Evaluating Scale-Up Cultivation Modes for Aspergillus oryzae Biomass Production Using VFA-Rich Effluents from Agro-Industrial Residues

Abstract

1. Introduction

2. Materials and Methods

2.1. Substrate Preparation

2.2. Fungal Strains

2.3. Fungal Cultivation in Pilot-Scale Bubble Column Bioreactor (26 L Capacity)

2.3.1. Repeated-Batch Cultivation

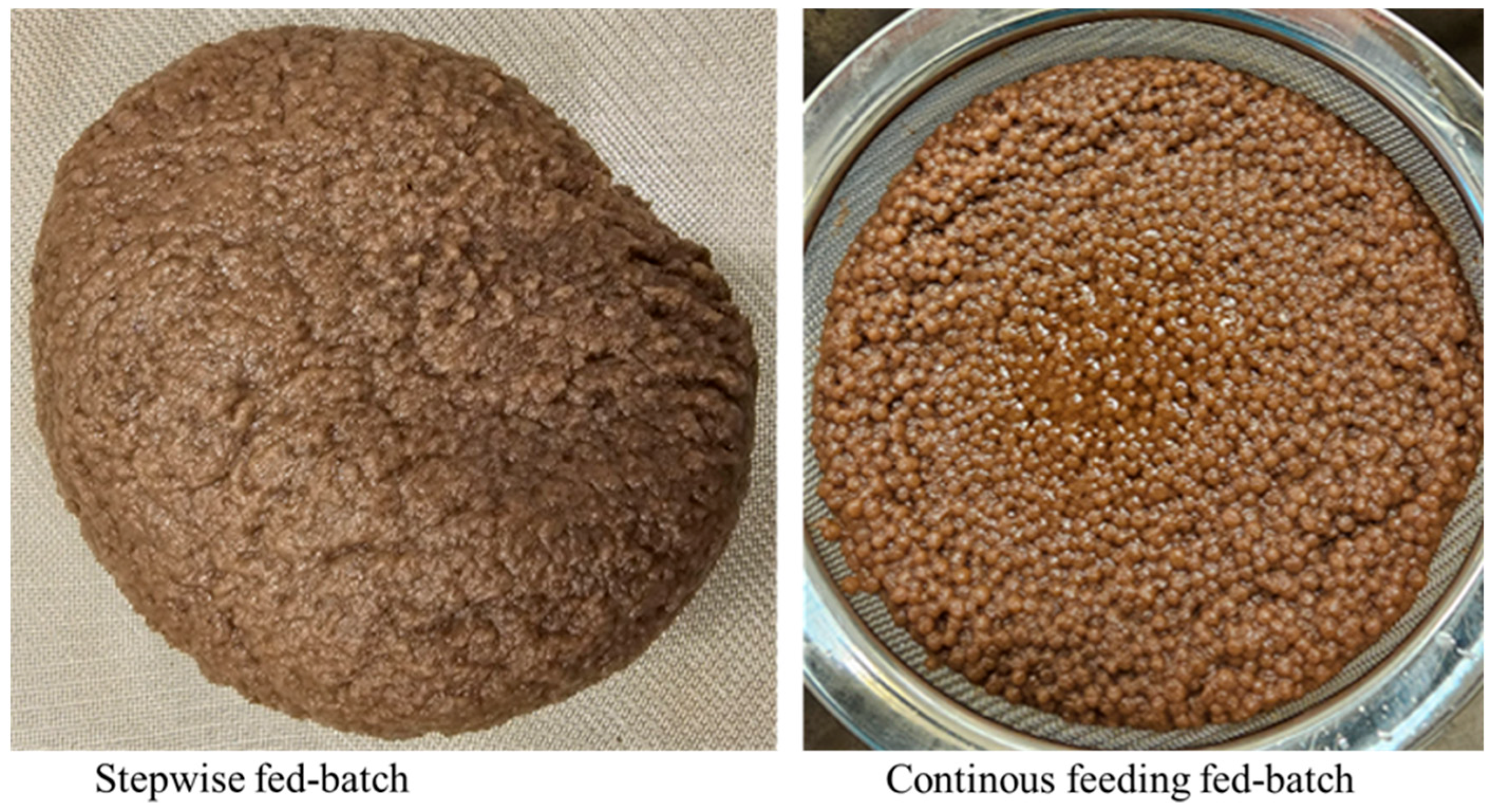

2.3.2. Fed-Batch Cultivation

2.4. Analytical Methods

2.5. Statistical Analysis

3. Results and Discussion

3.1. Effect of Cultivation Mode on Fungal Biomass Production Using VFAs

3.2. Effect of Cultivation Mode on Fungal Biomass Composition

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AD | Anaerobic digestion |

| ADF | Acid detergent fiber |

| Ba | Barium |

| Ca | Calcium |

| COD | Chemical oxygen demand |

| Cr | Chromium |

| Cu | Copper |

| Fe | Iron |

| iMBR | Immersed membrane bioreactor |

| K | Potassium |

| Mg | Magnesium |

| Mn | Manganese |

| Na | Sodium |

| NDF | Neutral detergent fiber |

| NH4+-N | Ammonium nitrogen |

| VFAs | Volatile fatty acids |

References

- United Nations. World Population Prospects 2024: Methodology of United Nations Population Estimates and Projections. 2024, U. DESA/POP/2024/DC/NO. Available online: https://www.un.org/development/desa/pd/sites/www.un.org.development.desa.pd/files/files/documents/2024/Jul/undesa_pd_2024_wpp2024_methodology-report.pdf (accessed on 28 February 2025).

- Aiking, H.; de Boer, J. The next protein transition. Trends Food Sci. Technol. 2020, 105, 515–522. [Google Scholar] [CrossRef]

- OECD/FAO. OECD-FAO Agriculture Outlook 2024–2033; O. Publishing, Paris/FAO: Rome, Italy, 2024. [Google Scholar] [CrossRef]

- FAO. The Future of Food and Agriculture–Trends and Challenges. 2017, Rome. Available online: https://openknowledge.fao.org/server/api/core/bitstreams/2e90c833-8e84-46f2-a675-ea2d7afa4e24/content (accessed on 28 February 2025).

