1. Introduction

The double effect of the up-coming growth population and the need for more sustainable agriculture led to a call for higher yield production without expanding agricultural land use. Additionally, due to the COVID-19 pandemic, there are increasingly alarming reports about imminent threats on a global scale regarding economic sustainability and food security and quality. Due to this, protected cultivation, where crops are cultivated in a controlled environment (especially soilless—growing a crop without soil), has become an important part of the agricultural industry.

However, in order to increase productivity in the existing greenhouse-covered area, there is a need to redesign the operational control system, among others, to establish more demonstrative greenhouses. Nowadays, in order to maintain the desired indoor climate, a great variety of controllers are used. The controllers are supported by automated control models that are based on the obtained environmental data. However, to achieve satisfactory results, one should consider not only controlling the greenhouse climate, but also the crop. Monitoring of the plant responses and processes under specific environmental and root conditions in real time could improve climate and irrigation control and the overall production over time and space [

1]. Especially in commercial production systems, it is more advantageous to apply a real-time plant canopy health, growth, and quality monitoring system with multi-sensor platforms [

2].

Up to now, it has not been feasible to monitor crop physiological parameters in real time without requiring plant contact or destructive sampling. Current computational intelligence techniques have allowed the development of a hyperspectral optic system that supplies information about crop physiology and morphology. Based on the current technology, a series of reflectance indices, such as Normalized Vegetation Index (NDVI) and Photochemical Reflectance Index (PRI), were significantly correlated with crop green biomass and photosynthesis rate [

3]. Originally, PRI was interpreted as a reflectance parameter enabling detection of the spectral signature of xanthophyll cycle pigments that were involved in the dissipation of excess light through non-photochemical quenching [

4,

5]

Optic systems of measuring canopy reflectance factors offer advantages over the traditional approach of leaf-scale measuring reflectance factors using integrating spheres [

6]. However, these methods are high-cost sensors, difficult to handle, and unable to be adjusted in a multi-sensor platform. The recent development of remote soft-sensors (i.e., mathematical models using real-time sensor data) allows the development of models that integrate plant-based indices/indicators. Based on the current robust, easier to use methodology, the hourly variation of Ps under different climatic and fertigated conditions can be studied, not only for a few days, but for the entire cultivation season.

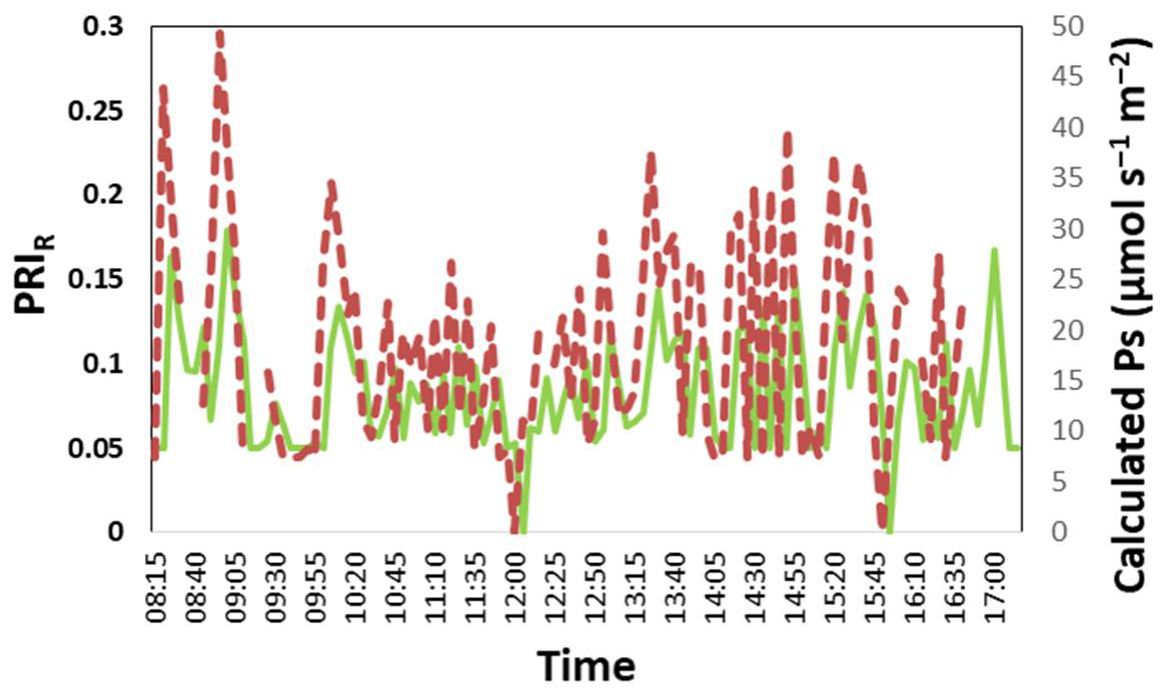

In the current research, a remote Spectral Reflectance Sensor (SRS) that measured crop PRI in distance was used to estimate crop Ps remotely under greenhouse conditions. The aim of the present research was (a) to study the sensor’s behavior; (b) to develop a regression that could estimate Ps by using PRI values. To achieve this goal, tomato crop was cultivated in perlite slabs, while the remote PRI values were evaluated with the Ps values that were recorded by a portable sensor in contact with the leaf.

