The Effects of Spark-Plasma Sintering (SPS) on the Microstructure and Mechanical Properties of BaTiO3/3Y-TZP Composites

Abstract

:1. Introduction

2. Results and Discussion

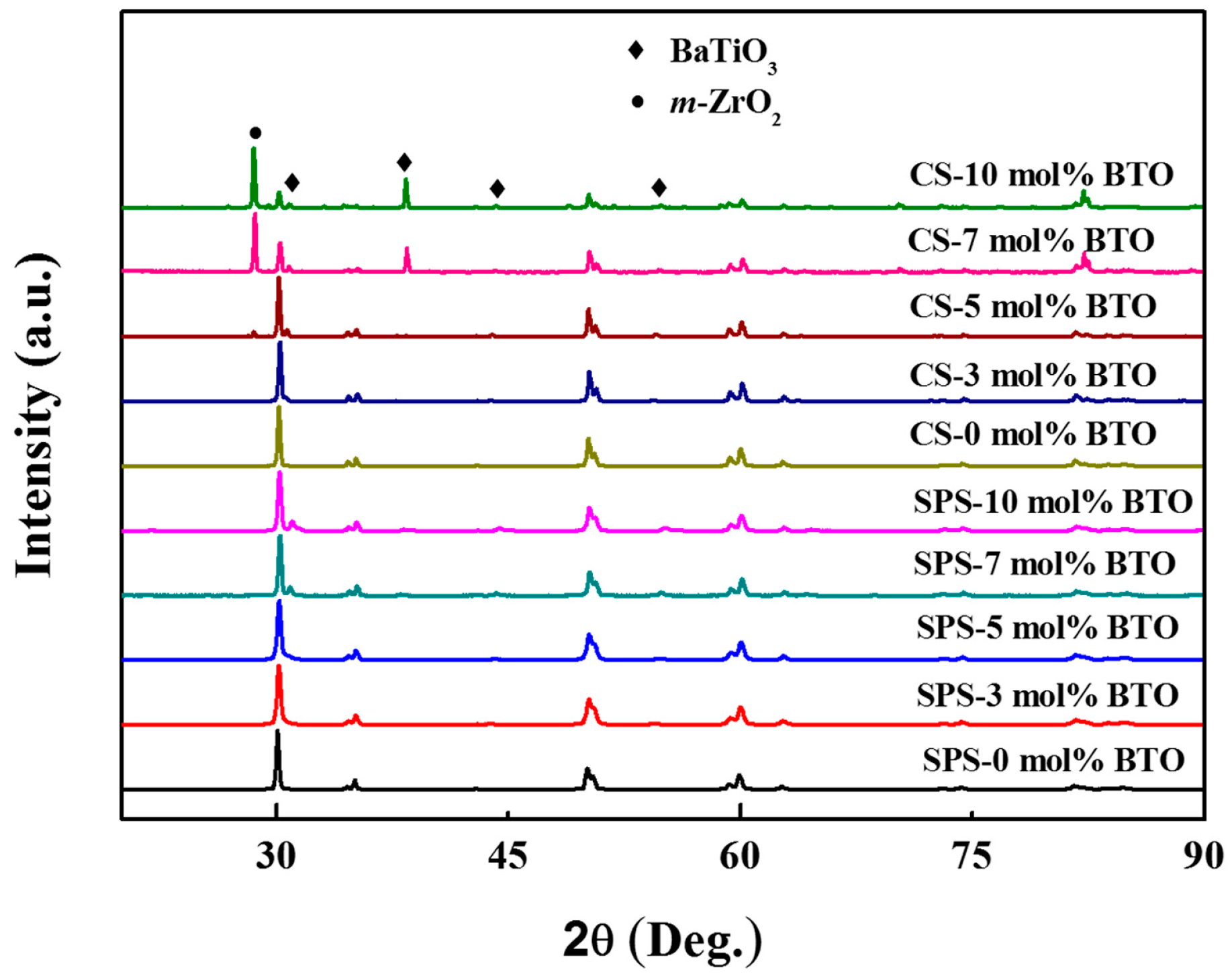

2.1. Phase Structure Analysis

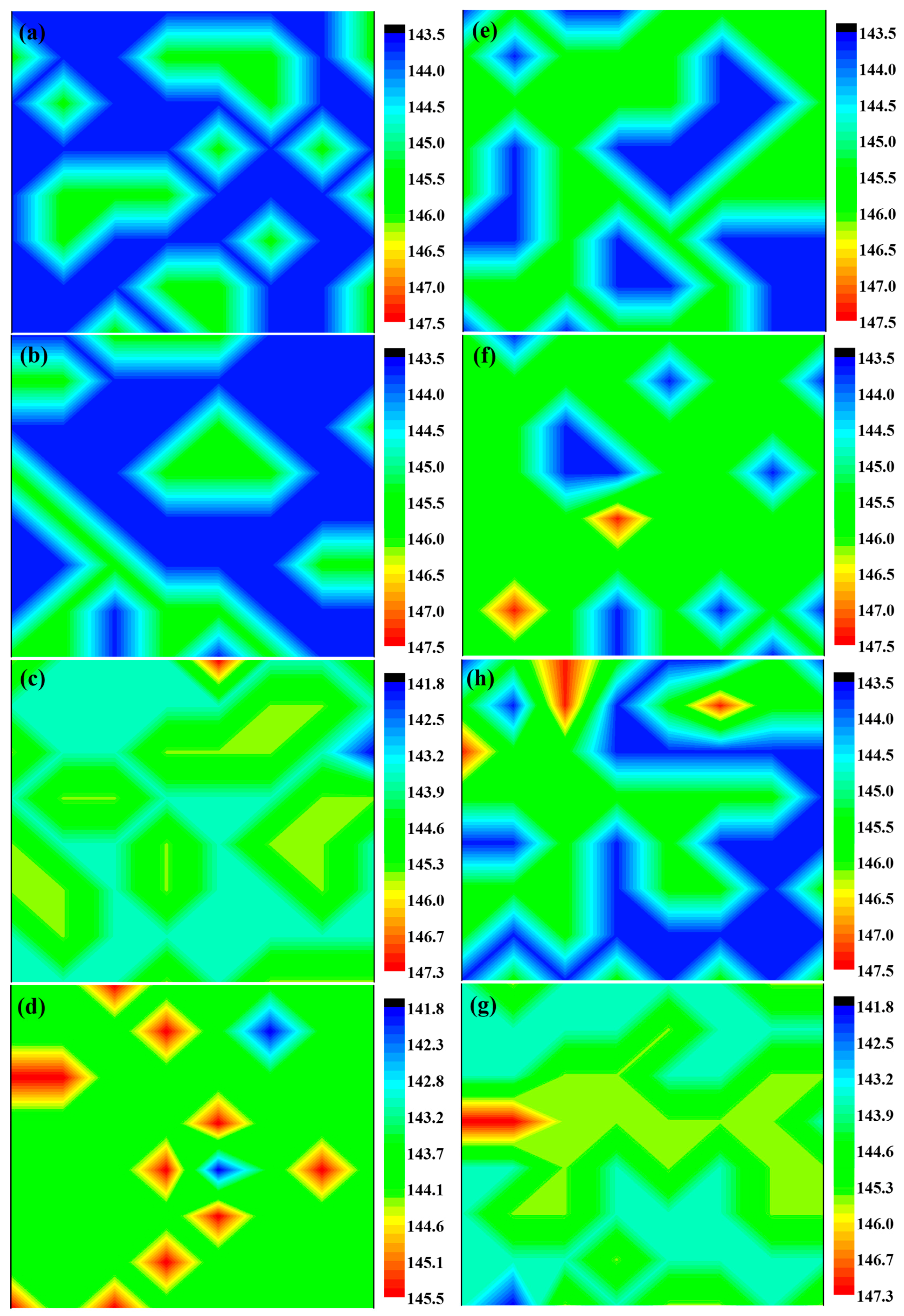

2.2. Microstructure Analysis

