Evaluating the Environmental Footprint of Steel-Based Bottle Closures: A Life Cycle Assessment Approach

Abstract

1. Introduction

Literature Review

2. Materials and Methods

2.1. Life Cycle Analysis

- Upstream processes—Initial processes from resource extraction (“cradle”) to the factory gate (“gate”) before being transferred to the consumer (“cradle to gate”).

- Core processes—Main processes from gate to gate (“gate to gate”).

- Downstream processes—Final processes from the factory gate to the use and disposal phase (“grave”) (“gate to grave”) [57].

2.2. Crown Cork Metal Caps—Production and Characteristics

- Crown caps;

- Vacuum lug closures;

- Aluminum bottle caps.

- Pry off: Can only be opened with a cap opener.

- Twist off: Can be opened by twisting while applying slight pressure with the hand.

- Pry off: With two sealing rings, which offer better tightness as they come into contact with both the inside and outside of the bottle neck.

- Twist off: With one sealing ring.

- In the case of the double ring, the gasket comes into contact with both the inside and outside of the bottle neck [60].

- Processed steel.

- Internal varnish for improved impermeability.

- Varnish substrate on the outer surface for better paint adhesion.

- Inks on the outer surface.

- Outer varnish for protection and durability.

- Plastic gasket on the inner side for waterproofing

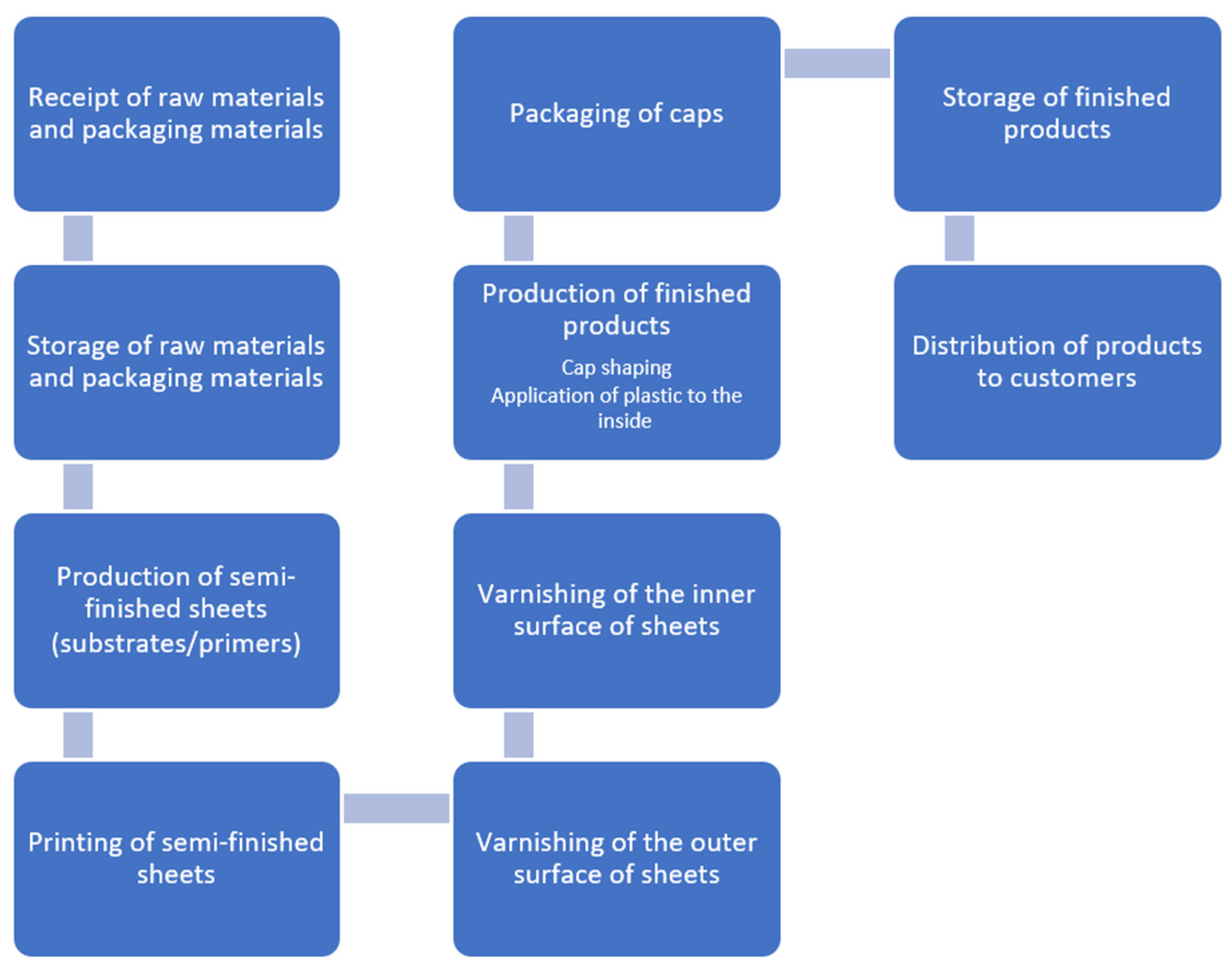

- Receipt of raw materials and packaging materials.

- Storage of raw materials and packaging materials.

- 3.

- Production of semi-finished sheets (substrates/primers).

- 4.

- Printing of semi-finished sheets.

- 5.

- Varnishing of the outer surface of sheets.

- 6.

- Varnishing of the inner surface of sheets.

- 7.

- Production of finished products.

- 8.

- Packaging of caps.

- 9.

- Storage of finished products.

- 10.

- Distribution of products to customers.