2. Materials and Methods

The calibration procedure was performed in June of 2020 in a multi-tunnel greenhouse with a total ground area of 1500 m2 (250 m2 each compartment). The establishments were located at the facilities of the University of Thessaly, Velestino, Volos (Latitude 39°22′, longitude 22°44′ and altitude 85 m), in the continental area of eastern Greece. The greenhouse was covered by a transparent film and equipped with fans, a thermal screen, a heating system, and a cooling system. The air temperature and relative humidity were automatically controlled with the help of a climate control computer (SERCOM, Automation SL, The Netherlands), in order to achieve the optimal indoor climate conditions.

The tomato plants were cultivated rockwool slabs (Grodan Delta, NL 100 × 15 × 7.5 cm, 0.18 g cm−3, 90% water retention capacity). The plants were fertigated with fresh nutrient solution with set-points of electrical conductivity (EC) around 2 dS m−1 and a pH of 5.8. The water that was used to prepare the NS had a pH of 7.1 and an EC of 0.8 dS m−1. The nutrient solution that was supplied to the crop was a standard nutrient solution for tomato, grown in open hydroponic systems, adapted to Mediterranean climatic conditions, with the following composition: 5.2 mM L−1 Ca2+; 2.9 mM L−1 Mg2+; 2.5 mM L−1 K+; 1.5 Na+; 11 mM L−1 NO3−; 0.8 mM L−1 H2PO4−; 23.50 µmM L−1 Fe; 5.00 µmM L−1 Mn; 3.80 µmM L−1 Zn. Moreover, micronutrients were added to NS: chelated with EDTA containing Fe 6%; Mn 13%; Zn 15%; B 21%; Cu 0.3%; Mo 0.2%.

PRI was measured through an SRS sensor (SRS-PRI sensor; METER Group Inc., NE Hopkins Court, Pullman, WA 99163, USA,) (

Figure 1). The remote PRI sensor was radiometrically calibrated by default to a NIST-traceable standard and centered at 532 nm and 570 nm with a 10 nm FWHM. The corrected PRI was calculated as the ratio between reflected and incident radiation, measured using down-looking and up-looking sensors, respectively. The readings of both up and down-looking sensor are PRI outputs (Equation (1)):

where R is the reflectance in units of the radiant flux density (W m

−2 nm

−1) in nanometers, the PRI is calculated. In the reading outputs, the ratio between R531 and R570 is also adjusted. The up-looking SRS sensor was mounted above the canopy with an unobstructed view of the sky. The down-looking SRS sensor was placed 2 m above the ground, 0.20 m from the crop, at a constant angle of 45° from the vertical axis, in order to view a leaf area of young and fully developed leaves. The sensed surface area was approximately t 2000 mm

2. Additionally, a solar radiation sensor (Rn, W m

−2; SP-SS, Apogee Instruments, North Logan, UT 8432, USA) was used to measure the light intensity above the canopy. The microclimatic sensors that are installed in the greenhouse are connected to a device-to-web data logger, which feeds a respective database. The measurements were performed every 30 s and the 5-min average was recorded.

