FEM Investigation of the Roughness and Residual Stress of Diamond Burnished Surface

Abstract

1. Introduction

2. Materials and Methods

- ➢

- n is the integer determined by the order given;

- ➢

- λ is the wave-length of the X-ray;

- ➢

- dhkl is the spacing between the planes in the atomic lattice;

- ➢

- Θ is the angle between the incident ray and the scattering planes.

3. Results

4. Discussion and Conclusions

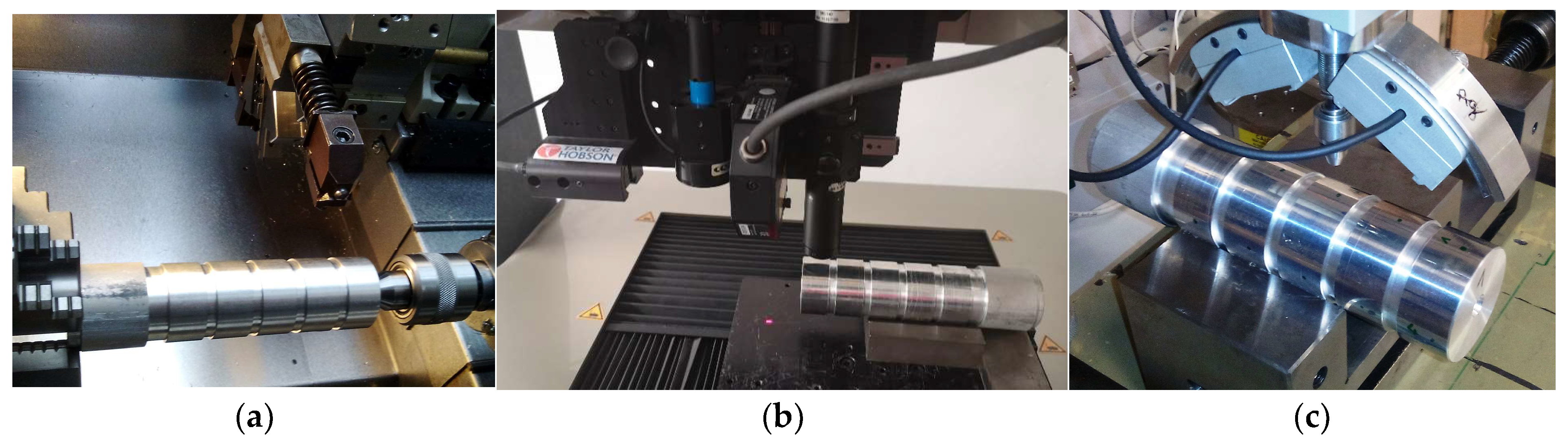

- The value obtained during the theoretical determination of the indentation depth of the tool—which is of key importance—was 2.34 µm, while in the real case, it was 3.62 µm. The two results come close enough to form the basis for further theoretical and experimental investigations.

