Spark-Plasma Sintering and Related Field-Assisted Powder Consolidation Technologies

Printed Edition Available!

A printed edition of this Special Issue is available

here.

Share This Topical Collection

Editor

Prof. Dr. Eugene A. Olevsky

Prof. Dr. Eugene A. Olevsky

Prof. Dr. Eugene A. Olevsky

Prof. Dr. Eugene A. Olevsky

E-Mail

Website

Collection Editor

Powder Technology Laboratory, Department of Mechanical Engineering, College of Engineering, San Diego State University, San Diego, CA 92182-1323, USA

Interests: spark plasma sintering; advanced ceramic and ceramic composite processing; functionally graded materials; thick and thin film technologies

Topical Collection Information

Dear Colleagues,

Electromagnetic field-assisted sintering techniques have increasingly attracted attention of scientists and technologists. Spark-plasma sintering (SPS) and other field-assisted powder consolidation approaches provide remarkable capabilities to the processing of materials into configurations previously unattainable. Of particular significance is the possibility of using very fast heating rates, which, coupled with the field-assisted mass transport, stand behind the purported ability to achieve high densities during consolidation and to maintain the nanostructure of consolidated materials via these techniques. Potentially, SPS and related technologies have many significant advantages over the conventional powder processing methods, including the lower process temperature, the shorter holding time, dramatically improved properties of sintered products, low manufacturing costs, and environmental friendliness.

In this Special Issue, modern trends of field-assisted sintering, including the processing fundamentals and optimization of final product properties, are highlighted and discussed.

It is my pleasure to invite you to submit a manuscript for this Special Issue. Full papers, communications, and reviews are all welcome.

Prof. Dr. Eugene A. Olevsky

Collection Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Materials is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript.

The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs).

Submitted papers should be well formatted and use good English. Authors may use MDPI's

English editing service prior to publication or during author revisions.

Keywords

-

sintering

-

field-assisted

-

current-assisted

-

spark-plasma

-

powder consolidation

-

ceramics

-

metal powder

-

desification

Published Papers (31 papers)

Open AccessArticle

Development of Alternative Method for Manufacturing Structural Zirconium Elements for Nuclear Engineering

by

Kirill Ozhmegov, Anna Kawalek, Dariusz Garbiec, Henryk Dyja and Alexandr Arbuz

Cited by 2 | Viewed by 2412

Abstract

Zirconium is used as a structural material for use in aggressive environments, including the core of nuclear reactors. The traditional technology of manufacturing the structural elements of zirconium nuclear reactors is characterized by a long technological process and a significant amount of waste

[...] Read more.

Zirconium is used as a structural material for use in aggressive environments, including the core of nuclear reactors. The traditional technology of manufacturing the structural elements of zirconium nuclear reactors is characterized by a long technological process and a significant amount of waste in the form of metal shavings. The paper presents the results of an alternative technology, spark plasma sintering, for manufacturing zirconium products. A complex of microstructural and mechanical studies of the obtained samples was carried out according to the ASTMB-351 standard. The sintering of zirconium powder and options for subsequent processing by various methods, including non-standard ones such as radial shear rolling, are justified.

Full article

►▼

Show Figures

Open AccessArticle

Proportional Integral Derivative Control in Spark Plasma Sintering Simulations

by

Runjian Jiang, Elisa Torresani, Guodong Cui and Eugene A. Olevsky

Cited by 1 | Viewed by 2086

Abstract

The prediction of microstructure evolution and densification behavior during the spark plasma sintering (SPS) process largely depends on accurate temperature regulation. A loop feedback control algorithm called proportional integral derivative (PID) control is a practical simulation tool, but its coefficients are often determined

[...] Read more.

The prediction of microstructure evolution and densification behavior during the spark plasma sintering (SPS) process largely depends on accurate temperature regulation. A loop feedback control algorithm called proportional integral derivative (PID) control is a practical simulation tool, but its coefficients are often determined by an inefficient “trial and error” method. This paper is devoted to proposing a numerical method based on the principles of variable coefficients to construct an optimal linear PID controller in SPS electro-thermal simulations. Different types of temperature profiles were applied to evaluate the feasibility of the proposed method. Simulation results showed that, for temperature profiles conventionally used in SPS cycles, the PID output keeps pace with the desired profile. Characterized by an imperfect time delay and overshoot/undershoot, the constructed PID controller needs further advancement to provide a more satisfactory temperature regulation for non-continuous temperature profiles. The first step towards a numerical rule for the optimal PID controller design was undertaken in this work. It is expected to provide a valuable reference for the advanced electro-thermal modeling of SPS.

Full article

►▼

Show Figures

Open AccessArticle

Gd/Sm-Pr Co-Doped Ceria: A First Report of the Precipitation Method Effect on Flash Sintering

by

Luca Spiridigliozzi, Lorenzo Pinter, Mattia Biesuz, Gianfranco Dell’Agli, Grazia Accardo and Vincenzo M. Sglavo

Cited by 17 | Viewed by 3428

Abstract

In this work, ceria-based ceramics with the composition Gd

0.14Pr

0.06Ce

0.8O

2-δ and Sm

0.14Pr

0.06Ce

0.8O

2-δ, were synthesized by a simple co-precipitation process using either ammonium carbonate or ammonia solution as a precipitating

[...] Read more.

In this work, ceria-based ceramics with the composition Gd

0.14Pr

0.06Ce

0.8O

2-δ and Sm

0.14Pr

0.06Ce

0.8O

2-δ, were synthesized by a simple co-precipitation process using either ammonium carbonate or ammonia solution as a precipitating agent. After the calcination, all of the produced samples were constituted by fluorite-structured ceria only, thus showing that both dopant and co-dopant cations were dissolved in the fluorite lattice. The ceria-based nanopowders were uniaxially compacted and consequently flash-sintered using different electrical cycles (including current-ramps). Different results were obtained as a function of both the adopted precipitating agent and the applied electrical cycle. In particular, highly densified products were obtained using current-ramps instead of “traditional” flash treatments (with the power source switching from voltage to current control at the flash event). Moreover, the powders that were synthesized using ammonia solution exhibited a low tendency to hotspot formation, whereas the materials obtained using carbonates as the precipitating agent were highly inhomogeneous. This points out for the first time the unexpected relevance of the precipitating agent (and of the powder shape/degree of agglomeration) for the flash sintering behavior.

Full article

►▼

Show Figures

Open AccessArticle

Tribological Characterization of Micron-/Nano-Sized WC-9%Co Cemented Carbides Prepared by Spark Plasma Sintering at Elevated Temperatures

by

Saleh Al Wohaibi, Abdul Samad Mohammed, Tahar Laoui, Abbas Saeed Hakeem, Akeem Yusuf Adesina and Faheemuddin Patel

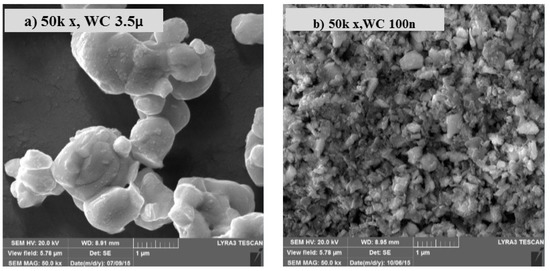

Cited by 17 | Viewed by 3599

Abstract

The present study investigates the high temperature tribological performance of spark plasma sintered, nano- and micron-sized tungsten carbide (WC) bonded by 9 wt.% cobalt (Co). The composites were fabricated using a two-step procedure of mixing followed by spark plasma sintering (SPS). Ball-on-disc wear

[...] Read more.

The present study investigates the high temperature tribological performance of spark plasma sintered, nano- and micron-sized tungsten carbide (WC) bonded by 9 wt.% cobalt (Co). The composites were fabricated using a two-step procedure of mixing followed by spark plasma sintering (SPS). Ball-on-disc wear tests were conducted at a normal load of 30 N, linear speed of 0.1 m/s under dry conditions and at three different temperatures (room temperature, 300 °C and 600 °C). Field emission scanning electron microscopy (FESEM), optical profilometry and energy dispersive X-ray (EDS) spectroscopy were used to analyze the surface morphology and the wear track area. At room temperature, it was observed that the nano-sized WC composites exhibited better wear resistance than the micron-sized WC composites. The wear resistance of the nano-sized samples declined significantly relative to that of the micron-sized samples with an increase in temperature. This decline in performance was attributed to the higher surface area of nano-sized WC particles, which underwent rapid oxidation at elevated temperatures, resulting in poor wear resistance. The wear rate observed at 600 °C for the micron-sized WC composites was 75% lower than that of the nano-sized cemented carbide. Oxidative wear was observed to be the predominant wear mechanism for both cemented carbide samples at elevated temperatures.

Full article

►▼

Show Figures

Open AccessArticle

Ordered Domains and Microwave Properties of Sub-micron Structured Ba(Zn1/3Ta2/3)O3 Ceramics Obtained by Spark Plasma Sintering

by

Fei Liu, Shaojun Liu, Xuejiao Cui, Lijin Cheng, Hao Li, Jie Wang and Weidong Rao

Cited by 7 | Viewed by 2977

Abstract

The degree of Zn

2+ and Ta

5+ ions ordering could play an important role in the dielectric loss in Ba(Zn

1/3Ta

2/3)O

3 (BZT) ceramics. However, the influence of the grain size of Ba(B′

1/3B″

2/3)O

3 ceramics

[...] Read more.