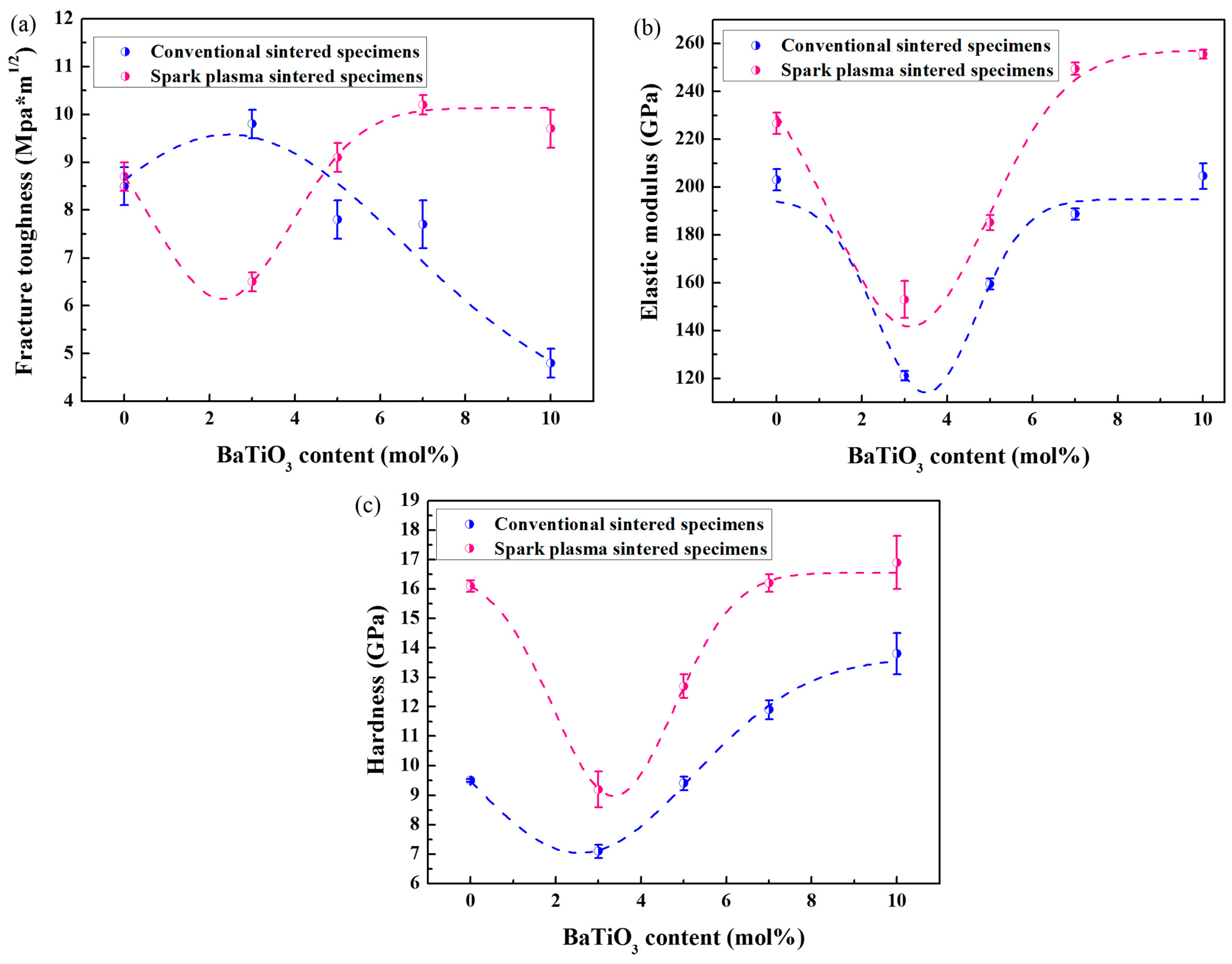

2.3. Mechanical Properties

3. Materials and Methods

3.1. Materials

3.2. Preparation of Porous Zirconia Ceramic

3.3. Characterization

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hulbert, D.M.; Anders, A.; Andersson, J.; Lavernia, E.J.; Mukherjee, A.K. A discussion on the absence of plasma in spark plasma sintering. Scr. Mater. 2009, 60, 835–838. [Google Scholar] [CrossRef]

- Orrù, R.; Licheri, R.; Locci, A.M.; Cincotti, A.; Cao, G. Consolidation/synthesis of materials by electric current activated/assisted sintering. Mater. Sci. Eng. R-Rpt. 2009, 63, 127–287. [Google Scholar] [CrossRef]