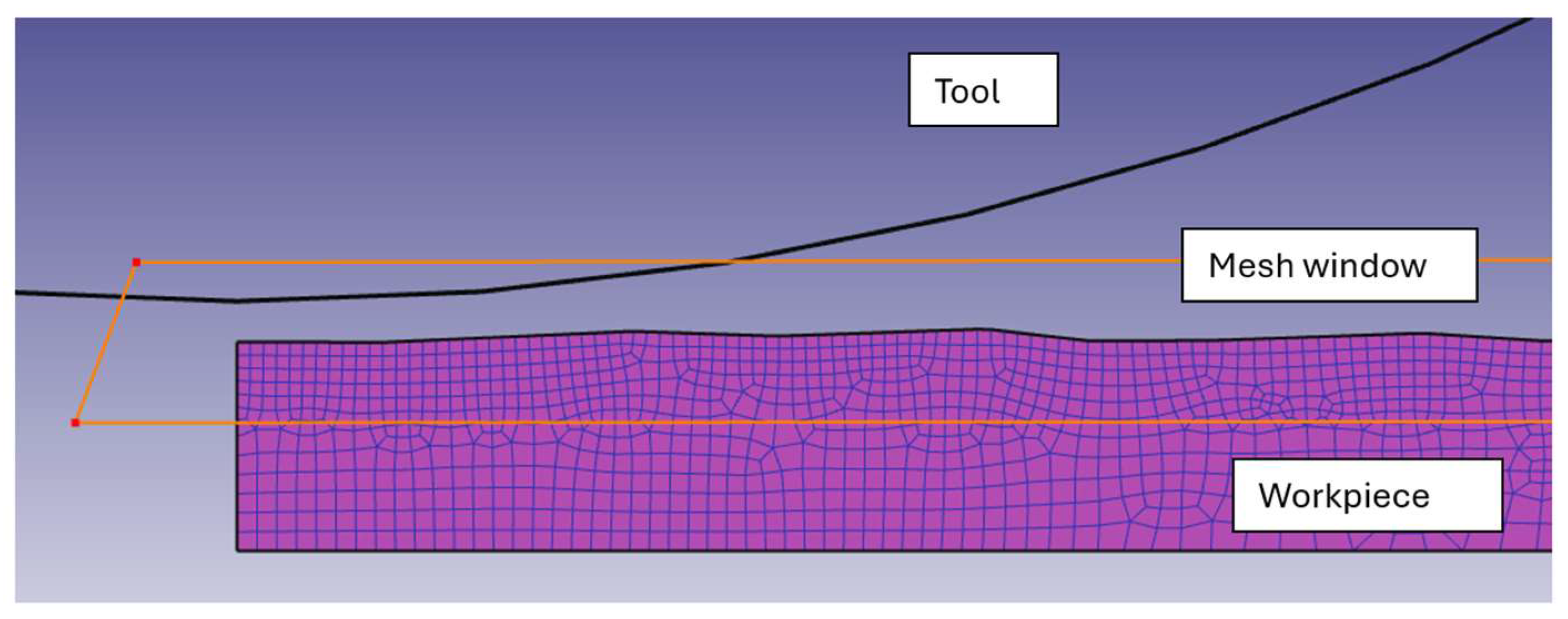

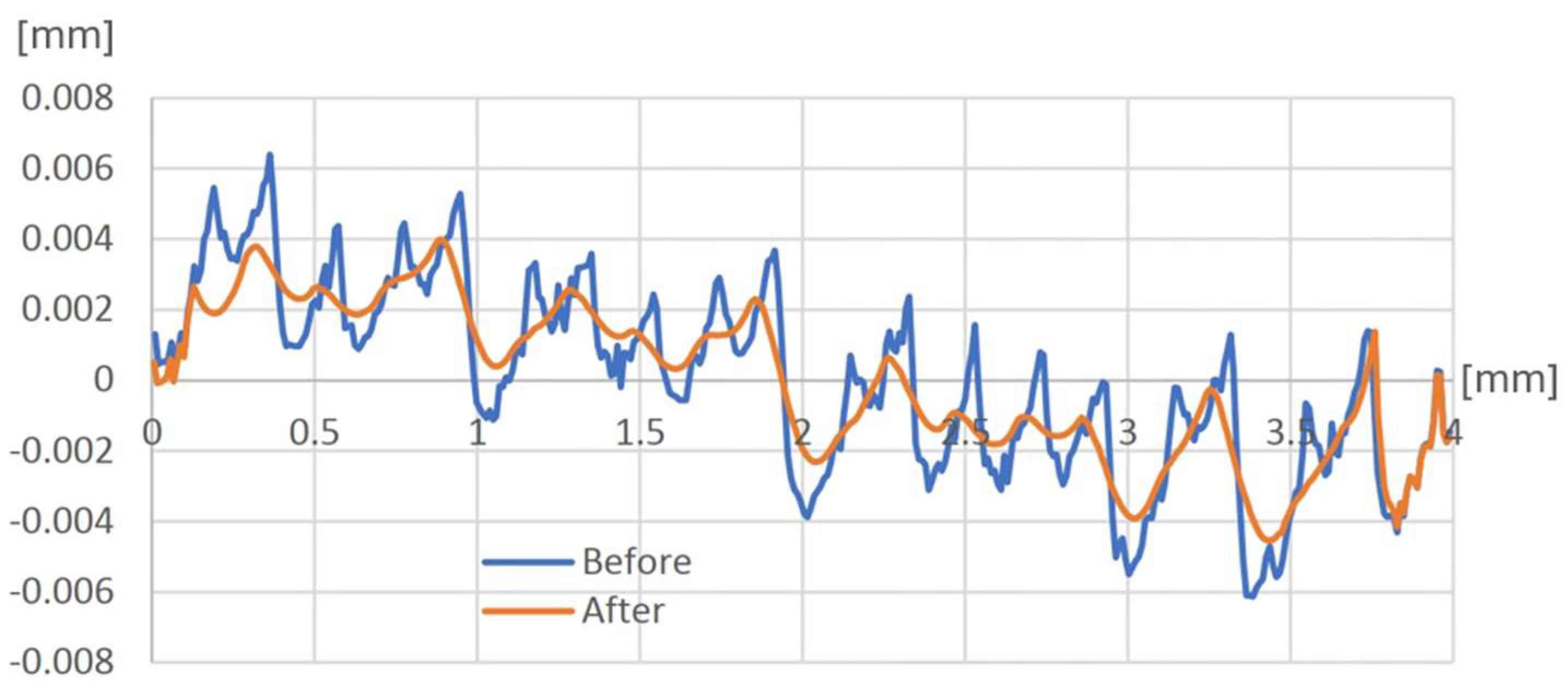

- Correct modeling of surface roughness requires a high number of elements and nodes in the mesh, which significantly increases the calculation time, but it is still possible and preferable to model the process in two dimensions than in 3D. The numerical results of the realized experiment and the simulation are summarized in Table 3.