The degree of Zn

2+ and Ta

5+ ions ordering could play an important role in the dielectric loss in Ba(Zn

1/3Ta

2/3)O

3 (BZT) ceramics. However, the influence of the grain size of Ba(B′

1/3B″

2/3)O

3 ceramics with nano or sub-micron grains on the ordering domains structure is still not clear. In the present paper, highly dense (~98%) BZT microwave dielectric ceramics with homogeneous sub-micron structure (~330 nm) were prepared through spark plasma sintering (SPS). High resolution transmission electron microscopy combined with X-ray diffraction (XRD)clearly showed that the B-site ordering structure of sintered BZT samples by SPS becomes the B-site long-range 1:2 ordering as annealing proceeds. In contrast, the short-range 1:2 ordering in non-annealed counterparts was also present, which was not detectable by XRD. The size of B-site ordering domains enlarged with annealing temperature. The sub-micron structure of sintered BZT ceramics by SPS remained stable at up to 1400 C; however, the size of B-site 1:2 ordering domain was more than five times larger, which led to a significant increase of the quality factor (

Q·f) to 37,700 GHz from 15,000 GHz.

Full article

►▼

Show Figures

Open AccessArticle

Simultaneous Spark Plasma Sintering of Multiple Complex Shapes

by

Charles Manière, Elisa Torresani and Eugene A. Olevsky

Cited by 49 | Viewed by 5712

Abstract

This work addresses the two great challenges of the spark plasma sintering (SPS) process: The sintering of complex shapes and the simultaneous production of multiple parts. A new controllable interface method is employed to concurrently consolidate two nickel gear shapes by SPS. A

[...] Read more.

This work addresses the two great challenges of the spark plasma sintering (SPS) process: The sintering of complex shapes and the simultaneous production of multiple parts. A new controllable interface method is employed to concurrently consolidate two nickel gear shapes by SPS. A graphite deformable sub-mold is specifically designed for the mutual densification of both complex parts in a unique 40 mm powder deformation space. An energy efficient SPS configuration is developed to allow the sintering of a large-scale powder assembly under electric current lower than 900 A. The stability of the developed process is studied by electro-thermal-mechanical (ETM) simulation. The ETM simulation reveals that homogeneous densification conditions can be attained by inserting an alumina powder at the sample/punches interfaces, enabling the energy efficient heating and the thermal confinement of the nickel powder. Finally, the feasibility of the fabrication of the two near net shape gears with a very homogeneous microstructure is demonstrated.

Full article

►▼

Show Figures

Open AccessFeature PaperReview

Fabrication of Porous Materials by Spark Plasma Sintering: A Review

by

Dina V. Dudina, Boris B. Bokhonov and Eugene A. Olevsky

Cited by 100 | Viewed by 9890

Abstract

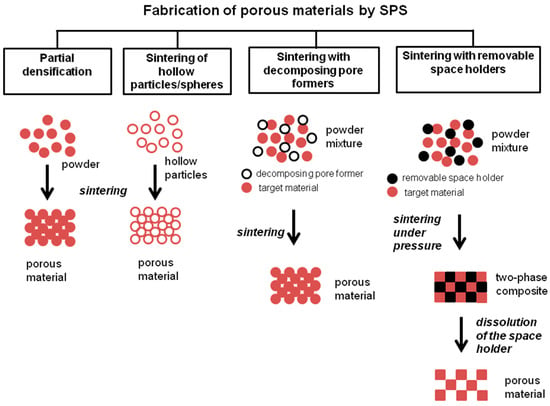

Spark plasma sintering (SPS), a sintering method that uses the action of pulsed direct current and pressure, has received a lot of attention due to its capability of exerting control over the microstructure of the sintered material and flexibility in terms of the

[...] Read more.

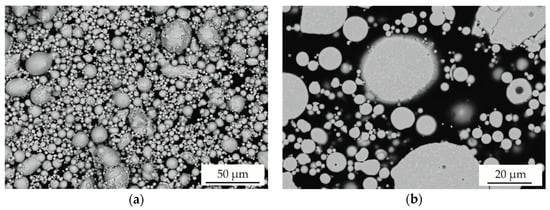

Spark plasma sintering (SPS), a sintering method that uses the action of pulsed direct current and pressure, has received a lot of attention due to its capability of exerting control over the microstructure of the sintered material and flexibility in terms of the heating rate and heating mode. Historically, SPS was developed in search of ways to preserve a fine-grained structure of the sintered material while eliminating porosity and reaching a high relative density. These goals have, therefore, been pursued in the majority of studies on the behavior of materials during SPS. Recently, the potential of SPS for the fabrication of porous materials has been recognized. This article is the first review to focus on the achievements in this area. The major approaches to the formation of porous materials by SPS are described: partial densification of powders (under low pressures, in pressureless sintering processes or at low temperatures), sintering of hollow particles/spheres, sintering of porous particles, and sintering with removable space holders or pore formers. In the case of conductive materials processed by SPS using the first approach, the formation of inter-particle contacts may be associated with local melting and non-conventional mechanisms of mass transfer. Studies of the morphology and microstructure of the inter-particle contacts as well as modeling of the processes occurring at the inter-particle contacts help gain insights into the physics of the initial stage of SPS. For pre-consolidated specimens, an SPS device can be used as a furnace to heat the materials at a high rate, which can also be beneficial for controlling the formation of porous structures. In sintering with space holders, SPS processing allows controlling the structure of the pore walls. In this article, using the literature data and our own research results, we have discussed the formation and structure of porous metals, intermetallics, ceramics, and carbon materials obtained by SPS.

Full article

►▼

Show Figures

Open AccessArticle

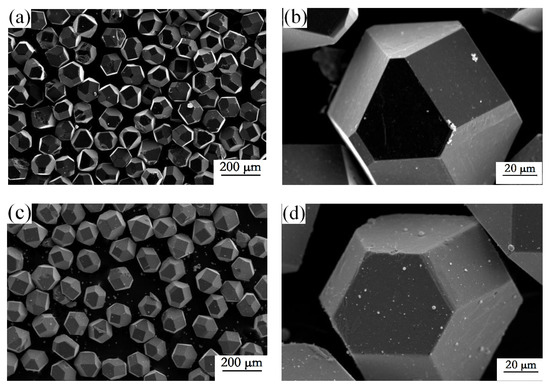

Improvement of ZrC/Zr Coating on the Interface Combination and Physical Properties of Diamond-Copper Composites Fabricated by Spark Plasma Sintering

by

Yanpeng Pan, Xinbo He, Shubin Ren, Mao Wu and Xuanhui Qu

Cited by 14 | Viewed by 3377

Abstract

In this study, diamond-copper composites were prepared with ZrC/Zr-coated diamond powders by spark plasma sintering. The magnetron sputtering technique was employed to coat the diamond particles with a zirconium layer. After heat treatment, most of the zirconium reacted with the surface of diamond

[...] Read more.

In this study, diamond-copper composites were prepared with ZrC/Zr-coated diamond powders by spark plasma sintering. The magnetron sputtering technique was employed to coat the diamond particles with a zirconium layer. After heat treatment, most of the zirconium reacted with the surface of diamond and was transformed into zirconium carbide. The remaining zirconium on the zirconium carbide surface formed the outer layer. Owing to the method used to produce the ZrC/Zr-coated diamond in this study, the maximum thermal conductivity (TC) of 609 W·m

−1·K

−1 was obtained for 60 vol. % diamond-copper composites and the corresponding coefficient of thermal expansion (CTE) reached as low as 6.75 × 10

−6 K

−1. The bending strength of 40 vol. % ZrC/Zr-coated diamond-copper composites reached 255.95 MPa. The thermal and mechanical properties of ZrC/Zr-coated diamond-copper composites were substantially superior to those of uncoated diamond particles. Excellent properties can be attributed to the strengthening of the interfacial combination and the decrease in the interfacial thermal resistance due to the improvement associated with the ZrC/Zr coating. Theoretical analysis was also proposed to compare the thermal conductivities and CTE of diamond-copper composites fabricated with these two kinds of diamond powders.

Full article

►▼

Show Figures

Open AccessArticle

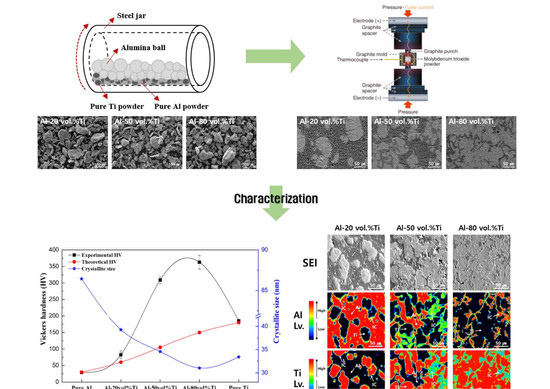

Behavior of Intermetallic Compounds of Al-Ti Composite Manufactured by Spark Plasma Sintering

by

Kwangjae Park, Dasom Kim, Kyungju Kim, Seungchan Cho and Hansang Kwon

Cited by 18 | Viewed by 4618

Abstract

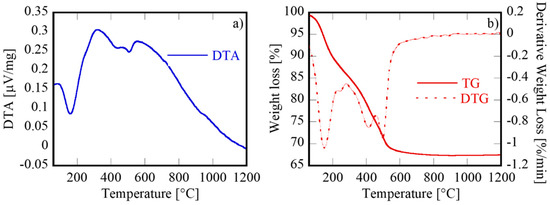

In this research, we successfully fabricate high-hardness and lightweight Al-Ti composites. Al-Ti composites powders with three compositions (Al-20, 50, and 80 vol.% Ti) are mixed using ball milling and subsequently subjected to spark plasma sintering (SPS). The microstructures and phases of the Al-Ti

[...] Read more.

