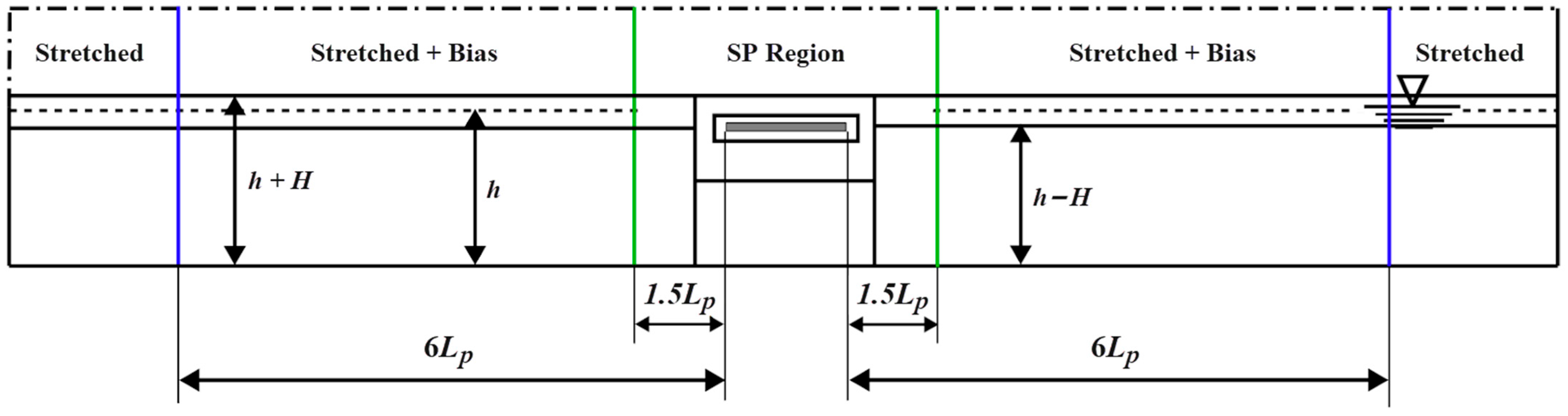

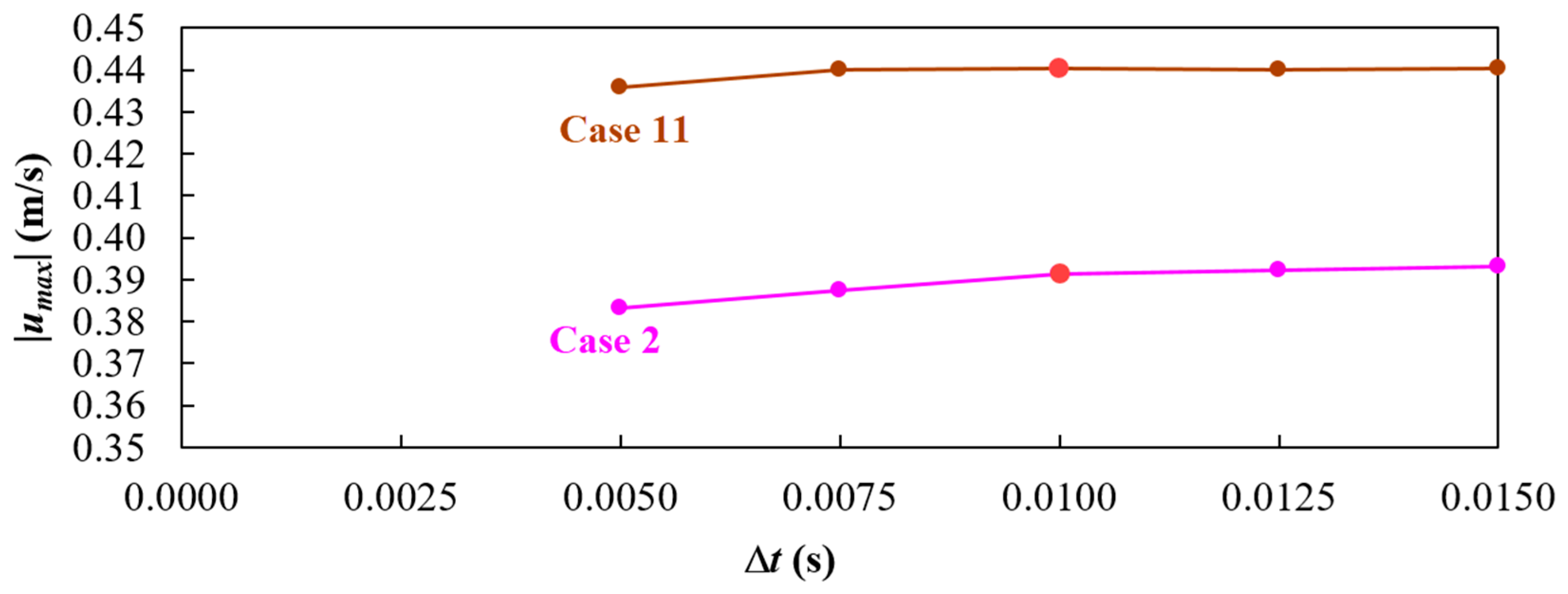

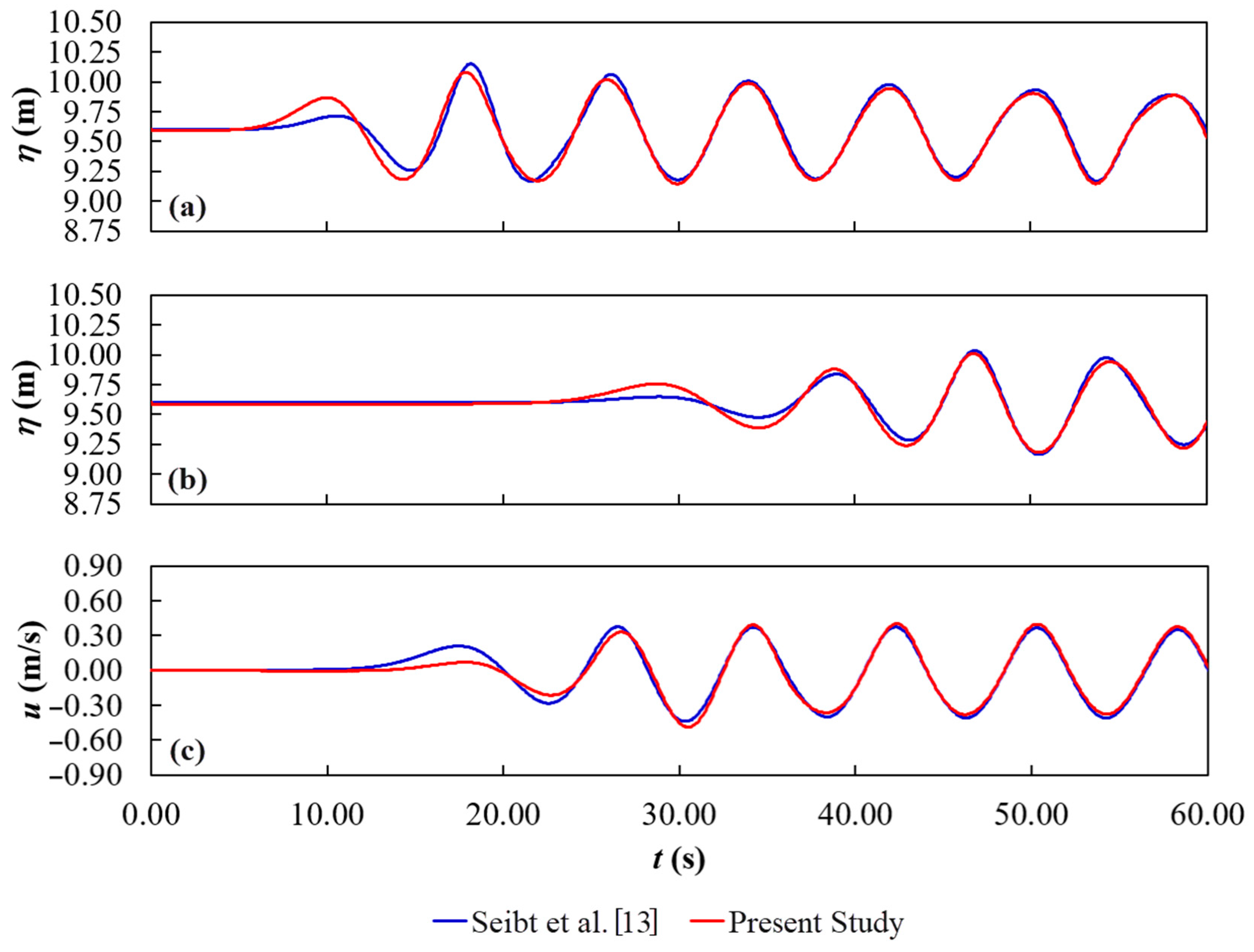

3.4. Results and Discussion of Cases 1–11

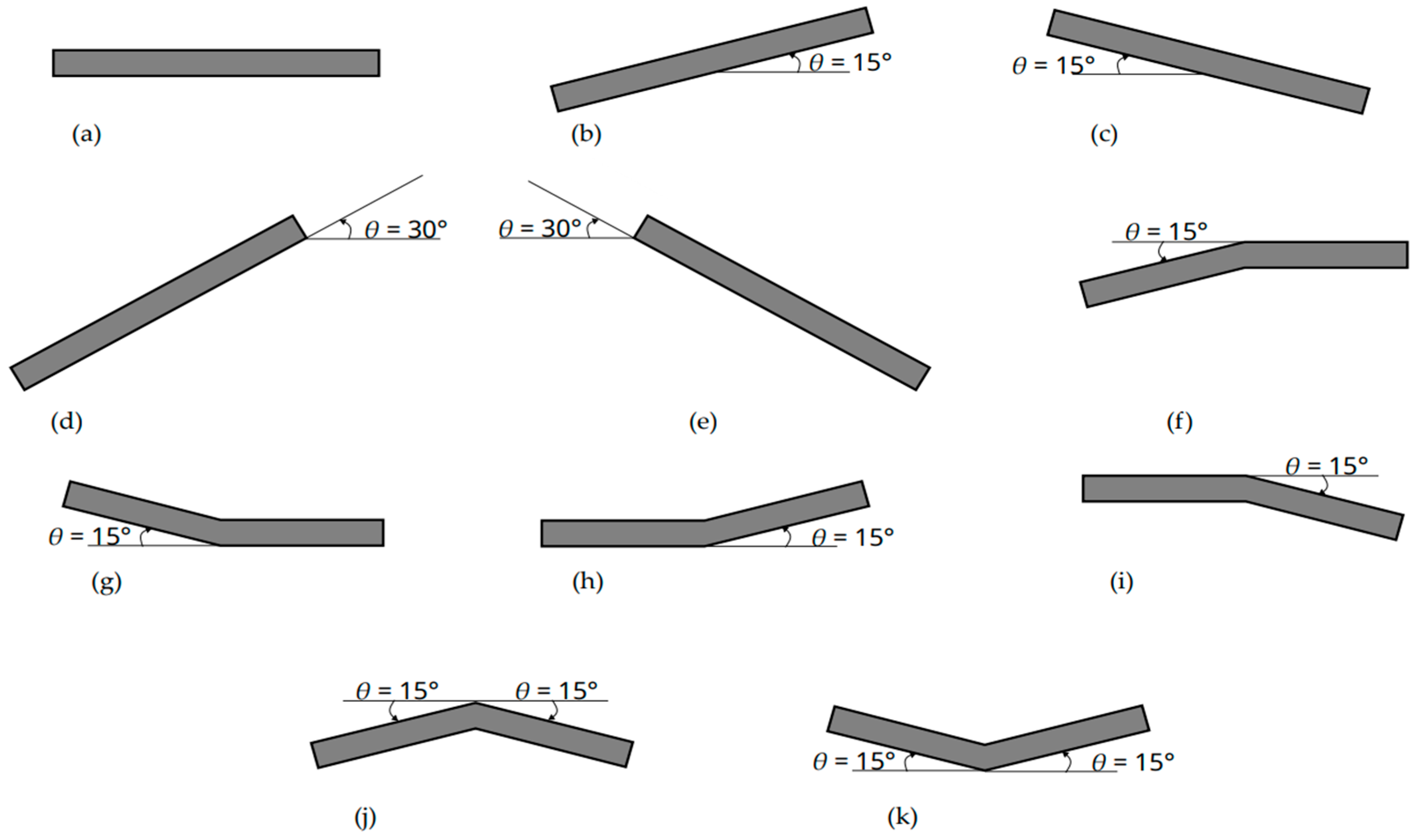

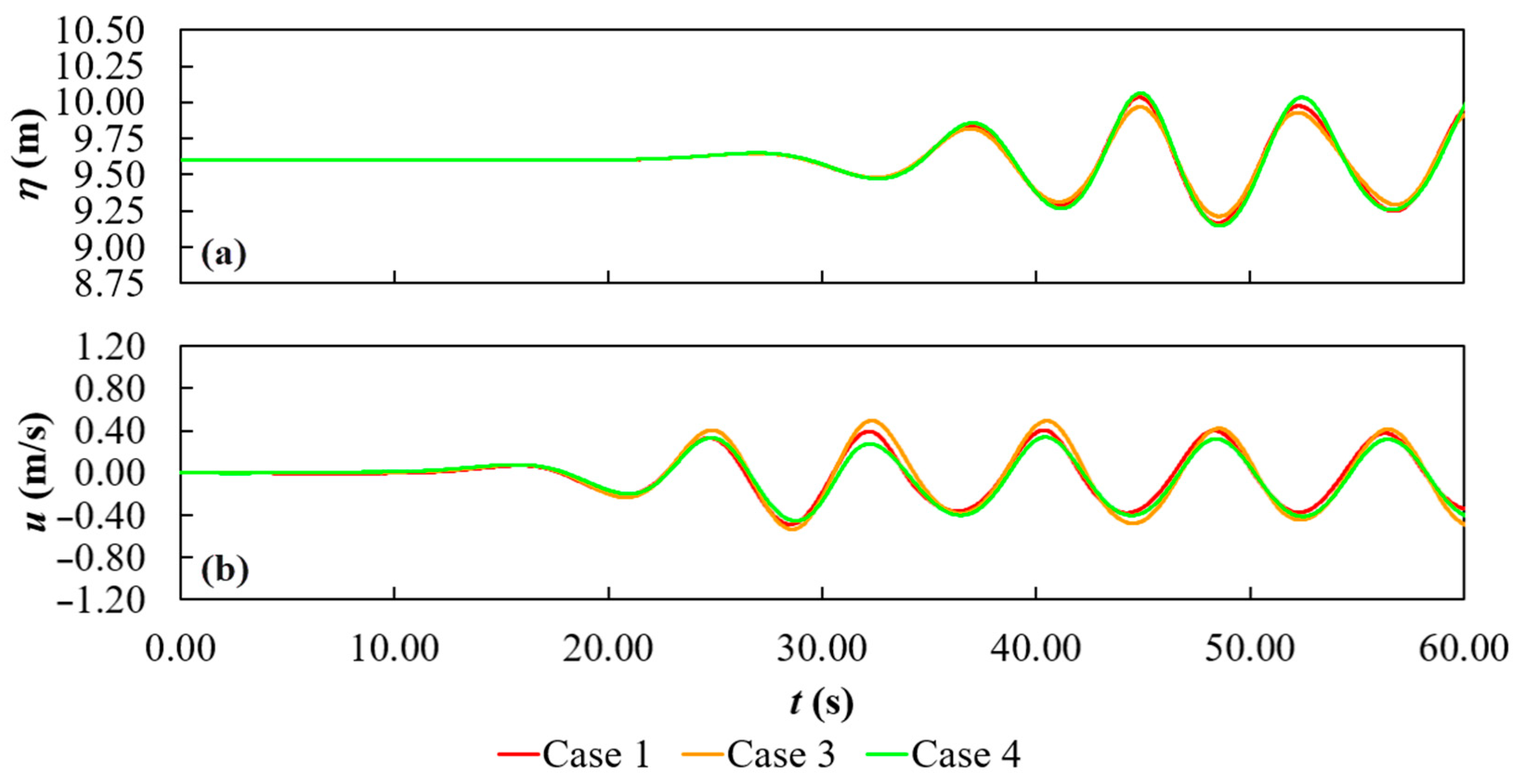

Figure 9,

Figure 10 and

Figure 11 show the results of Cases 2 to 11, proposed with some inclination for the SP (see

Figure 1b–k), plotted together with Case 1 (see

Figure 1a), which is the baseline result for comparison in this study. To improve the results visualization, the cases were grouped according to their methodology of variation in the geometric configuration earlier mentioned, always together with the SHP reference case.

One can observe in