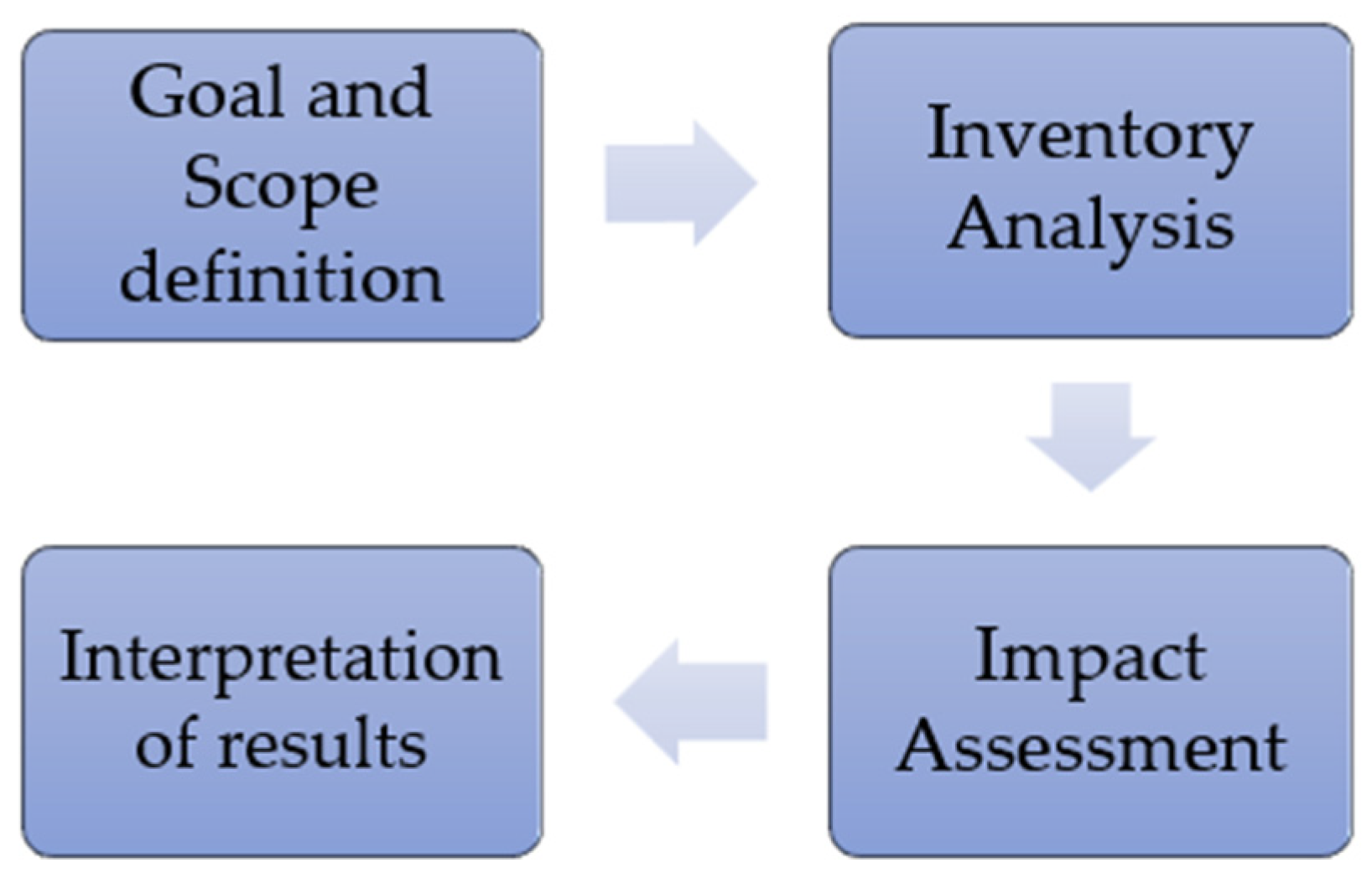

2.3. Crown Cork Metal Caps Life Cycle Assessment Methodology

2.3.1. Objectives and Research Questions

2.3.2. Assumptions of the Study and Input Data

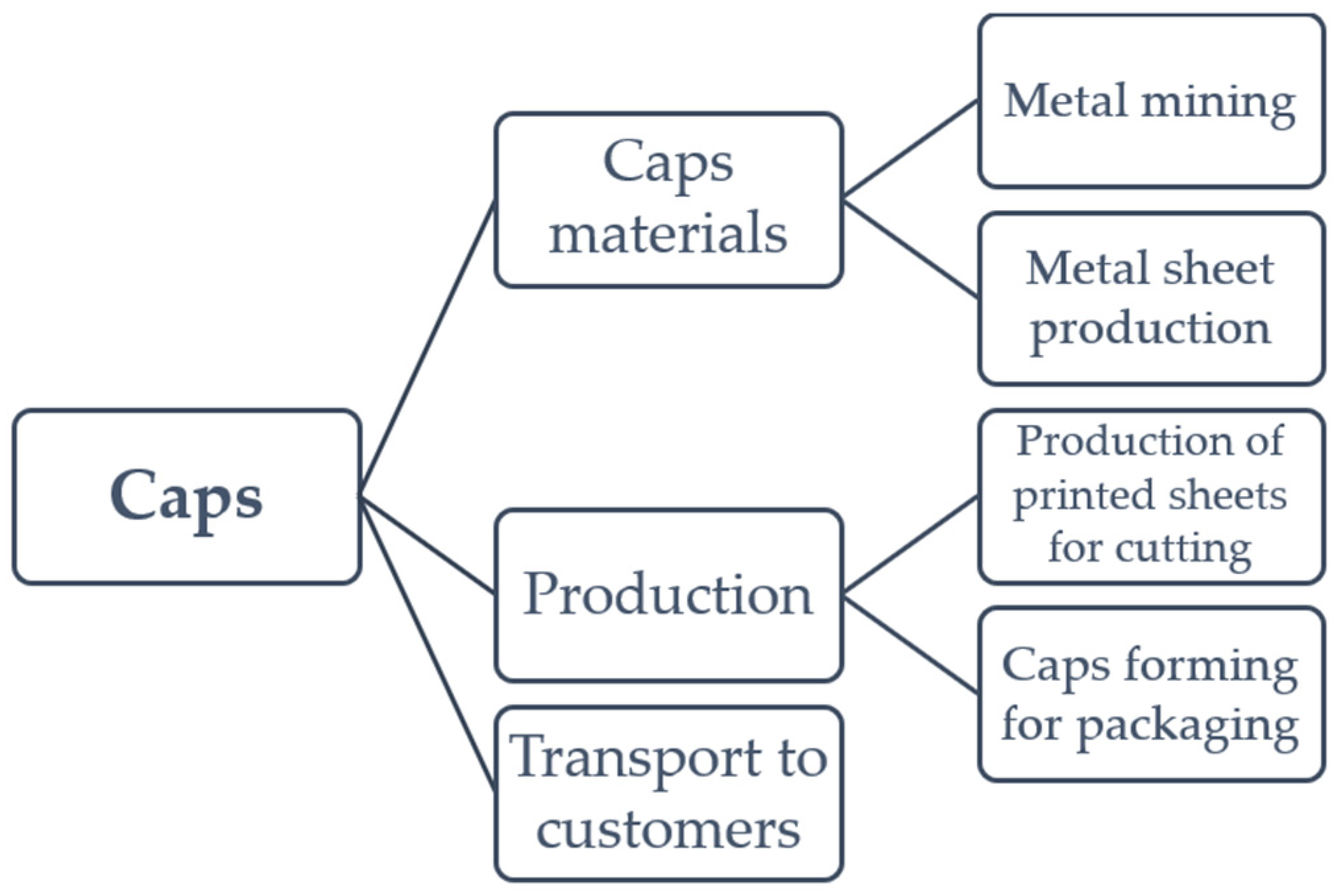

- Given the complexity of the manufacture of seals, some elements of this study are based on data and parameters drawn from the literature and studies related to steel production.

- Furthermore, due to the lack of data on the production of raw materials, only steel, which is the main component of the plugs, accounting for approximately 90%, has been analyzed.

- The transport of the final products is assumed to take place within Greece.

3. Results

3.1. Scope

3.1.1. A. Raw Materials and Packaging Materials Receiving and Storage

3.1.2. Lithography

3.1.3. Metal Cap Production

- Seal formation

- Sheet cutting and shaping

- Application and bonding of plastic

- Packaging

3.1.4. Storage and Shipping of Finished Products

- The environmental impacts of the construction of factories and production equipment;

- The impacts of the construction and operation of means of transport;

- Human resource activities during production;

- Production equipment is used during the processing of raw materials, as in the case of the production of cork.

3.2. Inventory Analysis

3.2.1. Inputs

- 0.94 t pig iron/t steel;

- 0.358 t coke/t pig iron and;

- 1.16 t sinter/t pig iron.

3.2.2. Outputs

3.3. Impact Assessment

3.3.1. Introduction to the Eco-Indicator 99 Methodology

- Input and Output Accounting: A complete record is made of all emissions, natural resource consumption and land use associated with the entire life cycle of the product under study. This stage forms the basis of every Life Cycle Assessment.

- Environmental Impact Assessment: The Eco-Indicator 99 method groups environmental impacts into three basic categories of damage. The environmental impacts resulting from the data obtained in the previous stage are classified and quantified in the following categories:

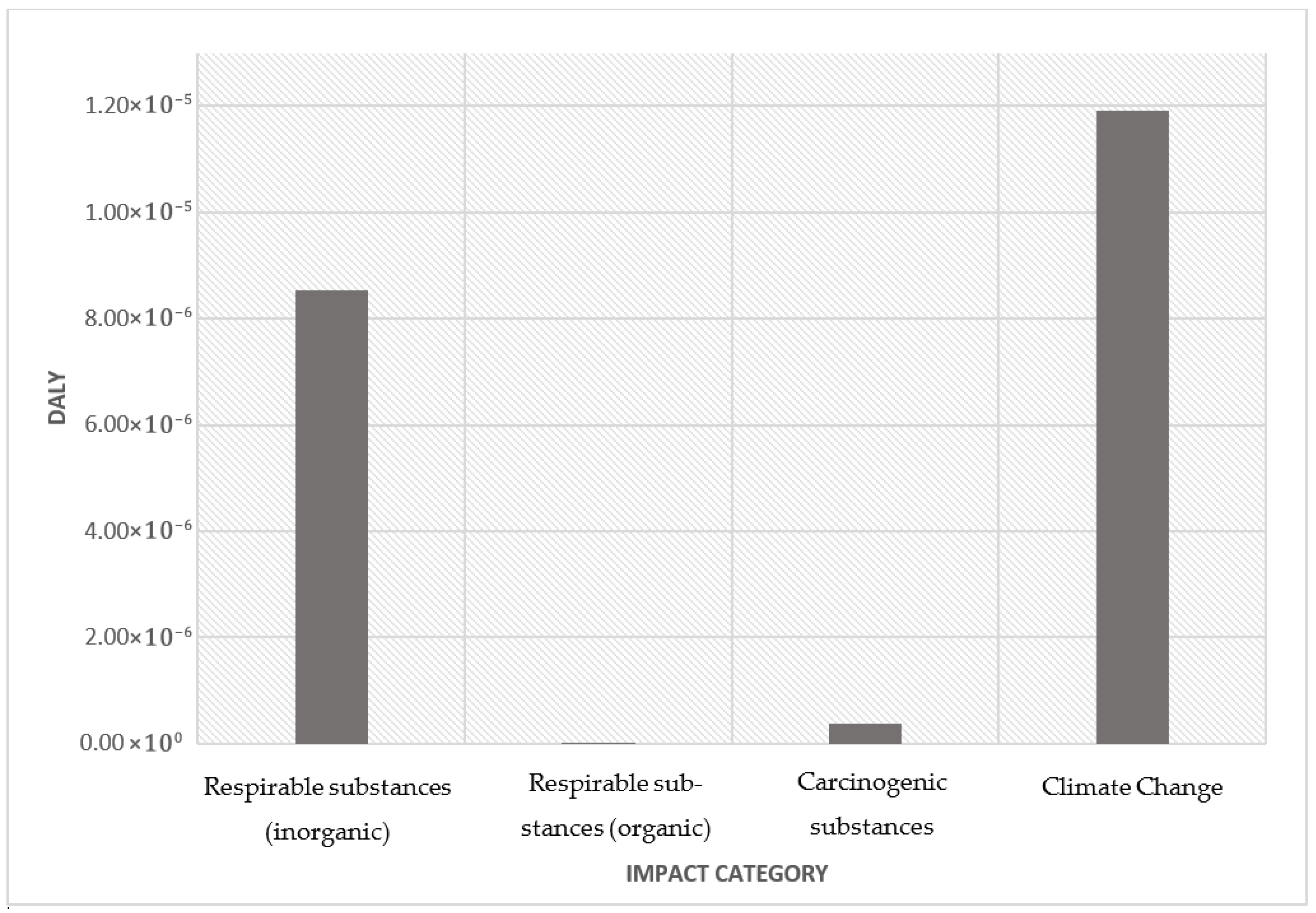

- Effects on human health (Human Health): The impact on human lives is assessed using the DALY (Disability Adjusted Life Years) indicator, which expresses the total number of years of life lost due to disability or premature death from exposure to toxic substances or other environmental burdens. The calculation is based on the number of years of disability, adjusted by a severity coefficient (0 for full health, 1 for death).

- Degradation of ecosystem quality (Ecosystem Quality): The degradation of natural ecosystems is expressed as the potential extinction of species (plants, animals, insects, etc.) due to environmental impacts. The unit of measurement is PDF·m2·year (Potentially Disappeared Fraction), which indicates the percentage of species threatened with extinction per unit of area and period.

- Consumption of natural resources (Resources): The impact in this category relates to the additional energy required to extract raw materials, such as metals and fossil fuels. It is expressed in MJ and reflects the difficulty of accessing resources due to depletion.

- Weighting and Integration of Impacts: The three impact categories above are weighted according to their relative importance in order to derive a consolidated environmental indicator that allows for comparative assessment between different products or scenarios [66].

- Impact of Carcinogenic Substances;

- Impact of Climate Change;

- Impact of Respirable Substances (inorganic);

- Impact of Respirable Substances (organic);

- Impact of Acidification/Eutrophication;

- Impact of Toxic Emissions on the Ecosystem;

- Impact of additional energy needed to extract minerals in the future.

3.3.2. Classification

- Impact of Carcinogenic Substances: As, Cd, HCB, Ni, PCB, Total 4 PAHs;

- Impact of Climate Change: CH4, CO2, N2O;

- Impact of Respirable Substances (inorganic): CO, NH3, NOx, PM10, PM2.5, SOx, TSP;

- Impact of Respirable Substances (organic): CH4, NMVOC;

- Impact of Acidification/Eutrophication: NH3, NOx, SOx;

- Impact of toxic emissions on the ecosystem: As, Cd, Cr, Cu, HCB, Hg, Ni, Pb, PCB, Total 4 PAHs, Zn;

- Impact of the additional energy needed to extract minerals in the future: Amount of iron extracted.

3.3.3. Characterization

3.3.4. Emissions’ Impact on Human Health

3.3.5. Impact of Emissions on the Ecosystem

3.4. Interpretation of Results

3.4.1. Total Impact on Human Health

3.4.2. Overall Impact on Ecosystem Quality

3.5. End-of-Life Modelling

4. Discussion

Limitations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Pollutant | Emission Factor | Unit | Emission Factor | Unit |

