Micromachines 2019, 10(12), 842; https://doi.org/10.3390/mi10120842 - 1 Dec 2019

Cited by 7 | Viewed by 3298

Abstract

In order to solve the problem of continuous and stable power supply for vehicle sensors, a resonant cavity piezoelectric energy harvester driven by driving wind pressure was designed. The harvester has an effective working range of wind speed. According to the energy conservation

[...] Read more.

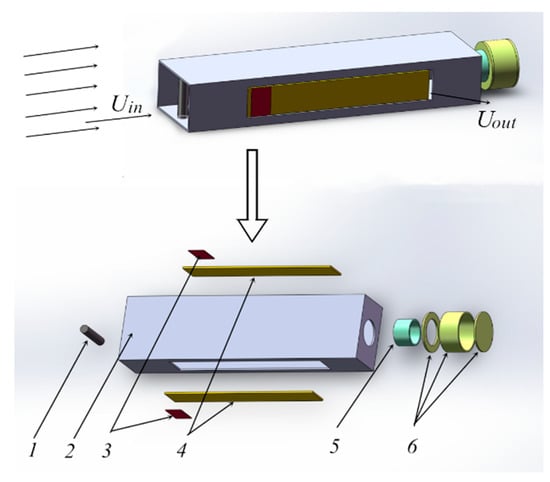

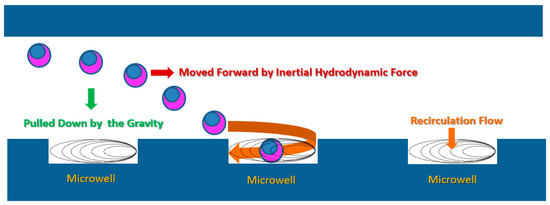

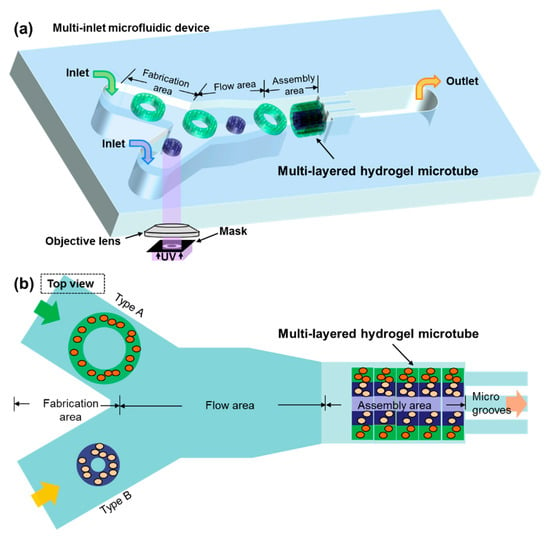

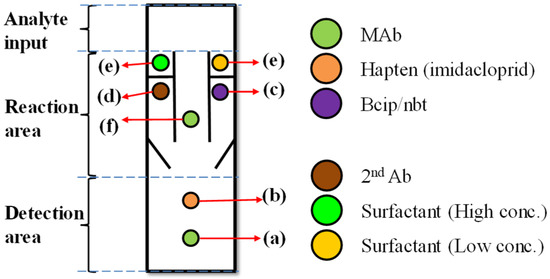

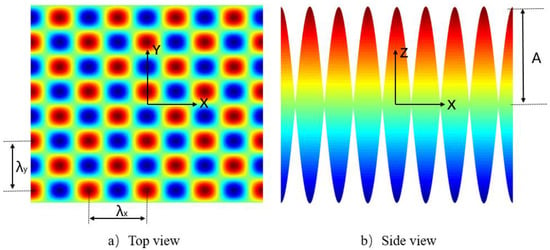

In order to solve the problem of continuous and stable power supply for vehicle sensors, a resonant cavity piezoelectric energy harvester driven by driving wind pressure was designed. The harvester has an effective working range of wind speed. According to the energy conservation law, the cut-in (initial) wind speed of the harvester was solved. The pressure distribution law of the elastic beam in the flow field was studied by the Fluent software package, and the results were loaded into a finite element model with a method of partition loading. The relationship between the wind speed and the maximum principal stress of the piezoelectric cantilever beam was analyzed, and the critical stress method was used to study the cut-out wind speed of the energy harvester. The results show that the cut-in wind speed of the piezoelectric energy harvester is 5.29 m/s, and the cut-out wind speed is 24 m/s. Finally, an experiment on the power generation performance of the energy harvester was carried out. The experimental results show that the cut-in and cut-out wind speeds of the piezoelectric energy harvester are 5 m/s and 24 m/s, respectively, and the best matching load is 60 kΩ. The average output power, generated by the harvester when the driving wind speed is 22 m/s, is 0.145 mW, and the corresponding power density is 1.2 mW/cm3.

Full article

(This article belongs to the Special Issue Piezoelectric Transducers: Materials, Devices and Applications)

►

Show Figures