1. Introduction

3D food printing has been an innovative technique in recent years. This technique has great potential both in terms of research and in terms of application in industry. It allows the personalization of food, both at a sensory and nutritional level. It offers great versatility in terms of shape, dimensions, taste, texture, etc. [

1].

Within food 3D printing, the technique of additive deposition by extrusion becomes as most relevant. It has been applied to produce different foods such as biscuits [

2], mashed potatoes [

3], fruit and vegetables [

4], gels [

5], cereal snacks [

6], bread [

7], etc., and also as a tool for the use of by-products [

8].

Despite the applications that have already been studied, it is important to expand to new formulations. To obtain biomaterials suitable for printing, it is important to study their printability. Printability is the ability of a material to be printed while maintaining its shape and is related to rheological and textural properties [

9].

Due to the infinite possibilities in terms of the formulation of these printable biomaterials, it is tedious trial and error to find good printable materials. Therefore, some authors have tried to predict the stability of these materials by obtaining rheological and textural values and applying models. TPA tests to observe the existence of fracturability and shear modulus related to self-weight deformation [

10] and the prediction of deformation due to weight by rheological and physical parameters of the sample [

11].

The objective of this study was to characterize the textural and rheological properties of three gels with different formulations by means of the extrusion and oscillatory test, respectively, to select which parameters are more suitable to predict their printability.

2. Materials and Methods

2.1. Gel Production

To produce the gels, different hydrocolloids were used, porcine gelatin (Gp), bovine gelatin (Gb), iota-carrageenan (I), kappa-carrageenan (K) and methylcellulose (MC) (Sosa, Barcelona, Spain).

Three gels were prepared: bovine gelatin plus kappa-carrageenan (Gb + K), porcine gelatin plus iota-carrageenan (Gp + I) and methylcellulose (MC).

2.1.1. Bovine Gelatine plus Kappa-Carrageenan (Gb + K)

A solution of 4% Gb and 0.5% K was prepared in distilled water. The total volume of water was separated into two equal parts, one part was heated to 65 °C to dissolve the gelatine and the other one to 75 °C for the K solution. A colorant was added to improve the visualization of the gel. This mixture was placed in a syringe at room temperature for 1 h and then placed in a fridge at 4 °C for 30 min. The sample was allowed to warm prior to use at room temperature.

2.1.2. Porcine Gelatin plus Iota-Carrageenan (Gp + I)

A total of 5% of Gp and 2% of I were dissolved in distilled water. For this purpose, half part of the water was heated to 65 °C and dissolved the gelatine and the other fraction was heated to 75 °C where the iota-carrageenan was dissolved. A colourant was added to improve the visualization of the gel. The mixture was placed in a syringe and cooled at room temperature for 1 h and 30 min.

2.1.3. Methylcellulose (MC)

Next, 4% of methylcellulose was dissolved in distilled water at room temperature. Once dissolved, a colorant was added to improve the visualization of the gel; then, the dispersion was placed in a syringe, and refrigerated for 24 h at 4 °C. The sample was tempered at room temperature prior to use.

2.2. Rheological Properties

The rheological properties of the three gels were characterized on a Kinexus Pro + rotational rheometer (Malvern Instruments, Worcesterchire, UK) with rSpace software at 25 °C using a stainless steel 40 mm parallel plate geometry with a 1 mm gap. An amplitude sweep was performed to determine the linear viscoelastic region. The initial shear stress ranged from 0.1% to 100% at the end at 1 Hz frequency. The samples had a yield stress of 31.73, 101.4 and 20.01 Pa for Gp + I, MC and Gb + K, respectively. An oscillatory test was carried out at a fixed strain of 1 Pa, and a frequency range of 0.1 to 10 Hz. Complex modulus (G*), elastic modulus (G′), viscous modulus (G″), the damping factor or tan δ (G″/G′) and apparent viscosity (η*) values were obtained for different frequency values (Hz). All tests were performed in triplicate.

2.3. Extrusion Test

For the extrusion test, the printing conditions were transferred (velocity, needle diameter, temperature and syringe) (

Figure 1). An extrusion test was performed using a TA.XT.plus texturometer (Stable Micro Systems, Godalming, Surrey, UK) and Texture Ex-ponent 32 program (Stable Micro Systems, Godalming, Surrey, UK). The printer plunger, syringe (35 mm diameter) with the sample and needle (1.63 mm diameter) and a cylindrical press attachment were used for syringe stability as

Figure 1 shows. The test conditions were 0.04 mm/s downstroke speed and 15 mm distance travelled. All tests were performed at least six times.