|---|---|---|---|---|

| CO2 | 2.5 | t/Mg steel | 2500 | g/kg |

| CH4 | 76.336 | g/Mg steel | 0.076336 | g/kg |

| NOx | 643.94 | g/Mg steel | 0.64394 | g/kg |

| CO | 19,660 | g/Mg steel | 19.66 | g/kg |

| SOx | 540.39 | g/Mg steel | 0.54039 | g/kg |

| NMVOC | 150 | g/Mg steel | 0.15 | g/kg |

| TSP | 442.8 | g/Mg steel | 0.4428 | g/kg |

| PM10 | 250 | g/Mg steel | 0.25 | g/kg |

| PM2.5 | 147 | g/Mg steel | 0.147 | g/kg |

| Pb | 4.6 | g/Mg steel | 0.0046 | g/kg |

| Cd | 0.02 | g/Mg steel | 0.00002 | g/kg |

| Hg | 0.1 | g/Mg steel | 0.0001 | g/kg |

| As | 0.4 | g/Mg steel | 0.0004 | g/kg |

| Cr | 4.5 | g/Mg steel | 0.0045 | g/kg |

| Cu | 0.07 | g/Mg steel | 0.00007 | g/kg |

| Ni | 0.14 | g/Mg steel | 0.00014 | g/kg |

| Se | 0.02 | g/Mg steel | 0.00002 | g/kg |

| Zn | 4 | g/Mg steel | 0.004 | g/kg |

| PCB | 2.5 | mg/Mg steel | 0.0000025 | g/kg |

| Total 4 PAHs | 0.48 | g/Mg steel | 0.00048 | g/kg |

| HCB | 0.03 | mg/Mg steel | 0.00000003 | g/kg |

| Pollutant | Emission Factor | Unit | Emission Factor | Unit |

|---|---|---|---|---|

| CO2 | 55.68 | kg/GJ | 55.68 | kg/GJ |

| CH4 | 1 | kg/TJ | 0.001 | kg/GJ |

| N2O | 0.1 | kg/TJ | 0.0001 | kg/GJ |

| NOx | 74 | g/GJ | 0.074 | kg/GJ |

| CO | 29 | g/GJ | 0.029 | kg/GJ |

| NMVOC | 23 | g/GJ | 0.023 | kg/GJ |

| SOx | 0.67 | g/GJ | 0.00067 | kg/GJ |

| PM10 | 0.78 | g/GJ | 0.00078 | kg/GJ |

| PM2.5 | 0.78 | g/GJ | 0.00078 | kg/GJ |

| TSP | 0.78 | g/GJ | 0.00078 | kg/GJ |

| Pollutant | Emission Factor | Unit | Emission Factor | Unit |

|---|---|---|---|---|

| CO2 | 371.68 | g/kWh | 371.68 | g/kWh |

| CH4 | 0.006322 | g/kWh | 0.006322 | g/kWh |

| N2O | 0.0026031 | g/kWh | 0.0026031 | g/kWh |

| NOx | 128.89 | mg/kWh | 0.12889 | g/kWh |

| CO | 303.68 | mg/kWh | 0.30368 | g/kWh |

| NMVOC | 101.97 | mg/kWh | 0.10197 | g/kWh |

| SOx | 2.23 | g/kWh | 2.23 | g/kWh |

| PM | 212.74 | mg/kWh | 0.21274 | g/kWh |

| Pollutant | Emission Factor | Unit |

|---|---|---|

| CO2 | 3180 | g/kg |

| CH4 | 0.16 | g/kg |

| N2O | 0.07 | g/kg |

| NOx | 25.95 | g/kg |

| CO | 6.1 | g/kg |

| SO2 | 0.000384 | g/kg |

| NMVOC | 0.9 | g/kg |

| PM | 0.55 | g/kg |

| Pb | 0.000966 | g/kg |

| NH3 | 0.02 | g/kg |

| Categories (Damage and Impact) | Total Emissions—LCI (Kg) | Characterization Factors (DALY/Kg) | Impact (DALY) |

|---|---|---|---|

| Harm to Human Health | |||

| Impact from Carcinogenic Substances | |||

| As | 1.00 × 10−5 | 0.0246 | 2.46 × 10−7 |

| Cd | 4.00 × 10−7 | 0.135 | 5.40 × 10−8 |

| HCB | 6.00 × 10−10 | 0.0825 | 4.95 × 10−11 |

| Ni | 3.00 × 10−6 | 0.0235 | 7.05 × 10−8 |

| PCB | 5.00 × 10−8 | 0.0204 | 1.02 × 10−9 |

| Total 4 PAHs | 1.00 × 10−5 | 0.00017 | 1.70 × 10−9 |

| Total | 2.35 × 10−5 | 3.73 × 10−7 | |

| Impact from Climate Change | |||

| CH4 | 1.67 × 10−3 | 0.0000044 | 7.35 × 10−9 |

| CO2 | 5.67 × 101 | 0.00000021 | 1.19 × 10−5 |

| N2O | 2.00 × 10−5 | 0.000069 | 1.38 × 10−9 |

| Total | 5.67 × 101 | 1.19 × 10−5 | |

| Impact from Respirable Substances (Inorganic) | |||

| CO | 4.23 × 10−1 | 0.000000731 | 3.10 × 10−7 |

| NH3 | 2.00 × 10−6 | 0.000085 | 1.70 × 10−10 |

| NOx | 1.95 × 10−2 | 0.0000887 | 1.73 × 10−6 |

| PM10 | 6.12 × 10−3 | 0.000375 | 2.30 × 10−6 |

| PM2.5 | 3.12 × 10−3 | 0.0007 | 2.18 × 10−6 |

| SOx | 1.77 × 10−2 | 0.0000546 | 9.68 × 10−7 |

| TSP | 9.52 × 10−3 | 0.00011 | 1.05 × 10−6 |

| Total | 4.79 × 10−1 | 8.53 × 10−6 | |

| Impact from Respirable Substances (Organic) | |||

| CH4 | 1.67 × 10−3 | 1.28 × 10−8 | 2.14 × 10−11 |

| NMVOC | 4.30 × 10−3 | 0.00000128 | 5.50 × 10−9 |

| Total | 5.97 × 10−3 | 5.53 × 10−9 | |

| Grand total | 5.72 × 101 | 2.08 × 10−5 | |

References

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; Zelm, R. ReCiPe2016: A harmonized life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- European Commission, Joint Research Centre (JRC). Environmental Footprint (EF) 3.0 Method—Overview and Detailed Guidance; Publications Office of the EU: Luxembourg, 2021; Available online: https://data.jrc.ec.europa.eu (accessed on 23 June 2025).

- Hughes, A.E.; Haque, N.; Northey, S.A.; Giddey, S. Platinum Group Metals: A Review of Resources, Production and Usage with a Focus on Catalysts. Resources 2021, 10, 93. [Google Scholar] [CrossRef]

- Flannery, B.P.; Mares, J.W. Greenhouse Gas Index for Products in 39 Industrial Sectors: Iron, Steel, and Ferroalloys (NAICS 331110); Working Paper 22-16 M6, updated February 2023; Resources for the Future: Washington, DC, USA, 2022; Available online: https://media.rff.org/documents/WP_22-16_M6_Feb_2023_Update.pdf (accessed on 16 July 2025).

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- FAO. How to Feed the World in 2050? Food and Agriculture Organization of the United Nations: Rome, Italy, 2008. [Google Scholar]

- Tilman, D.; Clark, M. Global diets link environmental sustainability and human health. Nature 2014, 515, 518–522. [Google Scholar] [CrossRef]

- Boutros, M.; Saba, S.; Manneh, R. Life cycle assessment of two packaging materials for carbonated beverages (polyethylene terephthalate vs. glass): Case study for the Lebanese context and importance of the end-of-life scenarios. J. Clean. Prod. 2021, 314, 128289. [Google Scholar] [CrossRef]

- Wansink, B. Household food waste solutions for behavioral economists and marketers. J. Food Prod. Mark. 2018, 24, 500–521. [Google Scholar] [CrossRef]

- FPM (Food Packaging Market). Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023–2028. 2023. Available online: https://www.imarcgroup.com/food-packaging-market (accessed on 29 December 2024).

