossRef]

- Alsoufi, M.S.; Elsayed, A. Warping deformation of desktop 3D printed parts manufactured by open source fused deposition modeling (FDM) system. Int. J. Mech. Mechatron. Eng. 2017, 17, 7–16. [Google Scholar]

| PLA/PBAT/PBS/nano talc | PLA (wt. %) | PBAT (wt. %) | PBS (wt. %) | nano talc (wt. %) |

|---|---|---|---|---|

| 70/30/0/10 | 63 | 27 | 0 | 10 |

| 70/0/30/10 | 63 | 0 | 27 | 10 |

| 70/10/20/10 | 63 | 9 | 18 | 10 |

| Parameters | Conditions |

|---|---|

| Nozzle Temperature | 210 °C |

| Bed Temperature | 60 °C |

| Printing Speed | 25 mm/s |

| Infill Density | 100% |

| Infill Type | Rectilinear |

| Layer Height | 0.2 mm |

| Shell Thickness | 2 layers |

| PLA/PBAT/PBS/nano talc | Tc (°C) | Tg (°C) | Tcc (°C) | ΔHcc (J/g) | PBS Tm (°C) | PLA Tm1 (°C) | PLA Tm2 (°C) | ΔHm (J/g) | Xc (%) |

|---|---|---|---|---|---|---|---|---|---|

| Neat materials 1 | |||||||||

| Neat PLA | - | 59.1 | - | - | - | 174.5 | - | 7.7 | 8.24 |

| Neat PBAT 2 | 39.6 | −31.0 | - | - | - | - | - | 20.7 | 18.2 |

| Neat PBS | 86.3 | −35.7 | - | - | 114.2 | - | - | 69.0 | 62.6 |

| 3D printed dumbbell 1st heating | |||||||||

| 70/30/0/10 | 114.0 | 60.7 | 87.3 | 12.2 | - | 174.1 | - | 34.5 | 37.7 |

| 70/0/30/10 | 116.9 | 60.1 | 84.8 | 2.8 | 112.9 | 174.0 | - | 33.9 | 52.8 |

| 70/10/20/10 | 113.5 | 59.4 | 87.1 | 5.9 | 112.7 | 174.3 | - | 33.9 | 47.3 |

| 3D printed dumbbell 2nd heating | |||||||||

| 70/30/0/10 | - | 60.4 | - | - | - | 170.8 | 177.3 | 29.8 | 50.5 |

| 70/0/30/10 | - | 58.3 | - | - | 112.8 | 171.1 | 177.0 | 30.4 | 51.5 |

| 70/10/20/10 | - | 60.0 | - | - | 112.9 | 170.6 | 177.3 | 30.2 | 51.1 |

| PLA/PBAT/PBS/nano talc | Storage Modulus 1 (GPa) | Onset Temperature (°C) | Tan δ Peak (Tg PLA) (°C) |

|---|---|---|---|

| Neat PLA 2 | 2.7 | 58.7 | 65.9 |

| Neat PBAT 2 | 0.1 | - | - |

| Neat PBS 2 | 0.6 | - | - |

| 70/30/0/10 | 2.4 | 57.3 | 66.4 |

| 70/0/30/10 | 3.0 | 53.8 | 64.8 |

| 70/10/20/10 | 2.6 | 54.7 | 65.6 |

| PLA/PBAT/PBS/nano talc | Tensile Strength (MPa) | Young’s Modulus (GPa) | Elongation at Break (%) | |||

|---|---|---|---|---|---|---|

| Horizontal | Vertical | Horizontal | Vertical | Horizontal | Vertical | |

| 70/30/0/10 | 42.5 ± 1.09 | 17.6 ± 0.88 | 0.9 ± 0.02 | 0.6 ± 0.07 | 128.2 ± 73.56 | 3.0 ± 0.22 |

| 70/0/30/10 | 56.9 ± 1.36 | 26.3 ± 2.55 | 1.1 ± 0.04 | 0.8 ± 0.03 | 6.3 ± 0.47 | 3.3 ± 0.44 |

| 70/10/20/10 | 50.4 ± 0.97 | 23.3 ± 0.86 | 1.0 ± 0.01 | 0.7 ± 0.03 | 55.9 ± 19.87 | 3.4 ± 0.19 |

| PLA/PBAT/PBS/nano talc | Flexural Strength (MPa) | Flexural Modulus (GPa) | Deflection Distance (mm) | |||