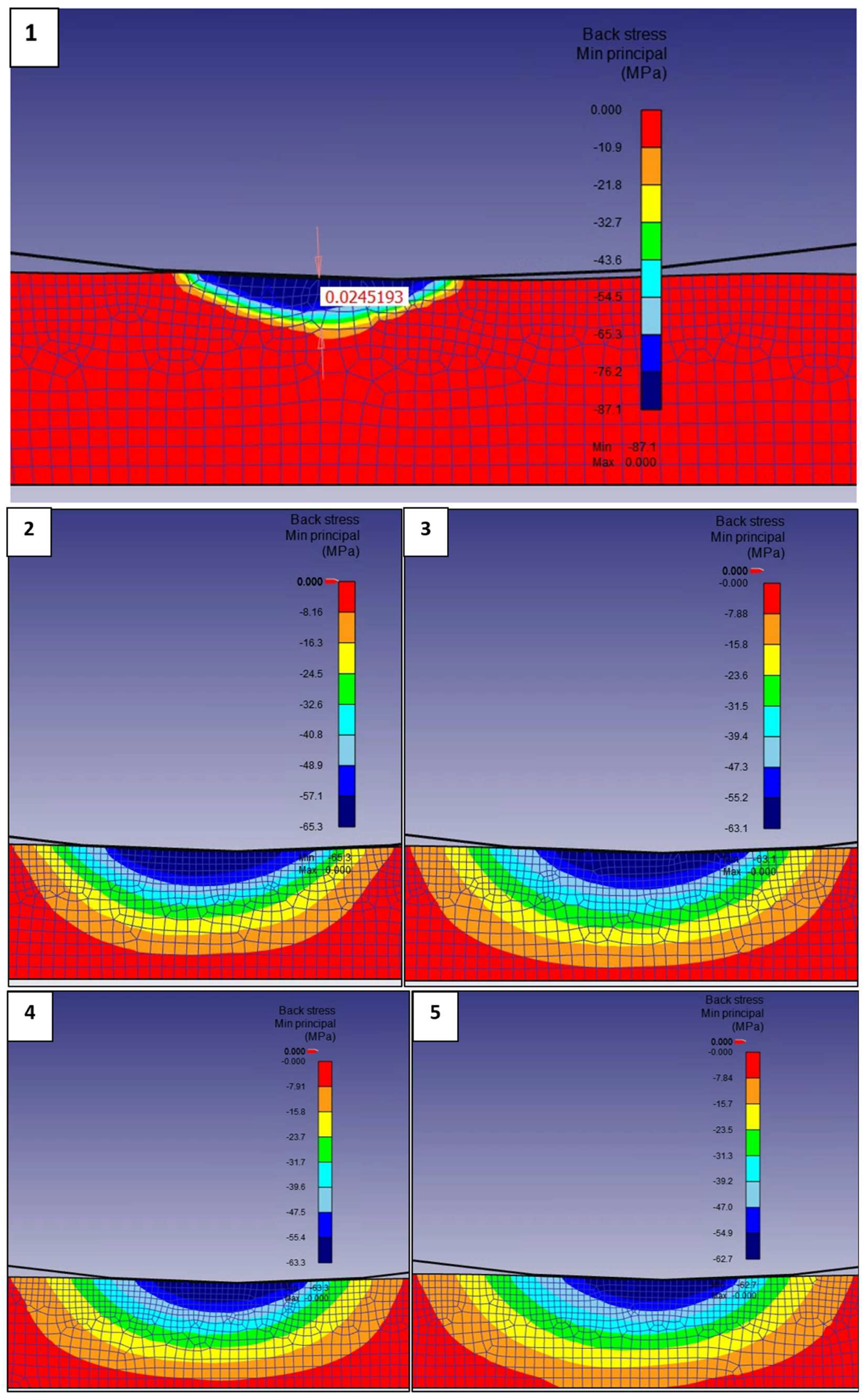

- The results of the X-ray diffraction measurements showed that the burnished surface had a compressive residual stress between (−88.6) and (−138.6) MPa. Comparing these values with the FEM simulation results, where this range was between (−58.6) and (−87.1) MPa, it can be observed that these values were the same only for the first tool penetration. One possible explanation for this may be that different remeshing criteria should be set and/or the material quality should not be selected from the software library, but should also be set to its real parameter values on the basis of a preliminary yield strength examination.