In this research, we successfully fabricate high-hardness and lightweight Al-Ti composites. Al-Ti composites powders with three compositions (Al-20, 50, and 80 vol.% Ti) are mixed using ball milling and subsequently subjected to spark plasma sintering (SPS). The microstructures and phases of the Al-Ti composites are characterized using scanning electron microscopy (SEM), X-ray diffraction (XRD) spectroscopy, and field emission-electron probe microanalysis (FE-EPMA). These tests confirm the presence of several intermetallic compounds (ICs) (Al

3Ti, Al

5Ti

2, Al

11Ti

5) in the composites, and we are able to confirm that these ICs are produced by the reaction of Al and Ti during the SPS process. Furthermore, thermogravimetric-differential thermal analysis (TG-DTA) is used to analyze the formation behavior of the ICs. In addition, the mechanical properties of the composites are measured using their Vickers hardness and it is observed that the Al-80 vol.% Ti composite exhibits the highest hardness. Consequently, it is assumed that SPS is suitable for fabricating Al-Ti composites which represent the next-generation materials to be used in various industrial fields as high-hardness and lightweight materials.

Full article

►▼

Show Figures

Open AccessArticle

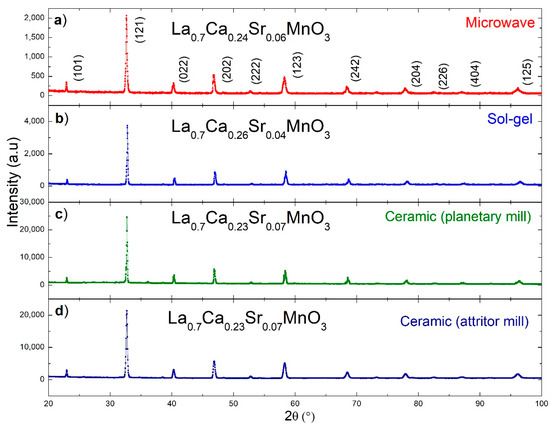

Preparation of La0.7Ca0.3−xSrxMnO3 Manganites by Four Synthesis Methods and Their Influence on the Magnetic Properties and Relative Cooling Power

by

María E. Botello-Zubiate, María C. Grijalva-Castillo, Daniel Soto-Parra, Renee J. Sáenz-Hernández, Carlos R. Santillán-Rodríguez and José A. Matutes-Aquino

Cited by 9 | Viewed by 3865

Abstract

Manganites of the family La

0.7Ca

0.3−xSr

xMnO

3 were fabricated by four preparation methods: (a) the microwave-assisted sol-gel Pechini method; (b) sol-gel Pechini chemical synthesis; (c) solid-state reaction with a planetary mill; and (d) solid-state reaction with an attritor

[...] Read more.

Manganites of the family La

0.7Ca

0.3−xSr

xMnO

3 were fabricated by four preparation methods: (a) the microwave-assisted sol-gel Pechini method; (b) sol-gel Pechini chemical synthesis; (c) solid-state reaction with a planetary mill; and (d) solid-state reaction with an attritor mill, in order to study the effect of the preparation route used on its magnetocaloric and magnetic properties. In addition, the manganites manufactured by the Pechini sol-gel method were compacted using Spark Plasma Sintering (SPS) to determine how the consolidation process influences its magnetocaloric properties. The Curie temperatures of manganites prepared by the different methods were determined in ~295 K, with the exception of those prepared by a solid-state reaction with an attritor mill which was 301 K, so there is no correlation between the particle size and the Curie temperature. All samples gave a positive slope in the Arrot plots, which implies that the samples underwent a second order Ferromagnetic (FM)–Paramagnetic (PM) phase transition. Pechini sol-gel manganite presents higher values of Relative Cooling Power (RCP) than the solid-state reaction manganite, because its entropy change curves are smaller, but wider, associated to the particle size obtained by the preparation method. The SPS technique proved to be easier and faster in producing consolidated solids for applications in active magnetic regenerative refrigeration compared with other compaction methods.

Full article

►▼

Show Figures

Open AccessArticle

Enhanced Wear Behaviour of Spark Plasma Sintered AlCoCrFeNiTi High-Entropy Alloy Composites

by

Martin Löbel, Thomas Lindner and Thomas Lampke

Cited by 23 | Viewed by 4056

Abstract

High hardness and good wear resistance have been revealed for the high-entropy alloy (HEA) system AlCoCrFeNiTi, confirming the potential for surface protection applications. Detailed studies to investigate the microstructure and phase formation have been carried out using different production routes. Powder metallurgical technologies

[...] Read more.

High hardness and good wear resistance have been revealed for the high-entropy alloy (HEA) system AlCoCrFeNiTi, confirming the potential for surface protection applications. Detailed studies to investigate the microstructure and phase formation have been carried out using different production routes. Powder metallurgical technologies allow for much higher flexibility in the customisation of materials compared to casting processes. Particularly, spark plasma sintering (SPS) enables the fast processing of the feedstock, the suppression of grain coarsening and the production of samples with a low porosity. Furthermore, solid lubricants can be incorporated for the improvement of wear resistance and the reduction of the coefficient of friction (COF). This study focuses on the production of AlCoCrFeNiTi composites comprising solid lubricants. Bulk materials with a MoS

2 content of up to 15 wt % were produced. The wear resistance and COF were investigated in detail under sliding wear conditions in ball-on-disk tests at room temperature and elevated temperature. At least 10 wt % of MoS

2 was required to improve the wear behaviour in both test conditions. Furthermore, the effects of the production route and the content of solid lubricant on microstructure formation and phase composition were investigated. Two major body-centred cubic (bcc) phases were detected in accordance with the feedstock. The formation of additional phases indicated the decomposition of MoS

2.

Full article

►▼

Show Figures

Open AccessArticle

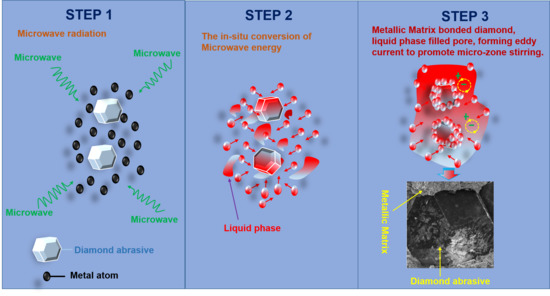

Optimization of Process Parameters for Preparing Metallic Matrix Diamond Tool Bits by Microwave Pressureless Sintering Using Response Surface Methodology

by

Li Yang, Liang Wang, Jiyun Gao, Shenghui Guo, Xiaolei Ye, Sivasankar Koppala, Tu Hu, Ming Hou and Longtao Hu

Cited by 10 | Viewed by 3733

Abstract

The process of preparing metallic matrix diamond tool bits by microwave pressureless sintering (MPS) was exclusively studied in this paper. The effects of the sintering temperature, the cold pressure, and the holding time on the mechanical properties of the bit were determined by

[...] Read more.

The process of preparing metallic matrix diamond tool bits by microwave pressureless sintering (MPS) was exclusively studied in this paper. The effects of the sintering temperature, the cold pressure, and the holding time on the mechanical properties of the bit were determined by using the response surface methodology (RSM) with Box-Behnken Design (BBD). In addition, with RSM, the second-order polynomial equation of mechanical properties was obtained. The solutions were well matched with the experimental values. This indicates that major variations in mechanical properties of the sintered sample could be predicted by the models, which shows that the applied model is accurate. Conventional pressureless sintering (CPS) experiments were also conducted to make a comparison. The experimental results showed that the MPS can enhance the mechanical properties of sintered samples. A possible MPS mechanism is proposed in this work after analyzing all the experimental results.

Full article

►▼

Show Figures

Open AccessArticle

Fabrication of Cu Based Metallic Binder for Diamond Tools by Microwave Pressureless Sintering

by

Shenghui Guo, Xiaolei Ye, Liang Wang, Sivasankar Koppala, Li Yang, Tu Hu, Jiyun Gao, Ming Hou and Longtao Hu

Cited by 7 | Viewed by 4724

Abstract

Microwave pressureless sintering (MPS) method is successfully applied in the fabrication of Cu based metallic matrix for diamond tools. The main purpose of this work is to obtain better mechanical properties when the metal binder of the diamond tools was prepared by the

[...] Read more.

