Abstract

Umbu (Spondias tuberosa) is a Brazilian Caatinga native fruit that has socioeconomic importance. Pulp is the main product of its agro-industrialization. However, de-pulping gives rise to about 25% residue. It is known that fruit peels and seeds are composed of macro and micronutrients as well as bioactive compounds, offering the umbu residue an opportunity to add value to the fruit agro-chain. As the recovery of bioactive compounds from umbu seeds has not yet been optimized, this work aimed to evaluate their recovery through a more sustainable approach, using propylene glycol as a solvent in microwave-assisted solid–liquid extraction. For that, an experimental design varying the propylene glycol percentage (15–85%) and temperature (59–201 °C) was adopted. The total phenolic compounds (TPC) and antioxidant capacity according to DPPH• were evaluated as responses. The highest values were found at 201 °C and 50% propylene glycol (3242 mg GAE/100 g and 162 µmol Trolox/g for TPC and DPPH•, respectively). The values observed were, at least, 8 times higher than those obtained in the worst experimental condition (25% propylene glycol and 80 °C), showing that the independent variables had an effect on the evaluated responses (p < 0.05). All models were significant, displaying p value < 0.05, and no lack of fit was observed. High adjusted R2 values (>0.95) confirm the good fit of the data to the models. Thus, microwave-assisted extraction employing propylene glycol as a solvent could be a more sustainable method for the use of umbu seeds.

1. Introduction

The umbu tree (Spondias tuberosa) is a fruit tree native to the Brazilian Caatinga and belongs to the Anacardiaceae family, also known as the “sacred tree of the Sertão”, named by Euclides da Cunha. Its name in Tupi-Guarani is “ymbu”, which means “drinking tree” due to its ability to store water in its roots [1]. Relevant bioactive compounds, such as quercetin, rutin and vitamin C, are part of its phytochemical composition, as already reported by Ribeiro et al. [2]. Therefore, it has interesting biological properties for different areas of industry. In addition, the fruit presents relevant socioeconomic importance since it is present in the diet of the population and because its cultivation can increase the income of families in semi-arid regions. The main product of the agro-industrialization of this fruit is the frozen pulp. However, the de-pulping process can generate a significant amount of residue. A total of 25% in mass can be obtained after processing. This residue is composed of seeds, peels, and refining cake, which contains compounds with high added value, making the use of this material very advantageous [2].

The extraction process of bioactive compounds conventionally uses solvents known for their toxicity and inflammability, which makes the procedure dangerous and means that it requires purification steps before their application. Thus, in order to avoid these problems and make the process more sustainable, safer and more environmentally friendly green solvents have been evaluated [3].

Propylene glycol is a clear, slightly viscous, water-miscible liquid. It is used as a solvent for aromas, essences and fragrances [4]. These characteristics make it a potential substitute for the most inflammable and toxic conventional solvents. Due to its non-toxic nature, propylene glycol bioactive extract offers the advantage of its direct use in a formulation [5].

In order to increase the extraction efficiency and enhance the sustainability of the process, the solid–liquid extraction process can be microwave-assisted. When compared to conventional heating methods, it exhibits a shorter processing time as it is possible to reach high temperatures in a short time as the heat is dissipated evenly in the plant material, reducing the degradation of the target compounds [6].

Therefore, this work aimed to evaluate the recovery of the bioactive compounds of umbu seeds through a more sustainable approach, using propylene glycol as a solvent in microwave-assisted solid–liquid extraction.

2. Materials and Methods

2.1. Samples

The umbu seeds used in this study were obtained from the de-pulping process carried out in the pilot plant of Embrapa Agroindústria de Alimentos (Guaratiba, Rio de Janeiro, Brazil). The residue was dried at 50 °C in an oven with forced air ventilation and disintegrated to obtain a pulverized material. By means of the granulometric analysis of the sample, it was possible to identify that approximately 54% of the material was composed of particles with a diameter between 1.00 and 1.68 mm.