2.4. Statistical Analysis

All trials were replicated in triplicate. Data obtained from the trials were processed with the statistical software Statgraphics Centurion 18 program, version 18.1.13 (Statgraphics Technologies, Inc., The Plains, VA, USA). An analysis of variance (ANOVA) for a 95% confidence interval (p < 0.05) was performed to evaluate the differences between the different samples. In addition, Pearson’s correlation coefficient between rheological and extrusion parameters with a 95% significance level was carried out.

3. Results

3.1. Extrusion Test

The extrusion test provides information on the maximum force required to print the desired sample and is related to the requirements of the printer’s extruder. With the average force, it can be deduced whether the sample shows peaks of higher or lower force, which would be attributed to particle occlusion and air bubble outgassing, respectively. The presence of these peaks could also be due to the analysis of an inhomogeneous sample, poor gelation of the sample or samples with fracturability. The maximum force, average force and gradient values obtained in the extrusion test are shown in

Table 1.

The sample that needs the highest force to extrude is MC, which differs little from its average force. The two gelatin samples showed lower maximum force, with Gb + K being the lowest, but its average force showed a greater difference with respect to the maximum force. These results indicate a higher formation of air bubbles in the gelatine samples. These bubbles can be a problem when printing as they cause stops in the deposition of the material on the surface, giving figures with voids and less stability. This could be solved by controlling the agitation when making the gel or by introducing an ultrasound phase prior to gelation.

Figure 2 shows a representative curve of each sample in the extrusion test. MC sample was the one with the highest maximum force and the lowest variation over time. In the sample Gp + I, the presence of some bubbles could be observed, as a punctual decrease in the force was observed and a subsequent increase in the same when the air was eliminated. Gb + K had the line very irregular, which could be interpreted as a sample that presents fractures when extruded. The samples that show fracturability in the tests are usually discarded due to the poor reproducibility of the figures to be printed [

10].

3.2. Rheological Properties

The rheological parameters provide an insight into the behavior of the gels as well as the calculation of factors used for the prediction of the stability of the 3D figures.

Table 2 shows the results of the rheological parameters for the three gels studied. Data values at 1 Hz were used to compare the results. The results showed significant differences (

p < 0.05) in all parameters for each gel. The gels presented different behavior, but all of them are characterized by a more elastic behavior (G′ > G″ and G* ≈ G′).

Results have been compiled from studies in 3D food printing [

12]. The rheological parameters obtained from successfully printed samples comply that: G′ and G″ present values between 100 Pa and 10,000 Pa, viscosities ranging from 1000 to 10 Pa and present a pseudoplastic behavior against shear stress.