- Boesen, S.; Bey, N.; Niero, M. Environmental sustainability of liquid food packaging: Is there a gap between Danish consumers’ perception and learnings from life cycle assessment? J. Clean. Prod. 2019, 210, 1193–1206. [Google Scholar] [CrossRef]

- Schulze, G. Growth within: A Circular Economy Vision for a Competitive Europe; Ellen MacArthur Foundation and McKinsey Center for Business and Environment: London, UK, 2016; pp. 1–22. [Google Scholar]

- Geueke, B.; Groh, K.; Muncke, J. Food packaging in the circular economy: Overview of chemical safety aspects for commonly used materials. J. Clean. Prod. 2018, 193, 491–505. [Google Scholar] [CrossRef]

- Sæter, F.; Alvarado, I.O.; Pettersen, I.N. Reuse principle for primary packaging circularity in the food system. In Proceedings of the NordDesign 2020, Lyngby, Denmark, 11–14 August 2020; pp. 1–12. [Google Scholar]

- Mufarrij, F.; Ashrafi, O.; Navarri, P.; Khojasteh, Y. Development and lifecycle assessment of various low- and high-density polyethylene production processes based on CO2 capture and utilization. J. Clean. Prod. 2023, 414, 137624. [Google Scholar] [CrossRef]

- Tiseo, I. Global Plastic Production. Statista. 2022, pp. 1950–2020. Available online: https://www.statista.com/statistics/282732/global-production-of-plastics-since-1950/ (accessed on 8 June 2025).

- Ghaib, K.; Ben-Fares, F.-Z. Power-to-Methane: A state-of-the-art review. Renew. Sustain. Energy Rev. 2018, 81, 433–446. [Google Scholar] [CrossRef]

- Cabernard, L.; Pfister, S.; Oberschelp, C.; Hellweg, S. Growing environmental footprint of plastics driven by coal combustion. Nat. Sustain. 2021, 5, 139–148. [Google Scholar] [CrossRef]

- Zheng, J.; Suh, S. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Change 2019, 9, 374–378. [Google Scholar] [CrossRef]

- Eurostat. Packaging Waste Statistics; Eurostat: Luxembourg, 2019; Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Packaging_waste_statistics (accessed on 29 May 2025).

- Beitzen-Heineke, E.F.; Balta-Ozkan, N.; Reefke, H. The prospects of zero-packaging grocery stores to improve the social and environmental impacts of the food supply chain. J. Clean. Prod. 2017, 140, 1528–1541. [Google Scholar] [CrossRef]

- Sazdovski, I.; Bala, A.; Fullana-i-Palmer, P. Linking LCA literature with circular economy value creation: A review on beverage packaging. Sci. Total Environ. 2021, 771, 145322. [Google Scholar] [CrossRef]

- Manfredi, S.; Allacker, K.; Chomkhamsri, K.; Pelletier, N.; Maia de Souza, D. Product Environmental Footprint (PEF) Guide; European Commission: Brussels, Belgium; Joint Research Centre: Brussels, Belgium; Institute for Environment and Sustainability: Ispra, Italy, 2012; Available online: https://www.vliz.be/imisdocs/publications/396125.pdf (accessed on 16 June 2025).

- Tascione, V.; Simboli, A.; Taddeo, R.; Del Grosso, M.; Raggi, A. A comparative analysis of recent life cycle assessment guidelines and frameworks: Methodological evidence from the packaging industry. Environ. Impact Assess. Rev. 2024, 108, 107590. [Google Scholar] [CrossRef]

- Ferrara, C.; De Feo, G. Comparative life cycle assessment of alternative systems for wine packaging in Italy. J. Clean. Prod. 2020, 259, 120888. [Google Scholar] [CrossRef]

- Curran, M.A. Assessing environmental impacts of biofuels using lifecycle-based approaches. Manag. Environ. Qual. Int. J. 2013, 24, 34–52. [Google Scholar] [CrossRef]

- Zampori, L.; Pant, R. Suggestions for Updating the Product Environmental Footprint (PEF) Method; EUR 29682 EN; Publications Office of the European Union: Luxembourg, 2019; ISBN 978-92-76-00654-1. [Google Scholar] [CrossRef]

- World Steel Association. Life Cycle Inventory Data and Eco-Profiles (2020 Dataset). Available online: https://worldsteel.org/steel-topics/life-cycle-thinking/life-cycle-inventory (accessed on 28 June 2025).

- European Commission, Joint Research Centre (JRC). PEFCR Guidance v6.3; Publications Office of the European Union: Luxembourg, 2019; Available online: https://eplca.jrc.ec.europa.eu/permalink/PEFCR_guidance_v6.3-2.pdf (accessed on 23 June 2025).

- Metal Packaging Europe; RDC Environment. Life Cycle Assessment of Metal Packaging in Europe. In Executive Summary and Methodological Report; Metal Packaging Europe: Brussels, Belgium, 2022; Available online: https://www.metalpackagingeurope.org/wp-content/uploads/2025/06/Metal-Packaging-Europe_LCA_Executive-Summary_2022.pdf (accessed on 23 June 2025).

- Bher, A.; Auras, R. Life cycle assessment of packaging systems: A meta-analysis to evaluate the root of consistencies and discrepancies. J. Clean. Prod. 2024, 476, 143785. [Google Scholar] [CrossRef]

- UNEP. Single-Use Plastic Bottles and Their Alternatives: Recommendations from Life Cycle Assessments. United Nations Environment Programme. 2020. Available online: https://www.lifecycleinitiative.org/resources/single-use-plastic-bottles (accessed on 22 June 2025).

- Shadar, H.; Shach-Pinsly, D. Maintaining Community Resilience through Urban Renewal Processes Using Architectural and Planning Guidelines. Sustainability 2024, 16, 560. [Google Scholar] [CrossRef]

- IBWA; Trayak. Life Cycle Assessment of Common Drink Packaging; International Bottled Water Association: Alexandria, VA, USA, 2024; Available online: https://bottledwater.org/wp-content/uploads/2024/04/IBWA-Trayak-Full-Report-32321.pdf (accessed on 2 July 2025).