2.2. Microwave-Assisted Solid-Liquid Extraction

In order to optimize the extraction process, an experimental design was used (Table 1). Different propylene glycol concentrations (15–85%) and temperatures (59–201 °C) were evaluated as independent variables. The extraction time and solid–liquid ratio were fixed at 10 min and 1:30 (m/v), respectively. The extraction was performed in microwave Ethos 1, Milestone. At the end of each extraction, the extracts were vacuum filtered and stored under freezing until analysis for total phenolic compounds (TPC) and the antioxidant capacity by the DPPH• assay. Experimental data were analyzed by a response surface methodology using a second-order polynomial equation. Analysis of variance (ANOVA), a test to determine the lack of fit of the models, and the coefficient of determination (R2) were used to verify the significance of the model, considering a significance level of 5%.

Table 1.

Experimental design for optimization of microwave-assisted extraction of antioxidant compounds from umbu seeds using propylene glycol as a solvent and results for the content of total phenolic compounds (TPC) and antioxidant capacity according to DPPH• assay.

2.3. Methods

2.3.1. DPPH• Assay

The DPPH• method was performed according to the methodology proposed by Hidalgo, Sanchez-Moreno and Pascual-Teresa [7]. For the reactions, 100 µL of each extract was added to 2900 µL of DPPH• solution (6 × 10−5 M in methanol and diluted to obtain an absorbance of 0.700 at 517 nm) and allowed to react for 30 min at room temperature. Then, the absorbance was read at 517 nm using methanol as a blank. The results were obtained from the elaboration of a standard curve of Trolox with different concentrations in a range of 80–700 µmol. Results were expressed as μmol Trolox/g.

2.3.2. Total Phenolic Compounds (TPC)

This analysis was performed with the Folin–Ciocalteu reagent according to the method described by Georgé et al. [8]. For that, 250 µL of each extract was mixed with 1250 µL of 10% Folin–Ciocalteu reagent (v/v) and 1000 µL of 7.5% Na2CO3 (w/v). Subsequently, the mixtures were heated to 50 °C for 15 min, being cooled in an ice bath to read the absorbance at 760 nm. The results were obtained with the aid of a calibration curve prepared from gallic acid solutions with concentrations ranging from 10 to 100 mg/L. The content of TPC in the extracts was expressed as mg gallic acid equivalents per 100 g of sample (mg GAE/100 g).

2.4. Statistical Analysis of Data

The experimental data obtained were evaluated on Statistica software version 13 (Dell Inc.), through an analysis of variance (ANOVA) and Pareto chart. Tests to determine the model’s lack of fit and determination of R2 were employed to verify the model significance, considering a confidence interval of 95%.

3. Results and Discussions

By observing Table 1, it is possible to verify that both the solvent composition and processing temperature influenced the evaluated responses, since the antioxidant capacity and the content of TPC varied considerably among the obtained extracts. The analysis of the antioxidant capacity of the extracts via the DPPH• method shows that this potential ranged from 16 to 162 µmol Trolox/g, reaching a value ten times higher in trial 8, with 201 °C and 50% propylene glycol.

The content of TPC in the extracts ranged from 406 to 3242 mg GAE/100 g, resulting in a value eight times higher compared to the worst experimental condition (trial 1: 25% propylene glycol, 80 °C), corroborating the results for antioxidant capacity. It is worth noting that the best response is twice as high as the result reported by Petchsomrit et al. [5] (1503 mg GAE/100 g), which evaluated the extraction of bioactive compounds from Buchanania siamensis in a microwave-assisted extraction process at a temperature of 60 °C, using a solvent of 50% propylene glycol in water for 20 min.

The extract obtained in the best condition of the experimental design (trial 8) also showed a higher concentration of TPC (3242 mg GAE/100 g) when compared to the extracts obtained using microwaves, as in the case of red onion (1239 GAE/100 g) [9], different pepper species (82–2939 mg GAE/100 g) [10], cherry processing residue (1414 GAE/100 g) [11], and umbu seeds obtained by conventional extraction using acetone as the solvent (947 g GAE/ 100 g) [12].

