Coatings 2019, 9(9), 547; https://doi.org/10.3390/coatings9090547 - 26 Aug 2019

Cited by 50 | Viewed by 5610

Abstract

It is expected that the applications of photocatalytic coatings will continue to extend into many areas, so it is important to explore their potential for enhanced functionality and design flexibility. In this study, we investigated the effect of a subwavelength surface structure in

[...] Read more.

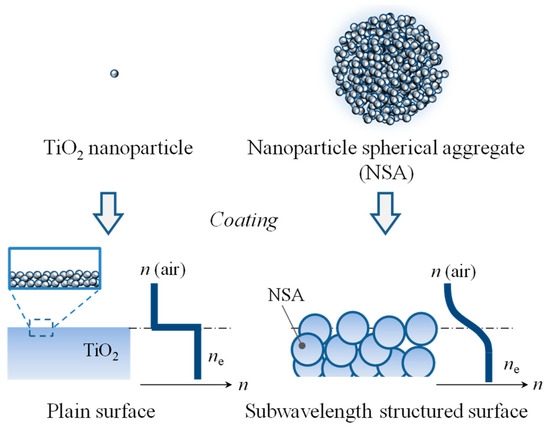

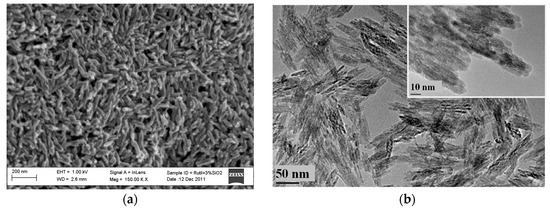

It is expected that the applications of photocatalytic coatings will continue to extend into many areas, so it is important to explore their potential for enhanced functionality and design flexibility. In this study, we investigated the effect of a subwavelength surface structure in a TiO2 coating on its optical and superhydrophilic characteristics. Using submicron-scale spherical aggregates of TiO2 nanoparticles, we fabricated a TiO2 film with a subwavelength surface structure. Optical examination showed the enhanced transmittance of visible light compared to that of a plain surface. This was considered to be a result of a graded refractive index at the air–TiO2 interface. The effect of the subwavelength surface structure on optical transmittance was also demonstrated by the numerical simulation of visible light propagation in which Maxwell’s equations were solved using the finite-difference time-domain method. In addition, superhydrophilic behavior without ultraviolet light illumination was observed for the subwavelength-structure film via the measurement of the contact angle of a water drop. Furthermore, it was confirmed that the photocatalytic activity of the proposed film was comparable with that of a standard TiO2 film. It was suggested that the control of the subwavelength surface structure of a TiO2 film could be utilized to achieve novel properties of photocatalytic coatings.

Full article

(This article belongs to the Special Issue Photocatalytic Thin Films)

►

Show Figures