- International Aluminium Institute. Comparing the Carbon Footprints of Beverage Containers; International Aluminium Institute: London, UK, 2024; Available online: https://international-aluminium.org/wp-content/uploads/2024/04/Comparing-the-carbon-footprints-of-beverage-containers.pdf (accessed on 22 June 2025).

- Garcia, E.S.; Huysveld, S.; Nhu, T.T.; Meester, S.D.; Dewulf, J. Technical substitutability of recycled materials in life cycle assessment. Waste Manag. 2023, 164, 182–193. [Google Scholar] [CrossRef]

- Marrucci, L.; Daddi, T.; Iraldo, F. Identifying the most sustainable beer packaging through a Life Cycle Assessment. Sci. Total Environ. 2024, 948, 174941. [Google Scholar] [CrossRef] [PubMed]

- Bergsma, G.; Sevenster, M. End-of-Life Best Approach for Allocating Recycling Benefits in LCAs of Metal Packaging. Delft: CE Delft, February 2013. Available online: https://kidv.nl/media/engelse_rapporten/end-of-life-best-approach-for-allocating-recycling-benefits-in-lcas-of-metal-packaging.pdf?development (accessed on 2 July 2025).

- Dolci, G.; Puricelli, S.; Cecere, G.; Daddi, T.; Iraldo, F. How does plastic compare with alternative materials in the packaging sector? A systematic review of LCA studies. Waste Manag. Res. 2024, 43, 339–357. [Google Scholar] [CrossRef]

- Closed Loop Partners. Accelerating Circular Supply Chains for Plastics: The Molecular Recycling Landscape; Closed Loop Partners: New York, NY, USA, 2022; Available online: https://www.closedlooppartners.com/reports/molecular-recycling-landscape (accessed on 9 September 2025).

- Kang, D.H.; Auras, R.; Singh, J. Life-cycle assessment of non-alcoholic single-serve polyethylene terephthalate beverage bottles in the state of California. Resour. Conserv. Recycl. 2017, 116, 45–52. [Google Scholar] [CrossRef]

- Sauer, B.; Absar, M.; Cornell, D.; Quay, B.; Selke, S.; Keoleian, G. Life Cycle Assessment of Predominant U.S. Beverage Container Systems for Carbonated Soft Drinks and Domestic Still Water: Final Peer Reviewed Report. Franklin Associates (A Division of Eastern Research Group, Inc.), Submitted to The National Association for PET Container Resources (NAPCOR), February 4 2023. Available online: https://positivelypet.org/wp-content/uploads/2023/03/NAPCOR-Beverage-Container-LCA-Report-2023.pdf (accessed on 9 September 2025).

- Niero, M.; Olsen, S.I. Circular economy: To be or not to be in a closed product loop? A life-cycle assessment of aluminium cans with inclusion of alloying elements. Resour. Conserv. Recycl. 2017, 114, 18–31. [Google Scholar] [CrossRef]

- Vendries, J.; Hawkins, T.R.; Mosley, J.; Hottle, T.; Allaway, D.; Canepa, P.; Rivin, J.; Mistry, M. The Significance of Environmental Attributes as Indicators of the Life Cycle Environmental Impactsof Packaging and Food Service Ware; State of Oregon Department of Environmental Quality: Portland, OR, USA, 2018. Available online: https://www.oregon.gov/deq/FilterDocs/MaterialAttributes.pdf (accessed on 9 September 2025).

- Oliveira, P.; Kilchert, S.; May, M.; Panzera, T.; Scarpa, F.; Hiermaier, S. Environmental assessment of discarded plastic caps as a honeycomb core: An eco-mechanical perspective. J. Ind. Ecol. 2021, 26, 643–654. [Google Scholar] [CrossRef]

- World Steel Association. World steel LCI Datasets and Access Information. Available online: https://worldsteel.org/steel-by-topic/sustainability/life-cycle-assessment (accessed on 9 September 2025).

- Reuters. Global Steel Sector Lagging on Green Transition as Coal-Powered Production Rises, Research Shows. Reuters (Sustainability/COP). 20 May 2025. Available online: https://www.reuters.com/sustainability/cop/global-steel-sector-lagging-green-transition-coal-powered-production-rises-2025-05-20/ (accessed on 9 September 2025).

- Shen, X.; Schäpe, B. Closing the Loop: From Stalled Green Steel Targets to a Strategic Reset in China—China Steel Industry Decarbonisation Biannual Review H1 2025. Centre for Research on Energy and Clean Air (CREA), Helsinki, 22 July 2025. Available online: https://energyandcleanair.org/wp/wp-content/uploads/2025/07/CREA_China_Steel-Industry-Decarbonisation-Biannual-Review_H1-2025.pdf (accessed on 9 September 2025).

- Reuters. ArcelorMittal, MHI Launch Pilot CO2-Capture Unit at Gent Blast Furnace. Reuters (Sustainability/COP), 21 May 2024. Available online: https://www.reuters.com/sustainability/arcelormittal-mhi-launch-pilot-co2-capture-unit-gent-blast-furnace-2024-05-21 (accessed on 9 September 2025).