Figure 9 that, in general and as expected, there is no significant difference among the water-free surface elevations upstream for the studied SPs. The small variations that occurred are due to the reflection caused by the different geometric configurations of each SP. This aspect indicates that the generation and propagation of the regular waves are being carried out properly.

From

Figure 10, it is possible to qualitatively perceive behaviors that are more relevant. For instance, Case 3 (

Figure 10a), Case 10 (

Figure 10e), and Case 8 (

Figure 10d) have a transient variation of the water-free surface elevation, lower, higher, and similar to those in Case 1. Remembering that for its use as BW, a reduction in

η is desired.

Figure 11 indicates behaviors even more different among the studied cases, being for SP as WEC necessary an augmentation in axial velocity. Case 11 (

Figure 11e) presented a very similar variation than Case 1 for the axial velocity. Case 2 was the one that had the inferior performance, i.e., the highest reduction in magnitude of axial velocity under de SP. Cases 3 (

Figure 11a) and 10 (

Figure 11e) presented an axial velocity augmentation; however, Case 10 was the only one with a discrepant behavior among all cases. This aspect will be further discussed later.

Despite the important insights from the qualitative evaluation allowed by

Figure 9,

Figure 10 and

Figure 11, a quantitative analysis is essential for a more precise understanding of the influence of SP geometric configurations on its efficiency.

Table 9 therefore presents the integral values

Iη and

Iu for the curves in

Figure 10 and

Figure 11, respectively, along with the ratios between these integral values for Cases 2 to 11 relative to the corresponding value for Case 1.