- Lenkiewicz, Z.; Bernardes, F.; Halpaap, A.; Louzada, L.; Ramola, A.; Silva Filho, C.; Souza, H.H.S.; Smith, J.; Ternald, D.; Wilson, D. Global Waste Management Outlook 2024: Beyond an Age of Waste: Turning Rubbish into a Resource; United Nations Environment Programme: New York, NY, USA, 2024. [Google Scholar] [CrossRef]

- Šelo, G.; Planinić, M.; Tišma, M.; Tomas, S.; Koceva Komlenić, D.; Bucić-Kojić, A. A Comprehensive Review on Valorization of Agro-Food Industrial Residues by Solid-State Fermentation. Foods 2021, 10, 927. [Google Scholar] [CrossRef]

- Lee, W.S.; Chua, A.S.M.; Yeoh, H.K.; Ngoh, G.C. A review of the production and applications of waste-derived volatile fatty acids. Chem. Eng. J. 2014, 235, 83–99. [Google Scholar] [CrossRef]

- Annunziata, G.; Arnone, A.; Ciampaglia, R.; Tenore, G.C.; Novellino, E. Fermentation of Foods and Beverages as a Tool for Increasing Availability of Bioactive Compounds. Focus on Short-Chain Fatty Acids. Foods 2020, 9, 999. [Google Scholar] [CrossRef] [PubMed]

- Bhatia, S.K.; Gurav, R.; Choi, T.-R.; Jung, H.-R.; Yang, S.-Y.; Song, H.-S.; Jeon, J.-M.; Kim, J.-S.; Lee, Y.-K.; Yang, Y.-H. Poly (3-hydroxybutyrate-co-3-hydroxyhexanoate) production from engineered Ralstonia eutropha using synthetic and anaerobically digested food waste derived volatile fatty acids. Int. J. Biol. Macromol. 2019, 133, 1–10. [Google Scholar]

- Caporusso, A.; Capece, A.; De Bari, I. Oleaginous yeasts as cell factories for the sustainable production of microbial lipids by the valorization of agri-food wastes. Fermentation 2021, 7, 50. [Google Scholar] [CrossRef]

- Uwineza, C.; Mahboubi, A.; Atmowidjojo, A.; Ramadhani, A.; Wainaina, S.; Millati, R.; Wikandari, R.; Niklasson, C.; Taherzadeh, M.J. Cultivation of edible filamentous fungus Aspergillus oryzae on volatile fatty acids derived from anaerobic digestion of food waste and cow manure. Bioresour. Technol. 2021, 337, 125410. [Google Scholar] [CrossRef]