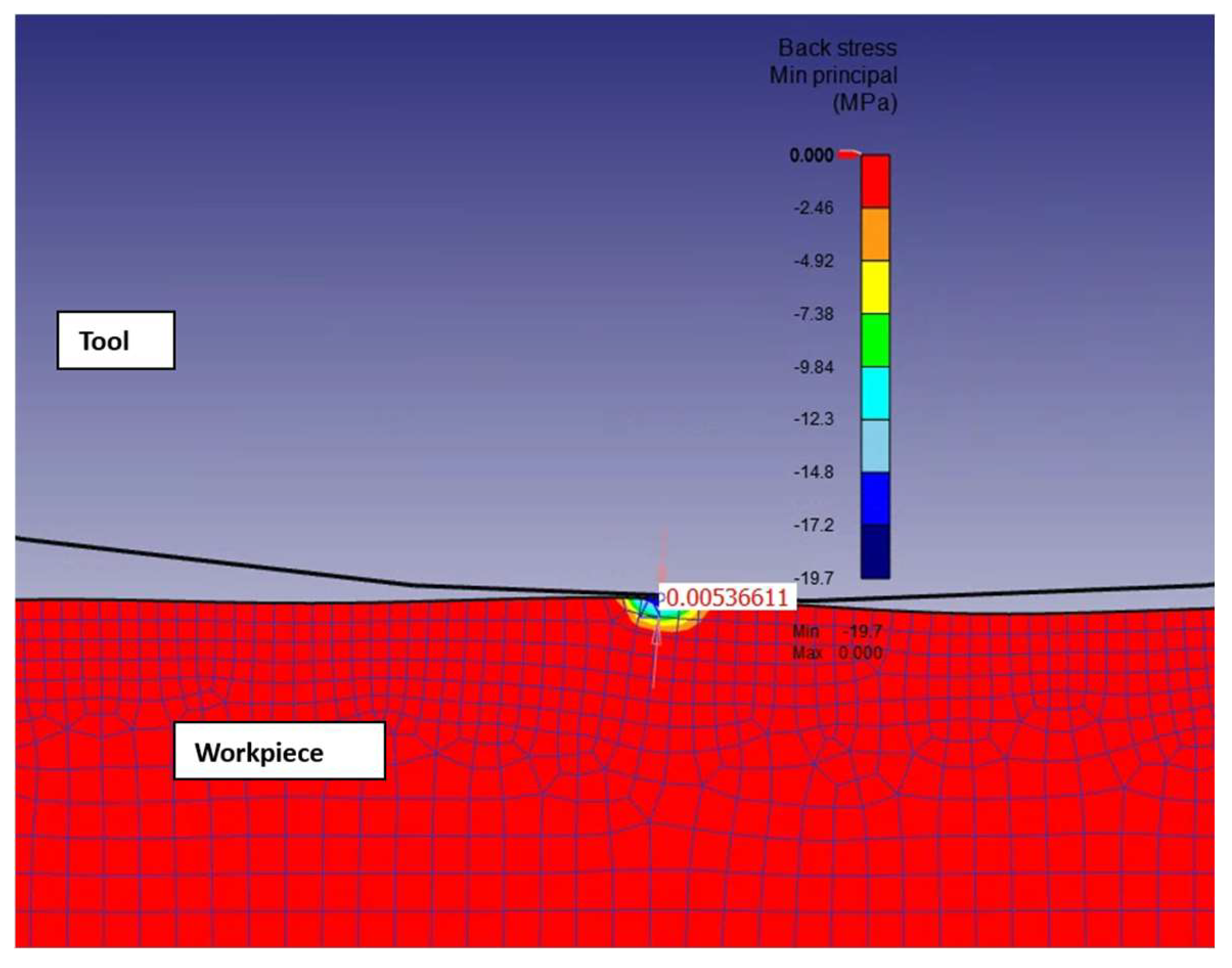

- One of the advantages of FEM is that it provides information on the residual stress distribution, and it can be seen that the minimum (and preferred) value of residual stress at the first contact between the tool and the workpiece was 0.005366 mm, increasing to 0.03383 mm at the end of the machining (Figure 5);

- In relation to the former statement, it can also be stated that the distribution of residual stress is more characteristic at a greater depth than expected, so it is necessary to extend the thickness of the workpiece to a greater value during the simulation.

- The values of the residual stress vary unfavorably as it relaxes excessively, which leads to the conclusion that the value of the burnishing feed rate is too low. This is significant because, by increasing this parameter setting, time and cost can be saved in terms of both real burnishing and simulation calculations.

- Based on the results obtained so far, it may be considered that it is preferable to test the finite element simulation of the process for surface roughness and residual stress conditions separately, and then the effect of a higher feed rate should be investigated.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Sztankovics, I.; Varga, G. FEM analysis of the burnishing process of X5CrNi18-10 stainless steel. Cut. Tools Technol. Syst. 2022, 97, 137–144. [Google Scholar]

- Suraratchai, M.; Limido, J.; Mabru, C.; Chieragatti, R. Modelling the influence of machined surface roughness on the fatigue life of aluminium alloy. Int. J. Fatigue 2008, 30, 2119–2126. [Google Scholar] [CrossRef]

- Qi, B.; Huang, X.; Guo, W.; Ren, X.; Chen, H.; Chen, X. A novel comprehensive framework for surface roughness prediction of integrated robotic belt grinding and burnishing of Inconel 718. Tribol. Int. 2024, 195, 109574. [Google Scholar] [CrossRef]

- Chomienne, V.; Valiorgue, F.; Verdu, C. Influence of ball burnishing on residual stress profile of a 15-5PH stainless steel. CIRP J. Manuf. Sci. Technol. 2016, 13, 90–96. [Google Scholar] [CrossRef]

- Kato, H.; Ueki, H.; Yamamoto, K.; Uasunaga, K. Wear resistant improvement by nanostructured surface layer produced by burnishing. Mater. Sci. Forum 2018, 917, 231–235. [Google Scholar] [CrossRef]

- Skoczylas, A.; Zaleski, K. Selected properties of the surface layer of C45 steel parts subjected to laser cutting and ball burnishing. Materials 2020, 13, 3429. [Google Scholar] [CrossRef]