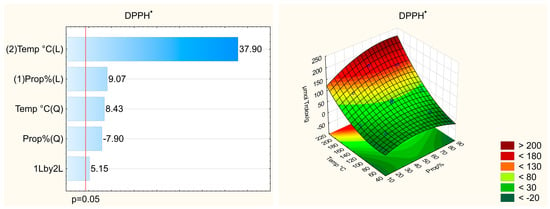

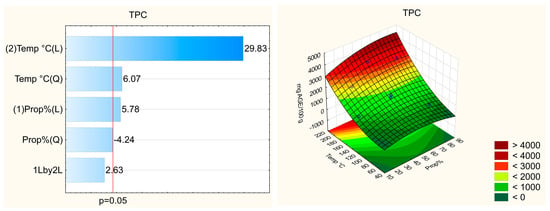

The Pareto diagram (Figure 1 and Figure 2) presents the effects of the independent variables on responses. It is possible to observe that the temperature and propylene glycol had an effect on the TPC and DPPH•. The linear effect of the temperature showed a positive value (p < 0.05), demonstrating that the increase in the temperature favors the recovery of bioactive compounds. Furthermore, the quadratic effect was also significant, proving that there is a limit to this behavior. Higher temperatures favor the extraction of biocompounds by reducing the solvent’s viscosity, making the solvent–sample interaction easier, and increasing the solubility of the target compounds and the diffusion coefficient [13]. However, very high temperatures can result in the degradation of certain substances, reducing the efficiency of the extraction process, which requires studies of process optimization [5,14]. The positive linear effect of the propylene glycol concentration in the solvent was also significant, showing that an increase in the propylene glycol concentration in the extractive solution improves the efficiency of the process. This behavior is explained by the chemical affinity of propylene glycol with the sample’s compounds, that is, a solvent with an intermediate polarity interacts well with a wide range of bioactive compounds, such as phenolic compounds. Furthermore, the combination of propylene glycol with water is required in order to reduce the viscosity of the solvent system [15]. Regarding the statistical analysis, all models were significant for predicting the behavior of the responses, since the calculated F values (36 and 295 for TPC and DPPH•, respectively) were higher than the listed F value (F5,5 = 5.05) at α = 0.05. The adjusted R2 values were higher than 0.95, which explains at least 95% of the data variability.

Figure 1.

Effect of the independent variables on the antioxidant capacity according to DPPH• assay and response surface.

Figure 2.

Effect of the independent variables on the total phenolic compounds (TPC) and response surface.

Thus, these results show the potential of the umbu seeds to provide an antioxidant extract and that the more sustainable approach, which combined microwaves and propylene glycol, provided promising results.

4. Conclusions

From the results, it is possible to conclude that using propylene glycol as a green solvent in microwave-assisted solid–liquid extraction favored the recovery of bioactive compounds from the umbu seeds. Also, the conditions that produce an extract with a higher antioxidant capacity and higher content of total phenolic compounds was 201 °C and using a 50% propylene glycol solution as solvent. Thus, microwave-assisted extraction employing propylene glycol as the solvent can be a more sustainable way to add value to umbu seeds, which are considered a residue in this agro-chain.

Author Contributions

Conceptualization, L.d.O.R. and E.P.J.; methodology, C.N.K. and E.P.J.; formal analysis, E.F.d.C. and A.A.N.; investigation, E.F.d.C. and A.A.N.; resources, L.d.O.R. and E.P.J.; data curation, A.A.N., C.N.K. and L.d.O.R.; writing—original draft preparation, E.F.d.C.; writing—review and editing, A.A.N. and C.N.K. and L.d.O.R.; supervision, E.P.J. and L.d.O.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used to support the findings of this study can be made available by the corresponding author upon request.

Acknowledgments

The authors would like to thank Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) for its financial support, the Embrapa Agroindústria de Alimentos and the National Institute of Technology (INT).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Barreto, L.S.; Castro, M.S. Good Management Practices for Sustainable Umbu Extraction; Embrapa Genetic Resources and Biotechnology: Brasilia, Brazil, 2010. [Google Scholar]

- Ribeiro, L.O.; Viana, E.S.; Godoy, R.L.O.; Freitas, S.C.; Freitas, S.P.; Matta, V.M. Nutrients and compounds of pulp, peel and seed from umbu fruit. Cienc. Rural. 2019, 49, e20180806. [Google Scholar] [CrossRef]

- Oreopoulo, A.; Tsimogiannis, D.; Oreopolou, V. Extraction of polyphenols from aromatic and medicinal plants: An overview of the methods and the effect extraction parameters. In Polyphenols in Plants; Watson, R.R., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 243–259. [Google Scholar]