- Uwineza, C.; Sar, T.; Mahboubi, A.; Taherzadeh, M.J. Evaluation of the Cultivation of Aspergillus oryzae on Organic Waste-Derived VFA Effluents and Its Potential Application as Alternative Sustainable Nutrient Source for Animal Feed. Sustainability 2021, 13, 12489. [Google Scholar] [CrossRef]

- Bentley, R. From miso, sake and shoyu to cosmetics: A century of science for kojic acid. Nat. Prod. Rep. 2006, 23, 1046–1062. [Google Scholar] [CrossRef]

- Chan, L.G.; Cohen, J.L.; de Moura Bell, J.M.L.N. Conversion of Agricultural Streams and Food-Processing By-Products to Value-Added Compounds Using Filamentous Fungi. Annu. Rev. Food Sci. Technol. 2018, 9, 503–523. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.J.; Liu, L.P.; Wen, P.; Li, N.; Zong, M.H.; Wu, H. Effects of acetic acid and pH on the growth and lipid accumulation of the oleaginous yeast Trichosporon fermentans. BioResources 2015, 10, 4152–4166. [Google Scholar] [CrossRef]

- Wilson, N.R. Chapter 13—Contamination: Bacteria and wild yeasts in whisky fermentation. In Whisky and Other Spirits, 3rd ed.; Russell, I., Stewart, G.G., Kellershohn, J., Eds.; Academic Press: Cambridge, MA, USA, 2022; pp. 237–245. [Google Scholar]

- Garcia-Aguirre, J.; Aymerich, E.; González-Mtnez. de Goñi, J.; Esteban-Gutiérrez, M. Selective VFA production potential from organic waste streams: Assessing temperature and pH influence. Bioresour. Technol. 2017, 244, 1081–1088. [Google Scholar] [CrossRef]

- Vázquez-Fernández, A.; Suárez-Ojeda, M.E.; Carrera, J. Review about bioproduction of Volatile Fatty Acids from wastes and wastewaters: Influence of operating conditions and organic composition of the substrate. J. Environ. Chem. Eng. 2022, 10, 107917. [Google Scholar] [CrossRef]

- Arpornwichanop, A.; Kittisupakorn, P.; Mujtaba, I.M. On-line dynamic optimization and control strategy for improving the performance of batch reactors. Chem. Eng. Process. Process Intensif. 2005, 44, 101–114. [Google Scholar] [CrossRef]

- Fontanille, P.; Kumar, V.; Christophe, G.; Nouaille, R.; Larroche, C. Bioconversion of volatile fatty acids into lipids by the oleaginous yeast Yarrowia lipolytica. Bioresour. Technol. 2012, 114, 443–449. [Google Scholar] [CrossRef] [PubMed]

- Taherzadeh, M.J.; Niklasson, C.; Liden, G. On-line control of fed-batch fermentation of dilute-acid hydrolyzates. Biotechnol. Bioeng. 2000, 69, 330–338. [Google Scholar] [CrossRef]

- Parchami, M.; De Wever, H.; Sar, T.; Taherzadeh, M.J.; Mahboubi, A. Production of volatile fatty acids from agro-food residues for ruminant feed inclusion using pilot-scale membrane bioreactor. Environ. Technol. Innov. 2025, 38, 104193. [Google Scholar] [CrossRef]

- Sues, A.; Millati, R.; Edebo, L.; Taherzadeh, M.J. Ethanol production from hexoses, pentoses, and dilute-acid hydrolyzate by Mucor indicus. FEMS Yeast Res. 2005, 5, 669–676. [Google Scholar] [CrossRef]

- León Peláez, A.M.; Serna Cataño, C.A.; Quintero Yepes, E.A.; Gamba Villarroel, R.R.; De Antoni, G.L.; Giannuzzi, L. Inhibitory activity of lactic and acetic acid on Aspergillus flavus growth for food preservation. Food Control 2012, 24, 177–183. [Google Scholar] [CrossRef]

- Ge, Y.; Wu, Y.; Aihaiti, A.; Wang, L.; Wang, Y.; Xing, J.; Zhu, M.; Hong, J. The Metabolic Pathways of Yeast and Acetic Acid Bacteria During Fruit Vinegar Fermentation and Their Influence on Flavor Development. Microorganisms 2025, 13, 477. [Google Scholar] [CrossRef] [PubMed]