|---|---|---|---|---|---|---|

| Horizontal | Vertical | Horizontal | Vertical | Horizontal | Vertical | |

| 70/30/0/10 | 62.7 ± 1.29 | 16.8 ± 0.69 | 1.9 ± 0.14 | 1.1 ± 0.06 | 12.1 ± 0.19 | 1.3 ± 0.02 |

| 70/0/30/10 | 83.7 ± 1.23 | 24.2 ± 4.22 | 2.6 ± 0.01 | 1.5 ± 0.00 | 8.8 ± 1.53 | 1.4 ± 0.24 |

| 70/10/20/10 | 73.9 ± 1.07 | 26.0 ± 1.41 | 2.3 ± 0.12 | 1.5 ± 0.04 | 13.1 ± 0.09 | 1.6 ± 0.09 |

| PLA/PBAT/PBS/nano talc | Void Area (mm2) | η* 1 (kPa·s) | Tc (°C) | 1st Xc (%) | |

|---|---|---|---|---|---|

| Horizontal | Vertical | ||||

| 70/30/0/10 | 0.07 | 0.01 | 4.0 | 114.0 | 37.7 |

| 70/0/30/10 | 0.08 | 0.01 | 7.1 | 116.9 | 52.8 |

| 70/10/20/10 | 0.05 | 0.02 | 3.8 | 113.5 | 47.3 |

| PLA/PBAT/PBS/nano talc | Width Side | Thickness Side |

|---|---|---|

| Ra (µm) | Ra (µm) | |

| Horizontal | ||

| 70/30/0/10 | 16.0 ± 0.19 | 9.7 ± 0.09 |

| 70/0/30/10 | 17.3 ± 0.15 | 5.5 ± 0.20 |

| 70/10/20/10 | 15.2 ± 0.24 | 4.6 ± 0.27 |

| Vertical | ||

| 70/30/0/10 | 17.5 ± 0.04 | 23.1 ± 0.34 |

| 70/0/30/10 | 18.4 ± 0.18 | 30.0 ± 0.49 |

| 70/10/20/10 | 17.7 ± 0.05 | 24.4 ± 0.78 |

| PLA/PBAT/PBS/nano talc | Width (mm) | Deviation (%) | Length (mm) | Deviation (%) | Thickness (mm) | Deviation (%) |

|---|---|---|---|---|---|---|

| Horizontal | ||||||

| 70/30/0/10 | 10.08 ± 0.03 | −0.75 | 59.87 ± 0.02 | 0.22 | 1.97 ± 0.03 | 1.35 |

| 70/0/30/10 | 9.98 ± 0.07 | 0.20 | 59.49 ± 0.01 | 0.84 | 2.03 ± 0.03 | −1.35 |

| 70/10/20/10 | 10.03 ± 0.04 | −0.28 | 59.72 ± 0.02 | 0.47 | 2.01 ± 0.03 | −0.56 |

| Vertical | ||||||

| 70/30/0/10 | 10.03 ± 0.05 | −0.32 | 59.92 ± 0.07 | 0.14 | 2.03 ± 0.02 | −1.54 |

| 70/0/30/10 | 9.95 ± 0.06 | 0.55 | 59.96 ± 0.05 | 0.06 | 2.13 ± 0.04 | −6.45 |

| 70/10/20/10 | 9.97 ± 0.06 | 0.34 | 59.93 ± 0.02 | 0.11 | 2.07 ± 0.02 | −3.65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prasong, W.; Ishigami, A.; Thumsorn, S.; Kurose, T.; Ito, H. Improvement of Interlayer Adhesion and Heat Resistance of Biodegradable Ternary Blend Composite 3D Printing. Polymers 2021, 13, 740. https://doi.org/10.3390/polym13050740

Prasong W, Ishigami A, Thumsorn S, Kurose T, Ito H. Improvement of Interlayer Adhesion and Heat Resistance of Biodegradable Ternary Blend Composite 3D Printing. Polymers. 2021; 13(5):740. https://doi.org/10.3390/polym13050740

Chicago/Turabian StylePrasong, Wattanachai, Akira Ishigami, Supaphorn Thumsorn, Takashi Kurose, and Hiroshi Ito. 2021. "Improvement of Interlayer Adhesion and Heat Resistance of Biodegradable Ternary Blend Composite 3D Printing" Polymers 13, no. 5: 740. https://doi.org/10.3390/polym13050740