- Santos, J.S.B.; Misael, C.G.A.; Fernandes, C.V.; Chaves, F.J.F.; Cavalcante, J.N.A.; Vasconcelos, S.F. Conversion Analysis of the Propylene Glycol Reaction. In Proceedings of the V Regional Chemistry Meeting & IV National Chemistry Meeting, São Paulo, Brazil, 31 August–3 September 2015. [Google Scholar]

- Petchsomrit, A.; Chanthathamrongsiri, N.; Manmuan, N.; Leelakanok, N.; Wangpradit, N.; Vongsak, B.; Sirirak, T. Green extraction of Buchanania siamensis and water-based formulations. Sustain. Chem. Pharm. 2022, 30, 100883. [Google Scholar] [CrossRef]

- Tsukui, A.; Rezende, C.M. Microwave Assisted Extraction and Green Chemistry. Rev. Virtual Quim. 2014, 6, 1713–1725. [Google Scholar] [CrossRef]

- Hidalgo, M.; Sánchez-Moreno, C.; de Pascual-Teresa, S. Flavonoid—Flavonoid interaction and its effect on their antioxidant activity. Food Chem. 2010, 121, 691–696. [Google Scholar] [CrossRef]

- Georgé, S.; Brat, P.; Alter, P.; Amiot, M.J. Rapid Determination of Polyphenols and Vitamin C in Plant-Derived Products. J. Agric. Food Chem. 2005, 53, 1370–1373. [Google Scholar] [CrossRef]

- Dairi, S.; Dahmoune, F.; Belbahi, A.; Remini, H.; Kadri, N.; Aoun, O.; Bouaoudia, N.; Madani, K. Optimization of microwave extraction method of red onion phenolic compounds using response surface methodology and inhibition of low-density lipoprotein oxidation. J. Appl. Res. Med. Aromat. Plants 2021, 22, 100301. [Google Scholar] [CrossRef]

- Gallo, M.; Ferracane, R.; Graziani, G.; Ritieni, A.; Fogliano, V. Microwave Assisted Extraction of Phenolic Compounds from Four Different Spices. Molecules 2010, 15, 6365–6374. [Google Scholar] [CrossRef]

- Simsek, M.; Sumnu, G.; Sahin, S. Microwave Assisted Extraction of Phenolic Compounds from Sour Cherry Pomace. Sep. Sci. Technol. 2012, 47, 1248–1254. [Google Scholar] [CrossRef]

- Freitas, B.P.; Oliveira, A.H.; Kunigami, C.N.; Novo, A.A.; Matta, V.M.; Jung, E.P.; Ribeiro, L.O. Effect of the solvent on the recovery of bioactive compounds from Umbu residue. In Proceedings of the 61° CBQ—Congresso Brasileiro de Química, Rio de Janeiro, Brazil, 14–3 November 2022. [Google Scholar]

- Ribeiro, L.O.; Freitas, B.P.; Lorentino, C.M.A.; Frota, H.F.; Santos, A.L.S.; Moreira, D.L.; Amaral, B.S.; Jung, E.P.; Kunigami, C.N. Umbu Fruit Peel as Source of Antioxidant, Antimicrobial and α-Amylase Inhibitor Compounds. Molecules 2022, 27, 410. [Google Scholar] [CrossRef] [PubMed]

- Neves-Brito, B.S.; Láscaris, M.P.S.; Moreira, J.J.S.; Nunes, T.P.; Pagani, A.A.C.; Silva, G.F. Influence of rota-evaporation temperature and type of residue on the extraction of bioactive compounds from jamelão (Syzygium cumini). Res. Soc. Dev. 2021, 10, e16210212272. [Google Scholar] [CrossRef]

- Nikolic, V.G.; Troter, D.Z.; Savic, I.M.; Gajic, I.M.S.; Zvezdanovic, J.B.; Konstantinovic, I.B.; Konstantinovic, S.S. Design and optimization of “greener” and sustainable ultrasound-assisted extraction of valuable bioactive compounds from common centaury (Centaurium erythraea Rafn) aerial parts: A comparative study using aqueous propylene glycol and ethanol. Ind. Crops Prod. 2023, 192, 116070. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).