Microwave pressureless sintering (MPS) method is successfully applied in the fabrication of Cu based metallic matrix for diamond tools. The main purpose of this work is to obtain better mechanical properties when the metal binder of the diamond tools was prepared by the MPS method. The orthogonal experimental method is adopted to design the sintering process parameters. The optimized experimental conditions are suggested as 880 °C of sintering temperature, 375 MPa of cold pressure, and 35 min of withholding time. The contrastive investigation of the MPS and conventional pressureless sintering (CPS) are performed under optimized conditions. The microstructures information are obtained by scanning electron microscopy (SEM), X-ray diffraction (XRD), electron probe microanalysis (EPMA), and the necessary mechanical properties, such as relative density, hardness, and flexural strength are tested. Experimental results show that the MPS method, compared with CPS, can significantly improve the mechanical properties of the metallic matrix. The factors of relative density, hardness, and flexural strength increase 1.25%, 3.86%, and 6.28%, respectively. The possible sintering mechanism of the MPS method is also discussed. This work may provide a reference for the fabrication of metal-based diamond tools by microwave heating method.

Full article

►▼

Show Figures

Open AccessArticle

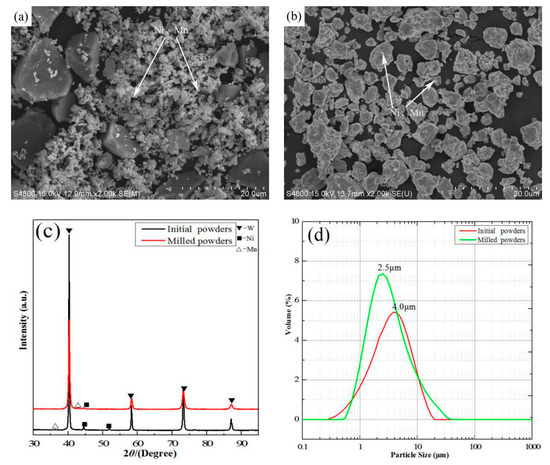

Mechanical Milling-Assisted Spark Plasma Sintering of Fine-Grained W-Ni-Mn Alloy

by

Yanlin Pan, Daoping Xiang, Ning Wang, Hui Li and Zhishuai Fan

Cited by 8 | Viewed by 3640

Abstract

Fine-grained W-6Ni-4Mn alloys were fabricated by spark plasma sintering (SPS) using mechanical milling W, Ni and Mn composite powders. The relative density of W-6Ni-4Mn alloy increases from 71.56% to 99.60% when it is sintered at a low temperature range of 1000–1200 °C for

[...] Read more.

Fine-grained W-6Ni-4Mn alloys were fabricated by spark plasma sintering (SPS) using mechanical milling W, Ni and Mn composite powders. The relative density of W-6Ni-4Mn alloy increases from 71.56% to 99.60% when it is sintered at a low temperature range of 1000–1200 °C for 3 min. The spark plasma sintering process of the alloy can be divided into three stages, which clarify the densification process of powder compacts. As the sintering temperature increases, the average W grain size increases but remains at less than 7 µm and the distribution of the binding phase is uniform. Transmission electron microscopy (TEM) observation reveals that the W-6Ni-4Mn alloy consists of the tungsten phase and the γ-(Ni, Mn, W) binding phase. As the sintering temperature increases, the Rockwell hardness and bending strength of alloys initially increases and then decreases. The optimum comprehensive hardness and bending strength of the alloy are obtained at 1150 °C. The main fracture mode of the alloys is W/W interface fracture.

Full article

►▼

Show Figures

Open AccessArticle

Closed Die Upsetting of Aluminum Matrix Composites Reinforced with Molybdenum Disulfide Nanocrystals and Multilayer Graphene, Implemented using the SPS Process—Microstructure Evolution

by

Marek Kostecki, Mateusz Petrus, Jarosław Woźniak, Tomasz Cygan and Andrzej Olszyna

Cited by 5 | Viewed by 4423

Abstract

New methods for producing composite materials such as SPS (Spark Plasma Sintering) are becoming more and more popular due to the ease of implementation in industrial conditions and the versatility of the materials used for processing. In order to fully exploit the potential

[...] Read more.

New methods for producing composite materials such as SPS (Spark Plasma Sintering) are becoming more and more popular due to the ease of implementation in industrial conditions and the versatility of the materials used for processing. In order to fully exploit the potential of this method, modifications were proposed which consisted in the deliberate induction of deformation during the sintering process. The influence of the manufacturing method on the microstructure of aluminum alloy matrix composites reinforced with layered crystals in the form of nanoflakes was investigated. Composites with the addition of 10 vol % of multilayer graphene and molybdenum disulfide were prepared and their density, hardness, and the influence of the deformation ratio on the changes occurring in the microstructure were examined. The potential of the method to shape the properties of the tested composites and the strong dependence of the obtained results on the morphology of the reinforcing phase was indicated. An interesting phenomenon observed for composites with the addition of MoS

2 during the process was the reaction of the components leading to in situ formation of the Al

12Mo intermetallic phase.

Full article

►▼

Show Figures

Open AccessArticle

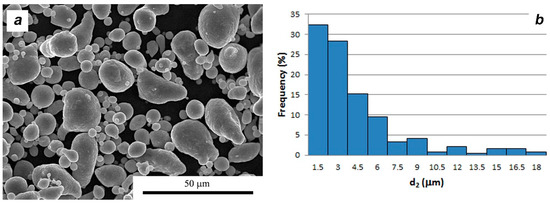

Fabrication of Titanium-Niobium-Zirconium-Tantalium Alloy (TNZT) Bioimplant Components with Controllable Porosity by Spark Plasma Sintering

by

Jack Rechtin, Elisa Torresani, Eugene Ivanov and Eugene Olevsky

Cited by 15 | Viewed by 5559

Abstract

Spark Plasma Sintering (SPS) is used to fabricate Titanium-Niobium-Zirconium-Tantalum alloy (TNZT) powder—based bioimplant components with controllable porosity. The developed densification maps show the effects of final SPS temperature, pressure, holding time, and initial particle size on final sample relative density. Correlations between the

[...] Read more.

Spark Plasma Sintering (SPS) is used to fabricate Titanium-Niobium-Zirconium-Tantalum alloy (TNZT) powder—based bioimplant components with controllable porosity. The developed densification maps show the effects of final SPS temperature, pressure, holding time, and initial particle size on final sample relative density. Correlations between the final sample density and mechanical properties of the fabricated TNZT components are also investigated and microstructural analysis of the processed material is conducted. A densification model is proposed and used to calculate the TNZT alloy creep activation energy. The obtained experimental data can be utilized for the optimized fabrication of TNZT components with specific microstructural and mechanical properties suitable for biomedical applications.

Full article

►▼

Show Figures

Open AccessFeature PaperArticle

On the Mechanism of Microwave Flash Sintering of Ceramics

by

Yury V. Bykov, Sergei V. Egorov, Anatoly G. Eremeev, Vladislav V. Kholoptsev, Ivan V. Plotnikov, Kirill I. Rybakov and Andrei A. Sorokin

Cited by 67 | Viewed by 8129

Abstract

The results of a study of ultra-rapid (flash) sintering of oxide ceramic materials under microwave heating with high absorbed power per unit volume of material (10–500 W/cm

3) are presented. Ceramic samples of various compositions—Al

2O

3; Y

2O

[...] Read more.

The results of a study of ultra-rapid (flash) sintering of oxide ceramic materials under microwave heating with high absorbed power per unit volume of material (10–500 W/cm

3) are presented. Ceramic samples of various compositions—Al

2O

3; Y

2O

3; MgAl

2O

4; and Yb(LaO)

2O

3—were sintered using a 24 GHz gyrotron system to a density above 0.98–0.99 of the theoretical value in 0.5–5 min without isothermal hold. An analysis of the experimental data (microwave power; heating and cooling rates) along with microstructure characterization provided an insight into the mechanism of flash sintering. Flash sintering occurs when the processing conditions—including the temperature of the sample; the properties of thermal insulation; and the intensity of microwave radiation—facilitate the development of thermal runaway due to an Arrhenius-type dependency of the material’s effective conductivity on temperature. The proper control over the thermal runaway effect is provided by fast regulation of the microwave power. The elevated concentration of defects and impurities in the boundary regions of the grains leads to localized preferential absorption of microwave radiation and results in grain boundary softening/pre-melting. The rapid densification of the granular medium with a reduced viscosity of the grain boundary phase occurs via rotation and sliding of the grains which accommodate their shape due to fast diffusion mass transport through the (quasi-)liquid phase. The same mechanism based on a thermal runaway under volumetric heating can be relevant for the effect of flash sintering of various oxide ceramics under a dc/ac voltage applied to the sample.