- Hulbert, D.M.; Anders, A.; Dudina, D.V.; Andersson, J.; Jiang, D.; Unuvar, C.; Anselmi-Tamburini, U.; Lavernia, E.J.; Mukherjee, A.K. The absence of plasma in “spark plasma sintering”. J. Appl. Phys. 2008, 104, 033305. [Google Scholar] [CrossRef]

- Biswas, K.; He, J.; Blum, I.D.; Wu, C.I.; Hogan, T.P.; Seidman, D.N.; Dravid, V.P.; Kanatzidis, M.G. High-performance bulk thermoelectrics with all-scale hierarchical architectures. Nature 2012, 489, 414–418. [Google Scholar] [CrossRef] [PubMed]

- Munir, Z.A.; Anselmi-Tamburini, U.; Ohyanagi, M. The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method. J. Mater. Sci. 2006, 41, 763–777. [Google Scholar] [CrossRef]

- Zhou, M.; Li, J.F.; Kita, T. Nanostructured AgPbmSbTem+2 system bulk materials with enhanced thermoelectric performance. J. Am. Chem. Soc. 2008, 130, 4527–4532. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.-P.; Li, J.-F.; Wang, K.; Zhang, H. Compositional dependence of piezoelectric properties in Naxk1−xNbO3 lead-free ceramics prepared by spark plasma sintering. J. Am. Ceram. Soc. 2006, 89, 1605–1609. [Google Scholar] [CrossRef]

- Yanagiya, S.; Van Nong, N.; Xu, J.; Pryds, N. The effect of (Ag, Ni, Zn)-addition on the thermoelectric properties of copper aluminate. Materials 2010, 3, 318–328. [Google Scholar] [CrossRef] [Green Version]

- Li, J.-F.; Wang, K.; Zhang, B.-P.; Zhang, L.-M. Ferroelectric and piezoelectric properties of fine-grained Na0.5k0.5NbO3 lead-free piezoelectric ceramics prepared by spark plasma sintering. J. Am. Ceram. Soc. 2006, 89, 706–709. [Google Scholar] [CrossRef]

- Deng, X.; Wang, X.; Wen, H.; Kang, A.; Gui, Z.; Li, L. Phase transitions in nanocrystalline barium titanate ceramics prepared by spark plasma sintering. J. Am. Ceram. Soc. 2006, 89, 1059–1064. [Google Scholar] [CrossRef]

- Wang, S.F.; Zhang, J.; Luo, D.W.; Gu, F.; Tang, D.Y.; Dong, Z.L.; Tan, G.E.B.; Que, W.X.; Zhang, T.S.; Li, S.; et al. Transparent ceramics: Processing, materials and applications. Prog. Solid State Chem. 2013, 41, 20–54. [Google Scholar] [CrossRef]

- Kim, B.N.; Hiraga, K.; Morita, K.; Yoshida, H. Spark plasma sintering of transparent alumina. Scr. Mater. 2007, 57, 607–610. [Google Scholar] [CrossRef]

- Alaniz, J.E.; Perez-Gutierrez, F.G.; Aguilar, G.; Garay, J.E. Optical properties of transparent nanocrystalline yttria stabilized zirconia. Opt. Mater. 2009, 32, 62–68. [Google Scholar] [CrossRef]

- Chaim, R.; Kalina, M.; Shen, J.Z. Transparent yttrium aluminum garnet (yag) ceramics by spark plasma sintering. J. Eur. Ceram. Soc. 2007, 27, 3331–3337. [Google Scholar] [CrossRef]

- Denry, I.; Holloway, J. Ceramics for dental applications: A review. Materials 2010, 3, 351–368. [Google Scholar] [CrossRef]

- Chen, X.M.; Yang, B. A new approach for toughening of ceramics. Mater. Lett. 1997, 33, 237–240. [Google Scholar] [CrossRef]

- Liu, Y.G.; Jia, D.C.; Zhou, Y. Microstructure and mechanical properties of a lithium tantalate-dispersed-alumina ceramic composite. Ceram. Int. 2002, 28, 111–114. [Google Scholar] [CrossRef]

- Li, J.Y.; Dai, H.; Zhong, X.H.; Zhang, Y.F.; Ma, X.F.; Meng, J.; Cao, X.Q. Lanthanum zirconate ceramic toughened by BaTiO3 secondary phase. J. Alloy. Compd. 2008, 452, 406–409. [Google Scholar] [CrossRef]