- Xue, B.; Wei, G.; Dong, B.; Conejo, A.N.; Wang, H.; Zhu, R. Analysis of energy consumption and carbon emissions of electric arc furnace steelmaking using hydrogen-based direct reduced iron. Process Saf. Environ. Prot. 2025, 201, 107617. [Google Scholar] [CrossRef]

- Brusseau, M.L. Sustainable development and other solutions to pollution and global change. In Global Systems and the Human Dimensions to Environmental Pollution; Elsevier: Amsterdam, The Netherlands, 2019; pp. 585–603. [Google Scholar]

- Barbosa, A.J.D.; Santos, V.H.P.; Araújo, P.C.; Medeiros, F.L.; Otaviano, L.Y.S. Eco product development combining eco design and life cycle assessment. Benchmarking 2021, 28, 502–516. [Google Scholar] [CrossRef]

- Laurin, L. Overview of LCA—History, Concept, and Methodology. In Encyclopedia of Sustainable Technologies; Elsevier: Amsterdam, The Netherlands, 2017; pp. 217–228. [Google Scholar]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.-P.; Suh, S.; Weidema, B.P.; Pennington, D.W. Life cycle assessment Part 1: Framework, goal and scope definition, inventory analysis, and applications. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef]

- EPD International System. Product Category Rules (PCR) 2019:13, Version 1.1: Packaging; EPD International AB: Stockholm, Sweden, 2020. [Google Scholar]

- Oldring, P.K.T.; Nehring, U. Metal Packaging for Foodstuffs; ILSI Europe: Brussels, Belgium, 2007. [Google Scholar]

- Coles, R.; McDowell, D.; Kirwan, M.J. (Eds.) Food Packaging Technology; Blackwell Publishing: Oxford, UK, 2003. [Google Scholar]

- Turan, D.; Poulis, J.A. The influence of surface roughness, creep and relaxation on the performance of elastomeric liners for sustainable glass bottle closures. Food Packag. Shelf Life 2022, 32, 100840. [Google Scholar] [CrossRef]

- Briggs, D.E.; Boulton, C.A.; Brookes, P.A.; Stevens, R. Brewing: Science and Practice; Woodhead Publishing and CRC Press: Cambridge, UK, 2004. [Google Scholar]

- EN 17177:2020; Glass Packaging—Crown Cap—26 mm Diameter, 6 mm Height Crown Cap. European Committee for Standardization (CEN): Brussels, Belgium, 2020. [CrossRef]

- Agarski, B.; Budak, I.; Micunovic, M.I.; Vukelic, D. Life cycle assessment of injection moulding tools and multicomponent plastic cap production. J. Clean. Prod. 2023, 413, 137639. [Google Scholar] [CrossRef]

- Donahue, L.M.; Petit, H.J.; Thiel, C.L.; Sullivan, G.A.; Gulack, B.C.; Shah, A.N. A life cycle assessment of reusable and disposable surgical caps. J. Surg. Res. 2024, 299, 112–119. [Google Scholar] [CrossRef] [PubMed]

- IPCC. Chapter 4: Metal Industry Emissions. In 2006 IPCC Guidelines for National Greenhouse Gas Inventories, Volume 3: Industrial Processes and Product Use; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2006. [Google Scholar]

- Marathe, K.V.; Chavan, K.R.; Nakhate, P. Life Cycle Assessment (LCA) of PET bottles. In Recycling of Polyethylene Terephthalate Bottles; Elsevier: Amsterdam, The Netherlands, 2019; pp. 149–165. [Google Scholar]

- European Environment Agency (EEA). 2.A.5.a Quarrying and Mining of Minerals Other than Coal. In EMEP/EEA Air Pollutant Emission Inventory Guidebook 2023; EEA: Copenhagen, Denmark, 2023. [Google Scholar]

- World Resources Institute (WRI); World Business Council for Sustainable Development (WBCSD). Technical Guidance for Calculating Scope 3 Emissions, Version 1.0; WRI and WBCSD: Washington, DC, USA, 2013. [Google Scholar]

- Hellenic Ministry of Environment and Energy. National Inventory Report for Greenhouse Gas Emissions; Ministry of Environment and Energy: Athens, Greece, 2023. [Google Scholar]

- ISO 14064-1:2018; Greenhouse Gases—Part 1: Specification with Guidance at the Organization Level for Quantification and Reporting of Greenhouse Gas Emissions and Removals. International Organization for Standardization (ISO): Geneva, Switzerland, 2018. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:14064:-1:ed-2:v1:en (accessed on 9 September 2025).

- World Resources Institute (WRI); World Business Council for Sustainable Development (WBCSD). The Greenhouse Gas Protocol: A Corporate Accounting and Reporting Standard; WRI and WBCSD: Geneva, Switzerland, 2004. [Google Scholar]

| Cap | Height (mm) | Outer Diameter (mm) | Metal Thickness (mm) | Weight of Sheet (Dimensions 894 × 1038 mm) (kg) | Weight of Cap (g) |

|---|---|---|---|---|---|

| 26 mm (capped on bottle) | 6.00 ± 0.15 | 32.1 ± 0.2 | 0.21 ± 0.01 | 1.53 | 2.0 ± 5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spyrolari, I.; Alexandropoulou, A.; Didaskalou, E.; Georgakellos, D. Evaluating the Environmental Footprint of Steel-Based Bottle Closures: A Life Cycle Assessment Approach. J. Exp. Theor. Anal. 2025, 3, 35. https://doi.org/10.3390/jeta3040035

Spyrolari I, Alexandropoulou A, Didaskalou E, Georgakellos D. Evaluating the Environmental Footprint of Steel-Based Bottle Closures: A Life Cycle Assessment Approach. Journal of Experimental and Theoretical Analyses. 2025; 3(4):35. https://doi.org/10.3390/jeta3040035

Chicago/Turabian StyleSpyrolari, Irini, Alexandra Alexandropoulou, Eleni Didaskalou, and Dimitrios Georgakellos. 2025. "Evaluating the Environmental Footprint of Steel-Based Bottle Closures: A Life Cycle Assessment Approach" Journal of Experimental and Theoretical Analyses 3, no. 4: 35. https://doi.org/10.3390/jeta3040035

APA StyleSpyrolari, I., Alexandropoulou, A., Didaskalou, E., & Georgakellos, D. (2025). Evaluating the Environmental Footprint of Steel-Based Bottle Closures: A Life Cycle Assessment Approach. Journal of Experimental and Theoretical Analyses, 3(4), 35. https://doi.org/10.3390/jeta3040035