Full article

►▼

Show Figures

Open AccessArticle

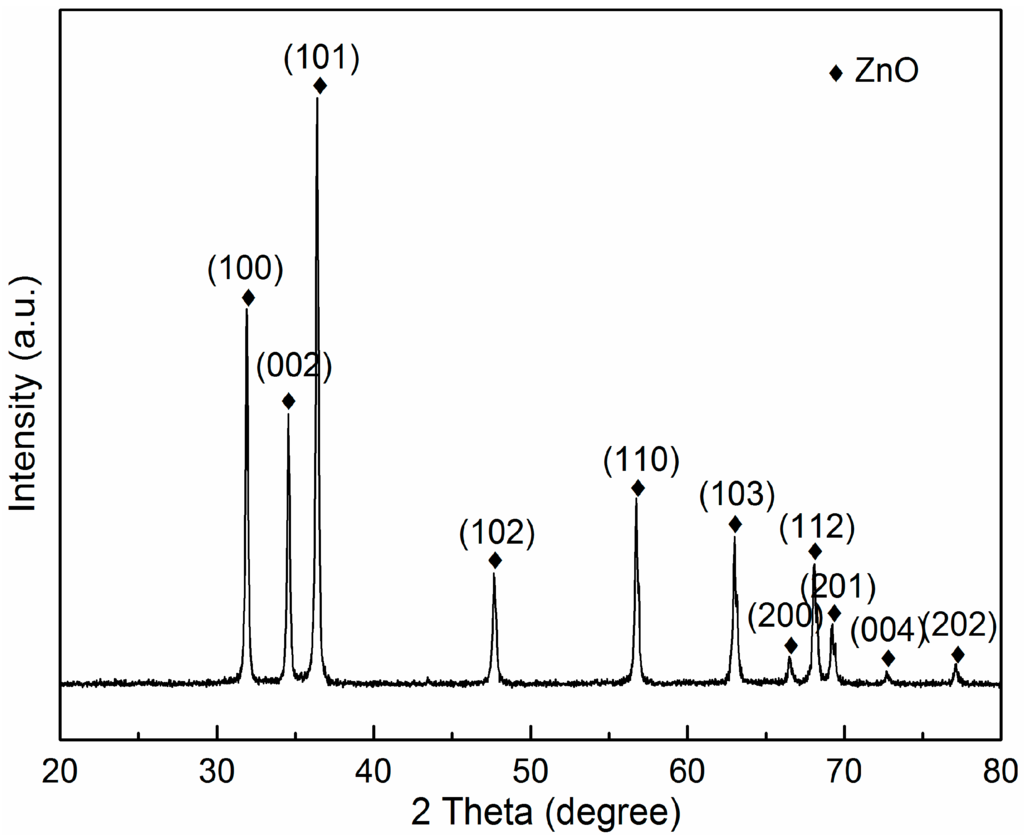

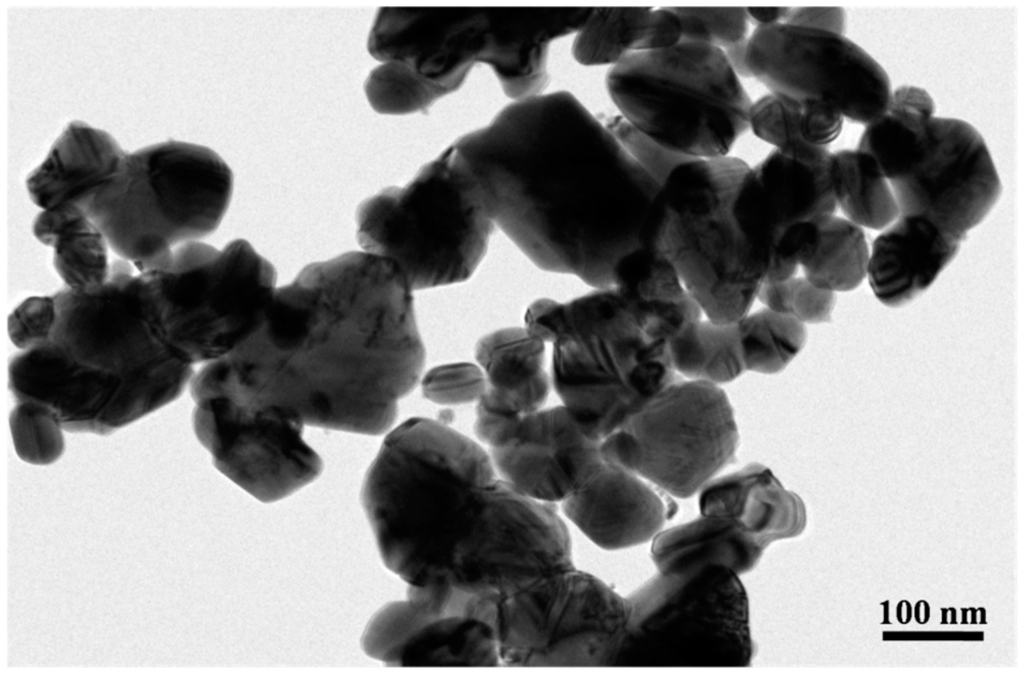

Microstructure and Electrical Properties of AZO/Graphene Nanosheets Fabricated by Spark Plasma Sintering

by

Shuang Yang, Fei Chen, Qiang Shen, Enrique J. Lavernia and Lianmeng Zhang

Cited by 8 | Viewed by 5431

Abstract

In this study we report on the sintering behavior, microstructure and electrical properties of Al-doped ZnO ceramics containing 0–0.2 wt. % graphene sheets (AZO-GNSs) and processed using spark plasma sintering (SPS). Our results show that the addition of <0.25 wt. % GNSs enhances

[...] Read more.

In this study we report on the sintering behavior, microstructure and electrical properties of Al-doped ZnO ceramics containing 0–0.2 wt. % graphene sheets (AZO-GNSs) and processed using spark plasma sintering (SPS). Our results show that the addition of <0.25 wt. % GNSs enhances both the relative density and the electrical resistivity of AZO ceramics. In terms of the microstructure, the GNSs are distributed at grain boundaries. In addition, the GNSs are also present between ZnO and secondary phases (e.g., ZnAl

2O

4) and likely contribute to the measured enhancement of Hall mobility (up to 105.1 cm

2·V

−1·s

−1) in these AZO ceramics. The minimum resistivity of the AZO-GNS composite ceramics is 3.1 × 10

−4 Ω·cm which compares favorably to the value of AZO ceramics which typically have a resistivity of 1.7 × 10

−3 Ω·cm.

Full article

►▼

Show Figures

Open AccessArticle

Zirconium Carbide Produced by Spark Plasma Sintering and Hot Pressing: Densification Kinetics, Grain Growth, and Thermal Properties

by

Xialu Wei, Christina Back, Oleg Izhvanov, Christopher D. Haines and Eugene A. Olevsky

Cited by 25 | Viewed by 9479

Abstract

Spark plasma sintering (SPS) has been employed to consolidate a micron-sized zirconium carbide (ZrC) powder. ZrC pellets with a variety of relative densities are obtained under different processing parameters. The densification kinetics of ZrC powders subjected to conventional hot pressing and SPS are

[...] Read more.

Spark plasma sintering (SPS) has been employed to consolidate a micron-sized zirconium carbide (ZrC) powder. ZrC pellets with a variety of relative densities are obtained under different processing parameters. The densification kinetics of ZrC powders subjected to conventional hot pressing and SPS are comparatively studied by applying similar heating and loading profiles. Due to the lack of electric current assistance, the conventional hot pressing appears to impose lower strain rate sensitivity and higher activation energy values than those which correspond to the SPS processing. A finite element simulation is used to analyze the temperature evolution within the volume of ZrC specimens subjected to SPS. The control mechanism for grain growth during the final SPS stage is studied via a recently modified model, in which the grain growth rate dependence on porosity is incorporated. The constant pressure specific heat and thermal conductivity of the SPS-processed ZrC are determined to be higher than those reported for the hot-pressed ZrC and the benefits of applying SPS are indicated accordingly.

Full article

►▼

Show Figures

Open AccessArticle

Characterizations of Rapid Sintered Nanosilver Joint for Attaching Power Chips

by

Shuang-Tao Feng, Yun-Hui Mei, Gang Chen, Xin Li and Guo-Quan Lu

Cited by 23 | Viewed by 7718

Abstract

Sintering of nanosilver paste has been extensively studied as a lead-free die-attach solution for bonding semiconductor power chips, such as the power insulated gated bipolar transistor (IGBT). However, for the traditional method of bonding IGBT chips, an external pressure of a few MPa

[...] Read more.

Sintering of nanosilver paste has been extensively studied as a lead-free die-attach solution for bonding semiconductor power chips, such as the power insulated gated bipolar transistor (IGBT). However, for the traditional method of bonding IGBT chips, an external pressure of a few MPa is reported necessary for the sintering time of ~1 h. In order to shorten the processing duration time, we developed a rapid way to sinter nanosilver paste for bonding IGBT chips in less than 5 min using pulsed current. In this way, we firstly dried as-printed paste at about 100 °C to get rid of many volatile solvents because they may result in defects or voids during the out-gassing from the paste. Then, the pre-dried paste was further heated by pulse current ranging from 1.2 kA to 2.4 kA for several seconds. The whole procedure was less than 3 min and did not require any gas protection. We could obtain robust sintered joint with shear strength of 30–35 MPa for bonding 1200-V, 25-A IGBT and superior thermal properties. Static and dynamic electrical performance of the as-bonded IGBT assemblies was also characterized to verify the feasibility of this rapid sintering method. The results indicate that the electrical performance is comparable or even partially better than that of commercial IGBT modules. The microstructure evolution of the rapid sintered joints was also studied by scanning electron microscopy (SEM). This work may benefit the wide usage of nanosilver paste for rapid bonding IGBT chips in the future.