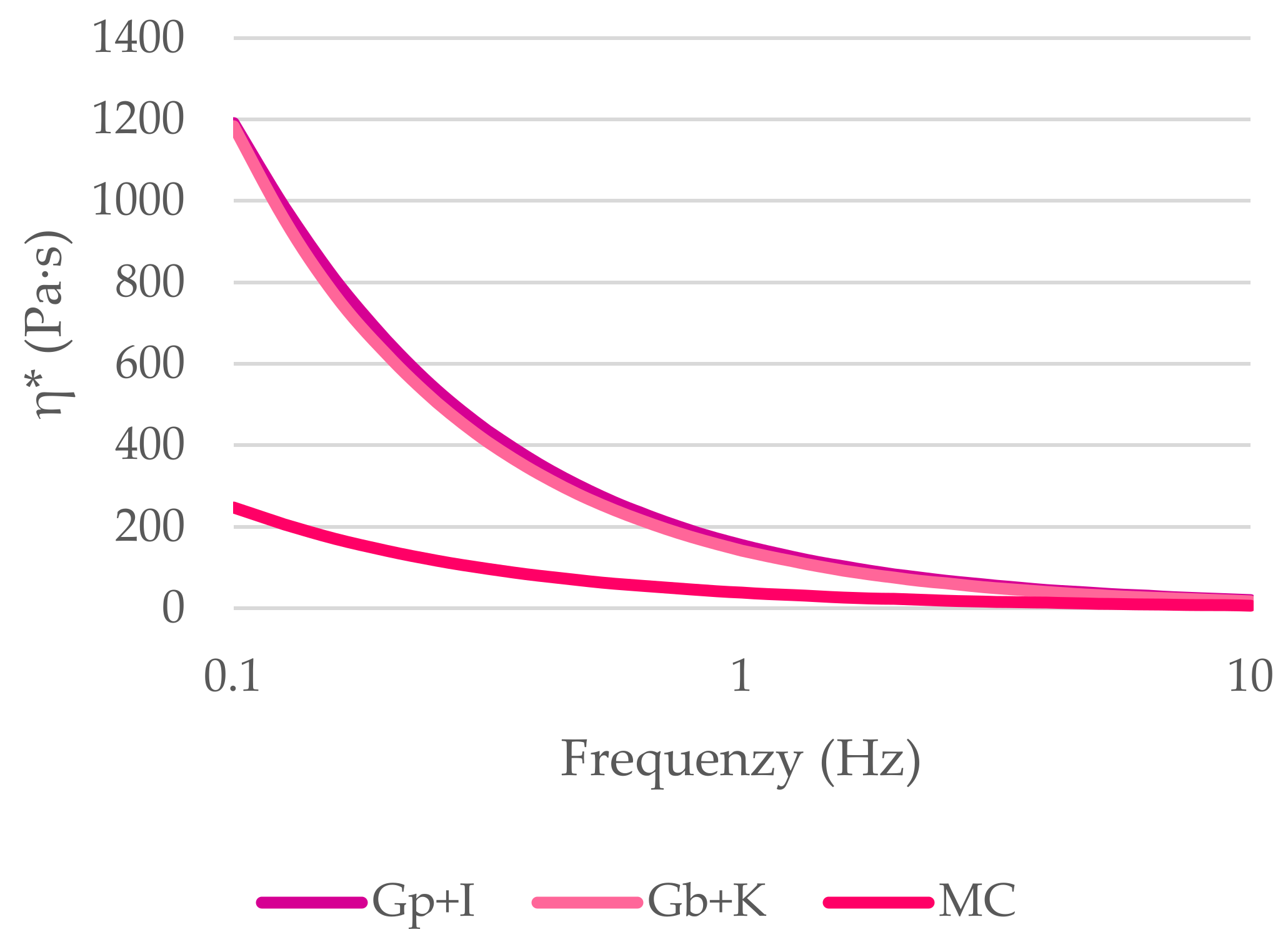

As can be seen in

Table 2, all the samples showed modulus values between 100 Pa and 10,000 Pa, except for MC, whose viscous modulus value was 84 Pa, outside the lower limit. All the samples presented values of apparent viscosity within the range mentioned above.

Figure 3 shows a representation of the variation of the apparent viscosity as the frequency at which the stress is applied increases. As the frequency increases, the apparent viscosity decreases, in a lower range for MC, so that the gels studied show a desired pseudoplastic behaviour.

Looking at Figure 7 from Nidjam’s study [

11], the equation of the line representing a 5% deformation of the sample after one hour was obtained. With the rheology data obtained for the samples and calculating the density for each of them, it was calculated what the maximum height of the figures should be to obtain a deformation of only 5% of the size after 1 h. It was obtained that the height of the samples had to be 0.77 cm for Gp + I, 1 cm for Gb + K and 0.008 cm for MC. With these results, it is possible to know the use of these samples, the samples with gelatins could be used to form figures up to 1 cm while MC only for the design of one-layer figures.

3.3. Pearson’s Correlation Coefficient

Table 3 shows Pearson’s correlation coefficients between the rheological and extrusion parameters. A correlation effect was observed between the rheological parameters and the maximum and average force except for the viscous modulus. G*, G′ and/or η* had a negative correlation; when increased, the maximum and average force decreased. On the other hand, Tanδ had the highest correlation factor; when Tanδ increased, the effect was positive and the maximum and average force increased.

4. Conclusions

The force necessary to print the three samples described has been obtained. A force of 60, 45, 83 N is needed to print Gp + I, Gb + K and MC, respectively.

On the other hand, with the obtained values of rheology and density, the maximum heights that each sample can reach to deform only 5% after 1 h were predicted. The sample Gb + K can form figures up to 1 cm, Gp + I up to 0.77 cm and MC up to 0.008 cm, single-layer figures.

With the predictions obtained, it is possible to know the use that can be made of each sample, but it remains to be verified that this prediction is valid and that other factors do not affect it.