- Yang, B.; Chen, X.M. Alumina ceramics toughened by a piezoelectric secondary phase. J. Eur. Ceram. Soc. 2000, 20, 1687–1690. [Google Scholar] [CrossRef]

- Liu, X.Q.; Chen, X.M. Microstructures and mechanical properties of Sr2Nb2O7-toughened 3Y-TZP ceramics. Ceram. Int. 2003, 29, 635–640. [Google Scholar] [CrossRef]

- Yang, B.; Chen, X.M.; Liu, X.Q. Effect of BaTiO3 addition on structures and mechanical properties of 3Y-TZP ceramics. J. Eur. Ceram. Soc. 2000, 20, 1153–1158. [Google Scholar] [CrossRef]

- Hastings, G.W.; Mahmud, F.A. The electromechanical properties of fluid-filled bone: A new dimension. J. Mater. Sci. Mater. Med. 1991, 2, 118–124. [Google Scholar] [CrossRef]

- Feng, J.Q.; Yuan, H.P.; Zhang, X.D. Promotion of osteogenesis by a piezoelectric biological ceramic. Biomaterials 1997, 18, 1531–1534. [Google Scholar] [CrossRef]

- Li, M.; Feng, Z.; Xiong, G.; Ying, P.; Xin, Q.; Li, C. Phase transformation in the surface region of zirconia detected by UV Raman spectroscopy. J. Phys. Chem. B 2001, 105, 8107–8111. [Google Scholar] [CrossRef]

- Djurado, E.; Bouvier, P.; Lucazeau, G. Crystallite size effect on the tetragonal-monoclinic transition of undoped nanocrystalline zirconia studied by XRD and Raman spectrometry. J. Solid State Chem. 2000, 149, 399–407. [Google Scholar] [CrossRef]

- Muñoz Tabares, J.A.; Anglada, M.J. Quantitative analysis of monoclinic phase in 3Y-TZP by Raman spectroscopy. J. Am. Ceram. Soc. 2010, 93, 1790–1795. [Google Scholar] [CrossRef]

- Garvie, R.C.; Hannink, R.H.; Pascoe, R.T. Ceramic steel? Nature 1975, 258, 703–704. [Google Scholar] [CrossRef]

- Maneshian, M.H.; Simchi, A. Solid state and liquid phase sintering of mechanically activated W–20 wt. % Cu powder mixture. J. Alloy. Compd. 2008, 463, 153–159. [Google Scholar] [CrossRef]

- Sivaprahasam, D.; Chandrasekar, S.B.; Sundaresan, R. Microstructure and mechanical properties of nanocrystalline WC–12Co consolidated by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2007, 25, 144–152. [Google Scholar] [CrossRef]

| BaTiO3 Content | 0 mol % | 3 mol % | 5 mol % | 7 mol % | 10 mol % |

|---|---|---|---|---|---|

| Porosity (%) (CS) | 2.7 | 5.9 | 9.6 | 12.5 | 14.8 |

| Porosity (%) (SPS) | 0.5 | 4.8 | 3.3 | 1.5 | 3.2 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Cui, B.; Wang, H.; Lin, Y.; Deng, X.; Li, M.; Nan, C. The Effects of Spark-Plasma Sintering (SPS) on the Microstructure and Mechanical Properties of BaTiO3/3Y-TZP Composites. Materials 2016, 9, 320. https://doi.org/10.3390/ma9050320

Li J, Cui B, Wang H, Lin Y, Deng X, Li M, Nan C. The Effects of Spark-Plasma Sintering (SPS) on the Microstructure and Mechanical Properties of BaTiO3/3Y-TZP Composites. Materials. 2016; 9(5):320. https://doi.org/10.3390/ma9050320

Chicago/Turabian StyleLi, Jing, Bencang Cui, Huining Wang, Yuanhua Lin, Xuliang Deng, Ming Li, and Cewen Nan. 2016. "The Effects of Spark-Plasma Sintering (SPS) on the Microstructure and Mechanical Properties of BaTiO3/3Y-TZP Composites" Materials 9, no. 5: 320. https://doi.org/10.3390/ma9050320