Polymers 2019, 11(3), 541; https://doi.org/10.3390/polym11030541 - 22 Mar 2019

Cited by 22 | Viewed by 5385

Abstract

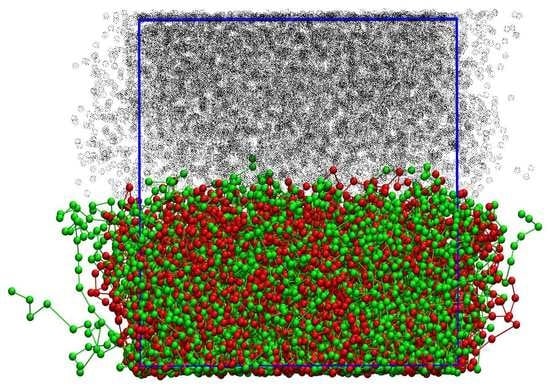

Single and double layers of polymer coated surfaces are investigated by means of Dissipative Particle Dynamics (DPD), focusing on the difference between grafted ring and linear chains. Several different surface coverages , as well as chain lengths N and brush separations D

[...] Read more.

Single and double layers of polymer coated surfaces are investigated by means of Dissipative Particle Dynamics (DPD), focusing on the difference between grafted ring and linear chains. Several different surface coverages , as well as chain lengths N and brush separations D, are analyzed for athermal, i.e., good solvent, conditions. The size in the form of the radius of gyration , the shape as asphericity , and orientation , as well as density profiles as functions of distance from grafting plane , are studied. The effect of an added bond repulsion potential to suppress bond crossing in DPD is analyzed. Scaling laws of and its components and are investigated. We find for surface coverages below the overlap surface concentration . For we find and of ring brushes with the standard DPD model and with added bond repulsion. The dependence of the radius of gyration was found to be with for surface coverages grater than . The perpendicular component scales independent of the bond repulsion potential as , whereas the scaling of the parallel component exhibits a topological repulsion dependence for standard DPD and for bond repulsion.

Full article

(This article belongs to the Special Issue Theory and Simulations of Entangled Polymers)

►

Show Figures