Micromachines 2019, 10(12), 812; https://doi.org/10.3390/mi10120812 - 25 Nov 2019

Cited by 5 | Viewed by 3961

Abstract

In a flow-focusing microdroplet generator, by changing the flow rates of the two immiscible fluids, production speed can be increased from tens to thousands of droplets per second. However, because of the nonlinearity of the flow-focusing microdroplet generator, the production speed of droplets

[...] Read more.

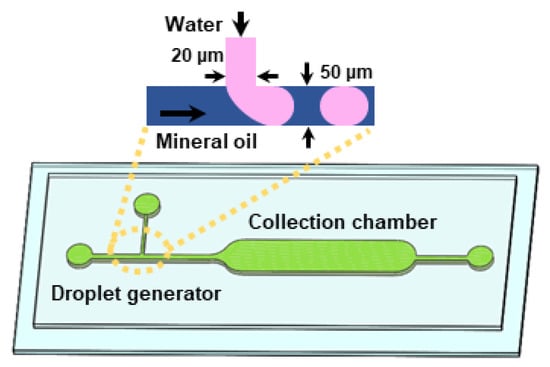

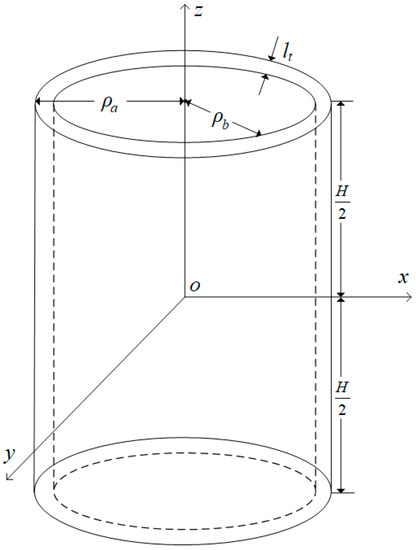

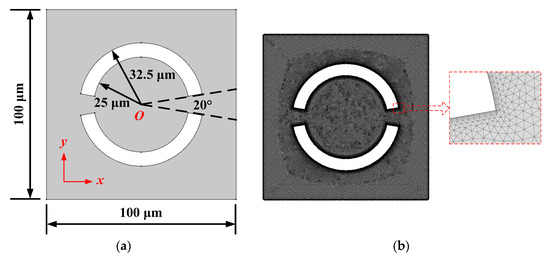

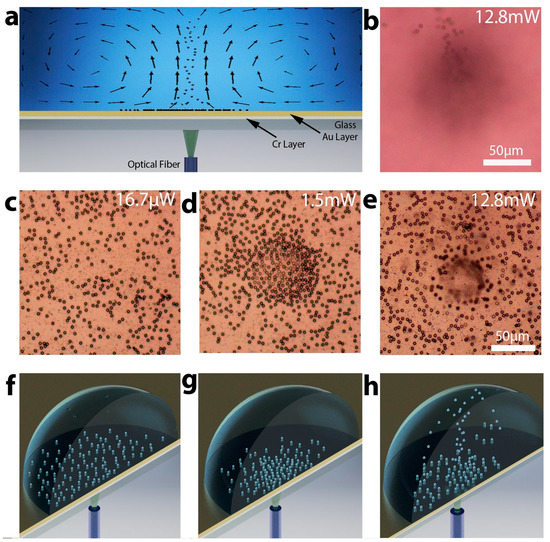

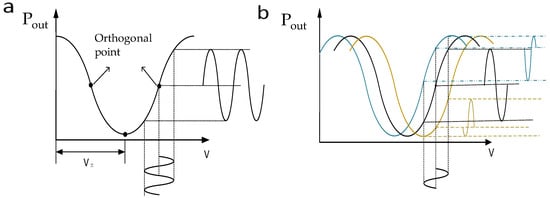

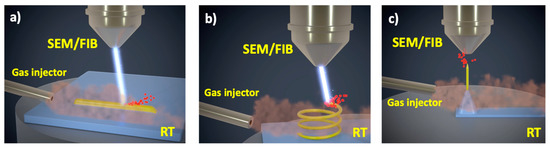

In a flow-focusing microdroplet generator, by changing the flow rates of the two immiscible fluids, production speed can be increased from tens to thousands of droplets per second. However, because of the nonlinearity of the flow-focusing microdroplet generator, the production speed of droplets is difficult to quantitatively study for the typical flow-focusing geometry. In this paper, we demonstrate an efficient method that can precisely predict the droplet production speed for a wide range of fluid flow rates. While monodisperse droplets are formed in the flow-focusing microchannel, droplet spacing as a function of time was measured experimentally. We discovered that droplet spacing changes periodically with time during each process of droplet generation. By comparing the frequency of droplet spacing fluctuations with the droplet production speed, precise predictions of droplet production speed can be obtained for different flow conditions in the flow-focusing microdroplet generator.

Full article

(This article belongs to the Special Issue Microfluidics for Soft Matter and Mechanobiology, Volume I)

►

Show Figures