- Bennett, G.N.; Rudolph, F.B. The central metabolic pathway from acetyl-CoA to butyryl-CoA in Clostridium acetobutylicum. FEMS Microbiol. Rev. 1995, 17, 241–249. [Google Scholar] [CrossRef]

- De Meur, Q.; Deutschbauer, A.; Koch, M.; Bayon-Vicente, G.; Cabecas Segura, P.; Wattiez, R.; Leroy, B. New perspectives on butyrate assimilation in Rhodospirillum rubrum S1H under photoheterotrophic conditions. BMC Microbiol. 2020, 20, 126. [Google Scholar] [CrossRef]

- Piper, P.; Calderon, C.O.; Hatzixanthis, K.; Mollapour, M. Weak acid adaptation: The stress response that confers yeasts with resistance to organic acid food preservatives. Microbiology 2001, 147, 2635–2642. [Google Scholar] [CrossRef]

- Tang, I.C.; Okos, M.R.; Yang, S.-T. Effects of pH and acetic acid on homoacetic fermentation of lactate by Clostridium formicoaceticum. Biotechnol. Bioeng. 1989, 34, 1063–1074. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Du, J.; Tsao, G.T. Mycelial pellet formation by Rhizopus oryzae ATCC 20344. Appl. Biochem. Biotechnol. 2000, 84, 779–789. [Google Scholar] [CrossRef] [PubMed]

- Jin, B.; Yan, X.Q.; Yu, Q.; Van Leeuwen, J.H. A comprehensive pilot plant system for fungal biomass protein production and wastewater reclamation. Adv. Environ. Res. 2002, 6, 179–189. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Jin, B.; Bai, Z.H.; Wang, X.Y. Production of fungal biomass protein using microfungi from winery wastewater treatment. Bioresour. Technol. 2008, 99, 3871–3876. [Google Scholar] [CrossRef]

- Braho, V.; Sar, T.; Taherzadeh, M.J. Cultivation of edible filamentous fungi on pomegranate by-products as feedstocks to produce mycoprotein. Syst. Microbiol. Biomanuf. 2024, 4, 675–686. [Google Scholar] [CrossRef]

- Barker, T.W.; Drouliscos, N.J.; Worgan, J.T. Composition and nutritional evaluation of Aspergillus oryzae biomass grown on palm oil processing effluents. J. Sci. Food Agric. 1981, 32, 1014–1020. [Google Scholar] [CrossRef]

- Banaszkiewicz, T. Nutritional value of soybean meal. In Soybean and Nutrition; IntechOpen: London, UK, 2011; pp. 1–20. [Google Scholar]

- Świątkiewicz, S.; Arczewska-Włosek, A.; Józefiak, D. The use of cottonseed meal as a protein source for poultry: An updated review. World’s Poult. Sci. J. 2016, 72, 473–484. [Google Scholar] [CrossRef]

- Stahl, P.D.; Klug, M.J. Characterization and differentiation of filamentous fungi based on Fatty Acid composition. Appl. Environ. Microbiol. 1996, 62, 4136–4146. [Google Scholar] [CrossRef]

- Karamerou, E.E.; Webb, C. Cultivation modes for microbial oil production using oleaginous yeasts—A review. Biochem. Eng. J. 2019, 151, 107322. [Google Scholar] [CrossRef]

- Chalima, A.; Oliver, L.; Fernández de Castro, L.; Karnaouri, A.; Dietrich, T.; Topakas, E. Utilization of Volatile Fatty Acids from Microalgae for the Production of High Added Value Compounds. Fermentation 2017, 3, 54. [Google Scholar] [CrossRef]

- Llamas, M.; Magdalena, J.A.; González-Fernández, C.; Tomás-Pejó, E. Volatile fatty acids as novel building blocks for oil-based chemistry via oleaginous yeast fermentation. Biotechnol. Bioeng. 2020, 117, 238–250. [Google Scholar] [CrossRef]

- Bowman, S.M.; Free, S.J. The structure and synthesis of the fungal cell wall. BioEssays 2006, 28, 799–808. [Google Scholar] [CrossRef]