Table 9 indicates that the results of the free surface elevation downstream of the SP showed that the inclined SP cases were mostly less efficient than the reference case. However, Cases 2, 3, 7, and 8 are exceptions, achieving values of

Iη inferior to Case 1, recommending its use as BW.

Regarding the axial velocity beneath the SP, one can identify in

Table 9 that the results of inclined geometries (Cases 2 to 11) were generally superior to Case 1, which is a desired response for its application as WEC. The exceptions are Cases 2, 4, 6, and 8, which had inferior results to Case 1.

Highlights include Cases 3 and 7, which outperformed Case 1 both as a BW and as a WEC, with Case 3 being 11.95% more efficient as a BW and 16.59% more efficient as a WEC, and Case 7 being 8.16% more efficient as a BW and 6.90% more efficient as a WEC.

Based on the results of the integrals, it was possible to define the best and worst cases of geometry variation based on efficiency as a BW and WEC compared to Case 1. As a BW, the best case was Case 3, achieving 11.95% more efficiency than Case 1. As a WEC, the best case was case 10, achieving 19.56% more efficiency than Case 1.

Analyzing the SP based on its multifunctionality as both a BW and WEC, the best case was Case 3. This is the recommended geometric configuration in this study. However, an interesting behavior is observed with Case 10: it achieved superior performance as a WEC while exhibiting the lowest performance as a BW. Thus, Case 10 can be considered for situations where only the WEC functionality is needed.