Full article

►▼

Show Figures

Open AccessFeature PaperArticle

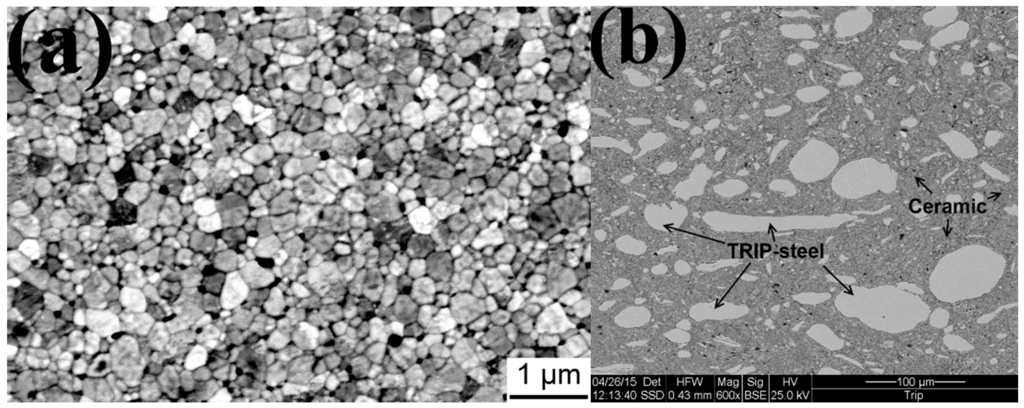

Bonding of TRIP-Steel/Al2O3-(3Y)-TZP Composites and (3Y)-TZP Ceramic by a Spark Plasma Sintering (SPS) Apparatus

by

Aslan Miriyev, Steffen Grützner, Lutz Krüger, Sergey Kalabukhov and Nachum Frage

Cited by 10 | Viewed by 6498

Abstract

A combination of the high damage tolerance of TRIP-steel and the extremely low thermal conductivity of partially stabilized zirconia (PSZ) can provide controlled thermal-mechanical properties to sandwich-shaped composite specimens comprising these materials. Sintering the (TRIP-steel-PSZ)/PSZ sandwich in a single step is very difficult

[...] Read more.

A combination of the high damage tolerance of TRIP-steel and the extremely low thermal conductivity of partially stabilized zirconia (PSZ) can provide controlled thermal-mechanical properties to sandwich-shaped composite specimens comprising these materials. Sintering the (TRIP-steel-PSZ)/PSZ sandwich in a single step is very difficult due to differences in the sintering temperature and densification kinetics of the composite and the ceramic powders. In the present study, we successfully applied a two-step approach involving separate SPS consolidation of pure (3Y)-TZP and composites containing 20 vol % TRIP-steel, 40 vol % Al

2O

3 and 40 vol % (3Y)-TZP ceramic phase, and subsequent diffusion joining of both sintered components in an SPS apparatus. The microstructure and properties of the sintered and bonded specimens were characterized. No defects at the interface between the TZP and the composite after joining in the 1050–1150 °C temperature range were observed. Only limited grain growth occurred during joining, while crystallite size, hardness, shear strength and the fraction of the monoclinic phase in the TZP ceramic virtually did not change. The slight increase of the TZP layer’s fracture toughness with the joining temperature was attributed to the effect of grain size on transformation toughening.

Full article

►▼

Show Figures

Open AccessArticle

The Manufacturing of High Porosity Iron with an Ultra-Fine Microstructure via Free Pressureless Spark Plasma Sintering

by

Guodong Cui, Xialu Wei, Eugene A. Olevsky, Randall M. German and Junying Chen

Cited by 18 | Viewed by 6412

Abstract

High porosity (>40 vol %) iron specimens with micro- and nanoscale isotropic pores were fabricated by carrying out free pressureless spark plasma sintering (FPSPS) of submicron hollow Fe–N powders at 750 °C. Ultra-fine porous microstructures are obtained by imposing high heating rates during

[...] Read more.

High porosity (>40 vol %) iron specimens with micro- and nanoscale isotropic pores were fabricated by carrying out free pressureless spark plasma sintering (FPSPS) of submicron hollow Fe–N powders at 750 °C. Ultra-fine porous microstructures are obtained by imposing high heating rates during the preparation process. This specially designed approach not only avoids the extra procedures of adding and removing space holders during the formation of porous structures, but also triggers the continued phase transitions of the Fe–N system at relatively lower processing temperatures. The compressive strength and energy absorption characteristics of the FPSPS processed specimens are examined here to be correspondingly improved as a result of the refined microstructure.

Full article

►▼

Show Figures

Open AccessFeature PaperArticle

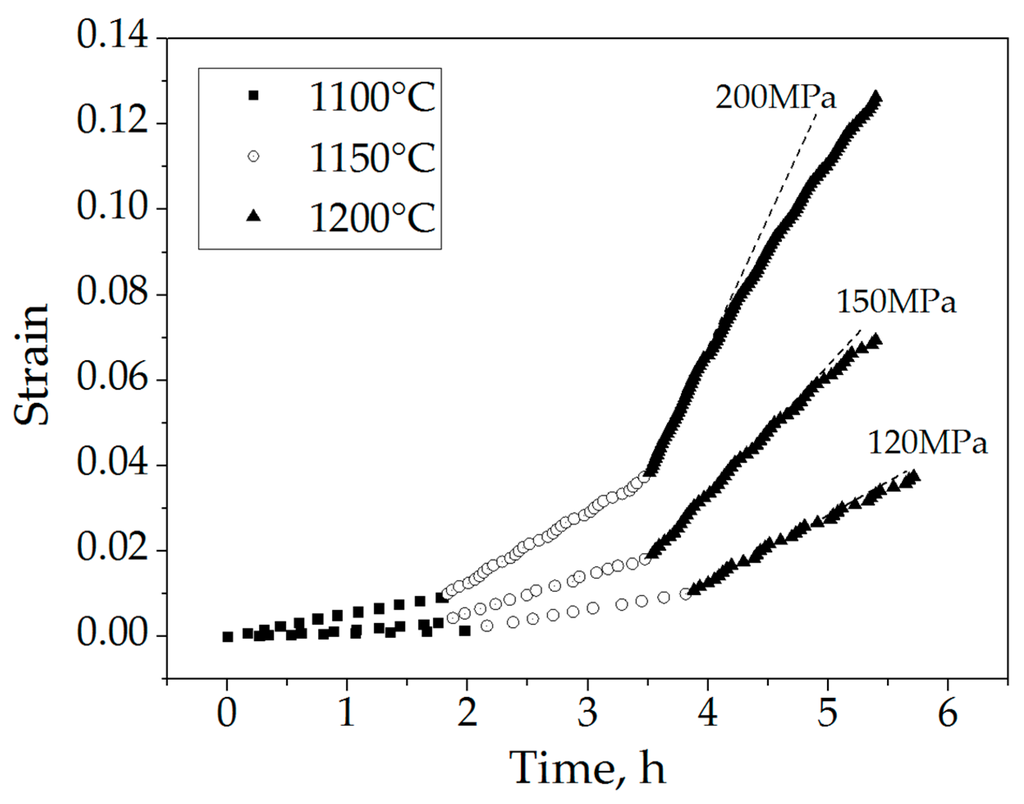

Creep of Polycrystalline Magnesium Aluminate Spinel Studied by an SPS Apparatus

by

Barak Ratzker, Maxim Sokol, Sergey Kalabukhov and Nachum Frage

Cited by 18 | Viewed by 7599

Abstract

A spark plasma sintering (SPS) apparatus was used for the first time as an analytical testing tool for studying creep in ceramics at elevated temperatures. Compression creep experiments on a fine-grained (250 nm) polycrystalline magnesium aluminate spinel were successfully performed in the 1100–1200

[...] Read more.

A spark plasma sintering (SPS) apparatus was used for the first time as an analytical testing tool for studying creep in ceramics at elevated temperatures. Compression creep experiments on a fine-grained (250 nm) polycrystalline magnesium aluminate spinel were successfully performed in the 1100–1200 °C temperature range, under an applied stress of 120–200 MPa. It was found that the stress exponent and activation energy depended on temperature and applied stress, respectively. The deformed samples were characterized by high resolution scanning electron microscope (HRSEM) and high resolution transmission electron microscope (HRTEM). The results indicate that the creep mechanism was related to grain boundary sliding, accommodated by dislocation slip and climb. The experimental results, extrapolated to higher temperatures and lower stresses, were in good agreement with data reported in the literature.

Full article

►▼

Show Figures

Open AccessArticle

Processing, Mechanical and Optical Properties of Additive-Free ZrC Ceramics Prepared by Spark Plasma Sintering

by

Clara Musa, Roberta Licheri, Roberto Orrù, Giacomo Cao, Diletta Sciti, Laura Silvestroni, Luca Zoli, Andrea Balbo, Luca Mercatelli, Marco Meucci and Elisa Sani

Cited by 17 | Viewed by 6311

Abstract

In the present study, nearly fully dense monolithic ZrC samples are produced and broadly characterized from microstructural, mechanical and optical points of view. Specifically, 98% dense products are obtained by Spark Plasma Sintering (SPS) after 20 min dwell time at 1850 °C starting

[...] Read more.