- Luo, H.; Liu, J.; Wang, L.; Zhong, Q. The effect of burnishing parameters on burnishing force and surface microhardness. Int. J. Adv. Manuf. Technol. 2006, 28, 707–713. [Google Scholar] [CrossRef]

- El-Axir, M.H.; Othman, O.M.; Abodiena, A.M. Improvements in out-of-roundness and micro-hardness of inner surfaces by internal ball burnishing process. J. Mater. Process. Technol. 2008, 196, 120–128. [Google Scholar] [CrossRef]

- Schubnell, J.; Farajian, M. Fatigue improvement of aluminum welds by means of deep rolling and diamond burnishing. Weld. World 2022, 66, 699–708. [Google Scholar] [CrossRef]

- Posdzich, M.; Stöckmann, R.; Morczinek, F.; Putz, M. Investigation of a plain ball burnishing process on differently machined AluminiumEN AW 2007 surfaces. MATEC Web Conf. 2018, 190, 11005. [Google Scholar] [CrossRef]

- Amini, C.; Jerez-Mesa, R.; Travieso-Rodriguez, J.A.; Lluma, J.; Estevez-Urra, A. Finite element analysis of ball burnishing on ball-end milled surfaces considering their original topology and residual stress. Metals 2020, 10, 638. [Google Scholar] [CrossRef]

- Saldana-Robles, A.; Aguilera-Gomez, E.; Plascencia-Mora, H.; Ledesma-Orozco, E.; Reveles-Arredondo, J.; Saldana-Robles, N. FEM burnishing simulation including roughness. Mechanik 2015, 2, 79–91. [Google Scholar] [CrossRef][Green Version]

- Aldrine, M.E.; Mahendra Babu, N.C.; Anil Kumar, S. Evaluation of induced residual stresses due to low plasticity burnishing through finite element simulation. AMMMT 2017, 4, 10850–10857. [Google Scholar] [CrossRef]

- Kunetsov, V.; Smolin, I.; Skorobogatov, A.; Akhmetov, A. Finite element simulation and experimental investigation of nanostructuring burnishing AISI 52100 steel using an inclined flat cylindrical tool. Appl. Sci. 2023, 13, 5324. [Google Scholar] [CrossRef]

- Chaudhary, A.; Kumar Baral, S.; Tiwari, G.; Dumpala, R. Finite element analysis of ball burnishing: Evolution of residual stresses and surface profile in Ti-6Al-7Nb alloy. Eng. Res. Express 2023, 5, 045015. [Google Scholar] [CrossRef]

- Charfeddine, Y.; Youssef, S.; Sghaier, S.; Sghaier, J.; Hamdi, H. Study of the simultaneous grinding/ball-burnishing of AISI 4140 based on finite element simulations and experiments. Int. J. Mech. Sci. 2021, 192, 106097. [Google Scholar] [CrossRef]

- Ferencsik, V.; Gal, V. FE investigation of surface burnishing technology. Rezan. I Instrum. V Tehnol. Sist./Cut. Tool Technol. Syst. 2020, 93, 3–8. [Google Scholar] [CrossRef]

- Ferencsik, V. Finite element analysis of changing of stress condition caused by diamond burnishing. Rezan. I Instrum. V Tehnol. Sist./Cut. Tool Technol. Syst. 2024, 100, 139–147. [Google Scholar]

- Ferencsik, V. Analytical analysis of the theoretical surface roughness in the case of burnishing of cylindrical workpiece. Rezan. I Instrum. V Tehnol. Sist./Cut. Tool Technol. Syst. 2023, 99, 101–109. [Google Scholar]

- Felho, C.; Sztankovics, I.; Maros, Z.; Kun-Bodnar, K. FEM simulation of the flange turning in the production of aluminium aerosol cans. Manuf. Technol. 2023, 23, 810–818. [Google Scholar] [CrossRef]

- Horvath, R.; Dregelyi-Kiss, A.; Matyasi, G. The examination of surface roughness parameters in the fine turning of hypereutectic aluminium alloys. Sci. Bull.-Univ. Politeh. Buchar. Ser. D 2015, 77, 205–216. [Google Scholar]