In order to visualize how the geometric configuration of the SP influences the downstream wave attenuation as a BW and the alternating axial velocity as a WEC,

Figure 12 depicts the best, worst, and reference cases for each device function.

The results of

Figure 12a evidence the difference among the best (Case 3), worst (Case 4), and reference (Case 1) cases, since Case 3 achieved shorter water-free surface elevations than Case 1 and Case 4. In the same way, it is easy to infer in

Figure 12b that Case 10 reached a superior magnitude for the axial velocity under the SP than the reference (Case 1) and the worst (Case 2) geometries.

However, if the BW and WEC functions are taken into account in a concomitant way, the results for the best (Case 3) and worst (Case 4) geometric configurations, together with the reference case (Case 1), are plotted in

Figure 13, making it evident that Case 3 conducted to the smaller elevation of the water-free surface after the SP (

Figure 13a) and higher axial velocity under the SP, thus reaching superior performance. It is worth highlighting that the worst case was defined among the cases that obtained relative efficiencies lower than 1 for both SP functionalities, being the one that reached the lowest average value between

Iη1/I

ηi and I

ui/I

u1 (see

Table 9).

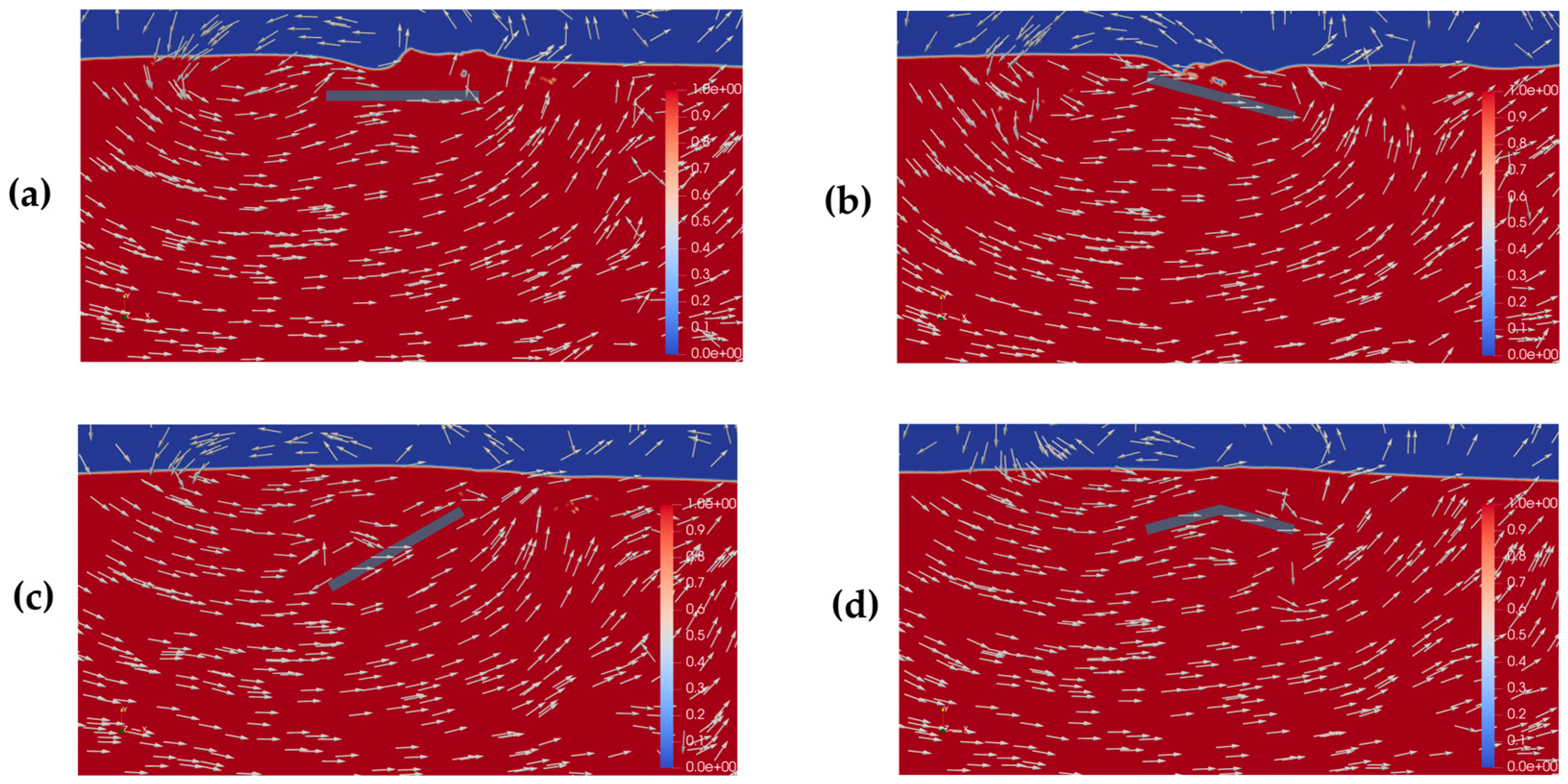

Alongside the integrals

Iη and

Iu of the probes 1, 2, and 3 results (see

Table 9), the ParaView post-processing visualization engine was used to plot the velocity field among the wave channel for 40 s, 50 s, and 60 s (

Figure 14,

Figure 15, and

Figure 16, respectively); with the red color representing water and the blue color representing air. These time values were chosen to have an idea of how the hydrodynamic behavior of the SP varies during the simulation. The cases considered for this additional study were Case 1 (the reference), Case 3 (the case with the best efficiency results), Case 4 (the case with the worst efficiency results), and Case 10 (the case with the unusual yet best axial velocity behavior).

Cases 1, 3, 4, and 10 (see, respectively,

Figure 14a,

Figure 14b,

Figure 14c, and

Figure 14d) showed an expected and approximately similar behavior of axial velocity at 40 s, having a velocity field profile without significant variation below the SP region. However, it is possible to visualize one of the reasons for Case 4’s low BW efficiency: the SP has a limited effect on dissipating the upcoming wave’s energy, as it remains farther from the waves along most of its length, except at its rightmost edge. This increased distance results in less impact of the SP in the incident regular waves.