- Vieira, D.J.C.; Grigoletto, N.T.S.; Poletti, G.; Chesini, R.G.; Diepersloot, E.C.; Takiya, C.S.; Ferraretto, L.F.; Rennó, F.P. Impact of decreasing undigested neutral detergent fiber concentration in corn silage–based diets for dairy cows: Nutrient digestibility, ruminal fermentation, feeding behavior, and performance. J. Dairy Sci. 2025, 108, 8462–8475. [Google Scholar] [CrossRef]

- Uwineza, C.; Bouzarjomehr, M.; Parchami, M.; Sar, T.; Taherzadeh, M.J.; Mahboubi, A. Evaluation of in vitro digestibility of Aspergillus oryzae fungal biomass grown on organic residue derived-VFAs as a promising ruminant feed supplement. J. Anim. Sci. Biotechnol. 2023, 14, 120. [Google Scholar] [CrossRef] [PubMed]

- National Research Council. Nutrient Requirements of Dairy Cattle: 2001; National Academies Press: Washington, DC, USA, 2001; Available online: http://www.nap.edu/catalog/9825.html (accessed on 22 July 2025).

- Cheng, Y.-C.; Kim, S.W. Use of microorganisms as nutritional and functional feedstuffs for nursery pigs and broilers. Animals 2022, 12, 3141. [Google Scholar] [CrossRef]

- Lee, K.; Lee, S.K.; Lee, B.D. Aspergillus oryzae as probiotic in poultry-A review. Int. J. Poult. Sci. 2006, 5, 1–3. [Google Scholar]

- Safaei, Z.; Karimi, K.; Zamani, A. Impact of phosphate, potassium, yeast extract, and trace metals on chitosan and metabolite production by Mucor indicus. Int. J. Mol. Sci. 2016, 17, 1429. [Google Scholar] [CrossRef]

- Pinotti, L.; Manoni, M.; Ferrari, L.; Tretola, M.; Cazzola, R.; Givens, I. The Contribution of Dietary Magnesium in Farm Animals and Human Nutrition. Nutrients 2021, 13, 509. [Google Scholar] [CrossRef] [PubMed]

- Preston, R.L.; John, L.R. Potassium in Animal Nutrition. In Potassium in Agriculture; ASA, CSSA, and SSSA Books: Madison, WI, USA, 1985; pp. 595–617. [Google Scholar]

- Takeda, E.; Yamamoto, H.; Yamanaka-Okumura, H.; Taketani, Y. Dietary phosphorus in bone health and quality of life. Nutr. Rev. 2012, 70, 311–321. [Google Scholar] [CrossRef] [PubMed]

- Anderson, J.J.; Garner, S.C. Calcium and Phosphorus in Health and Disease; CRC Press: Boca Raton, FL, USA, 1995; Volume 10. [Google Scholar]

| Parameters | Units | VFA Effluent |

|---|---|---|

| tCOD | g/L | 140 ± 13.41 |

| NH4+-N | mg/L | 450 ± 32.57 |

| tVFAs | g/L | 7.99 ± 0.31 |

| Acetic acid | % | 23 |

| Propionic acid | % | 6 |

| Isobutyric acid | % | 15 |

| Butyric acid | % | 23 |

| Isovaleric acid | % | 1 |

| Valeric acid | % | 6 |

| Caproic acid | % | 26 |

| pH | 6.5 | |

| Sodium (Na) | g/L | 22.13 ± 0.08 |

| Magnesium (Mg) | g/L | 11.18 ± 0.02 |

| Calcium (Ca) | g/L | 2.45 ± 0.00 |

| Potassium (K) | g/L | 12.33 ± 0.52 |

| Iron (Fe) | g/L | 69.40 ± 1.60 |

| Chromium (Cr) | mg/L | 17.16 ± 0.45 |

| Manganese (Mn) | mg/L | 289.91 ± 8.73 |

| Copper (Cu) | mg/L | 24.26 ± 1.15 |

| Barium (Ba) | mg/L | 10.23 ± 0.61 |

| Incubation Time (h) | Dry Biomass (g/L) | Biomass Yield (g Dry Biomass/gVFAsfed) | Crude Protein (%) | |