In the present study, nearly fully dense monolithic ZrC samples are produced and broadly characterized from microstructural, mechanical and optical points of view. Specifically, 98% dense products are obtained by Spark Plasma Sintering (SPS) after 20 min dwell time at 1850 °C starting from powders preliminarily prepared by Self-propagating High-temperature Synthesis (SHS) followed by 20 min ball milling. A prolonged mechanical treatment up to 2 h of SHS powders does not lead to appreciable benefits. Vickers hardness of the resulting samples (17.5 ± 0.4 GPa) is reasonably good for monolithic ceramics, but the mechanical strength (about 250 MPa up to 1000 °C) could be further improved by suitable optimization of the starting powder characteristics. The very smoothly polished ZrC specimen subjected to optical measurements displays high absorption in the visible-near infrared region and low thermal emittance at longer wavelengths. Moreover, the sample exhibits goodspectral selectivity (2.1–2.4) in the 1000–1400 K temperature range. These preliminary results suggest that ZrC ceramics produced through the two-step SHS/SPS processing route can be considered as attractive reference materials for the development of innovative solar energy absorbers.

Full article

►▼

Show Figures

Open AccessArticle

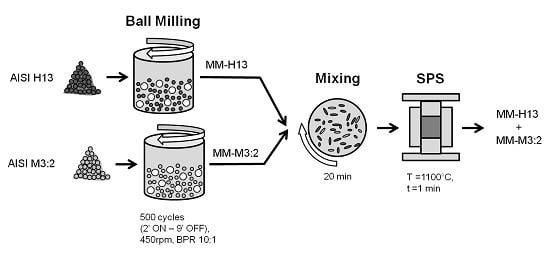

Spark Plasma Co-Sintering of Mechanically Milled Tool Steel and High Speed Steel Powders

by

Massimo Pellizzari, Anna Fedrizzi and Mario Zadra

Cited by 9 | Viewed by 7914

Abstract

Hot work tool steel (AISI H13) and high speed steel (AISI M3:2) powders were successfully co-sintered to produce hybrid tool steels that have properties and microstructures that can be modulated for specific applications. To promote co-sintering, which is made difficult by the various

[...] Read more.

Hot work tool steel (AISI H13) and high speed steel (AISI M3:2) powders were successfully co-sintered to produce hybrid tool steels that have properties and microstructures that can be modulated for specific applications. To promote co-sintering, which is made difficult by the various densification kinetics of the two steels, the particle sizes and structures were refined by mechanical milling (MM). Near full density samples (>99.5%) showing very fine and homogeneous microstructure were obtained using spark plasma sintering (SPS). The density of the blends (20, 40, 60, 80 wt % H13) was in agreement with the linear rule of mixtures. Their hardness showed a positive deviation, which could be ascribed to the strengthening effect of the secondary particles altering the stress distribution during indentation. A toughening of the M3:2-rich blends could be explained in view of the crack deviation and crack arrest exerted by the H13 particles.

Full article

►▼

Show Figures

Open AccessArticle

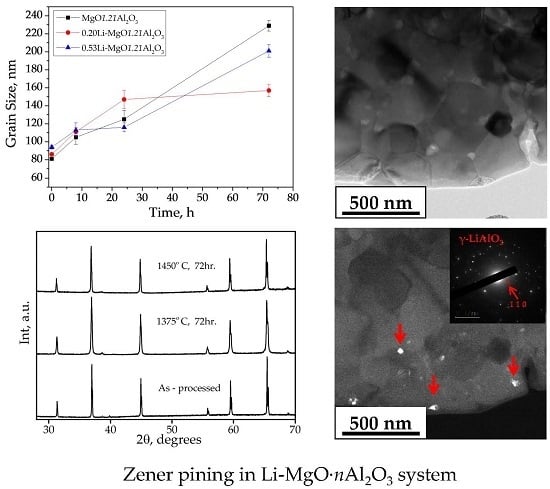

The Effect of Lithium Doping on the Sintering and Grain Growth of SPS-Processed, Non-Stoichiometric Magnesium Aluminate Spinel

by

Yuval Mordekovitz, Lee Shelly, Mahdi Halabi, Sergey Kalabukhov and Shmuel Hayun

Cited by 15 | Viewed by 6081

Abstract

The effects of lithium doping on the sintering and grain growth of non-stoichiometric nano-sized magnesium aluminate spinel were studied using a spark plasma sintering (SPS) apparatus. Li-doped nano-MgO·

nAl

2O

3 spinel (

n = 1.06 and 1.21) powders containing 0,

[...] Read more.

The effects of lithium doping on the sintering and grain growth of non-stoichiometric nano-sized magnesium aluminate spinel were studied using a spark plasma sintering (SPS) apparatus. Li-doped nano-MgO·

nAl

2O

3 spinel (

n = 1.06 and 1.21) powders containing 0, 0.20, 0.50 or 1.00 at. % Li were synthesized by the solution combustion method and dense specimens were processed using a SPS apparatus at 1200 °C and under an applied pressure of 150 MPa. The SPS-processed samples showed mutual dependency on the lithium concentration and the alumina-to-magnesia ratio. For example, the density and hardness values of near-stoichiometry samples (

n = 1.06) showed an incline up to 0.51 at. % Li, while in the alumina rich samples (

n = 1.21), these values remained constant up to 0.53 at. % Li. Studying grain growth revealed that in the Li-MgO·

nAl

2O

3 system, grain growth is limited by Zener pining. The activation energies of undoped, 0.2 and 0.53 at. % Li-MgO·1.21Al

2O

3 samples were 288 ± 40, 670 ± 45 and 543 ± 40 kJ·mol

−1, respectively.

Full article

►▼

Show Figures

Open AccessArticle

Formation of Aluminum Particles with Shell Morphology during Pressureless Spark Plasma Sintering of Fe–Al Mixtures: Current-Related or Kirkendall Effect?

by

Dina V. Dudina, Boris B. Bokhonov and Amiya K. Mukherjee

Cited by 13 | Viewed by 6119

Abstract

A need to deeper understand the influence of electric current on the structure and properties of metallic materials consolidated by Spark Plasma Sintering (SPS) stimulates research on inter-particle interactions, bonding and necking processes in low-pressure or pressureless conditions as favoring technique-specific local effects

[...] Read more.

A need to deeper understand the influence of electric current on the structure and properties of metallic materials consolidated by Spark Plasma Sintering (SPS) stimulates research on inter-particle interactions, bonding and necking processes in low-pressure or pressureless conditions as favoring technique-specific local effects when electric current passes through the underdeveloped inter-particle contacts. Until now, inter-particle interactions during pressureless SPS have been studied mainly for particles of the same material. In this work, we focused on the interactions between particles of dissimilar materials in mixtures of micrometer-sized Fe and Al powders forming porous compacts during pressureless SPS at 500–650 °C. Due to the chemical interaction between Al and Fe, necks of conventional shape did not form between the dissimilar particles. At the early interaction stages, the Al particles acquired shell morphology. It was shown that this morphology change was not related to the influence of electric current but was due to the Kirkendall effect in the Fe–Al system and particle rearrangement in a porous compact. No experimental evidence of melting or melt ejection during pressureless SPS of the Fe–Al mixtures or Fe and Al powders sintered separately was observed. Porous FeAl-based compacts could be obtained from Fe-40at.%Al mixtures by pressureless SPS at 650 °C.