With the results of the parameters, it has been observed that the rheology parameter with the highest correlation is the damping factor. It presents a directly proportional relationship with the maximum and average force involved in the extrusion.

Author Contributions

Conceptualization, P.G.-S., J.M.-M. and M.I.; methodology, M.I., A.M. and M.d.C.M.-M.; software, A.M. and M.d.C.M.-M.; formal analysis, M.I. and A.M.; investigation, P.G.-S., J.M.-M., M.I., A.M. and M.d.C.M.-M.; resources, P.G.-S. and J.M.-M.; data curation, A.M. and M.I.; writing—original draft preparation, A.M.; writing—review and editing, M.I., P.G.-S. and J.M.-M.; supervision, M.I.; project administration, P.G.-S. and J.M.-M.; funding acquisition, J.M.-M. and P.G.-S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Conselleria de Innovación, Universidades, Ciencia y Sociedad Digital, Generalitat Valenciana, grant number AICO/2021/137, from MCIN/AEI/10.13039/501100011033/through project PID2020-115973RB-C22 and Predoctoral grant from the Universitat Politècnica de València MCIN/AEI/10.13039/501100011033/.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Caporizzi, R.; Derossi, A.; Severini, C. Cereal-based and insect-enriched printable food: From formulation to postprocessing treatments. Status and perspectives. In Fundamentals of 3D Food Printing and Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 93–116. [Google Scholar] [CrossRef]

- Uribe-Wandurraga, Z.N.; Igual, M.; Reino-Moyón, J.; García-Segovia, P.; Martínez-Monzó, J. Effect of Microalgae (Arthrospira platensis and Chlorella vulgaris) Addition on 3D Printed Cookies. Food Biophys. 2021, 16, 27–39. [Google Scholar] [CrossRef]

- Martínez-Monzó, J.; Cárdenas, J.; García-Segovia, P. Effect of Temperature on 3D Printing of Commercial Potato Puree. Food Biophys. 2019, 14, 225–234. [Google Scholar] [CrossRef]

- Ricci, I.; Derossi, A.; Severini, C. 3D printed food from fruits and vegetables. In Fundamentals of 3D Food Printing and Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 117–149. [Google Scholar] [CrossRef]

- García-Segovia, P.; García-Alcaraz, V.; Balasch-Parisi, S.; Martínez-Monzó, J. 3D printing of gels based on xanthan/konjac gums. Innov. Food Sci. Emerg. Technol. 2020, 64, 102343. [Google Scholar] [CrossRef]

- Uribe-Wandurraga, Z.N.; Zhang, L.; Noort, M.W.J.; Schutyser, M.A.I.; García-Segovia, P.; Martínez-Monzó, J. Printability and Physicochemical Properties of Microalgae-Enriched 3D-Printed Snacks. Food Bioprocess Technol. 2020, 13, 2029–2042. [Google Scholar] [CrossRef]

- Matas, A.; Igual, M.; García-Segovia, P.; Martínez-Monzó, J. Application of 3D Printing in the Design of Functional Gluten-Free Dough. Foods 2022, 11, 1555. [Google Scholar] [CrossRef] [PubMed]

- Jagadiswaran, B.; Alagarasan, V.; Palanivelu, P.; Theagarajan, R.; Moses, J.A.; Anandharamakrishnan, C. Valorization of food industry waste and by-products using 3D printing: A study on the development of value-added functional cookies. Future Foods 2021, 4, 100036. [Google Scholar] [CrossRef]

- Godoi, F.C.; Prakash, S.; Bhandari, B.R. 3D printing technologies applied for food design: Status and prospects. J. Food Eng. 2016, 179, 44–54. [Google Scholar] [CrossRef]

- Kim, H.W.; Bae, H.; Park, H.J. Classification of the printability of selected food for 3D printing: Development of an assessment method using hydrocolloids as reference material. J. Food Eng. 2017, 215, 23–32. [Google Scholar] [CrossRef]

- Nijdam, J.J.; LeCorre-Bordes, D.; Delvart, A.; Schon, B.S. A rheological test to assess the ability of food inks to form dimensionally stable 3D food structures. J. Food Eng. 2021, 291, 110235. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Pandya, J.K.; McClements, D.J.; Lu, J.; Kinchla, A.J. Advancements in 3D food printing: A comprehensive overview of properties and opportunities. In Critical Reviews in Food Science and Nutrition; Bellwether Publishing, Ltd.: Columbia, MD, USA, 2021. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).