- Basak, H.; Ozkan, M.T.; Toktas, I. Experimental Research and ANN Modelling on the Impact of the Ball Burnishing Process on the Mechanical Properties of 5083 Al-Mg Material. Kovove Mater. 2019, 57, 61–74. [Google Scholar] [CrossRef]

- Rodriguez, A.; Calleja, A.; Lopez de Lacalle, L.N.; Pereira, O.; Gonzalez, H.; Urbikain, G.; Laye, J. Burnishing of SFW Aluminium Al-Cu-Li Components. Metals 2019, 9, 260. [Google Scholar] [CrossRef]

- Horvath, R.; Sipos, S. Gyémántszerszámmal esztergált alumínium felületek mikrogeometriai jellemzőinek vizsgálata. Óbuda Univ. E-Bull. 2010, 1, 325–343. (In Hungarian) [Google Scholar]

- Abodena, A. Optimization of surface roughness of brass by burnishing. Int. J. Eng. Inf. Technol. 2019, 5, 90–96. [Google Scholar]

- Swamy, S.; Usha, P.; Meheta, A.; Al-Fatlawi, M.; Thethi, H.P.; Pratap, B.; Bandhu, D. RETRACTED: A review of numerical simulation and modeling in high strain rate deformation processes. E3S Web Conf. 2024, 505, 03005. [Google Scholar] [CrossRef]

- Gribovszki, L. Gépipari Megmunkálások; Tankönyvkiadó Vállalat: Budapest, Hungary, 1977; pp. 418–442. (In Hungarian) [Google Scholar]

- Dudas, I. Gépgyártástechnológia III; Műszaki Könyvkiadó: Komárom-Esztergom, Hungary, 2011; Volume 3, pp. 77–152. (In Hungarian) [Google Scholar]

- Qian, W.; Wang, Y.; Liu, K.; Yin, W.; He, X.; Xie, L. Experimental Study on the Effect of Shot Peening and Re-Shot Peening on the Residual Stress Distribution and Fatigue Life of 20CrMnTi. Coatings 2023, 13, 1210. [Google Scholar] [CrossRef]

- Fitzpatrick, M.E.; Fry, A.T.; Holdway, P.; Kandil, F.A.; Shackleton, J.; Suominen, L. Determination of residual stresses by X-ray diffraction. Meas. Good Pract. Guide 2005, 52, 5–68. [Google Scholar]

| Parameter | Value |

|---|---|

| material constant c | 414.98 |

| strain exponent n | 0.2245 |

| strain rate exponent m | 0.0176 |

| initial value y | 139.3 MPa |

| Young modulus E | 7 × 104 N/mm2 |

| Poisson’s ratio υ | 0.33 |

| Parameter | Value |

|---|---|

| Burnishing force F | 20 N |

| Feed rate f | 0.001 mm/rev |

| Burnishing speed v | 15 m/min |

| Number of passes i | 1 |

| Average roughness Ra | 1.478 µm |

| Maximum height of the profile Rt | 7.1963 µm |

| Axial residual stress σa | −23.47 MPa |

| Ra (µm) | ||

|---|---|---|

| Experiment | FE Model | |

| Turned | 1.478 | 1.457 |

| Burnished | 0.0965 | 0.0916 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferencsik, V. FEM Investigation of the Roughness and Residual Stress of Diamond Burnished Surface. J. Exp. Theor. Anal. 2024, 2, 80-90. https://doi.org/10.3390/jeta2040007

Ferencsik V. FEM Investigation of the Roughness and Residual Stress of Diamond Burnished Surface. Journal of Experimental and Theoretical Analyses. 2024; 2(4):80-90. https://doi.org/10.3390/jeta2040007

Chicago/Turabian StyleFerencsik, Viktoria. 2024. "FEM Investigation of the Roughness and Residual Stress of Diamond Burnished Surface" Journal of Experimental and Theoretical Analyses 2, no. 4: 80-90. https://doi.org/10.3390/jeta2040007

APA StyleFerencsik, V. (2024). FEM Investigation of the Roughness and Residual Stress of Diamond Burnished Surface. Journal of Experimental and Theoretical Analyses, 2(4), 80-90. https://doi.org/10.3390/jeta2040007