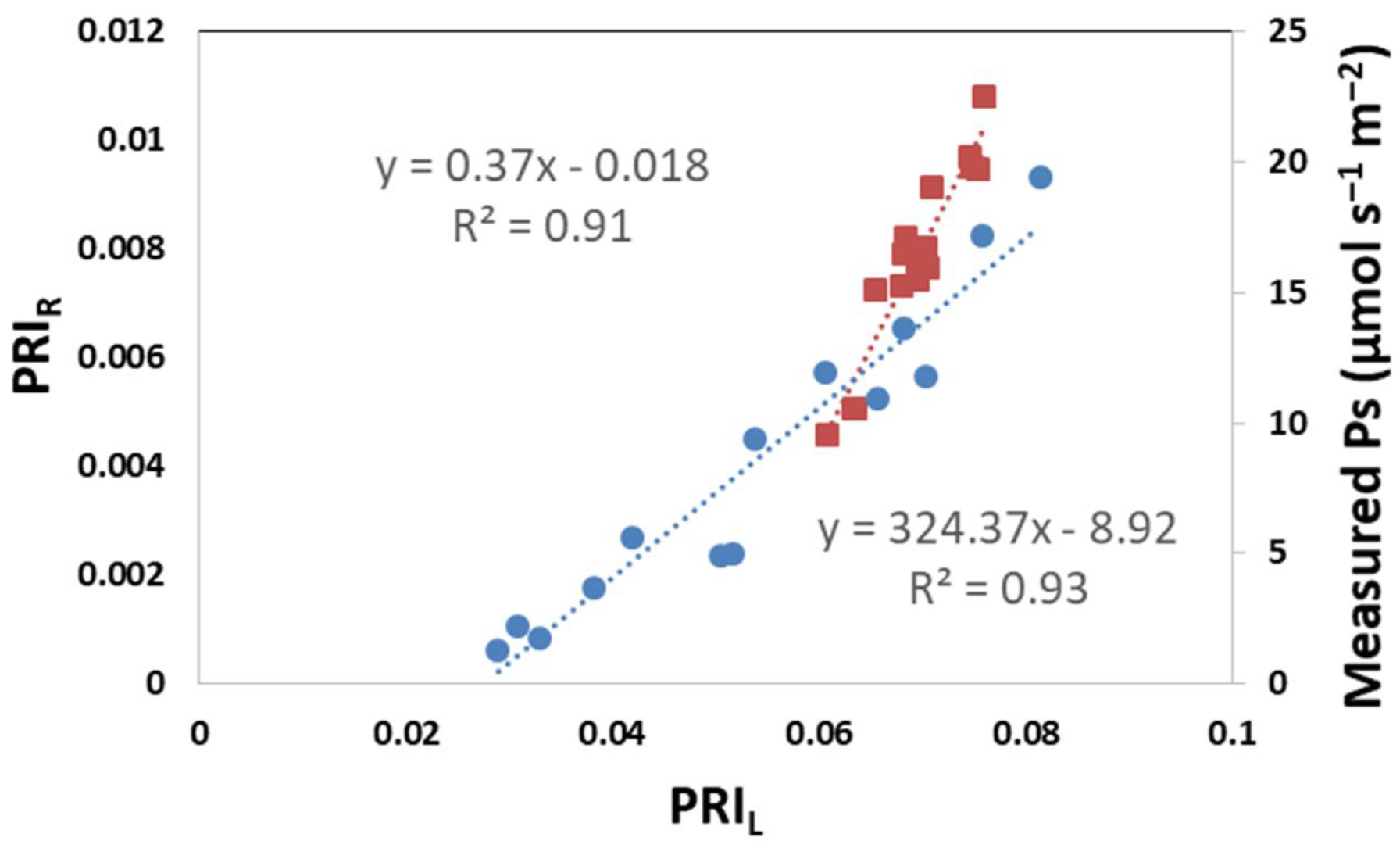

The mean PRI of the crop that was measured using remote sensing (PRIR) was correlated by the mean of the PRI sensor (PRIL) performing measurements in contact with the leaf (PlantPen PRI Meter, Alpha Omega-Electronics, Spain) for the same dataset. Additionally, the PRIR values were correlated with the photosynthesis rate (As, μmol m−2 s−1), which was obtained using a portable photosynthesis measurements system (LCpro, ADC Bioscientific Ltd., Hoddesdon, Herts, EN11 0NT, London, UK) for the same leaf set. The correlation was performed under different climatic conditions and light intensity.

4. Discussion

The fraction of photosynthetically active radiation that was absorbed by the canopy can be estimated by remotely sensed vegetation indices. The PRI for instance, derived from narrow-band spectro-radiometers, is a spectral index that is increasingly being used as an indicator of photosynthetic efficiency [

7].

Gammon et al. [

8] were among the first to present a correlation between the physiological reflectance index and the depoxidation state of the xanthophylls cycle pigments. Thenot et al. [

9] carried out experiments under greenhouse conditions to connect PRI with a correlated Photosynthetic Active Radiation-PAR level of 1800 mmol m

−2 s

−1 in Chenopodium quinoa with significant results. Sarlikioti et al. [

10] used a handheld sensor to measure PRI in tomato crop under greenhouse conditions. According to their data, a good correlation was observed (R

2 > 0.6) between the PRI and relative water content, CO

2 assimilation, stomatal conductance, operating efficiency of PSII (Photosystem II) and NPQ. However, the resulted correlation was significant only when the light intensity was higher than 700 mmol m

−2 s

−1. In the current research, the index was measured remotely and the correlation between PRI and Ps variation was observed when the light intensity within the greenhouse reached the minimum value of 100 W m

−2 s

−1.

Ground-based remote sensing is well established as a tool for assessing crop eco-physiological variables; it has gained wide interest from agricultural practitioners to track crop performance with higher temporal and spatial resolution than the handheld sensors [

11]. The mechanistic basis for PRI index has changed from leaf scale to canopy and larger scales [

7,

12]. In the current calibration process, a difference between the canopy PRI and actual leaf PRI due to atmospheric conditions was noticed. The resulting values, however, were strongly influenced by the canopy shading that was caused by the sun angle. As a result, the PRI

R recorded signal was less intense than the PRI

L signal. Magney et al. [

12] used a spectral remote sensor to evaluate PRI under different environmental conditions. Their results showed that the use of a smoothing algorithm eliminated the data variation due to the ambient conditions.