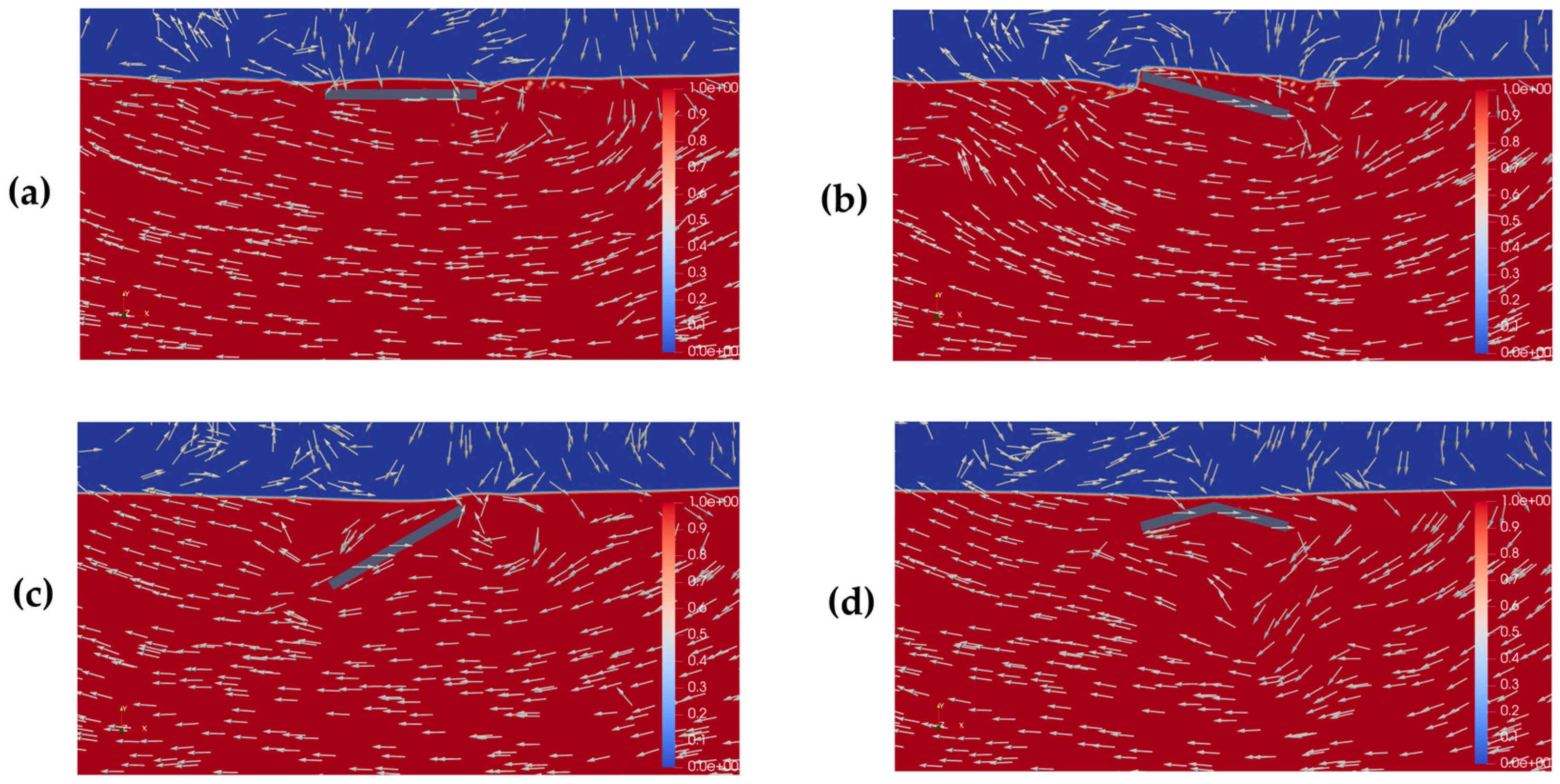

At 50 s, one of the reasons for the superior performance of Case 3 regarding the WEC becomes evident (see

Figure 15b), because the 15° clockwise inclination of the SP causes the incoming waves to deflect downward, resulting in a greater contribution of their velocity components to the axial velocity measured at probe 3. In turn, Cases 1 and 4 (see

Figure 15a,c) showed approximately similar velocity fields, and Case 10 (see

Figure 15d) started showing a vortex formation below the SP, justifying its higher mean of velocity on the negative axis, especially after 55 s (see

Figure 12b).

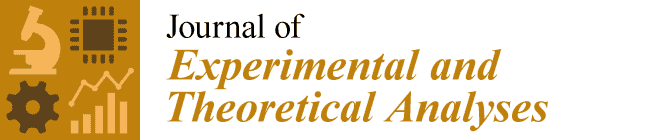

Additionally, the velocity vectors of Cases 1, 3, and 4 (

Figure 16a,

Figure 16b, and

Figure 16c, respectively) had similar directions for their velocity vectors below the SP at 60 s. Case 10 continued to exhibit vortices in its velocity field beneath the SP, which explains the higher axial velocity reached by this SP geometric configuration (see

Figure 12b).

Based on the efficiency results of Cases 3, 5, 7, and 9 (see

Table 9), which were more efficient as WECs compared to Case 1, and the discussion of

Figure 16b, it can be stated that all the studied clockwise inclination cases demonstrated superior performance as WECs. A possible reason for this superiority is attributed to the downward deflection of the waves, as previously mentioned.

Considering the efficiency results of Cases 2, 3, 7, and 8 (see

Table 9), one can infer that all cases with an increased height at one end of the SP demonstrated superior performance as BWs compared to Case 1. This occurs because this geometric alteration reduces the transmission of wave energy, as the raised end of the plate, being closer to the free surface, prevents a part of the wave’s energy from transmitting over the SP, forcing their energy to be dissipated or reflected (see

Figure 14c,

Figure 15c, and

Figure 16c). This effectively reduces the wave amplitude in the region downstream of the structure.