|---|---|---|---|---|

| Stepwise | 42 h | 2.88 ± 0.31 | 0.27 ± 0.001 | Not analyzed |

| 48 h | 2.25 ± 0.22 | 0.24 ± 0.005 | 42.62 ± 4.75 | |

| 71 h | 1.00 ± 0.02 | 0.15 ± 0.006 | 34.02 ± 2.91 | |

| Continuous | 41 h | 2.75 ± 0.11 | 0.41 ± 0.004 | 53.31 ± 0.29 |

| 46 h | 2.36 ± 0.29 | 0.35 ± 0.000 | 47.98 ± 0.46 | |

| 48 h | 1.52 ± 0.18 | 0.23 ± 0.003 | 45.85 ± 0.03 |

| Incubation Time (h) | Crude Fat (%) | ADF (%) | NDF (%) | |

|---|---|---|---|---|

| Stepwise | 48 | 0.72 ± 0.14 | 9.08 ± 0.31 | 25.43 ± 2.93 |

| Continuous | 48 | 1.82 ± 0.14 | 11.38 ± 1.31 | 25.80 ± 3.76 |

| Incubation Time (h) | Nitrogen (%) | Carbon (%) | Hydrogen (%) | |

|---|---|---|---|---|

| Acetic acid | 24 | 8.94 ± 0.08 | 44.78 ± 0.10 | 6.44 ± 0.07 |

| Stepwise | 67 | 4.27 ± 0.54 | 16.48 ± 3.44 | 5.00 ± 0.61 |

| 71 | 5.39 ± 0.18 | 19.25 ± 0.70 | 5.81 ± 0.20 | |

| Continuous | 41 | 8.53 ± 1.32 | 32.30 ± 4.12 | 5.79 ± 1.10 |

| 48 | 6.91 ± 0.35 | 25.77 ± 1.44 | 6.29 ± 0.33 |

| Minerals | Biomass from Acetic Acid | Stepwise | Continuous |

|---|---|---|---|

| Na (g/kg) | 4.64 ± 0.30 | 3.46 ± 0.37 | 2.82 ± 0.38 |

| Mg (g/kg) | 1.68 ± 0.05 | 67.74 ± 2.92 | 42.30 ± 0.13 |

| Ca (g/kg) | 0.76 ± 0.01 | 3.21 ± 0.22 | 5.39 ± 0.05 |

| K (g/kg) | 13.62 ± 0.24 | 13.56 ± 0.65 | 10.73 ± 0.39 |

| Fe (g/kg) | 4.33 ± 1.07 | 2.60 ± 0.34 | 3.20 ± 0.05 |

| Cr (mg/kg) | 58.09 ± 2.07 | 38.88 ± 1.38 | 43.69 ± 3.28 |

| Mn (mg/kg) | 147.79 ± 2.36 | 415.83 ± 7.15 | 534.19 ± 0.06 |

| Cu (mg/kg) | 987.70 ± 28.31 | 181.14 ± 8.81 | 417.14 ± 1.82 |

| Ba (mg/kg) | 134.14 ± 2.63 | 119.75 ± 6.14 | 148.52 ± 14.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sar, T.; Uwineza, C.; Taherzadeh, M.J.; Mahboubi, A. Evaluating Scale-Up Cultivation Modes for Aspergillus oryzae Biomass Production Using VFA-Rich Effluents from Agro-Industrial Residues. BioTech 2025, 14, 76. https://doi.org/10.3390/biotech14040076

Sar T, Uwineza C, Taherzadeh MJ, Mahboubi A. Evaluating Scale-Up Cultivation Modes for Aspergillus oryzae Biomass Production Using VFA-Rich Effluents from Agro-Industrial Residues. BioTech. 2025; 14(4):76. https://doi.org/10.3390/biotech14040076

Chicago/Turabian StyleSar, Taner, Clarisse Uwineza, Mohammad J. Taherzadeh, and Amir Mahboubi. 2025. "Evaluating Scale-Up Cultivation Modes for Aspergillus oryzae Biomass Production Using VFA-Rich Effluents from Agro-Industrial Residues" BioTech 14, no. 4: 76. https://doi.org/10.3390/biotech14040076

APA StyleSar, T., Uwineza, C., Taherzadeh, M. J., & Mahboubi, A. (2025). Evaluating Scale-Up Cultivation Modes for Aspergillus oryzae Biomass Production Using VFA-Rich Effluents from Agro-Industrial Residues. BioTech, 14(4), 76. https://doi.org/10.3390/biotech14040076