Full article

►▼

Show Figures

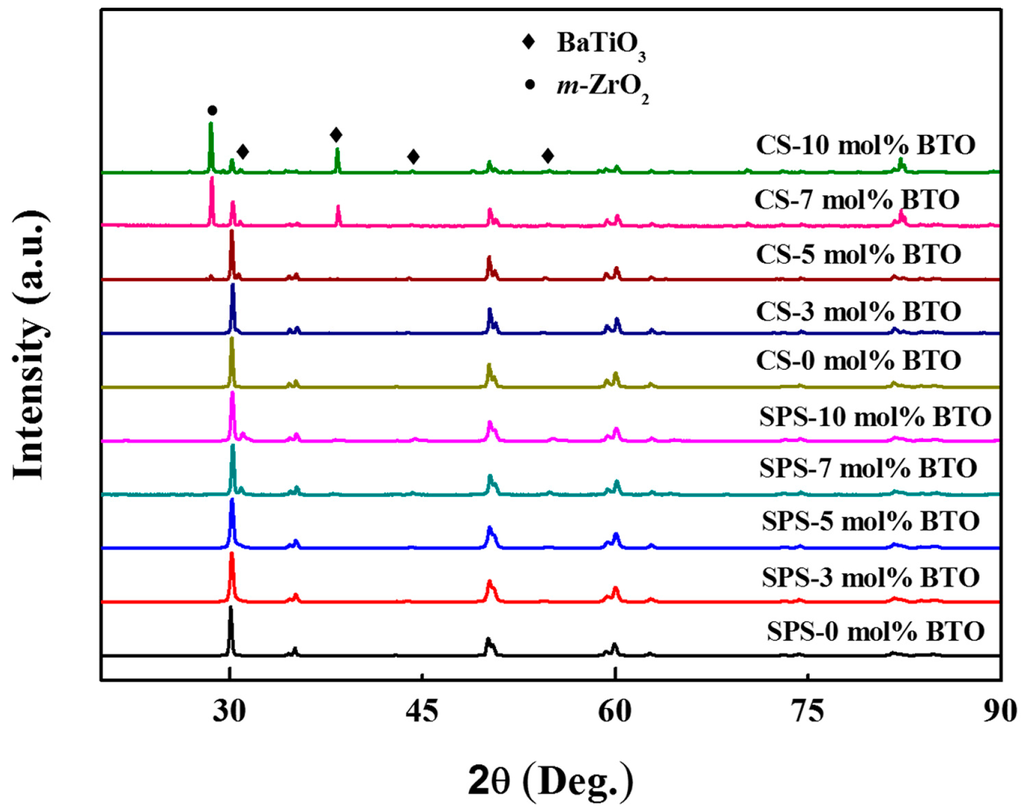

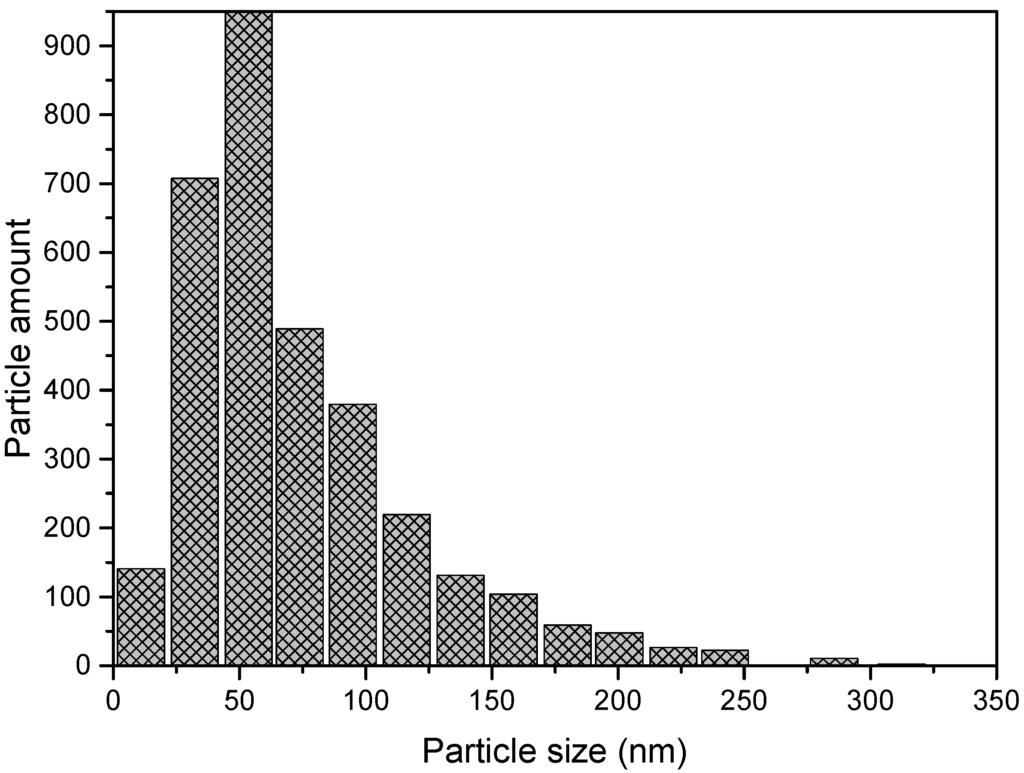

Open AccessArticle

The Effects of Spark-Plasma Sintering (SPS) on the Microstructure and Mechanical Properties of BaTiO3/3Y-TZP Composites

by

Jing Li, Bencang Cui, Huining Wang, Yuanhua Lin, Xuliang Deng, Ming Li and Cewen Nan

Cited by 15 | Viewed by 5888

Abstract

Composite ceramics BaTiO

3/3Y-TZP containing 0 mol %, 3 mol %, 5 mol %, 7 mol %, and 10 mol % BaTiO

3 have been prepared by conventional sintering and spark-plasma sintering (SPS), respectively. Analysis of the XRD patterns and Raman spectra

[...] Read more.

Composite ceramics BaTiO

3/3Y-TZP containing 0 mol %, 3 mol %, 5 mol %, 7 mol %, and 10 mol % BaTiO

3 have been prepared by conventional sintering and spark-plasma sintering (SPS), respectively. Analysis of the XRD patterns and Raman spectra reveal that the phase composition of

t-ZrO

2,

m-ZrO

2, and BaTiO

3 has been obtained. Our results indicate that SPS can be effective for the decrease in grain size and porosity compared with conventional sintering, which results in a lower concentration of

m-ZrO

2 and residual stress. Therefore, the fracture toughness is enhanced by the BaTiO

3 phase through the SPS technique, while the behavior was impaired by the piezoelectric second phase through conventional sintering.

Full article

►▼

Show Figures

Open AccessFeature PaperArticle

Liquid Film Capillary Mechanism for Densification of Ceramic Powders during Flash Sintering

by

Rachman Chaim

Cited by 76 | Viewed by 6993

Abstract

Recently, local melting of the particle surfaces confirmed the formation of spark and plasma during spark plasma sintering, which explains the rapid densification mechanism via liquid. A model for rapid densification of flash sintered ceramics by liquid film capillary was presented, where liquid

[...] Read more.

Recently, local melting of the particle surfaces confirmed the formation of spark and plasma during spark plasma sintering, which explains the rapid densification mechanism via liquid. A model for rapid densification of flash sintered ceramics by liquid film capillary was presented, where liquid film forms by local melting at the particle contacts, due to Joule heating followed by thermal runaway. Local densification is by particle rearrangement led by spreading of the liquid, due to local attractive capillary forces. Electrowetting may assist this process. The asymmetric nature of the powder compact represents an invasive percolating system.

Full article

►▼

Show Figures

Open AccessArticle

Discussion on Local Spark Sintering of a Ceramic-Metal System in an SR-CT Experiment during Microwave Processing

by

Yongcun Li, Feng Xu, Xiaofang Hu, Bo Dong, Yunbo Luan and Yu Xiao

Cited by 2 | Viewed by 5293

Abstract

In this paper, local spark sintering of a ceramic-metal system (SiO

2-Sn) during microwave processing was examinedby means of synchrotron-radiation-computed tomography technology. From the reconstructed 3-D and cross-section images of the specimen, adensification process was observed below the melting point of Sn,

[...] Read more.

In this paper, local spark sintering of a ceramic-metal system (SiO

2-Sn) during microwave processing was examinedby means of synchrotron-radiation-computed tomography technology. From the reconstructed 3-D and cross-section images of the specimen, adensification process was observed below the melting point of Sn, and then the specimen came into a rapid densification stage. These results may be due to the local spark sintering induced by the high-frequency alternating microwave electric fields. As the metallic particles Sn were introduced, the microstructure of “ceramic-metal” will lead to a non-uniform distribution and micro-focusing effect from electric fields in some regions (e.g., the neck). This will result in high-intensity electric fields and then induce rapid spark sintering within the micro-region. However, in the subsequent stage, the densification rate declined even when the specimen was not dense enough. The explanation for this is that as the liquid Sn permeated the gaps between SiO

2, the specimen became dense and the micro-focusing effect of electric fields decreased. This may result in the decrease or disappearance of spark sintering. These results will contribute to the understanding of microwave sintering mechanisms and the improvement of microwave processing methods.

Full article

►▼

Show Figures

Open AccessArticle

Microstructure Investigation of 13Cr-2Mo ODS Steel Components Obtained by High Voltage Electric Discharge Compaction Technique

by

Igor Bogachev, Artem Yudin, Evgeniy Grigoryev, Ivan Chernov, Maxim Staltsov, Oleg Khasanov and Eugene Olevsky

Cited by 8 | Viewed by 6134

Abstract

Refractory oxide dispersion strengthened 13Cr-2Mo steel powder was successfully consolidated to near theoretical density using high voltage electric discharge compaction. Cylindrical samples with relative density from 90% to 97% and dimensions of 10 mm in diameter and 10–15 mm in height were obtained.

[...] Read more.

Refractory oxide dispersion strengthened 13Cr-2Mo steel powder was successfully consolidated to near theoretical density using high voltage electric discharge compaction. Cylindrical samples with relative density from 90% to 97% and dimensions of 10 mm in diameter and 10–15 mm in height were obtained. Consolidation conditions such as pressure and voltage were varied in some ranges to determine the optimal compaction regime. Three different concentrations of yttria were used to identify its effect on the properties of the samples. It is shown that the utilized ultra-rapid consolidation process in combination with high transmitted energy allows obtaining high density compacts, retaining the initial structure with minimal grain growth. The experimental results indicate some heterogeneity of the structure which may occur in the external layers of the tested samples due to various thermal and electromagnetic in-processing effects. The choice of the optimal parameters of the consolidation enables obtaining samples of acceptable quality.

Full article

►▼

Show Figures

Planned Papers

The below list represents only planned manuscripts. Some of these

manuscripts have not been received by the Editorial Office yet. Papers

submitted to MDPI journals are subject to peer-review.

1.

Type of the paper: Article

Tentative title: Behavior of intermetallic compounds of Al-Ti composites manufactured by spark plasma sintering

Authors: Kwangjae Park1, Dasom Kim1, Kyungju Kim1,2, Seungchan Cho3, Hansang Kwon1,2*

Affiliations: 1 Pukyong National University (Republic of Korea)

2 Next Generation Materials Co., Ltd. (Republic of Korea)

3 Korea Institute of Materials Science (Republic of Korea)